White Outdoor LT-5 - 700 Service Manual

Service Manual

LT-5 - 700 Series Rider

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accurate as possible at the time of publication. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2005 MTD Products Inc. All Rights Reserved

MTD Products Inc - Product Training and Education Department

FORM NUMBER - 769-01415

10/2005

TABLE OF CONTENTS

Introduction ............................................................................................................................1

Deck Removal .......................................................................................................................2

Deck Details and Updates for 2005 .......................................................................................3

PTO Cable .............................................................................................................................5

Deck Lift ................................................................................................................................6

Hydrostatic Transaxle ............................................................................................................9

Transaxle Control Linkage ..................................................................................................12

Drive Belt: Hydrostatic Drive ...............................................................................................14

Clutch/Brake Linkage : Hydrostatic .....................................................................................16

Parking Brake : Hydrostatic Drive .......................................................................................17

Belt Replacement: Variable Speed Belt Drive .....................................................................18

Speed Control Linkage Adjustment: Variable Speed Belt Drive ..........................................20

Cruise Control/Parking Brake Adjustment: Variable Speed Belt Drive ................................21

Steering ......................................................................................................................

.........22

Steering Gear ......................................................................................................................25

Pivot Bar ..............................................................................................................................28

Electrical System .................................................................................................................30

Fastener Installation Specs .................................................................................................47

700 SERIES LAWN TRACTORS

700 SERIES LAWN TRACTORS

1. INTRODUCTION

1.1. Disclaimer: This service manual was intended

for the use, by trained technicians. The information contained in this manual is current and

accurate at the time of writing, but is subject to

change without notice.

1.2. Description: A new step-through rider platform

was introduced for the ‘05 mowing season. It is

designated as the 700 series rider. This series

replaces the 660 through 690 series box frame

riders. The mower depicted in most of this

manual is branded “White”, and designated by

factory #13A2791

the portion of this manual that covers the variable speed drive system is branded “Troy-Bilt”,

and designated by factory # 13AN779

representative of the series. See Figure 1.2.

G790. The mower depicted in

G766. It is

1.5. Variations: Other The 700 series platform will

accommodate a variety of single and twin cylinder engines, and a range of styles and brands

will be applied to it. The steel dash panel is

common to all 700 series, and plastic inserts will

be used to match the different hoods used.

1.6. Spotter’s Guide: The 700 series is visibly similar to the existing step-through platform 600 and

610 series lawn tractors, but there are substantial differences.

• Drive System: Hydro The 790 series declutches the traction drive belt when the clutch/

brake pedal is depressed, without moving the

fender-mounted transmission control lever. In

contrast, the 610 series hydro is controlled by a

foot-operated rocker pedal. The operator of the

610 series must remove their foot from the

rocker pedal to apply the brake. The rocker

pedal is spring-loaded to return to neutral.

• Drive System: Non-hydro The 770 and 600

series transmission are both operated by a gear

selector lever on the right fender. Ground

speed is controlled by a clutch/brake pedal on

the left side of the 770. Ground speed is controlled by an automotive style drive pedal and a

separate brake pedal on the right side of the

tractor on the 610 series. The variable speed

pulley principal is the same, but pedal operation

is reversed.

Figure 1.2

1.3. Variations: Drive Systems The 700 series is

available with a HydroGear hydrostatic transmission or a variable-speed pulley system driving a

simple Forward-Neutral-Reverse transmission

manufactured by MTD. The Hydrostatic versions

will have model numbers in the 790 range. Nonhydro versions have model numbers in the 770

range.

1.4. Variations: Cutting Decks Two decks will be

available on the 700 series platform: 38” (97cm)

designated by an F in the eighth position of the

model number, and 42” (107cm), designated by

a G in the eighth position of the model number.

• Deck Engagement: The PTO belt is engaged

on the 700 series using a lever on the right

fender. The 600 series uses a dash-mounted

lever or an electric PTO clutch.

• Decks: While the 700 series accepts only an F

or G deck, the 600 series will accept a variety of

decks that include 46” (H deck), 50” (P deck).

Both series have Fast-Attach

600 series has “J” pins to connect the rear of the

deck, while the 700 series decks are secured

directly to the lift rods and lift links by locking

internal cotter pins (“hairpin clips” that resemble

a bow-tie in configuration).

1

TM decks, but the

700 SERIES LAWN TRACTORS

2. DECK REMOVAL

2.1. The engine should be turned off long enough for

the exhaust system to cool before starting work.

2.2. The controls should be in the following positions:

PTO lever: OFF Deck height: lowest position

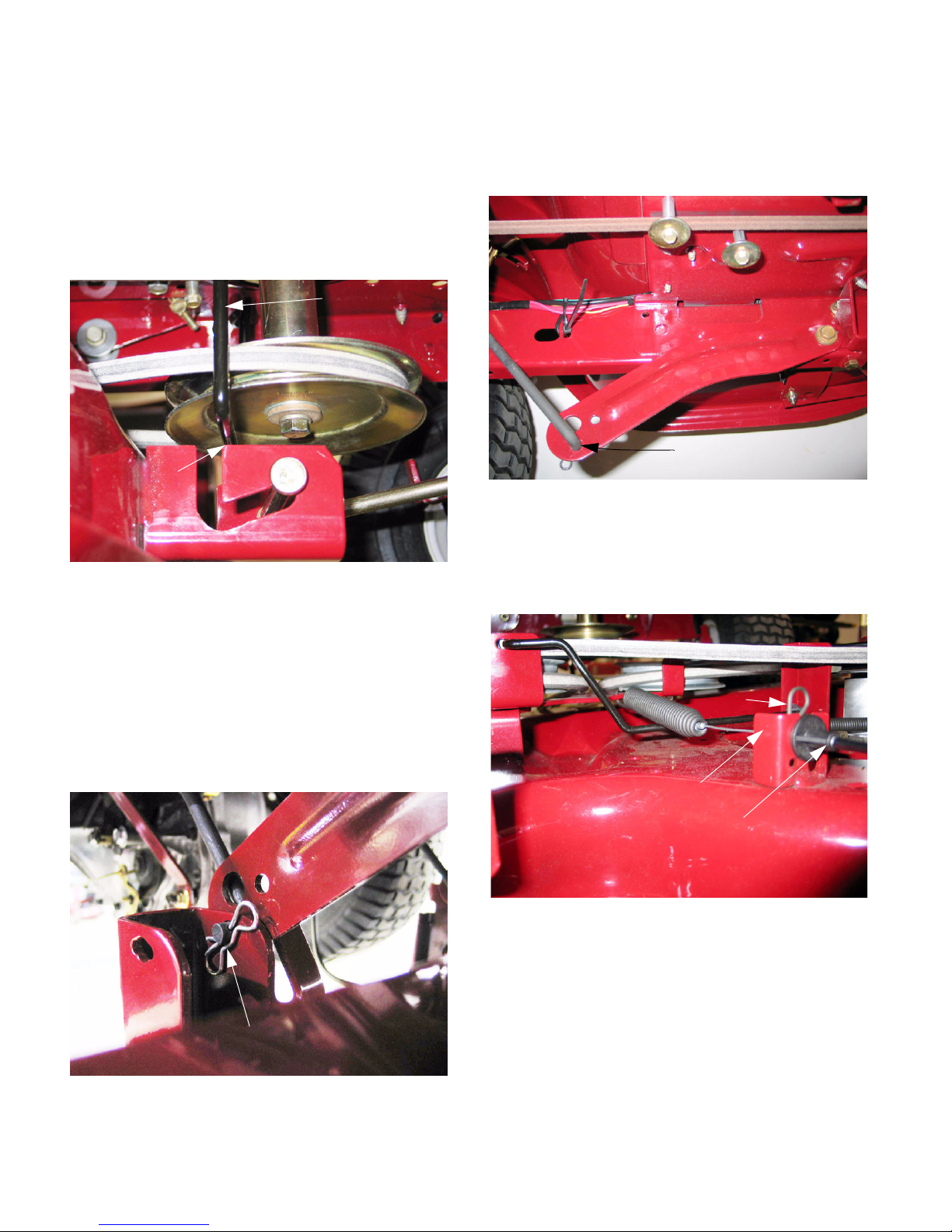

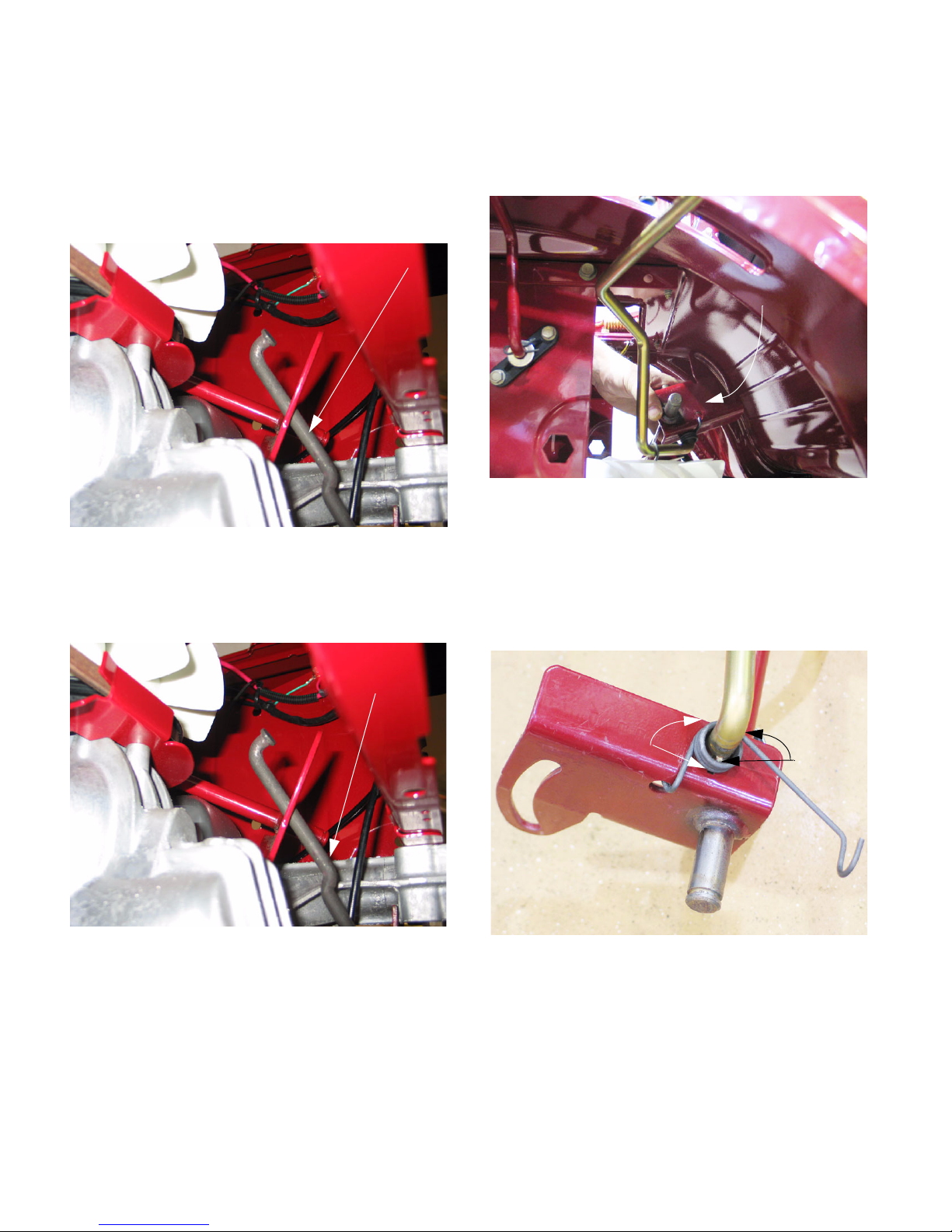

2.3. Remove the crankshaft pulley belt keeper using

a 1/2” wrench. See Figure 2.3.

Belt keeper

Contact point

Figure 2.3

2.5. With the deck on the ground, the lift rods can be

reconnected to the lift links. This will enable the

rods and links to be moved out of the way by lifting the deck height lever. See Figure 2.5.

Lift rod reconnected

Figure 2.5

2.6. Working from the right side of the tractor,

remove the hairpin clip that secures the PTO

cable housing to the bracket on the deck. Separate the cable from the bracket. See Figure 2.6.

NOTE: The belt keeper doubles as the deck upstop.

NOTE: The correct place for the pin-end of the

belt keeper is the small hole in the right frame

channel, roughly in-line with the crankshaft.

2.4. Remove the hairpin clips that secure the deck lift

rods to the cutting deck and the deck lift links.

See Figure 2.4.

New locking hairpin clips

secure lift rods to lift links

and cutting deck

Figure 2.4

Hairpin clip

Bracket

PTO Cable

Figure 2.6

NOTE: There is a small plastic spacer that fits

between the hairpin clip and the bracket

2.7. Unhook the PTO cable spring from the idler pulley bracket, and move the cable out of the way.

NOTE: Some early production units were

equipped with a brake rod that passed above the

PTO cable spring. On these models it is necessary to disconnect the brake rod before removing the spring.

2

700 SERIES LAWN TRACTORS

2.8. Slide the deck forward slightly, and slip the PTO

belt off of the crankshaft pulley.

2.9. Because of angular interference between the

inside angle of the front deck support rod and

the hooks on the front of the deck, the following

manipulations will ease deck removal:

See Figure 2.9.

Cold-headed end

Left side slot

Figure 2.9

• Align the rod with the slot in the left side of the

bracket on the deck.

• Pivot the rod up on the left side to clear the slot.

• Move the deck forward slightly so that the right

side (cold-headed end) of the rod may be lifted

out of the right side bracket on the deck.

2.10. Reverse the removal process to install the deck.

Test the operation of the mower and it’s safety

features before returning it to service.

3. DECK DETAILS AND UPDATES FOR 2005

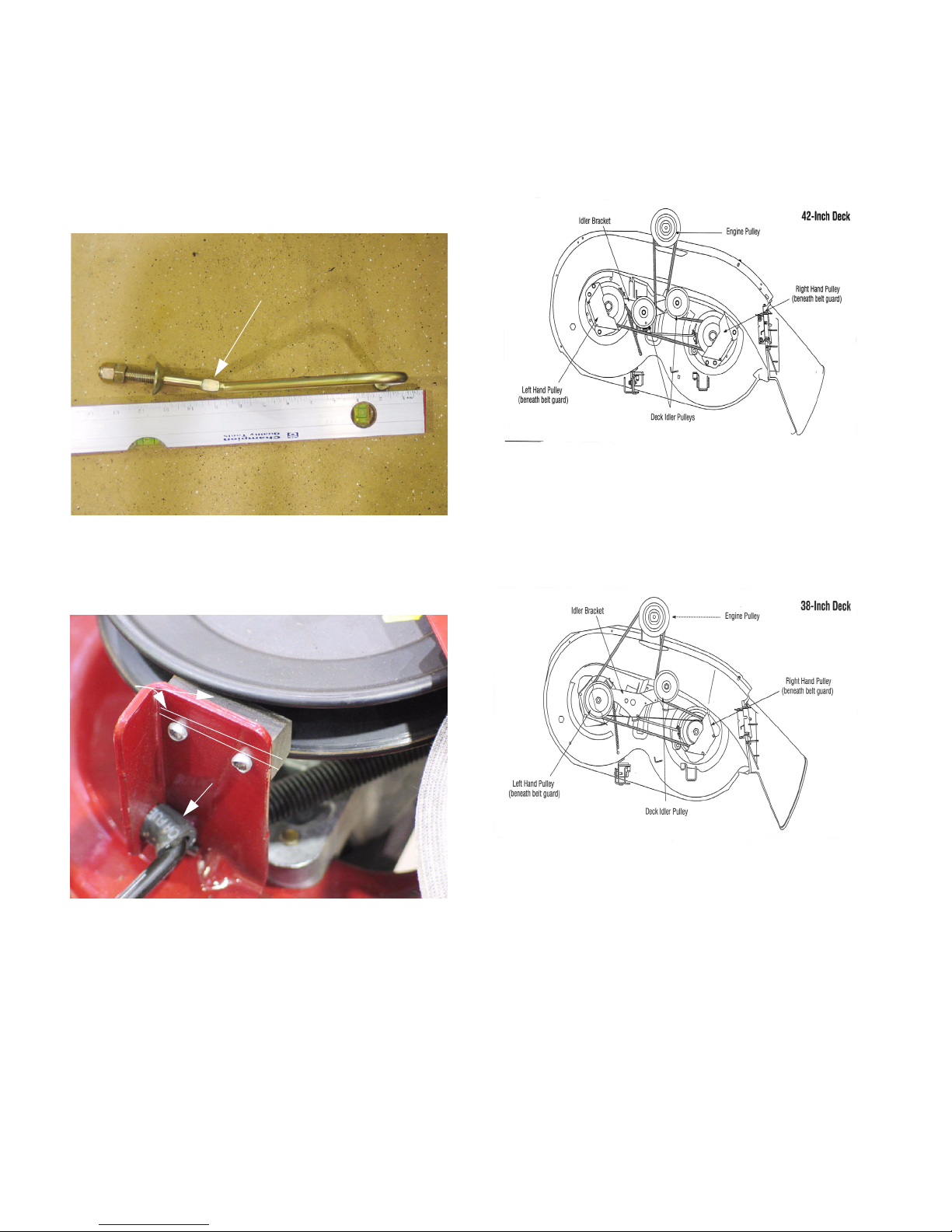

3.1. The front deck support rod is easily removed by

slipping it forward until the coined spot slips

through the opening in the bracket that supports

it. See Figure 3.1.

Front deck

support rod

Figure 3.1

• The nut and jam nut are used to make and

secure fore / aft deck level adjustment using a

pair of 3/4” wrenches.

• The deck should be set slightly nose-down:1/4”

(1.27cm) to 3/8” (1.9cm) to maintain vacuum

beneath the deck, improving cutting performance.

• Measurement is made from blade-tip to ground,

with the blades oriented front-to-back.

• Slots are provided in the muffler cover for easy

removal of the rod.

Pivot cup

NOTE: Using a length of 2X4 dimensional lumber, or similar object to support the front edge of

the deck will make it easier to connect the deck

lift rods and deck lift links.

• The hemispherical pivot cup nestles in a recess

in the front of the bracket.

• Side-to-side leveling is accomplished using a

pinion gear and clamp screw on the left-rear

deck hanger bracket. The deck should be set

level from side-to-side, as measured from the

blade tip to the ground with the blades oriented

end-to-end. Adjustment is made using a 1/2”

wrench and a 1 1/4” wrench.

3

700 SERIES LAWN TRACTORS

3.2. The hooked side of the front deck support rod

belongs on the left. This is important because

there is a slight bend in the rod. The rod needs

to angle down to clear the steering tie-rod before

extending back to meet the deck.

See Figure 3.2.

Note bend in rod compared to straight-edge

Coined flat spot

Figure 3.2

3.3. The re-configured brake rod now uses a short bit

of 5/16” fuel line as a damper. See Figure 3.3.

3.5. The 42” deck has a fixed idler pulley to provide

better wrap on the left spindle pulley, and a tensioner pulley to tighten the belt. See Figure 3.5.

Figure 3.5

3.6. The 38” deck has a shorter belt, and a single

tensioner pulley to tighten the belt.

See Figure 3.6.

Angled

brake pad

Damper

Figure 3.3

3.4. The blade brake pads are attached at a slight

angle to prevent chatter on PTO disengagement.

Figure 3.6

4

700 SERIES LAWN TRACTORS

4. PTO CABLE

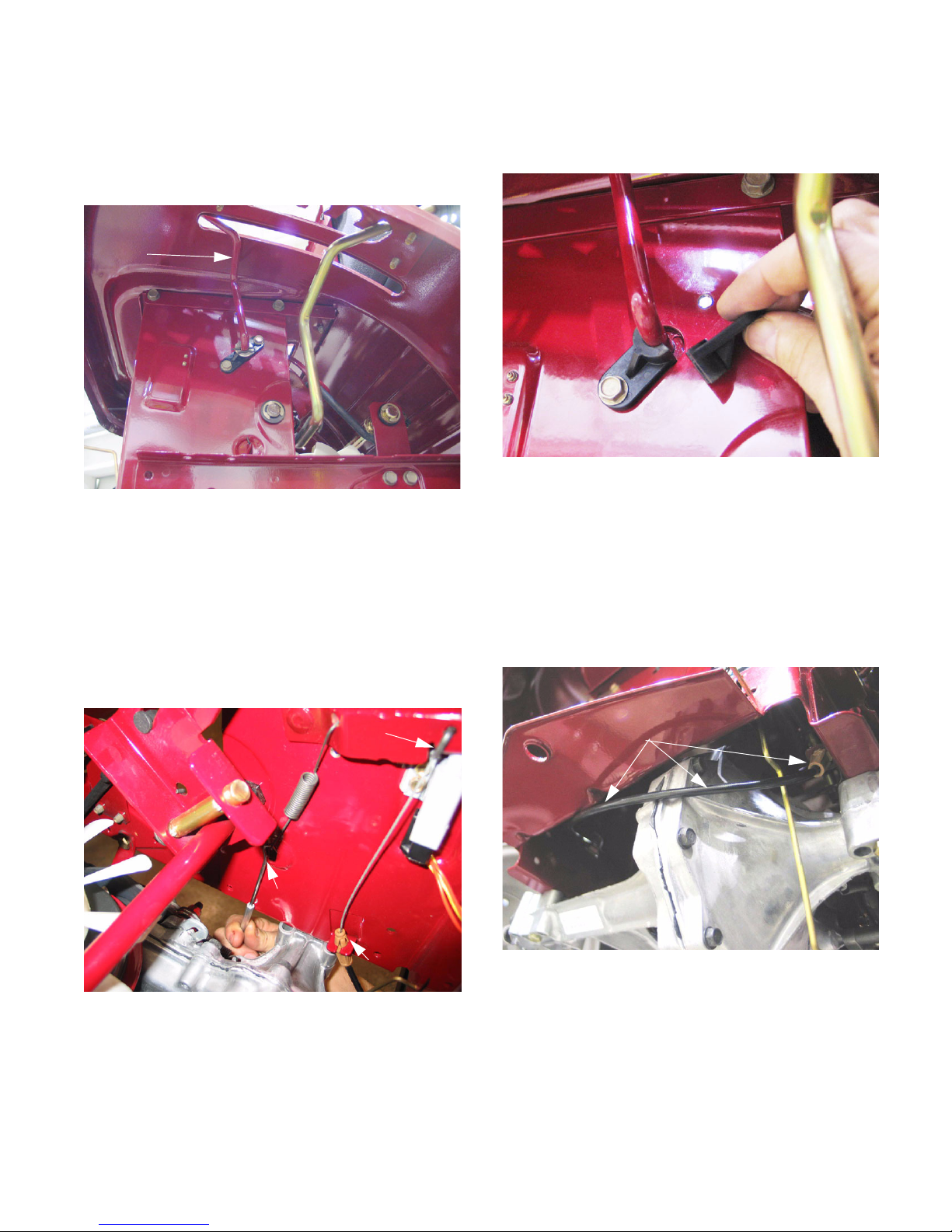

4.1. The deck engagement lever is supported by a

two-piece bushing under the right fender.

See Figure 4.1.

Deck

engagement

lever

Figure 4.1

4.2. The return spring can be removed from the

inside of the lever using a hooked tool, with the

PTO lever in the OFF position.

4.3. The PTO cable can be removed from its bracket

by squeezing the barbs to release it. Once

released, there will be enough slack in the cable

to unhook the Z-fitting from the PTO lever.

See Figure 4.3.

4.4. The bushing is easily replaced by simply unbolting the two halves using a 3/8” wrench.

See Figure 4.4.

Figure 4.4

NOTE: The washer and hairpin clip have been

removed here for the sake of visibility.

NOTE: The lever itself is difficult to replace without removing the fender.

4.5. The cable is properly routed behind the transmission to reach the left side frame channel,

where it is secured by a clip. See Figure 4.5.

Hook tool

Figure 4.3

Z-Fitting

Barbed end

Note cable routing

Figure 4.5

4.6. From there, the cable reaches forward, secured

beneath the foot-pad on the fender by a hairpin

clip and bracket similar to the deck-end mounting.

5

700 SERIES LAWN TRACTORS

5. DECK LIFT

5.1. In an advancement over the box-frame design,

the deck height and engagement functions are

isolated from one-another.

5.2. The deck lift control, located on the right fender,

rotates a cross-shaft and two slotted bell-cranks

(lift shaft assembly) that draw up and back on

the deck lift rods. See Figure 5.2.

Deck lift lever

Lift-shaft

bushing

Figure 5.2

NOTE: The slotted configuration of the bell-

crank arms suspends the deck, yet allows it to

float upward as the anti-scalp wheels encounter

bumps.

5.3. The the deck lift links are distinct from left to

right: there are two different part numbers.

See Figure 5.3.

Left-side has flat at front

Bellcrank (right side)

Lift rod

5.4. The bushings that support the lift shaft assembly

are easily replaced. See Figure 5.4.

Hex bushing

E-clip

retaining ring

Figure 5.4

• Remove the cutting deck, or support it using

2”X4” dimensional lumber or similar, to relieve

the weight from the linkages.

• Lift and safely support the back of the tractor.

• Remove the rear wheels using a 1/2” wrench

(not absolutely necessary, but eases access).

• Remove the “E” clips from the shaft, and replace

the bushings one at a time.

• Reverse the removal process to install deck lift

shaft assembly bushings.

5.5. If it is necessary to remove the lift shaft assembly, the job can be done without removing the

fenders.

Embossed ridge faces inboard,

away from frame channel

Figure 5.3

NOTE: Lift link position and orientation.

6

5.6. Preliminary steps: See Figure 5.6.

The old blow-gun trick

Figure 5.6

700 SERIES LAWN TRACTORS

NOTE: The stepped “bow” in the middle goes

outboard, riding against the transaxle control

brackets.

5.9. Remove the bushings that support the lift shaft

assembly. See Figure 5.9.

• Remove the cutting deck.

• Disconnect and remove the battery.

• Remove the handle from the deck lift lever.

5.7. Remove the transaxle control linkage, complete

with the brackets that support it, as described in

the “TRANSAXLE CONTROL LINKAGE” section

of this manual. See Figure 5.7.

Unbolt transaxle

control linkage

here

Bushings

removed

Figure 5.9

NOTE: Use care not to damage the cooling fan

when removing the lift shaft assembly. The shaft

is in close proximity to the fan, and worn bushings may reduce the fan/lift shaft clearance to a

negative figure.

5.10. Remove the notched plate that surrounds the lift

lever using a T-40 Tor-X driver. See Figure 5.10.

Figure 5.7

5.8. If the deck lift rods have been re-connected to

the deck lift links to provide clearance for sliding

the cutting deck out from under the tractor, disconnect them.

NOTE: The deck lift rods are interchangeable

left-to-right, but it is important to maintain the

correct orientation.

7

Notched plate

Figure 5.10

700 SERIES LAWN TRACTORS

5.11. Slide the lift shaft to the right, so that the left end

clears the opening in the frame that the hexagonal bushing fits in.

5.12. Maneuver the left side lift rod out of the curved

slot in the lift-shaft arm, and up through the battery opening. See Figure 5.12.

Left side lift rod

Figure 5.12

5.13. Rotate the lift shaft arms up and back so that the

right side lift rod can be removed.

See Figure 5.13.

5.14. Once the lift rods are removed, the lift shaft can

be withdrawn, complete with the lift lever, out the

opening beneath the left fender.

See Figure 5.14.

Withdraw lift shaft

Figure 5.14

5.15. On the bench, the lift lever can be rotated in its

mounting hole in the lift shaft assembly to relieve

the torsion spring tension and align the coined

“ears” on the lever with the notches in the

bracket, so that it may be removed.

See Figure 5.15.

Figure 5.13

Right lift rod

Notches

Ears

Figure 5.15

8

700 SERIES LAWN TRACTORS

5.16. Installation notes: See Figure 5.16.

Figure 5.16

• Slide the lift shaft assembly into the frame

through the opening in front of the wheel.

• Position the lift lever through the opening in the

right fender.

• Install the lift rods onto the arms on the lift shaft,

from the inside-out.

• Confirm that the right side lift rod passes above

and in front of the lever and the end of the lift

shaft.

6. HYDROSTATIC TRANSAXLE

6.1. A Hydro-Gear model 348-0510 transaxle drives

the hydrostatic transmission equipped 790

series. See Figure 6.1.

Figure 6.1

6.2. If a warrantable problem occurs in the first two

years of service, the transaxle will be replaced

as a unit by an authorized White dealer, returning the transaxle to MTD for vendor recovery. It

may also be repaired by a Hydro-Gear authorized MTD dealer under the Hydro-Gear warranty.

• Insert each end of the lift shaft assembly through

the hexagonal openings in the frame.

• The remainder of the assembly is simply matter

of reversing the removal process.

• Check deck for side-to-side levelness and correct fore-aft adjustment of 1/4”-5/16” (6.35-8.00

mm) lower at the front, as measured at the blade

tips.

• Confirm correct operation of the blades and all

tractor safety features before returning the tractor to service.

6.3. If any non-warranty hydrostatic transaxle service is required, it can be performed by a White

or Hydro-Gear authorized MTD dealer. These

transmissions are feasible to repair, and the

repair / replace decision is left to the judgement

of the shop and the customer.

6.4. These transaxles frequently last the life of the

tractor with no need for service. To help increase

the life of the transaxle:

• Clean off accumulated mud or debris to aid cooling.

• Avoid using a pressure washer, as it may force

water past the seals, contaminating the fluid.

• Remove the rear wheels annually, clean the

axles, and apply a fresh coating of anti-seize

compound.

• Keep linkages and brakes properly adjusted.

• Replace the cooling fan promptly if it gets damaged.

• In normal service, do not attempt to drain and fill

the transaxle. There is no drain plug.

9

700 SERIES LAWN TRACTORS

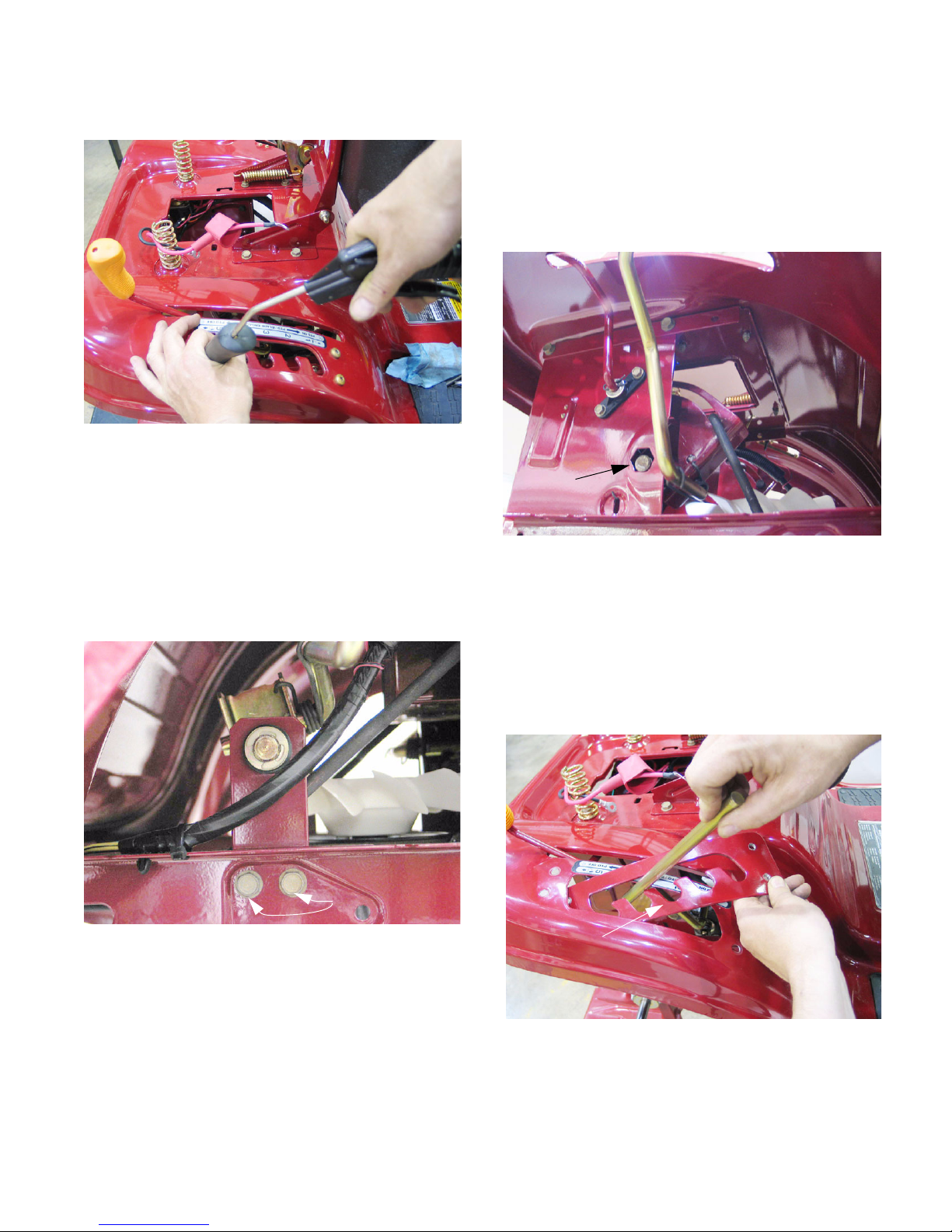

6.5. Access to the fill plug can be gained by removing

the battery and the tray that supports the battery.

See Figure 6.5.

Figure 6.5

• Disconnect the negative (black) cable first, and

reconnect it last when the battery is reinstalled.

• After both cables are removed using a pair of 7/

16” wrenches, remove the battery hold-down.

• Carefully lift-out the battery.

6.7. After a thorough cleaning, to prevent contamination of the fluid, the fill plug can be removed

using a 1/4” allen wrench. See Figure 6.7.

20W-50

Figure 6.7

6.8. Between 5 deg. - 100 deg. f (10 deg. - 38 deg.

c), the fluid level should be 1” - 1.25” (2.54cm -

3.18cm) from the top of the housing.

Total capacity is .600 - .632 gal. (2271ml 2391ml) of 20W-50 motor oil having an API classification of SH/CD.

• Remove the battery tray.

6.6. Customers and unfamiliar technicians may

attempt to add or check the fluid level at the vent

cap on the plastic over-flow reservoir.

See Figure 6.6.

Expansion tank

Vent cap

Check/fill plug

Figure 6.6

6.9. The transaxle must be removed and inverted to

drain the fluid out.

6.10. After a fluid change, purge the system and topup the fluid to the correct level:

• With the engine at idle speed, and the by-pass

valve open, slowly cycle the control lever from

full forward to full reverse positions 5 or 6 times.

• Check fluid level, close the by-pass valve, and

repeat the previous step. When the transaxle

operates normally, without excessive noise, the

purge process is complete; all the air is out of

the system.

• Air in the system will cause a “growling” noise,

and sluggish performance.

6.11. In normal service, fluid replacement should not

be necessary, but in the event of fluid contamination or degradation, it can be done.

10

700 SERIES LAWN TRACTORS

6.12. The by-pass valve and brake are visible beneath

the right side frame channel. See Figure 6.12.

Brake

caliper

By-pass valve

•The by-pass valve is open when the by-pass

rod and lever are back. It is closed for normal

operation when the rod and lever are at the forward end of their travel.

Brake rotor

Figure 6.12

6.13. The brake rod pulls on a spring that is hooked to

the cam-arm on the brake caliper. The cam-arm

forces two pins inward against a backing plate

and brake pad. The pad forces the floating rotor

against a second pad located behind the rotor.

The pinching action creates the friction necessary to stop or hold the tractor.

6.14. A return spring pulls the cam arm back to relieve

the friction when the brake pedal is released.

See Figure 6.14.

Return spring

Extension spring

Cam arm

Brake rod

• An open by-pass valve will disable the transaxle.

• Open the by-pass to push the tractor.

•The brake is properly adjusted when a .015”

(.381 mm) feeler gauge will slip between the pad

and the rotor.

• Brake adjustment is made by removing the cotter pin from the castle-nut and rotating the nut to

tighten or loosen the clearance between the

pads and the rotor. There is no linkage adjustment.

• Replace the cotter pin with a new one after

making any brake adjustment.

•A tight or stuck brake can cause symptoms

similar to low fluid: noisy operation and sluggish

performance. In addition to these symptoms,

the brake will become extremely hot, and the

rotor will become discolored.

Figure 6.14

6.15. Slightly above and behind the brake assembly is

the friction pack. The friction pack maintains a

set amount of resistance in the control linkage:

See Figure 6.15.

Friction pack

Figure 6.15

• Too much resistance may raise control effort to

an unacceptable level. This would be caused by

an over-tightened nut on the friction pack.

11

700 SERIES LAWN TRACTORS

• Too little resistance may allow the linkage to drift

back to neutral, particularly when ascending a

grade conforming to the 15 degree description in

the Operators Manual. This condition may indicate that it is necessary to tighten the friction

pack nut slightly.

6.16. The factory setting on the friction pack is to

torque the nut to 100 in-lbs (11.3 n-m), then back

the nut off one full turn (360 deg.).

6.17. This setting should result in about 5 lbs (2.67

kg.) of resistance in the lever, measured as near

the end of the lever as possible.

See Figure 6.17.

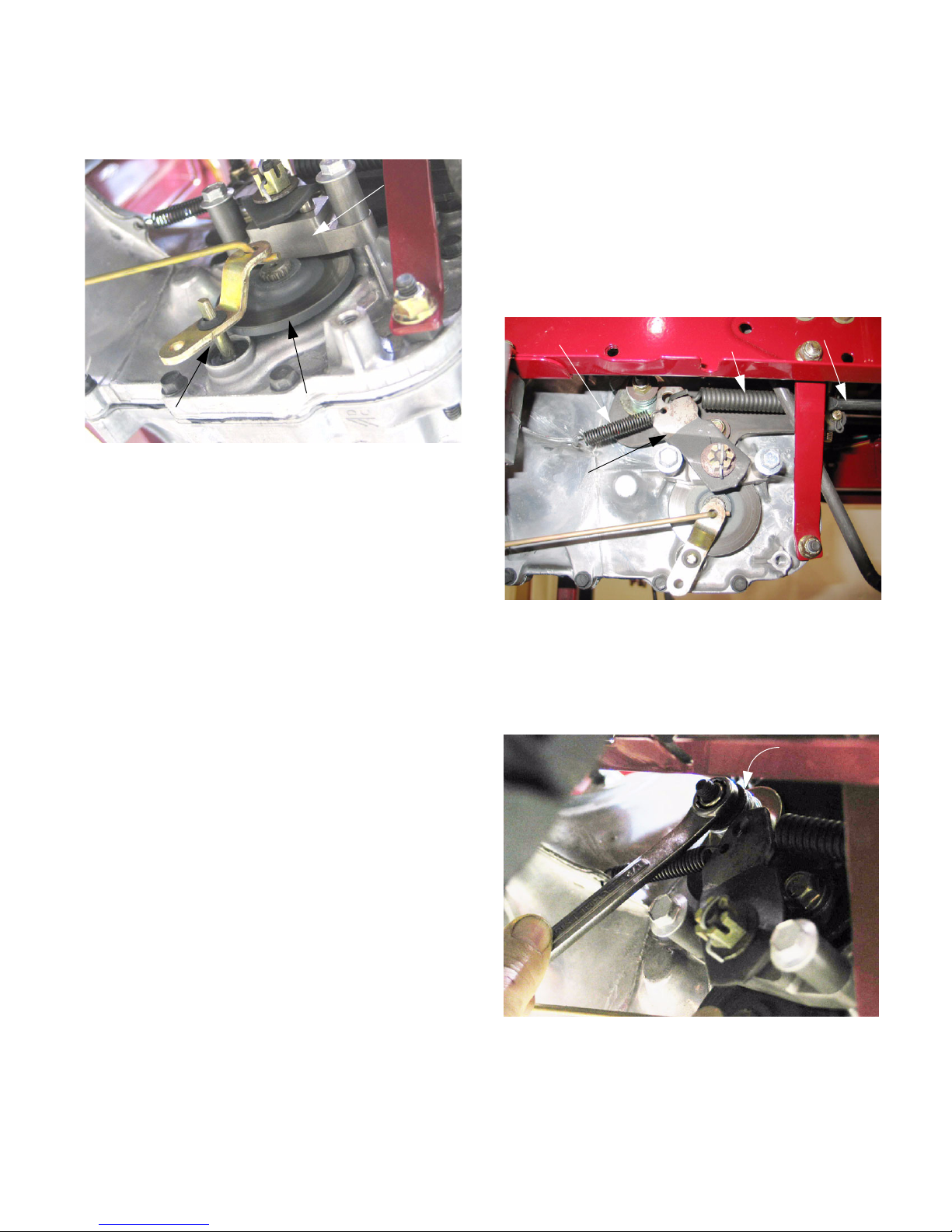

7. TRANSAXLE CONTROL LINKAGE

7.1. The lever that controls the ground speed and

direction of travel is located on the right rear

fender.

7.2. The lever rotates a cross-shaft and bellcrank.

An adjustable rod connects the bellcrank to the

input arm on the left side of the transaxle.

See Figure 7.2.

Bellcrank Cross shaft

Adjustable rod

Input arm

Measuring control

force

Figure 6.17

NOTE: A belt tension checker such as that man-

ufactured by Browning is useful for checking

control resistance.

Figure 7.2

7.3. The input arm on the transaxle will return to neutral when the rod is disconnected. The rod

length should be adjusted so that the neutral

position of the control lever on the fender corresponds with neutral position of the input arm.

• If mis-adjusted, the tractor will “creep” in neutral,

or lurch as soon as the brake is released, even

though the control lever is in neutral.

• If one end of the rod is disconnected, with the

control lever in neutral, the centering action of

the input arm should not draw the end of the rod

a way from the hole it connects to.

• Lengthen or shorten the rod as necessary to

adjust, by threading it into or out of the ferrule.

• Reconnect the rod and test the operation of the

linkage and the tractor’s safety features before

returning the tractor to service.

12

Loading...

Loading...