Whirlpool WPRERADWMW8637 Tech Sheet

W11266094A

WARNING

Pin

Pin 1

Locking tab

Hinge hook

housing base

When performing live voltage measurements, you must do the following:

Voltage Measurement Safety Information

Verify the controls are in the off position so that the appliance does not start when energized.

Allow enough space to perform the voltage measurements without obstructions.

Keep other people a safe distance away from the appliance to prevent potential injury.

Always use the proper testing equipment.

After voltage measurements, always disconnect power before servicing.

FOR SERVICE TECHNICIAN’S USE ONLY

NOTE: This sheet contains important Technical Service Data.

Tech Sheet

Do not remove or destroy

DANGER

Electrical Shock Hazard

Only authorized technicians should perform diagnostic

voltage measurements.

After performing voltage measurements, disconnect

power before servicing.

Failure to follow these instructions can result in death

or electrical shock.

Specications

ELECTRICAL SUPPLY:

(Under load) 60 Hz, 120 VAC

SUPPLY WATER FLOW RATE:

To ll 2 qt (1.9 L) in 27 seconds, 120 psi maximum, 20 psi minimum

SUPPLY WATER TEMPERATURE:

120°F (49°C) (Before starting a cycle, run water from sink faucet until

hot.)

WATER CHARGE:

0.9 gal. (3.5 L) approximate

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

LOWER SPRAY ARM ROTATION:

12 to 40 rpm

UPPER SPRAY ARM ROTATION:

12 to 30 rpm

Rast Connector Pinout

1

IMPORTANT: Connector box and brace must be reattached to control when service is completed.

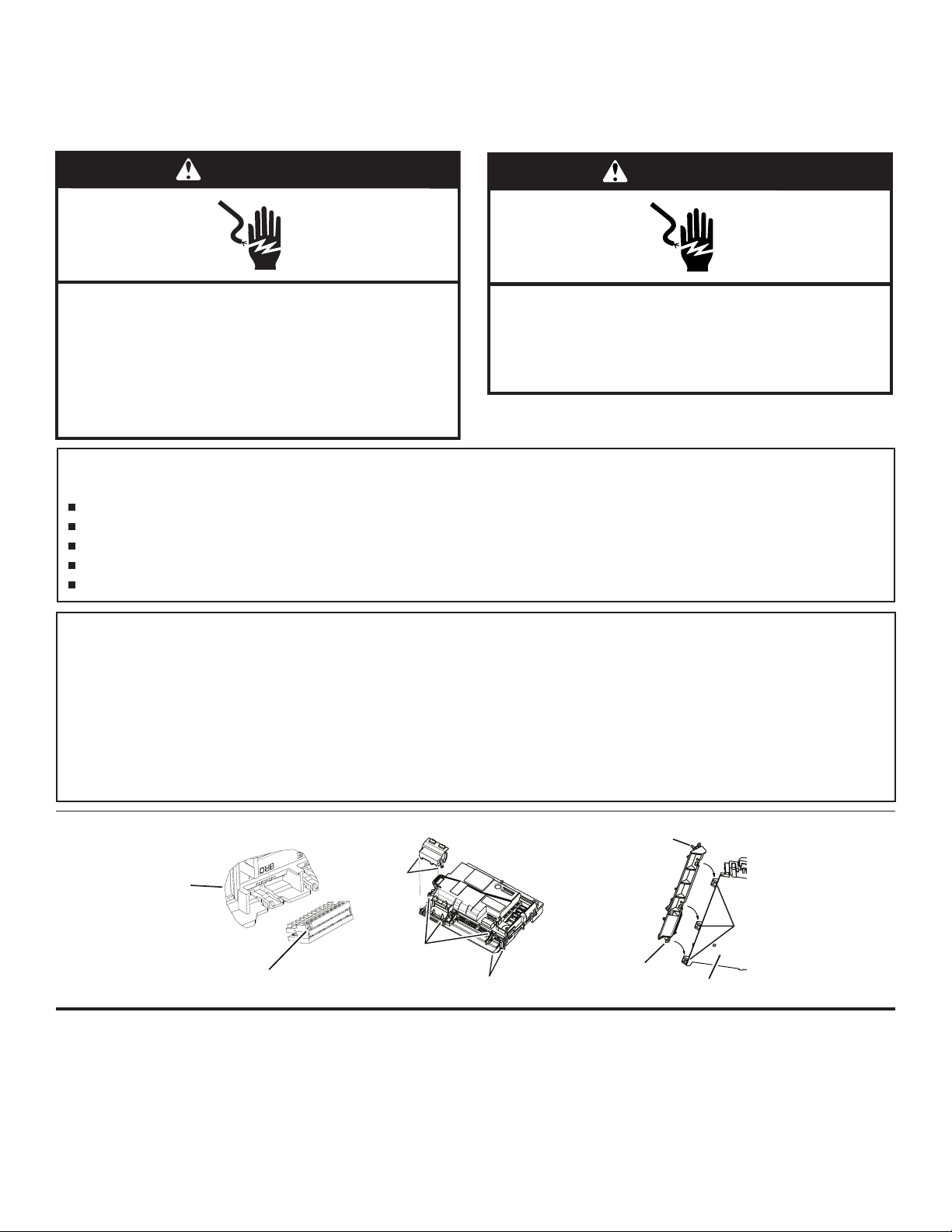

Steps to Access Control for Servicing

1. Connector Box Removal:

Press inward on the retainer tabs as indicated while lifting up on the

connector box. This can be done with a screwdriver or similar tool

from either the top or bottom side of the control.

2. Connector Brace Removal:

Locate the 3 brace locking tabs as shown. Push each tab in the

direction required while applying light downward rotational force on

the brace. It is easiest to unlock one tab at a time, working from one

end of the brace to the other.

3. Once all 3 tabs are unlocked, pivot the brace to allow removal and

gain access to the wiring harness connectors and control for required

servicing.

Control Assembly

1

2

3

4. Connector Brace Reattachment:

Attach the brace hinge hooks into holes in the hinge tabs on control

housing base. Pivot brace until all 3 locking tabs snap into housing

lid. Make sure the harness wires lay at and are not pinched.

5. Connector Box Reattachment:

Position the connector box over P4 and P5 connectors, insert the

retainer tabs into brace mounting holes, and snap box onto control

housing lid. Make sure box is sitting ush against both the brace and

housing and harness wires are at and not pinched.

1

4

Underside of

FOR SERVICE TECHNICIAN’S USE ONLY

(bl cl)

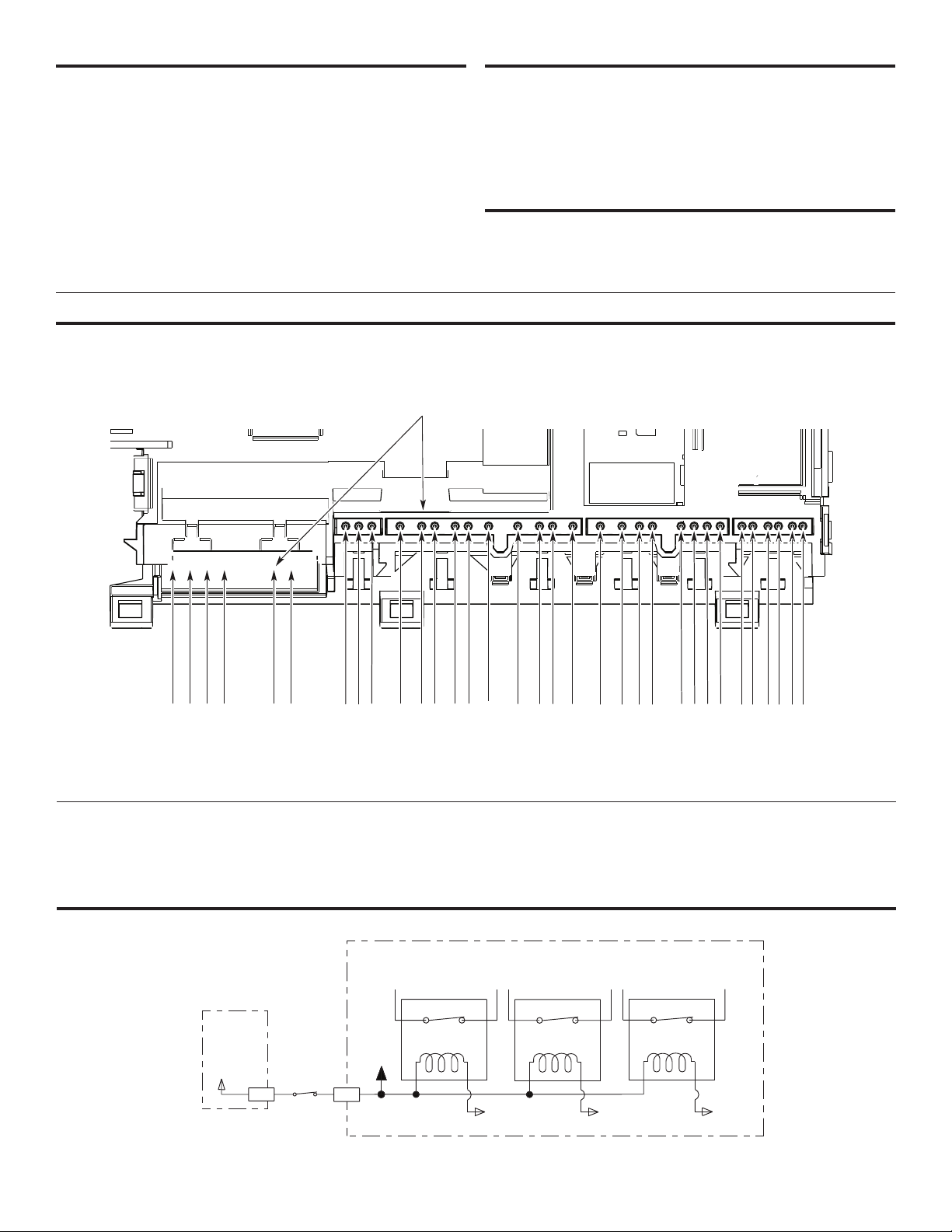

Fuse test points. See “Fuse Resistance Check” in “Meter Check of Loads and Fuses” section.

ltimètre”.

Module de commande électronique

Fuse Service Check:

F601 = Small triac load fuse

F600 = Wash pump motor fuse

Check operation of loads during Service Diagnostics cycle.

If any of the triac loads work (ll, dispenser, drain), F601 fuse is OK.

If all triac loads fail to work, F601 fuse could be open.

If wash pump motor runs, F600 is OK.

If wash pump motor does not run, F600 fuse could be open. If either

fuse could be open, See the “Fuse Resistance Check” section.

Fuse Resistance Check:

Unplug dishwasher or disconnect power.

Measure resistance of fuses F600 and F601.

a. Disconnect wash pump motor wiring jumper P5 from the control board.

b. Using a resistance meter, measure the resistance between

control board connection pins P5-2 and P6-3. See “Control

Pinout” diagram.

If resistance is < 3 Ω, both fuses are OK.

If resistance is > 3 Ω, replace control.

What To Do If Fuse Open:

Inspect and check resistance of all loads on fuses. If any loads are open,

shorted, or have evidence of overheating or pinched wires, replace loads

and/or repair wires.

Control Pinout

Metering of Triac Loads

Load must be connected for triac to operate correctly. Meter checks are best made at the control. See illustration below and “Dishwasher Strip

Circuits.”

Points de test du fusible. Voir “Contrôle de résistance des fusibles” de la section “Contrôle des charges et des fusibles au mu

-1

-3

-4

-2

P4

-2

P5

-3

-1

-2

-1

-1

P14

Turq

(LBU)

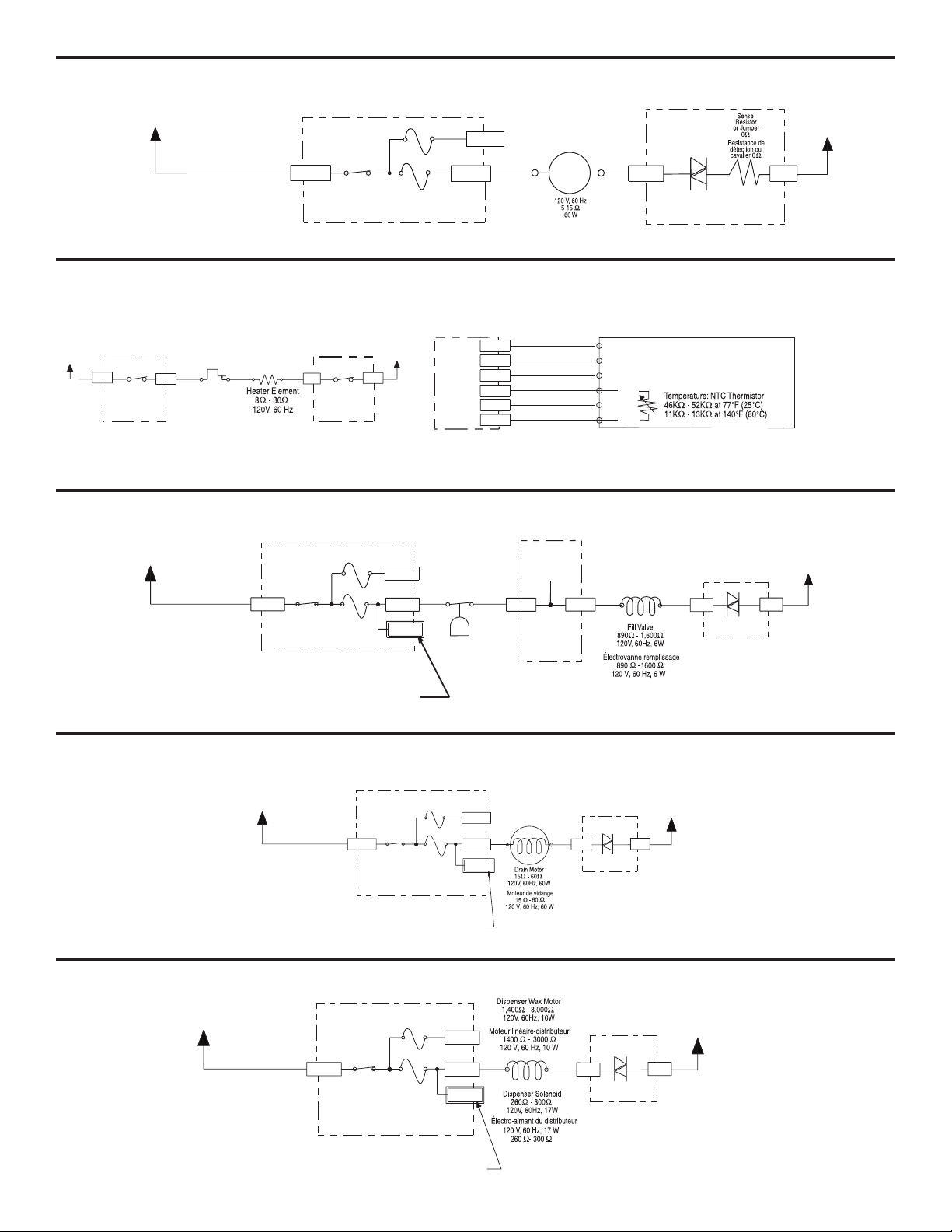

Dishwasher Strip Circuits

-6

-9

-3

-7

-4

P6

BR BU V

MAR

The following individual circuits are for use in diagnoses. Do not continue with the diagnosis of the appliance if a fuse has blown, a circuit breaker is

tripped, or if there is less than a 120 V power supply at the wall outlet.

Unplug dishwasher or disconnect power.

Perform resistance checks. To check resistance of a component, disconnect harness leads rst.

-1

-3 -4 -6

P7

-3

-4

-1

-3

-5

-1

P9

-2

-1

-6

P11

RD

VI

R

-2

-3

-4

-5

-6

P12

YL

JA

Door Switch

Electronic Control

Module de

commande

électronique

12V

P9-6

Door Switch

Contacteur porte

V

N.O.

VI

Pin 1 Pin 3

Broche 1

Broche 3

Door

Switch

Sensing

Input

Détection

contacteur

de porte

- entrée

V

VI

P9-5

(To Heater)

(vers élément chauffant)

N.O.

Heater (N) Relay

Relais élément

chauffant (NEU)

(ToWash Motor,

Vent, and Tr iac Loads)

(vers moteur lavage,

évent et charges triac)

N.O. N.O.

Pilot (L1) Relay

Relais d'alimentation

(L1)

Micro Pin Micro Pin

Microbroche Microbroche Microbroche

(To Heater)

(vers élément chauffant)

Heater (L1) Relay

Relais élément

chauffant (L1)

Micro Pin

Electronic Control

2

Puissance du moteur L1

NEU

FOR SERVICE TECHNICIAN’S USE ONLY

Electronic Control

chauffant

(97 °C - 103 °C)

Float

E

et P6-7. Utiliser la cosse de test sur P7-3.

Utiliser la cosse de test sur P7-3.

Wash/Rinse

See “Meter Check of Loads and Fuses” to diagnose possible open fuse issues.

Motor Power L1

Fuse F601

BK

N

P4-2 P5-2

N.O.

Fuse F600

Pilot L1 Relay

(Also see Door

Fusible F600

Switch circuit.)

Relais d'alimentation

L1 (voir également le circuit

du contacteur porte)

Electronic Control

Module de commande électronique

Fusible F601

P6-4

Turq

(LBU)

(Bl cl)

1-PH Sync

Turq

Wash

Motor

Moteur delavage

sync.

Pin 1

monophasé

Broche 1 Broche 3

Pin 3

Turq

(LBU)

Turq

(Bl cl)

P5-1

Motor Triac

Triac

Electronic Control

Module de commande électronique

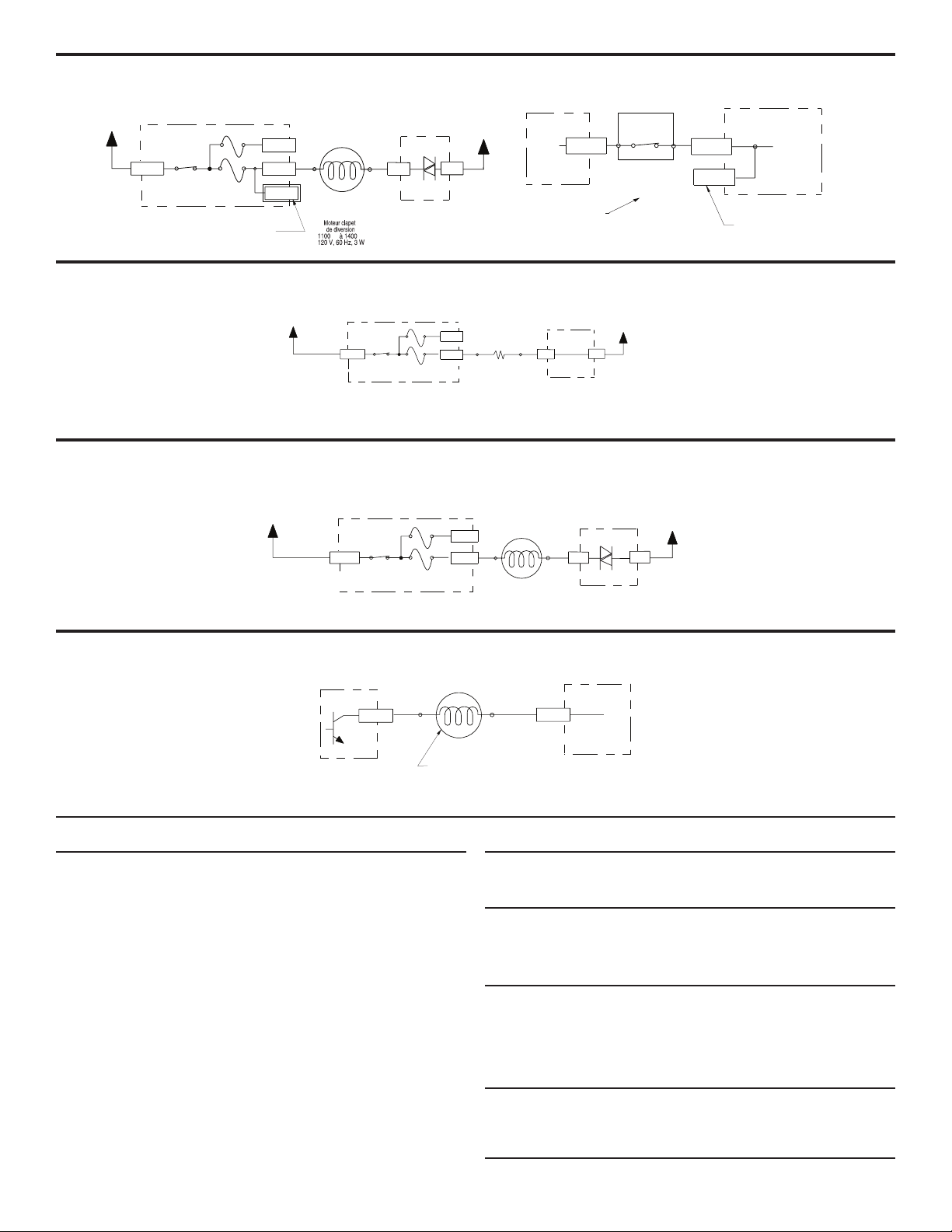

Water Heating/Heat Dry and Water Sensing with OWI Soil Sensor (Water/Air/Soil/Temperature)

Pump is washing and control monitors temperature during water heating periods. See “Wash/Rinse” and “Water Sensing with OWI Sensor (Water/Air/

Soil/Temperature)” circuits.

Heater

Élément

L1

Electronic Control

BK

N

P4-2

Relais élément

(voir également

contacteurde porte)

Module de

commande

électronique

N.O.

Heater L1 Relay

(Also see Door

Switch circuit)

chauffant - L1

lecircuit du

P4-3

N.C.

N.F.

BU/R

Hi-Limit

Thermostat

Opens

207°F - 217°F

(97°C - 103°C)

Limite haute

ouverture du

thermostat

207 °F - 217 °F

BU/R

785 W Wet

500 W Dry

Élément chauffant

Ω

8 - 30

120 V, 60 Hz

785 W humide

500 W sec

BU/W

BU/BL

Ω

Module de

commande

électronique

P4-4

Heater N Relay

(Also see Door

Switch circuit)

Relaisélément

chauffant - N

(voir

le circuit du

contacteur porte)

N.O.

également

P4-1

N

W

BL

Control

Module de

commande

électronique

P12-5

P12-4

P12-3

P12-2

P12-1

YJA

YJA

YJA

YJA

YJA

YJA

P12-6

Electronic

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Broche 1

Broche 2

Broche 3

Broche 4

Broche 5

Broche 6

Turbidity Drive

Foam Drive

OPT Sig

VCC

Ref

RÉF

NTC

Circuit dÊactivation détecteur turbidité

Lecture moussage

OPT SIG

O.W.I. Sensor

(on some models)

Measure NTC resistance at P12-1 and P12-3 connector disconnected from control.

Mesurer la résistance NTC aux connecteurs P12-1 et P12-3, déconnectés du module de commande

W

BL

P4-1

(sur certains modèles)

Température :

thermistance NTC

Ω - 52 K Ω

46 K

11 K Ω - 13 K Ω

N

Détecteur

(OWI)

à 77 °F (25 °C)

à 140 °F (60 °C)

Fill

See “Meter Check of Loads and Fuses” to diagnose possible open fuse issues.

L1

BK

N

P4-2

Pilot L1 Relay

(Also see Door

Switch circuit.)

Fuse F600

Fusible F600

N.O.

Relais

d'alimentation

L1 (voir également le

circuit du contacteur

de porte)

Fuse

F601

Fusible

F601

Electronic Control

Module de commande électronique

Test hole for P6-3 and P6-4 may crowd P6-6 and P6-7.

Recommend using test hole for P7-3.

La cosse de test sur P6-3 et P6-4 peut obstruer P6-6

(In normal position

holdsswitch closed.)

(en position normale)

P5-2

maintient le contacteur fermé.

BR

MAR

P6-4

Pin 3

Broche 3Broche 1

P7-3

Overfill

Float Switch

remplissage

Le flotteur

N.O.

Contacteur

flotteur -

excess

Pin 1

Drain

See “Meter Check of Loads and Fuses” to diagnose possible open fuse issues.

Fuse F600

L1

BK

N

P4-2

Pilot L1 Relay

(Also see Door

Switch circuit.)

Relais d'alimentation

L1 (voir également le circuit

du contacteur de porte)

Module de commande électronique

Test hole for P6-3 and P6-4 may crowd P6-1.

Recommend using test hole for P7-3.

La cosse de test sur P6-3 et P6-4 peut obstruer P6-1.

Fusible F600

N.O.

Fuse F601

Fusible F601

Electronic Control

P5-2

P6-3

P7-3

BR

MAR

BR

MAR

Pin 1

Broche 1

Float Switch

Input

Contacteur

flotteur - entrée

P6-6

Electronic Control

Module de

commande

électronique

BR

MAR

Pin 3

Broche 3

BR

MAR

P6-7

Pin 3

Broche 3

P6-1

Triac

Electronic Control

Module de

commande

électronique

N

NU

BR

MAR

Pin 1

Broche 1

P6-9

Tr iac

P4-1

W

BL

Electronic Control

Module de

commande

électronique

N

NEU

WH

BL

P4-1

Dispenser (Detergent and Rinse Aid)

See “Meter Check of Loads and Fuses” to diagnose possible open fuse issues.

L1

BK

N

Fuse F600

Fusible F600

N.O.

P4-2

Pilot L1 Rel

ay

(Also see Door

Switch circuit.)

Relais

d'alimentation L1

(voir également le circuit

du contacteur de porte)

Module de commande électronique

Test hole fo r P9-3 may crowd P9-1.

Recommend using test hole for P7-3 .

La cosse de test sur P9-3 peut obstruer P9-1.

Utiliser la cosse de test sur P7-3.

Fuse F601

Fusible F601

Electronic Control

P5-2

P9-3

P7-3

3

V

VI

Pin 1

Broche 1

Pin 3

Broche 3

V

VI

P9-1

Electronic Control

Tr iac

Module de

commande

électronique

P4-1

N

NEU

WH

BL

Diverter Sensor

Utiliser la cosse de test sur P7-3.

.

contacteur porte)

Fan Motor

des modules de commande.

FOR SERVICE TECHNICIAN’S USE ONLY

Diverter Valve

See “Meter Check of Loads and Fuses” to diagnose possible open fuse issues.

L1

BK

N

N.O.

P4-2

Relais d'alimentation

Pilot L1 Relay

L1(voir également

(Also see Door

Switch Circuit.)

Module de commande électronique

Test hole for P7-6 may crowd P7-4

Recommend using test hole on P7-3.

La cosse de test P7-6 peut obstruer P7-4.

le circuitdu

contacteur porte)

Electronic Control

Fuse F600

Fusible F600

Fuse

F601

Fusible

F601

P5-2

BU

P7-4

Pin 3

Broche 3 Broche 1

P7-3

Diverter Motor

1,100

120V, 60Hz, 3W

Ω

Ω

- 1,400ΩΩ

Pin 1

P7-6

Triac

Electronic

Control

Module de

commande

électronique

Vent (not all models)

See “Meter Check of Loads and Fuses” to diagnose possible open fuse issues.

L1

BK

N

Electronic Control

Module de commande électronique

Fuse F600

N.O.

P4-2

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Relais dÊalimentation

L1(voir également

le circuit du

contacteur porte)

Fusible F600

Fuse F601

Fusible F601

AC Fan (not all models)

See “Meter Check of Loads and Fuses” to diagnose possible open fuse issues.

Electronic Control

L1

BK

N

Module de commande électronique

Fuse F600

N.O.

P4-2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Relais dÊalimentation

L1(voir également

le circuit du

Fusible F600

Fuse F601

Fusible F601

N

NEU

WH

BLBU

P4-1

P5-2

BU

P7-3

Pin 1

Broche 1 Broche 3

VENT MAX MOTOR

600 -1800 Ω

120 V, 60 Hz, 6 W

MOTEUR DE

VENTILATEUR MAX

120 V, 60 Hz, 6 W

P5-2

BU

P7-3

Pin 1

Broche 1Broche 3

Capteur Diversion

Sensor

Input

P11-4

Capteur Entrée

Electronic Control

Module de commande électronique

Switch closes momentarily

and then reopens as the diverter

reaches each potential diverter position.

Le contacteur se ferme momentanément,

puis s'ouvre de nouveau lorsque le module de diversion

atteint chaque position potentielle de diversion.

Electronic Control

Module de

commande

électronique

600 -1800 Ω

AC Fan Motor

120 V, 60 Hz

130 - 155

Moteur du ventilateur CA

120 V, 60 Hz

130 - 155 Ω

Pin 3

BU

P7-1

Ω

Pin 3

P4-1

Electronic Control

Module de

commande

électronique

P7-1

Tr iac

N

NEU

WBLH

N.O.

Diverter Position

Switch

Contacteur -

positionclapet

de diversion

WH

P4-1

P11-3

P11-2

Test hole for P11-4 may crowd P11-3.

Recommend using test pad on P11-2.

N

NEU

BLBU

3V

Electronic Control

Module de commande électronique

La cosse de test P11-4 peut obstruer P11-3

Utiliser la cosse de test sur P11-2.

DC Fan (not all models)

(Red stripe on plug)

(liseré R sur fiche

de branchement)

MAR

P11-2

DC Ref

Ref CC

Electronic Control

Module de commande électronique

Service Diagnostics Cycle Notes

To invoke the Service Diagnostics cycle, perform the following while

in Standby:

Press any 3 keys in the sequence 1-2-3-1-2-3-1-2-3 with no more

than 1 second between key presses.

The Service Diagnostics cycle will start when the door is closed.

To rapid advance 1 interval at a time, press START/RESUME.

Rapid advance may skip sensor checks as some checks require 2

complete intervals.

NOTE: The Service Diagnostic cycle will pause when the door

is opened and resume automatically upon door closure.

No Start/Resume key press is required to resume.

Invoking Service Diagnostics cycle clears all status and last run

information from memory and restores defaults. It also forces the

next cycle to be a Sensor Calibration cycle. Calibration cycle may

add additional rinses prior to the nal rinse to ensure clear water

and then calibrates the OWI during the ll at the beginning of the

nal rinse.

Drain and wash motors will pulsate on and off.

Last Ran cycles and options returned to default.

Last Ran Delay returns to the default delay setting.

Operating state returns to Standby upon completing or

terminating the Service Diagnostics cycle.

31K

Ω - 41K

5 V DC, 1W

Moteur ventilateur

BR

_

Pin 1

Borche 1

disconnected from controls.

La résistance doit être mesurée

avecla polarité correcte et déconnectée

Ω

Ω - 41K

Ω

31K

5 V DC, 1 W

+

Pin 3

Borche 3

Must measure resistance

with correct polarity and

21

3

4

5

(Red stripe on plug)

(liseré R sur fiche

de branchement)

BR

MAR

P11-1

Module de commande électronique

5V

Electronic Control

Press Hi Temp or cycles key in this interval to clear customer error

history.

Thermistor (temperature sensor) checks:

Turn Clean LED on if thermistor is in its normal temperature range

of 32°F–167°F (0°C–75°C).

Turn Sanitized LED on if Fill temperature is above 156°F (69°C).

OWI (Optical Soil Sensor) Checks:

Check OWI sensor for the presence of water during 5 second

pause in interval 16 and turn on Clean LED in interval 14 if water

detected.

Check OWI sensor for presence of bulk soil during interval 12 and

turn on Clean LED in interval 11 if bulk soil is detected.

Diverter will be on continuously in intervals 14 and 13. In all other

intervals, diverter will be on only until it reaches the intended position

for that interval.

6

DC fan motor is on during upper rack washing intervals.

4

13y 5y data GND

WIN/ WIDE

Connector P1A

RAST 2.5, 4 pin header OR JST 4 pin Header - Primary for External Uis

UI Connector Details

YLYLYLYLYL

YL

3

Diverter

Motor

1

BU

BU

P7-4

P7-6

Diverter

Pos

ition

Switch C

ontac

t

(Closed During

Transitions)

1 2 3 4

ORN P7-1

ORN P7-3

AC Fan

M

3

1

(A)

(B)

or

3

+-

1

DC Fan

Motor

5V, 1W, 200mA

This load

can be

turned

on/off by

(A) Tr aic - for

Regen value

or

(B) Pilot Relay

for vent

R4-11P

R3-11P

*Module de commande électronique

Détails du connecteur IU

RAST 2,5 à tête à 4 broches OU JST à tête à 4 broches –

pour IU externe

Connecteurs

13y 5y Données Neutre

Alimentation

électrique

Microbroche

Microbroche

Certains modèles

*Détecteur de souillures

(capteur NTC, moussage et turbidité)

ou

capteur NTC/turbidité

Clapet de diversion

position contact du

contacteur

les transitions)

(fermé durant

Moteur du

ventilateur CC

5 V, 1 W, 200 mA

Contacteur

de la porte

Moteur linéaire

Bobine du

distributeur

distribu teur

Moteur

clapet de

diversion

Moteur de

vidange

*Électrovanne

de remplissage

Contacteur flotteur remplissageexcessif

Ventilateur CA

Pompe de

moteur de

monoph.

lavage synchro.

La ligne de retour des bobines de relais - 12 V traverse le contacteur de porte.

Détection d'ouverture de porte

Détection de charge (courant) pour le triac de vidange, les petites charges triac et l'évent pour l'auto-diagnostic.

Thermostat

Élément

de limite haute

chauffant

remplissage

Détection

excessif

moussage

Lecture

S ig opt

Lecture turbo

Entrée

analogique

Entrée

numérique

Entrée

NTC

Ligne

NOIR

NEU

BL

ou

Cette charge

peut être activée/

désactivée par

(A) Traic - pour

valeur

Régénération

ou (B) Relais

d'alimentation

pour évent

LigneNEU

Détecte

moteur

Triac

Fusible

Fusible

Relais

dÊalimentation

Micro

broche

Turq (bl cl)

Turq (bl cl)

NEU

Relais

élém.

élém.

Relais

BU/BL

N

BU/R

BL

MAR

MAR

MAR

MAR

MAR

MAR

VI

VI

VI

VI

JAJAJA

JA

JA

JA

Réf

VDO

ou

FOR SERVICE TECHNICIAN’S USE ONLY

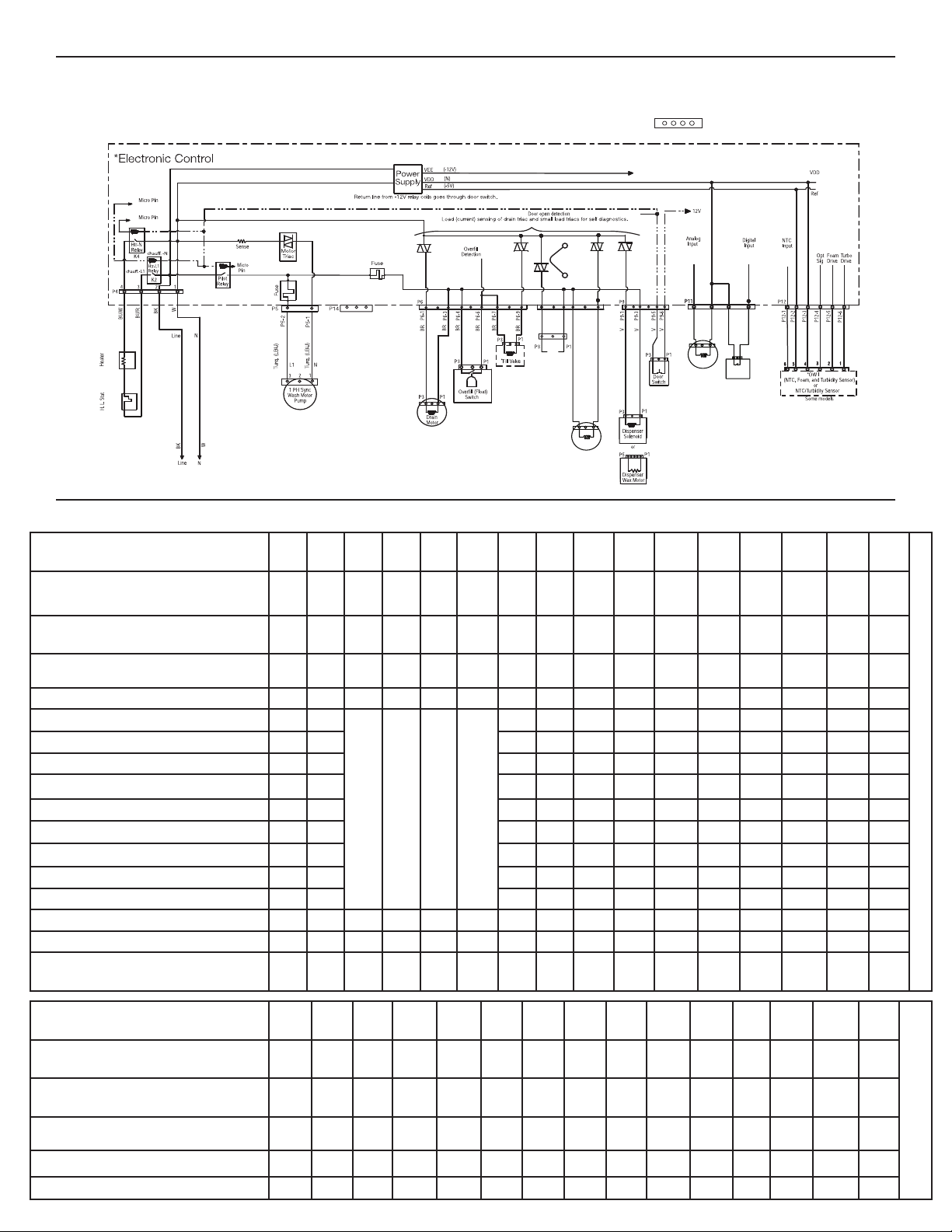

Wiring Diagram

Schematic shown with door switch and all other normally open contacts open.

*Denotes energy efcient components. Do not substitute.

Service Diagnostics Cycle

INTERNAL TIME (min:sec)

TOTAL TIME (MAX): 23:24

Thermistor Check Intervals

(Temperature Sensor) NOTE 3

OWI Check Intervals

(Optical Soil Sensor) NOTE 4

NOTE: OWI has thermistor built in (see

above).

Diverter Position Sensor Check NOTE 5

LOADS

Pilot Relay PLT P LT P LT PLT PLT PLT PLT PLT PLT

Fill Valve FIL FIL FIL FIL

Wash Pump Motor WSH WSH WSH WSH

Dispenser (detergent/rinse aid) DISP

Diverter (DIV)

Diverter Position UPR UPR UPR UPR UPR UPR UPR

Drain Pump Motor

Heater

DC Fan (if present) NOTE 6 FAN FAN FAN FAN FAN FAN FAN

AC Fan (if present)

REFERENCE NOTES: See the “Service

Diagnostics Cycle Notes” section.

INTERNAL TIME (min:sec)

TOTAL TIME (MAX): 23:24

Thermistor Check Intervals

(Temperature Sensor) NOTE 3

OWI Check Intervals

(Optical Soil Sensor) NOTE 4

NOTE: OWI has thermistor built in (see

above).

Diverter Position Sensor Check NOTE 5 DIV

LOADS

0:05 0:01 1:21 1:21 1:21 1:21 0:10 0:01 0:02 0:42 0:05 0:03 0:08 0:12 0:05 0:02

THR THR

Customer Error 1

Customer Error 2

Customer Error 3

Customer Error 4

1 1 1 1 2 3 3

1:00 2:00 0:30 1:00 0:30 4:00 0:01 0:01 0:01 0:01 1:58 2:30 0:15 1:21 1:21

OWI

5

OWI

S

T

A

N

D

B

Y

S

T

A

N

D

B

Y

Loading...

Loading...