Specifications and Main Features

- Maximum number of threads: 4, 3, or 2 threads

- Maximum number of needles: 2 Needles (1 needle)

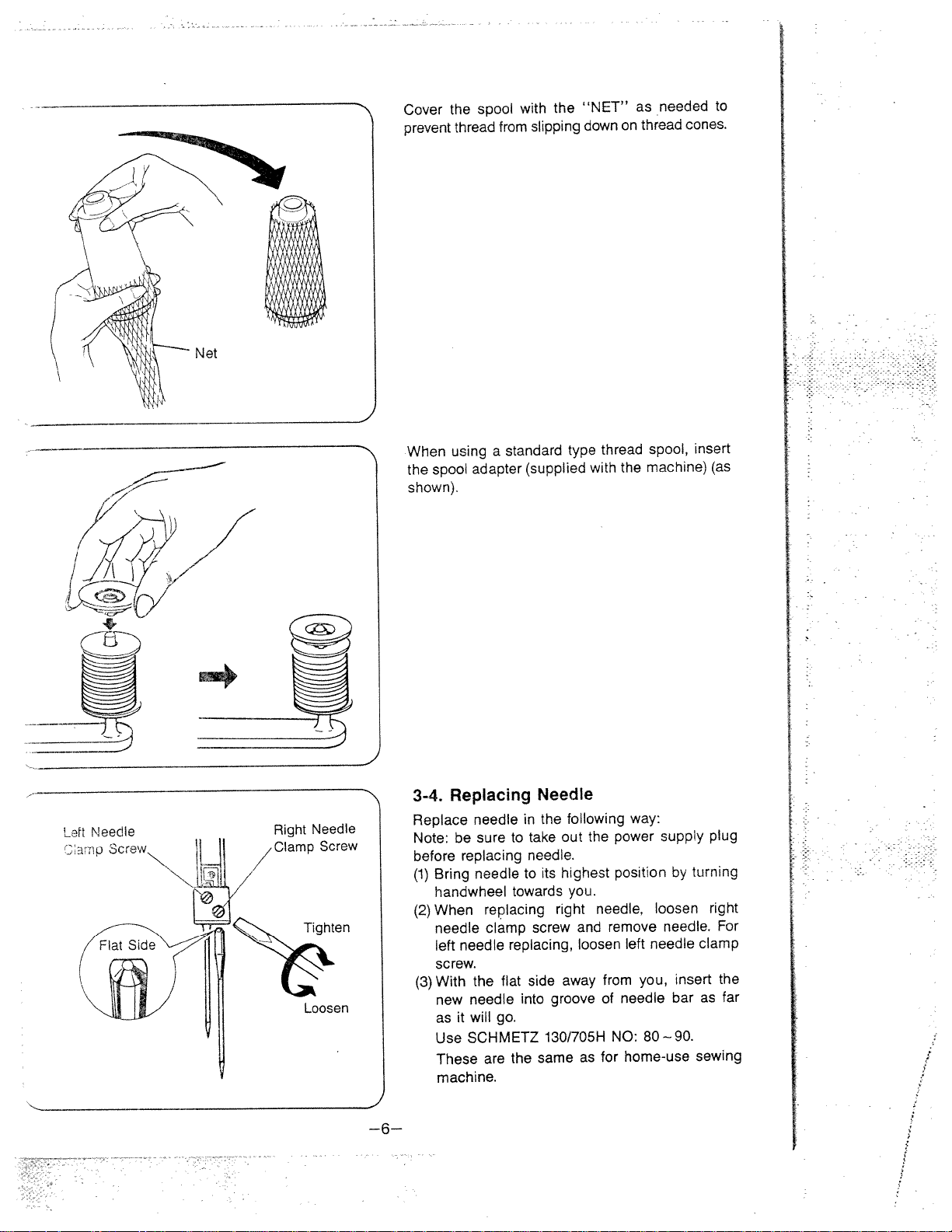

- Needles: Standard SCHMETZ 130/705H NO: 80 ~ 90

- Inter-Needle Spacing: 2mm

- Overlock Edge Width: Standard 5.5 mm (Range 5.2 ~ 7 mm)

- Stitch Length: Length of 1: 5 mm

- Ratio of differential feeds: Normal 1: (0.7 ~ 2)

- Sewing Speed: 1500 RPM

- Specifications of the Sewing Machine:

- Width: 300mm

- Depth: 230mm (Maximum 340mm)

- Height: 290mm (Maximum 350mm)

- Weight: 8.7 kg

Frequently Asked Questions

Q: What are the steps to removing and installing a needle in the sewing machine?

A: For needle removal, ensure that the electric supply to the sewing machine has been cut off. Effect the highest level of the needle using the hand wheel, and start untightening the screw of the needle clamp. Remove the old needle and fit in a new one while ensuring the flat end points toward you and tighten the screw once again.

Q: Who are the people who recommend this machine, and for which materials can this machine be used?

A: It is mainly designed for hercules polyester (spun, filament) products, and for thicker substances #60/2 to #50/2 twisted threads are advised.

Q: How do I regulate the cutting width?

A: You can see the dial that changes the cutting width from around 5.2 mm (0.2”) to about 7mm (0.28”) based on the material that is used on the sewing machine upon opening the front cover.

Q: What should I do if the machine does not sew?

A: Examine whether the sewing machine has been plugged in properly or if the foot pressing down is properly fastened. In addition, check that the needle is not bent and is inserted correctly in its designated place.

Q: Is this machine able to sew through fabric of different thickness?

A: The machine is equipped with an adjustable presser foot pressure mechanism which allows it to sew through fabric of different thickness.

User Manual

Loading...

Loading...