User Guide

Upright Freezer

THANK YOU for purchasing this high-quality product. Register your freezer at www.whirlpool.com. In Canada, register your freezer

at www.whirlpool.ca.

For future reference, please make a note of your product model and serial numbers. These numbers can be found inside your freezer.

Model Number ___________________________________________

Serial Number ____________________________________________

TABLE OF CONTENTS

SAFETY ...........................................................................................1

INSTALLING YOUR FREEZER .....................................................2

Unpacking ....................................................................................2

Location Requirements ................................................................3

Electrical Requirements ...............................................................3

Water Supply Requirements

(on some models) .........................................................................4

Connect the Water Supply

(on some models) .........................................................................4

Remove and Replace the Handle ................................................5

Freezer Door .................................................................................5

Freezer Leveling and Door Closing ..............................................6

OPERATING YOUR FREEZER .....................................................7

Ensuring Proper Air Circulation ....................................................7

Using the Control .........................................................................7

Key Eject Lock (on some models) ...............................................8

Ice Maker (on some models) ........................................................8

Freezer Features ...........................................................................8

CARING FOR YOUR FREEZER ....................................................9

Cleaning Your Frost-Free Freezer ................................................9

Changing the Light Bulb ............................................................10

TROUBLESHOOTING .................................................................10

Power Interruptions ....................................................................10

Moving Care ...............................................................................10

Freezer Operation.......................................................................11

Ice Production ............................................................................12

Ice Quality ...................................................................................12

WARRANTY ..................................................................................13

SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

W10854516A

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

■ Plug into a grounded 3 prong outlet.

■ Do not remove ground prong.

■ Do not use an adapter.

■ Do not use an extension cord.

■ Disconnect power before servicing.

■ Replace all parts and panels before operating.

■ Remove doors from your old refrigerator.

■ Connect to a potable water supply only.

■ Use nonflammable cleaner.

■ Keep flammable materials and vapors, such as gasoline,

away from refrigerator.

■ Use two or more people to move and install refrigerator.

To reduce the risk of fire, electric shock, or injury when using your refrigerator, follow these basic precautions:

SAVE THESE INSTRUCTIONS

■ Disconnect power before installing ice maker (on ice maker

kit ready models only).

■ Use a sturdy glass when dispensing ice (on some models).

■ Do not hit the refrigerator glass doors (on some models).

■ This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their

safety.

■ Children should be supervised to ensure that they do not

play with the appliance.

Proper Disposal of Your Old

Freezer or Refrigerator

WARNING

Suffocation Hazard

Remove doors or lid from your old freezer or

refrigerator.

Failure to do so can result in death or brain damage.

IMPORTANT: Child entrapment and suffocation are not

problems of the past. Junked or abandoned freezers or

refrigerators are still dangerous — even if they will sit for

“just a few days.” If you are getting rid of your old refrigerator

or freezer, please follow these instructions to help prevent

accidents.

INSTALLING YOUR FREEZER

Unpacking

WARNING

Excessive Weight Hazard

Use two or more people to move and install freezer.

Failure to do so can result in back or other injury.

Before You Throw Away Your Old

Freezer or Refrigerator:

■ Take off the doors or lid.

■ Leave the shelves in place so

that children may not easily

climb inside.

Important information to know about disposal of

refrigerants:

Dispose of freezer in accordance with Federal and Local

regulations. Refrigerants must be evacuated by a licensed,

EPA certified refrigerant technician in accordance with

established procedures.

When Moving Your Freezer:

Your freezer is heavy. When moving the freezer for

cleaning or service, be sure to cover the floor with cardboard

or hardboard to avoid floor damage. Always pull the freezer

straight out when moving it. Do not wiggle or “walk” the

freezer when trying to move it, as floor damage could occur.

Remove Packaging Materials

■ Remove tape and glue residue from surfaces before turning

on the freezer. Rub a small amount of liquid dish soap over the

adhesive with your ngers. Wipe with warm water and dry.

■ Do not use sharp instruments, rubbing alcohol, ammable

uids, or abrasive cleaners to remove tape or glue. These

products can damage the surface of your freezer. For more

information, see “Safety.”

2

Clean Before Using

After you remove all of the packaging materials, clean the inside

of your freezer before using it. See the cleaning instructions in the

“Caring for Your Freezer” section.

Important information to know about glass shelves

and covers:

Do not clean glass shelves or covers with warm water when

they are cold. Shelves and covers may break if exposed to

sudden temperature changes or impact, such as bumping.

Tempered glass is designed to shatter into many small,

pebble-size pieces. This is normal. Glass shelves and covers

are heavy. Use both hands when removing them to avoid

dropping.

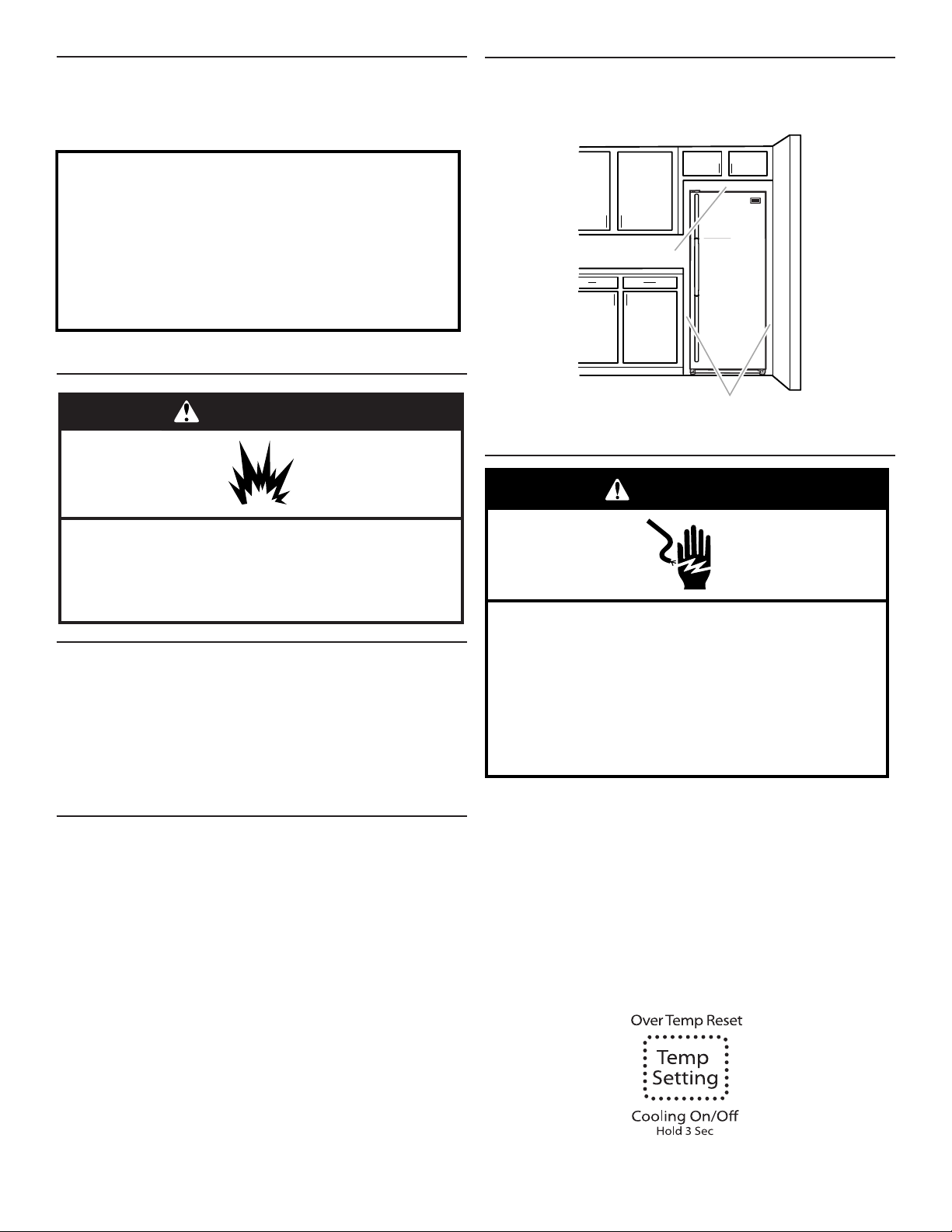

Location Requirements

Upon Moving to Final Location

NOTE: Allow for a 3" (7.5 cm) clearance at the top and sides

and a ¹⁄4" (6.4 mm) clearance between the appliances.

3" (7,5 cm)

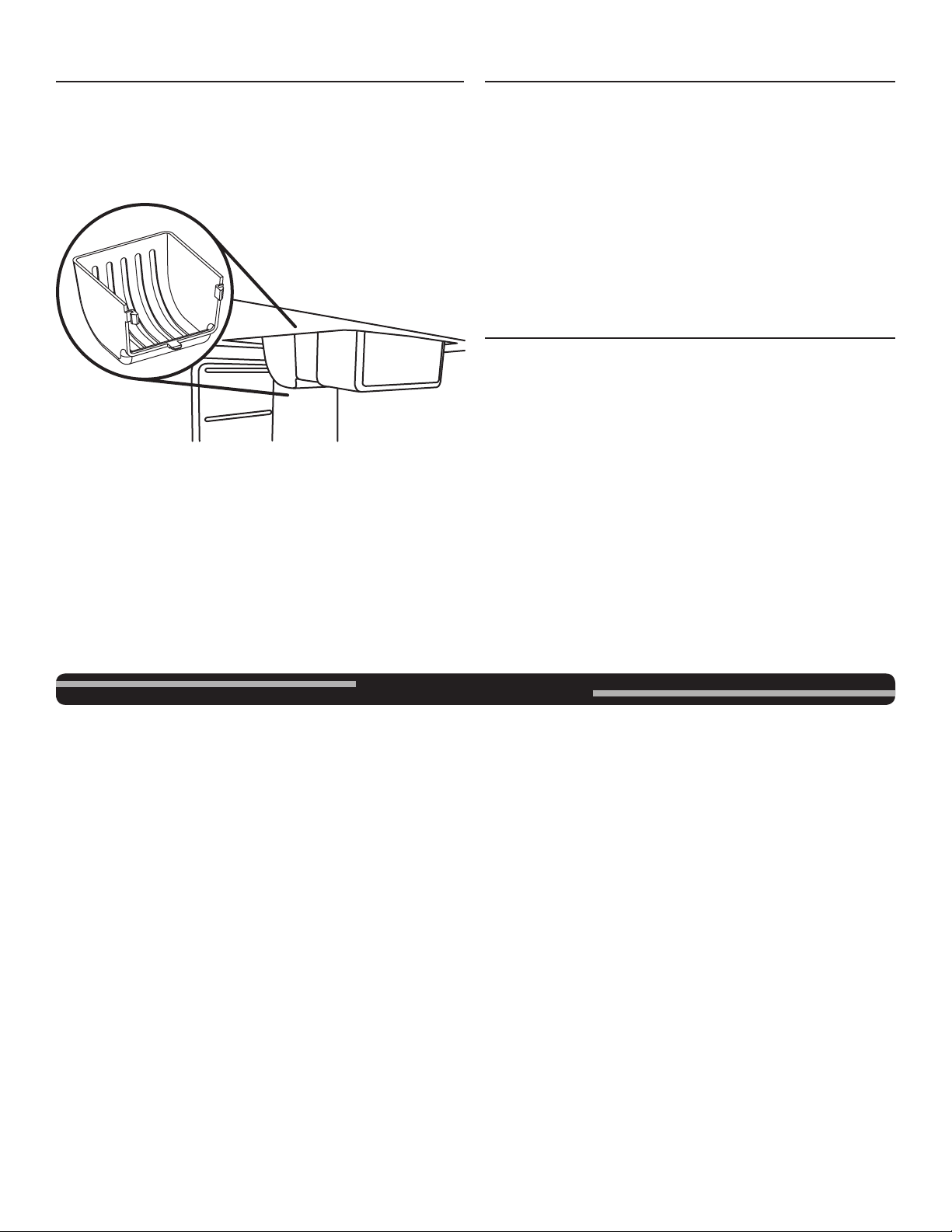

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from freezer.

Failure to do so can result in death, explosion, or fire.

Ventilation and Clearance

■ Keep ammable materials and vapors, such as gasoline, away

from freezer.

■ Do not cover the freezer with items such as blankets, sheets,

tablecloths, etc. This reduces air circulation.

■ Allow at least 3" (7.5 cm) of air space at the top and on both

sides of the freezer and 1" (2.5 cm) between the back of the

freezer and the wall. If the freezer is to be next to a xed wall,

leave extra space on the hinge side so the door can open

wider.

Temperature

Your freezer operates most efciently when located in an area

where the temperature will not fall below 40°F (5°C). Place your

freezer in a location where the temperature will not fall below this

recommended temperature.

3" (7,5 cm)

Electrical Requirements

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Before you move your freezer into its nal location, it is important

to make sure you have the proper electrical connection.

Recommended Grounding Method

A 115 Volt, 60 Hz., AC-only, 15- or 20-amp fused, grounded

electrical supply is required. It is recommended that a separate

circuit serving only your freezer be provided. Use an outlet that

cannot be turned off by a switch. Do not use an extension cord.

NOTE: Before performing any type of installation, cleaning, or

removing a light bulb, press and hold TEMP SETTING for

3 seconds to turn off cooling, and then disconnect the freezer

from the electrical source.

3

Water Supply Requirements

A

DEF

G

(on some models)

Gather the required tools and parts before starting installation. Read

and follow the instructions provided with any tools listed here.

Tools Needed

■ Flat-blade screwdriver

7

■

⁄16" and ½" open-end

or 2 adjustable wrenches

NOTE: Your freezer dealer has a kit available with a ¼"(6.35 mm)

saddle-type shut-off valve, a union, and plastic tubing. Before

purchasing, make sure a saddle-type valve complies with

your local plumbing codes. Do not use a piercing-type or

³⁄16" (4.76 mm) saddle valve which reduces water ow and

clogs more easily.

IMPORTANT:

■ If you turn the freezer on before the water line is connected,

turn the ice maker off.

■ All installations must meet local plumbing code requirements.

■ Use plastic tubing and check for leaks. Install plastic tubing

only in areas where temperatures will remain above freezing.

Water Pressure

A cold water supply with water pressure of between 30 and

120 psi (207 to 827 kPa) is required to operate the water

dispenser and ice maker. If you have questions about your

water pressure, see “Troubleshooting” or call a licensed,

qualied plumber.

Reverse Osmosis Water Supply

If a reverse osmosis water ltration system is connected to your

cold water supply, the water pressure to the system needs to be

a minimum of 40 to 60 psi (276 to 414 kPa).

If the water pressure to the reverse osmosis system is less than

40 to 60 psi (276 to 414 kPa), a booster pump can be inserted

into the small tubing that goes from the cold water line to the

reverse osmosis system.

If the water dispenser is still not dispensing water properly:

■ Check to see whether the sediment lter in the reverse

osmosis system is blocked. Replace the lter if necessary.

■ Allow the storage tank on the reverse osmosis system to rell

after heavy usage.

■ If your refrigerator has a water lter, it may further reduce

the water pressure when used in conjunction with a reverse

osmosis system. Remove the water lter.

If you have questions about your water pressure, refer to

“Troubleshooting” or call a licensed, qualied plumber.

■ ¼" nut driver

■ ¼" drill bit

■ Cordless drill

Connect the Water Supply

(on some models)

4. Determine the length of plastic tubing you need. Measure from

the connection on the lower-left rear of freezer to the water

pipe. Add 7 ft (2.1 m) to allow for cleaning. Use ¼" (6.35 mm)

O.D. (outside diameter) plastic tubing. Be sure both ends of

plastic tubing are cut square.

5. Using a cordless drill, drill a ¼" (6.35 mm) hole in the cold

water pipe you have selected.

B

C

A. Cold water pipe

B. Pipe clamp

C. Plastic tubing

D. Compression nut

E. Compression sleeve

F. Shut-off valve

G. Packing nut

6. Fasten the shut-off valve to the cold water pipe with the pipe

clamp. Be sure the outlet end is solidly in the ¼" (6.35 mm)

drilled hole in the water pipe and that the washer is under the

pipe clamp. Tighten the packing nut. Tighten the pipe clamp

screws slowly and evenly so washer makes a watertight seal.

Do not overtighten or you may crush the plastic tubing.

7. Slip the compression sleeve and compression nut on the

plastic tubing as shown. Insert the end of the tubing into the

outlet end squarely as far as it will go. Screw compression nut

onto outlet end with adjustable wrench. Do not overtighten.

8. Place the free end of the tubing in a container or sink and turn

on the main water supply. Flush the tubing until water is clear.

Turn off the shut-off valve on the water pipe. Coil the plastic

tubing.

Connect to Freezer

1. Attach the plastic tube to the valve inlet using a compression

nut and sleeve as shown. Tighten the compression nut. Do not

overtighten.

2. Use the tube clamp on the back of the freezer to fasten the

tubing to the freezer as shown. This will help avoid damage

to the tubing when the freezer is pushed back against the wall.

3. Turn shut-off valve on.

4. Check for leaks. Tighten any connections (including

connections at the valve) or nuts that leak.

A

B

C

Connect to Water Line

1. Unplug freezer or disconnect power.

D

E

2. Turn off main water supply. Turn on nearest faucet long

enough to clear line of water.

3. Locate a ½" to 1¼" (12.7 mm to 3.18 cm) vertical cold water

pipe near the freezer.

A. Tube clamp

B. Tube clamp screw

C. Plastic tubing

D. Compression nut

E. Valve inlet

IMPORTANT:

■ Make sure it is a cold water pipe.

■ Horizontal pipe will work, but drill on the top side of the pipe,

not the bottom. This will help keep water away from the drill

and normal sediment from collecting in the valve.

5. The ice maker is equipped with a built-in water strainer. If your

water conditions require a second water strainer, install it in

the ¹⁄4" (6.35 mm) water line at either tube connection. Obtain

a water strainer from your nearest appliance dealer.

4

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

6. Plug into a grounded 3 prong outlet.

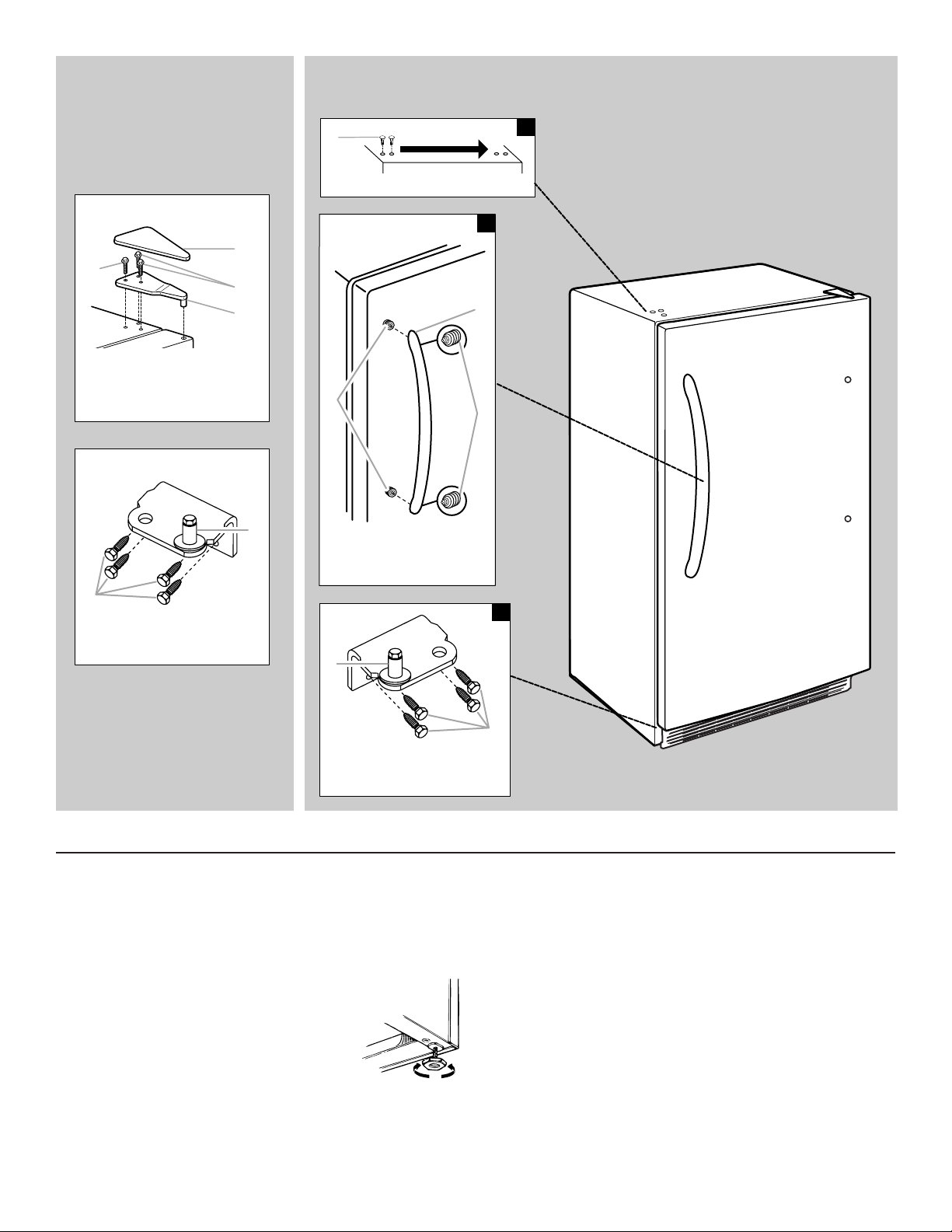

Remove and Replace the Handle

To Remove the Handle:

1. Loosen the setscrews located on the side of handle at each

end. See “Door Swing Reversal and Handle Removal” graphic.

2. Remove the handle from the grommets.

To Replace the Handle:

1. Place the handle onto the grommets making sure the

grommets are tted into the handle holes.

2. Tighten the upper and lower setscrews with the hex key

provided. See “Door Swing Reversal and Handle Removal”

graphic. Do not overtighten the setscrews.

Freezer Door

Tools Needed: 5⁄16" hex-head socket wrench, ³⁄8" hex-head

socket wrench, at 2" putty knife.

IMPORTANT:

■ All graphics referenced in the following instructions are

included later in this section after “Final Steps.” The graphics

shown are for a right-hand swing door (hinges factory

installed on the right).

■ If you only want to remove and replace the door, see the

“Remove Door and Hinges” and “Replace Door and Hinges.”

■ Before you begin, turn the control OFF and remove food and

adjustable door or utility bins from door.

Reverse Door (optional on some models)

IMPORTANT: If you want to reverse your door so that it opens in

the opposite direction, continue with “Reverse Door (optional on

some models)” instructions. If you are not reversing the door, see

“Replace Door and Hinges.”

Cabinet

1. Remove the cabinet hinge hole plugs from the cabinet top

and move them to the opposite side hinge holes as shown

in Graphic 2 in “Door Swing Reversal and Handle Removal”

section.

2. Remove the bottom hinge pin from the hinge bracket.

3. Remove the decals covering the holes on the opposite side of

the bottom hinge.

4. Reinstall the bottom hinge pin in the alternate hole in the hinge

bracket. See Graphic 3 in “Door Swing Reversal and Handle

Removal” section.

5. Reinstall the hinge bracket to the cabinet with the 4 hex-head

hinge screws.

Door

1. Remove the hinge thimble hole plug from the top of the door.

2. Remove the door stop from the bottom of the door.

3. Move the door stop to the opposite side, making sure that the

hole in the door stop plate is aligned perfectly with the hole in

the door for the bottom hinge pin.

4. Using the screws removed in Step 2, fasten the door stop

bracket to the bottom of the door.

5. Tighten all screws. Set aside the door until the bottom hinge

is in place.

Replace Door and Hinges

NOTE: Graphic may be reversed if door swing is reversed.

1. Replace the parts for the bottom hinge as shown and tighten

screws. See Bottom Hinge graphic. Replace the freezer door.

NOTE: Provide additional support for the door while the hinges

are being moved. Do not depend on the door magnets to hold

the door in place while you are working.

2. Assemble the parts of the top hinge as shown in the Top Hinge

graphic in the “Door Swing Reversal and Handle Removal”

section. Do not tighten the screws completely.

Final Steps

1. Check all holes to make sure that hole plugs and screws are

in place. Reinstall top hinge cover. See Top Hinge graphic.

2. Using the provided decals, cover the remaining holes located

on the opposite side from the bottom hinge.

WARNING

Remove Door and Hinges

Hex-head hinge screws

1. Unplug freezer or disconnect power.

2. Keep the freezer door closed until you are ready to lift it

free from the cabinet.

NOTE: Provide additional support for the door while

he hinges are being moved. Do not depend on the door

magnets to hold the door in place while you are working.

3. Remove the parts for the top hinge as shown in Top Hinge

graphic in the “Door Swing Reversal and Handle Removal”

section.

4. Lift the freezer door free from the lower hinge and cabinet

and set aside.

5. Remove the 4 hex-head hinge screws and bottom hinge

assembly. See Bottom Hinge graphic in the “Door Swing

Reversal and Handle Removal” section.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

3. Plug into a grounded 3 prong outlet.

4. Reset the control. See “Using the Control.”

5. Return all removable door parts to door and food to freezer.

5

Door Removal &

Replacement

Door Swing Reversal and Handle Removal (optional)

Top Hinge

B

A. Top Hinge Cover

5

/16"

Hex-Head Hinge Screws

B.

C. Top Hinge

Bottom Hinge

B

A. Hinge Pin

3

B.

/8"

Hex-Head Hinge Screws

A

A. Cabinet Hinge Hole Plugs

2

1

A

B

C

A

A

A. Grommet

B. Handle

C. Setscrews

B

C

3

A

A. Hinge Pin

3

B.

/8"

Hex-Head Hinge Screws

Freezer Leveling and Door Closing

Style 1—without Grille

1. Locate the 2 front leveling legs taped among the packing

materials.

2. Screw these legs into the front holes on the bottom of the

freezer. The back of the freezer rests on 2 xed supports.

3. Adjust the front legs enough to lift the cabinet up off the oor.

4. Place a leveling tool on top of the freezer

rst side to side, then front to back. Turn leg

counterclockwise to raise a corner. Turn leg

clockwise to lower a corner.

5. Repeat Step 4 until freezer is level.

6. After freezer is fully loaded with food,

recheck with level as in Step 4.

B

Style 2—with Grille

Your freezer has 2 front adjustable legs — one on each side. The

back of the freezer rests on 2 xed rollers. The base grille covers

the adjustable brake feet and roller assemblies located at the

bottom of the freezer below the freezer door. Before making any

adjustments, remove the base grille and move the freezer to its

nal location.

Tools Needed: ¹⁄4" hex driver, Phillips head screwdriver

1. Remove the base grille screws. Grasp the grille rmly and pull

it toward you. Open the freezer door to access the brake feet.

NOTE: To allow the freezer to roll more easily, raise the brake

feet by turning them counterclockwise. The front rollers will be

touching the oor.

6

2. Move the freezer to its nal location.

A

C

B

3. Lower the brake feet, by turning them clockwise, until the

rollers are off the oor and both brake feet are snug against the

oor. This keeps the freezer from rolling forward when you are

opening the freezer door.

IMPORTANT: If you need to make further adjustments

involving the brake feet, you must turn both brake feet the

same amount to keep the freezer level.

4. Make sure the door closes easily. If you are satised with the

door opening and closing, skip the next section. If, however,

the door does not close easily or the door pops open, adjust

the tilt.

To Adjust the Cabinet Tilt:

NOTE: Having someone push against the top of the freezer takes

some weight off the brake feet. This makes it easier to turn them.

Open the freezer door. Use a ¼" hex driver to turn both brake feet

clockwise the same amount. This will raise the front of the freezer.

It may take several turns to allow the door to close

more easily.

OPERATING YOUR FREEZER

A. Brake foot

B. Front roller

5. Make sure the freezer is steady. If the freezer seems unsteady

or rolls forward when the door is pulled open, adjust the brake

feet.

To Steady the Refrigerator:

■ Open the freezer door. Using a ¹⁄4" hex driver, turn both

brake feet clockwise the same amount until the brake feet

are snug against the floor. Check again. If not satisfied,

continue to adjust the brake feet by half turns of the screw

until the freezer does not roll forward when the door is

opened.

6. Replace the base grille by aligning the ends of the grille with

the leveling assemblies on each side and snapping the grille

into place. Reinstall the Phillips screws.

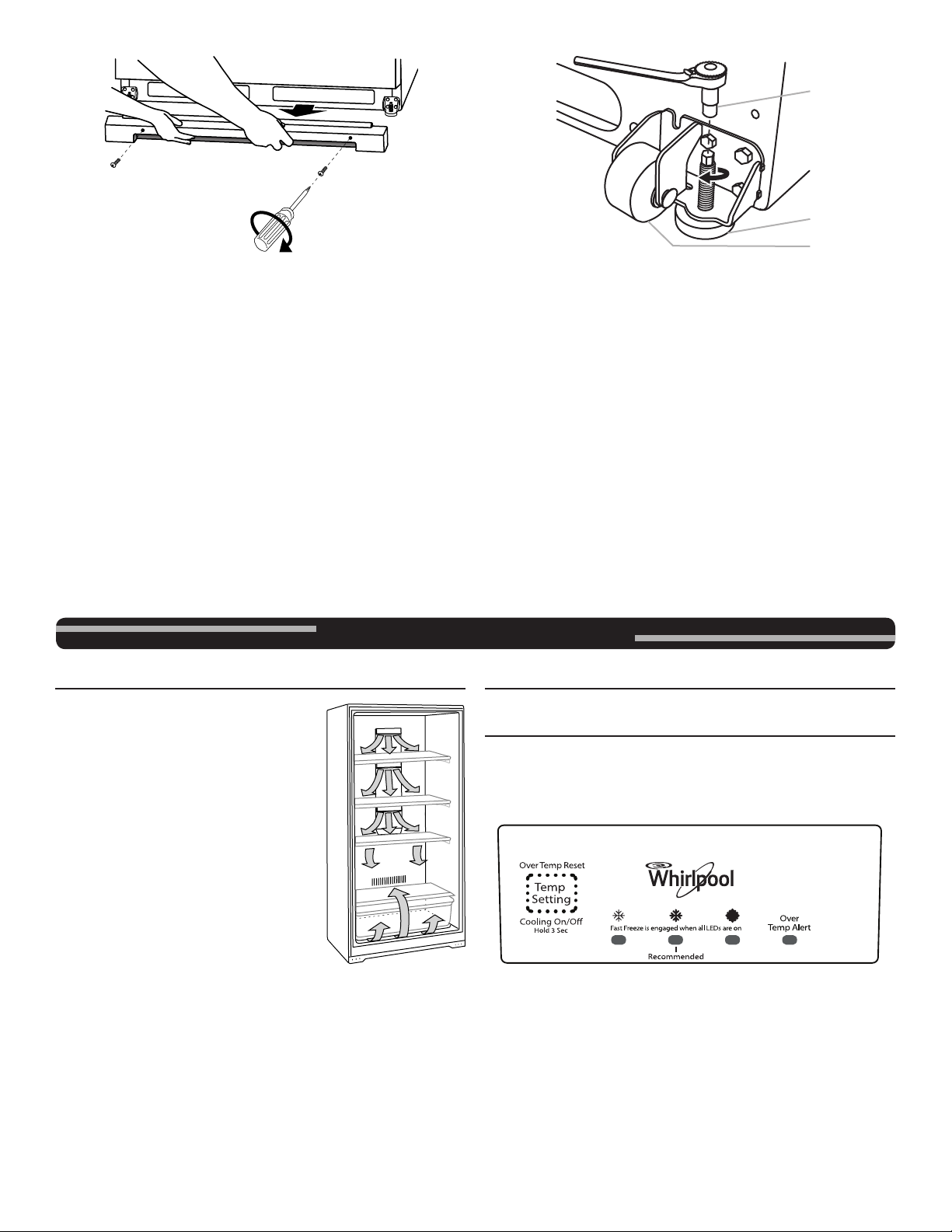

Ensuring Proper Air Circulation

In order to ensure proper temperature,

you need to permit proper airow in

the freezer. As shown in the illustration,

cool air enters from the freezer

wall and moves down. The air then

recirculates through the vent near the

bottom.

Do not block any of these vents

with food packages. If the vents are

blocked, airow will be restricted and

temperature and moisture problems

may occur.

IMPORTANT: To avoid odor transfer

and drying out of food, wrap or cover

foods tightly.

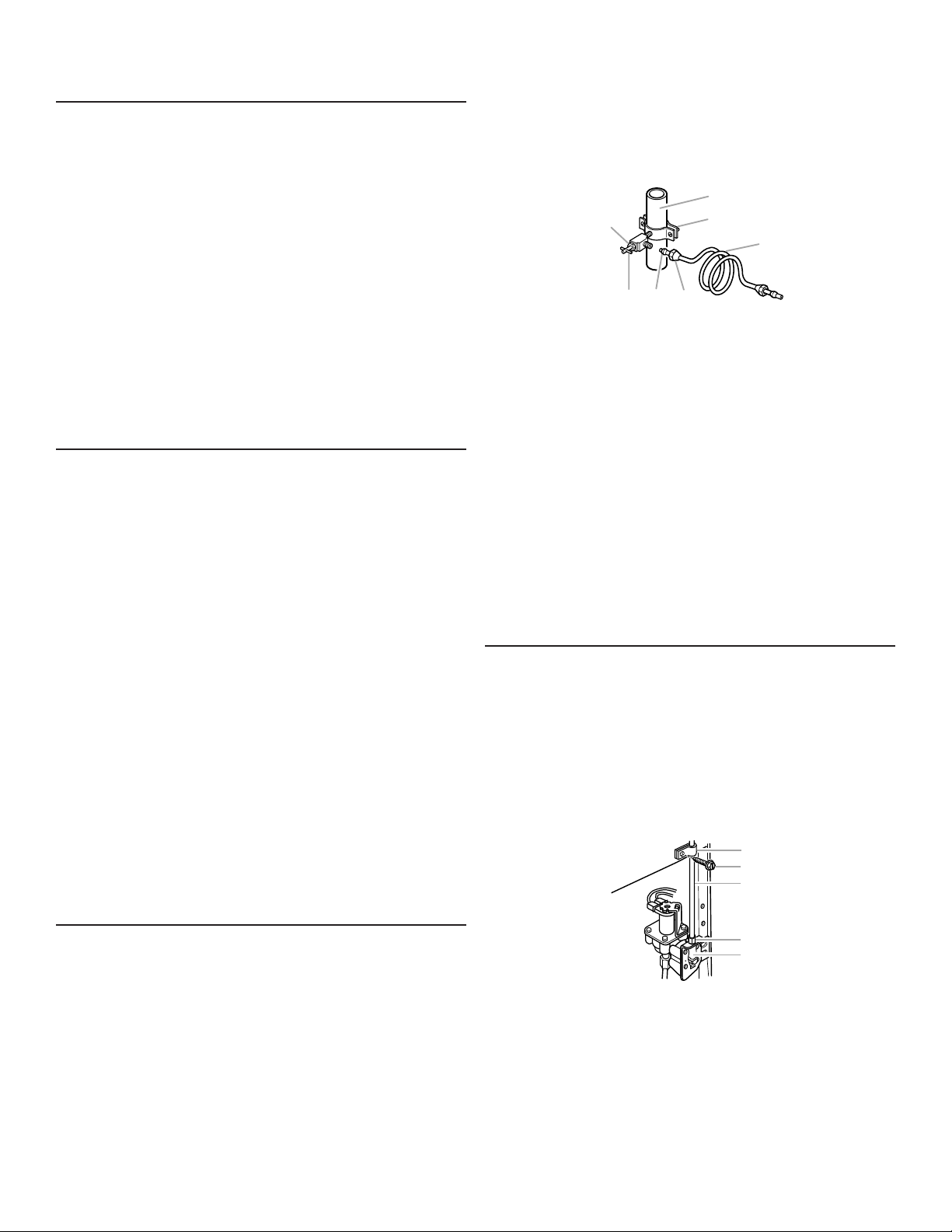

Using the Control

The temperature control is located at the top front of the freezer

compartment.

Temperature Control

For your convenience, the temperature control is preset at the

factory. When you rst install your freezer, check that the control

is still set to the recommended setting as shown.

IMPORTANT:

■ The recommended setting is designed to maintain the

temperature at or near 0°F (-17.8°C) under normal operating

conditions.

■ Allow the freezer to cool 6 to 8 hours before lling with frozen

food.

■ When the freezer is rst started, the compressor will run

constantly until the freezer is cooled. It may take up to 6 or

8 hours (or longer), depending on room temperature and

number of times the freezer door is opened. After the freezer

is cooled, the compressor will turn on and off as needed to

keep the freezer at the proper temperature.

7

■ The outside of your freezer may feel warm. This is normal.

The freezer’s design and main function is to remove heat

from packages and airspace inside the freezer. The heat is

transferred to the room air, making the outside of the freezer

feel warm.

Adjusting Control

If you need to adjust the temperature in the freezer compartment,

press TEMP SETTING to display the desired temperature setting

from the snowake on the left (least cold) to the snowake on the

right (coldest).

NOTE: Except when starting the freezer, do not adjust the

control more than one setting at a time. Wait 24 hours between

adjustments for the temperature to stabilize.

Key Eject Lock (on some models)

To lock or unlock the freezer, you must hold

the key in the lock while turning. The lock is

spring loaded, so the key cannot be left in

the lock.

If the key is lost, contact your dealer for a

replacement. Always give the model and

serial number of your freezer when requesting

a replacement key.

NOTE: Keep the key out of the reach of

children. Do not keep the key close to the

freezer/refrigerator.

Cooling On/Off

Your freezer will not cool when cooling is turned off.

To turn cooling off, press and hold TEMP SETTING for 3 seconds.

In the Off condition, none of the lights on the control panel will be

illuminated. The main freezer light bulb will still operate.

To turn cooling on, press and hold TEMP SETTING for 3 seconds.

When cooling is On, the control panel lights will be illuminated.

Fast Freeze

Use this feature before adding large amounts of unfrozen food.

For the best food quality, do not exceed 3 lbs (1,361 g) per cu. ft

(28.32 L) of freezer space.

To activate Fast Freeze, press TEMP SETTING until all the

snowake positions are illuminated simultaneously.

The freezer will remain in the Fast Freeze setting for 24 hours

after the extra-low temperature is reached. Once the time has

expired, the freezer will return to the previous temperature

setting. Fast Freeze may be manually turned off by pressing

TEMP SETTING to select the desired temperature setting from

the snowake on the left (least cold) to the snowake on the

right (coldest).

Over Temperature Alert (on some models)

The Over Temperature Alert lets you know if the freezer

temperature has risen to 19°F (-7°C) or higher. This alert feature

will sound a continuous alert tone and repeatedly ash a red

light on the control panel. The tone can be turned off by pressing

TEMP SETTING on the control panel once. As you press TEMP

SETTING, the red light will then also change from ashing to

continuously illuminated. The red light will remain illuminated until

the freezer temperature falls below 19°F (-7°C).

NOTE: If the red light on the control panel is repeatedly ashing,

but the alert tone is not sounding, this means that an overtemperature condition has occurred, but the freezer temperature

has since returned to below 19°F (-7°C). To turn off the red light

indicator for this condition, press TEMP SETTING on the control

panel once.

Door Ajar Alarm (on some models)

The Door Ajar alarm lets you know when the freezer door has

been open for 5 minutes or longer and the cooling is turned on.

This alarm feature will sound an alert tone that will repeat every

2 minutes. Close the door to turn off the tone. The feature is reset

and will reactivate when the door is again left open for 5 minutes.

NOTE: To mute the alert tone while keeping the door open, such

as while cleaning the inside of the freezer, press TEMP SETTING

on the control panel. The alert tone will be temporarily turned off.

Ice Maker (on some models)

To Turn the Ice Maker On/Off

NOTE: Do not force the wire shut-off arm up or down.

■ To turn the ice maker on, simply lower the wire shut-off arm.

NOTE: Your ice maker has an automatic shutoff. As ice is

made, the ice cubes ll the ice storage bin and the ice cubes

will raise the wire shut-off arm to the Off (arm up) position.

■ To manually turn the ice maker off, lift the

wire shut-off arm to the Off (arm up) position

and listen for the click to make sure the ice

maker will not continue to operate.

Ice Production Rate

The ice maker should produce approximately 7 to 9 batches of

ice in a 24-hour period. If ice is not being made fast enough,

press TEMP SETTING to display the next colder setting. Wait 24

hours and, if necessary, set the temperature control to the highest

setting, waiting 24 hours between each increase.

Remember

■ Allow 24 hours to produce the rst batch of ice. Discard the

rst three batches of ice produced.

■ The quality of your ice will be only as good as the quality of

the water supplied to your ice maker. Avoid connecting the ice

maker to a softened water supply. Water softener chemicals

(such as salt) can damage parts of the ice maker and lead to

poor quality ice. If a softened water supply cannot be avoided,

make sure the water softener is operating properly and is well

maintained.

■ Do not store anything on top of the ice maker or in the ice

storage bin.

Freezer Features

This manual covers several different models. The freezer you

have purchased may have some or all of the items listed. The

locations of the features may not match those of your model.

Door Bin

To Remove and Replace

the Bin:

1. Remove the bin by tipping the

front of the bin forward and

sliding out.

2. Replace the bin by sliding it

in above the desired support,

tilting it back into place.

8

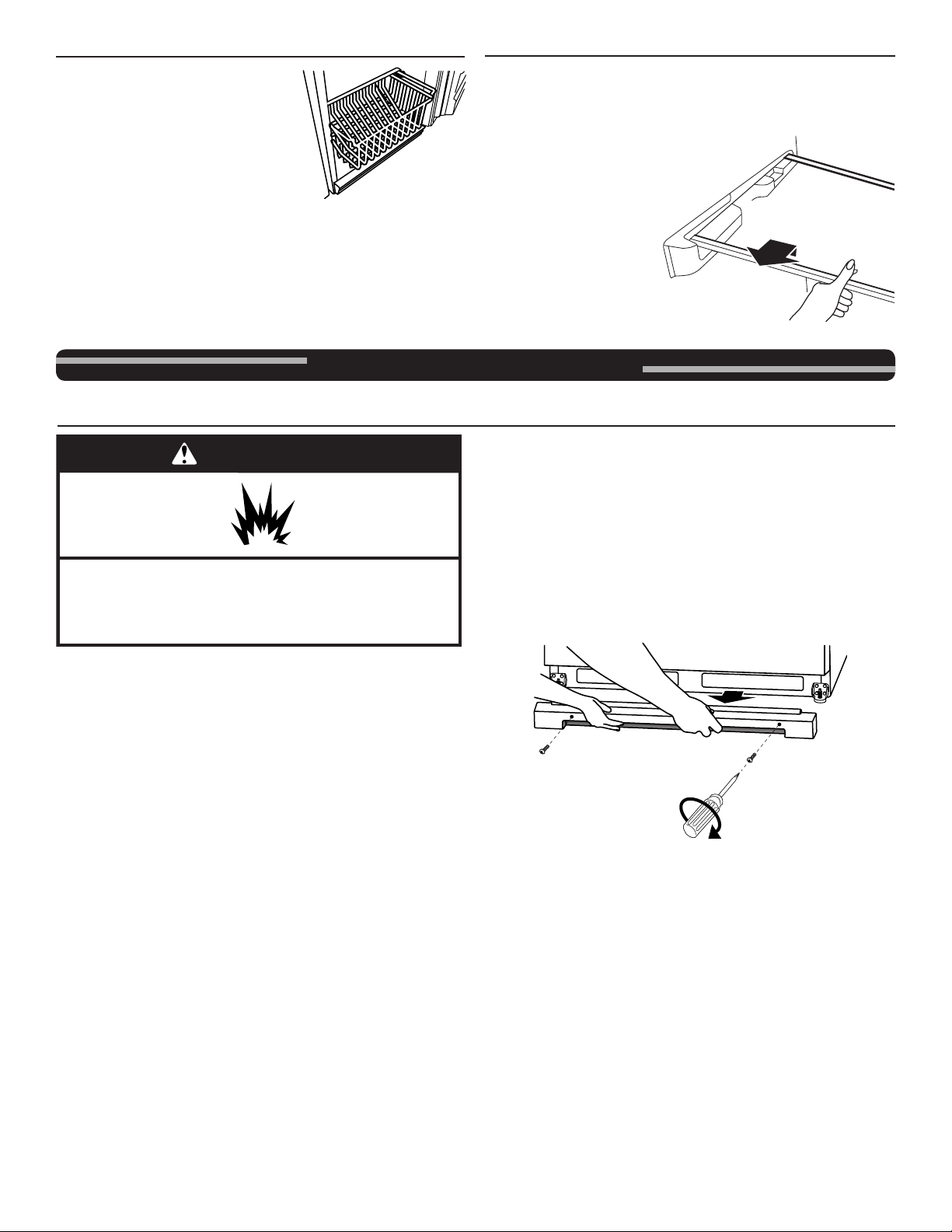

Storage Basket (on some models)

The slide-out basket provides

separate storage space for items

that are difcult to store on freezer

shelves. To remove the basket, pull

out and lift up.

Storage Gate (on some models)

To Remove the Storage Gate:

1. Lift up the top of the gate and out of the supports.

2. Return the gate to original position. Lower the gate

into the supports.

CARING FOR YOUR FREEZER

Cleaning Your Frost-Free Freezer

WARNING

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Freezer Shelves

Store similar foods together and adjust the shelves to t

different heights. This reduces the time the freezer door

is open and saves energy.

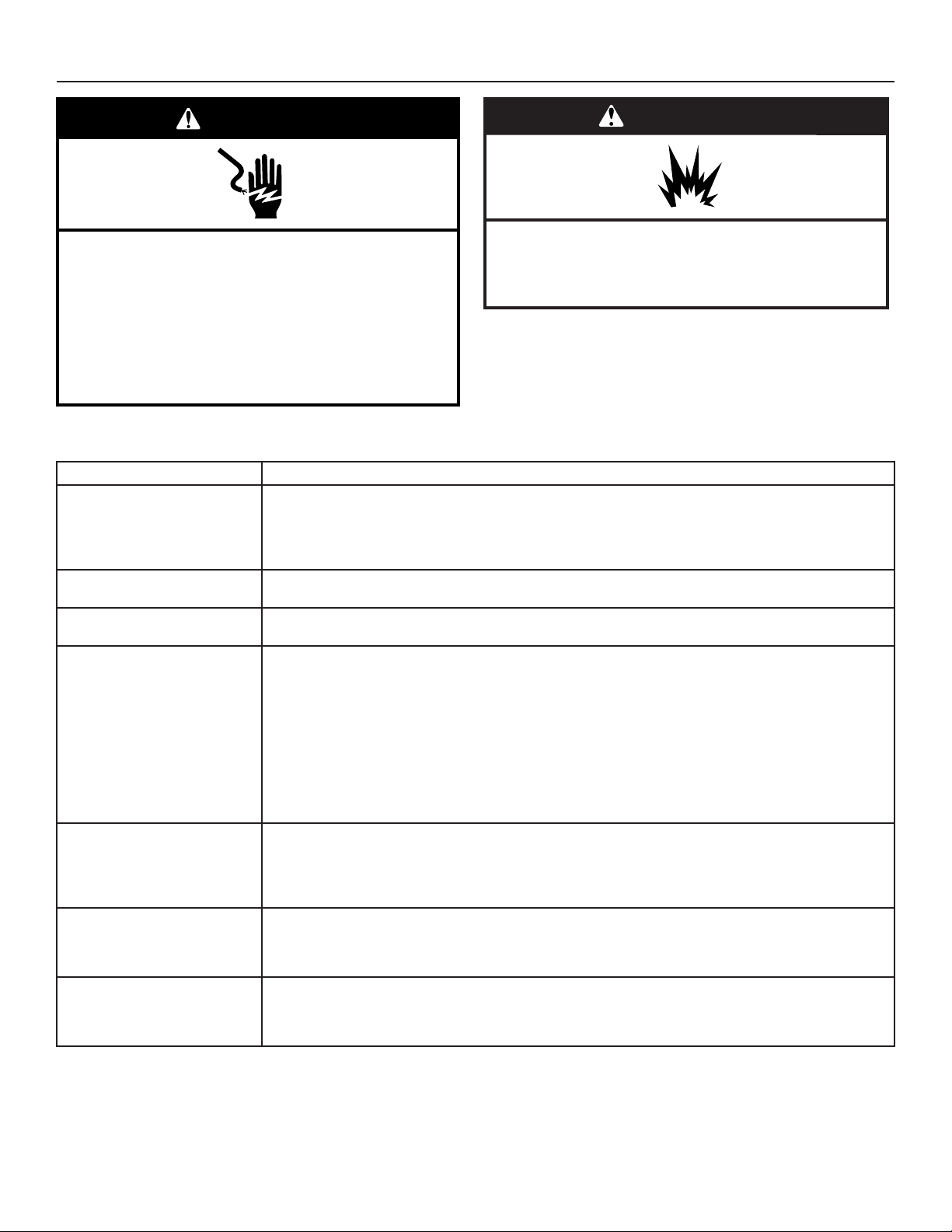

To Remove and

Replace a Shelf:

1. Remove the shelf by

lifting straight up and

pulling the shelf out.

2. Replace the shelf by

lowering the shelf onto

the supports on the

side wall.

7. Use the appropriate cleaning method for your exterior nish.

Painted metal: Wash exteriors with a clean sponge or soft

cloth and a mild detergent in warm water. Do not use abrasive

or harsh cleaners or cleaners designed for stainless steel. Dry

thoroughly with a soft cloth.

8. Clean the condenser coils regularly. Coils may need to be

cleaned as often as every other month. This may help save

energy.

■ Open the freezer door and remove the base grille by

removing 2 Phillips-head screws and pulling the grille

toward you.

■ Use a vacuum with an extended attachment to clean the

condenser coils when they are dusty or dirty.

Frost-free means that you will not have to defrost your freezer.

Frost is removed by air moving and collecting any moisture and

depositing it on the cooling coil. The cooling coil periodically

warms up enough to melt the frost, and it then ows down to the

drain pan (located behind the base grille) where it is evaporated.

Complete cleaning should be done at least once a year.

1. Press and hold TEMP SETTING for 3 seconds to turn off

cooling.

2. Unplug freezer or disconnect power.

3. Remove all frozen food. Wrap frozen food in several layers

of newspaper and cover with a blanket. Food will stay frozen

for several hours. You may also store frozen food in a cooler,

additional refrigerator-freezer, or in a cool area.

4. Remove all removable parts from inside, such as shelves,

bins, etc.

5. Hand wash, rinse, and dry removable parts and interior

surfaces thoroughly. Use a clean sponge or soft cloth and

a mild detergent in warm water.

■ Do not use abrasive or harsh cleaners such as window

sprays, scouring cleansers, ammable uids, cleaning

waxes, concentrated detergents, bleaches or cleansers

containing petroleum products on plastic parts, interior

and door liners, or gaskets. Do not use paper towels,

scouring pads, or other harsh cleaning tools. These can

scratch or damage materials.

■ To help remove odors, you can wash interior walls with

a mixture of warm water and baking soda (2 tbs to 1 qt

[26 g to 0.95 L] of water).

6. Replace the removable parts.

■ Replace the base grille by aligning the ends of the grille

with the leveling assemblies on each side and snapping

the grille into place. Reinstall the screws.

9. Replace all frozen food.

10. Plug in freezer or reconnect power.

11. Set temperature control to desired setting. See “Using the

Control.”

9

Changing the Light Bulb

Power Interruptions

NOTE: Not all appliance bulbs will t your freezer. Be sure to

replace the bulb with an appliance bulb of the same size, shape,

and wattage.

1. Unplug freezer or disconnect power.

2. Remove the light shield by squeezing the lens from the sides,

pushing back and pulling down.

3. Replace bulb with a 40-watt maximum appliance bulb

or an LED rated for wet/damp locations.

NOTE: Some LED replacement light bulbs are not

recommended for wet/damp environments. Refrigerator

fresh food and freezer compartments are considered wet/

damp environments. Read and follow all instructions on the

LED packaging when replacing the factory installed LED bulb.

A replacement LED bulb can be purchased from an authorized

dealer.

4. Replace the light shield.

5. Plug in freezer or reconnect power.

If the power will be out for 24 hours or less, keep the door closed

to help food stay cold and frozen.

If the power will be out for more than 24 hours, do one of the

following:

■ Remove all frozen food and store it in a frozen food locker.

■ If a food locker is not available, consume or can perishable

food at once.

REMEMBER: A full freezer stays cold longer than a partially lled

one. A freezer full of meat stays cold longer than a freezer full of

baked goods. If you see that food contains ice crystals, it may be

refrozen, although the quality and avor may be affected. If the

condition of the food is poor, dispose of it.

Moving Care

When you are moving your freezer to a new home, follow these

steps to prepare it for the move:

1. Remove all frozen food.

2. Unplug the freezer.

3. Take out all removable parts, wrap them well, and tape them

together so they don’t shift and rattle during the move.

4. Clean the freezer thoroughly.

5. Tape the freezer shut and tape the electrical cord to the

cabinet.

When you get to your new home, refer to the “Installing Your

Freezer” and “Operating Your Freezer” sections for information

on installation and setting the controls.

TROUBLESHOOTING

First try the solutions suggested here. If you need further assistance or more recommendations that may help you avoid a service call,

refer to the warranty page in this manual and scan the code there with your mobile device, or visit www.whirlpool.com/product_help

for recommendations that may help you avoid a service call. In Canada, visit http://www.whirlpool.ca.

Contact us by mail with any questions or concerns at the address below:

In the U.S.A.:

Whirlpool Brand Home Appliances

Customer eXperience Center

553 Benson Road

Benton Harbor, MI 49022-2692

Please include a daytime phone number in your correspondence.

In Canada:

Whirlpool Brand Home Appliances

Customer eXperience Centre

200 – 6750 Century Ave.

Mississauga ON L5N 0B7

10

Freezer Operation

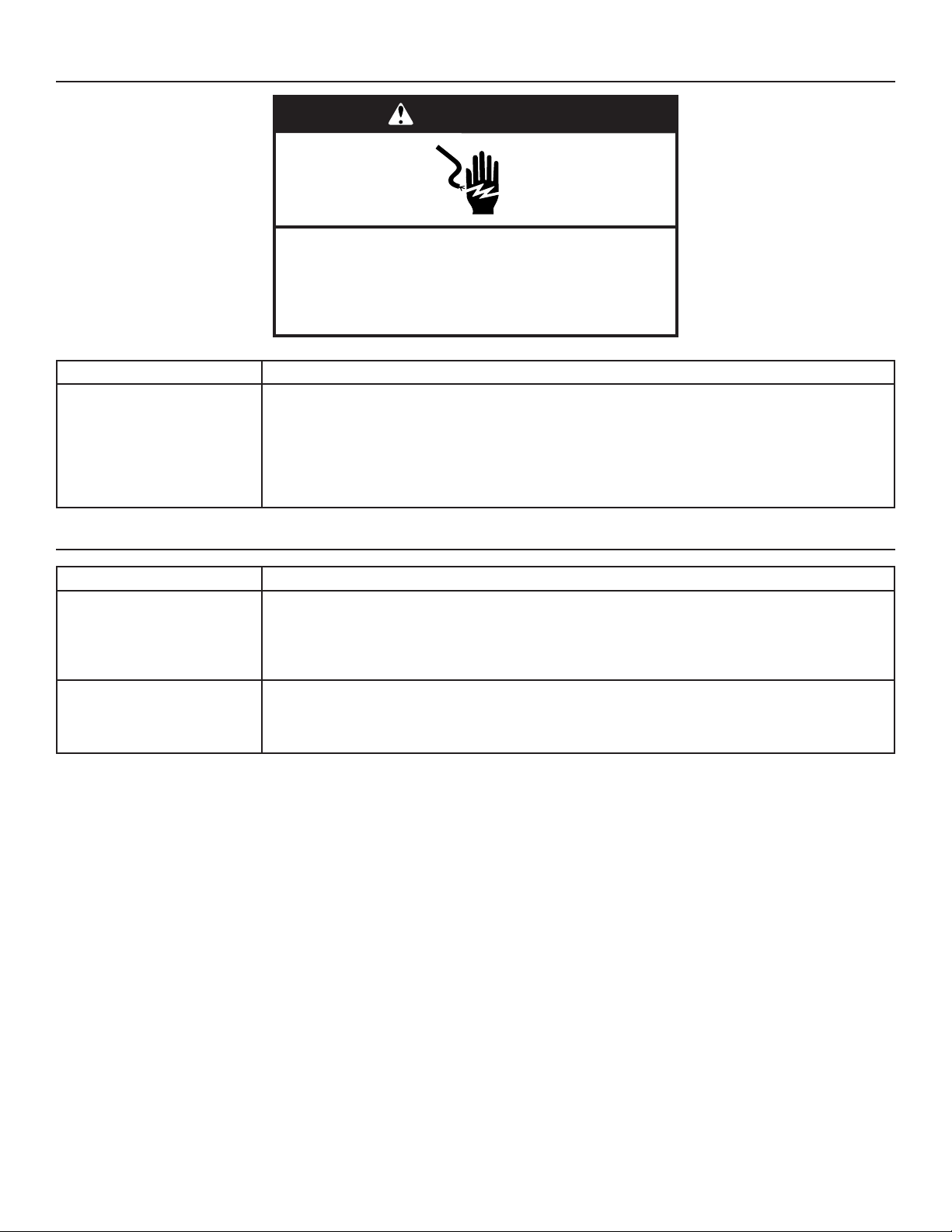

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

WARNING

Explosion Hazard

PROBLEM RECOMMENDED SOLUTIONS

Freezer Will Not Operate Check that the freezer is not running an Automatic Defrost cycle.

Check that it is plugged into a grounded 3 prong outlet.

Check that the temperature control is turned on.

Replace the fuse or reset the circuit breaker.

NOTE: If problems continue, contact an electrician.

Lights Do Not Work Check that it is plugged into a grounded 3 prong outlet.

Check that the light bulb is tight in the socket and is not burned out.

Water in Defrost Drain Pan It is normal for water to drip into the defrost drain pan when freezer is defrosting.

When humidity is high, it is normal for water in the defrost pan to take longer to evaporate.

Motor Seems to Run

Too Much

Temperature Is Too Warm Check that air vents are clear. See “Ensuring Proper Air Circulation” for air vent locations.

The Door Will Not Close

Completely or Is Difcult

To Open

Freezer Makes Loud

Buzzing/Clicking Sound

Check that door closes properly.

Defrost and clean the freezer to remove excessive frost.

Adding a large amount of food warms the freezer causing the freezer to run longer to cool back

down. If this is the situation, wait approximately 6 to 8 hours to allow the freezer to reach the

correct temperature.

Remove all items out at one time, keep food organized, and close door as soon as possible.

Check that the door gasket is sealed all the way around. If not, contact a qualied person or

technician.

Check that space around freezer meets air circulation requirements. See “Location Requirements.”

NOTE: If none of the above, your new freezer will run longer than your old one due to its highefciency motor.

Remove all items out at one time, keep food organized, and close door as soon as possible.

Adding a large amount of food warms the freezer causing the freezer to run longer to cool back

down.

Check that the temperature control is set correctly for surrounding conditions.

Check that there are no food packages blocking the door.

On some models, check that the shelves and basket are in the correct position.

Check that gaskets are clean. See the “Caring for Your Freezer” section.

Check that the freezer is stable. See “Freezer Leveling and Door Closing.”

If the freezer has recently been plugged in or turned on following a defrost or product move, or if

there has been an extended power failure, turn off the temperature alarm for the next 24 hours.

Adding a large amount of food warms the freezer. It can take several hours for the freezer to return

to normal temperature. Turn the temperature alarm off for the next 24 hours.

11

Ice Production

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

PROBLEM RECOMMENDED SOLUTIONS

Ice Maker Produces No Ice

or Very Little Ice

If ice maker has just been installed, wait 72 hours for full ice production to begin.

Check that the temperature control is cold enough.

Check that the wire shut-off arm is in the On (arm down) position.

Check that the water supply is properly connected and turned on.

Check that the ejector arm is not blocked by an ice cube.

If a large amount of ice has been removed recently, allow 24 hours to produce more ice.

NOTE: If not due to any of the above, there may be a problem with the water line. Call for service.

Ice Quality

PROBLEM RECOMMENDED SOLUTIONS

Off Taste, Odor, or Gray

Color in the Ice

Thin, Soft, or Clumps of Ice If there is unusually high mineral content in the water supply, the water may need to be treated.

Discard the rst few batches of ice.

If there is unusually high mineral content in the water supply, the water may need to be treated.

If there is mineral scale buildup, clean your ice maker mold.

If the ice cubes have been stored too long, throw the old ice away and make a new supply.

Check that the freezer and ice bin are clean.

If there is mineral scale buildup, clean your ice maker.

If there are clumps of ice in the bin and if ice is not used regularly, it will melt and form clumps.

Break the clumps with the ice scoop provided.

12

ATTACH YOUR RECEIPT HERE. PROOF OF PURCHASE IS REQUIRED

www.whirlpool.com/product_help

WHIRLPOOL®

MAJOR APPLIANCE

LIMITED WARRANTY

TO OBTAIN WARRANTY SERVICE.

Please have the following information available when you call the

Customer eXperience Center:

■ Name, address and telephone number

■ Model number and serial number

■ A clear, detailed description of the problem

■ Proof of purchase including dealer or retailer name and address

IF YOU NEED SERVICE:

1. Before contacting us to arrange service, please determine whether your product requires repair. Some

questions can be addressed without service. Please take a few minutes to review the Troubleshooting or

Problem Solver section of the Use and Care Guide, scan the QR code on the right to access additional

resources, or visit www.whirlpool.com/product_help.

2. All warranty service is provided exclusively by our authorized Whirlpool Service Providers

Canada, direct all requests for warranty service to:

Whirlpool Customer eXperience Center

In the U.S.A., call 1-800-253-1301. In Canada, call 1-800-807-6777.

If outside the 50 United States or Canada, contact your authorized Whirlpool dealer to determine whether another warranty applies.

ONE YEAR LIMITED WARRANTY

WHAT IS COVERED WHAT IS NOT COVERED

For one year from the date of purchase, when this

major appliance is installed, operated and maintained

according to instructions attached to or furnished with

the product, Whirlpool Corporation or Whirlpool

Canada LP (hereafter “Whirlpool”) will pay for Factory

Specified Replacement Parts and repair labor to

correct defects in materials or workmanship that

existed when this major appliance was purchased, or

at its sole discretion replace the product. In the event

of product replacement, your appliance will be

warranted for the remaining term of the original unit's

warranty period.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS

LIMITED WARRANTY SHALL BE PRODUCT REPAIR

AS PROVIDED HEREIN. Service must be provided by a

Whirlpool designated service company. This limited

warranty is valid only in the United States or Canada

and applies only when the major appliance is used in

the country in which it was purchased. This limited

warranty is effective from the date of original consumer

purchase. Proof of original purchase date is required to

obtain service under this limited warranty.

1. Commercial, non-residential, multiple-family use, or use inconsistent with published

user, operator or installation instructions.

2. In-home instruction on how to use your product.

3. Service to correct improper product maintenance or installation, installation not in

accordance with electrical or plumbing codes or correction of household electrical or

plumbing (i.e. house wiring, fuses or water inlet hoses).

4. Consumable parts (i.e. light bulbs, batteries, air or water filters, preservation

solutions, etc.).

5. Defects or damage caused by the use of non-genuine Whirlpool parts or accessories.

6. Conversion of products from natural gas or L.P. gas.

7. Damage from accident, misuse, abuse, fire, floods, acts of God or use with products

not approved by Whirlpool.

8. Repairs to parts or systems to correct product damage or defects caused by

unauthorized service, alteration or modification of the appliance.

9. Cosmetic damage including scratches, dents, chips, and other damage to the

appliance finishes unless such damage results from defects in materials and

workmanship and is reported to Whirlpool within 30 days.

10. Discoloration, rust or oxidation of surfaces resulting from caustic or corrosive

environments including but not limited to high salt concentrations, high moisture or

humidity or exposure to chemicals.

11. Food or medicine loss due to product failure.

12. Pick-up or delivery. This product is intended for in-home repair.

13. Travel or transportation expenses for service in remote locations where an authorized

Whirlpool servicer is not available.

14. Removal or reinstallation of inaccessible appliances or built-in fixtures (i.e. trim,

decorative panels, flooring, cabinetry, islands, countertops, drywall, etc.) that

interfere with servicing, removal or replacement of the product.

15. Service or parts for appliances with original model/serial numbers removed, altered

or not easily determined.

The cost of repair or replacement under these excluded circumstances shall be

borne by the customer.

. In the U.S. and

DISCLAIMER OF IMPLIED WARRANTIES

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. Some states and provinces do not allow

limitations on the duration of implied warranties of merchantability or fitness, so this limitation may not apply to you. This warranty gives you

specific legal rights, and you also may have other rights that vary from state to state or province to province.

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

Whirlpool makes no representations about the quality, durability, or need for service or repair of this major appliance other than the representations

contained in this warranty. If you want a longer or more comprehensive warranty than the limited warranty that comes with this major appliance,

you should ask Whirlpool or your retailer about buying an extended warranty.

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN. WHIRLPOOL

SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states and provinces do not allow the exclusion or limitation

of incidental or consequential damages, so these limitations and exclusions may not apply to you. This warranty gives you specific legal rights, and

you also may have other rights that vary from state to state or province to province.

13

11/14

Guide d’utilisation

Congélateur vertical

Nous vous REMERCIONS d'avoir acheté ce produit de haute qualité. Enregistrer le congélateur sur www.whirlpool.com. Au

Canada, enregistrer le congélateur sur www.whirlpool.ca.

Pour référence ultérieure, consignez par écrit les numéros de modèle et de série de votre produit. Vous trouverez les numéros de

modèle et de série à l'intérieur du congélateur.

Numéro de modèle_________________________________________

Numéro de série ___________________________________________

TABLE DES MATIÈRES

SÉCURITÉ .....................................................................................14

INSTALLATION DU CONGÉLATEUR ........................................16

Déballage ...................................................................................16

Exigences d’emplacement .........................................................16

Spécications électriques ..........................................................17

Spécications de l’alimentation en eau

(sur certains modèles) ................................................................17

Raccordement de la canalisation d’alimentation en eau

(sur certains modèles) ................................................................17

Retrait et réinstallation de la poignée ........................................18

Porte du congélateur..................................................................18

Nivellement du congélateur et fermeture de la porte ................20

UTILISATION DU CONGÉLATEUR ............................................21

Pour s’assurer d’une circulation

d’air appropriée ..........................................................................21

Utilisation de la commande .......................................................21

Serrure à éjection de clé

(sur certains modèles) ................................................................22

Machine à glaçons (sur certains modèles) ................................22

Caractéristiques du congélateur ................................................23

ENTRETIEN DU CONGÉLATEUR ..............................................23

Nettoyage du congélateur sans givre ........................................23

Remplacement de l’ampoule d’éclairage ..................................24

Pannes de courant électrique ....................................................24

Déménagement ..........................................................................24

DÉPANNAGE ................................................................................25

Fonctionnement du congélateur ................................................25

Production de glaçons ...............................................................27

Qualité des glaçons ....................................................................27

GARANTIE ....................................................................................28

SÉCURITÉ

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

14

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ

AVERTISSEMENT :

réfrigérateur, prendre quelques précautions fondamentales, y compris les suivantes :

■ Brancher l'appareil sur une prise à 3 alvéoles reliée à la terre.

■ Ne pas enlever la broche de liaison à la terre.

■ Ne pas utiliser un adaptateur.

■ Ne pas utiliser un câble de rallonge.

■ Débrancher la source de courant électrique avant l'entretien.

■ Replacer pièces et panneaux avant de faire la remise en marche.

■ Enlever les portes de votre vieux réfrigérateur.

■ Raccorder à la canalisation d'arrivée d'eau potable uniquement.

■ Utiliser un produit de nettoyage ininflammable.

■ Garder les matériaux et les vapeurs inflammables, telle que

l'essence, loin du réfrigérateur.

■ Utiliser deux ou plus de personnes pour déplacer et installer le

réfrigérateur.

Pour réduire les risques d'incendie, de choc électrique ou des blessures lors de l'utilisation du

■ Débrancher le réfrigérateur avant l'installation de la

machine à glaçons (seulement pour modèles prêts à

recevoir une machine à glaçons).

■ Utiliser un verre robuste pour prendre des glaçons (sur

certains modèles).

■ Ne pas heurter les portes en verre du réfrigérateur (sur

certains modèles).

■ Cet appareil ne convient pas à une utilisation par des

personnes (y compris des enfants) à capacités

physiques, sensorielles ou mentales réduites, ou

possédant un manque d'expérience et de

connaissances, à moins qu'elles ne soient placées sous

supervision ou qu'elles aient reçu des instructions

concernant l’utilisation de l'appareil par une personne

responsable de leur sécurité.

■ Les enfants doivent être placés sous surveillance afin de

s'assurer qu'ils ne jouent pas avec l'appareil.

CONSERVEZ CES INSTRUCTIONS

Avertissements de la proposition 65 de l'État de Californie :

AVERTISSEMENT : Ce produit contient au moins un produit chimique connu par l’État de Californie pour être à l’origine de

cancers.

AVERTISSEMENT : Ce produit contient au moins un produit chimique connu par l’État de Californie pour être à l’origine de

malformations et autres déficiences de naissance.

MISE AU REBUT APPROPRIÉE

DE VOTRE VIEUX CONGÉLATEUR

OU RÉFRIGÉRATEUR

AVERTISSEMENT

Risque de suffoquer

Enlever les portes ou le couvercle de votre vieux

congélateur ou réfrigérateur.

Le non-respect de cette instruction peut causer

un décès ou des lésions cérébrales.

IMPORTANT : Encore de nos jours, des enfants peuvent restés

pris ou s’étouffer à l’intérieur d’un appareil comme celui-ci. Les

congélateurs ou réfrigérateurs jetés ou abandonnés présentent

des dangers, même s’ils sont abandonnés pendant “quelques

jours” seulement. Si vous vous débarrassez de votre vieux

réfrigérateur ou congélateur, veuillez suivre les instructions

suivantes pour aider à éviter les accidents.

Avant de mettre au rebut votre vieux

congélateur ou réfrigérateur :

■ Enlever les portes ou le couvercle.

■ Laisser les tablettes en place, de

sorte que les enfants ne puissent pas

facilement se glisser à l’intérieur.

Renseignements importants à propos de la mise au

rebut des fluides réfrigérants :

Mettre le congélateur au rebut conformément à la

réglementation fédérale et locale. Les fluides réfrigérants

doivent être évacués par un technicien certifié et agréé par

l’EPA conformément aux procédures établies.

15

INSTALLATION DU CONGÉLATEUR

Déballage

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer et

installer le congélateur.

Le non-respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

Enlèvement des matériaux d’emballage

■ Enlever le ruban adhésif et la colle des surfaces du

congélateur avant de le mettre en marche. Frotter une petite

quantité de savon liquide pour la vaisselle sur l’adhésif avec

les doigts. Rincer à l’eau tiède et essuyer.

■ Ne pas utiliser d’instruments coupants, d’alcool à friction,

de liquides inammables ou de nettoyants abrasifs pour

enlever le ruban adhésif ou la colle. Ces produits peuvent

endommager la surface de votre congélateur. Pour plus de

renseignements, voir “Sécurité”.

Déplacement de votre congélateur :

Votre congélateur est lourd. Lors du déplacement de votre

congélateur pour le nettoyage ou un entretien, veiller à

recouvrir le plancher avec du carton ou un panneau de fibre

dur pour éviter qu'il ne subisse tout dommage. Toujours

tirer le congélateur tout droit lors du déplacement. Ne pas

incliner le congélateur d’un côté ou de l’autre ni le “faire

marcher” en essayant de le déplacer car le plancher pourrait

être endommagé.

Nettoyage avant l’utilisation

Après avoir enlevé tous les matériaux d’emballage, nettoyer

l’intérieur du congélateur avant l’utilisation. Voir les instructions

de nettoyage à la section “Entretien du congélateur”.

Importants renseignements à savoir au sujet des tablettes

et des couvercles en verre :

Ne pas nettoyer les tablettes ou couvercles en verre avec de

l’eau tiède quand ils sont froids. Les tablettes et les

couvercles peuvent se briser s'ils sont exposés à des

changements soudains de température ou à un impact tel

que coup brusque. Le verre trempé est conçu pour éclater

en d’innombrables pièces minuscules. Ceci est normal. Les

tablettes et les couvercles en verre sont lourds. Les saisir à

deux mains lors de leur dépose afin d'éviter de les faire

tomber.

Exigences d’emplacement

AVERTISSEMENT

Risque d'explosion

Garder les matériaux et les vapeurs inflammables, telle

que l'essence, loin du congélateur.

Le non-respect de cette instruction peut causer

un décès, une explosion ou un incendie.

Ventilation et dégagement

■ Garder les matériaux et les vapeurs inflammables, tel que

l’essence, loin du congélateur.

■ Ne pas couvrir le congélateur avec des articles tels que

couvertures, draps, nappes de table, etc. Ceci réduit la

circulation d’air.

■ Laisser un espace d’au moins 3" (7,5 cm) des deux côtés du

congélateur et de 1" (2,5 cm) entre l’arrière du congélateur et

le mur. Si le congélateur est installé contre un mur, laisser un

espace supplémentaire du côté des charnières pour une plus

grande ouverture de la porte.

Température

Le congélateur fonctionne à son efcacité maximale lorsqu’il

se trouve dans un endroit où la température ne descend pas

en dessous de 40 °F (5 °C). Installer le congélateur dans un

endroit où la température ne descend pas en dessous de cette

température recommandée.

Lors du déplacement à son emplacement nal

REMARQUE : Laisser un dégagement de 3" (7,5 cm) sur

le dessus et les côtés et un dégagement de ¹⁄4" (6,4 mm)

entre les appareils.

3" (7,5 cm)

16

3" (7,5 cm)

Spécications électriques

AVERTISSEMENT

Risque de choc électrique

Brancher sur une prise à 3 alvéoles reliée à la terre.

Ne pas enlever la broche de liaison à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Le non-respect de ces instructions peut causer

un décès, un incendie ou un choc électrique.

Avant de déplacer le congélateur à son emplacement nal,

il est important de vous assurer d'avoir le raccordement

électrique approprié.

Méthode recommandée de mise à la terre

Une source de courant électrique de 115 V, 60 Hz, CA seulement,

et protégée par un fusible de 15 ou 20 ampères, adéquatement

mise à la terre est nécessaire. Il est recommandé d’utiliser un

circuit distinct pour alimenter uniquement le congélateur. Utiliser

une prise de courant murale qui ne peut pas être mise hors

circuit à l’aide d’un commutateur. Ne pas employer un câble

de rallonge.

REMARQUE : Avant de procéder à tout type d’installation,

de nettoyage ou de changement d’une ampoule, appuyer sans

relâcher sur TEMP SETTING (réglage de la température) pendant

3 secondes pour désactiver le refroidissement, puis déconnecter

le congélateur de la source de courant électrique.

IMPORTANT :

■ Si on doit utiliser le congélateur avant qu’il soit raccordé à

la canalisation d’eau, placer la commande de la machine à

glaçons à la position d’ARRÊT.

■ Toutes les installations doivent être conformes aux exigences

des codes locaux de plomberie.

■ Utiliser un tube en plastique et vérier l’absence de fuites.

Installer les tubes en plastique seulement à des endroits où la

température se maintient au-dessus du point de congélation.

Pression de l’eau

Une alimentation en eau froide avec une pression entre

30 et 120 lb/po2 (207 et 827 kPa) est nécessaire pour faire

fonctionner le distributeur d’eau et la machine à glaçons. Si

vous avez des questions au sujet de la pression de votre eau,

consulter la section “Résolution de problèmes” ou faire appel à

un plombier qualié agréé.

Alimentation en eau par osmose inverse

Si un système de purication de l’eau par osmose inverse

est raccordé à votre alimentation en eau froide, la pression

de l’eau au système doit être d’un minimum de 40 à 60 lb/po2

(276 à 414 kPa).

Si la pression de l’eau au système d’osmose inverse est inférieure

à 40 à 60 lb/po2 (276 à 414 kPa), une pompe de surpression peut

être insérée dans le petit tube qui va de la canalisation d’eau

froide au système d’osmose inverse.

Si le distributeur d’eau ne distribue toujours pas l’eau

correctement :

■ Vérifier pour voir si le filtre à sédiments dans le système

d'osmose inverse est bloqué et le remplacer si nécessaire.

■ Laisser le réservoir du système d’osmose inverse se remplir

après une utilisation intense.

■ Si votre réfrigérateur comporte un filtre à eau, celui-ci peut

réduire encore plus la pression de l’eau lorsqu’il est utilisé

avec un système d’osmose inverse. Retirer le filtre à eau.

Si vous avez des questions au sujet de la pression de votre eau,

consulter la section “Résolution de problèmes” ou appeler un

plombier qualié agréé.

Raccordement de la canalisation

d’alimentation en eau

(sur certains modèles)

Spécications de l’alimentation en eau

(sur certains modèles)

Rassembler les outils et pièces nécessaires avant de commencer

l'installation. Lire et suivre les instructions fournies avec les outils

indiqués ici.

Outils requis

■ Un Tournevis à lame plate

■ Clés plates de

clés à molette réglables

REMARQUE : Votre marchand de congélateurs propose une

trousse disponible avec un robinet d’arrêt à étrier de ¹⁄4"

(6,35 mm), un raccord et un tube en plastique. Avant l’achat,

s’assurer que le robinet d’arrêt à étrier est conforme à vos codes

locaux de plomberie. Ne pas employer de robinet d’arrêt à étrier

de ³⁄16" (4,76 mm) ou de type à percer, ce qui réduit le débit d’eau

et cause une obstruction plus facilement.

7

⁄16" et ¹⁄2" ou deux

■ Tourne-écrou de ¼"

■ Foret de ¼"

■ Perceuse sans l

Raccordement à une canalisation d’eau

1. Débrancher le congélateur ou déconnecter la source

de courant électrique.

2. FERMER le robinet principal d’arrivée d’eau. OUVRIR le

robinet de puisage le plus proche pendant une période

sufsante pour que la canalisation d’eau se vide.

3. Trouver une canalisation d’eau froide verticale de ½" à 1¼"

(12,7 mm à 3,18 cm) près du congélateur.

IMPORTANT :

■ Assurez-vous qu’il s’agit d’un conduit d’eau froide.

■ Un conduit horizontal fonctionnera, mais percer par le dessus

de la canalisation et non pas par le dessous. Ainsi, l’eau ne

risquera pas d’arroser la perceuse. Ceci empêche également

les sédiments qu’on trouve normalement dans l’eau de

s’accumuler dans le robinet.

4. Pour déterminer la longueur du tube en plastique, il faut

mesurer la distance entre le point de connexion inférieur

gauche à l’arrière du congélateur et la canalisation d’eau.

Ajouter une longueur de 7 pi (2,1 m) pour permettre le

nettoyage. Utiliser un tube en plastique de ¼" (6,35 mm)

de diamètre extérieur. Veiller à ce que le tube soit coupé

d’équerre aux deux extrémités.

17

5. À l’aide d’une perceuse sans l, percer un trou de ¹⁄4"

A

DEF

G

(6,35 mm) dans le tuyau de canalisation d’eau froide choisi.

B

C

A. Canalisation d’eau froide

B. Bride de tuyau

C. Tube en plastique

D. Écrou de compression

6. Fixer le robinet d’arrêt sur la canalisation d’eau froide avec la

bride de tuyau. Vérier que l’extrémité du raccord de sortie

du robinet est bien engagée dans le trou de ¹⁄4" (6,35 mm)

percé dans la canalisation et que la rondelle d’étanchéité est

placée sous la bride de tuyau. Serrer l’écrou de serrage. Serrer

lentement et uniformément les vis xant la bride de tuyau sur

la tuyauterie an que la rondelle forme une jonction étanche.

Ne pas serrer excessivement, car ceci pourrait provoquer

l’écrasement du tube en plastique.

7. Enler l’écrou et la bague de compression du raccord sur le

tube en plastique comme on le voit sur l’illustration. Insérer

l’extrémité du tube directement et aussi loin que possible dans

l’ouverture de sortie du robinet. Visser l’écrou de compression

sur l’extrémité du raccord de sortie avec une clé à molette. Ne

pas serrer excessivement.

8. Placer le bout libre du tube dans un contenant ou évier et

ouvrir le robinet principal d’arrivée d’eau; laisser l’eau s’écouler

par le tube jusqu’à ce que l’eau soit limpide. fermer le robinet

de la canalisation d’eau. Enrouler le tube en plastique.

E. Bague de compression

F. Robinet d’arrêt

G. Écrou de serrage

Raccordement au congélateur

1. Fixer le tube en plastique à l’entrée du robinet d’eau en

utilisant un écrou et une bague de compression tel qu’illustré.

Serrer l’écrou de compression. Ne pas serrer excessivement.

2. Utiliser la bride du tube à l’arrière du congélateur pour xer le

tube au congélateur tel qu’illustré. Ceci aidera à empêcher les

dommages au tube lorsque le congélateur est poussé contre

le mur.

3. Ouvrir le robinet d’arrêt.

4. Vérier l’absence de fuites. Serrer tous les raccords (y compris

les raccordements du robinet d’arrivée d’eau) ou les écrous

qui coulent.

A

B

C

AVERTISSEMENT

Risque de choc électrique

Brancher sur une prise à 3 alvéoles reliée à la terre.

Ne pas enlever la broche de liaison à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Le non-respect de ces instructions peut causer

un décès, un incendie ou un choc électrique.

6. Brancher sur une prise à 3 alvéoles reliée à la terre.

Retrait et réinstallation de la poignée

Retrait de la poignée :

1. Desserrer les vis de blocage situées sur le côté de la poignée

à chaque extrémité. Voir l’illustration “Inversion du sens

d’ouverture de la porte et retrait de la poignée”.

2. Retirer la poignée des oeillets.

Réinstallation de la poignée :

1. Placer la poignée sur les oeillets en s’assurant que les oeillets

sont bien installés dans les trous de la poignée.

2. Serrer les vis de blocage supérieures et inférieures à l’aide de

la clé à tête hexagonale fournie. Voir l’illustration “Inversion du

sens d’ouverture de la porte et retrait de la poignée”. Ne pas

serrer excessivement les vis de blocage.

Porte du congélateur

Outillage nécessaire : clé à douille à tête hexagonale de 5⁄16",

clé à douille à tête hexagonale de ³⁄8", couteau à mastic de 2".

IMPORTANT :

■ Toutes les illustrations mentionnées dans les instructions

suivantes sont incluses plus loin dans cette section après

“Étapes nales”. Les illustrations correspondent à une porte

s’ouvrant à droite (charnières installées à droite à l’usine).

■ Si vous désirez seulement enlever et réinstaller la porte,

voir les sections “Démontage - Porte et charnières” et

“Réinstallation - Porte et charnières”.

■ Avant de commencer, tourner la commande à OFF (arrêt) et

retirer les aliments et tout balconnet réglable ou compartiment

utilitaire de la porte.

Démontage – Porte et charnières

D

E

A. Bride du tube

B. Vis de bride du tube

C. Tube en plastique

5. La machine à glaçons est équipée d’un ltre à eau incorporé.

Si la qualité de l’eau distribuée localement nécessite un

deuxième ltre à eau, l’installer dans la canalisation d’eau de

¹⁄4" (6,35 mm), à l’un ou l’autre des points de raccordement.

On peut obtenir un tel ltre à eau chez le marchand d’appareils

électroménagers le plus proche.

D. Écrou de compression

E. Entrée du robinet

1. Débrancher le congélateur ou déconnecter la source de

courant électrique.

2. Laisser la porte du congélateur fermée jusqu’à ce que vous

soyez prêt à la soulever pour la dégager de la caisse.

REMARQUE : Prévoir un support additionnel de la porte

pendant le déplacement des charnières. La force d’attraction

des aimants de porte ne suft pas à la maintenir en place.

18

Vis de charnière à tête hexagonale

3. Enlever les pièces de la charnière supérieure - voir l’illustration

de la charnière supérieure dans la section “Inversion du sens

de la porte et retrait de la poignée”.

4. Soulever la porte du congélateur pour la séparer de la

charnière inférieure et de la caisse et la conserver à part.

5. Retirer les 4 vis de charnière à tête hexagonale et la charnière

inférieure. Voir l’illustration de la charnière inférieure dans la

section “Inversion du sens de la porte et retrait de la poignée”.

Inversion du sens d’ouverture de la porte

(facultatif - sur certains modèles)

IMPORTANT : Si vous souhaitez inverser le sens d’ouverture

de la porte, suivre les instructions de cette section. S’il n’est

pas nécessaire de changer l’orientation de la porte, voir

“Réinstallation - Porte et charnières”.

Caisse

1. Enlever les bouchons d’obturation des trous de charnière

au sommet de la caisse; transférer ceux-ci dans les trous

de charnière du côté opposé (voir l’illustration 2 à la page

suivante).

2. Retirer l’axe de charnière inférieure de la bride de charnière.

3. Retirer les oeillets recouvrant les trous du côté opposé de la

charnière inférieure.

4. Réinstaller l’axe de charnière dans l’autre trou de la bride de

charnière. Voir l’illustration 3 à la page suivante.

5. Réinstaller la bride de charnière sur la caisse à l’aide des 4 vis

de charnière à tête hexagonale.

Porte

1. Enlever le bouchon d’obturation de la partie supérieure de

charnière au sommet de la porte.

2. Retirer la butée de porte du bas de la porte.

3. Placer la butée de porte du côté opposé en s’assurant que le

trou de la plaque de butée de porte est parfaitement aligné

avec le trou de la porte destiné à l’axe de charnière inférieure.

4. À l’aide des vis retirées à l’étape 2, xer le support de butée

de porte au bas de la porte.

5. Serrer toutes les vis. Conserver la porte du congélateur à part

jusqu’à la mise en place de la charnière inférieure.

Étapes nales

1. Inspecter tous les trous. Vérier que tous les bouchons

d’obturation et vis sont en place. Réinstaller le couvercle

de la charnière supérieure. Voir l’illustration de la charnière

supérieure.

2. À l’aide des oeillets fournis, recouvrir les trous restants situés

sur le côté opposé de la charnière inférieure.

AVERTISSEMENT

Risque de choc électrique

Brancher sur une prise à 3 alvéoles reliée à la terre.

Ne pas enlever la broche de liaison à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Le non-respect de ces instructions peut causer

un décès, un incendie ou un choc électrique.

3. Brancher sur une prise de courant à 3 alvéoles, reliée à la terre.

4. Réinitialiser la commande. Voir la section “Utilisation de la

commande”.

5. Réinstaller toutes les pièces amovibles de la porte et remettre

les aliments dans le congélateur.

Réinstallation – Porte et charnières

REMARQUE : Si on inverse le sens d’ouverture de la porte,

considérer l’image symétrique.

1. Assembler les pièces de la charnière inférieure (tel qu’indiqué)

et serrer les vis. Voir l’illustration de la charnière inférieure.

Réinstaller la porte du congélateur.

REMARQUE : Prévoir un support additionnel de la porte

pendant le déplacement des charnières. La force d’attraction

des aimants de porte ne suft pas à la maintenir en place.

2. Assembler les pièces de la charnière supérieure (voir

l’illustration de la charnière supérieure dans la section

“Inversion du sens de la porte et retrait de la poignée”.) Ne

pas complètement serrer les vis.

19

Dépose et réinstallation

de la porte

Inversion du sens d’ouverture de la porte

et retrait de la poignée (facultatif)

Charnière supérieure

B

A.

Couvercle de charnière supérieure

B.

Vis de charnière à tête hexagonale

5

de

C.

/16"

Charnière supérieure

Charnière inférieure

B

A.

Vis de butée de porte

Vis de charnière à tête hexagonale

B.

3

de

/8"

1

B

A

B

C

A

A

A. Œillets

B.

Poignée

C. Vis de montage

A

A.

Axe de charnière

B.

Vis de charnière à tête hexagonale

3

de

/8"

C

B

A

A.

Bouchons d’obturation des trous

de charnière de la caisse

3

2

Nivellement du congélateur et fermeture de la porte

Style 1—sans grille

1. Repérer les deux pieds de nivellement avant xés parmi les

matériaux d'emballage.

2. Visser ces pieds dans les trous avant situés au bas du

congélateur. L’arrière du congélateur repose sur 2 supports

xes.

3. Ajuster sufsamment les pieds avant pour séparer la caisse

du sol.

4. Placer un niveau au sommet de la caisse

du congélateur, transversalement puis

dans le sens avant-arrière. Pour soulever

un coin, faire tourner le pied dans le sens

antihoraire. Pour abaisser un coin, faire

tourner le pied dans le sens horaire.

5. Répéter l’étape 4 jusqu’à ce que le

congélateur soit d’aplomb.

6. Une fois le congélateur complètement

rempli d’aliments, vérier de nouveau

l’aplomb comme expliqué à l’étape 4.

Style 2—avec grille

Le congélateur est équipé de 2 pieds avant réglables, un de

chaque côté. L’arrière du congélateur repose sur 2 roulettes xes.

La grille de la base recouvre les pieds de stabilisation réglables

et les roulettes situées au bas du congélateur sous la porte du

congélateur. Avant de réaliser les ajustements, retirer la grille de

la base et déplacer le congélateur à son emplacement dénitif.

Outillage nécessaire : tourne-écrou de ¹⁄4", tournevis Phillips

1. Retirer les vis de la grille de la base. Saisir la grille fermement

et la tirer vers soi. Ouvrir la porte du congélateur pour accéder

aux pieds de stabilisation.