Whirlpool WML75011HZ Technician Use

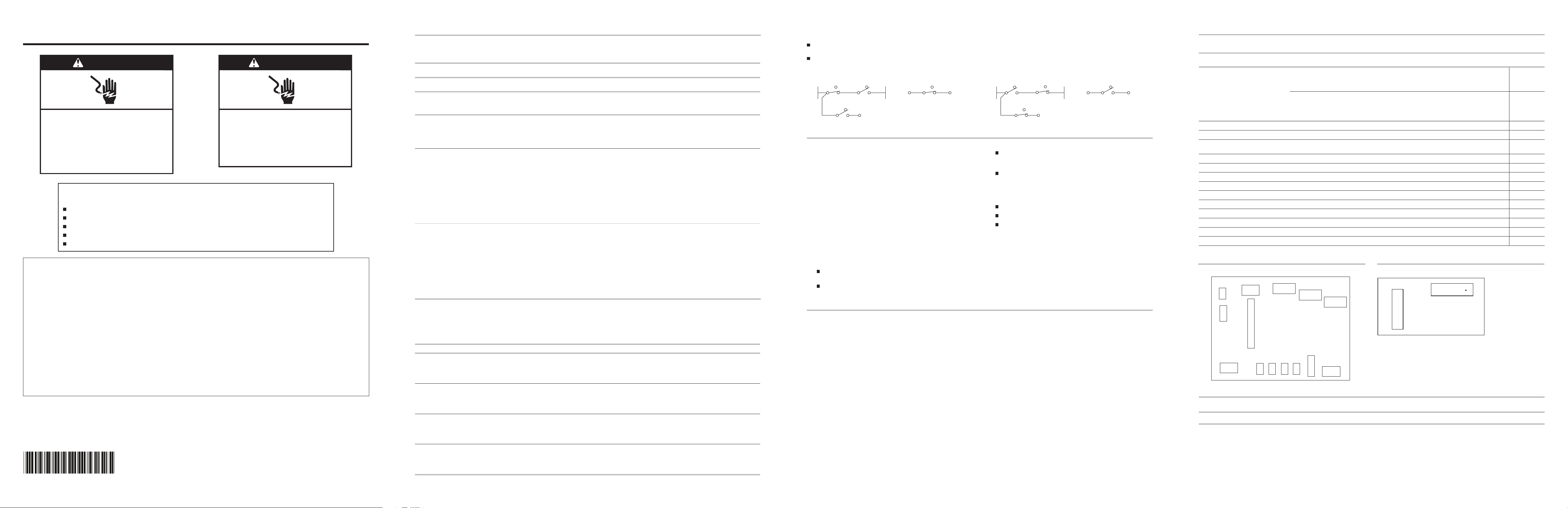

FOR SERVICE TECHNICIAN’S USE ONLY

N

P 2-1

L

Switch

N

P 2-1

L

Switch

Tech Sheet Do not discard

FAILURE CODE INDICATIONS

NOTE: Many of the problems listed in the chart below may be solved by power cycling: Unplug microwave oven or disconnect power. After 1 minute,

plug in microwave oven or reconnect power.

DANGER

WARNING

Display Likely Failure

Recommended Repair Procedure

Condition

Electrical Shock Hazard

Only authorized technicians should

perform diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

Electrical Shock Hazard

result in death or electrical shock.

Voltage Measurement Safety Information

When performing live voltage measurements, you must do the following:

Verify the controls are in the off position so that the appliance does not start when energized.

Allow enough space to perform the voltage measurements without obstructions.

Keep other people a safe distance away from the appliance to prevent potential injury.

Always use the proper testing equipment.

After voltage measurements, always disconnect power before servicing.

PRECAUTIONS TO BE OBSERVED BEFORE

AND DURING SERVICING TO AVOID POSSIBLE

“Enter

clock”

F2E1 Touch panel

F1E4 MW Relay 1. Unplug microwave oven or disconnect power.

F4E4 Humidity

F8E5 Exhaust air

Power failure After a power failure, “Enter clock” will be flashing. Press CANCEL to end this indication. The colon (:) will appear when in

Standby mode.

failure

1. Unplug microwave oven or disconnect power.

2. Replace touch panel.

3. Replace all parts and panels before operating.

4. Plug in microwave oven or reconnect power.

5. If problem persists, refer to “ACU Pin Voltage

Matrix.”

4. Replace all parts and panels before operating.

5. Plug in microwave oven or reconnect power.

6. If problem persists, refer to “ACU Pin Volatage

Matrix” to check P2-2 (Door), P1-3 (N), and

P1-1(L).

6. Enter the Diagnostics mode (press CANCEL CANCEL - START), then press COOK to see if

failure code reappears.

NOTE: There may be a delay (approximately

1 minute, 20 seconds) before the F4E4 failure

code is displayed.

7. If the F4E4 failure code reappears, unplug

microwave oven or disconnect power.

8. Replace ACU.

sensor error

2. Check wiring to Relay 4903

3. Check to see if relay (4903 on ACU) contact

has welded closed.

1. Enter the Diagnostics mode (press CANCEL - CANCEL START), and then press COOK to display the humidity sensor

reading. If display does not show The value between “2000 and

9000” continue to Step 2.

2. Unplug microwave oven or disconnect power.

3. Connect a new humidity sensor ACU to cable.

4. Replace all parts and panels before operating.

5. Plug in microwave oven or reconnect power.

9. Replace all parts and panels before operating.

10. Plug in microwave oven or reconnect power.

template

detection

failure

1. Enter the Diagnostics mode (press CANCEL - CANCEL START), and then press SETUP or CLOCK to display the

exhaust air temperature sensor reading. Verify the sensor

temperature reading is at room temperature (typically 50ºF

to 90ºF [10ºC to 32ºC]) and verify failure code. If failure code

matches complaint, continue to Step 2.

2. Unplug microwave oven or disconnect power.

3. Disconnect sensor from ACU.

5. Replace all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

7. Enter the Diagnostics mode (press CANCEL

- CANCEL - START), and then press SETUP

or CLOCK to display the cavity temperature

sensor reading. Verify the sensor temperature

reading. If it is still not correct, replace ACU.

8. If failure does not reappear, stop.

4. Measure sensor resistance between connector pins and confirm

reading is between 9.5 kΩ and 10.5 kΩ at room temperature. If

measurement is not correct or if a short or open circuit is found,

replace sensor.

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

a. Do not operate or allow the oven to be operated with the door

open.

b. Make the following safety checks on all ovens to be serviced

before activating the magnetron or other microwave source, and

make repairs as necessary:

1. Interlock Operation

2. Proper Door Closing

3. Seal and Sealing Surfaces (Arcing, Wear and Other Damage)

4. Damage to or Loosening of Hinges and Latches

5. Evidence of Dropping or Abuse

d. Any defective or misadjusted components in the interlock,

monitor, door seal, and microwave generation and transmission

systems shall be repaired, replaced, or adjusted by procedures

described in this manual before the oven is released to the

owner.

e. A microwave leakage check to verify compliance with the Federal

Performance Standard should be performed on each oven prior

to release to the owner.

f. Do not attempt to operate the oven if the door glass is broken.

IMPORTANT: Before checking the interlock switches, unplug microwave oven or disconnect power. Be sure to disconnect all of the wires at the

switch being tested before making any continuity readings.

NOTE: : The Secondary Interlock Switch, Monitor Interlock Switch, Primary Interlock Switch and Door Interlock Switch are mounted in the door lock

switch cradle. All the Interlock Switches can be identified by the wire colors that are connected to the terminals of the switches. See the chart below for

wire color designation.

Switch Check By Door Open Door Closed

Primary

Interlock

c. Before turning on microwave power for any service test or

inspection within the microwave generating compartments, check

the magnetron, wave guide or transmission line, and cavity for

proper alignment, integrity and connections.

Monitor

Interlock

Secondary

Interlock

Door

Interlock

W11279380C FOR SERVICE TECHNICIAN’S USE ONLY

(+) Continuity (-) No Continuity

PRIMARY, SECONDARY, MONITOR AND DOOR SWITCH CHECKOUT PROCEDURES

1. Unplug microwave oven or disconnect power.

2. Disconnect the wires at the Primary Interlock Switch.

3. Check from the common terminal (black/black wires) to the normally open terminal (black/white wires).

4. Reconnect wires to switch.

1. Unplug microwave oven or disconnect power.

2. Disconnect the wires at the Monitor Interlock Switch.

3. Check from the common terminal (white wire) to the normally closed terminal (blue/blue wires).

4. Reconnect wires to switch.

1. Unplug microwave oven or disconnect power.

2. Disconnect the wires at the Secondary Interlock Switch.

3. Check from the common terminal (white/white wires) to the normally open terminal (blue/black wires

4. Reconnect wires to switch.

1. Unplug microwave oven or disconnect power.

2. Disconnect the wires at the Door Interlock Switch.

3. Check from the common terminal (blue wire) to the normally closed terminal (orange wire).

4. Reconnect wires to switch.

).

- +

+ -

- +

+ -

NOTES:

These diagrams are not intended to show a complete circuit; they represent the position of switches during “DOOR OPEN” or “DOOR CLOSED”

(continuity checks only).

Interlock and Monitor switches cannot be adjusted and all these switches should be replaced if any one of them is found to be defective. After

replacing interlock/monitor switches, reconnect wires to switch and check for continuity. Safety interlocks and monitor switches will actuate

within 2 mm.

Door Closed Door Open

(NC)

(NO)

Primary

Interlock

Switch

(NC)

Door

Interlock

IMPORTANT: High-voltage is present at the magnetron and high-voltage

capacitor terminals. Avoid direct contact when power is connected to

these components to avoid serious injury or possible death. Always be

sure that the high-voltage capacitor is discharged before accessing any

of these components.

For a no-heat condition, refer to the following step-by-step instructions:

1. Unplug microwave oven or disconnect power.

2. Discharge the high-voltage capacitor.

3. Disconnect the high-voltage transformer primary windings.

4. Attach the voltmeter leads to the high-voltage transformer primary

input wires.

5. Plug in microwave oven or reconnect power.

6. Close door and program the microwave oven to operate

for 30 seconds.

7. Press START.

8. Check the input voltage at the high-voltage transformer primary

input wires. If the voltage is not close to the rating voltage

120 ± 15 VAC, unplug microwave oven or disconnect power. Check

the circuitry as follows:

Measure resistance of the fuse, micro-switches, and thermostats.

Replace any failed components. (Refer to the wiring diagram.)

Check for loose terminals. (Refer to the wiring diagram.) Check

all of the terminals on the main route from the power supply to

the high-voltage transformer.

Check for proper voltage by completing the following steps:

1. Unplug microwave oven or disconnect power.

2. Connect voltage measurement equipment to the terminals listed

below. (P1-3 and P2-3 are neutral.)

NOTE: For 50 V and over, the tolerance is ± 15 V. For 0 V, the tolerance is ± 3 V.

FOR SERVICE TECHNICIAN’S USE ONLYFOR SERVICE TECHNICIAN’S USE ONLY FOR SERVICE TECHNICIAN’S USE ONLY

Abbreviations

HL - Hood Light N - Neutral CL - Cavity Light HF - Hood Fan L - Line Voltage TT - Turntable Motor NFS - Neutral for Switch

NOTE: When checking voltage readings on ACU, connect the Negative test lead of voltmeter to connector P1-3. Use the positive test lead

to probe connectors designated below.

(NO)

(NO)

Monitor

Interlock

Switch

P 2-2

(NC)

P 2-3

(NC)

Secondary

Interlock

Switch

(NO)

(NC)

Primary

Interlock

Switch

(NC)

Interlock

(NO)

Door

(NO)

(NO)

Monitor

Interlock

Switch

P 2-2

NOT HEATING TROUBLESHOOTING INSTRUCTION

Check for loose or failed connectors on the PCBA (P1, P2).

If these check out OK, plug in microwave oven or reconnect

power.

Check for ACU failure. Refer to “ACU Pin Voltage Matrix.”

9. If the input voltage at the high-voltage transformer primary input

wires is close to the rating voltage 120 ± 15 VAC, unplug microwave

oven or disconnect power.

10. Check the power supply components. Refer to “Component Tests.”

High-voltage transformer

High-voltage capacitor

High-voltage diode

11. If the power supply components check out OK, check the

connection between the magnetron and the high-voltage

transformer.

12. If all of the components check out OK, replace the magnetron.

13. Reconnect the high-voltage transformer primary windings.

ACU PIN VOLTAGE MATRIX

3. Plug in microwave oven or reconnect power, and confirm

voltage reading.

4. Unplug microwave oven or disconnect power.

32 4

(NC)

P 2-3

(NC)

Secondary

Interlock

Switch

(NO)

MW Oven Plugged In—Sitting Idle—ACV Readings

Hood

Pin Name Wire Color

Power

On, Door

Closed

Power

On, Door

Open

Hood

Fan

Motor—

High

Fan

Motor—

MedHigh

Hood

Fan

Motor—

Medium

Hood

Fan

Motor—

Low

P1-1 (L) BLACK 120 120 120 N/A 120 120 120 120 120

P1-3 (N) BLUE 0 0 0 N/A 0 0 0 0 0

P2-1 (NFS) BLUE AND GREEN 0 0 0 N/A 0 0 0 0 0

P2-2 (Door) ORANGE 0 120 0 N/A 0 0 0 0 38

P2-3 (N) WHITE AND BLACK 0 120 0 N/A 0 0 0 0 0

P4-1 (CF) BLACK 0 120 0 N/A 0 0 0 0 120

P4-2 (TTM) RED 0 0 0 N/A 0 0 0 0 120

P4-4 (ODM) BLACK 0 0 0 N/A 0 0 0 0 0

P14-1 (L) BLACK 120 120 120 N/A 120 120 120 120 120

P14-3 (HF-H) BLACK 18 20 120 N/A 19 19 19 18 20

P14-4 (HF-L) WHITE 18 22 20 N/A 19 120 20 19 22

P14-5 (HF-M) GREY 18 25 19 N/A 120 20 19 18 23

P14-6 (HF-ML) BLACK 20 23 21 N/A 68 21 21 20 24

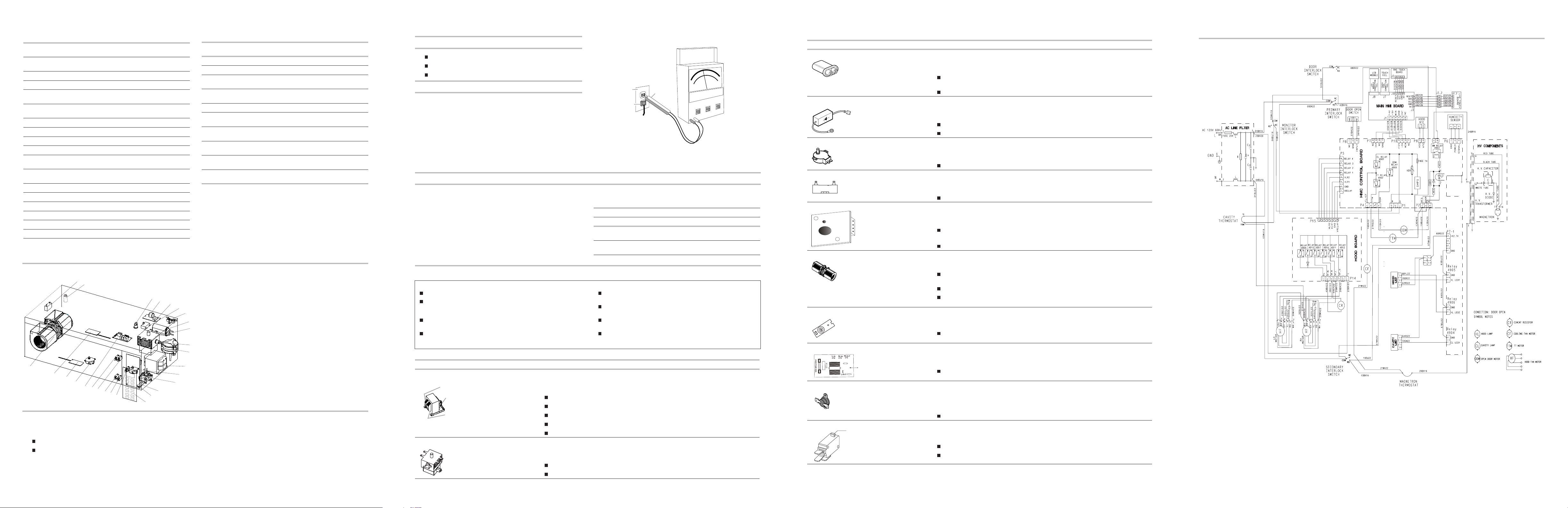

CONNECTORS ON PCBA CONNECTORS ON HOOD CONTROL BOARD

NF S

P9

2

1

3

2

1

DOOR

1 2 3

3 2 1P83 2 1

8

7

P6

6

5

4

3

2

1

N

P2

NOTE: There is a empty terminal on P1 and P4 connector.

4 3 2 1

P10

ACU

P5

4094-LC/CF

3094-WM

2

1

212

2

1

4 3 2 1

4 3 2 1

P7

P7-1

094-OL_LH/TS LLIRG 6

094-IH_LH/LLIRG 5

P4

1

2

P1

.

1

L

4

1 . 3

N

1

2

3

P15

8

NOTE: There is a empty terminal on P14

P14

TOUCH PANEL

Touch Panel and ACU Test

The microwave hood combination is provided with a self-diagnostic routine that can be accessed through the touch keypad.

To initiate this routine:

1. Plug in microwave oven or reconnect power, In idle mode, close the

door, turn off hood light and hood fan.

2. Open and close door, then press CANCEL - CANCEL - START

within 3 seconds.

All LED/LCD segments will be lit to indicate the Test mode has been

entered.

3. Open door. The model number will be displayed.

4. Close door. All display segments will be lit.

5. Press indicated keypad for correct display readout and beep.

NOTE: If the Cancel button is pressed during this diagnostic routine,

you will exit the Test mode.

Hood

Light—

High

344556677

1

Hood

Light—

Low

MW Oven

Running—

ACV

Readings

Microwave

Oven Start

FOR SERVICE TECHNICIAN’S USE ONLYFOR SERVICE TECHNICIAN’S USE ONLY FOR SERVICE TECHNICIAN’S USE ONLYFOR SERVICE TECHNICIAN’S USE ONLY

A

E

G

H

P

Z

Switch

Key Tables for Test Mode

Key Name The Upper

Function Buzzer

Row Display

Clock value such as

NTC sensor check 1 beep

0-200

Start ACU xx.xx.xx ACU SW version check 1 beep

Start UI:xx.xx.xx UI SW version check 1 beep

Start LT:xx Left touch SW version

1 beep

check

Start RT:xx Right touch SW version

1 beep

check

Start GEE:xx.xx.xx GEE SW version check 1 beep

Hood Light key 03 - 1 beep

Hood Fan key 04 - 1 beep

Timer key 05 - 1 beep

Turntable On/

key 09 - 1 beep

Off

Cook value between

Humidity sensor check 1 beep

2000 and 9000

Power - - 1 beep

Reheat key 24 - 1 beep

Defrost key 29 - 1 beep

AccuPop key 25 - 1 beep

Steam/Simmer key 31 - 1 beep

0 key 10 1 beep

Key Name The Upper

Function Buzzer

Row Display

1 CL Cavity lamp turn on 1 beep

2 11 1 beep

3 HF_Mid LOW Hood Fan turn on (Mid

1 beep

low Speed)

4 HF_Mid_

HIGH

Hood Fan turn on (Mid

_High Speed)

1 beep

5 LCD off Standby power check 1 beep

6 HL_HIGH Hood Light turn on (high

1 beep

level) )

7 HL_LOW Hood Light turn on (low

1 beep

level)

8 HF_HIGH Hood Fan turn on (High

1 beep

Speed)

9 HF_LOW Hood Fan turn on (LOW

1 beep

Speed)

Cancel : or xx:xx exit test mode to idle

1 beep

mode

Tools Needed

2-cup measuring cup

Thermometer

Voltmeter/ohmmeter

Voltage Measurement at Power Source

1. Fill the measuring cup with 2 cups (500 mL) of tap water.

2. Place in the center of the microwave oven cavity.

3. Operate the microwave oven on high power for 1 minute.

4. While the microwave oven is operating, measure the line voltage at

the power source. See “Measure Voltage” illustration.

5. Verify the voltage is constant during microwave oven operation.

If voltage drops below 108 V, contact a qualified electrician to check

your electrical supply.

6. Make note of the voltage while the microwave oven is running

and proceed to the output test.

Output Test

1. Fill the measuring cup with 2 cups (500 mL) of 70ºF (21ºC) tap water.

2. Stir the water with the thermometer to ensure uniform temperature.

Add warm or cool water to bring the water to the correct

temperature.

3. Place the measuring cup in the center of the microwave oven cavity.

4. Operate the microwave oven on high power for 1 minute.

5. Remove the measuring cup and stir the water with the thermometer

for about 20 seconds.

6. Record the temperature of the water.

7. Refer to the model serial tag on the microwave oven to acquire

wattage output rating of the microwave oven.

PARTS LAYOUT (NOT TO SCALE)

A A

A. Main fuse 20 amp

B. Motor capacitor

AB

AC

A

B

C. Cement resistor

D. H.V. capacitor

E. Magnetron

C

G. Magnetron Thermostat - opens

D

at 257° F (125° C ), closes at

203°F (95°C )

H. Hood motor

K. HV transformer

L. Open door motor

M. Cooling fan motor

N. NTC sensor

O. ACU

Y

X

W

V

U

T

S

R1

R

Q

N

O

K

L

M

POWER OUTPUT MEASUREMENT

The power output of the magnetron can be measured using the following “Voltage Measurement at Power Source” and “Output Test” sections. Before

you perform the test:

Make sure that the oven cavity is cool and clean.

Check the line voltage at the wall outlet while microwave oven is operating. See the “Voltage Measurement at Power Source” section.

P. Touch panel

Q. Door open switch

R. Secondary interlock switch

R1. Door interlock switch

S. Monitor interlock switch

T. Primary interlock switch

U. Hood control board

V Turntable motor

W Hood (cooktop) light

X. Cavity light

Y. Hood motor

Z. Motor capacitor

AA. AC filter filter

AB. Cavity thermostat-opens at

275°F (135°C ), nonresettable

AC. Filter board

Unplug microwave oven or disconnect power.

Discharge the high-voltage capacitor and remove the lead wires

from the primary winding of the high-voltage transformer before

conducting any of the following tests.

Remove the lead wires from the related component before

conducting any of the following tests.

All operational checks using microwave energy must be done

with the microwave oven loaded with a minimum of 8 oz

(250 mL) of water in a microwave-safe container.

Components Test/Results

H.V. Transformer

Filament

(orange/red wires)

Primary

Secondary (white

wire - ground to

transformer case)

Magnetron

1. Unplug microwave oven or disconnect power.

2. Remove wire leads.

3. Measure resistance:

1. Unplug microwave oven or disconnect power.

2. Remove wire leads.

3. Measure resistance:

COMPONENT TESTS

IMPORTANT:

Primary winding: Less than 0.5 ohm (approximate)

Secondary winding: 120 ohms (approximate)

Filament winding: 0 ohms

Primary winding to grounding: Normal: Infinite

Filament winding to grounding: Normal: Infinite

Filament terminal: Normal: Less than 1 ohm

Filament to chassis: Normal: Infinite

5 76

Measure Voltage

B

C

A. House power supply wall outlet

B. Voltmeter/ohmmeter test leads

C. Microwave oven plug

8. Using the following chart, determine if the output of the microwave

oven is within the range listed based on the line voltage and wattage

rating of the microwave oven.

Water Temperature for Line Voltage and Wattage Rating

Voltage 700 W 1000 W 1200 W

120 V 96ºF to 102ºF

(36ºC to 39ºC)

108 V 91ºF to 97ºF

(33ºC to 36ºC)

Conduct a microwave energy test after performing any tests or

repairs to the microwave oven.

Check that all wire leads are in the correct positions before

operating the microwave oven.

Grasp wire connectors when removing the wire leads from

microwave oven parts.

All testing must be done with an ohmmeter having a sensitivity

of 20,000 ohms per volt DC or greater and powered by at least

a 9 V battery.

110ºF to 116ºF

(43ºC to 47ºC)

101ºF to 107ºF

(38ºC to 42ºC)

124ºF to 130ºF

(51ºC to 54ºC)

111ºF to 117ºF

(44ºC to 47ºC)

Components Test/Results

H.V. Capacitor

1. Unplug microwave oven or disconnect power.

2. Remove wire leads.

3. Measure resistance:

Terminal to terminal: Normal: Momentarily indicates several ohms, gradually

returns to Infinite

Terminal to case: Normal: Infinite

H.V. Diode

NOTE: Some inexpensive meters may indicate infinite resistance in both directions.

1. Unplug microwave oven or disconnect power.

2. Measure resistance:

Forward: Normal: Continuity

Reverse: Normal: Infinite

Turntable Motor/Open Door Motor

1. Unplug microwave oven or disconnect power.

2. Remove wire leads.

3. Measure resistance:

Normal: 2.4k to 3.2k ohms (approximate)

Motor Capacitor

1. Unplug microwave oven or disconnect power.

2. Remove wire leads.

3. Measure resistance:

Normal: Momentarily 0 ohms, then goes to Infinite

Humidity Sensor PCBA

1. Unplug microwave oven or disconnect power.

2. Remove the 4-pin connector from the cable.

1

2

3

4

Hood Exhaust Fan Motor

3. Measure resistance across pins 1 and 2.

Normal: 10K ohms +/-5% at 77°F (25°C)

4. Measure capacity value across pins 3 and 4.

Normal: 180pF +/-5% at 55%RH

1. Unplug microwave oven or disconnect power.

2. Remove wire leads.

3. Measure resistance:

High Speed—Normal: Red (RD) and Blue (BU) wires: 70 to 170 ohms (approximate);

Blue (BU) and Black (BK) wires: 20 to 100 ohms (approximate)

Middle Speed-Normal: Grey(GY) and Blue(BU) wires: 50 to 130 (approximate)

Low Speed—Normal: White(WH) and Blue (BU) wires: 60 to 160 ohms (approximate);

Blue (BU) and White (WH) wires: 80 to 150 ohms (approximate)

HF NTC Thermistor

1. If “NTC SHORT, CALL FOR SERVICE” or “NTC OPEN, CALL FOR SERVICE” scrolls on

display, unplug microwave oven or disconnect power.

1

5

5

3

5

P

AC Line Filter Board

2. Measure hood thermistor:

Normal: 10k ohms +/-5% at 77ºF (25ºC)

1. Unplug microwave oven or disconnect power.

2. Remove wire leads.

3. Measure resistance:

Normal: L-IN to L-OUT (coil): Less than 1 ohm; N-IN to N-OUT (coil): Less than 1 ohm

Thermostats

NOTE: Refer to “Parts Layout” for opening and closing temperatures.

1. Unplug microwave oven or disconnect power.

Cavity Thermostats

Magnetron Thermostat

Open Door Switch

2. Remove wire leads.

3. Measure continuity:

Normal: Continuity

1. Unplug microwave oven or disconnect power.

2. Remove wire leads.

3. Make sure the switch is pressed

4. Measure resistance:

Normal: >1M ohm

Abnormal: <5 ohm

W11279380C

©2018 All rights reserved.

SCHEMATIC DIAGRAM

DWG NO.

W11104704B

12/18

FOR SERVICE TECHNICIAN’S USE ONLY

Loading...

Loading...