Whirlpool WTW2000HW Maintance Manual

WASHER

USE AND CARE GUIDE

Table of Contents

WASHER SAFETY ..................................................................... 2

INSTALLATION REQUIREMENTS ............................................ 3

PERMANENT INSTALLATION INSTRUCTIONS ...................... 6

PORTABLE INSTALLATION INSTRUCTIONS........................ 10

CONTROL PANEL AND FEATURES ...................................... 13

USING YOUR WASHER .......................................................... 15

WASHER MAINTENANCE ...................................................... 18

TROUBLESHOOTING ............................................................. 20

WARRANTY ............................................................................. 25

W11254174A

W11254180A-SP

Designed to use only HE High Efciency detergents.

Diseñada para utilizar solamente detergentes de alto rendimiento (HE).

WASHER SAFETY

2

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

The parts supplied are in the washer basket.

Portable Installation

Parts supplied:

Permanent Installation

Parts needed (not provided with washer):

NOTE: Replace inlet hoses

after 5 years of use to reduce

the risk of hose failure.

Record hose installation or

replacement dates for future

reference.

Inlet hoses with at washers

Parts supplied:

Flat washers for faucet

adapter and ll hoses

Faucet adapter Fill-and-drain hose

Hose bracket

Tools needed for installation:

Silver, double-wire hose

clamp (for bottom of drain

hose)

Drain hose with clamp

Leveling feet

Tools needed for installation

Pliers that open to

19/16" (3.95 cm)

Cable tie

Utility knife

Pliers that open to

19/16" (3.95 cm)

Flashlight (optional)

Utility knife

Flashlight (optional) Adjustable or open-end

wrench 9/16" (14 mm)

Measuring tape Phillips screwdriver

Level

3

Alternate Parts

Your installation may require additional parts. For information

on ordering, please refer to the back cover of this manual.

If You Have: You Will Need to Buy:

Laundry tub or standpipe

taller than 72" (183 cm)

1" (2.5 cm) diameter

standpipe

Sump pump system

(if not already available)

2" (5 cm) diameter to

1" (2.5 cm) diameter

standpipe adapter,

Part Number 3363920

Overhead sewer Standard 20 gal. (76 L)

39" (990 mm) tall drain tub

or utility sink, sump pump,

and connectors (available

from local plumbing

suppliers)

Floor drain Siphon break, Part Number

285320; additional drain

hose, Part Number 3357090

and connector kit,

Part Number 285442

Water faucets beyond reach

of ll hoses

2 longer water ll hoses:

6 ft (1.8 m)

Part Number 76314

10 ft (3.0 m)

Part Number 350008

Drain hose too short Drain hose, Part Number

388423 and hose kit,

Part Number 285442

Drain hose that is too long Hose kit, Part Number

285442

Lint clogged drain Drain protector,

Part Number 367031

Location Requirements

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer “walk.”

Your washer can be installed in a basement, laundry room,

closet, or recessed area. See “Drain System.”

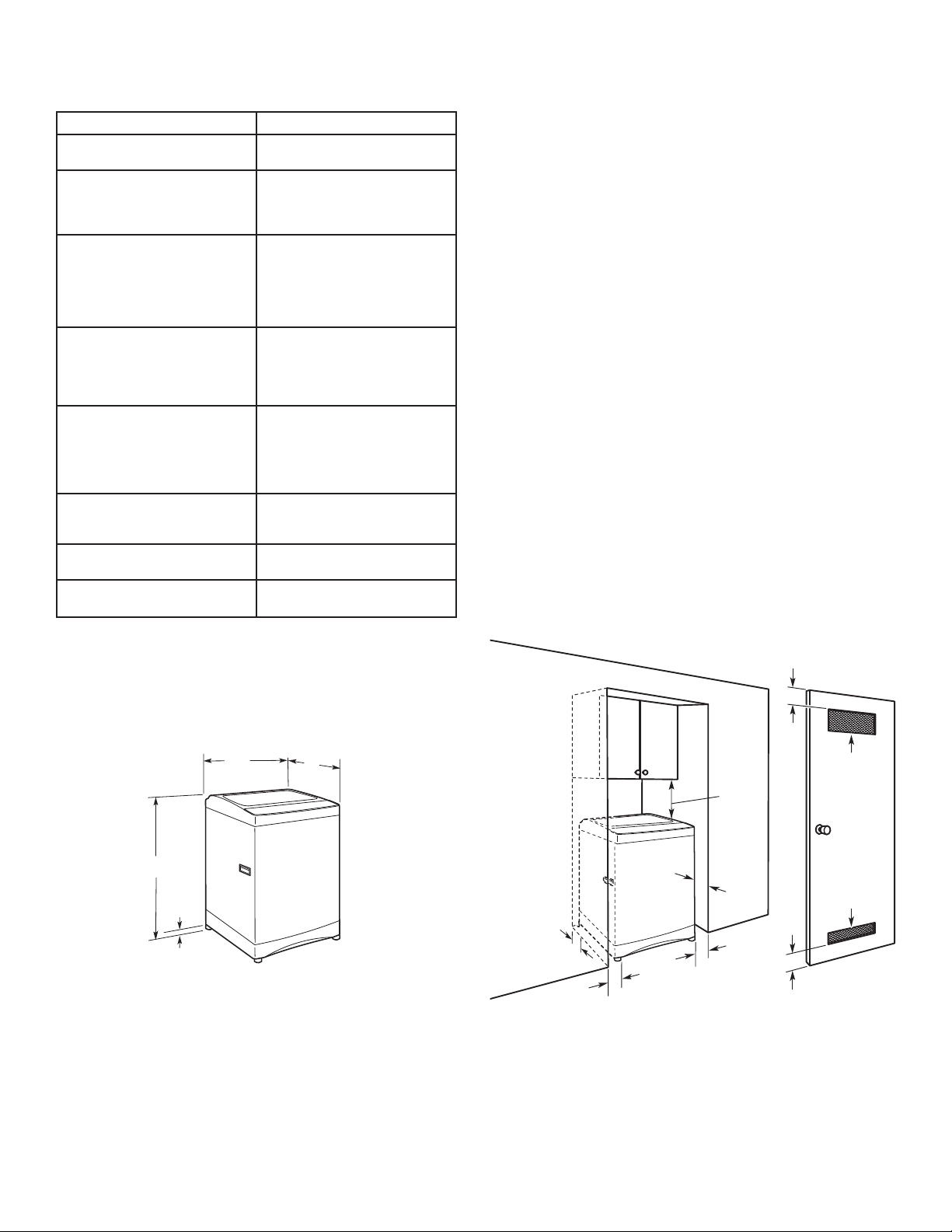

Washer Dimensions

21"

(533 mm)

23"

(584 mm)

You will need:

■ A water heater set to deliver 120°F (49°C) water to

the washer.

■ A grounded electrical outlet located within 5 ft (1.5 m) of

where the power cord is attached to the back of the washer.

See “Electrical Requirements.”

■ Hot and cold water faucets located within 3½ ft (1.1 m) of

the hot and cold water ll valves, and water pressure of

5–100 psi (34.5–690 kPa).

■ A level oor with a maximum slope of ¾" (1.9 cm) under

entire washer. Installing the washer on carpeting is not

recommended.

■ A sturdy oor to support the washer weight (washer, water,

and load) of 225 lbs (102 kg).

Do not store or operate your washer in temperatures at or

below 32°F (0°C). Some water can remain in the washer and

can cause damage in low temperatures. See “Washer Care”

for winterizing information.

Recessed area or closet installation

The dimensions shown are for the recommended spacing

allowed, except the closet door ventilation openings. The

dimensions shown for the closet door ventilation openings

are the minimum required.

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances may be required for wall, door,

and oor moldings.

■ Additional spacing of 1" (2.5 cm) on all sides of the washer

is recommended to reduce noise transfer.

■ If a closet door is installed, the minimum air openings

in the top and bottom of the door are required. Louvered

doors with air openings in the top and bottom are

acceptable.

■ Companion appliance spacing should also be considered.

Washer Only

3"

(76 mm)

2

48 in.

(310 cm2)

12"

(305 mm)

37"

(940 mm)

3

/4"

(19 mm)*

*Minimum measurement with leveling feet installed.

IMPORTANT: Do not install or store the washer where it will be

exposed to the weather.

Proper installation is your responsibility.

4

4"

(102 mm)

1"

(25 mm)

Recessed area

1"

(25 mm)

1"

(25 mm)

3"

(76 mm)

Closet door with vents

2

24 in.

(155 cm2)

Stacked

(76 mm)

(305 mm)

3"

12"

1"

(25 mm)

12"

(305 mm)

DRYER

WASHER

1"

(25 mm)

1"

(25 mm)

Closet door with ventsRecessed area

3"

(76 mm)

3"

(76 mm)

2

48 in.

(310 cm2)

2

24 in.

(155 cm2)

■ Check with a qualied electrician if you are not sure the

washer is properly grounded.

■ Do not have a fuse in the neutral or ground circuit.

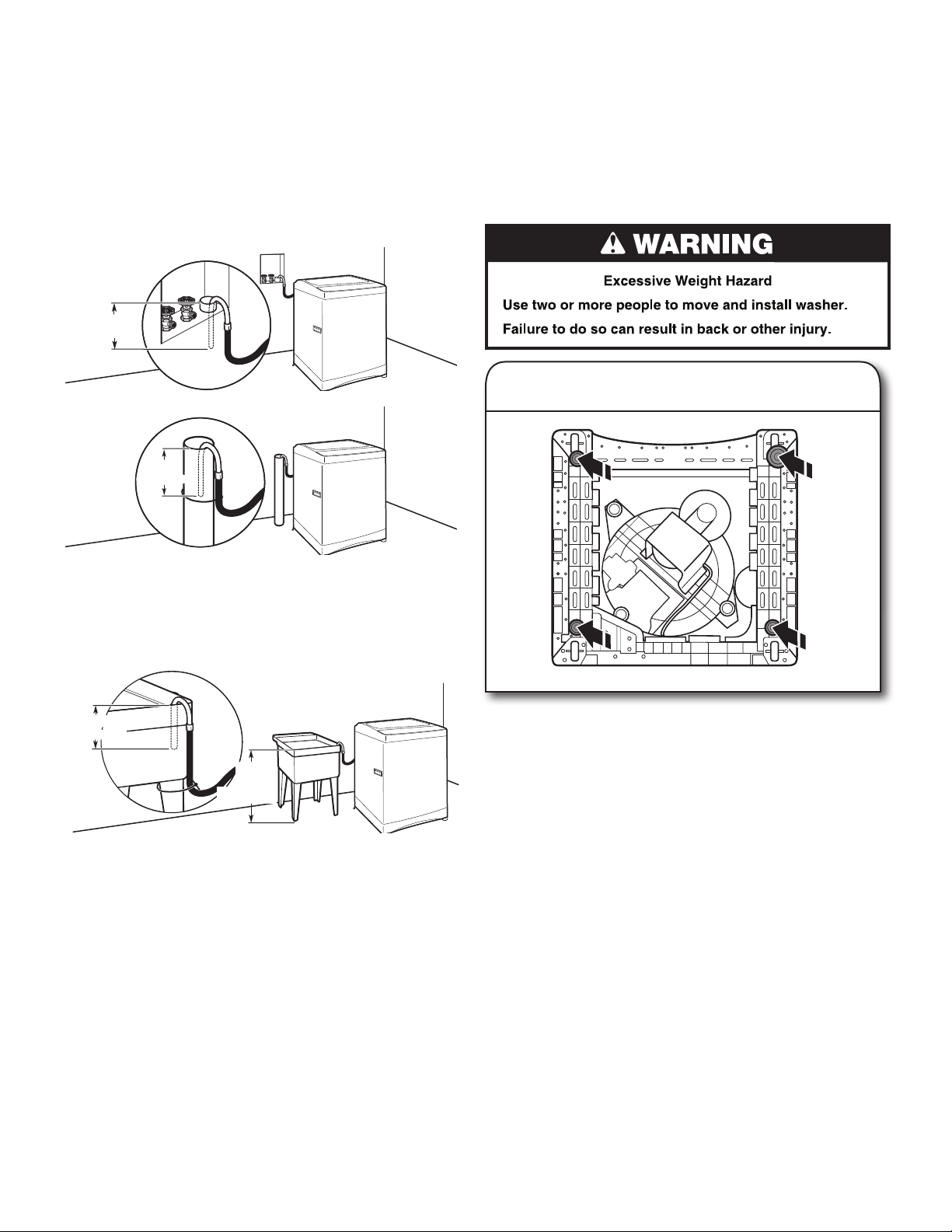

Remove Shipping Material

Before you install your washer, remove all shipping material.

Electrical Requirements

■ A 120 V, 60 Hz., AC only, 15 or 20 A, fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is recommended that a separate circuit

serving only this appliance be provided.

■ This washer is equipped with a power supply cord having

a 3 prong grounding plug.

■ To minimize possible shock hazard, the cord must be

plugged into a mating, 3 prong, grounding-type outlet,

grounded in accordance with local codes and ordinances. If a

mating outlet is not available, it is the personal responsibility

and obligation of the customer to have the properly grounded

outlet installed by a qualied electrician.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that

the ground path is adequate.

■ Do not ground to a gas pipe.

To avoid damaging oor, use a large at piece of cardboard

from the washer carton. Place cardboard under entire back

of the washer.

Firmly grasp the body of the washer and gently lay it on the

corner posts.

Remove plastic foam packaging from underneath the washer.

Stand the washer up.

Remove tape from washer lid. Open washer lid and remove

foam shipping piece, parts bag, and hoses from washer basket.

Close the lid.

5

Drain System

(114 mm)

(114 mm)

The washer can be installed using the standpipe drain system

(oor or wall), the laundry tub drain system, or the oor drain

system. Select the drain hose installation method you need.

See “Tools and Parts.”

Standpipe drain system – wall or floor (views A & B)

The standpipe drain requires a minimum diameter standpipe

of 2" (50 mm). The minimum carry-away capacity (for permanent

installations) can be no less than 17 gal. (64.5 L) per minute.

The top of the standpipe must be at least 39" (990 mm) high

and no higher than 72" (183 cm) from the bottom of the washer.

4.5"

(114 mm)

PERMANENT INSTALLATION

INSTRUCTIONS

Install Leveling Feet – Optional

(for permanent installation only)

IMPORTANT: Installation of the leveling feet is permanent.

Once the leveling feet are installed into the base of the washer,

they cannot be removed and the washer wheels will no longer be

able to roll.

A

4.5"

4.5"

(114 mm)

(114 mm)

B

Laundry tub drain system (view C)

The laundry tub requires a minimum carry-away capacity

of 17 gal. (64.5 L) per minute (for permanent installations).

The top of the laundry tub must be at least 39" (990 mm) above

the oor and no higher than 72" (183 cm) from the bottom of

the washer.

4.5"

4.5"

min.

min.

39"

30"

(990 mm)

(762 mm)

1. Install leveling feet

Front

Large

black

rubber

foot

Lay washer on its back. Push in to snap the large black rubber

foot into the right front corner of the washer base. Repeat to

install the remaining leveling feet on the other 3 corners.

C

6

■ To avoid damage to the oor, set the washer onto cardboard

before moving across oor.

■ Move the washer to within approximately 3 ft (900 mm)

of the nal location.

Connect Drain Hose

2. Attach drain hose to drain port

If clamp is not already in place on elbow end of drain hose,

slide it over end as shown. Squeeze clamp with pliers and slide

black elbow end of drain hose onto black drain port and secure

with clamp.

For a laundry tub or standpipe drain, go to step 3.

For a oor drain, remove the pre-installed drain hose form as

shown in Step 4.

4. Remove drain hose form

(Floor drain installations only)

For oor drain installations, you will need to remove the drain

hose form from the end of the drain hose. You may need

additional parts with separate directions. See “Tools and Parts.”

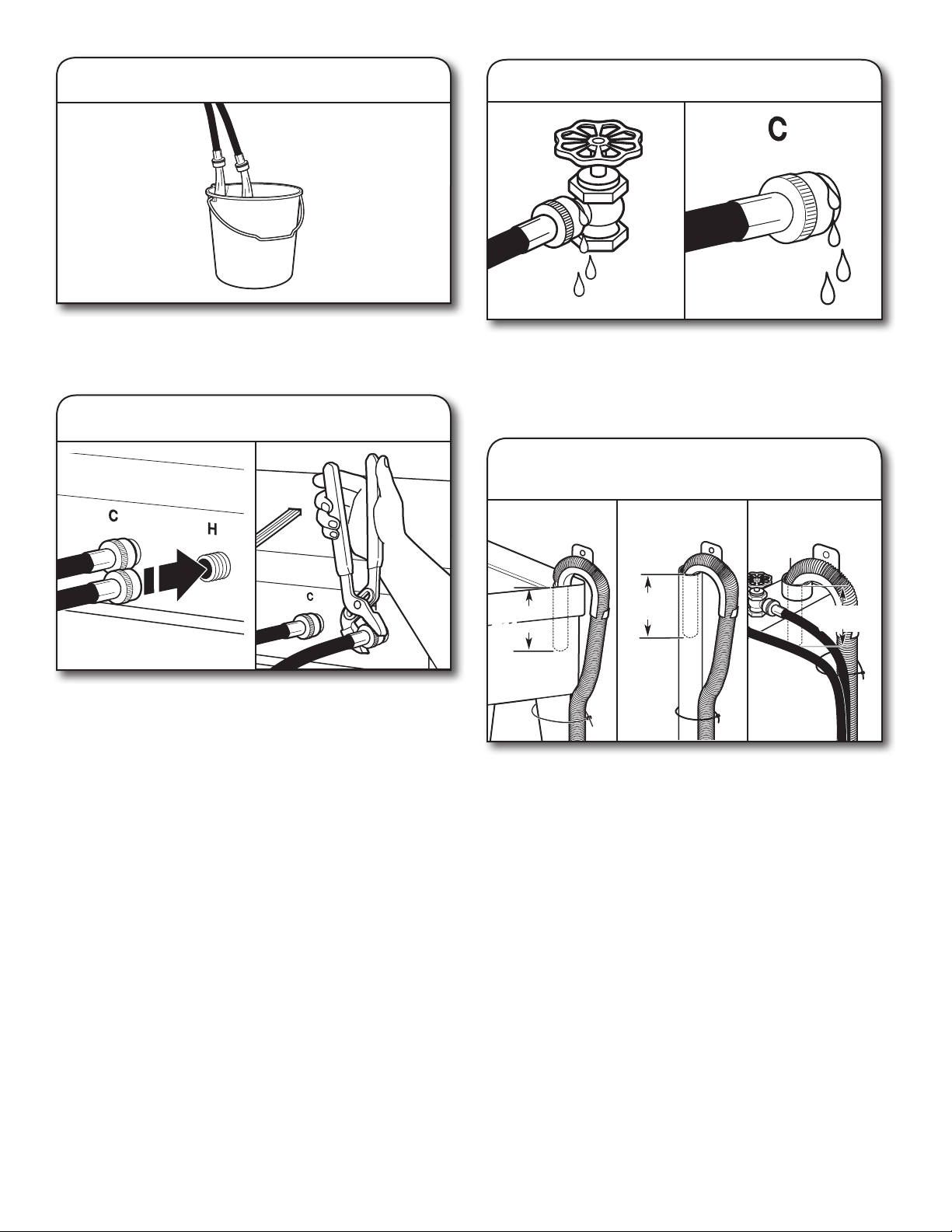

Connect Inlet Hoses

The washer must be connected to the water faucets using

new inlet hoses (not provided). Do not use old hoses.

5. Insert new at washers into inlet

hoses

Install Drain Hose

3. Place drain hose in standpipe

Drain

hose form

4.5"

(114 mm)

Place hose into standpipe (shown in picture) or over side

of laundry tub.

IMPORTANT: 4.5" (114 mm) of drain hose should be inside

standpipe; do not force excess hose into standpipe or lay

on bottom of laundry tub. Drain hose form must be used.

Coupling Washer

Insert new at washers (not provided) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

6. Connect inlet hoses to water

faucets

Check that the washer basket is empty.

Attach hose to hot water faucet. Screw on coupling by hand

until it is seated on washer. Use pliers to tighten couplings an

additional 2/3 turn. Repeat this step with second hose

for cold water faucet.

IMPORTANT: Do not overtighten or use tape or sealants on valve

when attaching to faucets or washer. Damage can result.

7

7. Clear water lines

9. Check for leaks

Run water for a few seconds through hoses into a laundry tub,

drainpipe, or bucket to avoid clogs. Water should run until clear.

Make note of which hose is connected to hot water to help in

attaching hoses to washer correctly.

8. Connect inlet hoses to washer

Remove inlet cap and attach hot water hose to hot water (right)

inlet valve. Screw coupling by hand until it is snug. Use pliers

to tighten couplings an additional 2/3 turn. Repeat with cold

water (left) inlet valve.

IMPORTANT: To reduce risk of hose failure, replace the hoses

every 5 years. Record hose installation or replacement dates

for future reference.

■ Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

Turn on water faucets to check for leaks. A small amount of

water may enter washer. It will drain later.

■ If you connect only one water hose, you must cap (supplied)

off the remaining water inlet port.

Secure Drain Hose

10. Secure drain hose to laundry tub,

standpipe or wall

Laundry Tub Standpipe Wall

4.5"

4.5"

(114 mm)

(114 mm)

Secure drain hose to laundry tub leg, drain standpipe, or inlet

hoses for wall standpipe with cable tie (provided).

■ Do not force excess drain hose back into the rear of

the washer.

■ To avoid siphoning, do not seal or put more than 4½"

4.5"

(114 mm)

(114 mm) of the drain hose into drainpipe or

standpipe.

4.5"

4.5"

(113 mm)

(114 mm)

8

Loading...

Loading...