Whirlpool xcgm2765fq, xcem2765fq Installation Instructions

INSTALLATION INSTRUCTIONS

Original instructiOns

cOmmercial gas Or

mODels Xcem2765 anD Xcgm2765

electric

Dryer

INSTRUCTIONS D’INSTALLATION

instructiOns D’Origine

sèche-linge À gaz Ou

mODèles Xcem2765 et Xcgm2765

électrique

À usage cOmmercial

INSTRUCCIONES DE INSTALACIÓN

instrucciOnes Originales

secaDOra a gas O

mODelOs Xcem2765 y Xcgm2765

eléctrica

cOmercial

ISTRUZIONI D’INSTALLAZIONE

istruziOni Originali

asciugatrice a gas O

mODelli Xcem2765 e Xcgm2765

elettrica

cOmmerciale

www.whirlpoolcommerciallaundry.com

W10868678A

TABLE OF CONTENTS

TABLE DES MATIÈRES

DRYER SAFETY ........................................................................3

FOR OWNER

MAINTENANCE INSTRUCTIONS............................................ 6

IF YOU NEED ASSISTANCE ................................................... 6

FOR WHIRLPOOL AUTHORIZED SERVICE PERSON

TOOLS & PARTS ..................................................................... 7

DIMENSIONS/CLEARANCES ............................................... 8

DRYER INSTALLATION REQUIREMENTS ........................... 9

INSTALLING LEVELING LEGS .............................................. 10

LEVELING ............................................................................... 11

ELECTRIC DRYER INSTALLATION REQUIREMENTS ...... 12

GAS DRYER INSTALLATION REQUIREMENTS ................. 13

DRYER VENTING REQUIREMENTS ................................... 15

GAS SUPPLY CONNECTION ............................................... 17

TECHNICAL SPECIFICATIONS–GAS DRYER ..................... 18

COMPLETE INSTALLATION ................................................. 19

REVERSING DRYER DOOR SWING .................................... 20

DRYER DISPOSAL ................................................................. 21

WARRANTY ........................................................................... 22

SÉCURITÉ DU SECHE-LINGE ............................................... 23

POUR LE PROPRIÉTAIRE

INSTRUCTIONS D’ENTRETIEN ............................................ 26

SI VOUS AVEZ BESOIN D'ASSISTANCE .............................. 26

POUR LE PERSONNEL D’ENTRETIEN

AUTORISÉ PAR WHIRLPOOL

OUTILS ET PIÈCES ................................................................ 27

DIMENSIONS/DISTANCES DE DÉGAGEMENT ................... 28

EXIGENCES D’INSTALLATION POUR

LE SECHE-LINGE .................................................................. 29

INSTALLATION DES PIEDS DE NIVELLEMENT .................. 30

NIVELLEMENT ....................................................................... 31

EXIGENCES D’INSTALLATION POUR

LE SECHE-LINGE ÉLECTRIQUE .......................................... 32

EXIGENCES D’INSTALLATION POUR

LE SECHE-LINGE À GAZ ...................................................... 33

EXIGENCES CONCERNANT L’ÉVACUATION

DU SECHE-LINGE ................................................................. 35

RACCORDEMENT A LA CANALISATION DE GAZ .............. 37

CARACTÉRISTIQUES TECHNIQUES —

SECHE-LINGE À GAZ ............................................................ 38

ACHEVER L’INSTALLATION .................................................. 39

INVERSION DU SENS D’OUVERTURE DE LA PORTE ........ 40

ELIMINATION DU SECHE-LINGE ......................................... 41

GARANTIE ............................................................................. 42

ÍNDICE

SEGURIDAD DE LA SECADORA ........................................... 43

PARA EL PROPIETARIO

INSTRUCCIONES DE MANTENIMIENTO............................. 46

SI NECESITA ASISTENCIA .................................................... 46

PARA EL PERSONAL DE SERVICIO

AUTORIZADO DE WHIRLPOOL

HERRAMIENTAS Y PIEZAS................................................... 47

DIMENSIONES Y ESPACIOS LIBRES................................... 48

REQUISITOS DE INSTALACIÓN DE LA SECADORA .......... 49

INSTALACIÓN DE LAS PATAS NIVELADORAS.................... 50

NIVELACIÓN .......................................................................... 51

REQUISITOS DE INSTALACIÓN DE LA

SECADORA ELÉCTRICA ....................................................... 52

REQUISITOS DE INSTALACIÓN DE LA

SECADORA A GAS ................................................................ 53

REQUISITOS DE VENTILACIÓN DE LA SECADORA .......... 55

CONEXIÓN DEL SUMINISTRO DE GAS............................... 58

ESPECIFICACIONES TÉCNICAS - SECADORA A GAS ...... 59

INSTALACIÓN COMPLETA ................................................... 60

CAMBIO DE SENTIDO DE LA ABERTURA

DE LA PUERTA ....................................................................... 61

ELIMINACIÓN DE LA SECADORA ....................................... 62

GARANTÍA .............................................................................. 63

INDICE

SICUREZZA DELL'ASCIUGATRICE....................................... 64

PER IL PROPRIETARIO

ISTRUZIONI PER LA MANUTENZIONE ............................... 67

COME RICHIEDERE ASSISTENZA ...................................... 67

PER IL PERSONALE DI ASSISTENZA

AUTORIZZATO WHIRLPOOL

ATTREZZI E COMPONENTI .................................................. 68

DIMENSIONI/SPAZI ............................................................. 69

REQUISITI DELL'INSTALLAZIONE

DELL'ASCIUGATRICE ........................................................... 70

INSTALLAZIONE DEI PIEDINI DI REGOLAZIONE ............... 71

LIVELLAMENTO ..................................................................... 72

REQUISITI DELL'INSTALLAZIONE

DELL'ASCIUGATRICE ELETTRICA ...................................... 73

REQUISITI DELL'INSTALLAZIONE

DELL'ASCIUGATRICE A GAS ............................................... 74

REQUISITI DI SCARICO DELL'ASCIUGATRICE .................. 76

COLLEGAMENTO DI ALIMENTAZIONE DEL GAS .............. 78

CARATTERISTICHE TECNICHE -

ASCIUGATRICE A GAS ......................................................... 79

COMPLETAMENTO DELL'INSTALLAZIONE ....................... 80

INVERSIONE IL SENSO DI APERTURA

DELLO SPORTELLO ............................................................. 81

ELIMINAZIONE DELL'ASCIUGATRICE ................................ 82

GARANZIA ............................................................................. 83

2

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

WARNING – “Risk of Fire”

This is an additional safety alert symbol that alerts you to the risk of fire.

WARNING

-

“Risk of Fire”

- Clothes dryer installation and service must be performed by a Whirlpool authorized

installer.

- Install the clothes dryer according to the manufacturer’s instructions and local codes.

- Do not install a clothes dryer with exible plastic venting materials or exible metal

(foil type) duct. If exible metal duct is installed, it must be of a specic type identied

by the appliance manufacturer as suitable for use with clothes dryers. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airow and increase the risk of re.

- To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

■ It is recommended that the owner post, in a prominent location, instructions for the customer’s use in the event the customer

smells gas. This information should be obtained from your gas supplier.

■ Post the following warning in a prominent location.

FOR YOUR SAFETY

1. DO NOT USE OR STORE GAS OR OTHER FLAMMABLE MATERIALS IN THIS APPLIANCE OR NEAR THIS APPLIANCE.

2. DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

3. DO NOT MODIFY THIS APPLIANCE.

3

DRYER SAFETY

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

– Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Clear the room, building, or area of all occupants.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the fire department.

•

– Installation and service must be performed by a Whirlpool authorized installer,

Whirlpool authorized service agency, or the gas supplier.

IMPORTANT: When discarding or storing your old clothes dryer, remove the door.

4

DRYER SAFETY

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of re, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

■ Read all instructions before using the dryer.

■ This dryer is intended only for drying clothes and textiles

that have been washed in water. Do not use for any other

purpose.

■ WARNING: If you smell gas, do not use the dryer or any

electrical equipment nearby. Warn other people to clear

the area. Contact the dryer owner immediately.

■ Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to a

chemical reaction that could cause a load to catch re.

■ If it is unavoidable that fabrics that contain vegetable or

cooking oil or that have been contaminated by hair care

products be placed in a tumble dryer, they should rst

be washed in hot water with extra detergent – this will

reduce, but not eliminate the hazard.

■ Do not dry articles that have been previously cleaned

in, washed in, soaked in, or spotted with gas,

dry-cleaning solvents, other ammable, or explosive

substances as they give off vapors that could ignite

or explode.

■ Items that have been soiled with substances such as

acetone, alcohol, gas, kerosene, spot removers,

turpentine, waxes, and wax removers should be washed

in hot water with extra detergent before being dried in

the dryer.

■ Do not dry unwashed items in the dryer.

■ Do not use this dryer if industrial chemicals have been

used for cleaning. The possible presence of residual

quantities of aggressive or decomposed chemicals in the

load may produce damage to the dryer and harmful fumes.

■ Do not allow children to play on, in, or with the dryer.

Close supervision of children is necessary when the dryer

is used near children.

■ This dryer is not intended for use by persons (including

children) with reduced physical, sensory, or mental

capabilities, or lack of experience or knowledge,

unless they have been given supervision or instruction

concerning use of the dryer by a person responsible for

their safety.

■ Before the dryer is removed from service or discarded,

remove the door to the dryer compartment.

■ Do not reach into the dryer if the drum is moving.

■ Do not open door while dryer is in operation. It will stop.

■ When loading or re-loading the dryer, avoid touching hot

metal parts of the drum (burn risk).

■ Remove all objects from pockets such as lighters and

matches.

■ Cleaning and user maintenance shall not be made by

children without supervision.

■ WARNING: The appliance must not be supplied through

an external switching device, such as a timer, or connected

to a circuit that is regularly switched on and off by a utility.

■ The dryer must not be installed behind a lockable door, a

sliding door, or a door with a hinge on the opposite side to

that of the dryer in such a way that full opening of the dryer

door is restricted.

SAVE THESE INSTRUCTIONS

■ The appliance is intended, but not limited, to be used in

public areas.

■ Children of less than 3 years should be kept away unless

continuously supervised.

■ The appliance must be disconnected from it's power

source during service and when replacing parts.

■ If drum rotation is blocked due to trapped textiles,

disconnect the dryer from the electrical supply before

gently removing the blockage.

■ If the dryer is not heating, or appears to be defective or

damaged, do not use it. Contact the owner.

■ Do not install or store the dryer where it will be exposed

to the weather.

■ Do not tamper with controls.

■ Clean dryer lint screen before or after each load.

■ Do not use this dryer without the lint screen in place.

■ Do not repair or replace any part of the dryer or attempt

any servicing unless specically recommended in this

Installation Instructions that you understand and have the

skills to carry out.

■ Fabric softeners, or similar products, should be used as

specied by the fabric softener instructions.

■ Items such as foam rubber (latex foam), shower caps,

waterproof textiles, rubber-backed articles and clothes or

pillows tted with foam rubber pads should not be dried

in the tumble dryer.

■ The nal part of a tumble dryer cycle occurs without

heat (cool-down cycle) to ensure that the articles are left

at a temperature that ensures that the items will not be

damaged.

■ WARNING: Never stop a tumble dryer before the end of

the drying cycle unless all items are quickly removed and

spread out so that the heat is dissipated. (Avoids risk of

spontaneous combustion).

■ In case of electrical supply failure, remove the load

quickly and spread it out to avoid risk of spontaneous

combustion.

■ Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

■ The fresh air ventilation openings into the room and into

the dryer must not be blocked or sealed.

■ Emergency stop control: After installation, access to

mains plug (gas dryer) or mains supply (electric dryer)

via a double-pole switch must be maintained at all times

in order to ensure immediate deactivation of the dryer in

case of emergency.

■ The interior of the dryer and dryer exhaust vent should

be cleaned periodically by Whirlpool authorized service

personnel.

■ See “Electrical Requirements” section for earthing

instructions.

■ Adequate ventilation has to be provided to avoid the

back-ow of gases into the room from appliances burning

fuels, including open res.

5

MAINTENANCE INSTRUCTIONS

■ Clean lint screen before and after each cycle.

■ Removing accumulated lint:

From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done by

a Whirlpool authorized person.

From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

■ Keep area around dryer clear and free from combustible

materials, gas, and other ammable vapors and liquids.

■ Keep dryer area clear and free from items that would

obstruct the ow of combustion and ventilation air.

If dryer does not operate, check the following:

■ Electrical supply is connected.

■ Circuit breaker is not tripped or house fuse is not blown.

■ Door is closed. Listen closely to hear the door switch

activate.

■ Controls are set in a running or “on” position.

■ START button has been pushed rmly.

■ For gas dryers, check that gas supply shut-off valves are

set in open position.

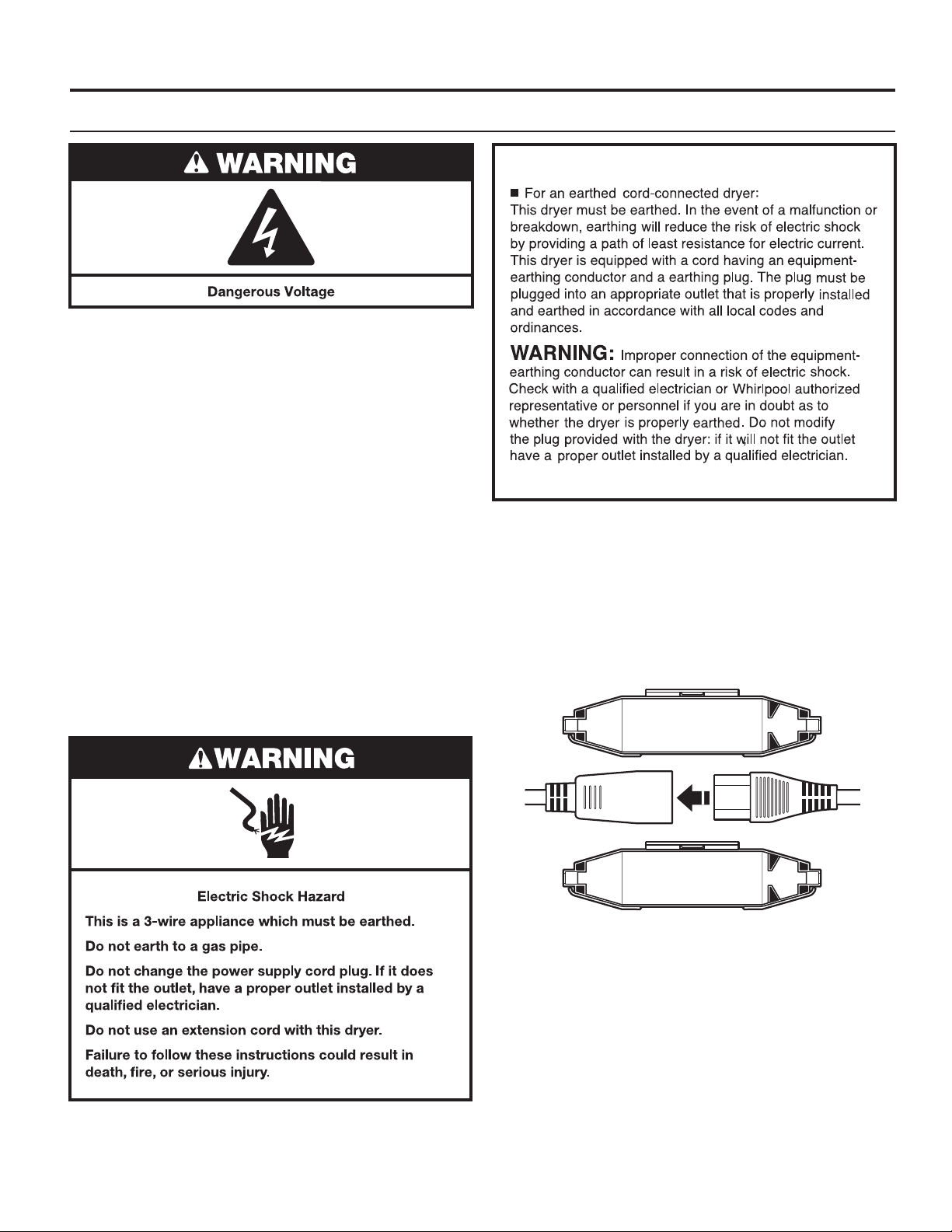

WARNING: Improper connection of the equipment-earthing conductor can result in a risk of electric

shock. It is your responsibility to check with a qualied electrician or service representative if you are in doubt

as to whether the dryer is properly grounded and meets all local codes and ordinances. Do not modify the

plug provided with the dryer: If it will not t the outlet, have a proper outlet installed by a qualied electrician.

IF YOU NEED ASSISTANCE

If you need help, contact the dealer from whom you purchased the appliance, or a Whirlpool designated service company. When

calling, please know the purchase date and the complete model and serial number of your appliance. This information will help us to

better respond to your request.

IF YOU NEED SERVICE:

Contact your authorized Whirlpool Commercial Laundry distributor. To locate your authorized Whirlpool Commercial Laundry

distributor, visit www.WhirlpoolCommercialLaundry.com.

For written correspondence:

Whirlpool Commercial Laundry Service Department

2000 N M 63

Benton Harbor, Michigan 49022-2632 USA

6

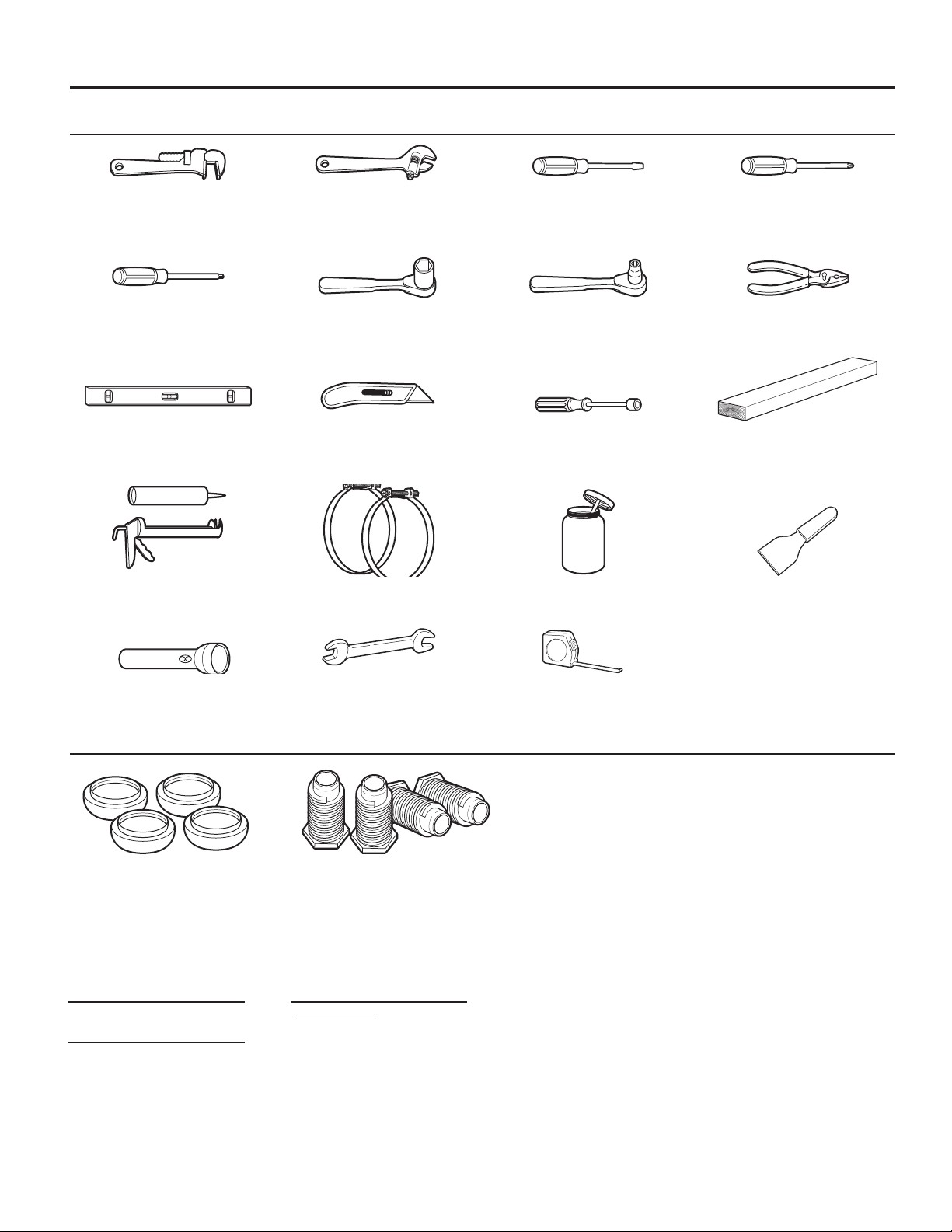

TOOLS & PARTS

Tools Needed:

203 mm (8") 203 mm (8") or 254 mm (10") Flat-Blade Screwdriver Phillips Screwdriver

or 254 mm (10") Adjustable Wrench

Pipe Wrench that opens to 25 mm ( 1")

Torx† T-20† Security 25 mm (1") Hex-Head 8 mm ( 5⁄16") Socket Wrench Pliers (that open to

Screwdriver or Bit Socket Wrench 39 mm [19/16"])

Level Utility Knife 6 mm (1/4") Nut Driver 686 mm (27")

Wood Block

Caulk Gun and Caulk Vent Clamps Pipe-Joint Compound Putty Knife

(for installing new exhaust vent) Suitable for Gas Type

Flashlight (optional) 25 mm (1") Ruler or Measuring Tape

Open-End Wrenches

Parts Supplied:

Foot Boots (4) Leveling Legs (4)

NOTE: The circuit diagram for this dryer is located inside the

lower front panel, within the Tech Sheets.

Electric Model:

Technical Specications:

220 – 240 V, 50 Hz. AC

4575W

Total mass: 68 kg max.

Clothes Capacity:

IEC Capacity

9 kg

NOTE: Sound Pressure Level, LpA: 58 dB(A)

[uncertainty, KpA: +/–10 dB(A)].

†TORX and T20 are trademarks of Acument Intellectual Properties, LLC.

7

DIMENSIONS/CLEARANCES

Dimensions

Side View Back View

Clearances

35"

(889 mm)

1"

(25 mm)

(743 mm)

(660 mm)

1

/2"

7

(191 mm)

291/4"

26"

1

8

/4"

(210 mm)

31/4"

(83 mm)

11/2"

(38 mm)

5

(140 mm)

1

(343 mm)

/2"

(343 mm)

131/2"

Gas

13

(686 mm)

Electric

1

/2"

27"

(273 mm)

4" dia

(102 mm)

103/4

"

(83 mm)

(914 mm)

(electric models)

31/4"

Front View, Recessed Opening Side View, Recessed In Closet

36"

(953 mm)

(gas models)

371/2"

41"

(1042 mm)

14" max

(356 mm)

(0 mm)

14" max

(356 mm)

3"/3"

(76 mm)

15"

(381 mm)

0"

0"

0"

(0 mm)

(0 mm)

0"

(0 mm)

0"

(0 mm)

15"

(381 mm)

1"

(25 mm)

Closet Door to

Front of Dryer

3"/3"

(76 mm)

2

48"

/48"

(310 cm2)

2/

24"

24"

(155 cm2)

2

2

8

DRYER INSTALLATION REQUIREMENTS

(155 cm

)

Location Requirements

Your dryer can be installed in a basement, laundry room, or

recessed area.

This dryer is not intended for installation in a mobile home.

Companion appliance location requirements should also be

considered.

IMPORTANT: Do not install or store the dryer where it will be

exposed to water and/or the weather. Proper installation is your

responsibility.

You will need:

■ A grounded electrical outlet located within 6 ft. (1.8 m) of

where the power cord is attached to the back of the dryer.

See “Electrical Requirements.”

■ A level oor with a maximum slope of 1" (25 mm) under

entire dryer. Installing the dryer on soft oor surfaces,

such as carpets or surfaces with foam backing, is not

recommended.

Gas dryer installation clearances

■ The location must be large enough to allow the dryer door to

be fully opened.

■ Additional spacing should be considered for ease of

installation and servicing. The door opens more than 180°.

■ Additional clearances might be required for wall, door, and

oor moldings.

■ Additional spacing of 1" (25 mm) on all sides of the dryer is

recommended to reduce noise transfer.

When installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

■ Check code requirements: Some codes limit or do not

permit installation of clothes dryers in garages, closets, or

sleeping quarters. Contact your local building inspector.

■ Make sure that lower edges of the cabinet, plus the back

and bottom sides of the dryer, are free of obstructions to

permit adequate clearance of air openings for combustion

air. See “Recessed Area and Closet Installation Instructions”

below for minimum spacing requirements.

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet. For

recessed area and closet installations, minimum clearances

can be found on the warning label on the rear of the dryer

or in “Dimensions/Clearances.”

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air

opening in the top and bottom is required. The unobstructed

opening needs to be 1 square inch per 1,000 Btu (252 kcal)

of gas burner output. Output on North American gas dryers

is typically 22,000 Btu; however, Canadian dryers may have

lower output. Louvered doors with equivalent air openings are

acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

2

48 in.

(310 cm2)

Front

Front

View

View

2

24 in.

2

Closet

Closet

Door

door

)

3"

(76 mm)

3"

(76 mm

9

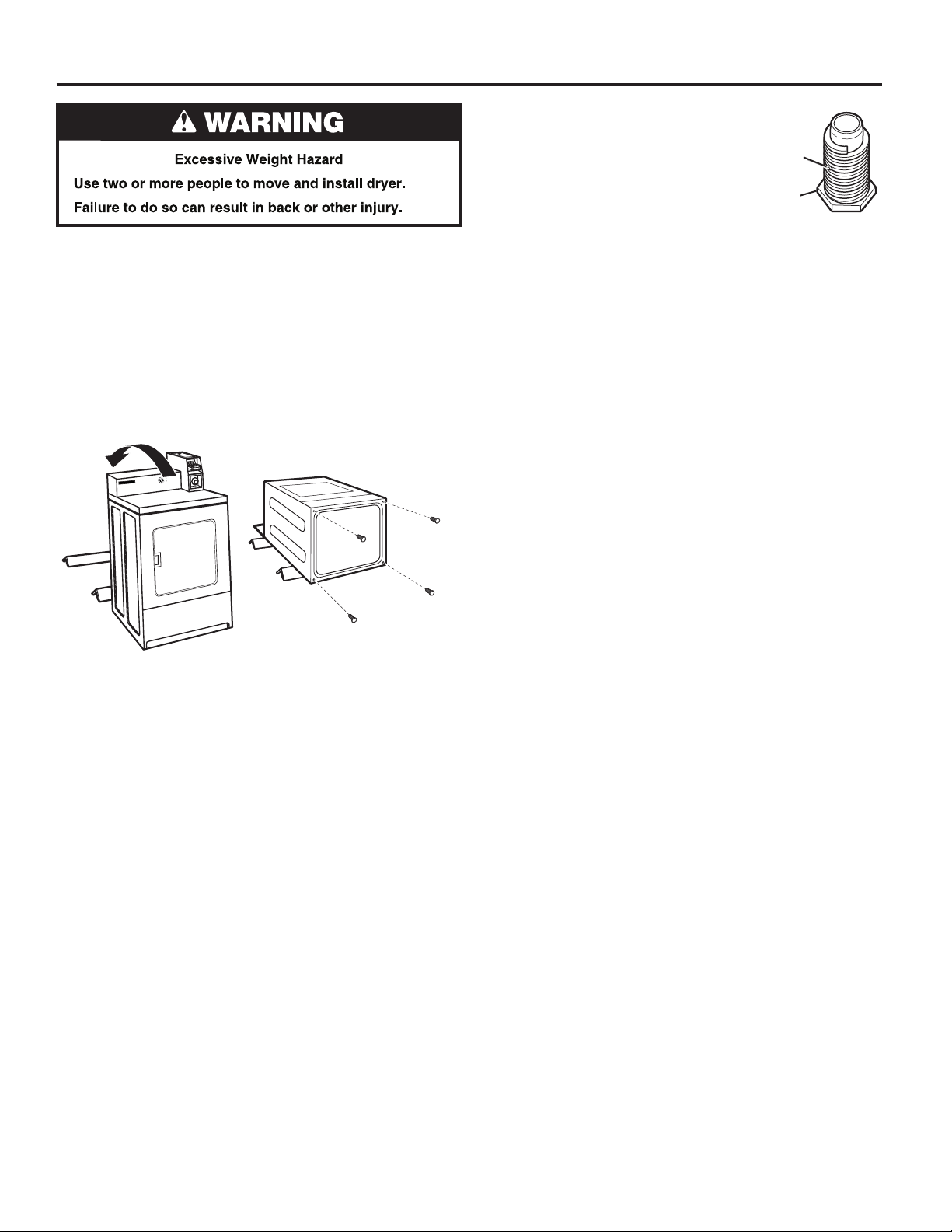

INSTALLING LEVELING LEGS

1. Prepare dryer for leveling legs

NOTE: Slide dryer onto cardboard or hardboard before moving

to avoid damaging oor covering.

Using two or more people, move dryer to desired installation

location.

Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe drum interior with a

damp cloth to remove any dust.

Take two cardboard corners from the dryer carton and place

them on the oor in back of the dryer. Firmly grasp the body of

the dryer and gently lay it on its back on the cardboard corners.

2. Screw in leveling legs

Examine leveling legs and nd diamond

marking. Screw legs into leg holes by

hand. Use an adjustable wrench or

25 mm (1") hex-head socket wrench

to nish turning legs until diamond

marking is no longer visible. Then t

a covered foot boot over each leg foot.

To protect the oor, use a large piece of cardboard from the

dryer carton. Stand dryer up on the cardboard. Slide the dryer

until it is close to its nal location. Leave enough room for

electrical connection and to connect the exhaust vent.

A longer leveling foot is available if needed on extremely sloped

oors, Part Number 279810.

Diamond

Marking

Foot

10

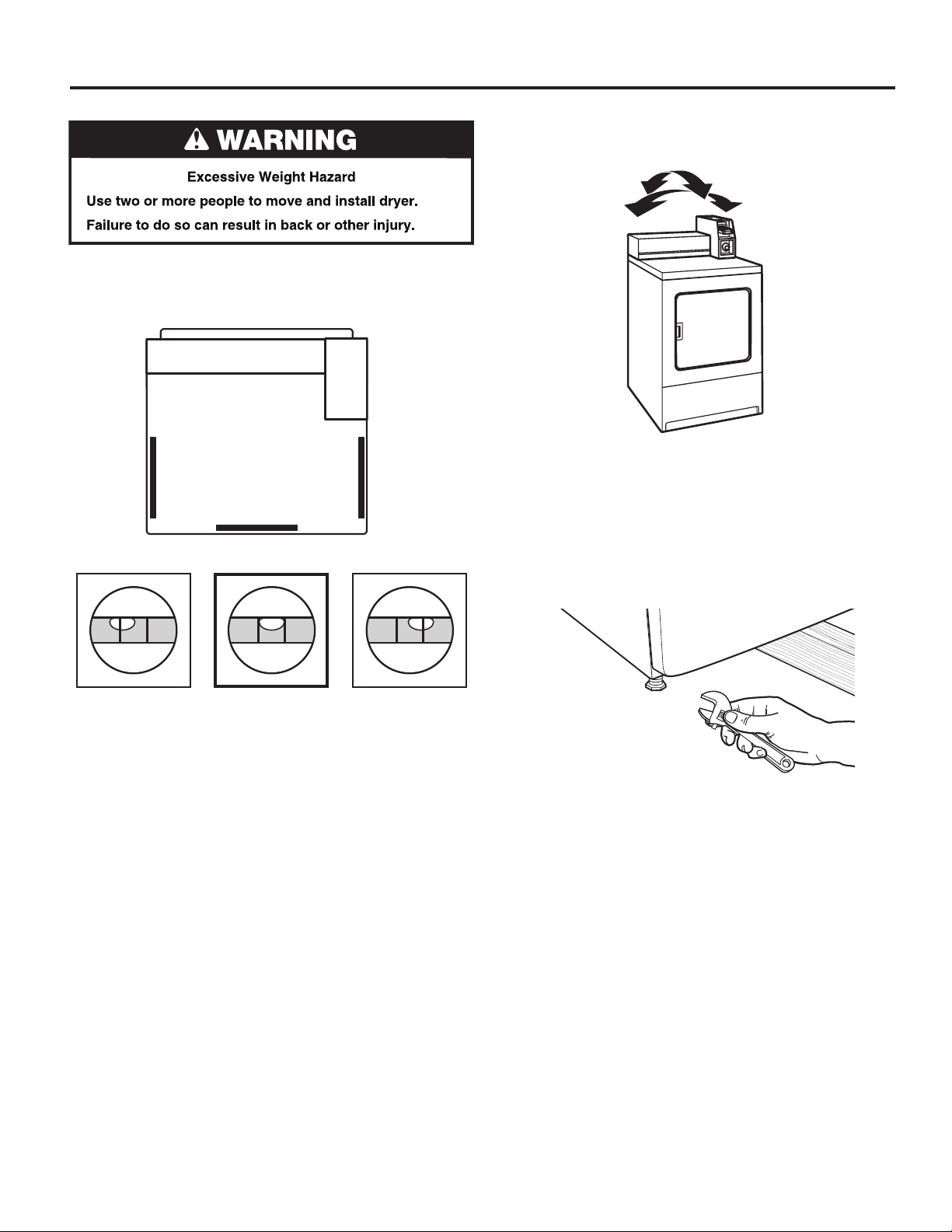

LEVELING

Leveling your dryer properly reduces excess noise and vibration.

1. Remove cardboard from beneath dryer. Place a level on top

edges of dryer, checking each side and front. If not level,

tip dryer and adjust legs up or down as shown in Step 3,

repeating as necessary.

(appearance may vary)

2. Grip dryer from top and rock back and forth, making sure all

four legs are rmly on oor. Repeat, rocking dryer from side

to side. If dryer rocks, go to Step 3 and adjust leveling legs.

(appearance may vary)

3. If dryer is not level, use a 1" or 25 mm open-end or

adjustable wrench to turn the leveling leg counterclockwise

to lower the dryer or clockwise to raise the dryer. Recheck

levelness of dryer and that all four legs are rmly in contact

with the oor. Repeat as needed.

HELPFUL TIP: You may want to prop up front of dryer about

4" (102 mm) with a wood block or similar object that will

support weight of dryer.

Not Level LEVEL Not Level

11

ELECTRIC DRYER INSTALLATION REQUIREMENTS

Electrical Requirements

Electric Shock Hazard

This dryer is supplied without an electric cord and plug. It

must be connected by a Whirlpool authorized service person

to a single-phase electricity supply at the voltage shown

on the dataplate, using a suitable xed wiring installation in

accordance with local and national wiring regulations.

■ A 3-wire circular cord of minimum conductor size 2.5 mm2

cross-section area should be used.

■ A 25A (minimum) supply fuse should be used, and a

switch with a clear OFF marking having a contact

separation in both poles that provides full disconnection

under over-voltage category III conditions must be

incorporated into the xed wiring in accordance with local

wiring regulations by a competent electrician. The dryer

should be positioned so that the disconnection switch

is clearly visible and easily accessible to the user. This

disconnection switch also provides the function of an

emergency stop control for the user.

■ A cord clamp bush is provided on the dryer, and should

be tightened on completion of wiring. The electrical mains

terminals are located behind the small rear access panel

(terminal block cover), and connections should be made

in accordance with the terminal markings. Remember to

replace the terminal access panel (terminal block cover).

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electrical supply system

impedance to which the electric dryer should be connected

is declared to be 0.054 Ohm + j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has

chosen compliance with IEC/EN.60335 standards as the most

appropriate for this product.

This is 3-wire appliance which must be earthed.

Do not earth to a gas pipe.

Failure to follow these instructions could result in

death, re, or serious injury.

If codes permit and an additional ground bond wire is used, it

is recommended that a qualied electrician determine that the

ground bond path is adequate.

Recommended Earthing Method

It is your responsibility to contact a qualied electrical installer

to ensure that the electrical installation is adequate and in

conformance with all local codes and ordinances.

12

GAS DRYER INSTALLATION REQUIREMENTS

Electrical Requirements

IMPORTANT: Observe all governing codes and ordinances.

You will need a grounded electrical outlet located within

610 mm (2 feet) of either side of the dryer.

This dryer is supplied/tted with an electrical supply cord and

plug. It should be connected to electrical supply socket at

the voltage shown on the rating plate. The minimum supply

fuse capacity should be 10A. The dryer must be positioned so

that the plug is clearly visible and accessible. This plug also

provides the function of an emergency stop control for the user.

If the tted plug is not used, the electrical connection must be

carried out by a competent electrician in accordance with local

or national codes.

If the supply cord is damaged, it must be replaced with a

specially terminated cord by an authorized service agent

or a similarly competent person in order to avoid a hazard.

Do not use an adapter.

Do not use an extension cord.

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electricity supply system

impedance to which the gas dryer should be connected is

declared to be 0.29 Ohm + j0.18 Ohm.

NOTE: Electrical safety standards: The manufacturer has

chosen compliance with IEC/EN.60335 standards as the most

appropriate for this product.

EARTHING INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Using the universal cord included with this dryer:

The gas dryer is equipped with a universal cord with

interchangeable plugs.

1. To use the universal cord, select the plug end that ts your

electrical outlet, and plug it into the adapter on the supply

cord.

2. Secure the plug end in place on the cord by aligning the

2 cover halves over the cord adapter and clipping them

together.

If codes permit and an additional ground bond wire is used, it

is recommended that a qualied electrician determine that the

ground bond path is adequate.

13

GAS DRYER INSTALLATION REQUIREMENTS

Gas Supply

Supply line requirements:

Provide a rigid gas supply line to the dryer location. It should

be minimum 12.5 mm (1/2") ID. When acceptable to the gas

supplier and local codes, 10 mm (3/8") ID rigid supply line may

be used for lengths under 6.1 m (20'). Pipe-joint compounds

resistant to the action of L.P. gas must be used.

NOTE: For installation in Australia and New Zealand, refer to

AS/NZS 5601 for pipe sizing details. All piping is to be in

accordance with AS/NZS 5601.1 – Gas Installations.

Gas connection to the dryer itself should be made by means

of a exible gas hose suitable for the appliance and gas

category in accordance with national installation regulations.

If in doubt, contact the gas supplier. It should be minimum

10 mm (3/8") ID.

A means of restraint should be used between the dryer and the

wall to avoid straining of the rigid gas supply when the dryer

is moved. An appropriate length of chain and a wall hook is

recommended.

The dryer gas inlet connection is a 10 mm (3/8") NPT thread.

An adapter is supplied for conversion to standard ISO.228-1

thread (10 mm [3/8"] BSP).

IMPORTANT: Observe all governing codes and ordinances.

In Australia and New Zealand, refer to AS/NZS 5601.1 – Gas

Installations.

Gas Supply

Before installation, check that the local gas distribution

conditions, nature of gas and pressure, and the adjustment of

the appliance are compatible. Burner information will be found

on the model/serial rating plate in the door recess of the dryer.

If this information does not agree with the type of gas available,

see your dealer.

Natural Gas:

This dryer is factory adjusted for use with NATURAL GAS (G20),

and no further adjustment should be required at installation.

L.P. Gas:

This dryer is also certied for use with L.P. (propane or butane)

gases with appropriate conversion. No attempt shall be made

to convert the appliance from the gas specied on the model/

serial rating plate for use with a different gas without consulting

the serving gas supplier.

Conversion must be done by a Whirlpool authorized service

technician. Gas conversion kit (European Country), part number

W10233219, is available for purchase from your dealer. Gas

conversion kit (Australia), part number W10315369, is available

for purchase from your dealer. Full instructions are supplied

with the kit.

Natural Gas (France/Belgium):

This dryer is also certied for France/Belgium for use with G20/

G25 gases (20 mbar/25 mbar) with appropriate conversion. No

attempt should be made to convert this appliance from the gas

specied on the gas rating label for use with a different gas

without consulting the serving gas supplier. Gas conversion

must be done by a Whirlpool authorized gas service technician.

Conversion kit, part number (W10181947) is available for

purchase from your dealer. Full instructions are supplied with

the kit.

Check for leaks by using an approved noncorrosive leakdetection solution. Bubbles will show a leak. Correct any leak

found. A pressure measurement tapping is provided on the gas

valve within the dryer, accessible after removal of the lower

front panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

14

DRYER VENTING REQUIREMENTS

Elbows:

■ 45° elbows provide better airow than 90° elbows.

WARNING: To reduce the risk of re, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

In Australia and New Zealand, refer to AS/NZS 5601.1 – Gas

Installations.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or exible metal vent shall be used for

exhausting.

102 mm

(4")

Good

Better

Clamps:

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct

and catch lint. Do not use duct tape.

102 mm (4") Heavy, Metal Exhaust Vent

■ Only a 102 mm (4") heavy, metal exhaust vent and clamps

may be used.

■ Do not use plastic or metal foil vent.

Rigid metal vent:

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

■ Must be fully extended and supported in nal dryer location.

■ Remove excess to avoid sagging and kinking that may result

in reduced airow and poor performance.

■ Do not install in enclosed walls, ceilings, or oors.

■ The total length should not exceed 2.4 m (7

3

⁄4 ft.).

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not

plugged with lint. Replace plastic or metal foil vents with rigid

metal or exible metal vents. Review “Vent System Chart” and,

if necessary, modify existing vent system to achieve best drying

performance.

15

DRYER VENTING REQUIREMENTS

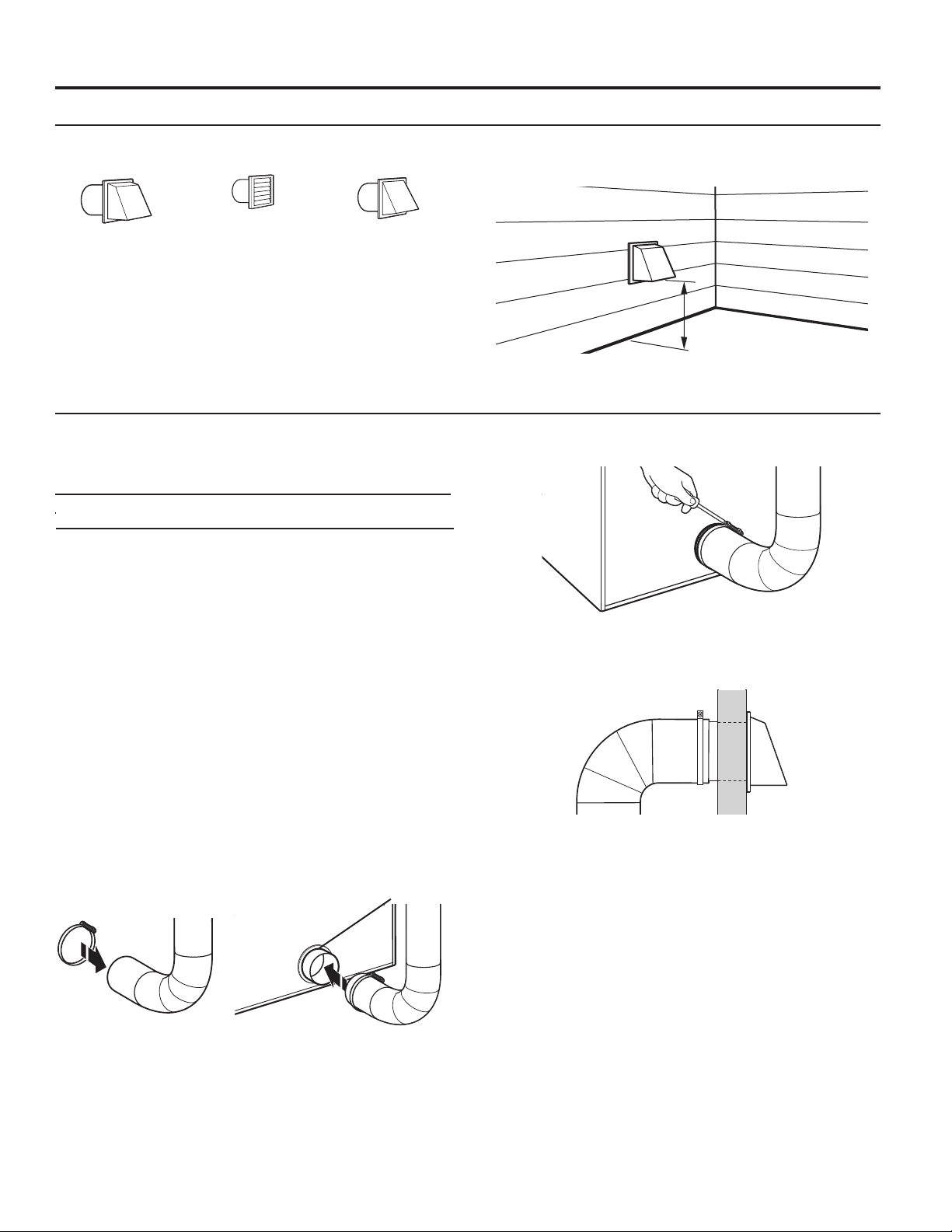

Vent Hoods

102 mm (4") Diameter Exhaust Hoods

Exhaust hood must be at least 305 mm (12") from the ground

or any object that may be in the path of the exhaust (such as

owers, rocks, bushes, or snow).

Box Hood Louvered Hood Angled Hood

Vent System Length

Maximum Vent Length/Vent Connection

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Vent System Chart (Rigid Metal Vent)

No. of Box and Angled

90˚ Turns Louvered Hood Hood

0 39.6 m (130 ft.) 39.3 m (129 ft.)

1 38.1 m (125 ft.) 36.3 m (119 ft.)

2 35.1 m (115 ft) 33.2 m (109 ft.)

3 32.3 m (106 ft.) 30.5 m (100 ft.)

4 29.9 m (98 ft.) 28.0 m (92 ft.)

For vent systems not covered by the vent specication chart,

see your parts distributor.

Provision must be made for enough air for combustion and

ventilation. (Check governing codes and ordinances.) See

“Recessed Area and Closet Installation Instructions” in the

“Location Requirements” section.

A 102 mm (4") outlet hood is preferred. However, a 64 mm

(21⁄2") outlet exhaust hood may be used. A 64 mm (21⁄2") outlet

creates greater back pressure than other hood types. For

permanent installation, a stationary vent system is required.

Connect Vent

1. If connecting to existing vent, make sure the vent is clean.

2. Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer.

Vent Collar

305 mm min.

12" min.

(305 mm)

(12")

3. Tighten hose clamp with Phillips screwdriver.

4. Make sure the vent is secured to exhaust hood with

a 102 mm (4") clamp.

5. Move dryer into nal position. Do not crush or kink vent.

Make sure dryer is level.

NOTE: Testing for proper ventilation should be done with a

Manometer. Minimum: 0.01" (0.2 mm). Maximum: 0.6" (16 mm).

NOTE: Do not remove vent collar.

16

DRYER VENTING REQUIREMENTS

If an Exhaust Hood Cannot be Used Multiple Dryer Venting

The outside end of main vent should have a sweep elbow

directed downward.

* Minimum clearance above any

accumulation of snow, ice, or

debris such as leaves

If main vent travels vertically through the roof, rather than

through wall, install a 180° sweep elbow on end of vent at least

610 mm (2 ft.) above surface of roof.

The opening in wall or roof shall have a diameter 13 mm (1⁄2")

larger than vent diameter. Vent should be centered in opening.

Do not install screening over end of vent for best performance.

A main vent can be used for venting a group of dryers. The

main vent should be sized to remove 5663 l/min. (200 CFM) of

air per dryer. Large-capacity lint screens of proper design may

be used in main vent if checked and cleaned frequently. The

room where the dryers are located should have make-up air

equal to or greater than CFM of all the dryers in the room.

Back-draft dampers are available from your distributor and

should be installed in the vent of each dryer to keep exhausted

air from returning into dryers and to keep exhaust in balance

within main vent. Unobstructed return air openings are required.

Although usually each single-load dryer should have an

unobstructed outdoor air opening of 154 cm2 (24 in.2) (based

on 6.5 cm2 [1 in.2] per 252 kcal [1,000 Btu]), common make-up

air openings are also acceptable. Set up common openings so

the make-up air is distributed equally to all of the dryers. Keep

in mind that the coverage area must be increased by 33% to

account for the use of registers or louvers over the openings.

Also, make-up air openings should not be installed near the

location where exhaust vents exit the building.

Each vent should enter the main vent at an angle pointing in

the direction of the airow. Vents entering from the opposite

side should be staggered to reduce the exhausted air from

interfering with the other vents.

Air Flow

Air ow

30˚ max.

GAS SUPPLY CONNECTION (on some models)

Make Gas Connection

1. Connect gas supply to dryer. If the exible gas hose has

10 mm (3/8") BSP thread, use the supplied conversion

thread adapter. Use pipe-joint compound resistant to the

action of L.P. gas for gas connections.

If necessary for service, open the toe panel. Use a putty

knife to press on the 2 toe panel locks located at the top

of the toe panel. Pull downward on the toe panel to open.

Toe panel is hinged at the bottom.

The maximum angle of each vent entering the main vent should

be no more than 30°.

Keep air openings free of dry cleaning uid fumes. Fumes

create acids which, when drawn through the dryer heating

units, can damage dryers and items being dried.

A clean-out cover should be located on the main vent for

periodic cleaning of the vent system.

NOTE: For more dryer venting information, please refer to

Whirlpool document W10100920.

2. Open the shut-off valve in the gas supply line and make sure

the dryer has its own gas supply opened.

3. Test all connections by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show

a leak. Correct any leaks found.

17

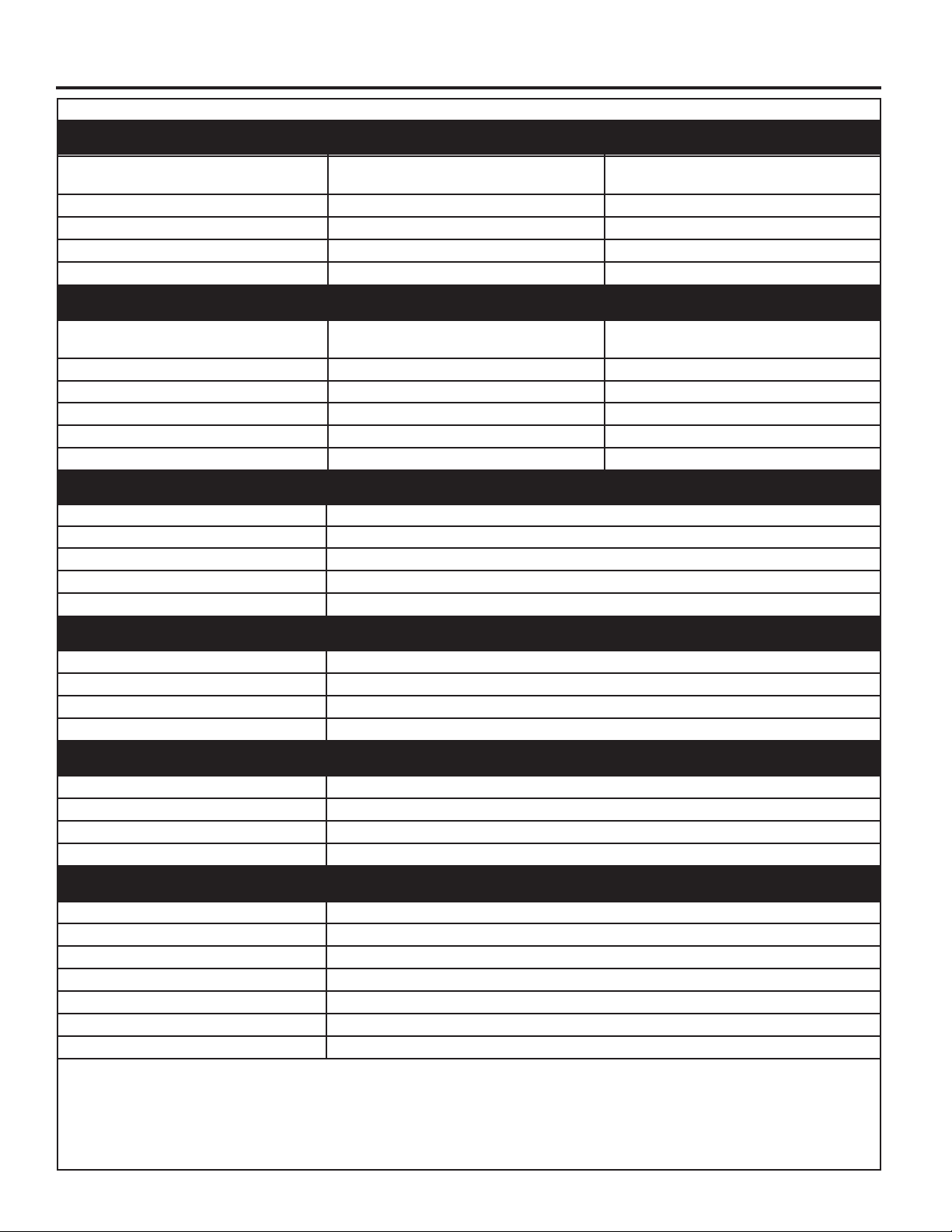

TECHNICAL SPECIFICATIONS – GAS DRYER

220–240V~50Hz 1ph 3A max. IP24 Clothes capacity: 9.0 kg max. Sound pressure level, Lpa: 58 dBA (uncertainty, Kpa: +/-10 dBA) Total mass: 68 kg max.

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: CH, CZ, CY, ES, GB, GR,

HR, IE, IT, PT, SI, SK, TR

European Gas Category:

Gas Flow Rate: .562703 m3/hr 0.562703 m3/hr

Supply Pressure (G20): 20 mbar 20 mbar

Factory Adjusted Pressure: 7.4 mbar 7.4 mbar

With LP Gas Conversion Kit: Injector size: 1.25 mm Heat input gross: 6.4 kW

European Country: CH, CZ, CY, ES, GB, GR, HR,

European Gas Category:

Butane Supply Pressure (G30): 28–30 mbar 30 mbar

Adjusted Pressure: N/A N/A

Propane Supply Pressure (G31): 37 mbar 30 mbar

Adjusted Pressure: N/A N/A

With France/Belgium NATURAL GAS conversion kit: Injector size 1.65 mm Heat input gross: 5.9 kW

European Country: FR, BE

European Gas Category:

Supply Pressure (G20): 20 mbar

Supply Pressure (G25): 25 mbar

Adjusted Pressure: N/A

II

2H3+

IE, IT, PT, SI, SK, TR

II

2H3+

I

2E+

CY, CZ, DK, EE, FI, GR, HU,

IT, NO, RO, SE, SK, TR

II

2H3B/P

CY, CZ, DK, EE, FI, GR, HU,

IT, NO, RO, SE, SK, TR

II

2H3B/P

Factory set for Australia/New Zealand NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: AS, NZS

Supply Pressure (G20) minimum 1.13 kPa

Adjusted Pressure (Test Point Pressure): 0.74 kPa

Nominal Hourly Gas Consumption 21.1 MJ/h

With Australia LG Gas Conversion Kit: Injector Size: 1.40 mm Heat input gross: 6.54 kW

Country: AS, NZS

Propane Supply Pressure: 2.75 kPa

Adjusted Pressure: 2.75 kPa

Nominal Hourly Gas Consumption: 23 MJ/h

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.0 kW

Country: NL

European Gas Category:

Gas Flow Rate: 0.562703 m3/hr

Supply Pressure (G25): 25 mbar

Factory Adjusted Pressure (G25) : 7.4 mbar

Supply Pressure (G30/G31): 30 mbar

Factory Adjusted Pressure (G30/G31): N/A

NOTE: Conversion kit: From Natural Gas to LP Gas - Europe: Whirlpool Part No. W10233219.

Conversion kit: From Natural Gas to LP Gas - Australia: Whirlpool Part No. W10315369.

Conversion kit: From Natural Gas to Natural Gas - France/Belgium: Whirlpool Part No. W10181947.

Manufacturer: Whirlpool Corporation, Benton Harbor, Michigan 49022, U.S.A.

Manufacturing Site: Whirlpool Corporation, 1300 Marion-Agosta Rd., Marion, OH, 43302, U.S.A.

EU Representative: Whirlpool Europe s.r.l. Viale Guido Borghi 27, 21025 Comerio (VA) Italy

II

2L3B/P

18

COMPLETE INSTALLATION

1. Check the electrical requirements. Be sure that you have

the correct electrical supply and the recommended earthing

method. See “Electrical Requirements.”

2. Check that all parts are now installed. If there is an extra part,

go back through the steps.

3. Check that you have all of your tools.

4. Dispose of/recycle all packaging materials.

WARNING

Electric Shock Hazard

This dryer must be earthed.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electric shock.

5. Plug into a grounded outlet, or connect power.

6. Check dryer operation (some accumulated time may be

on the timer due to factory testing). Close dryer door. Insert

coins in slide and press slide in slowly. (Operating time will

accumulate per number of coins and type of timing cam

used.) Push START button. Using a full heat cycle (not the

air cycle), let the dryer run for at least ve minutes. Dryer will

stop when time is used up.

NOTE: Dryer door must be closed for dryer to operate.

When door is open, dryer stops, but timer continues to run.

To restart dryer, close door and push START button.

7. Gas models only: Open the dryer door. Check that the

inside of the dryer is warm. If the burner does not ignite and

you can feel no heat inside the dryer, shut off dryer for ve

minutes. Check that all supply valve controls are in “ON”

position and that the electrical cord is plugged in. Repeat

ve-minute test.

8. If drying time is too long, make sure that the lint screen is

clean and that there are no obstructions to airow in the

dryer vent system.

9. Restart the dryer and allow it to complete a full heat cycle

(not air cycle) to make sure it is working properly.

19

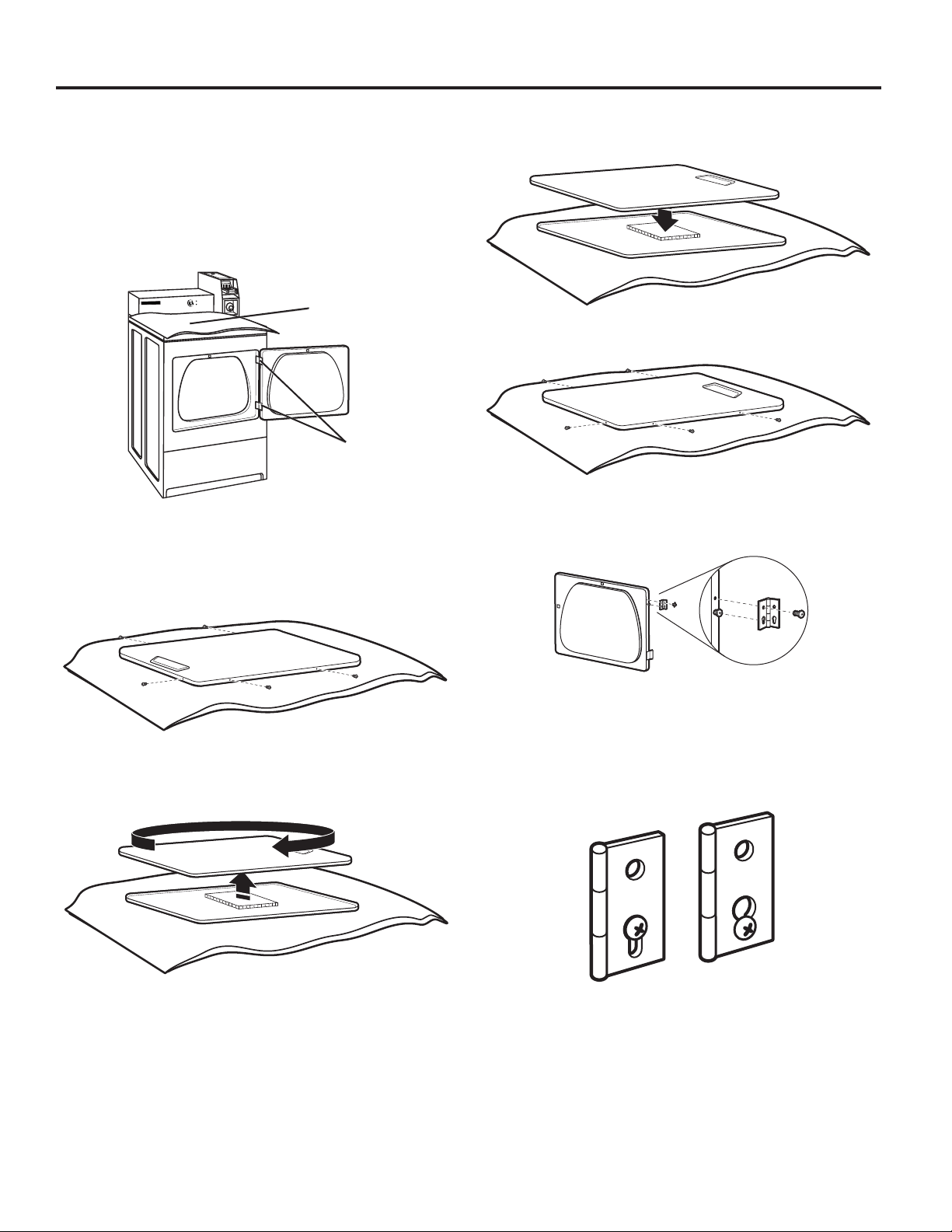

REVERSING DRYER DOOR SWING (OPTIONAL)

You can change your door swing from a right-side opening

to left-side opening, if desired.

Remove the Door Assembly

1. Place a towel or soft cloth on top of dryer or work space to

avoid scratching of the surface.

2. Open dryer door. Remove bottom screws from cabinet side

of hinges. Loosen (do not remove) top screws from cabinet

side of hinges.

Towel

Hinges

3. Lift door until top screws in cabinet are in large part of hinge

slot. Pull forward off screws. Set door (handle side up) on

top of dryer. Remove top screws from cabinet.

4. Remove screws attaching hinges to door.

5. Remove screws at top, bottom, and side of door (5 screws).

7. Be certain to keep cardboard spacer centered between

doors. Reattach outer door panel to inner door panel so

handle is on the side where hinges were just removed.

8. Reattach screws at top, bottom, and side of door (5 screws).

9. Attach door hinges to dryer door so that larger hole is at the

bottom of the hinge and the hinge pin is toward the door

front.

6. Holding door over towel on dryer, grasp sides of outer door

and gently lift to separate it from inner door. Do not use a

putty knife to pry apart. Do not pull on door seal or plastic

door catch.

10. Remove the 4 screws that attach 2 plugs on the left side.

Attach plugs to right side using the same 4 screws.

11. Insert screws into bottom holes on left side of cabinet.

Tighten screws halfway. Position door so large end of door

hinge slot is over screws. Slide door up so screws are in

bottom of slots. Tighten screws. Insert and tighten top

screws in hinges.

12. Close door and check that door strike aligns with door

catch. If needed, slide door catch left or right within slot to

adjust alignment.

20

MODEL NOMENCLATURE:

CGM – Whirlpool Gas FQ – Series Revision

CEM – Whirlpool Electric 2765 – Model Type Number

DRYER DISPOSAL

21

WHIRLPOOL COMMERCIAL LAUNDRY

LIMITED WARRANTY

IF YOU NEED SERVICE:

Contact your authorized Whirlpool Commercial Laundry distributor. To locate your authorized Whirlpool Commercial Laundry distributor,

visit www.WhirlpoolCommercialLaundry.com.

For written correspondence:

Whirlpool Commercial Laundry Service Department

2000 N M 63

Benton Harbor, Michigan 49022-2632 USA

THREE YEAR LIMITED WARRANTY

WHAT IS COVERED

THREE YEAR LIMITED WARRANTY

(PARTS ONLY — LABOR NOT INCLUDED)

For the first three years from the original date of

purchase, when this commercial appliance is installed,

maintained, and operated according to the instructions

attached to or furnished with the product, Whirlpool

Corporation (hereafter “Whirlpool”) will pay for factory

specified replacement parts to correct defects in

materials or workmanship that existed when this

commercial appliance was purchased. This limited

warranty does not include labor.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS

LIMITED WARRANTY SHALL BE PRODUCT REPAIR

AS PROVIDED HEREIN. Whirlpool recommends that

you use an “authorized” service provider to diagnose

and repair your Commercial Laundry product.

Whirlpool will not be responsible under this warranty

to provide additional replacement parts as a result

of incorrect diagnosis or repair by an “unauthorized”

service company. Except in the European Union, this

limited warranty is valid only when the commercial

appliance is used in the country in which it was

purchased. This limited warranty is effective from

the date of the original consumer purchase. Proof

of original purchase date is required to obtain service

under this limited warranty.

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO THREE YEARS OR THE SHORTEST PERIOD ALLOWED BY LAW. Some locations may not allow

limitations on the duration of implied warranties of merchantability or fitness, so this limitation may not apply to you. This warranty gives you

specific legal rights, and you also may have other rights that vary.

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

Whirlpool makes no representations about the quality, durability, or need for service or repair of this major appliance other than the

representations contained in this Warranty. If you want a longer or more comprehensive warranty than the limited warranty that comes

with this major appliance, you should ask your retailer about buying an extended warranty. The benefits to you given by this warranty

are in addition to other rights and remedies available to you under a law in relation to the goods or service to which this warranty relates.

Please contact Whirlpool for further information on warranty terms.

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN.

WHIRLPOOL SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some locations do not allow the exclusion or

limitation of incidental or consequential damages, so these limitations and exclusions may not apply to you. This warranty gives you specific

legal rights, and you also may have other rights that vary by location.

04/17

1. All other costs including labor, transportation, shipping, or custom duties for

covered parts.

2. Factory specified replacement parts if this commercial appliance is used for other

than normal, commercial use or when it is used in a manner that is inconsistent

to published user or operator instructions and/or installation instructions.

3. Service calls to correct the installation of your commercial appliance, to instruct

you on how to use your commercial appliance, to replace or repair house fuses,

or to correct external wiring or plumbing.

4. Service calls to repair or replace appliance light bulbs, air filters, or water filters.

Consumable parts are excluded from warranty coverage.

5. Damage resulting from improper handling of product during delivery, theft,

accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation,

installation not in accordance with local electrical or plumbing codes, or use of

products not approved by Whirlpool.

6. Pick up and delivery. This commercial appliance is designed to be repaired

on location.

7. Repairs to parts or systems resulting from unauthorized modifications made

to the commercial appliance.

8. The removal and reinstallation of your commercial appliance if it is installed

in an inaccessible location or is not installed in accordance with published

installation instructions.

9. Damage resulting from exposure to chemicals.

10. Changes to the building, room, or location needed in order to make the

commercial appliance operate correctly.

11. Factory specified replacement parts on commercial appliances with original

model/serial numbers that have been removed, altered, or cannot be easily

determined.

12. Discoloration, rust, or oxidation of stainless steel surfaces.

13. Factory specified replacement parts as a result of incorrect diagnosis or repair

by an “unauthorized” service company.

The cost of repair or replacement under these excluded circumstances shall

be borne by the customer.

DISCLAIMER OF IMPLIED WARRANTIES

WHAT IS NOT COVERED

22

SECURITE DU SECHE-LINGE

AVERTISSEMENT – “Risque d’incendie”

Ceci est un symbole supplémentaire d’alerte de sécurité vous signalant un risque d’incendie.

AVERTISSEMENT

- L'installation du sèche-linge et la maintenance doivent être réalisées par un installateur

agréé par Whirlpool.

- Installer le sèche-linge conformément aux instructions du fabricant et aux

réglementations locales.

- Ne pas installer de sèche-linge avec des évents en plastique exible ou un conduit

en métal exible (de type papier aluminium). Si un conduit en métal est installé,

il doit être d'un type spécique identié par le fabricant de l'appareil comme adapté

à l'utilisation avec des sèche-linge. On sait que les évents en matériaux exibles ont

tendance à se plier, s'écraser facilement et retenir la charpie. Ces conditions niront

par obstruer le ux d'air du sèche-linge et augmenteront le risque d'incendie.

- Pour réduire le risque de blessures graves ou de mort, respecter toutes les

instructions d'installation.

- Conserver ces instructions.

-

“Risque d'incendie”

23

SECURITE DU SECHE-LINGE

■ On recommande que le propriétaire place les instructions à l’usage du client en un lieu bien visible, au cas où le client percevrait

une odeur de gaz. Ces renseignements doivent être obtenus auprès de votre fournisseur en gaz.

■ Placer l’avertissement qui suit à un endroit bien visible.

POUR VOTRE SECURITE

1. NE PAS UTILISER OU REMISER D’ESSENCE OU AUTRES MATÉRIAUX INFLAMMABLES DANS CET APPAREIL MÉNAGER

O U À PROXIMITÉ DE CELUI-CI.

2. NE PAS VAPORISER D’AÉROSOLS À PROXIMITÉ DE CET APPAREIL MÉNAGER LORSQU’IL EST EN FONCTIONNEMENT.

3. NE PAS MODIFIER CET APPAREIL MÉNAGER.

AVERTISSEMENT : pour votre sécurité, les informations contenues dans ce manuel

doivent être respectées afin de réduire les risques d'incendie ou d'explosion et d'éviter

les dommages aux propriétés, les blessures ou les décès.

–

Ne pas utiliser ou conserver d’essence ni d'autres vapeurs et liquides inflammables

à proximité de cet appareil électrique ou de tout autre.

–

QUE FAIRE SI VOUS DÉTECTEZ UNE ODEUR DE GAZ :

Ne pas essayer d'allumer d'appareil.

•

Ne pas toucher d'interrupteur électrique ; ne pas utiliser de téléphone dans le bâtiment.

•

Faire sortir tous les occupants de la pièce, du bâtiment ou de la zone.

•

Appeler immédiatement votre fournisseur de gaz à partir du téléphone d'un voisin.

•

Suivre les instructions du fournisseur de gaz.

S'il est impossible de joindre le fournisseur de gaz, appeler les pompiers.

•

– L'installation et la maintenance doivent être réalisées par un installateur ou une agence

agréés par Whirlpool ou par le fournisseur de gaz.

IMPORTANT : Pour mettre l’ancien sèche-linge au rebut ou pour le remiser, enlever la porte.

24

SECURITE DU SECHE-LINGE

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ

AVERTISSEMENT : Pour réduire les risques d’incendie, de choc électrique ou de blessures lors de l’utilisation

du sèche-linge, suivre les précautions fondamentales dont les suivantes :

■ Lire toutes les instructions avant d’utiliser

le sèche-linge.

■ Ce sèche-linge est conçu uniquement pour le séchage

de vêtements et de textiles ayant été nettoyés à l’eau. Ne

pas l’utiliser à d'autres ns.

■ AVERTISSEMENT: Si l’on détecte une odeur de gaz,

ne pas utiliser le sèche-linge ou tout autre équipement

électrique situé à proximité. Avertir les autres personnes

qu’elles doivent évacuer cette zone. Contacter le

propriétaire du sèche-linge immédiatement.

■ Ne pas placer des articles exposés aux huiles de cuisson

dans votre sèche-linge. Les articles contaminés par des

huiles de cuisson peuvent contribuer à une réaction

chimique qui pourrait provoquer l'inammation de la

charge.

■ Si on doit absolument placer des tissus qui contiennent

de l’huile végétale ou de cuisson ou qui ont été

contaminés par des produits de soin capillaire dans

un sèche-linge, il faut d’abord les laver dans de l’eau

chaude avec un supplément de détergent; ceci réduira

le danger, sans toutefois l’éliminer.

■ Ne pas faire sécher des articles qui ont été nettoyés

ou lavés avec de l’essence ou imbibés d’essence, de

solvants de nettoyage à sec ou d’autres substances

inammables ou explosives ; ces substances peuvent

émettre des vapeurs susceptibles de s’enammer ou

d’exploser.

■ Les articles qui ont été souillés avec des substances

comme de l’acétone, de l’alcool, du pétrole, du kérosène,

des détachants, de la térébenthine, des cires et des

décapants pour cire doivent être lavés à l’eau chaude

avec un supplément de détergent avant d’être séchés

dans le sèche-linge.

■ Ne pas faire sécher dans le sèche-linge des

articles non lavés.

■ Ne pas utiliser ce sèche-linge si l’on a utilisé des

produits chimiques industriels pour le nettoyage.

La présence éventuelle de quantités résiduelles de

produits chimiques corrosifs ou décomposés dans

la charge peut endommager le sèche-linge et produire

des fumées toxiques.

■ Ne pas laisser d’enfants jouer sur, dans ou avec le

sèche-linge. Bien surveiller les enfants lorsque le

sèche-linge est utilisé à proximité d’enfants.

■ Ce sèche-linge n’est pas conçu pour une utilisation

par des personnes (notamment des enfants) aux

capacités physiques, sensorielles ou mentales réduites,

ou manquant d’expérience ou de connaissances, à

moins qu’elles soient supervisées par une personne

responsable ou aient reçu des instructions adaptées

pour utiliser le sèche-linge en toute sécurité.

■ Avant de retirer le sèche-linge du service ou de le mettre

au rebut, ôter la porte du compartiment du sèche-linge.

■ Ne pas insérer une partie du corps dans la cuve du

sèche-linge lorsque le tambour est en mouvement.

■ Ne pas ouvrir la porte lorsque le sèche-linge est

en marche. Il s’arrêtera.

■ L'appareil doit être débranché de sa source

d'alimentation pendant le service et lors du

remplacement des pièces.

■ Lors du chargement ou du rechargement du sèche-linge,

éviter de toucher les parties métalliques chaudes du

tambour (risque de brûlure).

■ Vériez que les poches des vêtements à sécher ne

contiennent pas d'objets tels que des briquets ou

des allumettes.

■ Les opérations de nettoyage et d'entretien par

l'utilisateur ne doivent pas être réalisées par des

enfants non surveillés.

■ AVERTISSEMENT : L’appareil ne doit pas être mis

sous tension via un dispositif de commutation externe,

tel qu'un minuteur, ni être connecté à un circuit

régulièrement mis sous tension et hors tension par un

utilitaire.

■ Évitez d'installer le sèche-linge derrière une porte

verrouillable, une porte coulissante ou une porte dont

les charnières se trouvent sur le côté opposé à celui de

la charnière de la porte du sèche-linge, de façon que

l'ouverture complète de cette dernière ne soit pas gênée.

■ L’appareil est conçu pour être utilisé dans des lieux

publics, sans toutefois être limité à une telle utilisation.

■ Les enfants de moins de 3 ans doivent être tenus à

distance de l'appareil ou être surveillés en permanence.

■ Si la rotation du tambour est entravée par des tissus

coincés, déconnecter le sèche-linge de l’alimentation

électrique avant de retirer la source d’obstruction avec

précaution.

■ Ne pas utiliser le sèche-linge s’il ne chauffe pas,

s’il semble défectueux ou endommagé. Contacter

le propriétaire.

■ Ne pas installer ou remiser ce sèche-linge à un endroit

où il serait exposée aux intempéries.

■ Ne pas modier les organes de commande.

■ Nettoyer le ltre à charpie avant et après chaque charge.

■ Ne pas utiliser ce sèche-linge si le ltre à peluches

n’est pas installé.

■ Ne pas réparer ou remplacer un composant quelconque

du sèche-linge, ni entreprendre une opération de

service, si ce n’est spéciquement recommandé

dans ce manuel ou dans un manuel d’instructions

de réparations destiné à l’utilisateur; il est alors essentiel

que la personne concernée comprenne ces instructions

et soit compétente pour les exécuter.

■ Les assouplissants et autres produits similaires doivent

être utilisés conformément aux instructions gurant sur

l'emballage.

■ Ne séchez pas au sèche-linge des articles en caoutchouc

mousse (mousse de latex), des bonnets de douche, des

articles imperméables ou au revers caoutchouté, ni des

vêtements ou des oreillers dont le rembourrage est en

caoutchouc mousse.

■ La dernière partie d’un programme de séchage

par culbutage a lieu sans chaleur (programme de

refroidissement) pour faire en sorte que les articles

soient laissés à une température qui garantit que les

articles ne seront pas endommagés.

CONSERVEZ CES INSTRUCTIONS

25

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ

AVERTISSEMENT : Pour réduire les risques d’incendie, de choc électrique ou de blessures lors de l’utilisation

du sèche-linge, suivre les précautions fondamentales dont les suivantes :

■ AVERTISSEMENT: Ne jamais arrêter le séchage par

culbutage avant la n du programme de séchage sauf

si tous les articles sont retirés rapidement et étendus

pour une dissipation de la chaleur (permet d’éviter le

risque de combustion spontanée).

■ En cas de coupure de l’alimentation électrique, retirer

rapidement la charge et l’étaler pour éviter tout risque

de combustion spontanée.

■ Ne pas laisser la charpie, la poussière, ou la saleté

s’accumuler autour du système d’évacuation ou autour

de l’appareil.

■ Les ouvertures de ventilation pour l’arrivée d’air frais

dans la pièce et dans le sèche-linge ne doivent pas être

obstruées ou scellées.

■ Commande d’arrêt d’urgence : Après l'installation,

l'accès à la prise secteur (sèche-linge à gaz) ou à

l'alimentation secteur (sèche-linge électrique) via un

interrupteur bipolaire doit être maintenu à tout moment

pour assurer une désactivation immédiate du sèche-linge

en cas d'urgence.

■ L’intérieur du sèche-linge et de son conduit d’évacuation

doit être nettoyé périodiquement par un technicien

d’entretien agréé par Whirlpool.

■ Voir la section “Spécications électriques” pour les

instructions de mise à la terre.

■ Une ventilation adéquate doit être prévue pour éviter que

les gaz ne retournent dans la pièce à partir d'appareils

brûlant des combustibles, y compris des feux nus.

CONSERVEZ CES INSTRUCTIONS

INSTRUCTIONS D’ENTRETIEN

■ Nettoyer le ltre à charpie avant ou après chaque

programme.

■ Comment enlever la charpie accumulée:

À l’intérieur de la caisse de le sèche-linge:

Retirer la charpie tous les 2 ans, ou plus souvent, selon

l’utilisation de le sèche-linge. Le nettoyage doit être réalisé

par une personne agréée par Whirlpool.

De l’intérieur du conduit d’évacuation:

Retirer la charpie tous les 2 ans, ou plus souvent, selon

l’utilisation de le sèche-linge.

■ Dégager l’espace autour de le sèche-linge; les matières

combustibles, à base de pétrole et les autres liquides ou

vapeurs inammables ne doivent pas s’y trouver.

■ Dégager l’emplacement de le sèche-linge de façon à ce qu’il

soit libre de tout élément susceptible d’obstruer le débit

d’air de combustion et de ventilation.

Si le sèche-linge ne fonctionne pas, vérifier ce qui suit:

■ La prise de courant est correctement alimentée.

■ Le disjoncteur ne s’est pas déclenché et aucun fusible n’est

grillé.

■ La porte est fermée. Écouter attentivement pour vérier que

le loquet de porte s’enclenche.

■ Les commandes sont réglées à la position de marche ou

« ON » (marche).

■ On a appuyé fermement sur le bouton START (mise en

marche).

■ Pour les sécheuses à gaz, vérier que le robinet d’arrêt est

ouvert.

AVERTISSEMENT: Un raccordement inapproprié du conducteur de liaison à la terre peut causer

un risque de choc électrique. Il incombe à l’utilisateur de vérier avec un électricien qualié ou avec un

représentant de service en cas de doute quant à la qualité de la liaison à la terre de l’appareil et pour savoir si

elle répond aux codes et règlements locaux. Ne pas modier la che fournie avec cette sécheuse: si elle ne

correspond pas à la prise de sortie, faire installer une che appropriée par un électricien qualié.

SI VOUS AVEZ BESOIN D’ASSISTANCE

Pour toute assistance, communiquer avec le marchand auprès duquel l’appareil a été acheté ou une compagnie de réparation

désignée par Whirlpool. Avant d’appeler, vous devez connaître la date d’achat et les numéros de modèle et de série complets

de votre appareil. Ces renseignements nous aideront à mieux répondre à votre demande.

POUR CONTACTER LE SERVICE APRÈS-VENTE:

Adressez-vous à votre distributeur Whirlpool Commercial Laundry agréé. Pour identier le distributeur Whirlpool Commercial

Laundry agréé le plus proche, consultez le site Internet www.WhirlpoolCommercialLaundry.com.

Pour écrire au service après-vente, ulisez cee adresse :

Whirlpool Commercial Laundry Service Department

2000NM63

Benton Harbor, Michigan 49022-2632, États-Unis

26

Loading...

Loading...