Whirlpool YWML75011HN, YWML55011HW, YWML75011HZ, YWML75011HW, YWML75011HV Installation Instructions

...

MICROWAVE HOOD COMBINATION

INSTALLATION INSTRUCTIONS

This product is suitable for use above electric or gas cooking products up to and including 36" (91.4 cm) wide. See the “Installation

Requirements” section for further notes.

These installation instructions cover different models. The appearance of your particular model may differ slightly from the illustration

in these installation instructions.

Table of Contents

MICROWAVE HOOD COMBINATION SAFETY. ........................... 1

INSTALLATION REQUIREMENTS ................................................2

Tools and Parts ............................................................................2

Location Requirements ................................................................ 2

Product Dimensions ..................................................................... 3

Electrical Requirements ...............................................................3

INSTALLATION INSTRUCTIONS ...................................................4

Wall Venting Installation Only ....................................................... 4

Install Damper Assembly (for wall venting only) .......................... 4

Roof Venting Installation Only ......................................................4

Install Damper Assembly (for roof venting only) .......................... 4

Vent Cover Installation...................................................................5

Locate Wall Stud(s) ......................................................................5

Mark Rear Wall .............................................................................7

Drill Holes in Rear Wall .................................................................8

Attach Mounting Plate to Wall .....................................................8

Prepare Upper Cabinet ................................................................9

Install the Microwave Oven .......................................................... 9

Complete Installation .................................................................10

VENTING DESIGN SPECIFICATIONS ......................................... 11

ASSISTANCE ................................................................................12

Replacement Parts .....................................................................12

Accessories ................................................................................12

MICROWAVE HOOD COMBINATION SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

instructions.

W11124890B

can be killed or seriously injured if you don't

follow

INSTALLATION REQUIREMENTS

Tools and Parts

Tools needed

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

■ Measuring tape

■ Pencil

■ Masking tape or

thumbtacks

■ Scissors

■ No. 3 Phillips screwdriver

for ¼- 20 x 3" bolts

■ Drill

3

■

/16" (5 mm), 3/8" (10 mm),

5

/8" (16 mm) drill bits

3

■

/4" (19 mm) hole saw

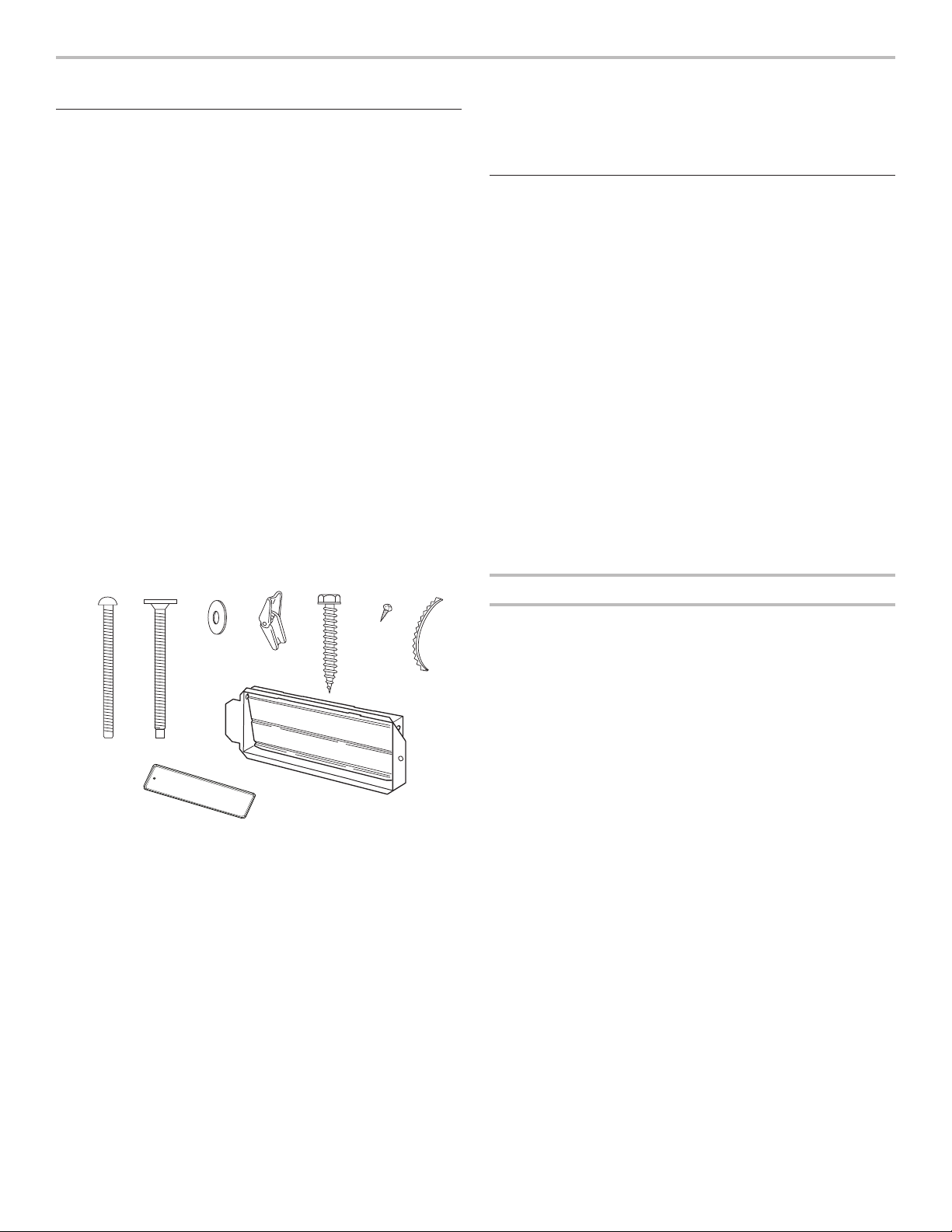

Parts supplied

For information on reordering, see the “Replacement Parts”

section.

NOTE: The hardware items listed here are for wood studs. For

other types of wall structures, be sure to use appropriate

fasteners.

A

B

C

J

■ Diagonal wire cutting

pliers

■ Stud finder

7

■

/16" socket wrench

(or box wrench) for

1

/4" x 2" lag screws

■ 1½" (3.8 cm) diam. hole

drill bit for wood or metal

cabinet

■ Keyhole saw

■ Caulking gun and

weatherproof caulking

compound

■ Duct tape

DEF

H

G

Materials Needed

Standard fittings for wall or roof venting. See the “Venting Design

Specifications” section.

Location Requirements

IMPORTANT: Check the opening where the microwave oven will

be installed. The location must provide:

■ Minimum installation dimensions. See the “Installation

Dimensions” illustration.

■ Minimum one 2" x 4" (50.8 x 101.6 mm) wood wall stud and

minimum 3/8" (10 mm) thickness drywall or plaster/lath within

cabinet opening.

■ Support for weight of 150 lbs (68 kg) which includes

microwave oven and items placed inside the microwave

oven and upper cabinet.

■ Grounded electrical outlet inside upper cabinet. See the

“Electrical Requirements” section.

NOTES:

■ If installing the microwave oven near a left sidewall, make

sure there is at least 6" (15.2 cm) of clearance between the

wall and the microwave oven so that the door can open fully.

■ Some cabinet and building materials are not designed to

withstand the heat produced by the microwave oven for

cooking. Check with your builder or cabinet supplier to make

sure that the materials used will not discolor, delaminate, or

sustain other damages.

Special Requirements

For Wall Venting Installation Only:

■ Cutout must be free of any obstructions so that the vent fits

properly and the damper blade opens freely and fully.

For Roof Venting Installation Only:

■ If you are using a rectangular-to-round transition piece, the

3" (7.6 cm) clearance needs to exist above the microwave

oven so that the damper blade can open freely and fully. See

“Rectangular to Round Transition” illustration in the “Venting

Design Specifications” section.

A. 3/16-24 x 3" round-head bolts (2)

1

B.

/4-20 x 3" flat-head bolts (2)

C. Washers (2)

3

D.

/16" toggle nuts (2)

1

E.

/4" x 2" lag screws (2)

F. Sheet metal screws (2)

G. Power supply cord bushing (1)

H. Damper assembly (for wall or roof

venting)

J. Vent cover (2)

Not Shown:

■ Upper cabinet template

■ Mounting plate

(Located on the upper

polyfoam)

■ Grease filters

■ Charcoal filters

NOTE: Depending on model, grease filter and charcoal filter may

be combined.

2

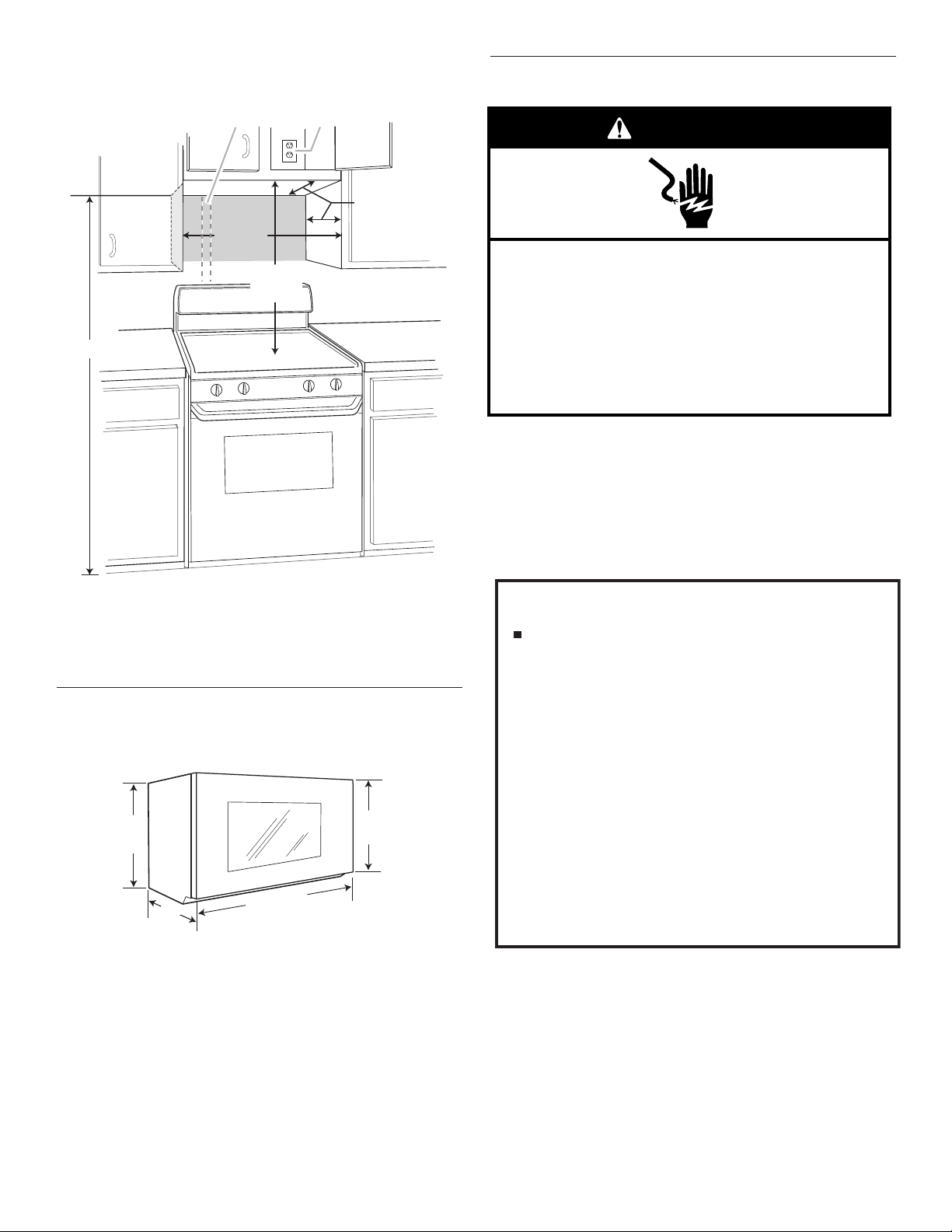

Installation Dimensions

A B

29

⁄

" (76.0 cm)

10

26.2cm

18"

45.5cm

10

26.2cm

/

"

/

"

NOTE: The grounded 3 prong outlet must be inside the upper

cabinet. See the “Electrical Requirements” section.

12" (30.5 cm) min.

14" (35.6 cm) max.

upper cabinet and

side cabinet depth

60" ( 152.4 cm) min.

30"

(76.2 cm)

min.

24"

(61 cm)

typical*

Electrical Requirements

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Observe all governing codes and ordinances.

Required:

■ A 120-volt, 60 Hz, AC-only, 15- or 20-amp electrical supply

with a fuse or circuit breaker

Recommended:

■ A time-delay fuse or time-delay circuit breaker

A. 2" x 4" wall stud

B. Grounded 3 prong outlet

*24” (61 cm) is typical for 60” (152.4 cm) installation height.

Exact dimensions may vary depending on type of range/

cooktop below.

Product Dimensions

*Overall depth of product will vary slightly depending on

door design.

■ A separate circuit serving only this microwave oven

GROUNDING INSTRUCTIONS

For all cord connected appliances:

The microwave oven must be grounded. In the event of

an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric

current. The microwave oven is equipped with a cord

having a grounding wire with a grounding plug. The plug

must be plugged into an outlet that is properly installed

and grounded.

WARNING: Improper use of the grounding plug can

result in a risk of electric shock. Consult a qualified

electrician or serviceman if the grounding instructions are

not completely understood, or if doubt exists as to whether

the microwave oven is properly grounded.

Do not use an extension cord. If the power supply cord is

too short, have a qualified electrician or serviceman install

an outlet near the microwave oven.

SAVE THESE INSTRUCTIONS

3

A

BC D

A

B

A

C

D

Charcoal filter

INSTALLATION INSTRUCTIONS

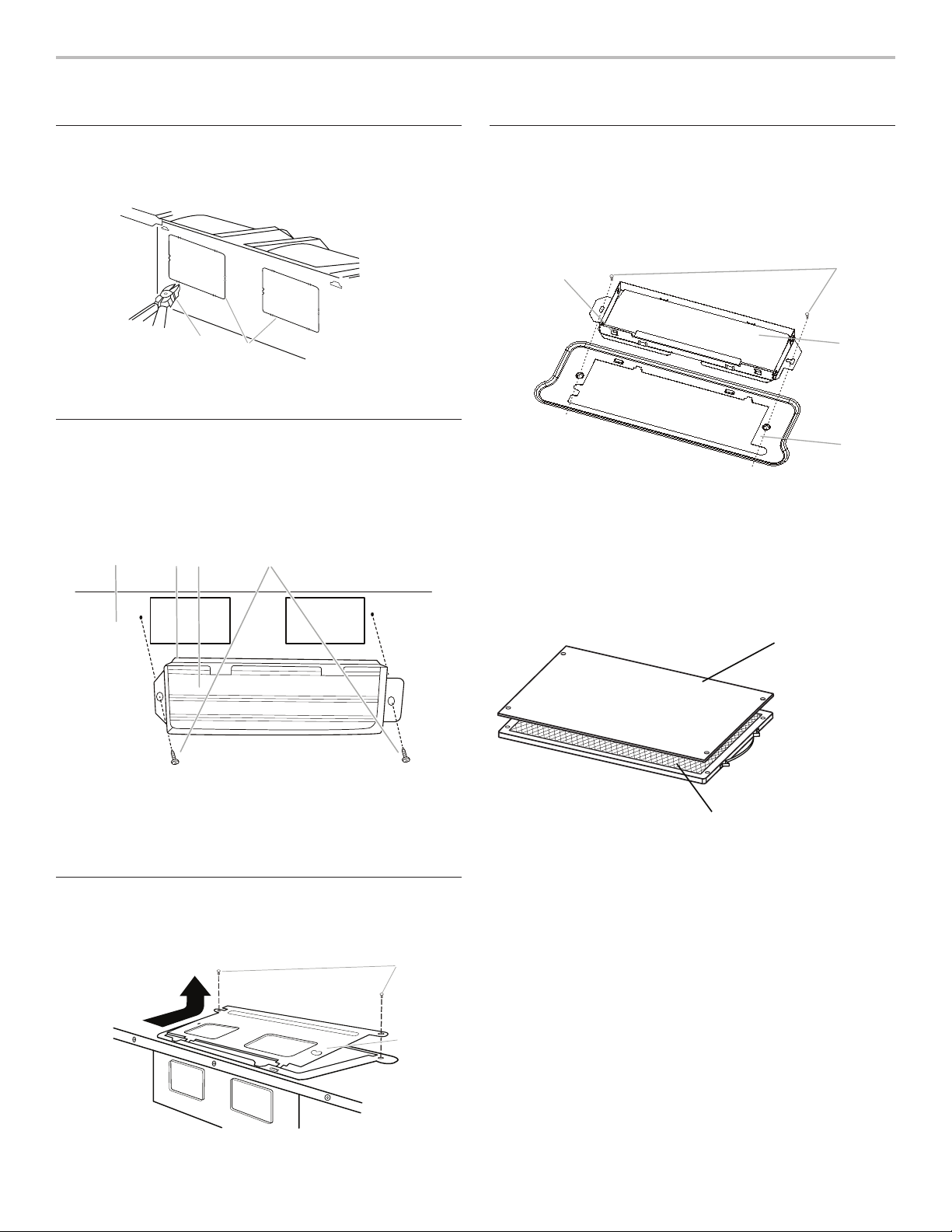

Wall Venting Installation Only

1. Using diagonal wire cutting pliers, gently snip out the

rectangular vent cover on the damper plate.

A

A. Diagonal wire cutting pliers

B. Damper vent covers

B

Install Damper Assembly

(for wall venting only)

1. Check that damper blade moves freely, and opens fully.

2. Position the damper assembly on the back of the microwave

oven so that the damper blade hinge is at the top, and the

damper blade opens away from the microwave oven.

Install Damper Assembly

(for roof venting only)

1. Check that damper blade moves freely, and opens fully.

2. Position the damper assembly on the top of microwave oven

so that the damper blade hinge is at the top, and the damper

blade opens away from the microwave oven.

B

A. Screws

B. Damper assembly

C Damper blade

D Top of the microwave oven

3. Secure damper assembly with 2 sheet metal screws.

Note: To ensure good performance of airflow, for Wall and Roof

venting, remove the charcoal filter from the bottom plate before

operating the microwave oven.

A. Back of microwave oven

B. Damper assembly

C. Damper blade

D. Sheet metal screw

3. Secure damper assembly with 2 sheet metal screws.

Roof Venting Installation Only

1. Remove screws attaching damper plate to top of microwave

oven exterior. Slide damper plate toward the front of the

microwave oven and lift up.

4

A. Screws

B. Damper plate

Grease filter

Vent Cover Installation

E

A

E

(for both upper vent and wall vent installation)

1. Remove screws attaching vent cover B, C and D to top of

microwave exterior. Slide out vent covers B, C and D.

Keep the vent cover C for step 2 use.

A

2. Place the vent cover C (removed from step 1) to the first

position to the left and rotate it 180 degrees.

C

B

C

D

A. Screws

B. Vent Cover

C. Vent Cover

D. Vent Cover

E. Top front of the

microwave

NOTE: Keep the vent cover B and vent cover D for recirculation

in future.

3. Remove the vent covers located in the upper polyfoam (see

item J in "Parts Supplied" section).

4. Attach the vent covers to vents B & C using the screws

removed in step 1.

B

C

A. Screw

B. Vent cover (located

in upper polyfoam)

C. Vent cover (located

in upper polyfoam)

E. Top front of the

microwave

Locate Wall Stud(s)

NOTE: If no wall studs exist within the cabinet opening, do not

install the microwave oven.

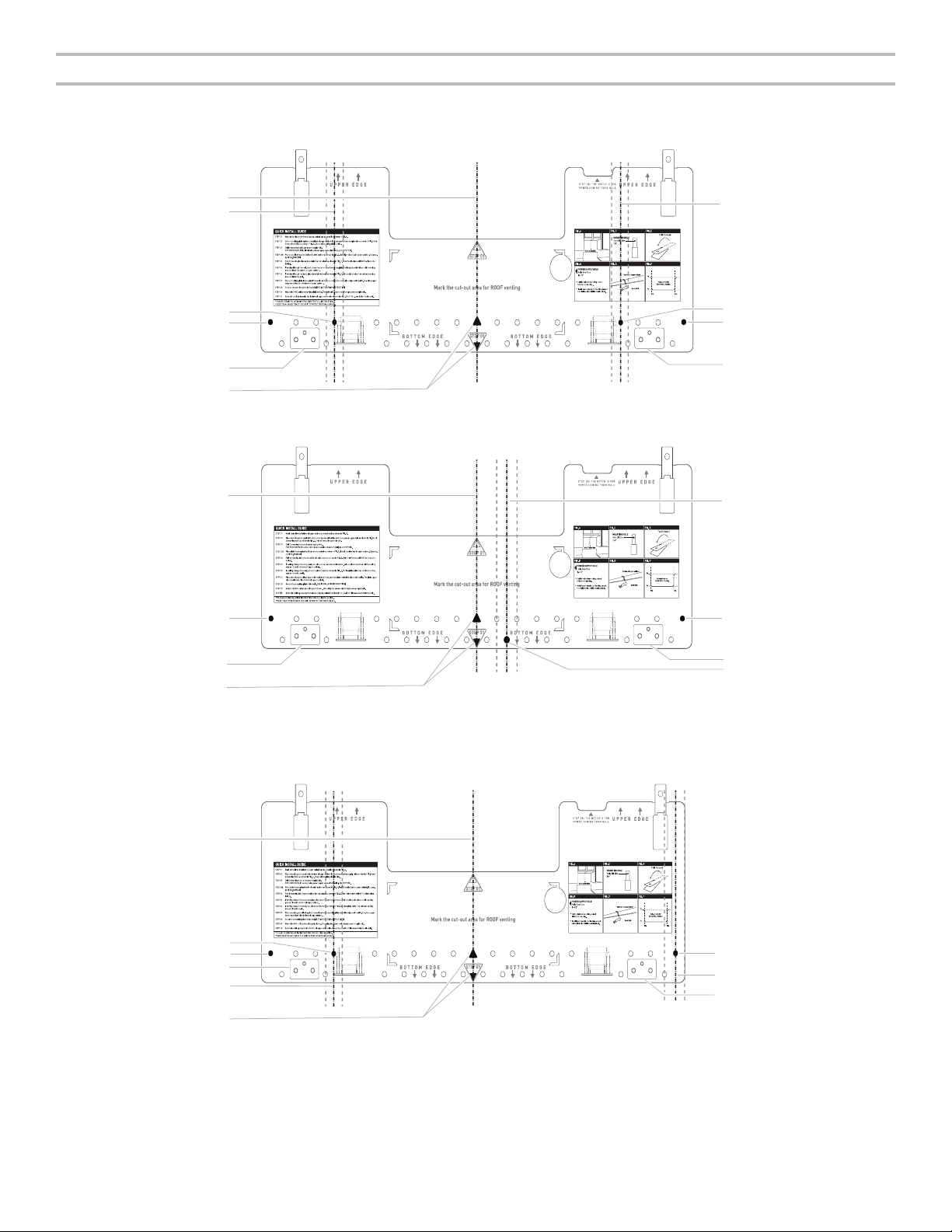

See illustrations in “Possible Wall Stud Configurations.”

1. Using a stud finder, locate the edges of the wall stud(s)

within the opening.

2. Mark the center of each stud and draw a plumb line down

each stud center. See illustrations in “Possible Wall Stud

Configurations.”

5

Possible Wall Stud Configurations

C

F

D

Figure 1

C

F

D

Figure 3

E

F

Figure 2

These depictions show examples of preferred installation configurations with the mounting plate.

No Wall Studs at End Holes

B

D

A

E

C

A

E

No Wall Studs at End Holes

B

A

C

A

E

D

NOTE: If wall studs is within 6" (15.2 cm) of the vertical centerline (see "Mark Rear Wall" section), only recirculation or roof venting

installation can be done.

Wall Studs at End Holes

B

D

A

E

A. End holes (on mounting plate)

B. Cabinet opening vertical centerline

C. Wall stud centerlines

D. Holes for lag screws

E. Support tabs

F. Mounting plate center markers

A,

C

E

6

Wall Studs at End Holes

Figure 4

A,D

F

D

A

A

Upper cabinet bottom

Mounting plate end hole

B

The microwave oven must be installed on a minimum of 1 wall

stud, preferably 2, using a minimum of 1 lag screw, preferably 2.

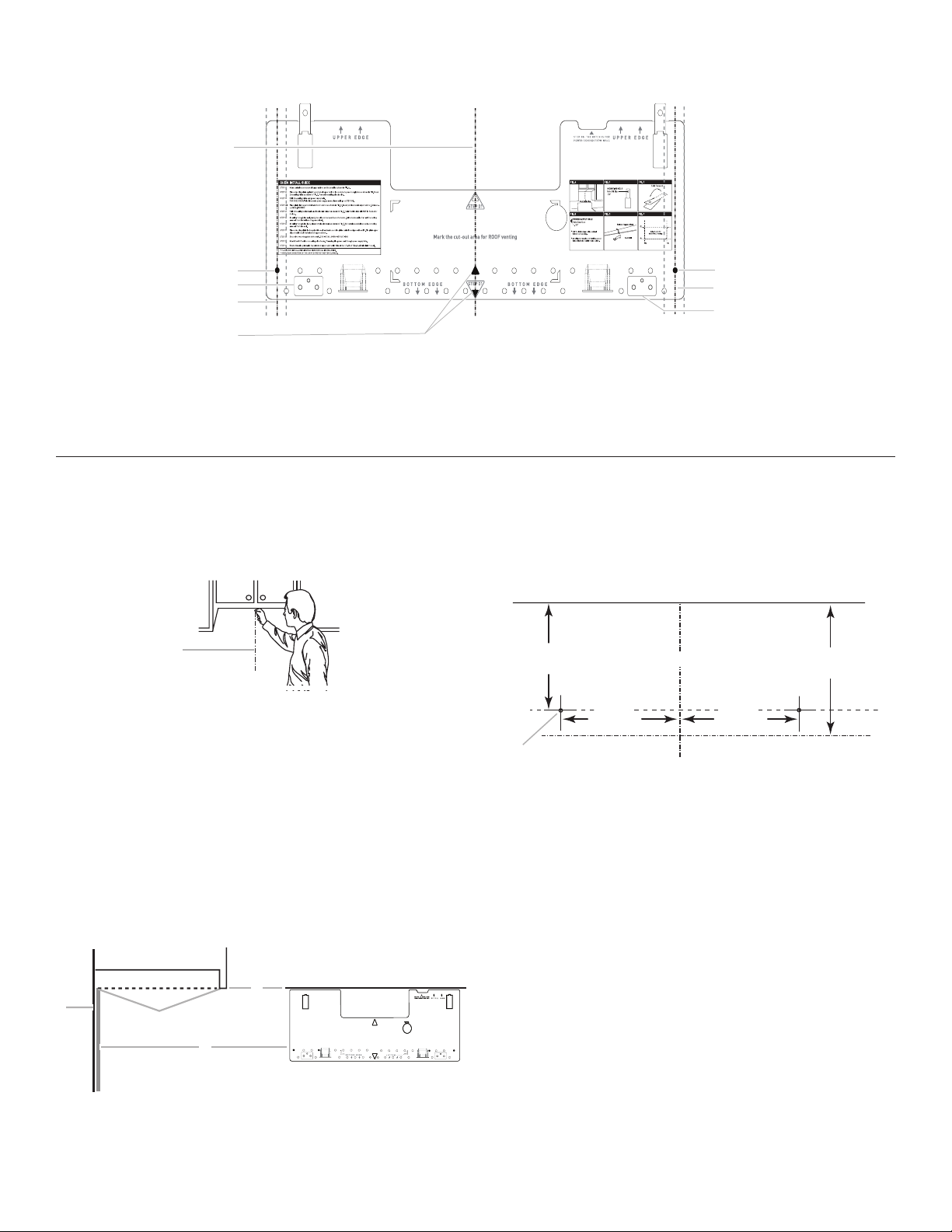

1. Using measuring tape, find and clearly mark the vertical

centerline of the opening.

2. Align the center markers on the mounting plate to the

centerline on the wall, making sure it is level, and that the top

of the mounting plate is butted up against the bottom edge

of the upper cabinet.

NOTES:

■ If the front edge of the upper cabinet is lower than the

back edge, lower the mounting plate so that its top is

level with the front edge of the cabinet.

■ If the mounting template is damaged or unusable,

measure and mark the wall with the dimensions

described in

Step 4.

E

C

A. End holes (on mounting plate)

B. Cabinet opening vertical centerline

C. Wall stud centerlines

D. Holes for lag screws

E. Support tabs

F. Mounting plate center markers

A,

C

E

Mark Rear Wall

3. Holding the mounting template in place, mark both holes

in the lower corners and draw a horizontal line across the

bottom edge of the mounting template. These represent the

mounting plate’s end holes and bottom edge.

4. Remove the mounting template and check the markings:

A. Centerline

15³⁄₄"

(40.0 cm)

14¹⁄₈"

(35.9 cm)

■ The bottom edge line must be 10.47" (26.6 cm) from the

Centerline

14¹⁄₈"

(35.9 cm)

Bottom of mounting plate

bottom of the upper cabinet and must be level.

■ The end holes must be 8.78" (22.3 cm) from the bottom edge

of the upper cabinet and must be on a level line with each

other. They must each be 14¹⁄8" (35.9 cm) from the centerline.

5. With the support tabs facing forward (see illustrations in

the “Locate Wall Stud(s)” section), align the mounting plate

center markers to the centerline on the wall, making sure its

bottom edge is aligned to the horizontal line drawn in Step 3

and that the end holes are properly marked. Make sure the

mounting plate is level.

6. Holding the mounting plate in place, find the wall stud

D

C

B

centerline(s) drawn in Step 2 of “Locate Wall Stud(s)” and

mark at least 1, preferably 2 hole(s) through the mounting

plate, closest to the wall stud centerline(s). See figures 1,

2, and/or 3 in “Possible Wall Stud Configurations” in the

“Locate Wall Stud(s)” section. The blackened holes in the

shaded areas are ideal hole locations.

7. Set the mounting plate aside.

17¹⁄₄"

(43.8 cm)

A. Rear wall

B. Mounting Template

C. Top of mounting template must

align with front edge of cabinet

D. Front edge of upper cabinet

7

Wall Venting Installation Only

A

A

B

Upper cabinet bottom

4" (10.2 cm)

6" (15.2 cm)6" (15.2 cm)

Centerline

8. Mark the centerline 3/8" (1 cm) down from the bottom edge of

the upper cabinet.

9. Using measuring tape, measure out 6" (15.2 cm) on both

sides of the centerline, and mark.

10. Measure down 4" (10.2 cm) from the mark made in step 8

and mark.

11. Using a straightedge, draw the 2 horizontal, level lines

through the marks made in steps 8 and 10.

12. Draw the 2 vertical plumb lines down from the marks made

in step 9 to complete the 12" x 4" (30.5 x 10.2 cm) rectangle.

This is the venting cutout area.

13. Cut a ³⁄4" (19 mm) hole in one corner of the cutout area.

14. Using a keyhole saw, cut out the venting cutout area.

³⁄₈" (1 cm)

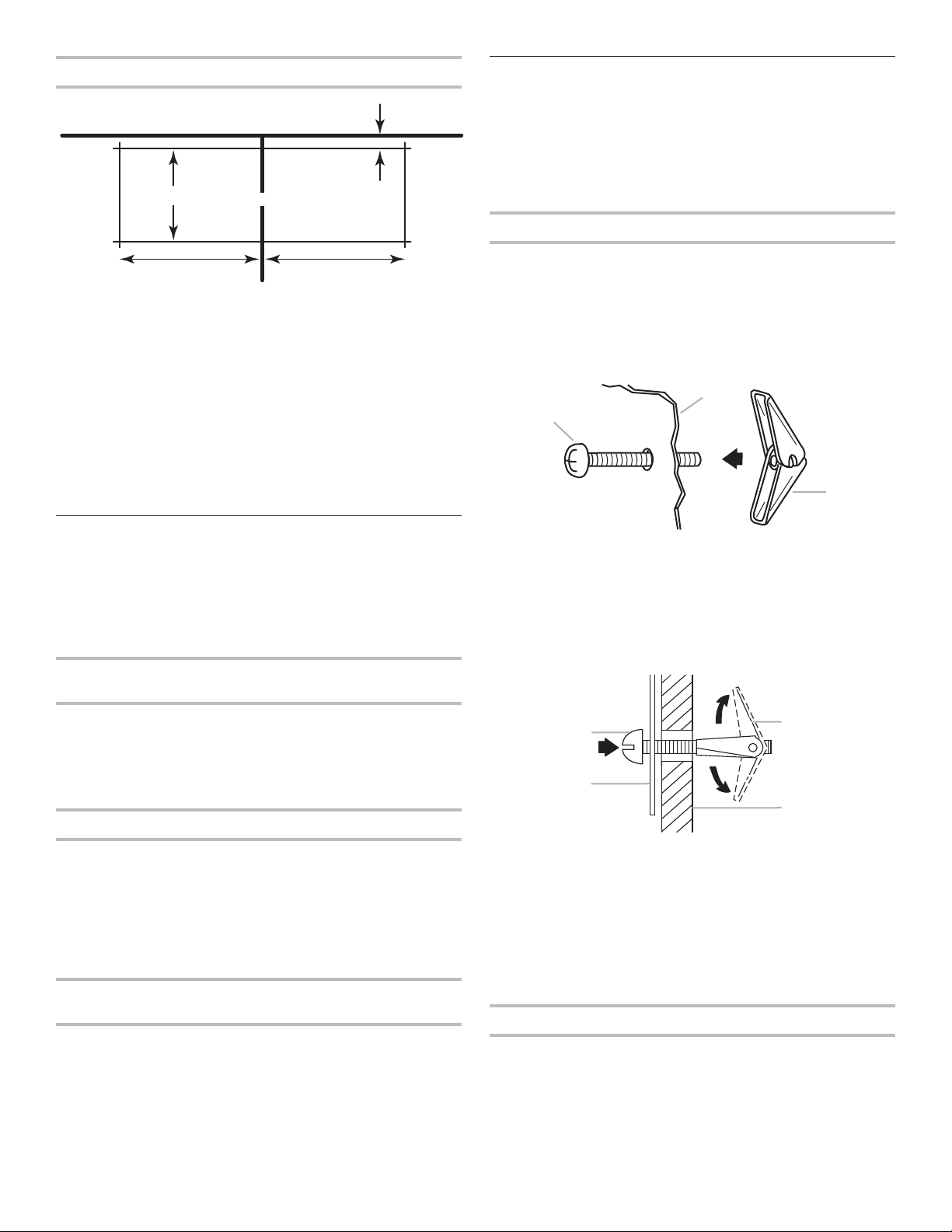

Attach Mounting Plate to Wall

NOTE: Secure the mounting plate to the wall at both end holes

drilled into the wall studs and/or drywall using either

round-head bolts and toggle nuts or

1/

4

" x 2" lag screws.

Refer to illustrations in “Possible Wall Stud Configurations” in the

“Locate Wall Stud(s)” section.

For fast wall and roof vent installation, see the quick reference

guide on the mounting plate.

No Wall Studs at End Holes (Figures 1 and 2)

NOTE: The mounting plate must be secured to the wall on at

least 1 wall stud as well as at both ends.

1. With the support tabs of the mounting plate facing forward,

2. Start toggle nuts on bolts from the back of the mounting

3/

16

insert

-24 x 3" round-head bolts through both end holes of

mounting plate.

plate. Leave enough space for the toggle nuts to go

through the wall and to open.

B

3/

16

-24 x 3"

C

Drill Holes in Rear Wall

In addition to being installed on at least 1 wall stud, the

mounting plate must attach to the wall at both end holes. If the

end holes are not over wall studs, use two 3/16-24 x 3" round

head bolts with toggle nuts; if 1 end hole is over a wall stud, use

1 lag screw and one 3/16-24 x 3" round-head bolt with toggle

nut; or if both end holes are over wall studs, use 2 lag screws.

Following are 3 installation configurations.

3. Position mounting plate on the wall.

4. Push the 2 bolts with toggle nuts through the drywall and

finger tighten the bolts to make sure toggle nuts have

A. 3/16-24 x 3" round-head bolt

B. Mounting plate

C. Spring toggle nut

opened against drywall.

Installation for No Wall Studs at End Holes (Figures 1

and 2)

1. Drill 5/8" (16 mm) holes through the wall at both end holes

marked in Step 3 of “Mark Rear Wall.”

2. Drill 3/16" (5 mm) hole(s) into the wall stud(s) at the hole(s)

marked in Step 6 of “Mark Rear Wall.” Refer to figures 1 and

2 in “Possible Wall Stud Configurations” in the “Locate Wall

Stud(s)” section.

C

D

Installation for Wall Stud at One End Hole (Figure 3)

1. Drill a 3/16" (5 mm) hole into the wall stud at the end hole

marked in Step 3 of “Mark Rear Wall.”

2. If installing on a second wall stud, drill a 3/16" (5 mm) hole

into the wall stud at the other hole marked in Step 6 of

“Mark Rear Wall.” Refer to Figure 3 in “Possible Wall Stud

Configurations” in the “Locate Wall Stud(s)” section.

3. Drill a 5/8" (16 mm) hole through the wall at the other end

hole.

Installation for Wall Studs at Both End Holes

(Figure 4)

1. Drill 3/16" (5 mm) hole into the wall stud at the end hole

marked in Step 3 of “Mark Rear Wall.

5. Insert lag screw(s) into the hole(s) drilled into wall stud(s) in

Step 2 of “Installation for No Wall Studs at End Holes” in the

“Drill Holes in Rear Wall” section.

6. Check alignment of mounting plate, making sure it is level.

7. Securely tighten all lag screws and bolts.

Wall Stud at One End Hole (Figure 3)

1. With the support tabs of the mounting plate facing forward,

insert a

3/

fits over the

for Wall Stud at One End Hole” in the “Drill Holes in Rear

Wall” section.

2. Start a toggle nut on the bolt from the back of the mounting

plate. Leave enough space for the toggle nut to go through

the wall and to open.

A. 3/16-24 x 3" round-head bolt

B. Mounting plate

C. Spring toggle nut

D. Drywall

16

-24 x 3" round-head bolt through the end hole that

5/

8

" (16 mm) hole drilled in Step 3 of “Installation

8

Loading...

Loading...