SLIDE-IN ELECTRIC RANGE OWNER’S MANUAL

CUISINIÈRES ÉLECTRIQUES ENCASTRÉES

MANUEL DU PROPRIÉTAIRE

Table of Contents/Table des matières

RANGE SAFETY.............................................................. 2

Range Safety................................................................ 2

RANGE MAINTENANCE AND CARE...................................4

Clean Cycle.................................................................. 4

General Cleaning...........................................................5

INSTALLATION INSTRUCTIONS ........................................ 6

REQUIREMENTS.............................................................6

Tools and Parts .............................................................6

Location Requirements ...................................................6

Electrical Requirements - U.S.A. Only ................................ 8

Electrical Requirements - Canada Only ..............................9

INSTALLATION ...............................................................9

Unpack Range ..............................................................9

Install Anti-Tip Bracket ....................................................9

Adjust Leveling Legs .................................................... 10

Level Range ............................................................... 11

Electrical Connection US............................................... 11

Verify Anti-Tip Bracket Is Installed and Engaged ................. 16

Remove/Replace Drawer............................................... 16

Oven Door.................................................................. 17

Complete Installation .................................................... 17

Moving the Range........................................................ 18

SÉCURITÉ DE LA CUISINIÈRE ........................................ 19

Sécurité de la cuisinière ................................................ 19

ENTRETIEN ET RÉPARATION DE LA CUISINIÈRE.............. 22

Programme de nettoyage .............................................. 22

Nettoyage général........................................................ 23

INSTRUCTIONS D’INSTALLATION ................................... 24

SPÉCIFICATIONS.......................................................... 24

Outils et pièces............................................................ 24

Exigences d’emplacement ............................................. 25

Spécifications électriques – É.-U. seulement...................... 27

Spécifications électriques – Canada seulement.................. 28

INSTALLATION ............................................................. 28

Déballage de la cuisinière.............................................. 28

Installation de la bride antibasculement ............................ 29

Réglage des pieds de nivellement ................................... 30

Réglage de l’aplomb de la cuisinière ................................ 30

Raccordement électrique É.-U. ....................................... 30

Vérifier que la bride antibasculement est bien installée et

engagée .................................................................... 36

Enlever/replacer le tiroir ................................................ 36

Porte du four............................................................... 37

Achever l’installation..................................................... 37

Déplacement de la cuisinière.......................................... 38

IMPORTANT:

Save for local electrical inspector's use.

IMPORTANT :

À conserver pour consultation par l'inspecteur local des installations électriques.

W11509603A

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.” These

words mean:

You can be killed or seriously injured if you don't

DANGER

immediately follow instructions.

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

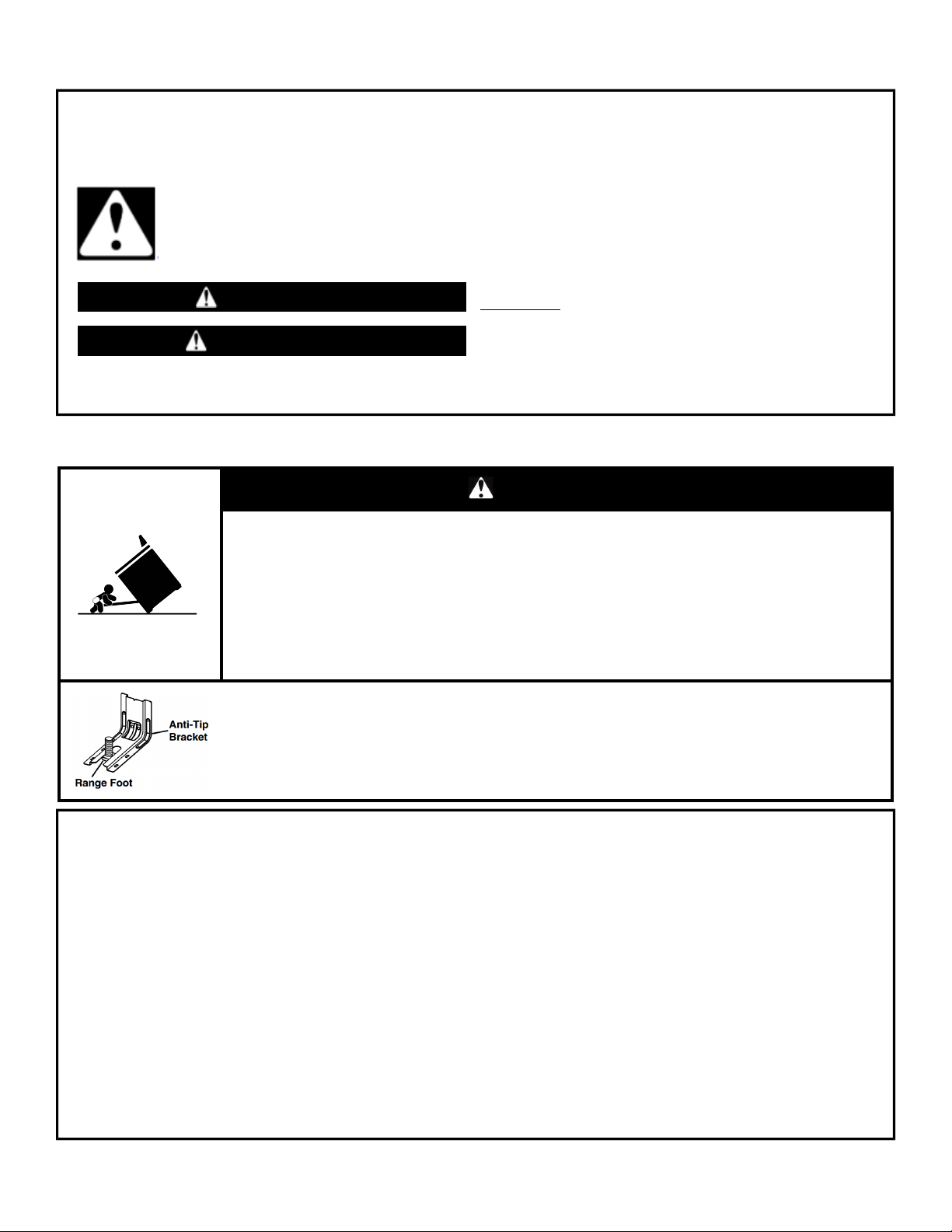

The range will not tip during normal use. However, the range can tip if you apply too much force or weight to the open door without having

the anti-tip bracket fastened down properly.

You can be killed or seriously injured if you don’t follow

instructions.

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

To verify the anti-tip bracket is properly installed and engaged:

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under the anti-tip bracket.

• See Installation Instructions for details.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the appliance, follow basic precautions,

including the following:

�

WARNING: TO REDUCE THE RISK OF TIPPING OF

THE RANGE, THE RANGE MUST BE SECURED BY

PROPERLY INSTALLED ANTI-TIP DEVICES. TO CHECK

IF THE DEVICES ARE INSTALLED PROPERLY, SLIDE

RANGE FORWARD, LOOK FOR ANTI-TIP BRACKET

SECURELYATTACHED TO FLOOR OR WALL, AND

SLIDE RANGE BACK SO REAR RANGE FOOT IS

UNDER ANTI-TIP BRACKET.

�

CAUTION: Do not store items of interest to children in

cabinets above an appliance or on the backguard of an

appliance - children climbing on the appliance to reach

items could be seriously injured.

� Proper Installation - The appliance, when installed, must be

electrically grounded in accordance with local codes, or in

the absence of local codes, with the National Electrical

Code, ANSI/NFPA 70 or the Canadian Electrical Code,

CSA C22.1-02. In Canada, the appliance must be

electrically grounded in accordance with Canadian

Electrical Code. Be sure your appliance is properly installed

and grounded by a qualified technician.

� Never Use Your Appliance for Warming or Heating the

Room.

SAVE THESE INSTRUCTIONS

2

IMPORTANT SAFETY INSTRUCTIONS

� Do Not Leave Children Alone - Children should not be left

alone or unattended in area where appliance is in use.

They should never be allowed to sit or stand on any part

of the appliance.

� Wear Proper Apparel – Loose-fitting or hanging garments

should never be worn while using the appliance.

� User Servicing – Do not repair or replace any part of the

appliance unless specifically recommended in the

manual. All other servicing should be referred to a

qualified technician.

� Storage in or on Appliance – Flammable materials should

not be stored in an oven or near surface units.

� This appliance is not intended for storage.

� Do Not Use Water on Grease Fires – Smother fire or

flame or use dry chemical or foam-type extinguisher.

� Do not use replacement parts that have not been

recommended by the manufacturer (e.g. parts made at

home using a 3D printer).

� Use Only Dry Potholders – Moist or damp potholders on

hot surfaces may result in burns from steam. Do not let

potholder touch hot heating elements. Do not use a towel

or other bulky cloth.

� DO NOT TOUCH SURFACE UNITS OR AREAS NEAR

UNITS – Surface units may be hot even though they are

dark in color. Areas near surface units may become hot

enough to cause burns. During and after use, do not

touch, or let clothing or other flammable materials contact

surface units or areas near units until they have had

sufficient time to cool. Among these areas are the coil

elements, the cooktop, and surfaces facing the cooktop.

� Use Proper Pan Size – This appliance is equipped with

one or more surface units of different size. Select utensils

having flat bottoms large enough to cover the surface unit

heating element. The use of undersized utensils will

expose a portion of the heating element to direct contact

and may result in ignition of clothing. Proper relationship

of utensil to burner will also improve efficiency.

� Never Leave Surface Units Unattended at High Heat

Settings – Boilover causes smoking and greasy spillovers

that may ignite.

� Make Sure Reflector Pans or Drip Bowls Are in Place –

Absence of these pans or bowls during cooking may

subject wiring or components underneath to damage.

� Protective Liners – Do not use aluminum foil to line

surface unit drip bowls or oven bottoms, except as

suggested in the manual. Improper installation of these

liners may result in a risk of electric shock, or fire.

� Glazed Cooking Utensils – Only certain types of glass,

glass/ceramic, ceramic, earthenware, or other glazed

utensils are suitable for range-top service without

breaking due to the sudden change in temperature.

� Utensil Handles Should Be Turned Inward and Not

Extend Over Adjacent Surface Units – To reduce the risk

of burns, ignition of flammable materials, and spillage due

to unintentional contact with the utensil, the handle of a

utensil should be positioned so that it is turned inward,

and does not extend over adjacent surface units.

� Do Not Soak Removable Heating Elements – Heating

elements should never be immersed in water.

� Do Not Cook on Broken Cook-Top – If cook-top should

break, cleaning solutions and spillovers may penetrate

the broken cook-top and create a risk of electric shock.

Contact a qualified technician immediately.

� Clean Cooktop With Caution – If a wet sponge or cloth is

used to wipe spills on a hot cooking area, be careful to

avoid steam burn. Some cleaners can produce noxious

fumes if applied to a hot surface.

� Use Care When Opening Door – Let hot air or steam

escape before removing or replacing food.

� Do Not Heat Unopened Food Containers – Build-up of

pressure may cause container to burst and result in injury.

� Keep Oven Vent Ducts Unobstructed.

� Placement of Oven Racks – Always place oven racks in

desired location while oven is cool. If rack must be moved

while oven is hot, do not let potholder contact hot heating

element in oven.

� DO NOT TOUCH HEATING ELEMENTS OR INTERIOR

SURFACES OF OVEN – Heating elements may be hot

even though they are dark in color. Interior surfaces of an

oven become hot enough to cause burns. During and

after use, do not touch, or let clothing or other flammable

materials contact heating elements or interior surfaces of

oven until they have had sufficient time to cool. Other

surfaces of the appliance may become hot enough to

cause burns – among these surfaces are oven vent

openings and surfaces near these openings, oven doors,

and windows of oven doors.

� Care must be taken to prevent aluminum foil and meat

probes from contacting heating elements.

For self-cleaning ranges –

� Do Not Clean Door Gasket – The door gasket is essential

for a good seal. Care should be taken not to rub, damage,

or move the gasket.

� Do Not Use Oven Cleaners – No commercial oven

cleaner or oven liner protective coating of any kind should

be used in or around any part of the oven.

� Clean Only Parts Listed in Manual.

� Before Self-Cleaning the Oven – Remove broiler pan and

other utensils.

For units with ventilating hood –

� Clean Ventilating Hoods Frequently – Grease should not

be allowed to accumulate on hood or filter.

� When flaming foods under the hood, turn the fan on.

For smart enabled ranges and ovens

� Remote operation – This appliance is configurable to

allow remote operation at any time. Do not store any

flammable materials or temperature sensitive items

inside, on top or near surface units of the appliance.

SAVE THESE INSTRUCTIONS

3

RANGE MAINTENANCE AND CARE

Clean Cycle

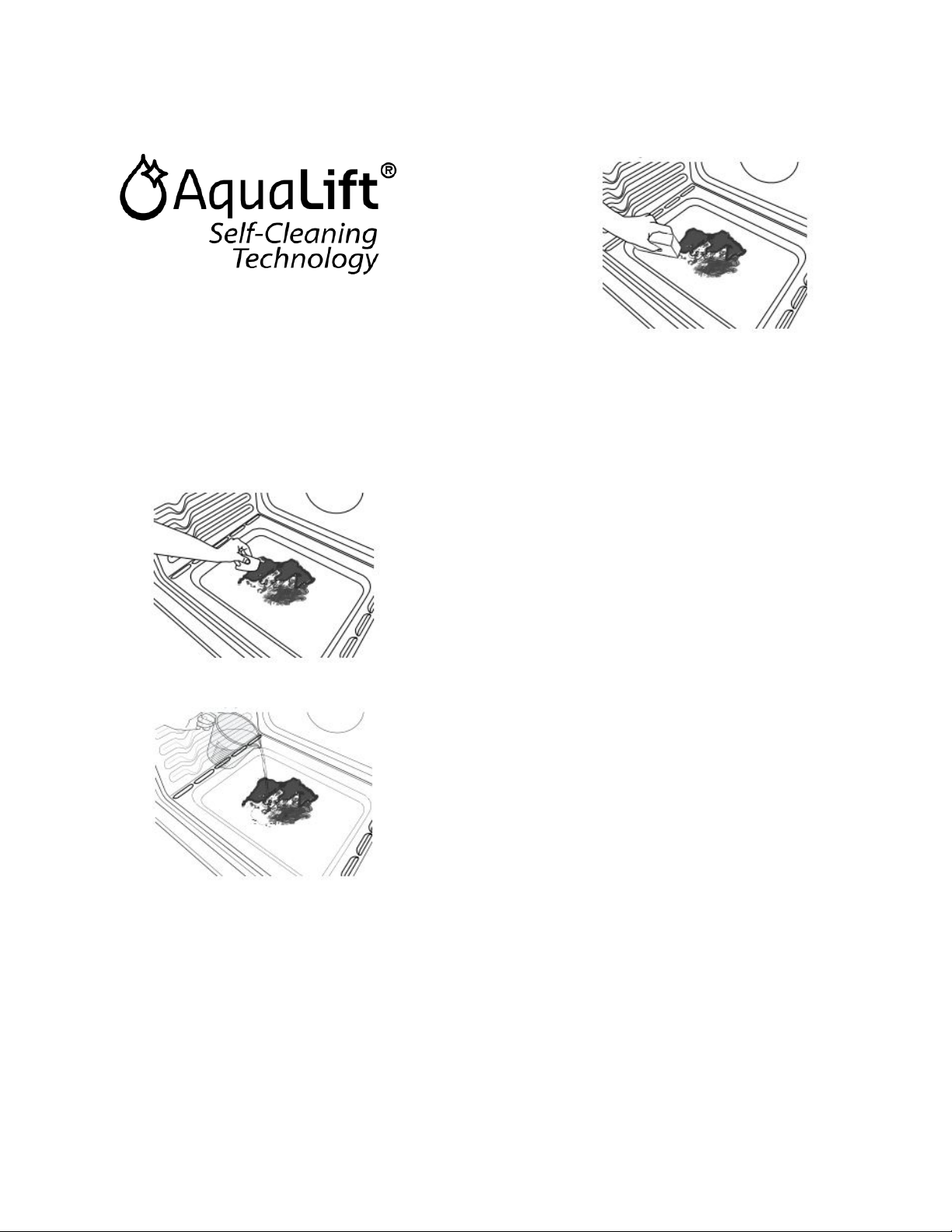

AquaLift®Technology is an innovative cleaning solution that

utilizes heat and water to release baked-on spills from the oven in

less than 1 hour. This new cleaning technology is a low-heat,

odor-free alternative to traditional self-cleaning options.

Allow the oven to cool to room temperature before using the Clean

cycle. If your oven cavity is above 200°F (93°C), it will appear in

the display, and the Clean cycle will not be activated until the oven

cavity cools down.

To Clean:

1. Remove all racks and accessories from the oven cavity, and

wipe excess soil. Use a plastic scraper to remove easily

removed soils

2. Pour distilled or filtered water onto the bottom of the empty

oven, and close the oven door.

IMPORTANT: Do not use chemicals or other additives with the

water. Do not open the oven door during the Clean cycle. The

water on the oven bottom is hot.

3. Press CLEAN or AQUALIFT SELF CLEAN and then START

on the oven control panel.

4. Allow 40 minutes for cleaning and cool down. A beep will

sound when the Clean cycle is complete.

5. Press CANCEL, CANCEL UPPER or OFF at the end of the

cycle. Cancel, Cancel Upper or Off may be pressed at any

time to stop the Clean cycle.

6. Remove the residual water and loosened soils with a sponge

or cloth immediately after the Clean cycle is complete. Much

of the initial 2 cups (16 oz [500 mL]) of water will remain in the

oven after the cycle is completed. If additional soils remain,

leave a small amount of water in the oven bottom to assist

with the cleaning.

7. If any soils remain, remove them with a non-scratch scrubbing

sponge or plastic scraper. Additional Clean cycles may be run

to help remove the stubborn soils.

IMPORTANT: Do not use oven cleaners. The use of

chemicals, including commercial oven cleaners or metal

scouring pads, may cause permanent damage to the

porcelain surface of the oven interior.

NOTES:

� The range should be level to ensure that the entire surface

of the bottom of the oven cavity is covered by water at the

beginning of the Clean cycle.

� For best results, use distilled or filtered water. Tap water

may leave mineral deposits on the oven bottom.

� Before removing the residual water and loosened soils at

the end of the Clean cycle, insert a cloth or paper towel

between the lower edge of the oven door and the front

frame to keep water from spilling onto the front of the

range and the floor.

� Soil baked on through several cooking cycles will be more

difficult to remove with the Clean cycle.

� Nonabrasive scrub sponges or eraser style cleaning pads

(without cleaners) can be effective for cleaning the oven

cavity walls, oven door and oven bottom for difficult soils.

For best results, moisten the pads and sponges before

use.

� Run an additional Clean cycle for stubborn soils.

�

�

®†

Affresh

Cleaner may be used to clean the oven bottom, walls, and

door when the oven has finished the cycle and returned to

room temperature. If affresh

is recommended to wipe out the cavity with distilled water

as well. Refer to the Quick Start Guide for ordering

information.

Additional AquaLift

obtained by ordering Part Number W10423113RP. Refer to

the Quick Start Guide for ordering information.

Kitchen Appliance Cleaner and affresh® Cooktop

®

Cooktop Cleaner is used, it

®

Technology Cleaning Kits may be

†®Affresh is a registered trademark of Whirlpool, U.S.A.

4

General Cleaning

IMPORTANT: Before cleaning, make sure all controls are off and

the oven and cooktop are cool. Always follow label instructions on

cleaning products.

Soap, water, and a soft cloth or sponge are suggested first, unless

otherwise noted.

EXTERIOR PORCELAIN ENAMEL SURFACES (on some

models)

Food spills containing acids, such as vinegar and tomato, should

be cleaned as soon as the entire range is cool. These spills may

affect the finish.

Cleaning Method:

� Glass cleaner, mild liquid cleaner, or nonabrasive scrubbing

pad: Gently clean around the model/serial/rating plate because

scrubbing may remove numbers.

� Affresh

STAINLESS STEEL (on some models)

NOTE: To avoid damage to stainless steel surfaces, do not use

soap-filled scouring pads, abrasive cleaners, Cooktop Cleaner,

steel-wool pads, gritty washcloths, or abrasive paper towels.

Damage may occur to stainless steel surfaces, even with one-time

or limited use.

Cleaning Method:

Rub in direction of grain to avoid damaging.

� Affresh

METALLIC PAINT (on some models)

Do not use abrasive cleaners, cleaners with bleach, rust

removers, ammonia, or sodium hydroxide (lye) because paint

surface may stain.

CERAMIC GLASS COOKTOP CLEANING

Cleaning Method:

To avoid damaging the cooktop, do not use steel wool, abrasive

powder cleansers, chlorine bleach, rust remover, or ammonia.

1. Remove food/residue with the Cooktop Scraper.

®

Kitchen and Appliance Cleaner Part Number

W10355010 (not included):

See the Quick Start Guide for contact information.

®

Stainless Steel Cleaner Part Number W10355016

(not included):

See the Quick Start Guide for contact information.

� For best results, use the Cooktop Scraper while the

cooktop is still warm but not hot to the touch. It is

recommended to wear an oven mitt while scraping the

warm cooktop.

� Hold the Cooktop Scraper at approximately a 45° angle

against the glass surface and scrape the residue. It will be

necessary to apply pressure in order to remove the

residue.

Allow the cooktop to cool down completely before proceeding

to Step 2.

2. Apply a few dime-sized drops of Cooktop Cleaner to the

affected areas.

� Rub affresh®Cleaner onto the cooktop surface with the

blue Cooktop Cleaning Pad. Some pressure is needed to

remove stubborn stains.

� Allow the cleaner to dry to a white haze before proceeding

to Step 3.

3. Polish with a clean, dry cloth or a clean, dry paper towel.

� Repeat steps 1 through 3 as necessary for stubborn or

burned-on stains.

The Complete Cooktop Cleaner Kit is available for order

including the following:

� Cooktop Scraper

� Affresh

®

Cooktop Cleaner

� Blue Cooktop Cleaning Pads

See the Quick Start Guide for ordering information.

COOKTOP CONTROLS

To avoid damage to the cooktop controls, do not use steel wool,

abrasive cleansers, or oven cleaner.

To avoid damage, do not soak knobs. When replacing knobs,

make sure knobs are in the Off position.

On some models, do not remove seals under knobs.

Cleaning Method:

� Soap and water: Pull knobs straight away from control panel to

remove

CONTROL PANEL AND OVEN DOOR EXTERIOR

To avoid damage to the control panel, do not use abrasive

cleaners, steel-wool pads, gritty washcloths, or abrasive paper

towels.

Cleaning Method:

� Glass cleaner and soft cloth or sponge: Apply glass cleaner to

soft cloth or sponge, not directly on panel.

� Affresh

®

Kitchen and Appliance Cleaner Part Number

W10355010 (not included):

See the Quick Start Guide for contact information.

OVEN RACKS

Cleaning Method:

� Steel-wool pad

� For racks that have discolored and are harder to slide, a light

coating of vegetable oil applied to the rack guides will help

them slide

� Dishwasher (steam rack water reservoir only, not racks):

Although the water reservoir is durable, it may lose its shine

and/or discolor when washed in a dishwasher

5

STORAGE DRAWER OR WARMING DRAWER (on some

models)

Check that storage drawer or warming drawer is cool and empty

before cleaning.

Cleaning Method:

� Mild detergent

BAKING DRAWER (on some models)

Check that baking drawer is cool and empty before cleaning.

Food spills should be cleaned when oven cools. At high

temperatures, foods react with porcelain. Staining, etching, pitting,

or faint white spots can result.

Cleaning Method:

� Mild detergent

OVEN CAVITY

Depending on your model, use AquaLift

Clean cycle regularly to clean oven spills.

Do not use oven cleaners

Food spills should be cleaned when oven cools. At high

temperatures, foods react with porcelain. Staining, etching, pitting,

or faint white spots can result.

Cleaning Method:

� Clean cycle: See “Clean Cycle” first.

®

Technology or Self-

INSTALLATION INSTRUCTIONS

REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

� Tape measure

� Flat-blade screwdriver

� Phillips screwdriver

� Level

� Hammer

� Hand or electric drill

� Wrench or pliers

� Marker or pencil

� Flashlight

� Torque Wrench

Parts supplied

Check that all parts are included.

� 10-32 hex nuts (attached to terminal block) (3)

� Direct wire lugs (3)

� #10 x 1

� Anti-tip bracket (inside oven cavity)

5

⁄8" (4.1 cm) screws (for mounting anti-tip bracket) (2)

Anti-tip bracket must be securely mounted to the back wall or

floor. Thickness of flooring may require longer screws to

anchor bracket to subfloor. Longer screws are available from

your local hardware store.

Parts needed

If using a power supply cord kit:

� A UL listed power supply cord kit marked for use with ranges.

The cord should be rated at 250 V minimum, 40 A or 50 A that

is marked for use with nominal 1

connection opening and must end in ring terminals or openend spade terminals with upturned ends.

� A UL listed strain relief.

� Masking tape

� 1/4" (6.4 mm) drive ratchet

� 1/4" (6.4 mm) nut driver

� 3/8" (9.5 mm) and 5/16"

(8 mm) nut driver

� 1/8" (3.2 mm) drill bit (for

wood floors)

� Tin snips or large wire

cutters (for cutting ground

strap if necessary)

3

⁄8" (3.5 cm) diameter

Check local codes. Check existing electrical supply. See the

appropriate “Electrical Requirements” section.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

NOTE: Be sure to purchase only Whirlpool factory-certified parts

and accessories for your appliance. Your installation may require

additional parts. To order, refer to the contact information

referenced in your Quick Start Guide.

Optional Parts

See the Quick Start Guide for ordering information.

� Side Trim Kits:

White - Order Part Number W10675027

Black - Order Part Number W10675026

Stainless Steel - Order Part Number W10675028

� Backsplash Kits:

High 6" (15.2 cm) White - Order Part Number W10655448

High 6" (15.2 cm) Black - Order Part Number W10655449

High 6" (15.2 cm) Stainless Steel - Order Part Number

W10655450

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

� It is the installer’s responsibility to comply with installation

clearances specified on the model/serial/rating plate. The

model/serial/rating plate is located behind the oven door on the

top right-hand side of the oven frame.

� To eliminate the risk of burns or fire by reaching over the

heated surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood or

microwave hood combination that projects horizontally a

minimum of 5" (12.7 cm) beyond the bottom of the cabinets.

� The range should be located for convenient use in the kitchen.

� Recessed installations must provide complete enclosure of the

sides and rear of the range.

� All openings in the wall or floor where range is to be installed

must be sealed.

� Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

� The anti-tip bracket must be installed. To install the anti-tip

bracket shipped with the range, see the “Install Anti-Tip

Bracket” section.

� Grounded electrical supply is required. See the appropriate

“Electrical Requirements” section.

� Contact a qualified floor covering installer to check that the

floor covering can withstand at least 200°F (93°C).

� Use an insulated pad or 1/4" (6.4 mm) plywood under range if

installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate, or sustain other damage. This oven

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194°F (90°C).

6

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD Part 280). When such standard is not

applicable, use the Standard for Manufactured Home Installations,

ANSI A225.1/NFPA 501A or with local codes.

Mobile Home Installations Require:

� When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing the

range is adequate as long as it conforms to the standards

listed above.

� Four-wire power supply cord or cable must be used in a mobile

home installation.

In Canada, the installation of this range must conform with the

current standards CAN/CSA-Z240.1-latest edition, or with local

codes.

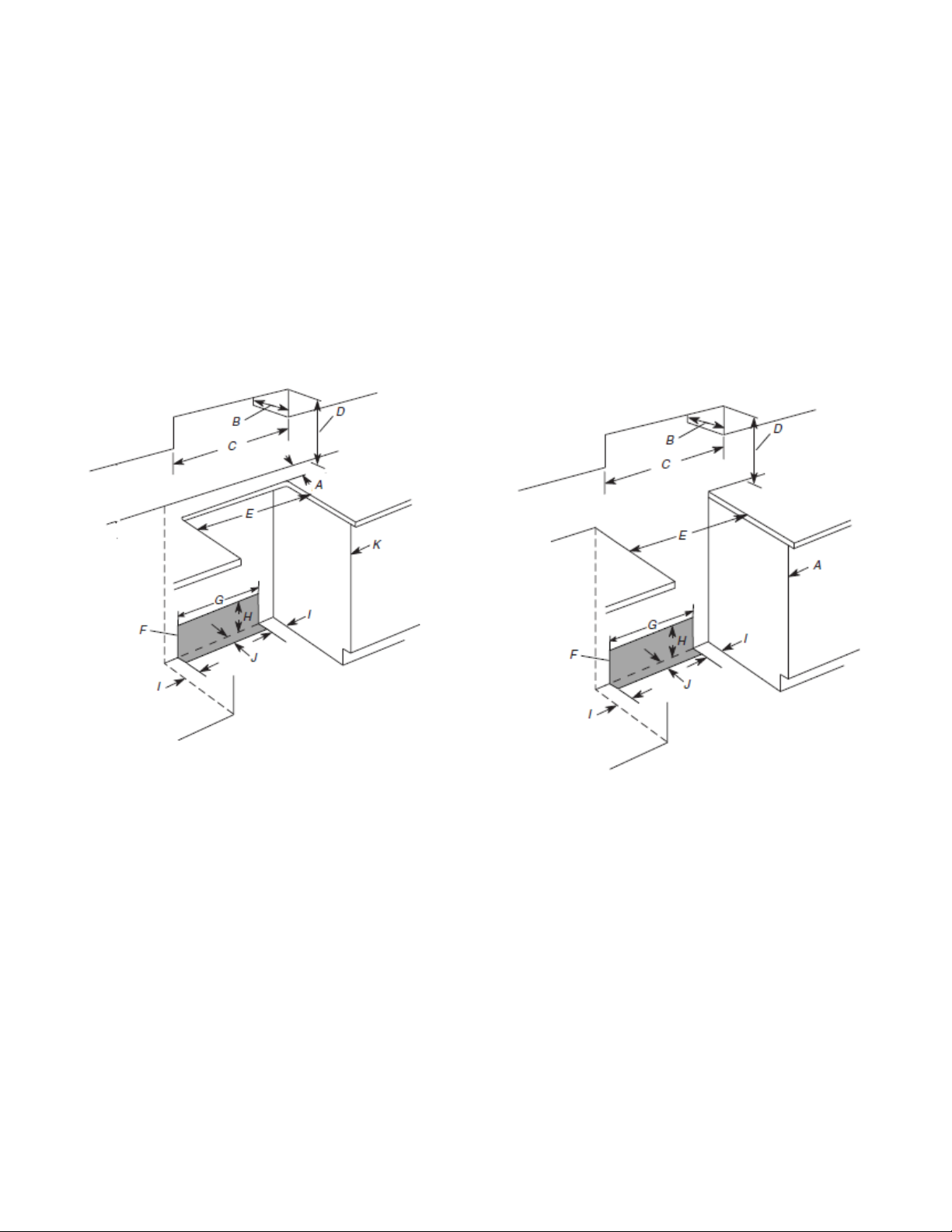

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm) countertop depth, 24" (61.0 cm) base cabinet depth and 36" (91.4 cm)

countertop height.

IMPORTANT: If installing a range hood or microwave hood combination above the range, follow the range hood or microwave hood

combination installation instructions for dimensional clearances above the cooktop surface.

Range may be installed next to combustible walls with zero clearance.

NOTE: When installed in a slide-in cutout, the front of oven door may protrude beyond the base cabinet.

Slide-In Cutout Freestanding Cutout

A. Remaining counter depth should not exceed 21/4" (5.7 cm).

B. 13" (33 cm) max. upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to top of cooktop, see NOTE*.

E. In U.S.A. and Canada: 30" (76.2 cm) min. opening width

F. The shaded area is recommended for installation of grounded outlet.

1

G. 13

⁄8" (33.3 cm)

11

H. 7

⁄16" (19.5 cm)

13

I. 4

⁄16" (12.2 cm)

11

J. 3

⁄16" (9.4 cm) plus measurement of L

K. Cabinet door or hinges should not extend into the cutout.

A. Cabinet door or hinges should not extend into the cutout.

B. 13" (33 cm) max. upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to top of cooktop, see NOTE*.

E. In U.S.A. and Canada: 30" (76.2 cm) min. opening width

F. The shaded area is recommended for installation of grounded outlet.

1

G. 13

⁄8" (33.3 cm)

11

H. 7

⁄16" (19.5 cm)

13

I. 4

⁄16" (12.2 cm)

11

J. 3

⁄16" (9.4 cm)

*NOTE: 24" (61.0 cm) minimum when bottom of wood or metal cabinet is shielded by not less than 1/4" (0.64 cm) flame retardant

millboard covered with not less than No. 28 MSG sheet steel, 0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking platform and the bottom of an uncovered wood or metal cabinet.

7

Electrical Requirements - U.S.A. Only

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Do not use an extension cord.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSI/NFPA

70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualified electrician or service technician if you are in doubt as to

whether the appliance is properly grounded. Do not modify the

power supply cord plug. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

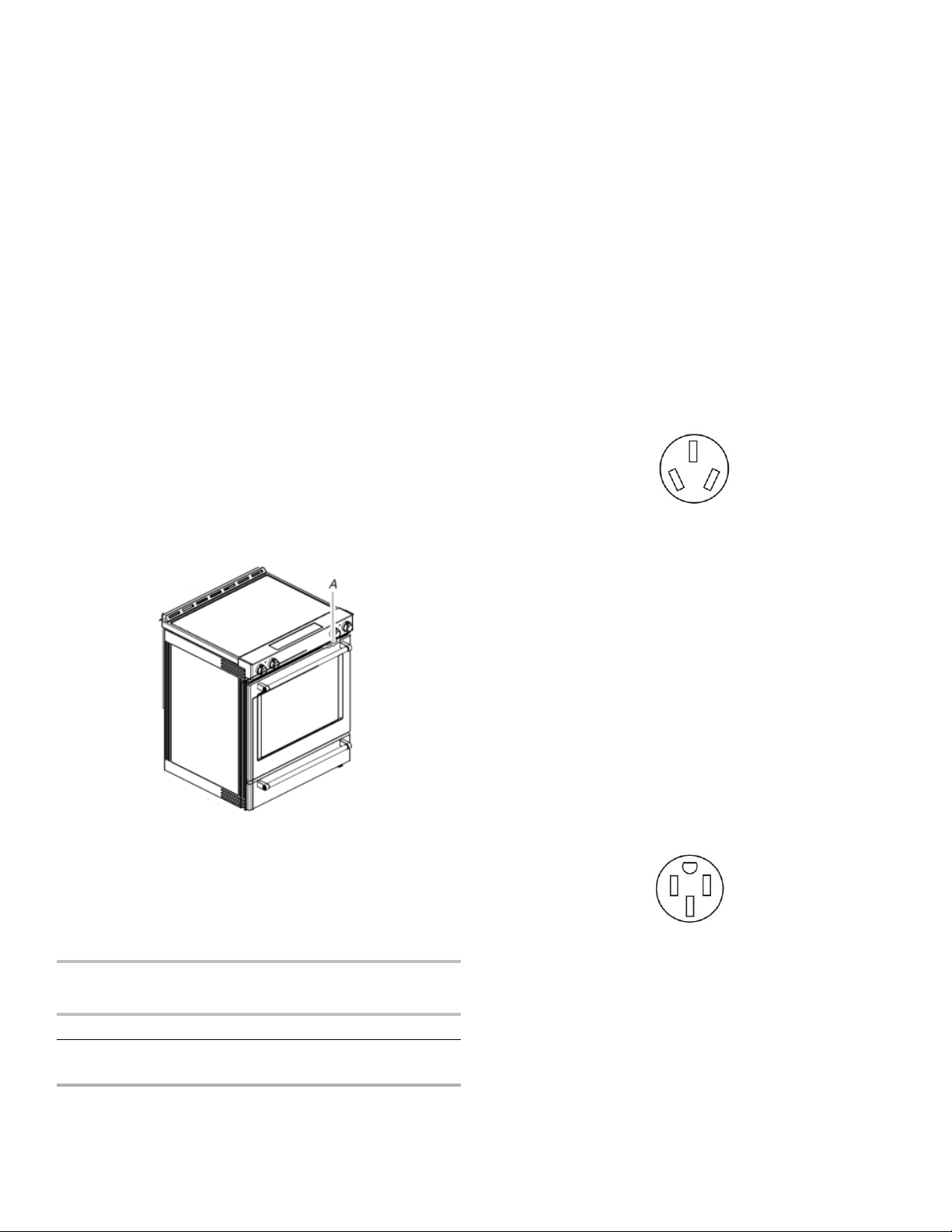

Electrical Connection

To properly install your range, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

� Range must be connected to the proper electrical voltage and

frequency as specified on the model/serial/rating plate. The

model/serial/rating plate is located behind the oven door on the

top right-hand side of the oven frame.

A. Model/serial/rating plate (located behind the oven door on the top

right-hand side of the oven frame)

� This range is manufactured with the neutral terminal

connected to the cabinet. Use a 3-wire, UL listed, 40 or 50 A

power supply cord (pigtail). See the following Range Rating

chart. If local codes do not permit ground through the neutral,

use a 4-wire power supply cord rated at 250 V, 40 or 50 A and

investigated for use with ranges.

Range Rating* Specified Rating of

Power Supply Cord Kit

and Circuit Protection

120/240 V 120/208 V Ampere

8.8-16.5 kW 7.8-12.5 kW 40 or 50**

16.6-22.5 kW 12.6-18.5 kW 50

** If connecting to a 50 A circuit, use a 50 A rated cord with kit. For

50 A rated cord kits, use kits that specify use with a nominal 1

(34.9 mm) diameter connection opening.

� A circuit breaker is recommended.

� The range can be connected directly to the circuit breaker box

(or fused disconnect) through flexible or nonmetallic sheathed,

copper or aluminum cable. See the “Electrical Connection -

U.S.A. Only” section.

� Allow at least 6 ft (182.9 cm) of slack in the line so that the

range can be moved if servicing is ever necessary.

� A UL Listed conduit connector must be provided at each end of

the power supply cable (at the range and at the junction box).

� Wire sizes and connections must conform with the rating of the

range.

If connecting to a 3-wire system:

Local codes may permit the use of a UL listed, 3-wire, 250 V, 40 or

50 A range power supply cord (pigtail). This cord contains 3

copper conductors with ring terminals or open-end spade

terminals with upturned ends, terminating in a NEMA Type 10-50P

plug on the supply end. Connectors on the appliance end must be

provided at the point the power supply cord enters the appliance.

This uses a 3-wire receptacle of NEMA Type 10-50R.

3-wire receptacle (10-50R)

If connecting to a 4-wire system:

This range is manufactured with the ground connected to the

neutral by a link. The ground must be revised so the green ground

wire of the 4-wire power supply cord is connected to the cabinet.

See “Electrical Connection - U.S.A. Only” section.

Grounding through the neutral conductor is prohibited for new

branch-circuit installations (1996 NEC); mobile homes; and

recreational vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

When a 4-wire receptacle of NEMAType 14-50R is used, a

matching UL listed, 4-wire, 250 V, 40 or 50 A, range power supply

cord (pigtail) must be used. This cord contains 4 copper

conductors with ring terminals or open-end spade terminals with

upturned ends, terminating in a NEMAType 14-50P plug on the

supply end.

The fourth (grounding) conductor must be identified by a green or

green/yellow cover and the neutral conductor by a white cover.

Cord should be Type SRD or SRDT with a UL listed strain relief

and be at least 4 ft (1.22 m) long.

4-wire receptacle (14-50R)

The minimum conductor sized for the copper 4-wire power cord

are:

40 A circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-10 green grounding

3

/8"

* The NEC calculated load is less than the total connected load

listed on the model/serial/rating plate.

8

Electrical Requirements - Canada Only

INSTALLATION

Unpack Range

WARNING

Electrical Shock Hazard

Electrically ground appliance.

Failure to do so could result in death, fire, or electrical

shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate and wire gauge are in accordance

with local codes.

Be sure that the electrical connection and wire size are adequate

and in conformance with CSA Standard C22.1, Canadian

Electrical Code, Part 1 - latest edition, and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

� Check with a qualified electrical installer if you are not sure the

range is properly grounded.

Range Rating* Specified Rating of

120/240 V 120/208 V Ampere

8.8-16.5 KW 7.8-12.5 KW 40 or 50**

16.6-22.5 KW 12.6-18.5 KW 50

* The NEC calculated load is less than the total connected load

listed on the model/serial/rating plate.

**If connecting to a 50 A circuit, use a 50 A rated cord with kit.

For 50 A rated cord kits, use kits that specify use with a

nominal 1

� When a 4-wire, single phase 250 V, 60 Hz, AC-only electrical

supply is available, a 40 A minimum circuit protection is

required on 30" (76.2 cm) ranges, fused on both sides of the

line.

� A circuit breaker is recommended.

� This range is equipped with a UL or CSA International Certified

Power Cord intended to be plugged into a standard 14-50R

wall receptacle. Be sure the wall receptacle is within reach of

range’s final location.

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

Power Supply Cord

Kit and Circuit

Protection

3

/8" (34.9 mm) diameter connection opening.

WARNING

Excessive Weight Hazard

Use two or more people to move and install or uninstall

appliance.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape and film from the range.

Keep cardboard bottom under range. Do not dispose of

anything until the installation is complete.

2. Remove oven racks and parts package from oven and

shipping materials.

3. To remove cardboard bottom, first take 4 cardboard corners

from the carton. Stack one cardboard corner on top of

another. Repeat with the other 2 corners. Place them

lengthwise on the floor behind the range to support the range

when it is laid on its back.

4. Using 2 or more people, firmly grasp the range and gently lay

it on its back on the cardboard corners.

5. Remove cardboard bottom.

The leveling legs can be adjusted while the range is on its

back. See the “Adjust Leveling Legs” section.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard on the floor in front of range

to protect the flooring. Using 2 or more people, stand range

back up onto the cardboard or hardboard.

Install Anti-Tip Bracket

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death or

serious burns to children and adults.

� Do not use an extension cord.

1. Remove the anti-tip bracket from the inside of the oven.

2. Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor, you can use the wall

mounting method. If you are installing the range in a mobile

home, you must secure the range to the floor.

This anti-tip bracket and screws can be used with wood or

metal studs.

9

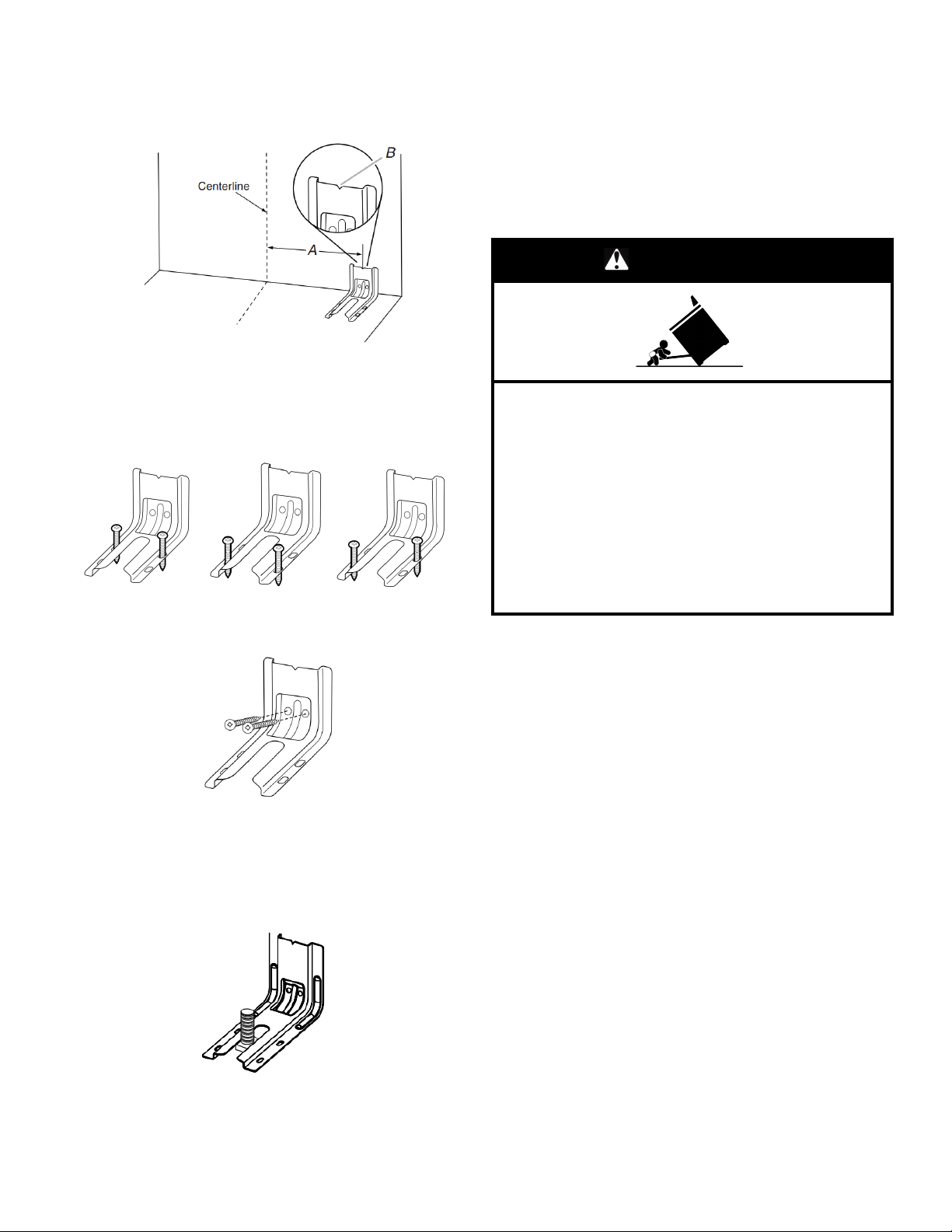

3. Determine and mark centerline of the cutout space. The

mounting can be installed on either the left-side or right-side of

the cutout. Position mounting bracket against the wall in the

cutout so that the V-notch of the bracket is 12

from centerline as shown.

A. 121/2" (31.8 cm)

B. Bracket V-notch

4. Drill two 1/8" (3 mm) holes that correspond to the bracket

holes of the determined mounting method. See the following

illustrations.

Floor Mounting

Rear Position Front Position Diagonal (2 options)

1

/2" (31.8 cm)

Adjust Leveling Legs

1. If range height adjustment is necessary, use a wrench or pliers

to loosen the four leveling legs.

This may be done with the range on its back or with the range

supported on two legs after the range has been placed back to

a standing position.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard in front of range. Using two

or more people, stand range back up onto the cardboard or

hardboard.

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death or

serious burns to children and adults.

Wall Mounting

5. Using the two #10 x 15/8" (4.1 cm) Phillips-head screws

provided, mount anti-tip bracket to the wall or floor.

6. Move range close enough to opening to allow for final

electrical connections. Remove shipping base, cardboard or

hardboard from under range.

7. Move range into its final location, making sure rear leveling leg

slides into anti-tip bracket.

2. Measure the distance from the top of the counter to the floor.

3. Measure the distance from the top of the cooktop to the

bottom of the leveling legs. This distance should be the same.

If it is not, adjust the leveling legs to the correct height. The

leveling legs can be loosened to add up to a maximum of

1" (2.5 cm). A minimum of 3/16" (5 mm) is needed to engage

the anti-tip bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, and then tilt forward

to adjust the rear legs.

4. When the range is at the correct height, check that there is

adequate clearance under the range for the anti-tip bracket.

Before sliding range into its final location, check that the

anti-tip bracket will slide under the range and onto the rear

leveling leg prior to anti-tip bracket installation.

NOTE: If a Trim Kit will be used, the top of the cooktop should

be higher than the counter. See the Installation Instructions

included with the Trim Kit for the correct height.

8. Move range forward onto shipping base, cardboard or

hardboard to continue installing the range using the following

installation instructions.

10

Level Range

1. Place level on the oven bottom, as indicated in one of the two

figures below, depending on the size of the level. Check with

the level side to side and front to back.

2. If range is not level, use a wrench or pliers to adjust leveling

legs up or down until the range is level.

NOTE: Range must be level for satisfactory baking

performance and best cleaning results using AquaLift

Clean Technology.

®

Self-

Electrical Connection - U.S.A. Only

If your home has a 3- or 4-wire receptacle, continue with “Install

Using a Power Supply Cord.” If your home has a 3- or 4-wire

direct connection, go to “Install Using Direct Wire.”

Install Using a Power Supply Cord

WARNING

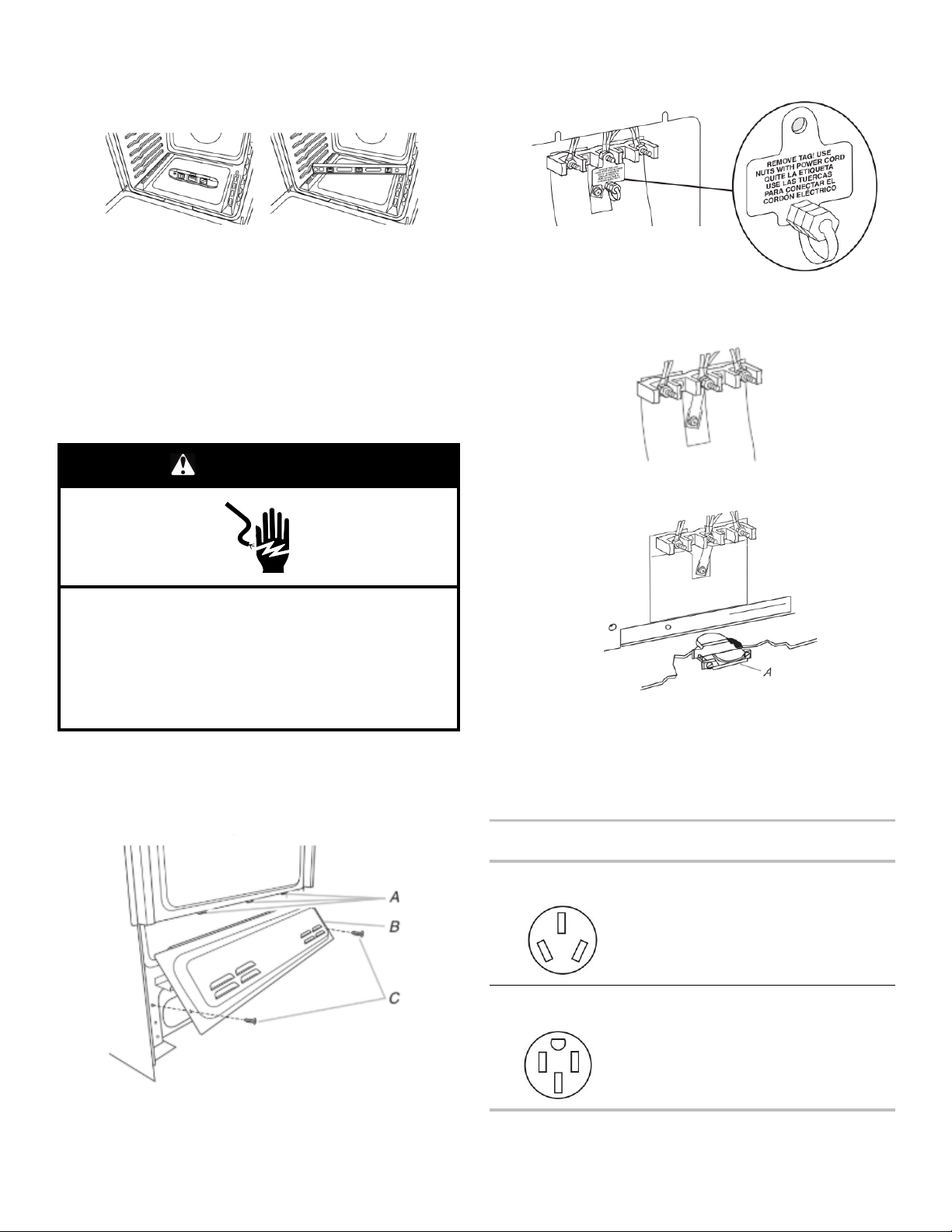

3. Remove plastic tag holding three 10-32 hex nuts from the

middle post of the terminal block.

OR

Remove the top 10-32 hex nut from each of the 3 terminal

blocks and set aside.

4. Assemble a UL listed strain relief in the opening.

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Power Supply Cord Strain Relief

1. Disconnect power.

2. Remove the lower access cover screws located on the back of

the range. Pull the bottom of the cover toward you and out to

remove cover from range.

A. UL listed strain relief

5. Complete installation following instructions for your type of

electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

Electrical Connection Options

If your home has:

3-wire receptacle

(NEMA type 10-50R)

4-wire receptacle

(NEMA type 14-50R)

And you will be

connecting to:

A UL listed, 250 V

minimum,

40 or 50 A, range

power supply cord

A UL listed, 250 V

minimum,

40 or 50 A, range

power supply cord

Go to Section:

3-Wire Connection:

Power Supply

Cord

4-Wire Connection:

Power Supply

Cord

A. Mounting tabs (3)

B. Lower access cover

C. Screws (2)

11

4-Wire Connection: Power Supply Cord

Use this method for:

� New branch-circuit installations (1996 NEC)

� Mobile homes

� Recreational vehicles

� In an area where local codes prohibit grounding through the

neutral

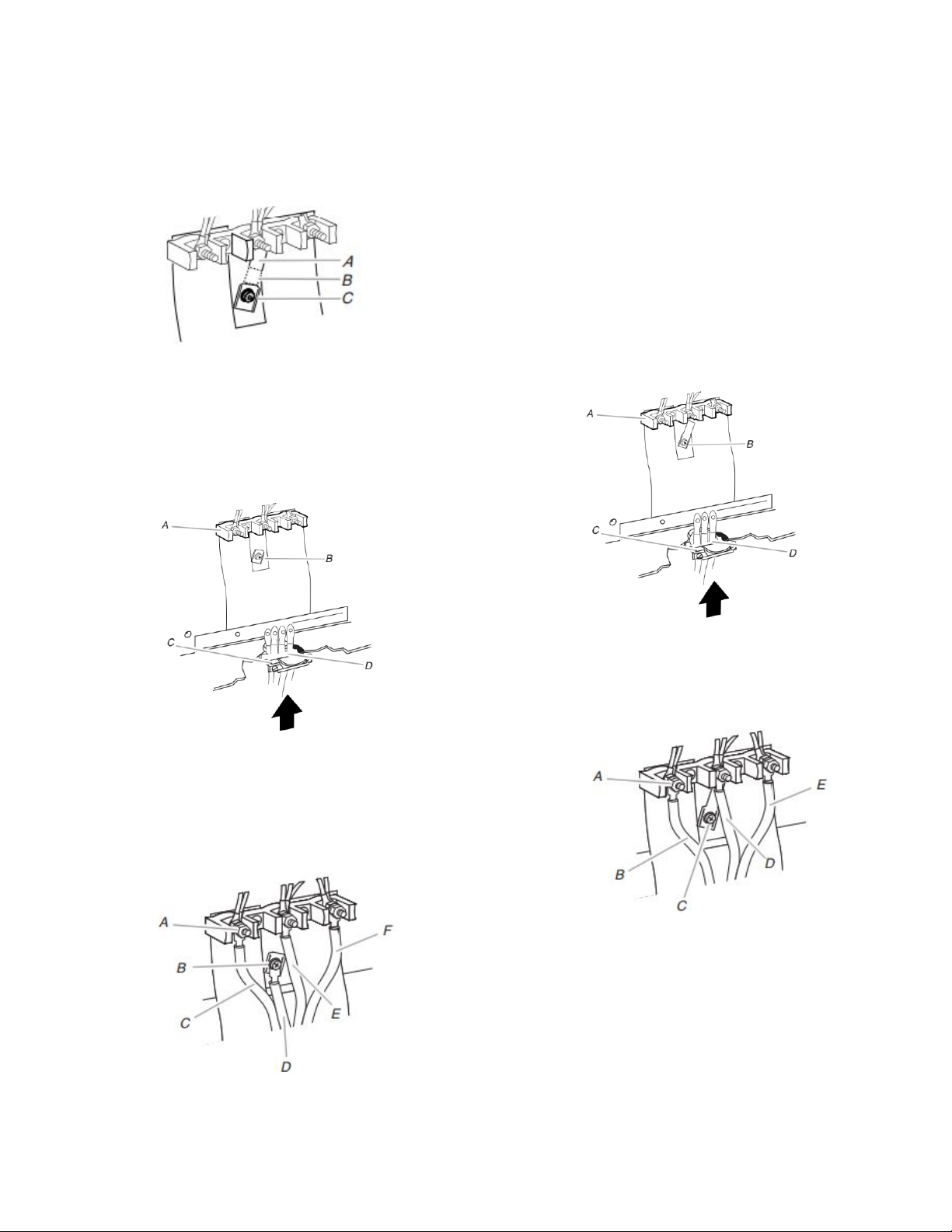

1. Part of metal ground strap must be cut out and removed.

A. Metal ground strap

B. Discard

C. Ground-link screw

2. Use a Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw and

the end of the ground link under the screw.

3. Feed the power supply cord through the strain relief on the

cord/conduit plate on bottom of range. Allow enough slack to

easily attach the wiring to the terminal block.

6. Connect line 2 (red) and line 1 (black) wires to the outer

terminal block posts with 10-32 hex nuts.

7. Using a torque wrench, tighten the hex nuts to a

recommended torque of 20 in-lbs (2.3 N-m).

NOTE: For power supply cord replacement, use only a power

cord rated at 250 V minimum, 40 A or 50 A that is marked for

use with nominal 1

3

⁄8" (3.5 cm) diameter connection opening,

with ring terminals and marked for use with ranges.

8. Tighten strain relief screws.

IMPORTANT: Verify the tightness of the hex nuts. Ensure all

harnesses are tightened to the terminal block and are not

loose.

9. Replace terminal block access cover.

3-Wire Connection: Power Supply Cord

Use this method only if local codes permit connecting chassis

ground conductor to neutral wire of power supply cord.

1. Feed the power supply cord through the strain relief in the

cord/conduit plate on bottom of range. Allow enough slack to

easily attach the wiring to the terminal block.

A. Terminal block

B. Ground-link screw

C. UL listed strain relief

D. Power supply cord wires

4. Use Phillips screwdriver to connect the green ground wire

from the power supply cord to the range with the ground-link

screw. The ground wire must be attached first.

5. Use 3/8" (9.5 mm) nut driver to connect the neutral (white)

wire to the center terminal block post with one of the 10-32

hex nuts.

A. 10-32 hex nut

B. Ground-link screw

C. Line 2 (red)

D. Green ground wire

E. Neutral (center) wire

F. Line 1 (black)

A. Terminal block

B. Ground-link screw

C. UL listed strain relief

D. Power supply cord wires -

large opening

2. Use 3/8" (9.5 mm) nut driver to connect the neutral (white)

wire to the center terminal block post with one of the 10-32

hex nuts.

A. 10-32 hex nut

B. Line 2 (red)

C. Ground-link screw

D. Neutral (white) wire

E. Line 1 (black)

3. Connect line 2 (red) and line 1 (black) wires to the outer

terminal block posts with 10-32 hex nuts.

4. Using a torque wrench, tighten the hex nuts to a

recommended torque of 20 in-lbs (2.3 N-m).

NOTE: For power supply cord replacement, only use a power

cord rated at 250 V minimum, 40 A or 50 A that is marked for

use with nominal 1

3

/8" (3.5 cm) diameter connection opening,

with ring terminals and marked for use with ranges.

12

Loading...

Loading...