Whirlpool WZF34X18DW00, WZF34X16DW00, WZF79R18DM00, WZF79R20DW00, WZF56R16DW00 Owner’s Manual

...

User Guide

Upright Freezer

THANK YOU for purchasing this high-quality product. Register your freezer at www.whirlpool.com. In Canada, register your freezer at

www.whirlpool.ca.

For future reference, please make a note of your product model and serial numbers. These numbers can be found inside your freezer.

Model Number ..........................................

Serial Number ..........................................

SAFETY ................................................................................................. 1

INSTALLING YOUR FREEZER ........................................................... 2

Unpacking .......................................................................................... 2

Location Requirements ..................................................................... 3

Electrical Requirements ..................................................................... 3

Water Supply Requirements ............................................................. 4

Connect the Water Supply ................................................................ 4

Remove and Replace the Handle ...................................................... 5

Freezer Door ...................................................................................... 5

Freezer Leveling and Door Closing ................................................... 6

OPERATING YOUR FREEZER ............................................................ 7

Ensuring Proper Air Circulation ......................................................... 7

Using the Control ............................................................................... 7

Key Eject Lock................................................................................... 8

Ice Maker ........................................................................................... 8

Freezer Features ................................................................................ 9

CARING FOR YOUR FREEZER .......................................................... 9

Cleaning Your Frost-Free Freezer ..................................................... 9

Changing the Light Bulb .................................................................. 10

Power Interruptions......................................................................... 10

Moving Care .................................................................................... 10

PROBLEM SOLVER ........................................................................... 11

Freezer Operation ............................................................................ 11

Ice Production ................................................................................. 12

Ice Quality ........................................................................................ 12

WAR RANTY ....................................................................................... 13

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately follow instructions.

You can be killed or seriously injured if you don't follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the

instructions are not followed.

W10668404B

iMPORTANT SAFETY iNSTRUCTiONS

WARNING:To reduce the risk of fire, electric shock, or injurywhen using your freezer, follow these basic precautions:

• Plug into a grounded 3 prong outlet.

• Do not remove ground prong.

• Do not use an adapter.

• Do not use an extension cord.

• Disconnect power before servicing.

• Replace all parts and panels before operating.

• Use nonflammable cleaner.

• Keep flammable materials and vapors, such as gasoline, away

from freezer.

[] Use two or more people to move and install freezer.

[] Keep key away from children.

• Remove doors or lid from your old freezer or refrigerator.

[] Disconnect power before installing ice maker (on ice maker kit

ready models only).

SAVETHESEINSTRUCTIONS

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other reproductive harm.

IIP oper IIIDisposal of Your

IIFYeezer or Refrigerator

Suffocation Hazard

Remove doors or lid from your old freezer or

refrigerator.

Failure to do so can result in death or brain damage.

IMPORTANT: Child entrapment and suffocation are not problems

of the past. Junked or abandoned freezers or refrigerators are still

dangerous -- even if they will sit for "just a few days." If you are

getting rid of your old refrigerator or freezer, please follow these

instructions to help prevent accidents.

Before You Throw Away Your Old Freezer or Refrigerator:

• Take off the doors or lid.

• Leave the shelves in place so that children may not easily climb

inside.

Excessive Weight Hazard

Use two or more people to move and install freezer.

Failure to do so can result in back or other injury.

Remove Packaging Materials

• Remove tape and glue residue from surfaces before turning on the

freezer. Rub a small amount of liquid dish soap over the adhesive

with your fingers. Wipe with warm water and dry.

important information to know about disposal of

refrigerants:

Dispose of freezer in accordance with Federal and Local

regulations. Refrigerants must be evacuated by a licensed,

EPA certified refrigerant technician in accordance with

established procedures.

Do not use sharp instruments, rubbing alcohol, flammable fluids, or

abrasive cleaners to remove tape or glue. These products can

damage the surface of your freezer. For more information, see

"Safety."

When Moving Your Freezer:

Your freezer is heavy. When moving the freezer for

cleaning or service, be sure to cover the floor with cardboard

or hardboard to avoid floor damage. Always pull the freezer

straight out when moving it. Do not wiggle or "walk" the

freezer when trying to move it as floor damage could occur.

CleanBeforeUsing

Afteryouremoveallofthepackagingmaterials,cleantheinsideofyour

freezerbeforeusingit.Seethecleaninginstructionsin"CaringforYour

Freezer."

important information to know about glass shelves

and covers:

Do not clean glass shelves or covers with warm water when

they are cold. Shelves and covers may break if exposed to

sudden temperature changes or impact, such as bumping.

Tempered glass is designed to shatter into many small,

pebble-size pieces. This is normal. Glass shelves and covers

are heavy. Use both hands when removing them to avoid

dropping.

IIIL,,,,ooatio IIRequi eme ts

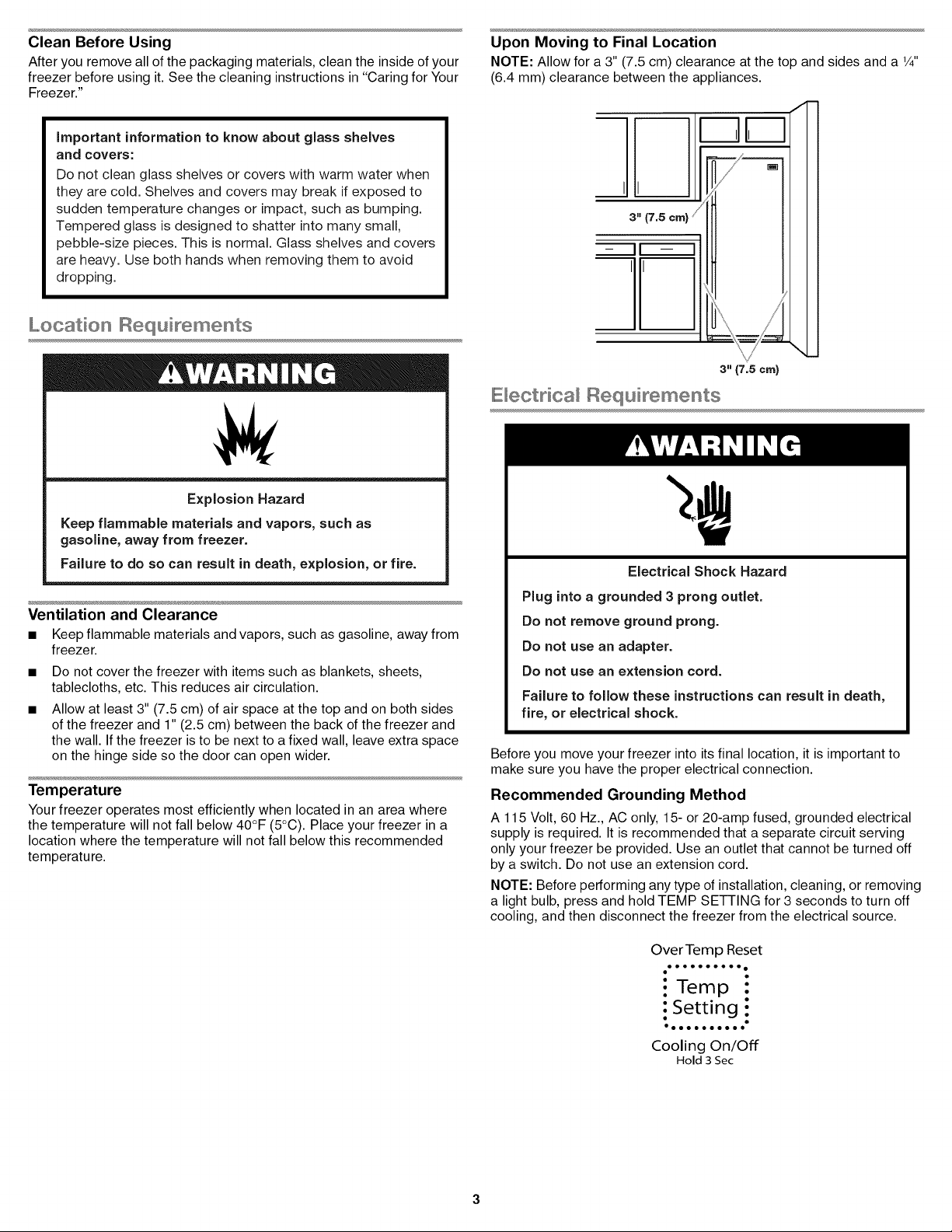

Upon Moving to Final Location

NOTE: Allow for a 3" (7.5 cm) clearance at the top and sides and a 1/4"

(6.4 mm) clearance between the appliances.

i i!!Ill

3" (7.5 crn)

IIE_eot_ies_ Requi_emeHts

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from freezer.

Failure to do so can result in death, explosion, or fire.

Ventilation and Clearance

• Keep flammable materials and vapors, such as gasoline, away from

freezer.

Do not cover the freezer with items such as blankets, sheets,

tablecloths, etc. This reduces air circulation.

Allow at least 3" (7.5 cm) of air space at the top and on both sides

of the freezer and 1" (2.5 cm) between the back of the freezer and

the wall. If the freezer is to be next to a fixed wall, leave extra space

on the hinge side so the door can open wider.

Temperature

Your freezer operates most efficiently when located in an area where

the temperature will not fall below 40°F (5°C). Place your freezer in a

location where the temperature will not fall below this recommended

temperature.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

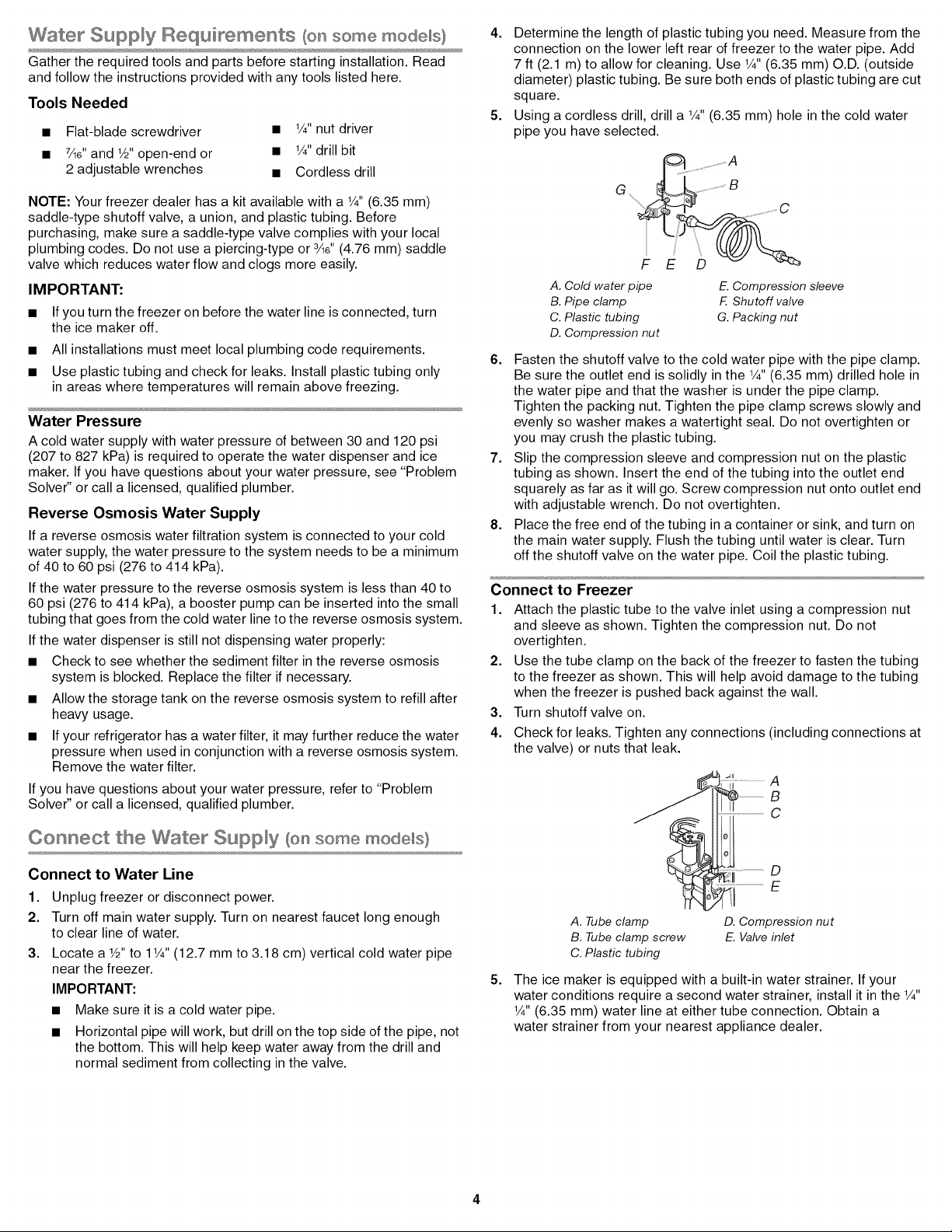

Before you move your freezer into its final location, it is important to

make sure you have the proper electrical connection.

Recommended Grounding Method

A 115 Volt, 60 Hz., AC only, 15- or 20-amp fused, grounded electrical

supply is required. It is recommended that a separate circuit serving

only your freezer be provided. Use an outlet that cannot be turned off

by a switch. Do not use an extension cord.

NOTE: Before performing any type of installation, cleaning, or removing

a light bulb, press and hold TEMP SETTING for 3 seconds to turn off

cooling, and then disconnect the freezer from the electrical source.

OverTemp Reset

oooooooooooe

i Temp

i Setting i

ooooooeoooe •

Cooling On/Off

Hold 3 Sec

Wate Supp)y IIAequi ements (on some mode s)

Gather the required tools and parts before starting installation. Read

and follow the instructions provided with any tools listed here.

Tools Needed

• Flat-blade screwdriver • 1/4"nut driver

• 7/le"and 1/2"open-end or • 1/4"drill bit

2 adjustable wrenches • Cordless drill

NOTE: Your freezer dealer has a kit available with a 1/4"(6.35 mm)

saddle-type shutoff valve, a union, and plastic tubing. Before

purchasing, make sure a saddle-type valve complies with your local

plumbing codes. Do not use a piercing-type or 3/le"(4.76 mm) saddle

valve which reduces water flow and clogs more easily.

IMPORTANT:

• If you turn the freezer on before the water line is connected, turn

the ice maker off.

• All installations must meet local plumbing code requirements.

• Use plastic tubing and check for leaks. Install plastic tubing only

in areas where temperatures will remain above freezing.

Water Pressure

A cold water supply with water pressure of between 30 and 120 psi

(207 to 827 kPa) is required to operate the water dispenser and ice

maker. If you have questions about your water pressure, see "Problem

Solver" or call a licensed, qualified plumber.

Reverse Osmosis Water Supply

If a reverse osmosis water filtration system is connected to your cold

water supply, the water pressure to the system needs to be a minimum

of 40 to 60 psi (276 to 414 kPa).

If the water pressure to the reverse osmosis system is less than 40 to

60 psi (276 to 414 kPa), a booster pump can be inserted into the small

tubing that goes from the cold water line to the reverse osmosis system.

If the water dispenser is still not dispensing water properly:

• Check to see whether the sediment filter in the reverse osmosis

system is blocked. Replace the filter if necessary.

• Allow the storage tank on the reverse osmosis system to refill after

heavy usage.

• If your refrigerator has a water filter, it may further reduce the water

pressure when used in conjunction with a reverse osmosis system.

Remove the water filter.

If you have questions about your water pressure, refer to "Problem

Solver" or call a licensed, qualified plumber.

4. Determine the length of plastic tubing you need. Measure from the

connection on the lower left rear of freezer to the water pipe. Add

7 ft (2.1 m) to allow for cleaning. Use 1/4"(6.35 mm) O.D. (outside

diameter) plastic tubing. Be sure both ends of plastic tubing are cut

square.

5. Using a cordless drill, drill a 1/4"(6.35 mm) hole in the cold water

pipe you have selected.

..........................A

A. Cold water pipe

B. Pipe clamp

C. Plastic tubing

D. Compression nut

E. Compression sleeve

F. Shutoff valve

G. Packing nut

6. Fasten the shutoff valve to the cold water pipe with the pipe clamp.

Be sure the outlet end is solidly in the 1/4"(6.35 mm) drilled hole in

the water pipe and that the washer is under the pipe clamp.

Tighten the packing nut. Tighten the pipe clamp screws slowly and

evenly so washer makes a watertight seal. Do not overtighten or

you may crush the plastic tubing.

7. Slip the compression sleeve and compression nut on the plastic

tubing as shown. Insert the end of the tubing into the outlet end

squarely as far as it will go. Screw compression nut onto outlet end

with adjustable wrench. Do not overtighten.

8. Place the free end of the tubing in a container or sink, and turn on

the main water supply. Flush the tubing until water is clear. Turn

off the shutoff valve on the water pipe. Coil the plastic tubing.

Connect to Freezer

1. Attach the plastic tube to the valve inlet using a compression nut

and sleeve as shown. Tighten the compression nut. Do not

overtighten.

2. Use the tube clamp on the back of the freezer to fasten the tubing

to the freezer as shown. This will help avoid damage to the tubing

when the freezer is pushed back against the wall.

3. Turn shutoff valve on.

4. Check for leaks. Tighten any connections (including connections at

the valve) or nuts that leak.

A

B

Connect the Water Supp)y (on some mode_s)

Connect to Water Line

1. Unplug freezer or disconnect power.

2. Turn off main water supply. Turn on nearest faucet long enough

to clear line of water.

3,

Locate a W' to 11/4"(12.7 mm to 3.18 cm) vertical cold water pipe

near the freezer.

IMPORTANT:

Make sure it is a cold water pipe.

Horizontal pipe will work, but drill on the top side of the pipe, not

the bottom. This will help keep water away from the drill and

normal sediment from collecting in the valve.

A. Tube clamp

B. Tube clamp screw

C. Plastic tubing

5,

The ice maker is equipped with a built-in water strainer. Ifyour

D. Compression nut

E. Valve inlet

water conditions require a second water strainer, install it in the 1/4"

1/4"(6.35 mm) water line at either tube connection. Obtain a

water strainer from your nearest appliance dealer.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

6. Plug into a grounded 3 prong outlet.

Remove and IIRep aoe [he, IIHa d ÷

To Remove the Handle:

1. Loosen the setscrews located on the side of handle at each end.

See "Door Swing Reversal and Handle Removal" graphic.

2. Remove the handle from the grommets.

To Replace the Handle:

1. Place the handle onto the grommets making sure the grommets

are fitted into the handle holes.

2. Tighten the upper and lower setscrews with the hex key provided.

See "Door Swing Reversal and Handle Removal" graphic. Do not

overtighten the setscrews.

IIIP eeze "IIDoo

Tools Needed: %e" hex-head socket wrench, 3/8"hex-head socket

wrench, flat 2" putty knife.

IMPORTANT:

• All graphics referenced in the following instructions are included

later inthis section after "Final Steps." The graphics shown are for a

right-hand swing door (hinges factory installed on the right).

• If you only want to remove and replace the door, see the "Remove

Door and Hinges" and "Replace Door and Hinges."

• Before you begin, turn the control OFF, and remove food and

adjustable door or utility bins from door.

Reverse Door (optional on some models)

IMPORTANT: If you want to reverse your door so that it opens in the

opposite direction, continue with "Reverse Door (optional on some

models)" instructions. If you are not reversing the door, see "Replace

Door and Hinges."

Cabinet

1. Remove the cabinet hinge hole plugs from the cabinet top and

move them to the opposite side hinge holes as shown in

Graphic 2.

2. Remove the bottom hinge pin from the hinge bracket.

3. Remove the decals covering the holes on the opposite side of the

bottom hinge.

4. Reinstall the bottom hinge pin in the alternate hole in the hinge

bracket. See Graphic 3.

5. Reinstall the hinge bracket to the cabinet with the 4 hex-head

hinge screws.

Door

1. Remove the hinge thimble hole plug from the top of the door. See

Graphic 4.

2. Remove the door stop from the bottom of the door.

3. Move the door stop to the opposite side making sure that the hole

in the door stop plate is aligned perfectly with the hole in the door

for the bottom hinge pin.

4.

Using the screws removed in Step 2, fasten the door stop bracket

to the bottom of the door.

5.

Tighten all screws. Set aside the door until the bottom hinge is in

place.

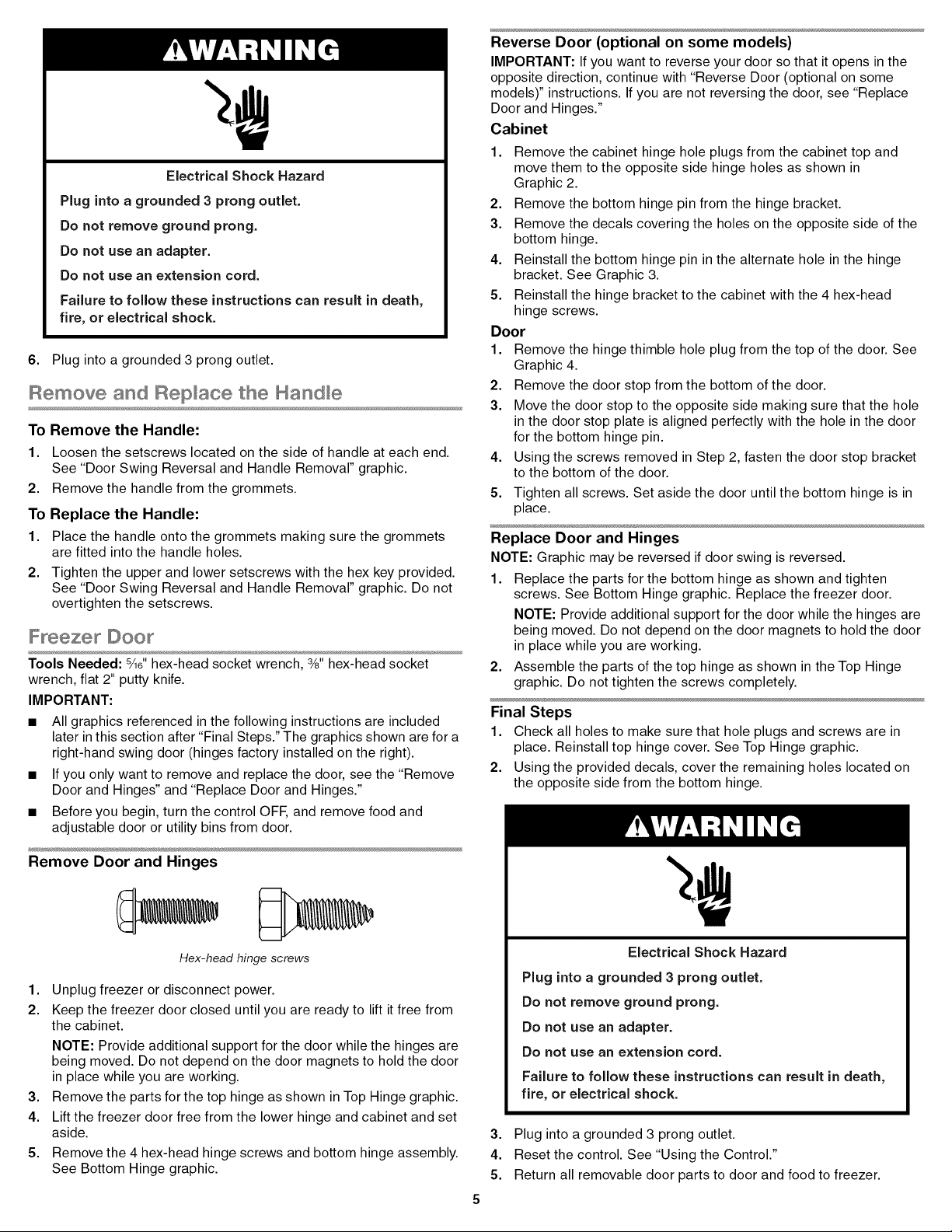

Replace Door and Hinges

NOTE: Graphic may be reversed if door swing is reversed.

1. Replace the parts for the bottom hinge as shown and tighten

screws. See Bottom Hinge graphic. Replace the freezer door.

NOTE: Provide additional support for the door while the hinges are

being moved. Do not depend on the door magnets to hold the door

in place while you are working.

2. Assemble the parts of the top hinge as shown in the Top Hinge

graphic. Do not tighten the screws completely.

Final Steps

1. Check all holes to make sure that hole plugs and screws are in

place. Reinstall top hinge cover. See Top Hinge graphic.

2. Using the provided decals, cover the remaining holes located on

the opposite side from the bottom hinge.

Remove Door and Hinges

Hex-head hinge screws

1. Unplug freezer or disconnect power.

2. Keep the freezer door closed until you are ready to lift it free from

the cabinet.

NOTE: Provide additional support for the door while the hinges are

being moved. Do not depend on the door magnets to hold the door

in place while you are working.

3.

Remove the parts for the top hinge as shown in Top Hinge graphic.

4.

Lift the freezer door free from the lower hinge and cabinet and set

aside.

5.

Remove the 4 hex-head hinge screws and bottom hinge assembly.

See Bottom Hinge graphic.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

3. Plug into a grounded 3 prong outlet.

4. Reset the control. See "Using the Control."

5. Return all removable door parts to door and food to freezer.

Top Hinge

A. Top Hinge Cover

B, 5/18" Hex-Head Hinge Screws

C. Top Hinge

Bottom Hinge

B

A, Hinge Pin

B, 3/8" Hex-Head Hinge Screws

A. Cabinet HingeHole Plugs

ic

A. Grommet

B, Handle

C, Setscrews

A. Hinge Pin

B, 3/8"Hex-Head Hinge Screws

IIF eeze Illevening and IIIDoo O osing

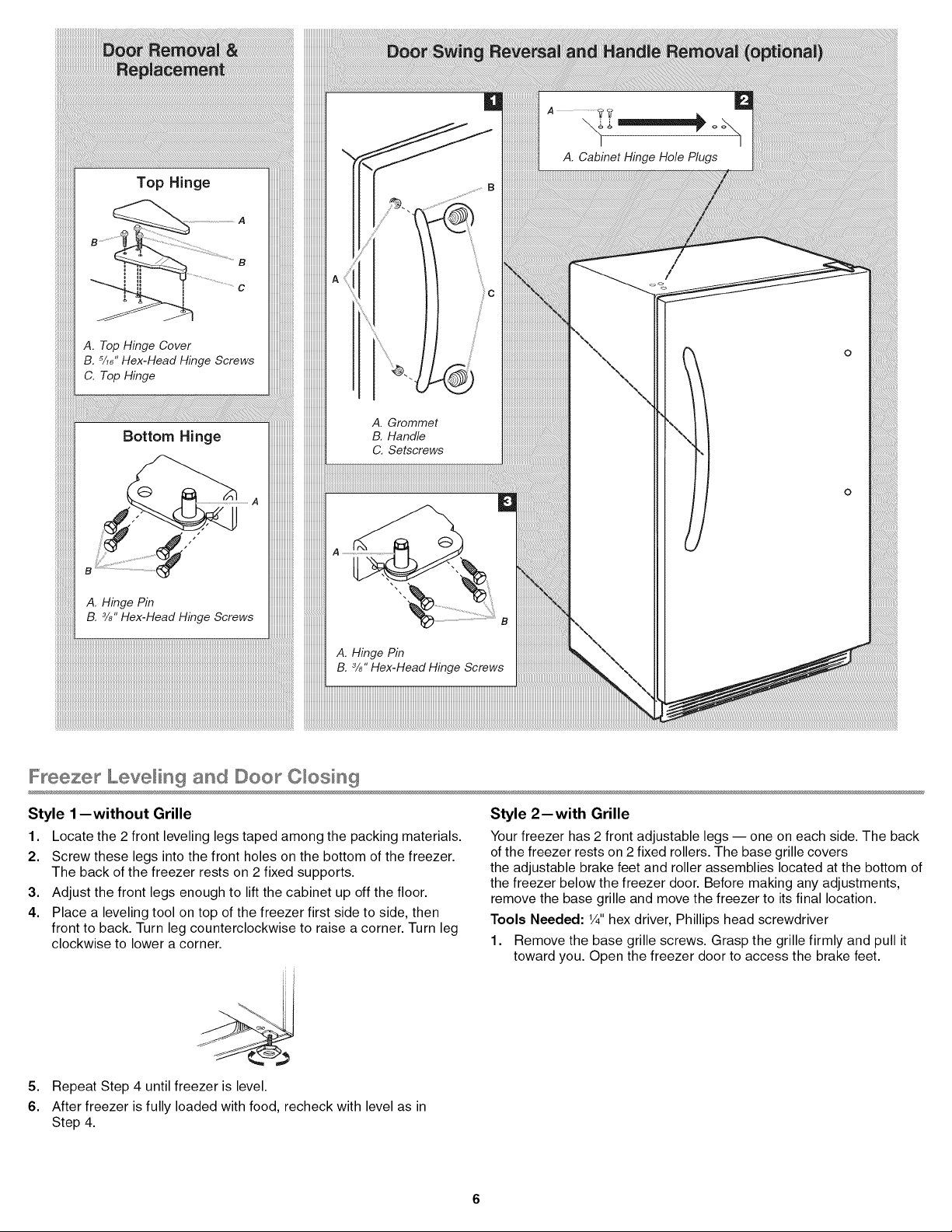

Style 1--without Grille

1. Locate the 2 front leveling legs taped among the packing materials.

2. Screw these legs into the front holes on the bottom of the freezer.

The back of the freezer rests on 2 fixed supports.

3. Adjust the front legs enough to lift the cabinet up off the floor.

4. Place a leveling tool on top of the freezer first side to side, then

front to back. Turn leg counterclockwise to raise a corner. Turn leg

clockwise to lower a corner.

5. Repeat Step 4 until freezer is level.

6. After freezer is fully loaded with food, recheck with level as in

Step 4.

Style 2--with Grille

Your freezer has 2 front adjustable legs i one on each side. The back

of the freezer rests on 2 fixed rollers. The base grille covers

the adjustable brake feet and roller assemblies located at the bottom of

the freezer below the freezer door. Before making any adjustments,

remove the base grille and move the freezer to its final location.

Tools Needed: 1/4"hex driver, Phillips head screwdriver

1. Remove the base grille screws. Grasp the grille firmly and pull it

toward you. Open the freezer door to access the brake feet.

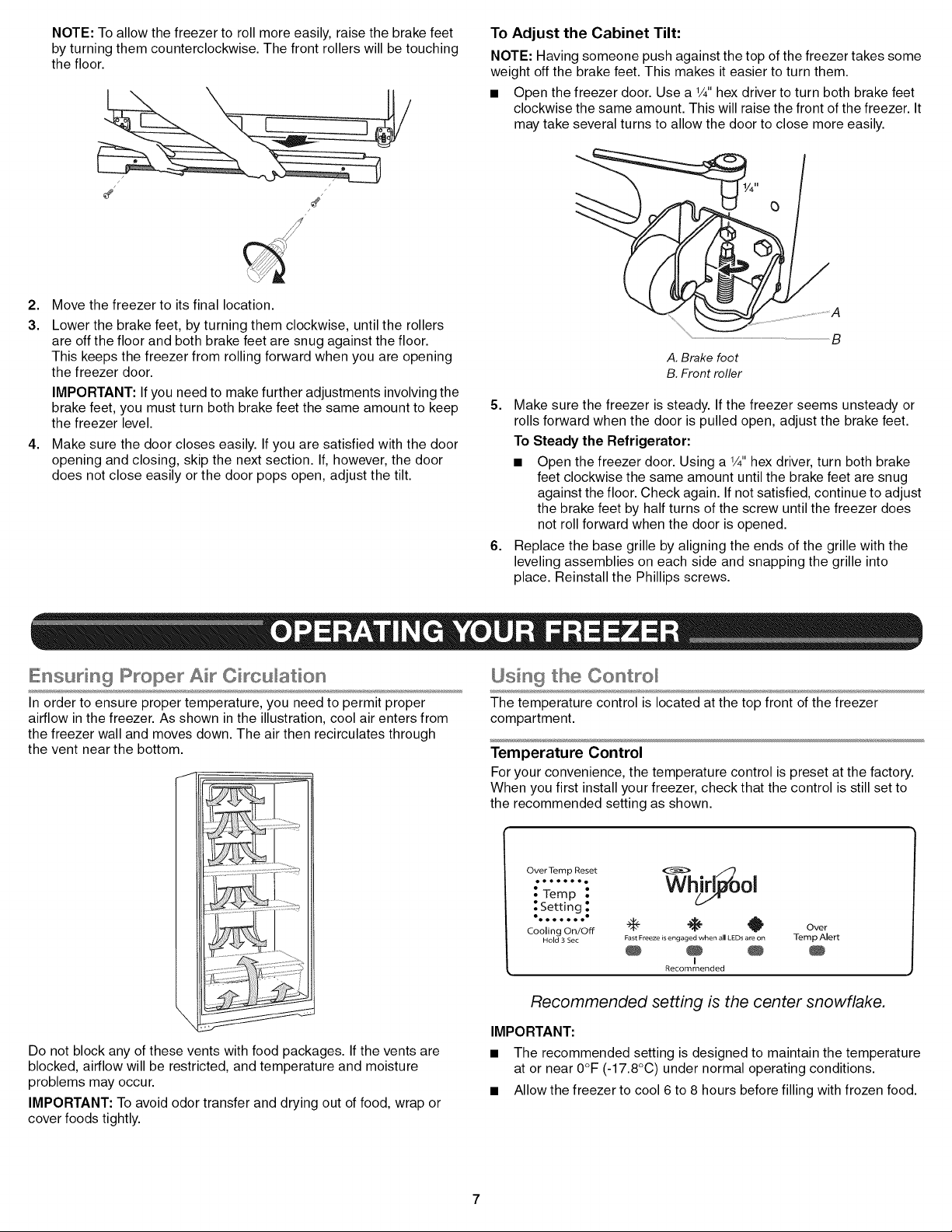

NOTE:Toallowthefreezertorollmoreeasily,raisethebrakefeet

byturningthemcounterclockwise.Thefrontrollerswillbetouching

thefloor.

2,

Move the freezer to its final location.

3.

Lower the brake feet, by turning them clockwise, until the rollers

are off the floor and both brake feet are snug against the floor.

This keeps the freezer from rolling forward when you are opening

the freezer door.

IMPORTANT: Ifyou need to make further adjustments involving the

brake feet, you must turn both brake feet the same amount to keep

the freezer level.

4,

Make sure the door closes easily. If you are satisfied with the door

opening and closing, skip the next section. If, however, the door

does not close easily or the door pops open, adjust the tilt.

To Adjust the Cabinet Tilt:

NOTE: Having someone push against the top of the freezer takes some

weight off the brake feet. This makes it easier to turn them.

• Open the freezer door. Use a 1/4"hex driver to turn both brake feet

clockwise the same amount. This will raise the front of the freezer. It

may take several turns to allow the door to close more easily.

/

A. Brake foot

B. Front roller

5. Make sure the freezer is steady. Ifthe freezer seems unsteady or

rolls forward when the door is pulled open, adjust the brake feet.

To Steady the Refrigerator:

• Open the freezer door. Using a 1/4"hex driver, turn both brake

feet clockwise the same amount until the brake feet are snug

against the floor. Check again. If not satisfied, continue to adjust

the brake feet by half turns of the screw until the freezer does

not roll forward when the door is opened.

6. Replace the base grille by aligning the ends of the grille with the

leveling assemblies on each side and snapping the grille into

place. Reinstall the Phillips screws.

In order to ensure proper temperature, you need to permit proper

airflow in the freezer. As shown in the illustration, cool air enters from

the freezer wall and moves down. The air then recirculates through

the vent near the bottom.

Do not block any of these vents with food packages. If the vents are

blocked, airflow will be restricted, and temperature and moisture

problems may occur.

IMPORTANT: To avoid odor transfer and drying out of food, wrap or

cover foods tightly.

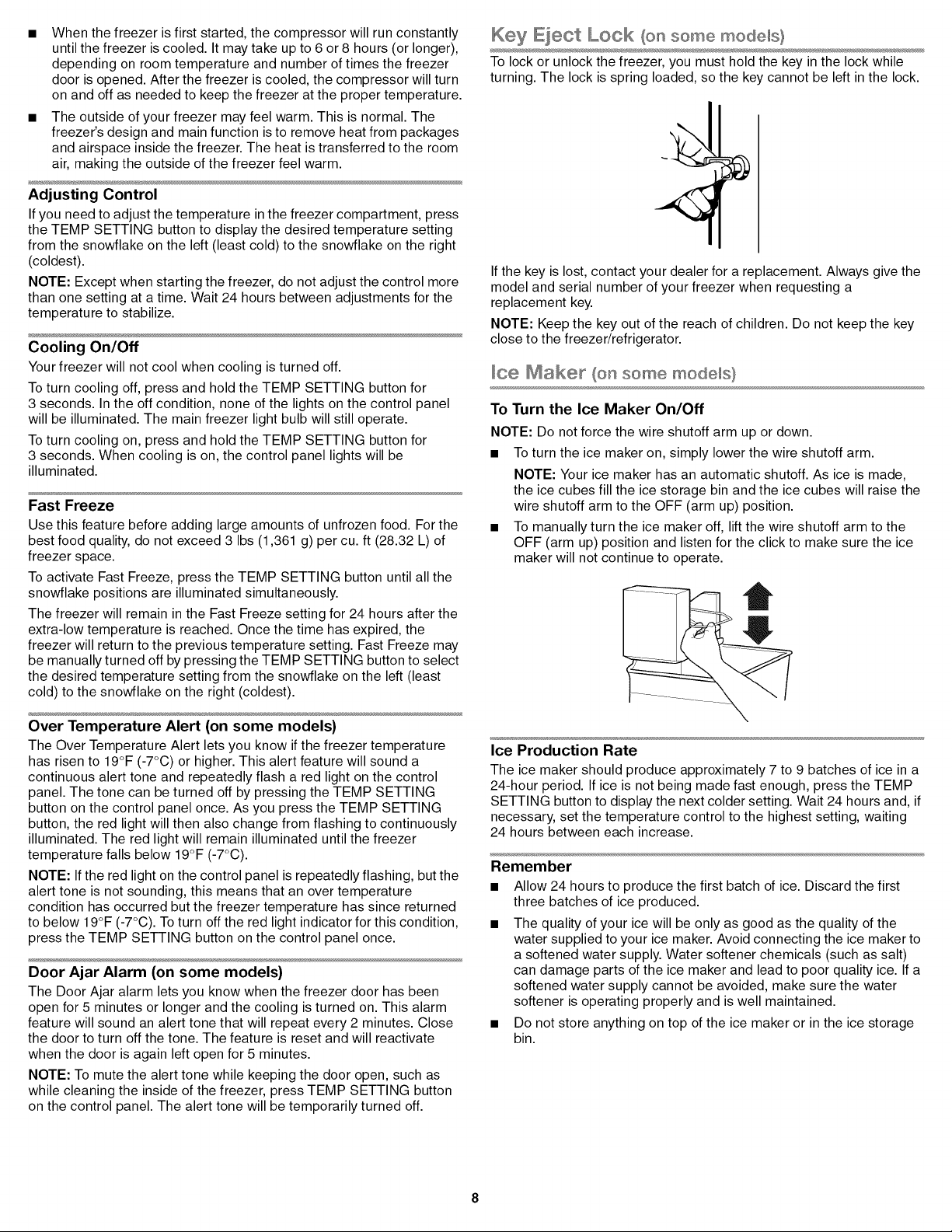

Using the Con tro

The temperature control is located at the top front of the freezer

compartment.

Temperature Control

For your convenience, the temperature control is preset at the factory.

When you first install your freezer, check that the control is still set to

the recommended setting as shown.

; Setting ;

eoooeooo °

Cooling On/Off "_ '_ O Over

Hold S Se( Fast Freeze is engaged when all LEDs are on Temp Alert

I

Recommended

Recommended setting is the center snowflake.

IMPORTANT:

• The recommended setting is designed to maintain the temperature

at or near 0°F (-17.8°C) under normal operating conditions.

• Allow the freezer to cool 6 to 8 hours before filling with frozen food.

Whenthefreezerisfirststarted,thecompressorwillrunconstantly

untilthefreezeriscooled.Itmaytakeupto6or8hours(orlonger),

dependingonroomtemperatureandnumberoftimesthefreezer

doorisopened.Afterthefreezeriscooled,thecompressorwillturn

onandoffasneededtokeepthefreezeratthepropertemperature.

Theoutsideofyourfreezermayfeelwarm.Thisisnormal.The

freezer'sdesignandmainfunctionistoremoveheatfrompackages

andairspaceinsidethefreezer.Theheatistransferredtotheroom

air,makingtheoutsideofthefreezerfeelwarm.

AdjustingControl

Ifyouneedtoadjustthetemperatureinthefreezercompartment,press

theTEMPSETTINGbuttontodisplaythedesiredtemperaturesetting

fromthesnowflakeontheleft(leastcold)tothesnowflakeontheright

(coldest).

NOTE:Exceptwhenstartingthefreezer,donotadjustthecontrolmore

thanonesettingatatime.Wait24hoursbetweenadjustmentsforthe

temperaturetostabilize.

Cooling On/Off

Your freezer will not cool when cooling is turned off.

Toturn cooling off, press and hold the TEMP SETTING button for

3 seconds. In the off condition, none of the lights on the control panel

will be illuminated. The main freezer light bulb will still operate.

Toturn cooling on, press and hold the TEMP SETTING button for

3 seconds. When cooling is on, the control panel lights will be

illuminated.

Fast Freeze

Use this feature before adding large amounts of unfrozen food. For the

best food quality,do not exceed 3 Ibs (1,361 g) per cu. ft (28.32 L) of

freezer space.

To activate Fast Freeze, press the TEMP SETTING button until all the

snowflake positions are illuminated simultaneously.

The freezer will remain in the Fast Freeze setting for 24 hours after the

extra-low temperature is reached. Once the time has expired, the

freezer will return to the previous temperature setting. Fast Freeze may

be manually turned off by pressing the TEMP SETTING button to select

the desired temperature setting from the snowflake on the left (least

cold) to the snowflake on the right (coldest).

Key IEieot Look (on sore÷ it"node,s)

To lock or unlock the freezer, you must hold the key in the lock while

turning. The lock is spring loaded, so the key cannot be left in the lock.

If the key is lost, contact your dealer for a replacement. Always give the

model and serial number of your freezer when requesting a

replacement key.

NOTE: Keep the key out of the reach of children. Do not keep the key

close to the freezer/refrigerator.

Ill)coMaker (on some mode_s)

To Turn the Ice Maker On/Off

NOTE: Do not force the wire shutoff arm up or down.

• To turn the ice maker on, simply lower the wire shutoff arm.

NOTE: Your ice maker has an automatic shutoff. As ice is made,

the ice cubes fill the ice storage bin and the ice cubes will raise the

wire shutoff arm to the OFF (arm up) position.

• To manually turn the ice maker off, lift the wire shutoff arm to the

OFF (arm up) position and listen for the click to make sure the ice

maker will not continue to operate.

Over Temperature Alert (on some models)

The Over Temperature Alert lets you know if the freezer temperature

has risen to 19°F (-7°C) or higher. This alert feature will sound a

continuous alert tone and repeatedly flash a red light on the control

panel. The tone can be turned off by pressing the TEMP SETTING

button on the control panel once. As you press the TEMP SETTING

button, the red light will then also change from flashing to continuously

illuminated. The red light will remain illuminated until the freezer

temperature falls below 19°F (-7°C).

NOTE: If the red light on the control panel is repeatedly flashing, but the

alert tone is not sounding, this means that an over temperature

condition has occurred but the freezer temperature has since returned

to below 19°F (-7°C). To turn off the red light indicator for this condition,

press the TEMP SETTING button on the control panel once.

Door Ajar Alarm (on some models)

The Door Ajar alarm lets you know when the freezer door has been

open for 5 minutes or longer and the cooling is turned on. This alarm

feature will sound an alert tone that will repeat every 2 minutes. Close

the door to turn off the tone. The feature is reset and will reactivate

when the door is again left open for 5 minutes.

NOTE: To mute the alert tone while keeping the door open, such as

while cleaning the inside of the freezer, press TEMP SETTING button

on the control panel. The alert tone will be temporarily turned off.

Ice Production Rate

The ice maker should produce approximately 7 to 9 batches of ice in a

24-hour period. If ice is not being made fast enough, press the TEMP

SETTING button to display the next colder setting. Wait 24 hours and, if

necessary, set the temperature control to the highest setting, waiting

24 hours between each increase.

Remember

• Allow 24 hours to produce the first batch of ice. Discard the first

three batches of ice produced.

• The quality of your ice will be only as good as the quality of the

water supplied to your ice maker. Avoid connecting the ice maker to

a softened water supply. Water softener chemicals (such as salt)

can damage parts of the ice maker and lead to poor quality ice. If a

softened water supply cannot be avoided, make sure the water

softener is operating properly and is well maintained.

• Do not store anything on top of the ice maker or in the ice storage

bin.

8

Thismanualcoversseveraldifferentmodels.Thefreezeryouhave StorageGate(onsomemodels)

purchasedmayhavesomeoralloftheitemslisted.Thelocationsof

thefeaturesmaynotmatchthoseofyourmodel.

Door Bin

To Remove and Replace the Bin:

1. Remove the bin by tipping the front of the bin forward and sliding

out.

2. Replace the bin by sliding it in above the desired support tilting it

back into place.

Storage Basket (on some models)

The slide out basket provides separate storage space for items that are

difficult to store on freezer shelves. To remove the basket, pull out and

lift up.

To Remove the Storage Gate:

1. Lift up the top of the gate and out of the supports.

2. Return the gate to original position. Lower the gate into the

supports.

Freezer Shelves

Store similar foods together and adjust the shelves to fit different

heights. This reduces the time the freezer door is open and saves

energy.

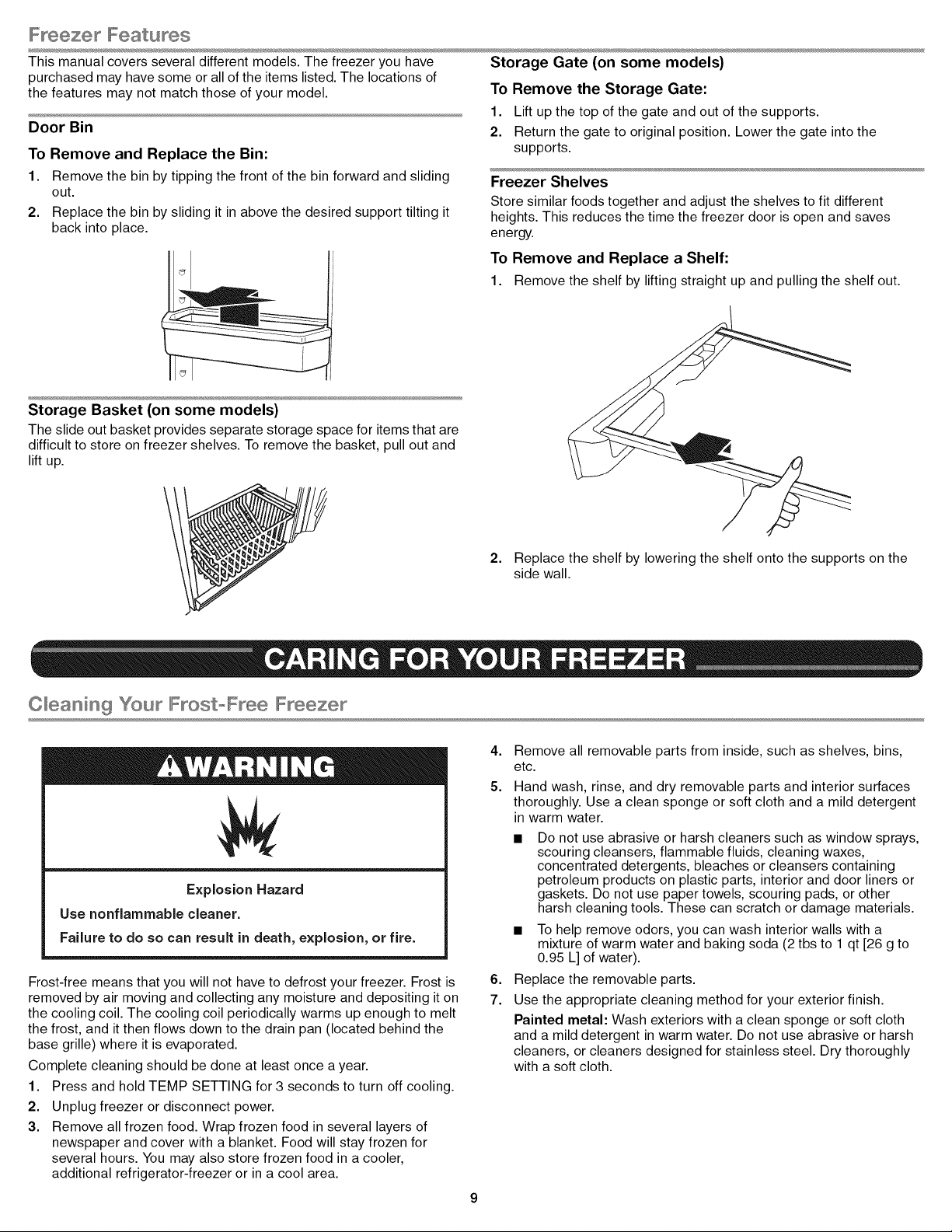

To Remove and Replace a Shelf:

1. Remove the shelf by lifting straight up and pulling the shelf out.

Oleaning Your IIIF: os W ee IIIF: eeze

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Frost-free means that you will not have to defrost your freezer. Frost is

removed by air moving and collecting any moisture and depositing it on

the cooling coil. The cooling coil periodically warms up enough to melt

the frost, and it then flows down to the drain pan (located behind the

base grille) where it is evaporated.

Complete cleaning should be done at least once a year.

1. Press and hold TEMP SETTING for 3 seconds to turn off cooling.

2. Unplug freezer or disconnect power.

3. Remove all frozen food. Wrap frozen food in several layers of

newspaper and cover with a blanket. Food will stay frozen for

several hours. You may also store frozen food in a cooler,

additional refrigerator-freezer or in a cool area.

2. Replace the shelf by lowering the shelf onto the supports on the

side wall.

4.

Remove all removable parts from inside, such as shelves, bins,

etc.

5.

Hand wash, rinse, and dry removable parts and interior surfaces

thoroughly. Use a clean sponge or soft cloth and a mild detergent

in warm water.

• Do not use abrasive or harsh cleaners such as window sprays,

scouring cleansers, flammable fluids, cleaning waxes,

concentrated detergents, bleaches or cleansers containing

petroleum products on plastic parts, interior and door liners or

gaskets. Do not use paper towels, scouring pads, or other

harsh cleaning tools. These can scratch or damage materials.

• To help remove odors, you can wash interior walls with a

mixture of warm water and baking soda (2 tbs to 1 qt [26 g to

0.95 L] of water).

6.

Replace the removable parts.

7.

Use the appropriate cleaning method for your exterior finish.

Painted metal: Wash exteriors with a clean sponge or soft cloth

and a mild detergent in warm water. Do not use abrasive or harsh

cleaners, or cleaners designed for stainless steel. Dry thoroughly

with a soft cloth.

8.

Clean the condenser coils regularly. Coils may need to be cleaned

as often as every other month. This may help save energy.

• Open the freezer door and remove the base grille by removing

2 Phillips-head screws and pulling the grille toward you.

\'/X

• Use a vacuum with an extended attachment to clean the

condenser coils when they are dusty or dirty.

• Replace the base grille by aligning the ends of the grille with the

leveling assemblies on each side and snapping the grille into

place. Reinstall the screws.

9. Replace all frozen food.

10. Plug in freezer or reconnect power.

11. Set temperature control to desired setting. See "Using the

Control."

Changing the Light Bulb

NOTE: Not all appliance bulbs will fit your freezer. Be sure to replace

the bulb with an appliance bulb of the same size, shape, and wattage.

1. Unplug freezer or disconnect power.

2. Remove the light shield by squeezing the lens from the sides,

pushing back and pulling down.

Power IIIn errup ions

If the power will be out for 24 hours or less, keep the door closed to help

food stay cold and frozen.

If the power will be out for more than 24 hours, do one of the following:

• Remove allfrozen food and store it in a frozen food locker.

• If a food locker is not available, consume or can perishable food at

once.

REMEMBER: A full freezer stays cold longer than a partially filled one.

A freezer full of meat stays cold longer than a freezer full of baked

goods. If you see that food contains ice crystals, it may be refrozen,

although the quality and flavor may be affected. Ifthe condition of the

food is poor, dispose of it.

Moving Care

When you are moving your freezer to a new home, follow these steps to

prepare it for the move.

1. Remove all frozen food.

2. Unplug the freezer.

3. Take out all removable parts, wrap them well, and tape them

together so they don't shift and rattle during the move.

4. Clean the freezer thoroughly.

5. Tape the freezer shut and tape the electrical cord to the cabinet.

When you get to your new home, refer to the "Installing Your Freezer"

and "Operating Your Freezer" sections for information on installation

and setting the controls.

3. Replace bulb with a 40-watt maximum appliance bulb or an LED

rated for wet/damp locations.

NOTE: Some LED replacement light bulbs are not recommended

for wet/damp environments. Refrigerator fresh food and freezer

compartments are considered wet/damp environments. Read

and follow all instructions on the LED packaging when replacing

the faactory installed LED bulb. A replacement LED bulb can be

purchased from an authorized dealer.

4. Replace the light shield.

5. Plug in freezer or reconnect power.

10

Firsttrythesolutionssuggestedhere.Ifyouneedfurtherassistanceormorerecommendationsthatmayhelpyouavoidaservicecall,refertothe

warrantypageinthismanualandscanthecodetherewithyourmobiledevice,orvisitwww.whirlpool.com/product_helpforrecommendations

thatmayhelpyouavoidaservicecall.InCanada,visithttp://www.whirlpool.ca.

Contactusbymailwithanyquestionsorconcernsattheaddressbelow:

IntheU.S.A.:

WhirlpoolBrandHomeAppliances

CustomereXperienceCenter

553BensonRoad

BentonHarbor,MI49022-2692

InCanada:

WhirlpoolBrandHomeAppliances

CustomereXperienceCentre

200- 6750CenturyAve.

MississaugaONL5N0B7

Pleaseincludeadaytimephonenumberinyourcorrespondence

IIIP eeze ©pe ation

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

FaiJure to folJow these instructions can result in death,

fire, or electrical shock.

PROBLEM RECOMMENDED SOLUTIONS

Freezer Will Not Operate

Lights Do Not Work

Water in Defrost Drain Pan

Motor Seems to Run Too

Much

Temperature Is Too Warm

Check that the freezer is not running an automatic defrost cycle.

Check that it is plugged into a grounded 3 prong outlet.

Check that the temperature control is turned on.

Replace the fuse or reset the circuit breaker.

NOTE: If problems continue, contact an electrician.

Check that it is plugged into a grounded 3 prong outlet.

Check that the light bulb is tight in the socket and is not burned out.

It is normal for water to drip into the defrost drain pan when freezer is defrosting.

When humidity is high, it is normal for water in the defrost pan to take longer to evaporate.

Check that door closes properly.

Defrost and clean the freezer to remove excessive frost.

Adding a large amount of food warms the freezer causing the freezer to run longer to cool back down. If this is

the situation, wait approximately 6 to 8 hours to allow the freezer to reach the correct temperature.

Get all items out at one time, keep food organized and close door as soon as possible.

Check that the door gasket is sealed all the way around. If not, contact a qualified person or technician.

Check that space around freezer meets air circulation requirements. See "Location Requirements."

NOTE: If none of the above, your new freezer will run longer than your old one due to its high-efficiency motor.

Check that air vents are clear. See "Ensuring Proper Air Circulation" for air vent locations.

Get all items out at one time, keep food organized and close door as soon as possible.

Adding a large amount of food warms the freezer causing the freezer to run longer to cool back down.

Check that the temperature control is set correctly for surrounding conditions.

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

11

PROBLEM

RECOMMENDED SOLUTIONS

The Door Will Not Close

Completely or Is Difficult To

Open

Freezer Makes Loud Buzzing/

Clicking Sound

IIIIoeIIP oduoti©

Check that there are no food packages blocking the door.

On some models, check that the shelves and basket are in the correct position.

Check that gaskets are clean. See "Caring for Your Freezer."

Check that the freezer is stable. See "Freezer Leveling and Door Closing."

Ifthe freezer has recently been plugged in or turned on following a defrost or product move, or if there has been

an extended power failure, turn off the temperature alarm for the next 24 hours.

Adding a large amount of food warms the freezer. It can take several hours for the freezer to return to normal

temperature. Turn the temperature alarm off for the next 24 hours.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

PROBLEM

Ice Maker Produces No Ice or

Very Little Ice

IIIIoe©ua ity

Off Taste, Odor or Gray Color

in the Ice

Thin, Soft or Clumps of Ice

RECOMMENDED SOLUTIONS

If ice maker has just been installed, wait 72 hours for full ice production to begin.

Check that the temperature control is cold enough.

Check that the wire shutoff arm is in the ON (arm down) position.

Check that the water supply is properly connected and turned on.

Check that the ejector arm is not blocked by an ice cube.

If a large amount of ice has been removed recently, allow 24 hours to produce more ice.

NOTE: If not due to any of the above, there may be a problem with the water line. Call for service.

RECOMMENDED SOLUTIONSPROBLEM

Discard the first few batches of ice.

If there is unusually high mineral content in the water supply, the water may need to be treated.

If there is mineral scale buildup, clean your ice maker mold.

If the ice cubes have been stored too long, throw the old ice away and make a new supply.

Check that the freezer and ice bin are clean.

If there is unusually high mineral content in the water supply, the water may need to be treated.

If there is mineral scale buildup, clean your ice maker.

Ifthere are clumps of ice in the bin and if ice is not used regularly, it will melt and form clumps. Break the clumps

with the ice scoop provided.

12

WHIRLPOOL ®

MAJOR APPLIANCE

LIMITED WARRANTY

ATTACH YOUR RECEIPT HERE. PROOF OF PURCHASE IS REQUIRED

TO OBTAIN WARRANTY SERVICE.

Please have the following information available when you call the

Customer eXperience Center:

• Name, address and telephone number

• Model number and serial number

• A clear, detailed description of the problem

• Proof of purchase including dealer or retailer name and address

IF YOU NEED SERVICE:

1. Before contacting us to arrange service, please determine whether your product requires repair. Some

questions can be addressed without service. Please take a few minutes to review the Troubleshooting or

Problem Solver section of the Use and Care Guide, scan the QR code on the right to access additional

resources, or visit www.whirlpool.com/product help.

2. All warranty service is provided exclusively by our authorized Whirlpool Service Providers. In the U.S. and

Canada, direct all requests for warranty service to:

Whirlpool Customer eXperience Center

In the U.S.A., call 1-800-253-1301. In Canada, call 1-800-807-6777.

If outside the 50 United States or Canada, contact your authorized Whirlpool dealer to determine whether another

warranty applies.

For one year from the date of purchase, when this major

appliance is installed, operated and maintained according to

instructions attached to or furnished with the product, Whirlpool

Corporation or Whirlpool Canada LP (hereafter "Whirlpool") will

pay for Factory Specified Replacement Parts and repair labor

to correct defects in materials or workmanship that existed

when this major appliance was purchased, or at its sole

discretion replace the product. In the event of product

replacement, your appliance will be warranted for the remaining

term of the original unit's warranty period.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS

LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS

PROVIDED HEREIN. Service must be provided by a Whirlpool

designated service company. This limited warranty is valid only

in the United States or Canada and applies only when the

major appliance is used in the country in which it was

purchased. This limited warranty is effective from the date of

original consumer purchase. Proof of original purchase date is

required to obtain service under this limited warranty.

1. Commercial, non-residential, multiple-family use, or use inconsistent with published

user, operator or installation instructions.

2. In-home instruction on how to use your product.

3. Service to correct improper product maintenance or installation, installation not in

accordance with electrical or plumbing codes or correction of household electrical

or plumbing (i.e. house wiring, fuses or water inlet hoses).

4. Consumable parts (i.e. light bulbs, batteries, air or water filters, preservation

solutions, etc.).

5. Conversion of products from natural gas or L.R gas.

6. Damage from accident, misuse, abuse, fire, floods, acts of God or use with products

not approved by Whirlpool.

7. Repairs to parts or systems to correct product damage or defects caused by

unauthorized service, alteration or modification of the appliance.

8. Cosmetic damage including scratches, dents, chips, and other damage to the

appliance finishes unless such damage results from defects in materials and

workmanship and is reported to Whirlpool within 30 days.

9. Discoloration, rust or oxidation of surfaces resulting from caustic or corrosive

environments including but not limited to high salt concentrations, high moisture or

humidity or exposure to chemicals.

10. Food or medicine loss due to product failure.

11. Pick-up or delivery. This product is intended for in-home repair.

12. Travel or transportation expenses for service in remote locations where an

authorized Whirlpool servicer is not available.

13. Removal or reinstallation of inaccessible appliances or built-in fixtures (i.e. trim,

decorative panels, flooring, cabinetry, islands, countertops, drywall, etc.) that

interfere with servicing, removal or replacement of the product.

14. Service or parts for appliances with original model/serial numbers removed, altered

or not easily determined.

The cost of repair or replacement under these excluded circumstances shall

be borne by the customer.

[]

E]

www.whirlpool.com/product_help

DISCLAIMER OF IMPLIED WARRANTIES

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. Some states and provinces do not allow

limitations on the duration of implied warranties of merchantability or fitness, so this limitation may not apply to you. This warranty gives you specific legal

rights, and you also may have other rights that vary from state to state or province to province.

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

Whirlpool makes no representations about the quality, durability, or need for service or repair of this major appliance other than the representations

contained in this warranty. If you want a longer or more comprehensive warranty than the limited warranty that comes with this major appliance, you

should ask Whirlpool or your retailer about buying an extended warranty.

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN. WHIRLPOOL

SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states and provinces do not allow the exclusion or limitation of

incidental or consequential damages, so these limitations and exclusions may not apply to you. This warranty gives you specific legal rights, and you

also may have other rights that vary from state to state or province to province.

13

1/14

Guide d'utilisation

Congelateur vertical

Nous vous REMERCIONS d'avoir achet6 ce produit de haute qualit& Enregistrer le cong61ateur sur www.whirlpool.com. Au Canada, enregistrer le

cong61ateur sur www.wh irlpool.ca.

Pour r6f6rence ult6rieure, consignez par 6crit les num6ros de modele et de s6rie de votre produit. Vous trouverez les num6ros de modele et de s6rie &

I'int6rieur du cong61ateur.

Num6ro de modele .........................................

Num6ro de s6rie ...........................................

SI_CURITI_ ............................................................................................ 14

INSTALLATION DU CONGI_LATEUR ................................................ 15

D6ballage .......................................................................................... 15

Exigences d'emplacement ............................................................... 16

Sp6cifications electriques ................................................................. 16

Sp6cifications de I'alimentation en eau ............................................ 17

Raccordement de la canalisation d'alimentation en eau ................. 17

Retrait et r6installation de la poignee ............................................... 18

Porte du cong61ateur ........................................................................ 18

Nivellement du congelateur et fermeture de la porte ...................... 20

UTILISATION DU CONGI_LATEUR ................................................... 21

Pour s'assurer d'une circulation d'air appropri6e ............................ 21

Utilisation de la commande .............................................................. 21

Serrure & ejection de cle ................................................................... 22

Machine & gla£:ons ............................................................................ 22

Caract6ristiques du cong61ateur ...................................................... 23

ENTRETIEN DU CONGleLATEUR .................................................... 23

Nettoyage du cong61ateur sans givre ............................................. 23

Remplacement de I'ampoule d'6clairage ....................................... 24

Pannes de courant 61ectrique ......................................................... 24

D6m6nagement ............................................................................... 24

RI_SOLUTION DE PROBLF:MES ...................................................... 25

Fonctionnement du congelateur ..................................................... 25

Production de gla£;ons .................................................................... 26

Qualit6 des gla£;ons......................................................................... 26

GARANTIE .......................................................................................... 27

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de securite importants dans ce manuel et sur votre appareil menager. Assurez-vous de

toujours lire tous les messages de s_curite et de vous y conformer.

Voici le symbole d'alerte de s6curit6.

Ce symbole d'alerte de securit6 vous signale les dangers potentiels de deces et de blessures graves & vous et b.

d'autres.

Tous les messages de securit6 suivront le symbole d'alerte de securit6 et le mot "DANGER" ou "AVERTISSEMENT".

Ces roots signifient :

imm6diatement les instructions.

Risque possible de d_c_s ou de blessure grave si vous ne suivez pas

lesRiSqueinstructions.P°ssiblede d_c_s ou de blessure grave si vous ne suivez pas

Tous les messages de s6curit_ vous diront quel est le danger potentiel et vous disent comment reduire le risque de blessure et ce qui peut

se produire en cas de non-respect des instructions.

llVlPORTANTES iNSTRUCTiONS DE SI_CURITE

AVERTISSEIVlENT : Pour reduire les risques d'incendie, de choc 61ectrique ou des blessures Iors de I'utilisation du

cong61ateur, prendre quelques pr6cautions fondamentales, y compris les suivantes :

• Brancher I'appareil sur une prise #,3 alv6oles reli6e &la terre.

• Ne pas enlever la broche de liaison & la terre.

• Ne pas utiliser un adaptateur.

• Ne pas utiliser un c&ble de rallonge.

• D6brancher la source de courant 61ectrique avant I'entretien.

• Replacer pieces et panneaux avant de faire la remise en

marche.

• Utiliser un produit de nettoyage ininflammable.

• Garder les mat6riaux et les vapeurs inflammables, telle que

I'essence, loin du cong61ateur.

• Utiliser deux ou plus de personnes pour d6placer et installer le

cong61ateur.

• Garder la cl6 loin des enfants.

• Enlever les portes ou le couvercle de votre vieux cong61ateur ou

r6frig6rateur.

• D6brancher la source de courant 61ectrique avant I'installation de

la machine &glagons (seulement pour modeles pr6ts & recevoir

une machine &glagons).

CONSERVEZ CES iNSTRUCTiONS

Avertissements de la proposition 65 de J'C:tat de Californie :

AVERTISSEMENT : Ce produit contient au moins un produit chimique connu par I'Etat de Califomie pour 6tre & J'origine de cancers.

AVERTISSEMENT : Ce produit contient au moins un produit chimique connu par H-2tatde Californie pour 6tre & J'origine de malformations

et autres d6ficiences de naissance.

M_SE AU REBUT APPROPR_EE DE VOTRE V_EUX

CONGCLATEUR OU RCFR_GERATEUR

Risque de suffoquer

Enlever Jes portes ou Je couvercle de votre vieux

cong61ateur ou r6frig6rateur.

Le non-respect de cette instruction peut causer

un d6c_s ou des 16sions c6r6brales.

IMPORTANT :Le probDme des enfants trouv6s enferm6s ou 6touff6s n'est

pas un probDme r6volu. Les cong61ateurs ou r6frig6rateurs jet6s ou

abandonn6s pr6sentent des dangers, m6me s'ils sont abandonn6s

pendant "quelques jours" seulement. Si vous vous d6barrassez de votre

vieux r6frig6rateur ou cong61ateur,veuillez suivre les instructions suivantes

pour aider & 6viter les accidents.

Avant de mettre au rebut votre vieux cong61ateur ou

r6frig6rateur :

• Enlever les portes ou le couvercle.

• Laisser les tablettes en place, de sorte que les enfants ne puissent pas

facilement se glisser & I'int6rieur.

Risque du poids excessif

UtiJiser deu× ou plus de personnes pour d6placer et

installer le cong_lateur.

Le non=respect de cette instruction peut causer

une biessure au dos ou d'autre biessure.

Enl_vement des mat6riaux d'emballage

• Enlever le ruban adh6sif et la colle des surfaces du cong61ateur avant

de le mettre en marche. Frotter une petite quantit6 de savon liquide

pour la vaisselle sur I'adh6sif avec les doigts. Rincer & I'eau tiede et

essuyer.

Renseignements importants _ propos de la raise au

rebut des fluides r6frig6rants :

Mettre le congelateur au rebut conformement & la

reglementation f6derale et locale. Les fluides r6frig6rants

doivent 6tre evacu6s par un technicien certifie et agre6 par

I'EPA conformement aux procedures 6tablies.

Ne pas utiliser d'instruments coupants, d'alcool & friction, de liquides

inflammables ou de nettoyants abrasifs pour enlever le ruban adh6sif

ou la colle. Ces produits peuvent endommager la surface de votre

cong61ateur. Pour plus de renseignements, voir "S6curit6".

D_piacement de votre cong61ateur :

Votre cong61ateur est Iourd. Lors du d6placement de votre

cong61ateur pour le nettoyage ou un entretien, veiller &

recouvrir le plancher avec du carton ou un panneau de fibre

dur pour 6viter qu'il ne subisse tout dommage. Toujours

tirer le cong61ateur tout droit Iors du d6placement. Ne pas

incliner lecong61ateur d'un c6t6 ou de I'autre nile "faire

marcher" en essayant de le d6placer car le plancher pourrait

6tre endommag&

15

Nettoyage avant I'utilisation

Apres avoir enlev6 tousles mat6riaux d'emballage, nettoyer I'int6rieur

du cong61ateur avant I'utilisation. Voir les instructions de nettoyage &

"Entretien du cong61ateur".

Jmportants renseignements & savoir au sujet des tablettes

et des couvercles en verre :

Ne pas nettoyer les tablettes ou couvercles en verre avec de

I'eau tilde quand ils sont froids. Les tablettes et les

couvercles peuvent se briser s'ils sont expos6s a des

changements soudains de temp6rature ou a un impact tel

que coup brusque. Le verre trempe est con£u pour eclater

en d'innombrables pieces minuscules. Ceci est normal. Les

tablettes et les couvercles en verre sont Iourds. Les saisir

deux mains Iors de leur d6pose afin d'6viter de les faire

tomber.

En cas de d6placement & son emplacement final

REMARQUE : Laisser un d6gagement de 3" (7,5 cm) sur le dessus et les

c6t6s et un d6gagement de 1/4"(6,4 mm) entre les appareils.

Exigences d_emp_acement

Risque d'explosion

Garder les mat6riaux et les vapeurs inflammables, telle

que J'essence, Join du cong61ateur.

Le non=respect de cette instruction peut causer

un d_c_s, une explosion ou un incendie.

Ventilation et d6gagement

• Garder les mat6riaux et les vapeurs inflammables, tels que I'essence,

loin du cong61ateur.

• Ne pas couvrir le cong61ateur avec des articles tels que couvertures,

draps, nappes de table, etc. Ceci r6duit la circulation d'air.

• Laisser un espace d'au moins 3" (7,5 cm) des deux c6t6s du

cong61ateuret de 1" (2,5 cm) entre I'arriere du cong61ateur et lemur. Si

le cong61ateurest install6 contre un mur, laisser un espace

suppl6mentaire du c6t6 des charni@es pour une plus grande ouverture

de la porte.

Temp6rature

Le cong61ateurfonctionne & son efficacit6 maximale Iorsqu'il se trouve

dans un endroit o_ la temp6rature ne descend pas en dessous de 40°F

(5°C). Installer le cong61ateur dans un endroit o_ la temp6rature ne

descend pas en dessous de cette temp6rature recommand6e.

3" (7,5cm)

Sp6cificatioHs 6_ectriques

Risque de choc 61ectrique

Brancher sur une prise &3 aJv_oJes reli6e & la terre.

Ne pas enJever la broche de liaison & la terre.

Ne pas utiliser un adaptateur.

Ne pas utiiiser un c&ble de rallonge.

Le non=respect de ces instructions peut causer

un d6c_s, un incendie ou un choc 61ectrique.

Avant de d6placer le cong61ateur &son emplacement final, il est important

de vous assurer d'avoir le raccordement 61ectriqueappropri6.

M6thode recommand6e de mise & la terre

Une source de courant 61ectrique de 115 V,60 Hz, CA seulement, et

prot6g6e par un fusible de 15 ou 20 amp@es, ad6quatement mise & la

terre est n6cessaire. II est recommand6 d'utiliser un circuit distinct pour

alimenter uniquement le cong61ateur. Utiliser une prise de courant murale

qui ne peut pas 6tre mise hors circuit & I'aide d'un commutateur. Ne pas

employer un c&ble de rallonge.

REMARQUE : Avant de proc6der & tout type d'installation, de nettoyage ou

de changement d'une ampoule, appuyer sans rel&cher sur TEMP

SETTING (r6glage de la temp6rature) pendant 3 secondes pour d6sactiver

le refroidissement, puis d6connecter le cong61ateurde la source de courant

61ectrique.

16

OverTemp Reset

oOOOOooooooo

i Temp :

i Setting i

eeoeoeooeoo °

Cooling On/Off

Hold 3 Sec

Sp6c[ficat[ons de [ a[[mentat[on en eau

(suit ce_aiins mod@/!es}

Rassembler les outils et pieces n6cessaires avant de commencer

I'installation. Lire et suivre les instructions fournies avec les outils indiqu6s

ici.

Outils requis

• Un tournevis & lame plate • Tourne-6crou de 1/4"

• CI6s plates de 7Ae"et 1_,,ou deux • Foret de 1/4"

cl6s &molette r6glables • Perceuse sans fil

REMARQUE : Votre marchand de cong61ateurs propose une trousse

disponible avec un robinet d'arr6t a 6trier de 1/4"(6,35 mm), un raccord et

un tube en plastique. Avant I'achat, s'assurer que le robinet d'arr6t a 6trier

est conforme a vos codes Iocaux de plomberie. Nepas employer de robinet

d'arr6t a 6trier de 3Ae"(4,76 mm) ou de type a percer, ce qui r6duit le d6bit

d'eau et cause une obstruction plus facilement.

IMPORTANT :

• Si on doit utiliser le cong61ateur avant qu'il soit raccord6 a la

canalisation d'eau, placer la commande de la machine a gla(_onsa la

position d'ARRET.

• Toutes les installations doivent 6tre conformes aux exigences des

codes Iocaux de plomberie.

• Utiliser un tube en plastique et v6rifier I'absence de fuites. Installer les

tubes en plastique seulement a des endroits o_ la temp6rature se

maintient au-dessus du point de cong61ation.

Pression de I'eau

Une alimentation en eau froide avec une pression entre 30 et 120 Ib/po2

(207 et 827 kPa) est n6cessaire pour faire fonctionner le distributeur d'eau

et la machine a gla(_ons.Sivous avez des questions au sujet de la pression

de votre eau, consulter "R6solution de problemes" ou faire appel a un

plombier qualifi6 agr66.

Alimentation en eau par osmose inverse

Si un systeme de purification de I'eau par osmose inverse est raccord6 a

votre alimentation en eau froide, la pression de I'eau au systeme doit 6tre

d'un minimum de 40 & 60 Ib/po2(276 a 414 kPa).

Si la pression de I'eau au systeme d'osmose inverse est inf6rieure a 40 &

60 Ib/p@(276 a 414 kPa), une pompe de surpression peut 6tre ins6r6e

dans le petit tube qui va de la canalisation d'eau froide au systeme

d'osmose inverse.

Si ledistributeur d'eau ne distribue toujours pas I'eau correctement :

• V6rifier pour voir si le filtre &s6diments dans le systeme d'osmose

inverse est bloqu6 et le remplacer si n6cessaire.

• Laisser le r6servoir du systeme d'osmose inverse se remplir apres une

utilisation intense.

• Si votre r6frig6rateur comporte un filtre a eau, celui-ci peut r6duire

encore plus la pression de I'eau Iorsqu'il est utilis6 avec un systeme

d'osmose inverse. Retirer le filtre a eau.

Si vous avez des questions au sujet de la pression de votre eau, consulter

"R6solution de problemes" ou appeler un plombier qualifi6 agr66.

Raccordement de cana isation

d°a imentation en eau (sur cell_ains mod@_es}

Raccordement & une canalisation d'eau

1. D6brancher le cong61ateur ou d6connecter la source de courant

61ectrique.

2. FERMER le robinet principal d'arriv6e d'eau. OUVRIR le robinet de

puisage le plus proche pendant une p6riode suffisante pour que la

canalisation d'eau se vide.

3. Trouver une canalisation d'eau froide verticale de 1/2"a 11/4'' (12,7 mm a

3,18 cm) pres du cong61ateur.

IMPORTANT :

• Assurez-vous qu'il s'agit d'un conduit d'eau froide.

Un conduit horizontal fonctionnera, mais percer par le dessus

de la canalisation et non pas par le dessous. Ainsi, I'eau ne

risquera pas d'arroser la perceuse. Ceci emp6che egalement

les s6diments qu'on trouve normalement dans I'eau de

s'accumuler dans le robinet.

4. Pour d6terminer la Iongueur du tube en plastique, il faut mesurer la

distance entre le point de connexion inf6rieur gauche a I'arriere du

cong61ateur et la canalisation d'eau. Ajouter une Iongueur de 7 pi

(2,1 m) pour permettre le nettoyage. Utiliser un tube en plastique de 1/4"

(6,35 mm) de diam_tre ext6rieur. Veiller ace que le tube soit coup6

d'6querre aux deux extr6mit6s.

5. ,_ I'aide d'une perceuse sans ill, percer un trou de 1/4"(6,35 mm) dans

le tuyau de canalisation d'eau froide choisi.

................A

G ............................B

A. Canafisation d'eau froide

B. Bride de tuyau

C. Tube en plastique

D. E-crou de compression

6. Fixer le robinet d'arr6t sur la canalisation d'eau froide avec la bride de

tuyau. V6rifier que I'extr6mit6 du raccord de sortie du robinet est bien

engag6e dans le trou de 1/4"(6,35 mm) perc6 dans la canalisation et

que la rondelle d'6tanch6it6 est plac6e sous la bride de tuyau. Serrer

1'6croude serrage. Serrer lentement et uniform6ment les vis fixant la

bride de tuyau sur la tuyauterie afin que la rondelle forme une jonction

6tanche. Ne pas serrer excessivement car ceci pourrait provoquer

1'6crasement du tube en plastique.

7. Enfiler 1'6crou et la bague de compression du raccord sur le tube en

plastique comme on le voit sur I'illustration. Ins6rer I'extr6mit6 du tube

directement et aussi loin que possible dans I'ouverture de sortie du

robinet. Visser 1'6croude compression sur I'extr6mit6 du raccord de

sortie avec une cl6 & molette. Ne pas serrer excessivement.

8. Placer le bout libre du tube dans un contenant ou 6vier et OUVRIR le

robinet principal d'arriv6e d'eau; laisser I'eau s'6couler par le tube

jusqu'& ce que I'eau soit limpide. FERMER le robinet de la canalisation

d'eau. Enrouler le tube en plastique.

E. Bague de compression

F. Robinet d'arr_t

G. E-crou de serrage

17

Raccordement au cong61ateur

1. Fixer le tube en plastique & I'entr6e du robinet d'eau en utilisant un

6crou et une bague de compression tel qu'illustr6. Serrer 1'6croude

compression. Ne pas serrer excessivement.

2. Utiliser la bride du tube & I'arriere du cong61ateur pour fixer le tube au

cong61ateurtel qu'illustr6. Ceci aidera & emp6cher les dommages au

tube Iorsque le cong61ateur est pouss6 contre lemur.

3. OUVRIR le robinet d'arr6t.

4. V6rifier I'absence de fuites. Serrer tousles raccords (y compris les

raccordements du robinet d'arriv6e d'eau) ou les 6crous qui coulent.

A

B

C

Retrait et r6[nstaHat[on de _a poig_6e

Retrait de la poign6e :

1. Desserrer lesvis de blocage situ6es sur le c6t6 de la poign6e &chaque

extr6mit6. Voir I'illustration "Inversion du sens d'ouverture de la porte et

retrait de la poign6e".

2. Retirer la poign6e des ceillets.

R6installation de la poign6e :

1.

Placer la poign6e sur les ceillets en s'assurant que les ceillets sont bien

install6s dans les trous de la poign6e.

2.

Serrer les vis de blocage sup6rieures et inf6rieures & I'aide de la cl6 &

t6te hexagonale fournie. Voir I'illustration "Inversion du sens

d'ouverture de la porte et retrait de la poign6e". Ne pas serrer

excessivement les vis de blocage.

D

E

A.Bride du tube

B. Visde bride du tube

D.Ecrou de compression

E.Entree du robinet

C. Tubeenplastique

5.

La machine & gla(pns est 6quip6e d'un filtre &eau incorpor6. Si la

qualit6 de I'eau distribu6e Iocalement n6cessite un deuxieme filtre &

eau, I'installer dans la canalisation d'eau de 1/4"(6,35 mm), &I'un ou

I'autre des points de raccordement. On peut obtenir un tel filtre & eau

chez le marchand d'appareils 61ectrom6nagers le plus proche.

Risque de choc 61ectrique

Brancher sur une prise &3 alv_oles reli6e _ Jaterre.

Ne pas enJever la broche de liaison & la terre.

Ne pas utiliser un adaptateur.

Ne pas utiJiser un c&bJe de railonge.

Le non=respect de ces instructions peut causer

un d6c_s, un incendie ou un choc 61ectrique.

6.

Brancher sur une prise & 3 alv6oles reli6e & la terre.

Porte du cong6_ateu_

Outillage necessaire : cl6 a douille a t6te hexagonale de sid', cl6 a douille

t6te hexagonale de s/s",couteau a mastic de 2".

IMPORTANT :

• Toutes les illustrations mentionn6es dans les instructions suivantes

sont incluses plus loin dans cette section apres "l_tapes finales". Les

illustrations correspondent a une porte s'ouvrant a droite (charni@es

install6es a droite a I'usine).

• Si vous d6sirez seulement enlever et r6installer la porte, voir

"D6montage - Porte et charnieres" et "R6installation - Porte et

charnieres".

• Avant de commencer, tourner la commande a OFF (arr6t), et retirer les

aliments et tout balconnet r6glable ou compartiment utilitaire de la

porte.

D6montage - Porte et charni_res

Visde charniere _ t_te hexagonale

1. D6brancher le cong61ateur ou d6connecter la source de courant

61ectrique.

2. Laisser la porte du cong61ateur ferm6e jusqu'& ce que vous soyez pr6t

&la soulever pour la d6gager de la caisse.

REMARQUE : Pr6voir un support additionnel de la porte pendant le

d6placement des charnieres. La force d'attraction des aimants de porte

ne suffit pas & la maintenir en place.

3. Enlever les pieces de la charni@e sup6rieure - voir I'illustration de la

charniere sup6rieure.

4. Soulever la porte du cong61ateur pour la s6parer de la charniere

inf6rieure et de la caisse et la conserver & part.

5. Retirer les 4 vis de charniere & t6te hexagonale et la charniere

inf6rieure. Voir I'illustration de la charniere inf6rieure.

18

Inversion du sens d'ouverture de la porte

(facultatif - sur certains modules)

IMPORTANT : Sivous souhaitez inverser le sens d'ouverture de la porte,

suivre les instructions de la section "Inversion du sens d'ouverture de la

porte (facultatif - sur certains modeles)". S'il n'est pas n6cessaire de

changer I'orientation de la porte, voir "R6installation - Porte et charnieres".

Caisse

1. Enlever les bouchons d'obturation des trous de charniere au sommet

de la caisse; transf@er ceux-ci dans les trous de charni@e du c6t6

oppos6 (voir I'illustration 2).

2. Retirer I'axe de charni@e inf@ieure de la bride de charniere.

3. Retirer les ceillets recouvrant les trous du c6t6 oppos6 de la charni@e

inf@ieure.

4. R6installer I'axe de charniere dans I'autre trou de la bride de charni@e.

Voir I'illustration 3.

5. R6installer la bride de charni@e sur la caisse & I'aide des 4 vis de

charni@e &t6te hexagonale.

Porte

1. Enlever le bouchon d'obturation de la partie sup@ieure de charniere au

sommet de la porte. Voir I'illustration 4.

2. Retirer la but6e de porte du has de la porte.

3. Placer la but6e de porte du c6t6 oppos6 en s'assurant que le trou de la

plaque de but6e de porte est parfaitement align6 avec le trou de la

porte destin6 & I'axe de charni@e inf@ieure.

4. ,_ I'aide des vis retir6es & 1'6tape2, fixer le support de but6e de porte

au has de la porte.

5. Serrer toutes les vis. Conserver la porte du cong61ateur & part jusqu'&

la raise en place de la charniere inf@ieure.

R6installation - Porte et charni_res

REMARQUE : Si on inverse le sens d'ouverture de la porte, consid@er

I'image sym6trique.

1. Assembler les pieces de la charni@e inf@ieure (tel qu'indiqu6) et

serrer les vis. Voir I'illustration de la charniere inf@ieure. R6installer

la porte du cong61ateur.

REMARQUE : Pr6voir un support additionnel de la porte pendant le

d@lacement des charnieres. La force d'attraction des aimants de porte

ne suffit pas & la maintenir en place.

2. Assembler les pieces de la charni@e sup@ieure (voir I'illustration de la

charniere sup@ieure). Ne pas completement serrer les vis.

Etapes finales

1. Inspecter tous les trous. V@ifier que tousles bouchons d'obturation et

vis sont en place. R6installer le couvercle de la charniere sup@ieure.

Voir I'illustration de la charniere sup@ieure.

2. ,_ I'aide des ceillets fournis, recouvrir les trous restants situ6s sur le

c6t6 oppos6 de la charniere inf@ieure.

Risque de choc 61ectrique

Brancher sur une prise &3 alv_oles reli6e _ la terre.

Ne pas enlever la broche de liaison _ la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un c_ble de rallonge.

Le non=respect de ces instructions peut causer

un d6c_s, un incendie ou un choc 61ectrique.

3. Brancher sur une prise de courant & 3 alv6oles, reli6e &la terre.

4. R6initialiser la commande. Voir"Utilisation de la commande".

5. R6installer toutes les pieces amovibles de la porte et remettre les

aliments dans le cong61ateur.

19

A

A, Bouchons d'obturafion des trous

de chamiere de/a caisse

B

Charniereinf6rieure

A

A. OEillets

B, Poignee

C, Vis de montage

A. Visde buteedeporte

B. Visde charnierea t_te

hexagonale de%"

A. Axe de charniere

B, Vis de chamiere a t_te

hexagonale de %"

IIIlliveHement du cong6_ateur et fermeture de _a porte

Style 1--sans grille Style 2--avec grille

1. Rep6rer les deux pieds de nivellement avant fix6s parmi les mat6riaux

d'emballage.

2. Visser ces pieds dans les trous avant situ6s au bas du cong61ateur.

!Jarriere du cong61ateur repose sur 2 supports fixes.

3. Ajuster suffisamment les pieds avant pour s6parer la caisse du sol.

4. Placer un niveau au sommet de la caisse du cong61ateur,

transversalement puis dans le sens avant-arriere. Pour soulever un

coin, faire tourner le pied dans le sens antihoraire. Pour abaisser un

coin, faire tourner le pied dans le sens horaire.

iii

Le cong61ateurest 6quip6 de 2 pieds avant r6glables, un de chaque c6t6.

I'arriere du cong61ateurrepose sur 2 roulettes fixes. La grille de la base

recouvre les pieds de stabilisation r6glables et les roulettes situ6es au bas

du cong61ateursous la porte du cong61ateur. Avant de r6aliser les

ajustements, retirer la grille de la base et d6placer le cong61ateur & son

emplacement d6finitif.

Outillage necessaire : tourne-6crou de 1/4",tournevis Phillips

1. Retirer les vis de la grille de la base. Saisir la grille fermement et la tirer

vers sol. Ouvrir la porte du cong61ateur pour acc6der aux pieds de

stabilisation.

5. R6p6ter 1'6tape4 jusqu'& ce que le cong61ateur soit d'aplomb.

6. Une fois le cong61ateur completement rempli d'aliments, v6rifier de

nouveau I'aplomb comme expliqu6 & 1'6tape4.

20

REMARQUE:Pourpermettreaucong61ateurderoulerplus

facilement,souleverlespiedsdestabilisationenlestournantdans

lesensantihoraire.Lesroulettesavanttoucherontleplancher.

Ouvrirlaporteducong61ateur.Utiliseruntourne-@roude1_,,pour

tournerlesdeuxpiedsdestabilisationdum_menombredetoursdans

lesenshoraire.CelasouleveI'avantducong61ateur.Celapeut

n@essiterplusieurstourspourpermettre&laportedesefermer

plusfacilement.

/

2. D@lacerlecong61ateurjusqu'&sonemplacementfinal.

3. Abaisserlespiedsdestabilisationenlestournantdanslesenshoraire,

jusqu'&cequelesroulettesnetouchentpluslesoletquelesdeux

piedsdestabilisationsoientfermementenappuisurlesol.Cet

arrangementvise&emp@herlecong61ateurderoulerversI'avant&

I'ouverturedesportes.

IMPORTANT:Sidesarrangementssontn@essairesparlasuiteetsi

celacomprendlespiedsdestabilisation,lesdeuxpiedsdestabilisation

doivent_tretourn6sdefagon6galepourconserverI'aplombdu

cong61ateur.

4. S'assurerquelaportefermefacilement.Sivous_tessatisfaitdela

facilit6aveclaquellelaportes'ouvreetseferme,sauterlasection

suivante.Cependant,silaportenefermepasfacilementouqu'elle

s'ouvred'elle-m_me,r6glerI'inclinaison.

R_glage de I'inclinaison de la caisse :

REMARQUE : Si une autre personne pousse le haut du cong61ateur, le

poids devient moins Iourd sur les pieds de nivellement. Ceci facilite leur

rotation.

Pour s_assurer d_une circulation d_ai_ appropri6÷

Pour s'assurer d'avoir des temp6ratures appropri6es, ilfaut permettre & I'air

de circuler dans le cong61ateur.Comme I'indique I'illustration, I'air froid

p6n_tre par la paroi du cong61ateuret se d@lace vers le bas. Eair recircule

ensuite par I'@ent pres de la base.

A. Pied de stabilisation

B. Roulette avant

5. S'assurer que le cong61ateur est stable. Si le cong61ateursemble

instable ou qu'il roule vers I'avant Iorsqu'on ouvre la porte, r6gler les

pieds de nivellement.

Stabilisation du congelateur :

• Ouvrir la porte du cong61ateur. Utiliser un tourne-@rou de 1/4"pour

tourner les deux pieds de stabilisation du m_me nombre de tours

dans le sens horaire, jusqu'& ce qu'ils soient fermement en appui

sur le sol. V6rifier de nouveau. Si le r6sultat n'est pas satisfaisant,

continuer de r6gler les pieds de nivellement en tournant la vis par

demi-tours jusqu'& ce que le cong61ateurne roule plus vers I'avant

Iors de I'ouverture de la porte.

6. R6installer la grille de la base en alignant les extr6mit6s de la grille

avec les dispositifs de nivellement de chaque c6t6 et embofter la grille.

R6installer les vis Phillips.

Ut[Hsat[on de command÷

La commande de la temp6rature se trouve dans la partie sup6rieure avant

du compartiment de cong61ation.

Commande de la temperature

Pour votre commodit6, la commande de temp6rature est pr6r6gl6e &

I'usine. Lors de I'installation initiale du cong61ateur, v6rifier que la

commande est encore pr6r6gl6e au point de r6glage recommand6 tel

qu'illustr&