Whirlpool WRX-17TM Service Manual

Model: Version: 12NC:

WRX-17TM WRX48FSBFW00 (Silver color)

Whirlpool LAR - Home Appliances Division MSEX0000i

International Business – SKIC 1st Edition

Prepared by Luciano Cidral January, 2008

Reviewed by Alvaro S Alcântara January, 2008

1

INDEX

1. INTRODUCTION ......................................................................................................................................................3

2. PRESENTATION......................................................................................................................................................3

3. CONCEPT & TECHNOLOGY ..................................................................................................................................3

3.1. ELECTRONIC SYSTEM ...................................................................................................................................3

3.2. AIR FLOW SYSTEM .........................................................................................................................................4

3.3. FUNCTIONS......................................................................................................................................................5

3.3.1. Adaptive Defrost ........................................................................................................................................5

4. MAIN COMPONENTS..............................................................................................................................................6

4.1. COOLING CIRCUIT ..........................................................................................................................................6

4.1.1. Compressor & Acessories .........................................................................................................................6

4.1.2. Condenser .................................................................................................................................................6

4.1.3. Evaporator .................................................................................................................................................7

4.2. DEFROST SYSTEM .........................................................................................................................................7

4.2.1. Defrost Heater............................................................................................................................................7

4.2.2. Defrost sensor............................................................................................................................................7

4.2.3. Thermofuse................................................................................................................................................8

4.3. FREEZER FAN MOTOR...................................................................................................................................8

4.4. REFRIGERATOR FAN MOTOR .......................................................................................................................8

4.5. ELECTRONIC CONTROL.................................................................................................................................8

4.6. INTERFACE BOARD (LCD DISPLAY) .............................................................................................................9

5. TESTS ......................................................................................................................................................................9

5.1. INITIAL TEST ROUTINE (FACTORY ROUTINE).............................................................................................9

5.2. SERVICE TEST ROUTINE .............................................................................................................................10

5.3. SENSOR .........................................................................................................................................................11

5.4. ALARM SYSTEM ............................................................................................................................................12

5.4.1. Party Mode time exceeded ......................................................................................................................12

5.4.2. Temperature Alarm ..................................................................................................................................13

5.4.3. Open door ................................................................................................................................................13

5.5. TECHNICAL TROUBLESHOOTING...............................................................................................................13

6. REQUIRED TOOLS ...............................................................................................................................................16

7. ASSEMBLAGE & DISMOUNT ..............................................................................................................................16

7.1. ELECTRONIC CONTROL...............................................................................................................................16

7.2. INTERFACE BOARD – LCD DISPLAY...........................................................................................................17

7.3. LAMP SWITCH ...............................................................................................................................................18

7.4. AIR DIFFUSER................................................................................................................................................19

7.5. EVAPORATOR ...............................................................................................................................................20

7.6. SENSORS (REFRIGERATOR, FREEZER & DEFROST) ..............................................................................21

7.7. DOOR REVERSAL .........................................................................................................................................22

2

1. INTRODUCTION

This following manual objectives give you general information that will allow you can evaluate and do

interventions in whole product family.

Specific information like values of electrical and mechanical specifications, diagrams must be consulted in the

Technical Data, sent by specific markets product codes. To Spare Parts and Exploded Views, consult the Spare

Parts List.

Instructions of working and installation must be consulted in the customer manual (Users Guide).

2. PRESENTATION

Their main characteristics are: Easy Ice system with automatic feeder, External handle, Door cooling system,

Can rack & Skin condenser (Clinched condenser).

1- Refrigerator light

2- Shelves

2a- Bottle holder (depending on model)

3- Crisper drawer

3a- Moisture control

4- Door trays

5- Removable bottle holder

6- Can holder (depending on model)

6a- Multiflow outlets

7- Crisper drawer divider (depending on

model)

8- Divider (depending on model)

9- Ice maker (depending on model)

10- Freezer shelves (depending on

model)

11- Egg tray

12- Freezer compartment door

13- Freezer compartment door trays

14- Fresh control compartment

C- Anti-bacterial filter (depending on

model)

Attention:

The anti-bacterial filter assures a higher level of hygiene in the refrigerator through continuous purifying the air

of bacteria. Remove it from the box (found in the crisper drawer) and insert into the grille in the back wall of the

refrigerator compartment (item C). Replace the filter every 6 months.

3. CONCEPT & TECHNOLOGY

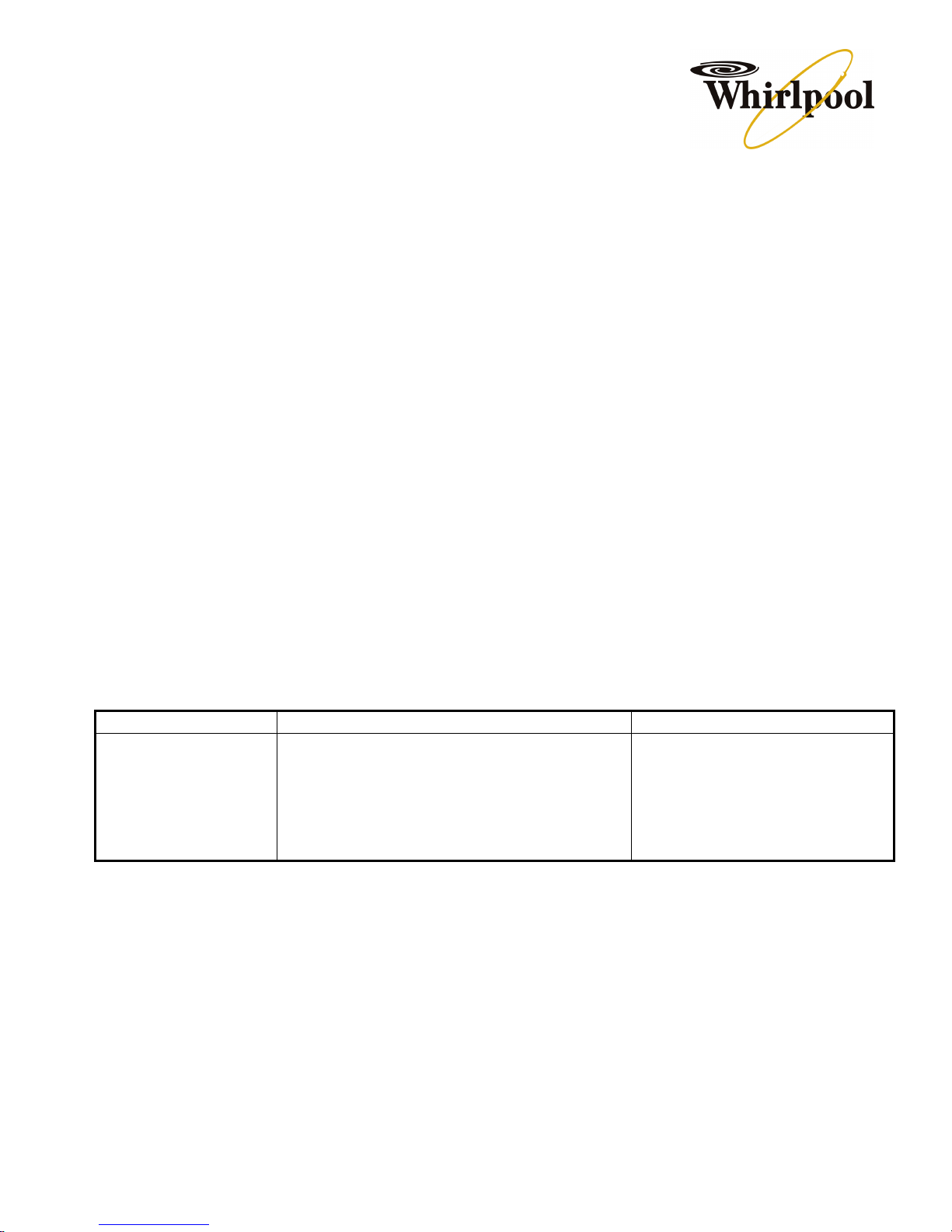

3.1. Electronic System

This is a no frost refrigerator managed by an electronic system, assisted by some peripherical components, as

follows:

- Electronic control;

- Interface board;

- Reed-switch board;

- Temperature sensors (Refrigerator , freezer & defrost);

- Compressor;

- Freezer Fan Motor (V dc);

- Refrigerator Fan Motor (V dc);

- Defrost Heater;

- Lamps.

3

Basically, the temperature read inside the freezer by the temperature sensor is sent to the electronic control,

which controls the working of the compressor, of the fan motor, and of the heater (each 8 hours of working of

the compressor (or each 4 fours in the adaptive mode, as you will see following this manual).

Variables:

a) The internal lamp is lighted when the door is opened. An electromechanical switch is connected in series

between the lamp and the electronic control.

b) The temperature inside the refrigerator compartment is controlled by an mechanical thermostatic damper,

which controls the air flow from the freezer to the refrigerator compartment, therefore, the changed air from

the refrigerator compartment rises till the temperature sensor located on the freezer. The factor which

defines when will occurs a defrost procedure, is therefore, strongly linked to the quantity of the opening of

doors, besides the quantity of food and external temperatures.

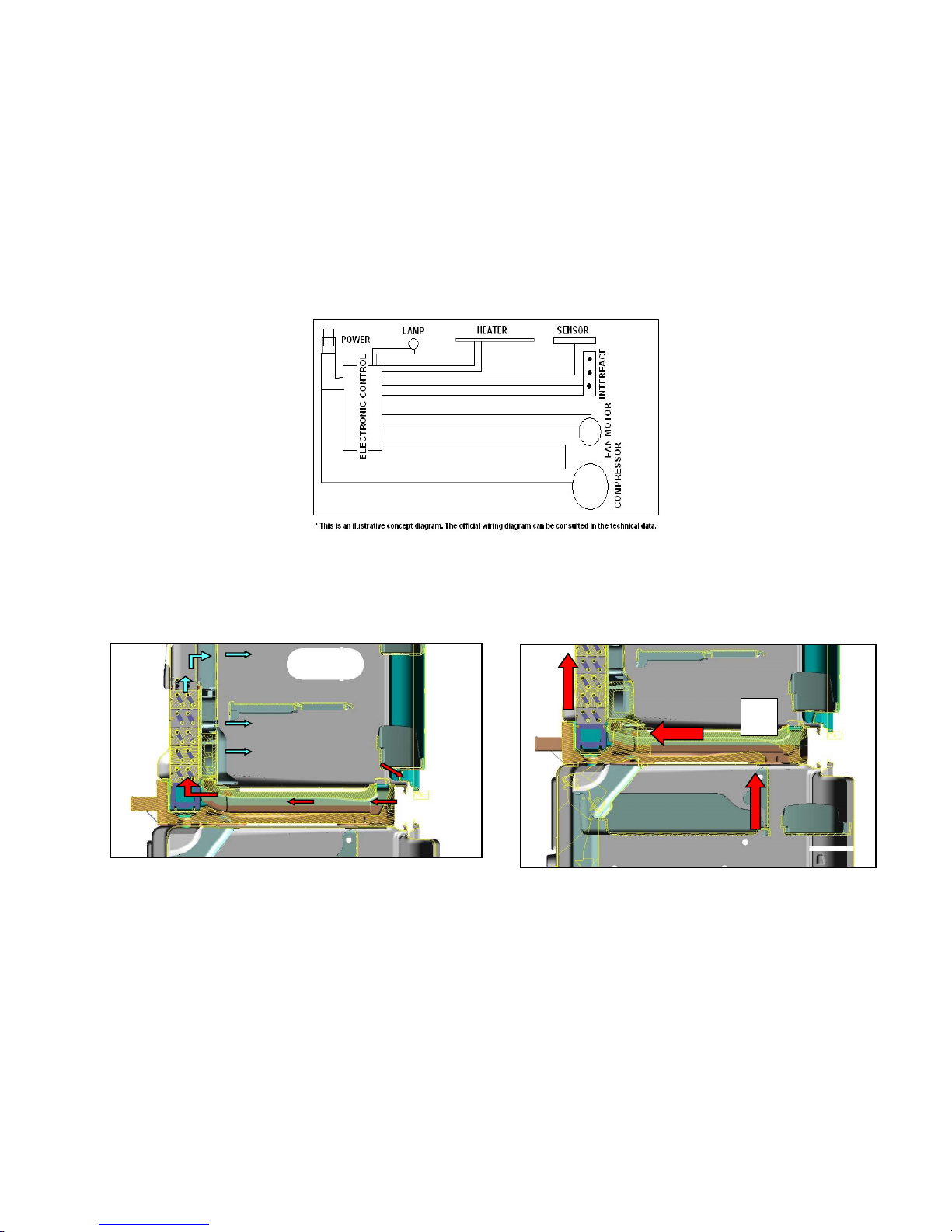

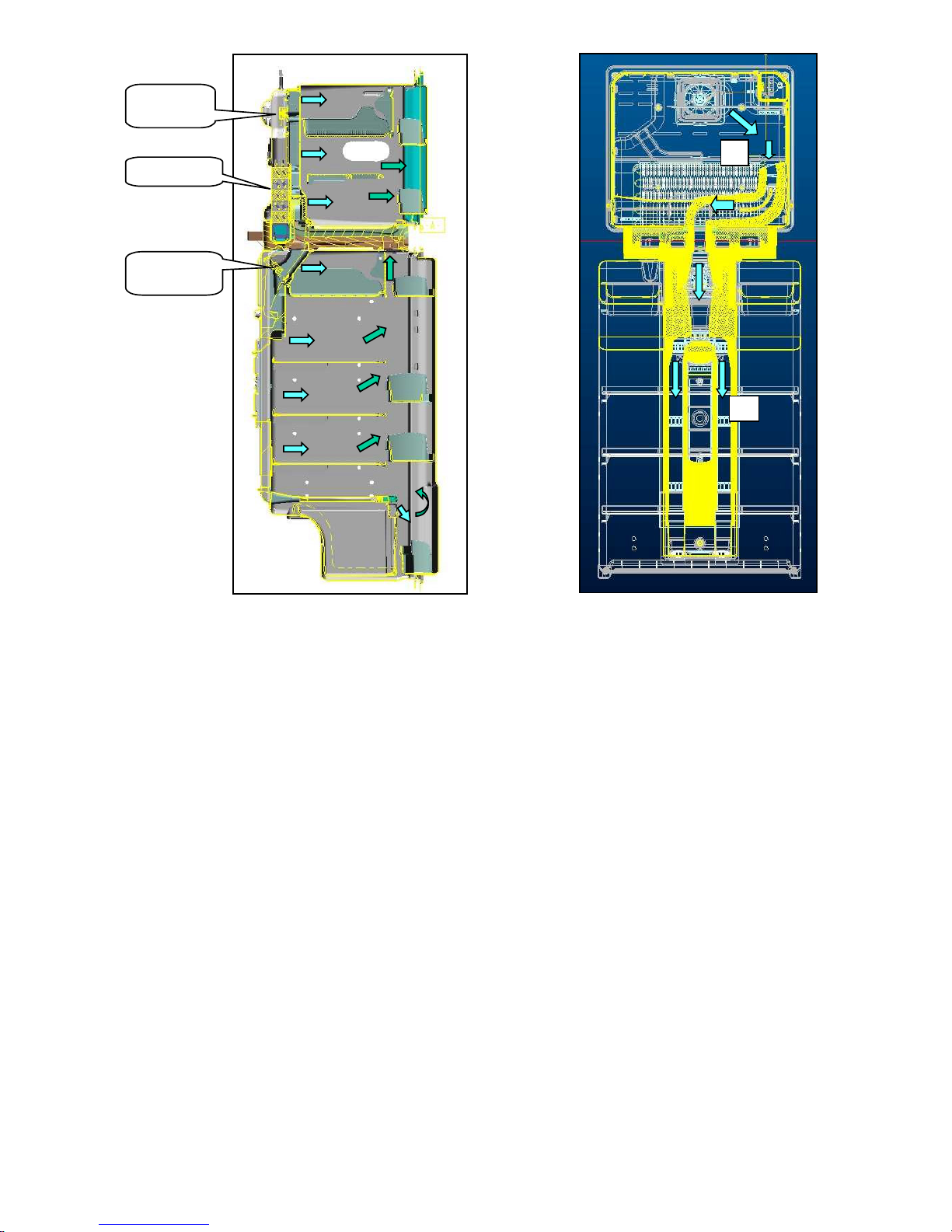

3.2. Air Flow System

The pictures below show us how the forced air, circulates on the product, and returns to the evaporator, when

suffers the cooling process again.

3

4

Freezer

1

2

Fan Motot

Evaporator

Thermostatic

Damper

The refrigerator air diffuser has a wind flow system, which provide a better air distribution over this compartment

due to the many outlets/windows available.

Protected by a front plastic cover, the air diffuser is made of styrofoam (expanded polyesthyrene - EPS). the

upper part houses the damper and the diffuser complement, whereas the rear portion is provided with several

seals to prevent air leaking through the sides

3.3. Functions

3.3.1. Adaptive Defrost

This refrigerator has an adaptive defrost system, which is adjustable according to client’s habits, environmental

conditions, etc.

Monitored by the electronic control, this system is constituted of the following components:

- Electronic control;

- Defrost heater;

- Defrost sensor temperature;

- Defrost gutter;

- Evaporation recipient (above the compressor).

The accurate frequency is defined by the electronic control throughout the following monitoring:

- Compressor activity time;

- Door opening frequency;

- Time of the last executed defrosts;

5

Defrosts shall occur in every 4 hours (of the compressor activity), able to be reduced (adaptive) to every 4 hours

(of the compressor activity) according to the usage (determined by the electronic control software). Defrost

average time is from 10 to 20 min. And the maximum is 40 min., Afterwards, the product will return to its normal

operation.

Summarily, the electronic control activates the defrost system, which will execute the following steps:

- Fan motor and compressors are turned-off;

- Heater is activated;

- Defrost sensor informs the defrost ending when reach 15°C (or 40 minutes, maximum time);

- Heater is turned-off;

- Compressor is turned on after 5 minutes the heater is off;

- Motor fan is turned on when the differential of temperature between defrost and freezer sensors reach

2°C;

- Product returns to the programmed function before defrost.

This defrost system has also a safety system which will put in action an immediate defrost in case of an existing

differential temperature between defrost sensor and freezer sensor higher than 10°C for 10 minutes, helping

contend against casual ice building up on the evaporator.

When the product is with fast freezing mode enable, the defrost system will be fixed and not adaptive, and 2

defrosts will occur during this period, it means, the first will occur 3 hours after the compressor activity and the

second just 9 hours after (compressor activity) the first defrost.

Upon ending the activity of the fast freezing function (18 hours), the next defrost cycles will occur as adaptive

normal cycles.

4. MAIN COMPONENTS

4.1. Cooling Circuit

4.1.1. Compressor & Acessories

Alternative hermetic and high efficient compressor, made by Embraco, to refrigerant R134a.

Remark: The compressor just works again when we have 7 minutes since its last cycle.

The relay and thermal protector are sold together the compressor, if necessary to change individually, consult

the spare parts list.

This compressor also has a capacitor (located on the electronic control box). Its function is help the compressor

works efficient and not to execute start-up.

The filter dryer to R134a is a filter with higher quantity of drier element. You can use a filter to R134a in systems

R12, but the inverse is not allowed.

To other information, norms and procedures, consult specific manuals to hermetic system interventions.

4.1.2. Condenser

This refrigerator has a new concept of built-in condenser, which is known as the “clinched”.

Different of a traditional built in condenser (which are inside the cabinet and in contact with another metallic

surface – by others manufacturers), the clinched condenser changes temperature direct to the ambient,

increases the yield, because its contact area is larger.

As this condenser does not be changed, like a normal condenser, it is necessary clean it very well when occurs

interventions on the hermetic systems. Use nitrogen pressure and/or the refrigerant gas (to severe

contamination).

6

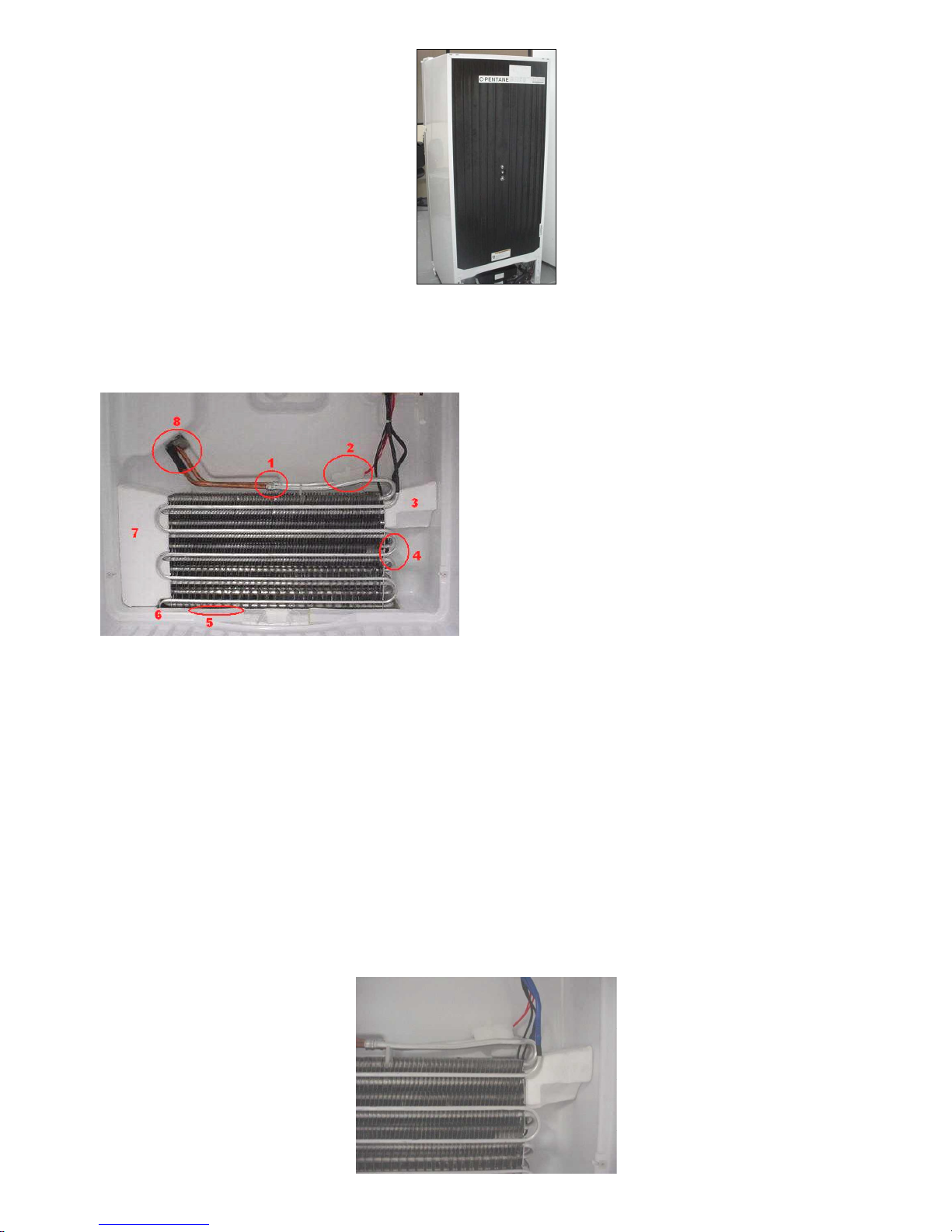

4.1.3. Evaporator

Frost Free Type Evaporator, with suction line injected in the cabinet. Only the Evaporator can be substituted.

Due the internal configuration we strongly recommend do the interventions with the lokring connections.

1. Lokring connector

2. Defrost sensor

3. EPS - shim right

4. Thermofuse

5. Defrost shield

6. Deforst heater

7. EPS - shim left

8. Suction line

4.2. Defrost System

4.2.1. Defrost Heater

The Defrost Heater involves all the evaporator extension, presenting a better performance of the system. Its

operation (on/off) is also commanded by the electronic control and its electrical features are: Power 275(W),

value 194 to 227 ohms.

The lower part of the defrost heater is fixed at the defrost gutter through claws in order to avoid ice building on

this place. Always ensure the contact between these parts.

4.2.2. Defrost sensor

It’s located at the freezer compartment, along with the evaporator returning pipe. The defrost sensor is

responsible for sending signs to the electronic control, which will command the ending of the adaptive defrost,

turning off the defrost heater, containing a similar function to the well-known defrost bimetal.

7

4.2.3. Thermofuse

Turned on in series connection with the heater defrost, the thermofuse protects the product and does not allow

that defrost heater be turned on continuously in case of failure of the defrost sensor. In case of failures in the

defrost system when the heater is continuously working, it will open at the range of 72 °C to 77 °C.

4.3. Freezer Fan Motor

The Fan motor is a (V dc) motor and is fixed to the rear cover of the evaporator through a rubber flexible holder

(freezer), that protects from occasional vibrations, and consequently noise.

Technical Characterístics:

Rated voltage: 24 Vdc

Operating range : 20,4 Vdc - 27,6 Vdc

Current max (a): 0,18 a

Potency max: 4,3 W

Speed rated: 3000 rpm

4.4. Refrigerator Fan Motor

The Refrigerator fan motor is also fed by direct voltage (V dc), therefore, located inside the wind flow, fixed

to a plastic housing by flexible rubber holder, which avoids occasional vibrations and consequently noise. it is

responsible for the forced air circulation inside the refrigerator compartment.

Technical Characterístics:

Rated voltage: 24 Vdc

Operating range : 20,4 Vdc - 27,6 Vdc

Current max (a): 0,1 a

Potency max: 2,9 W

Speed rated: 2900 to 3500 rpm

4.5. Electronic Control

The complete operation of this product is done by the electronic control, which executes the functions according

to the necessities, turning the components on or off through received/managed signals.

Inside its box, the electronic control is divided in 2 parts, a main board and a line filter.

Main board Line filter

CN1 – Compressor and power coard

CN2 – Load components and lamps

CN3 – Temperature sensors

CN4 – Interface board

Note: More details, check the wiring diagram

8

4.6. Interface Board (LCD Display)

The Interface board has the function of interacting with the user, indicating the product functions/programming

and operation (see use characteristics item) always put in operation by the electronic control.

5. TESTS

Two automatic test routines are available in these refrigerators in order to prove the main components of the

product: one executed automatically by the software of the electronic control, when the product is plugged on

the power supply and other handled by the own technician, which are described as follows:

5.1. Initial Test Routine (factory routine)

This refrigerator has an Automatic Testx Routine (works automatically, without manual operation) that is always

executed when the product is energized to the power supply, in order to verify the functioning of the main

components of the product. This routine operates as follow:

# Turn off the product from the wall socket, wait 10 seconds and turn it on again.

Note: At this moment, an inner temperature check will occur in the evaporator, through the Defrost Sensor, and

then the Routine will start automatically.

- The Defrost Heater is energized for 6 seconds

- Freezer Fan Motor is energized for 6 seconds

- Refrigerator Fan Motor is energized for 6 seconds

After 18 seconds, from the result (temperature) gained from the Defrost Sensor, the Electronic Control will

manage the activation of the compressor and fan motors, as follow:

# If the Defrost Sensor is warm (temperature > 0o C)

- Compressor and fans will be energized / turned on.

# If the Defrost Sensor is cold (temperature < 0o C)

- Compressor and fans will not be energized / (will keep off).

After 328 seconds (5.5 minutes) the product is energized, an automatic check will occur for all the Sensors

(Refrigerator, Freezer & Defrost)

# If any of the sensors present failure (open or in short circuit);

- The Automatic Routine will be aborted (348 seconds/ 5.8 minutes); then, after 2 minutes (468

seconds/ 7.8 minutes) the Alarm Code will be shown on the display and the operation proceedings will

follow as described in item – Alarm System.

# In case of no failure is detected

- Product will abort the Automatic Routine (348 seconds/ 5.8 minutes) and starts working in normal

activity, switching on the components due to the necessity (display temperature).

9

Loading...

Loading...