White Outdoor 950 User Manual

OPERATOR’S MANUAL

Chipper Shredder

Vacuum

Model Number

Yard Boss 950

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-9722.

WHITE OUTDOOR PRODUCTS COMPANY P.O. BOX 361131 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

FORM NO.

770-10052C.fm

(8/01)

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices...................................................................3

Assembling Your Chipper Shredder Vacuum ....................................................5

Know Your Chipper Shredder Vacuum..............................................................7

Operating Your Chipper Shredder Vacuum .......................................................8

Adjusting Your Chipper Shredder Vacuum ........................................................10

Maintaining Your Chipper Shredder Vacuum.....................................................10

Troubleshooting.................................................................................................14

Parts List............................................................................................................16

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new chipper shredder vacuum. It will help you

assemble, prepare and maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on

the model plate is very important if you need help from our Customer Support Department or

an authorized dealer.

• You can locate the model number by standing behind the unit and looking down at the frame below

the engine. A sample model plate is explained below. For future reference, please copy the model

number and the serial number of the equipment in the space below.

(Model Number)

(Serial Number)

WHITE OUTDOOR

PRODUCTS COMPANY

P.O. B OX 361131

CLEVELAND, OHIO 44136

Copy the model number here:

Copy the serial number here:

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Dealer Referral Line.

Call 1- (800)-949-4483 to reach the Customer Dealer Referral Line. Please have your unit’s

model number and serial number ready when you call. See previous section to locate this

information.

For more details about your machine, visit our website at www.whiteoutdoor.com

2

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of yourself and others. Read and follow all instructions in

this manual before attempting to operate this machine. Failure to comply with these instructions may

result in personal injury. When you see this symbol - heed its warning.

WARNING: Th e Engine Exhaust from this pr oduct contains chemicals kno wn to the

State of Californi a to cause cancer, birt h defects or other re productive h arm.

DANGER: This machine was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 16 years old to operate

this machine. Children 16 years old and over

should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Keep bystanders, helpers, pets, and children at

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

6. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

7. Do not put hands and feet near rotating parts or in

the feeding chambers and discharge opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

8. Never attempt to unclog either the feed intake or

discharge opening, remove or empty vacuum bag,

or inspect and repair the machine while the engine

is running. Shut the engine off and wait until all

moving parts have come to a complete stop.

Disconnect the spark plug wire and ground it

against the engine.

PREPARA TION

1. Thoroughly inspect the area where the equipment

is to be used. Remove all rocks, bottles, cans, or

other foreign objects which could be picked up or

thrown and cause personal injury or damage to the

machine.

2. Always wear safety glasses or safety goggles

during operation or while performing an adjustment

or repair, to protect eyes. Thrown objects which

ricochet can cause serious injury to the eyes.

3. Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Loose fitting clothes or

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals. Wear

leather work gloves when feeding material in the

chipper chute.

4. Before starting, check all bolts and screws for

proper tightness to be sure the machine is in safe

working condition. Also, visually inspect machine

for any damage at frequent intervals.

5. Maintain or replace safety and instructions labels,

as necessary.

6. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and

other source s of i gnitio n.

c. Never fuel machine indoors.

d. Never remove gas cap or add while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never over fill fuel tank. Fill tank to no more

than 1/2 inch below bottom of filler neck to

provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. Move machine to another

area. Wait 5 minutes before starting the

engine.

i. Never store the machine or fuel container

inside where there is an open flame, spark,

or pilot light (e.g. furnace, water heater,

space heater, clothes dryer, etc.)

3

j. To reduce a fire hazard, keep machine free

of grass, leaves, or other debris build-up.

Clean up oil or fuel spillage and remove any

fuel soaked debris.

k. Allow machine to cool at least 5 minutes

before storing.

OPERATION

1. Do not put hands and feet near rotating parts or in

the feeding chambers and discharge opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

2. Before starting the machine, make sure the chipper

chute, feed intake, and cutting chamber are empty

and free of all debris.

3. Thoroughly inspect all material to be shredded and

remove any metal, rocks, bottles, cans, or other

foreign objects which could cause personal injury

or damage to the machine.

4. If the impeller s trik es a fo reig n obj ect or if yo ur

machine should start making an unusual noise or

vibration, immediately shut the engine off. Allow the

impeller to come to a complete stop. Disconnect

the spark plug wire, ground it against the engine

and perform the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to

assure continued safe operation.

5. Do not allow an accumulation of processed

material to build up in the discharge area. This can

prevent proper discharge and result in kickback of

material through the feed opening.

6. Do not attempt to shred or chip material larger than

specified on the machine or in this manual.

Personal injury or machine damage could result.

7. Never attempt to unclog either the feed intake or

discharge opening while the engine is running.

Shut the engine off, wait until all moving parts have

stopped, disconnect the spark plug wire and

ground it against the engine before clearing debris.

8. Never operate without vacuum bag and discharge

chute properly attached to the machine. Never

empty or change vacuum bag while the engine is

running. Zippered end of vacuum bag must be kept

closed at all times during operation.

9. Never operate without either the inlet nozzle or

optional hose attachment properly attached to the

machine. Never attempt to attach or change either

attachment while the engine is running.

10. Keep all guards, deflectors and safety devices in

place and operating properly.

11. Keep your face and body back and to the side of

the chipper chute while feeding material into the

machine to avoi d acci dent al kick back i njur ies.

12. Never operate this machine without good visibility

or light. Always be sure of your footing and keep a

firm hold on the handles.

13. Do not operate this machine on a gravel surface.

14. Do not operate this machine while under the

influence of alcohol or drugs.

15. Muffler and engine become hot and can cause a

burn. Do not touch.

16. Never pick up or carry machine while the engine is

running.

MAINTENANCE AND STORAGE

1. Never tamper with safety devices. Check t heir

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the machine in safe

working condition. Also, visually inspect machine

for any damage and repair, if needed.

3. Before cleaning, repairing, or inspecting, stop the

engine and make certain the impeller and all

moving parts have stopped. Disconnect the spark

plug wire and ground it against the engine to

prevent unintended starting.

4. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer, etc.

8. Always refer to the operator’s manual for proper

instructions on off-season storage.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

4

WARNING: - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who read,

understand and follow the warnings and instr uctions in this manual and on the machine.

NOTE: Not all safety labels shown may apply to your chipper shredder vacuum.

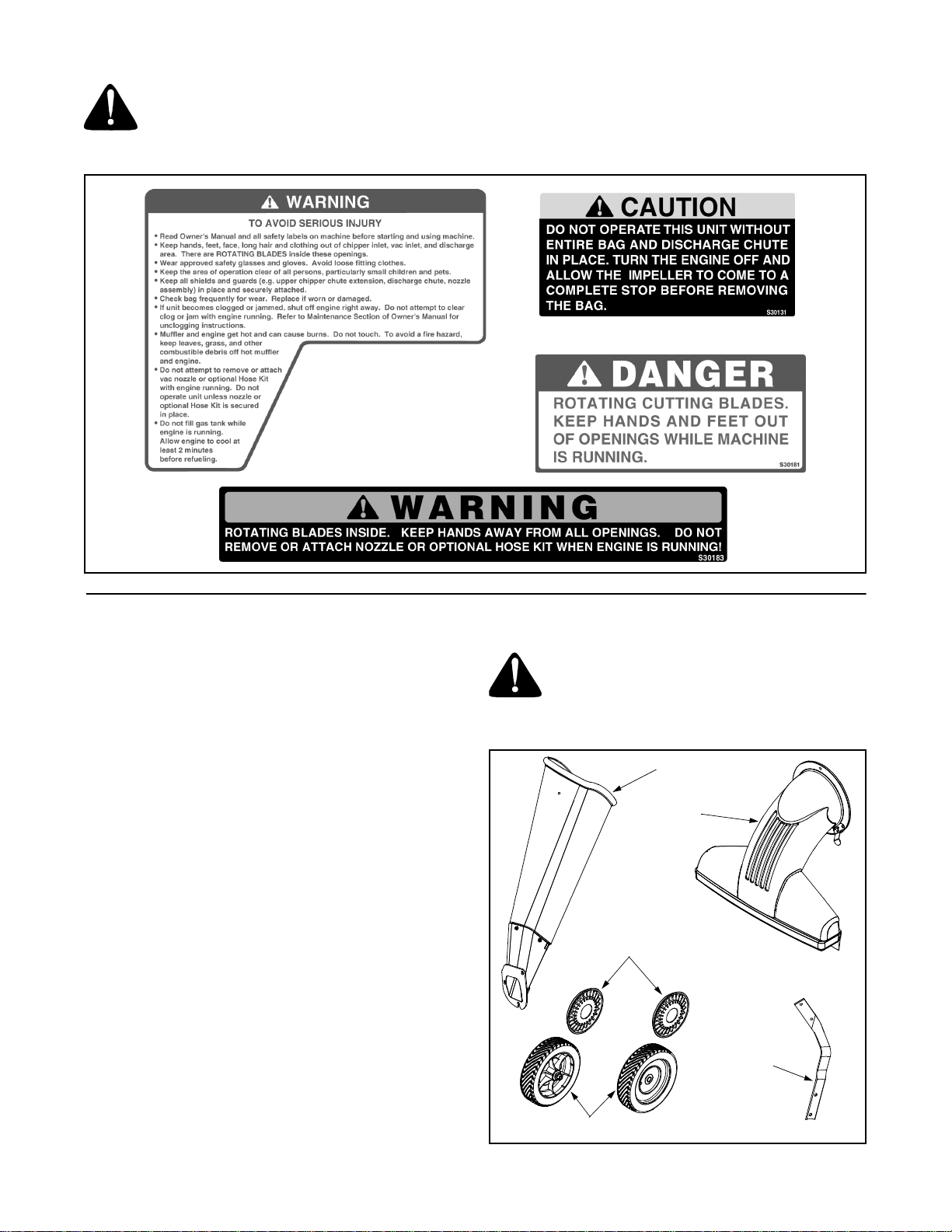

SECTION 2: ASSEMBLING YOUR CHIPPER SHREDDER VACUUM

IMPORT ANT :

in the engine. Be certain to service engine with gasoline

and oil as instructed in the separate engine manual

before operating your mower.

NOTE: Reference to right or left hand side of the

chipper shredder vacuum is observed from the

operating position.

Removing Unit From Carton

• Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to open

carton.

• Remove loose parts if included with unit (i.e.,

operator’s manual, etc.)

• Cut along corners, lay carton down flat, and remove

packing material.

• Roll or slide unit out of carton and check carton

thoroughly for loose parts.

Loose Parts In Carton (See Figure 1)

• Front Wheels

• Hub Caps

• Nozzle

• Chipper Chute

• Support Bracket

• Bag and Safety Glasses (Not Shown)

This unit is shipped without gasoline or oil

WARNING: Before setting up your chipper

shredder vacuum, disconnect the spark

plug wire from the spark plug and ground

against the engine.

Chipper

Chute

Nozzle

Hub Caps

Support

Bracket

Front Wheels

Figure 1

5

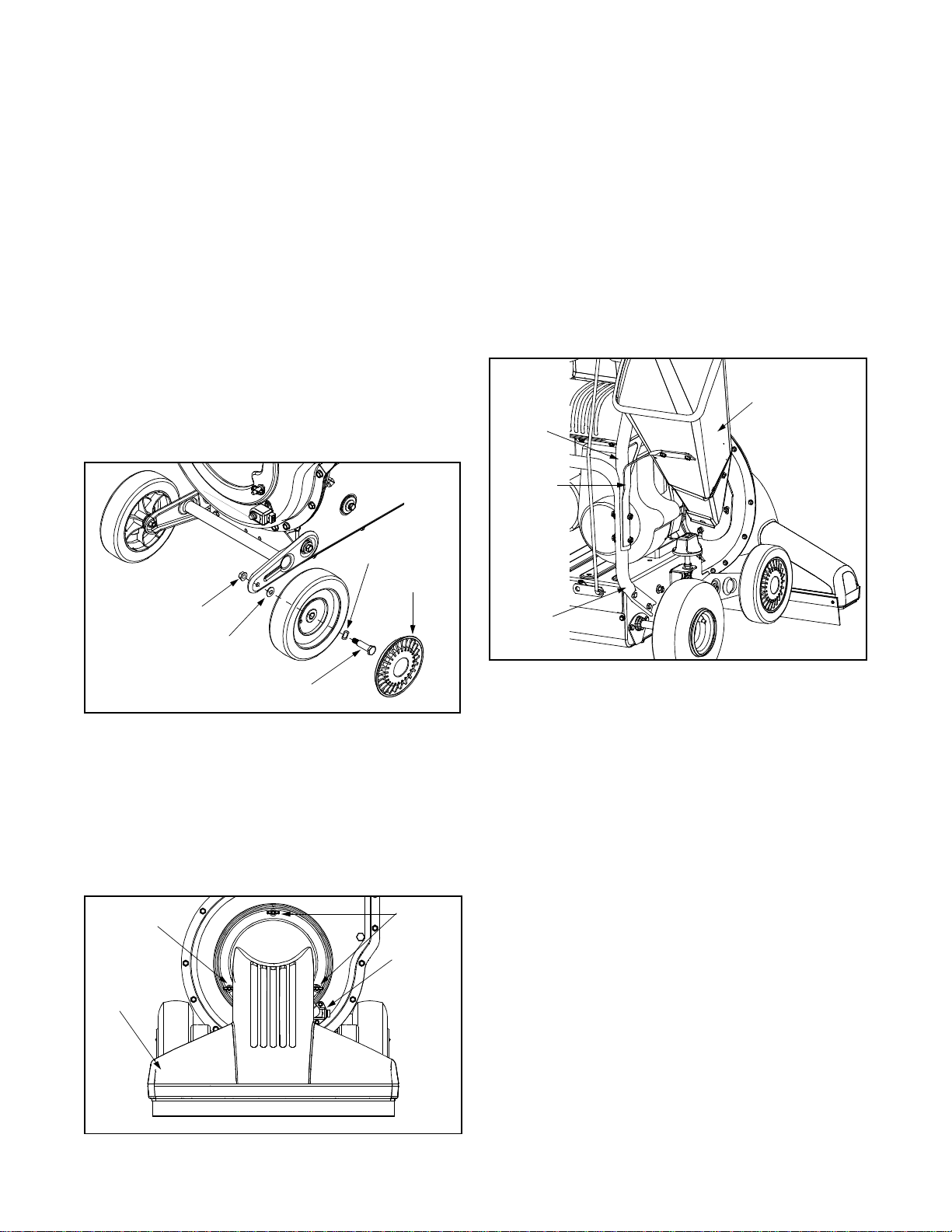

Attaching The Front Wheels

• Tilt the unit backward, so that it rests on the handle

(place a piece of cardboard under handle to avoid

scratches). Remove the packing material around

the wheel brackets.

• Remove the hex lock nuts and shoulder bolts from

the ends of the wheel bracket. See Figure 2.

• Place a wave washer on each shoulder bolt and

insert bolt through each wheel with the flat side of

wheel facing out.

• Place the cupped washer on shoulder bolt with the

crowned side against the wheel.

• Assemble each wheel to outside of wheel bracket

and secure with hex lock nut previously removed.

• Attach hub caps to wheels by placing hub cap

against the inner hub of wheel. Press firmly around

the center portion of hub cap in a circular motion.

The hub caps are flexible and it will snap over the

wheel hubs.

NOTE: The met al tab on the nozzle must de press the

safety switch button attached to the front of chipper

shredder vacuum or the engine will not start.

See Figure 3

• Set unit in the upright position.

Attaching The Chipper Chut e

• Remove the two hex bolts, flat washers, and hex

nuts that are attached to the support bracket.

• Attach the support bracket under the chipper chute

loosely using the hardware previously removed.

The hex bolts and washers should be inserted from

the inside of the chipper chute. See Figure 4.

Upper

Handle

Support

Bracket

Chipper Chute

Wave

Washer

Hub Cap

Hex Lock

Nut

Cupped

Washer

Shoulder

Bolt

Figure 2

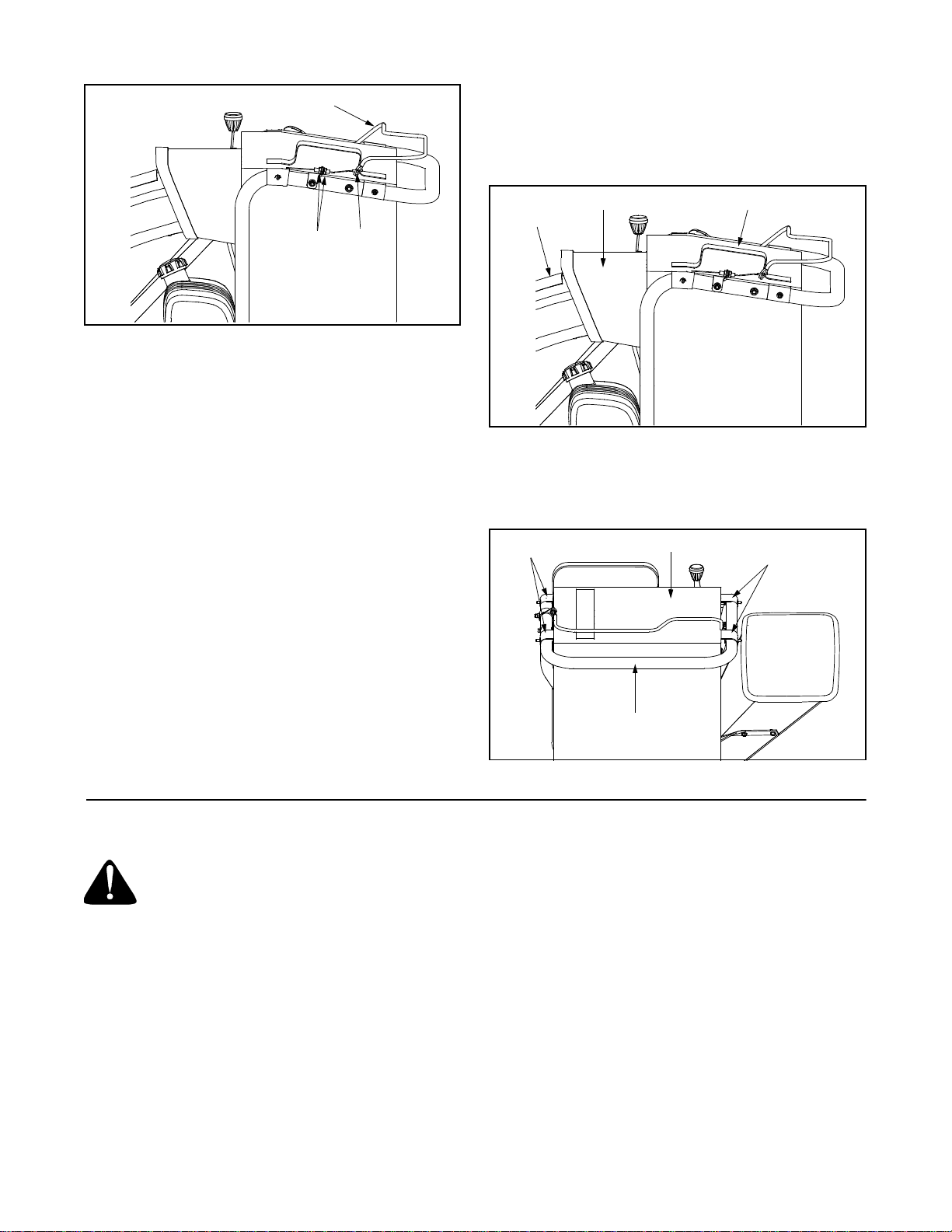

Attaching The Nozzle

• Remove three wing nuts from the front of the

chipper shredder vacuum.

• Place nozzle in position over the three studs on unit

and secure with wing nuts just removed.

See Figure 3.

Wing

Nut

Nozzle

Wing

Nuts

Safety

Switch

Lower

Handle

Figure 4

• Remove the two he x lock nuts f rom t he he x bol ts

that secure the right side of the upper handle to the

lower handle. Leave the bolts and washers in

place. See Figure 4.

• Remove three cupped washers and hex nuts from

the weld studs besides the opening on the right

side of the chipper shredder vacuum.

• Place the chipper chute over the weld studs with

the slot at the bottom. Secure with cupped washers

(cupped side of washer goes against the chipper

chute) and hex nuts just removed and only tighten

the nuts slight ly for ease of further a ssembly.

• Place the support bracket through the two bolts in

the handle. Lifting up on the chipper chute will aid in

the alignment of the holes in the support bracket

with the bolts in the handle.

• Tighten all hardware securely on the chipper chute,

support bracket, and handle.

Figure 3

Attaching The Clutch Cable To Handle

• Loosen the hex nuts at the cable bracket and back

the bottom he x nut all the way down .

• While holding the drive clutch handle up, hook the

“Z” end of the cable into the drive clutch handle

from the outside. See Figure 5.

6

Drive Clutch

Handle

Hex

Z End

Nuts

Figure 5

Clutch Cable Adjustment

Adjust the hex nuts at the cable bracket so there is no

slack in the cable, but the cable should not be tight. Do

not overtighten the cable. See Figure 5.

To check the clutch adjustment, proceed as follows:

• Push the chipper shredder vacuum backward and

forward with the drive clutch handle released. It

should move freely.

• If it does not, loosen both hex nuts at the cable

bracket. Turn bottom nut clockwise to loosen the

cable. See Figure 5.

• Engage the drive clutch handle and try to push unit

backward and forward. The wheels should lock up.

• If the wheels do not lock up, loosen both hex nuts at

the cable bracket. Turn bottom nut counterclockwise to tighten the cable.

• Recheck adjustment and tighten both hex nuts

when correct adjustment is reached.

Attaching The Bag

• Place bag under of upper handle assembly and slip

the front opening on the bag over the discharge

chute, making certain it is over the rim on the

discharge chute. See Figure 6.

Discharge

Chute

• Place the four straps on the top of the bag over

upper handle, hooking them on the studs to secure

in place. Be sure the bag is under the drive clutch

handle. See Figure 7.

Bag Straps

Bag Opening

Figure 6

Bag

Upper Handle

Bag

Bag Straps

Figure 7

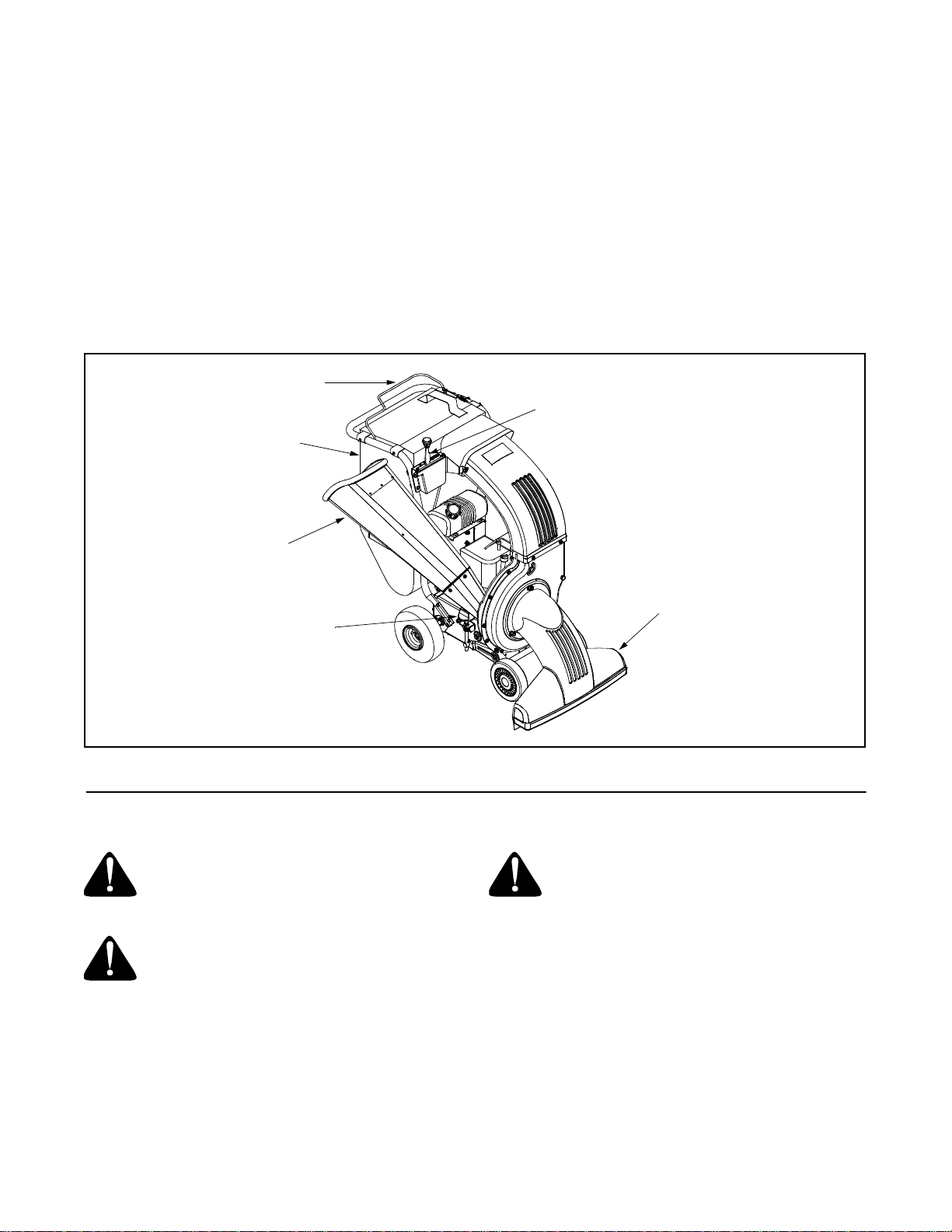

SECTION 3: KNOW YOUR CHIPPER SHREDDER VACUUM

WARNING: Be familiar with all controls

and their proper operation. Know how to

stop the machine and disengage them

quickly.

Bag

Collects shredded or chipped material fed through the

chipper chute or vacuumed up through the nozzle.

See Figure 8.

Chipper Chute

Allow twigs and small branches up to 3” in diameter to

be fed into the impeller for chipping. See Figure 8.

Nozzle Height Adjustment Knob

Used to adjust the nozzle ground clearance that will

provide the best performance for the operating

conditions. See Figure 8.

Nozzle

Yard waste such as leaves and pine needles can be

vacuumed up through the nozzle for shredding. See

Figure 8.

Drive Clutch Handle

The drive clutch handle is located above the upper

handle assembly. Squeezing the drive clutch handle

against the upper handle engages the wheel drive.

Release the drive clutch handle to stop the wheel drive.

See Figure 8.

7

Shift Lever

The shift lever is located on the top right hand side of

unit. It is used to adjust the ground speed of the chipper

shredder vacuum when the drive clutch handle is

engaged. The shift lever can be place in one of eight

positions: six forward and two reverse positions.

See Figure 8.

Starter Handle (Not Shown)

The starter handle is located on the engine. Pull the

starter handle to start engine.

Engine Controls

See the separate engine manual for the location and

function of the controls on the engine.

Drive Clutch

Handle

Bag

Throttle Control Lever (Not Shown)

The throttle control lever is located on the engine. It

controls the engine’s speed and stops the engine. See

separate engine manual packed with unit for details.

Stopping Engine

• Move throttle control lever to STOP or OFF

position.

• Disconnect spark plug wire from spark plug and

ground against the engine.

Shift Lever

Chipper

Chute

Nozzle Height

Adjustment Knob

Figure 8

Nozzle

SECTION 4: OPERATING YOUR CHIPPER SHREDDER VACUUM

WARNING: Read, understand, and follow

all instructions and warnings on the

machine and in this manual before

operating.

WARNING: Always wear the safety

glasses provided with this machine during

operation or while performing any adjustments or repairs. Thrown objects which

ricochet can cause serious injury to the

eyes.

Gas And Oil Fill-Up

Service the engine with gasoline and oil as instructed in

the separate engine manual packed with your chipper

shredder vacuum. Read instructions carefully.

Starting Engine

• Attach spark plug wire to spark plug. Make certain

• Make certain drive clutch handle is in the

WARNING: Use extreme care when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel machine indoors or while the

engine is hot or running. Extinguish

cigarettes, cigars, pipes, and other

sources of ignition.

the metal c ap on the end o f the spar k plug i s

fastened securely over the metal tip on the spark

plug.

disengaged (released) position.

8

Loading...

Loading...