Whirlwind W2 61 User Manual

Whirlwind

W2 61 Pin Connector System Technical Data

Materials and

Finishes:

• Contacts: Copper alloy,

hard gold plate over

nickel under plate per

MIL-G-45204

• Insulators: Low temperature

elastomer

• ‘O’ Rings and Seals:

Low temperature elastomer

• Shells and Dust Caps:

All aluminum alloy, black

anodized coating

Chain-Stainless steel

Mechanical Data:

• Operating Temperature:

• Contacts: #20 AWG Solder

type (7.5 Amp rating)

• Contact Retention:

15 lbs. minimum

• Connector Engagement

and Separation Forces:

44 in. lbs. maximum

• Polarization: 5 Keyways

Electrical Data:

• Operating Voltage: 850

VDC or 600 VAC rms

maximum

• Insulation Resistance:

5000 megohm minimum

• Contact Resistance:

6 milliohms maximum

-40°C to +105°C

-40°Fto -t-221°F

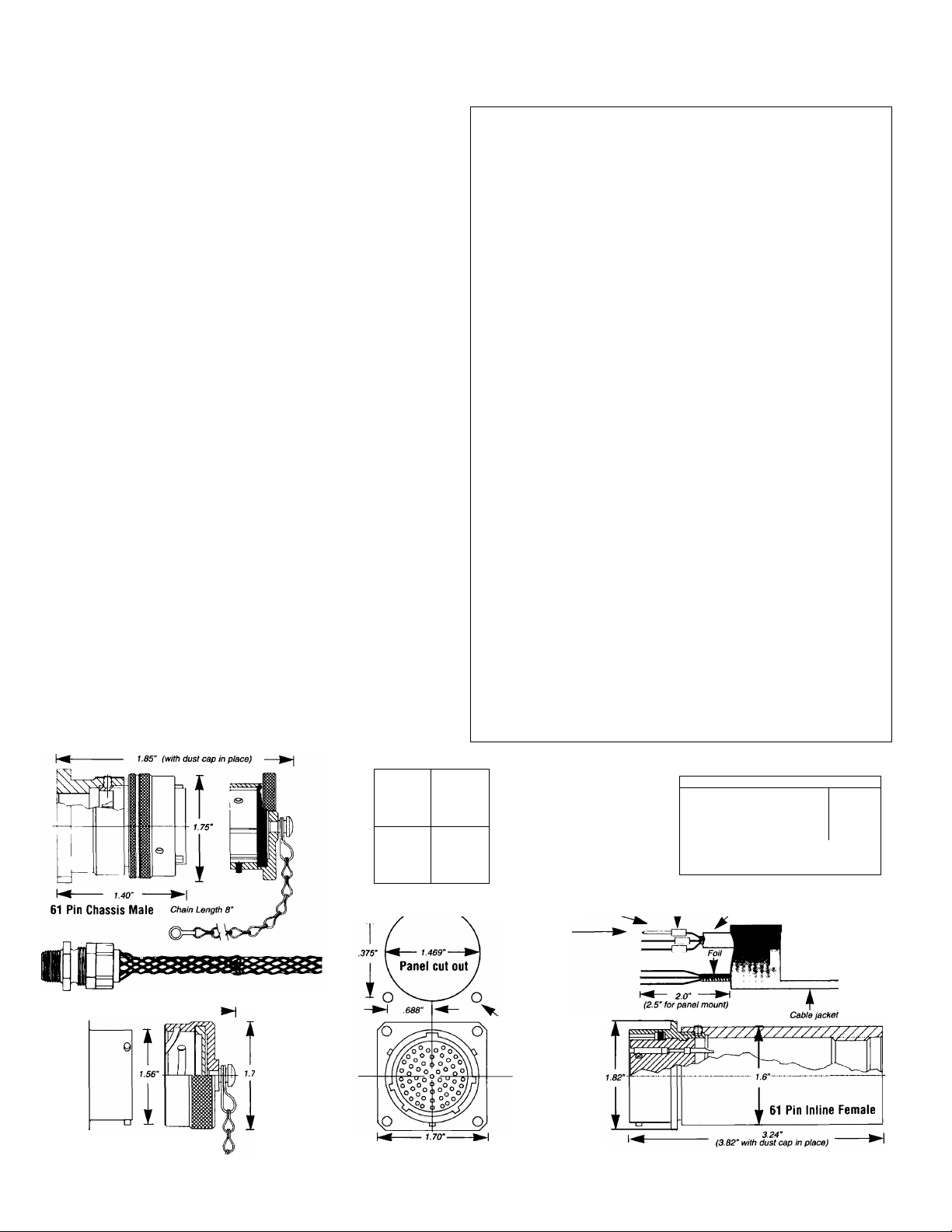

The Whirlwind W2 is a 61 contact, quick disconnect connector

system based on the proven MIL-26482 multipin standard. The pin

and socket modules are shell size 24 with a standard 61 contact

insert arrangement. The solder style contacts are permanently

mounted in resilient rubber insulators to provide years of trouble

free service.

Whirlwind manufactures a robust aluminum backshell to protect

the soldered connections and provides a waterproof mesh grip for

an absolutely reliable strain relief on the cable. The W2 system

utilizes a 61 pin male insert in a plug shell, with a quarter-turn

locking ring and a 61 socket female insert in a receptacle shell with

studs, that mates with the male plug shell.

Whirlwind provides the W2 in four standard configurations, male

and female inline and male and female chassis mount. The W2 can

be used to interconnect up to 20 balanced, shielded signal lines.

W2CF

AB60FP

AB60CAP

PT1-16BK-1.5

PT3-16BK-1.0

PT1-16BK-0.5

W2 Pin Out

W2CM

AB60MI

AB60CAPWT

AB60MPA

PT1-16BK-1.5

PT3-16BK-1.0

PT1-16BK-0.5

W2 Pin Out

W21F

AB60FI

AB60CAP

AB60H

AB60G

ABKR

PT1-16BK-1.1

PT3-16BK-0.5

PT1-16BK-0.5

W2 Pin Out

W2IM

AB60MI

AB60CAPWT

AB60H

AB60G

ABKR

PT1-16BK-1.1

PT3-16BK-0.5

PT1-16BK-0.5

W2 Pin Out

Inline kits available w/ DCG75-3/4 Oversize Strain Relief (grip range .75" - .875").

W2IF-OS Female Kit same as W2IF Kit (above) except with one DCG75-3/4.

W2IM-OS Male Kit same as W2IM Kit (above) except with one DCG75-3/4.

Female Panel Connector / Cap, Wiring Kit Complete

61 Pin Female Panel Mount Body with Studs

Dust Cap with Ring For Female 61 Pin

Drain Wire Insulator 1/16” BIk Shrink Tube 1.5”

Mylar / Foil Insulator 3/16” BIk Shrink Tube 1.0”

Solder Cup Insulator 1/16" BIk Shrink Tube 0.5”

Wiring Diagram For 61 Pin

Male Panel Connector / Cap, Wiring Kit Complete

61 Pin Male Inline Body with Ring

Dust Cap with Studs For Male 61 Pin

Panel Mount 61 Pin BIk Flange with Set Screw

Drain Wire Insulator 1/16” BIk Shrink Tube 1.5”

Mylar / Foil Insulator 3/16” BIk Shrink Tube 1.0”

Solder Cup Insulator 1/16” BIk Shrink Tube 0.5”

Wiring Diagram For 61 Pin

Female Inline Connector / Cap, Wiring Kit Complete

61 Pin Female Inline Body with Studs

Dust Cap with Ring For Female 61 Pin

61 Pin Inline Housing with Set Screws

39-61 Inline Strain Relief Grip Range .375”-.50”

16mm Split Ring For Dust Cap Chain

Drain Wire Insulator 1/16” BIk Shrink Tube 1.1”

Mylar / Foil Insulator 3/16" BIk Shrink Tube 0.5”

Solder Cup Insulator 1/16” BIk Shrink Tube 0.5”

Wiring Diagram For 61 Pin

Male Inline Connector / Cap, Wiring Kit Complete

61 Pin Male Inline Body with Ring

Dust Cap with Studs For Male 61 Pin

61 Pin Inline Housing with Set Screws

39-61 Inline Strain Relief Grip Range .375”-.50”

16mm Split Ring For Dust Cap Chain

Drain Wire Insulator 1/16” BIk Shrink Tube 1.1"

Mylar / Foil Insulator 3/16” BIk Shrink Tube 0.5”

Solder Cup Insulator 1/16" BIk Shrink Tube 0.5”

Wiring Diagram For 61 Pin

1

1

20

20

60

1

1

1

1

20

20

60

1

1

1

1

1

1

20

20

60

1

1

1

1

1

1

20

20

60

1

(Strain relief bushing adds approximately 2’ to rear of connector)

^ 1.35’ (with dust cap in place) -

61 Pin Chassis Female

mount on front of panel) g., p¡„ (,,,35515

(Chassis connectors

'q^

Ir o°i

°o °o

11° o“ o

\\WnO o

'\\\° o„ '

61 Pin Chassis Male

Q ________ Q Drain wire Solder cup insulator Foil insulator

3° 1 11

0^0

o°o o////

o/ j a

0 .147’ for 46 screw

0 .172" for 48 screw

-

--------- --------

//////

r 1

1.6’

----------

^ 61 pin Inline Male

(3.72’ with dust cap in place)

3.24’

Cable

Preparation

Diagram

61 Pin

56 Pair Color Code

XLR Pin 3

Pair # (-)

1

Black

2

Black

3 Black

4

Black

5 Black

6 Black

7

Black

8 Red

9

Red Green

10 Red

11

Red Yellow

12

Red Brown

13 Red

14

Green

15 Green

16 Green

17

Green

18

Green

19

White Blue

20

White Yellow

21

White Brown

22

White

23 Blue

24

Blue Brown

25 Blue

26 Brown

27

Brown

28

Orange Yellow

29

Purple

30

Purple

31

Purple

32

Purple Green

33

Purple

34

Purple Yellow

35 Purple

36

Purple Black

37

Gray

38

Gray Brown

39

Gray

40

Gray Green

41

Gray

42

Gray

43 Gray Black

44

Gray

45 Pink

Pink

46

47

Pink

48 Pink Yellow

49 Pink

50 Pink

51 Pink

52 Pink

53 Beige

54

Beige Green

55 Beige

56

Beige Yellow

Pin 2 Pin 1

(+) (g)

Red

White

Green

Blue

Yellow

Brown

Orange

White

Blue

Orange

White

Blue

Yellow

Brown

Orange

Orange

Yellow

Orange

Yellow

Orange

Orange

Red

White

Blue

Brown

White

Red

Orange

Yellow

Blue

White

Green

Blue

Brown

Orange

Purple

Gray

White

Blue

Whirlwind W2 61 Pin Connector

Male And Female Wiring Code

1. Use these drawings for wiring 61 contact connectors both Male (Pins) and Female (Sockets).

2. The standard Whirlwind layout begins at the stage box. Chassis mount Female connectors

with studs are the first choice for panel or box mounting. Inline Males with locking rings are the

first choice for cable connectors.

3. Systems using connectors of this series require only that a Male connector with ring plugs

into a Female connector with studs.

Solder Side of

MALE Connector

(Pins)

Solder Side of

FEMALE

Connector

(Sockets)

vfhirlwind

PO Box 12692 Rochester,

New York 14612

(716) 663-8820

Drawing can be used for mating face of opposite sex connector

Effective 11/93

Loading...

Loading...