Whirlpool WGTLV27FW0, WGT4027EW0 Installation Guide

24" (61 cm) & 27" (69 cm) Gas Washer/Dryer

Installation instructions

Instructions pour I'installation de la laveuse/s_cheuse

gaz de 24" (61 cm) et 27" (69 cm)

Instrucciones de instalaci6n de la lavadora/secadora

del gas de 24" (61 cm) y 27" (69 cm)

Table of Contents

WASHER/DRYER SAFETY .......................................................... 2

INSTALLATION REQUIREMENTS ............................................... 5

Tools and Parts ..................................................................... 5

LOCATION REQUIREMENTS ...................................................... 7

DIM ENSIONS/CLEARANCES ..................................................... 8

DRAIN SYSTEM ......................................................................... 10

ELECTRICAL REQUIREMENTS ................................................ 11

GAS SUPPLY REQUIREMENTS ................................................ 11

REMOVE SHiPPiNG STRAP ...................................................... 13

INSTALL LEVELING LEGS ......................................................... 14

REMOVE FOAM PACKING (24" models) .................................. 14

VENTING ..................................................................................... 15

Venting Requirements ........................................................ 15

Plan Vent System ................................................................ 16

Install Vent System ............................................................. 17

CONNECT DRAIN HOSE ........................................................... 18

CONNECT iNLET HOSES .......................................................... 19

MAKE GAS CONNECTION ........................................................ 21

CONNECT VENT ........................................................................ 21

LEVEL WASHER/DRYER ........................................................... 22

COMPLETE iNSTALLATiON CHECKLIST ................................ 23

p

Indice

SEGURIDAD DE LA LAVADORA/SECADORA ......................... 46

REQUISITOS DE INSTALAClON ............................................... 49

Herramientas y piezas.. ...................................................... 49

REQUISITOS DE UBICAClON ................................................... 51

DIMENSIONES Y ESPAClOS LIBRES ....................................... 52

SISTEMA DE DESAGOE ............................................................ 54

REQUISITOS EUeCTRICOS ...................................................... 55

REQUISITOS DEL SUMINISTRO DE GAS ................................ 55

QUITE EL FLEJE DE EMBALAJE .............................................. 57

INSTALACION DE LAS PATAS NIVELADORAS ........................ 58

QUITE EL EMBALAJE DE HULE

ESPUMA (modelos de 24"} ....................................................... 58

Table des mati_res

SECURITE DE LA LAVEUSFJSECHEUSE ................................ 24

EXlGENCES D'INSTALLATION ................................................. 27

Outillage et pi_ces ............................................................. 27

EXlGENCES D'EMPLACEMENT .............................................. 29

DIMENSIONS/DISTANCES DE DEGAGEMENT ....................... 30

SYSTI_ME DE VIDANGE ............................................................ 32

SPECIFICATIONS leLECTRIQUES ............................................ 33

SPleCIFICATIONS DE UAMMENTATION EN GAZ ................... 33

ENLEVER LA SANGLE D'EXPEDITION .................................... 35

iNSTALLATiON DES PIEDS DE NIVELLEMENT ...................... 36

ENLEVER L'EMBALLAGE EN MOUSSE (modUles de 24") ..... 36

EVACUATION ............................................................................. 37

Exigences concernant I'_vacuation ................................. 37

Planification du syst_me d'6vacuation ............................ 38

Installation du conduit d'_vacuation ................................ 39

RACCORDEMENT DU TUYAU DE VlDANGE ........................... 40

RACCORDEMENT DES TUYAUX D'ARRIVEE D'EAU ............. 41

RACCORDEMENT A LA CANALISATION DE GAZ .................. 42

RACCORDEMENT DU CONDUIT DqeVACUATION ................. 43

ETABLISSEMENT DE [.'APLOMB DE

LA LAVEUSF=/SECHEUSE .......................................................... 44

LISTE DE VERIFICATION POUR L'ACHEVEMENT

DE L'INSTALLATION .................................................................. 45

VENTILACKSN ............................................................................ 59

Requisitos de ventilaci6n .................................................. 59

Planificaci6n del sistema de ventilaci6n .......................... 60

Instalaci6n del sistema de ventilaci6n ............................. 61

CONECTE LA MANGUERA DE DESAGOE ............................... 62

CONECTE LAS MANGUERAS DE ENTRADA .......................... 63

CONEXI6N DEL SUMINISTRO DE GAS ................................... 64

CONECTE EL DUCTO DE ESCAPE .......................................... 65

NIVELACION DE LA LAVADORA/SECADORA ......................... 65

LISTA DE CONTROL PARA LA REALIZACION

DE LA INSTALACION ................................................................. 67

iNSTALLATiON NOTES

Date of purchase:

Date of installation:

Installer:

Model number:

Serial number:

W10761051A

NOTES CONCERNANT L'INSTALLATION

Date d'achat :

Date d'installation :

InstaHateur :

Num_ro de module :

Num_ro de s_rie :

NOTAS DE INSTALACION

Fecha de la compra:

Fecha de la instalaci6n:

Instalador:

NQmero de modelo:

NQmero de serie:

Washer/Dryer Safety

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

| " "Risk of Fire"

= Clothes dryer installation must be performed by a qualified installer,

= Install the clothes dryer according to the manufacturer's instructions and local codes,

- Do not install a clothes dryer with flexible plastic venting materials or flexible metal

(foil type) duct. if flexible metal duct is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use with clothes dryers. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

= To reduce the risk of severe injury or death, follow all installation instructions.

= Save these instructions.

2

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO iF YOU SMELL GAS:

= Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your buUding.

o Clear the room, building, or area of all occupants.

® Immediately carl your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

= if you cannot reach your gas supplier, carl the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

In the State of Massachusetts, the following installation instructions apply:

[] installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] if using a ball valve, it shall be a T=handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

iMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1iNFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the washer/dryer, follow basic

precautions, including the following:

[] Read all instructions before using the washer/dryer.

[] Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to a

chemical reaction that could cause a load to catch fire.

[] Do not wash or dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

[] Do not add gasoline, dry-cleaning solvents, or other

flammable, or explosive substances to the wash water.

These substances give off vapors that could ignite or

explode.

[] Do not allow children to play on or in the washer/dryer.

Close supervision of children is necessary when the

washer/dryer is used near children.

[] Before the washer/dryer is removed from service or

discarded, remove the doors to the washer/dryer

compartments.

[] Do not reach into the washer/dryer if the tub, agitator or

drum is moving.

[] Do not install or store the washer/dryer where it will be

exposed to the weather.

[] Do not tamper with controls.

[] Clean dryer lint screen before or after each load.

SAVE THESE INSTRUCTIONS

[] Under certain conditions, hydrogen gas may be produced

in a hot water system that has not been used for 2 weeks

or more. HYDROGEN GAS IS EXPLOSIVE. If the hot water

system has not been used for such a period, before using

the washing machine, turn on all hot water faucets and let

the water flow from each for several minutes. This will

release any accumulated hydrogen gas. As the gas is

flammable, do not smoke or use an open flame during

this time.

[] Do not repair or replace any part of the washer/dryer or

attempt any servicing unless specifically recommended in

this Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

[] Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

[] Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

[] The interior of the machine and dryer exhaust vent should

be cleaned periodically by qualified service personnel.

[] See "Electrical Requirements" section of the Installation

Instructions booklet for grounding instructions.

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

IMPORTANT." When discarding or storing your old clothes dryer, remove the door.

i

1

4

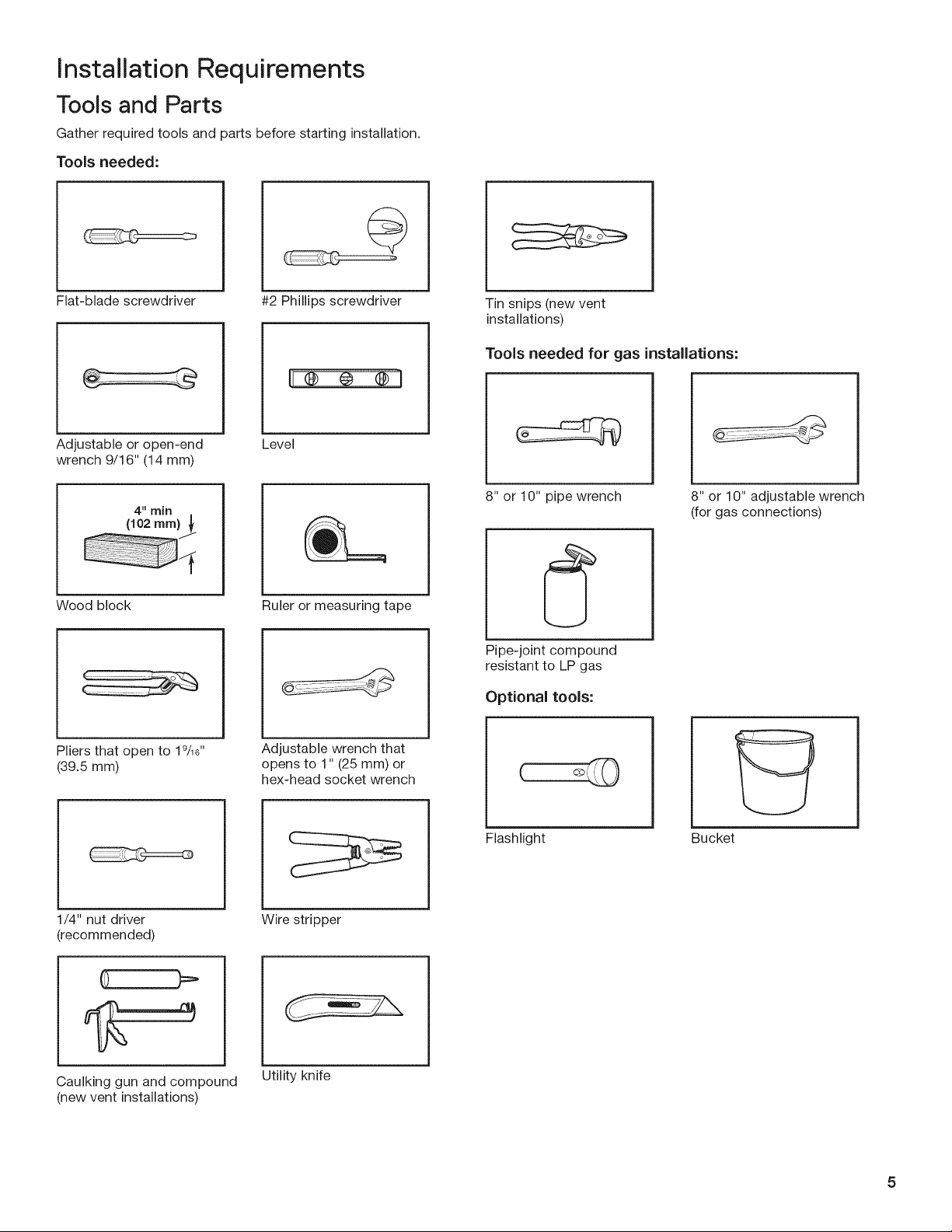

Installation Requirements

Tools and Parts

Gather required tools and parts before starting installation.

Tools needed:

Flat-blade screwdriver

Adjustable or open-end

wrench 9/16" (14 mm)

4"" i'Tl(n

(102 ram)

Wood block

Pliers that open to 19/16"

(39.5 mm)

#2 Phillips screwdriver

Level

Ruler or measuring tape

Adjustable wrench that

opens to 1" (25 mm) or

hex-head socket wrench

Tin snips (new vent

installations)

Tools needed for gas installations:

8" or 10" pipe wrench

Pipe-joint compound

resistant to LP gas

Optional tools:

8" or 10" adjustable wrench

(for gas connections)

1/4" nut driver

(recommended)

Caulking gun and compound

(new vent installations)

Wire stripper

Utility knife

Flashlight

Bucket

Parts supplied:

NOTE: Remove parts package from the washer basket.

Check that all parts were included.

Front leveling feet with

nuts (2) (27" models)

Rear leveling legs (2)

(24" models)

Plastic strap (24" models)

Front leveling legs (2)

(24" models)

Shipping strap (27" models

(Not in parts bag. See

"Remove Shipping Strap.")

Drain hose

Alternate parts: (Not supplied with washer/dryer)

Your installation may require additional parts. To order, please

refer to toll-free numbers on back page of your Use and Care

Guide.

If you have:

Overhead sewer

Floor drain

1" (25 mm) standpipe 2" (51 mm) diameter to 1" (25 mm)

Laundry tub or

standpipe taller than

96" (2.4 m)

Drain hose too short

Lint clogged drain Drain Protector Part Number 367031,

Water faucets

beyond reach

of fill hoses

You will need:

Standard 20 gal. (76 L) 39" (991 mm)

tall Drain Tub or Utility Sink, Sump

Pump and Connectors (available from

local plumbing suppliers)

Siphon Break Part Number 285320,

Additional Drain Hose Part Number

285702, and Connector Kit Part

Number 285442

diameter Standpipe Adapter

Part Number 3363920,

Connector Kit Part Number 285835

Sump pump system (if not already

available)

Extension Drain Hose

Part Number 285863,

Connector Kit Part Number 285835

Connector Kit Part Number 285835

2 longer water fill hoses:

6 ft (1.8 m) Part Number 76314,

10 ft (3.0 m) Part Number 350008

Silver double-wire hose clamp

Parts needed: (Not supplied with washer/dryer)

[] Vent clamps

[] Vent elbows and ductwork

[] Mobile Home Installation Kit

(Part Number 346764)

[] Metal exhaust system hardware

Net hoses with

flat washers

Check local codes, electrical supply and venting, and read

"Electrical Requirements" and "Venting Requirements" before

purchasing parts. Mobile home installations require metal

exhaust system hardware available for purchase from the

dealer from whom you purchased your washer/dryer. For

further information, please reference the "Assistance or

Service" section of the Washer/Dryer Use and Care Guide.

Optional equipment: (Not supplied with washer/dryer)

Refer to your Use and Care Guide for information about

accessories available for your washer/dryer.

6

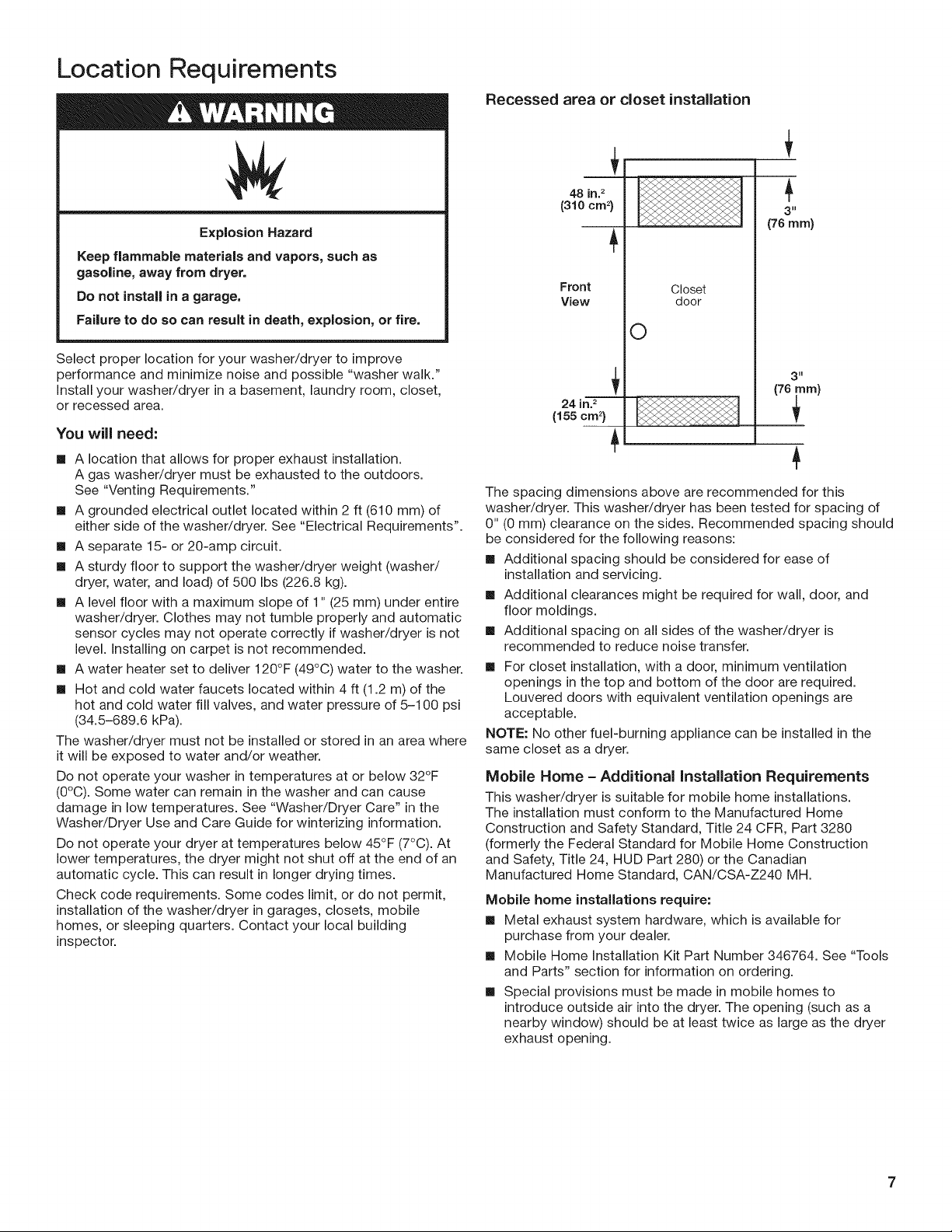

Location Requirements

Explosion Hazard

Keep flammable materials and vapors, such as

gaso|ine, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

Select proper location for your washer/dryer to improve

performance and minimize noise and possible "washer walk."

Install your washer/dryer in a basement, laundry room, closet,

or recessed area.

You will need:

[] A location that allows for proper exhaust installation.

A gas washer/dryer must be exhausted to the outdoors.

See "Venting Requirements."

[] A grounded electrical outlet located within 2 ft (610 mm) of

either side of the washer/dryer. See "Electrical Requirements".

[] A separate 15- or 20-amp circuit.

[] A sturdy floor to support the washer/dryer weight (washer/

dryer, water, and load) of 500 Ibs (226.8 kg).

[] A level floor with a maximum slope of 1" (25 mm) under entire

washer/dryer. Clothes may not tumble properly and automatic

sensor cycles may not operate correctly if washer/dryer is not

level. Installing on carpet is not recommended.

[] A water heater set to deliver 120°F (49°C) water to the washer.

[] Hot and cold water faucets located within 4 ft (1.2 m) of the

hot and cold water fill valves, and water pressure of 5-100 psi

(34.5-689.6 kPa).

The washer/dryer must not be installed or stored in an area where

it will be exposed to water and/or weather.

Do not operate your washer in temperatures at or below 32°F

(0°C). Some water can remain in the washer and can cause

damage in low temperatures. See "Washer/Dryer Care" in the

Washer/Dryer Use and Care Guide for winterizing information.

Do not operate your dryer at temperatures below 45°F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. This can result in longer drying times.

Check code requirements. Some codes limit, or do not permit,

installation of the washer/dryer in garages, closets, mobile

homes, or sleeping quarters. Contact your local building

inspector.

Recessed area or closet installation

48 in. 2

(310 cm 2)

Front

View

Closet

door

3"

(76ram)

O

24 in?

(155 cm2)

The spacing dimensions above are recommended for this

washer/dryer. This washer/dryer has been tested for spacing of

0" (0 mm) clearance on the sides. Recommended spacing should

be considered for the following reasons:

[] Additional spacing should be considered for ease of

installation and servicing.

[] Additional clearances might be required for wall, door, and

floor moldings.

[] Additional spacing on all sides of the washer/dryer is

recommended to reduce noise transfer.

[] For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

NOTE: No other fuel-burning appliance can be installed in the

same closet as a dryer.

Mobile Home = Additional Installation Requirements

This washer/dryer is suitable for mobile home installations.

The installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280) or the Canadian

Manufactured Home Standard, CAN/CSA-Z240 MH.

Mobile home installations require:

[] Metal exhaust system hardware, which is available for

purchase from your dealer.

[] Mobile Home Installation Kit Part Number 346764. See "Tools

and Parts" section for information on ordering.

[] Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

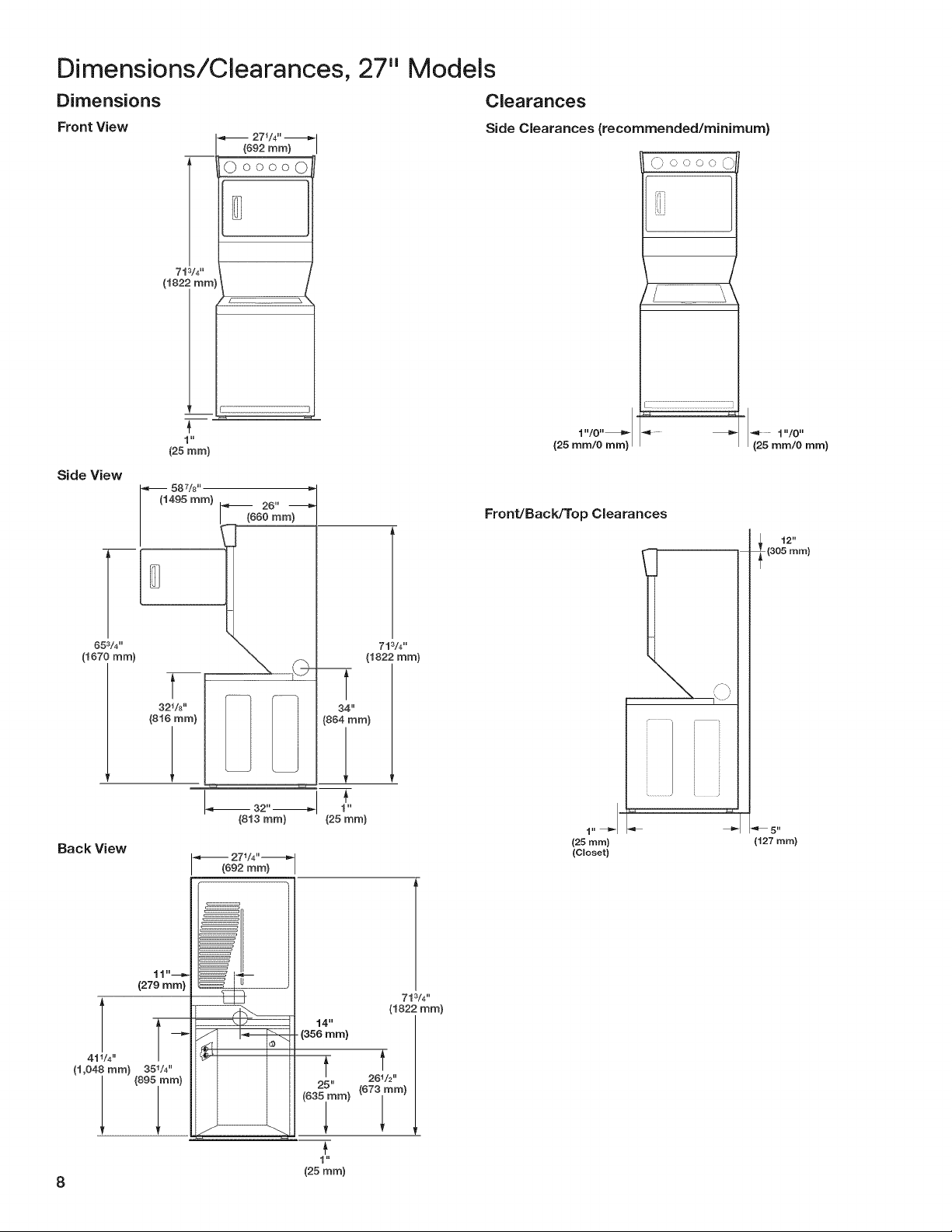

Dimensions/Clearances, 27"

Models

Dimensions

Front View

Side View

27t/4"

(392 rara)

0oooo0

713/4"

(182"- mini

1"

(25 ram)

387/8"

(1493 ram) _ 23" --

(833 ram)

Clearances

Side Clearances (recommended/minimum}

(_ c o o o' 0

\

]

1"/3"_ ___ -'_ 1"/3"

(25 rara/3 rara) (25 rara/3 ram)

Front/Back/Top Clearances

]

(305 ram)

12"

38s/4"

(1373 ram)

Back View

41 t/4"

32t/a"

(8!¢ ram)

(279 ram)

35t/4"

(8!3 ram) (25 ram)

27t/4"-_,._

(392 mra)

14"

-(356 rara)

34"

(834 ram)

t t

25'"

23t/2'"

(25 turn) (127 turn)

(Closet)

(1,34 i rara)

8

(3e5ira)

(8351tara) (3731rara)

1"

(25 ram)

Dimensions/Clearances, 24"

Models

Dimensions

Front View

Side View

708/4"

{179_ rnrn

I uu

(25 rnrn}

_-_ 237/8" -_

(806 ram)

£ %

(s21ram) I

Clearances

Side Clearances (recommended/minimum}

I"10 ''_ __ _ _ I"10"

(25 mm/O mm) (25 mm/O mm)

Front/Back/Top Clearances

t

(781 ram)

................... i

'"_ 287/8"-_'-I 1{"

(883 ram) (25 ram)

Back View

(608 ram)

(292 rnrn)

70s/4"

t

27V2"

(1797 ram)

14 II

(356 rnrn)

26"

(6801ram) (699 rnm)

1 H

(25 ram)

*Required spacing.

**Rear clearance may be 0" (0 mm) when house exhaust system is lined up directly with dryer exhaust.

(25 ram)

(Closet)

(127 ram)

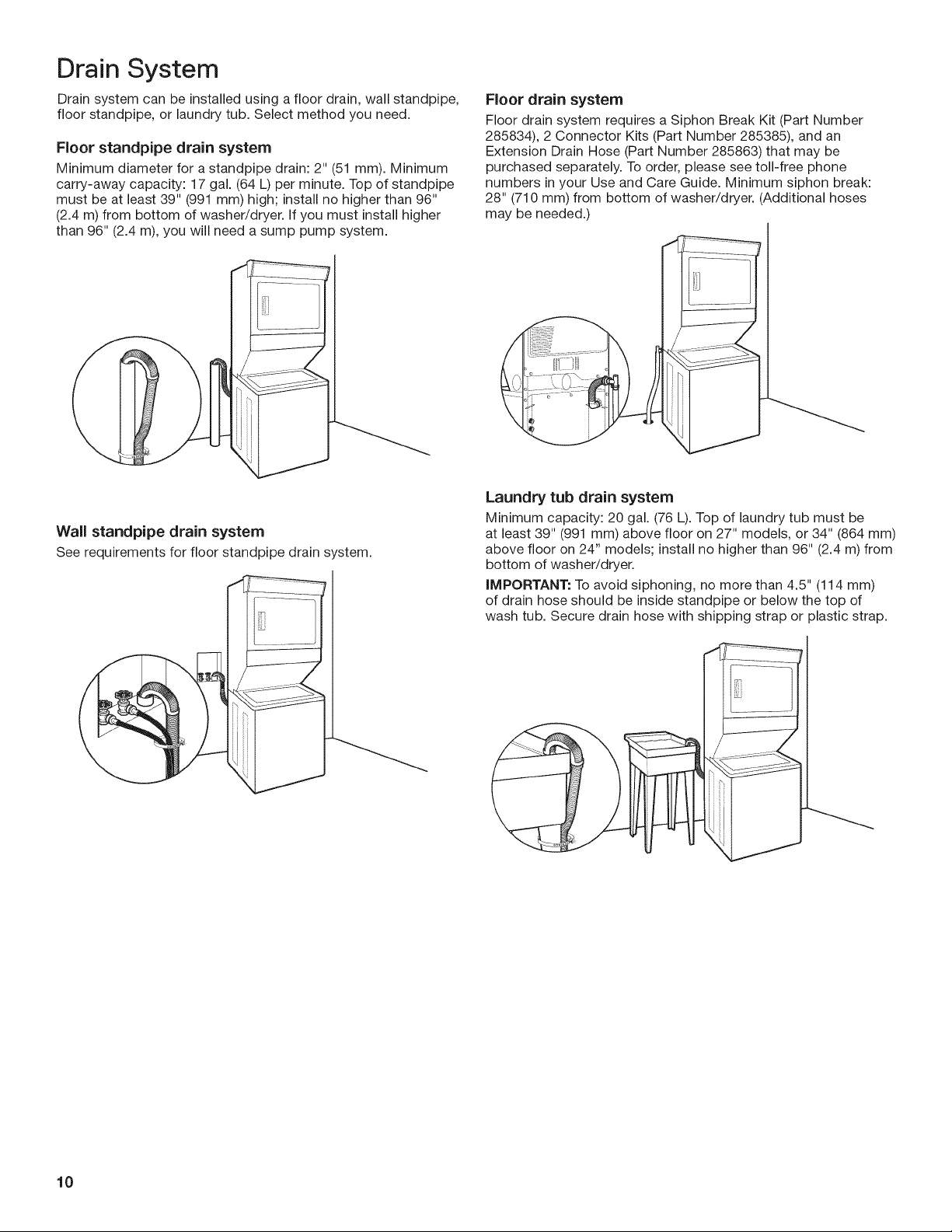

Drain System

Drain system can be installed using a floor drain, wall standpipe,

floor standpipe, or laundry tub. Select method you need.

Floor standpipe drain system

Minimum diameter for a standpipe drain: 2" (51 mm). Minimum

carry-away capacity: 17 gal. (64 L) per minute. Top of standpipe

must be at least 39" (991 mm) high; install no higher than 96"

(2.4 m) from bottom of washer/dryer. If you must install higher

than 96" (2.4 m), you will need a sump pump system.

Wall standpipe drain system

See requirements for floor standpipe drain system.

Floor drain system

Floor drain system requires a Siphon Break Kit (Part Number

285834), 2 Connector Kits (Part Number 285385), and an

Extension Drain Hose (Part Number 285863) that may be

purchased separately. To order, please see toll-free phone

numbers in your Use and Care Guide. Minimum siphon break:

28" (710 mm) from bottom of washer/dryer. (Additional hoses

may be needed.)

Laundry tub drain system

Minimum capacity: 20 gal. (76 L). Top of laundry tub must be

at least 39" (991 mm) above floor on 27" models, or 34" (864 mm)

above floor on 24" models; install no higher than 96" (2.4 m) from

bottom of washer/dryer.

IMPORTANT: To avoid siphoning, no more than 4.5" (114 mm)

of drain hose should be inside standpipe or below the top of

wash tub. Secure drain hose with shipping strap or plastic strap.

10

Electrical Requirements

Gas Supply Requirements

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

[] This washer/dryer is equipped with a power supply cord

having a 3-prong grounding plug.

[] To minimize possible shock hazard, the cord must be plugged

into a mating, 3-prong, grounding-type outlet, grounded in

accordance with local codes and ordinances. If a mating outlet

is not available, it is the personal responsibility and obligation

of the customer to have the properly grounded outlet installed

by a qualified electrician.

[] If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

[] Do not ground to a gas pipe.

[] Check with a qualified electrician if you are not sure the

washer is properly grounded.

[]

Do not have a fuse in the neutral or ground circuit.

[]

120 Volt, 60 Hz, AC only, 15- or 20- amp fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended, it is also recommended that a separate

circuit serving only this washer/dryer be provided.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected washer/dryer:

This washer/dryer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk of

electric shock by providing a path of least resistance for

electric current. This washer/dryer is equipped with a cord

having an equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate outlet

that is properly installed and grounded in accordance with

all local codes and ordinances.

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (330 rnm) water

colurnn.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

GAS TYPE

Natural Gas:

This washer/dryer is equipped for use with Natural gas. It is

design-certified by CSA International for LP (propane or butane)

gases with appropriate conversion.

[] Your washer/dryer must have the correct burner for the type of

gas in your home. Burner information is located on the rating

plate in the door well of your dryer. If this information does not

agree with the type of gas available, contact your dealer or call

the phone numbers referenced in the "Assistance or Service"

section of your Use and Care Guide.

LP Gas Conversion:

iMPORTANT." Conversion must be made by a qualified

technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting your gas company.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the

washer/dryer is properly grounded. Do not modify the plug

provided with the washer/dryer: if it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

11

GAS SUPPLY LINE

[] Must include 1/8" NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the washer/dryer. See illustration below.

[] 1/2" IPS pipe is recommended.

[] Must include shut-off valve:

in the U.S.A.:

An individual manual shut-off valve must be installed within

six (6) ft. (1.8 m) of the washer/dryer in accordance with the

National Fuel Gas Code, ANSi Z223.1. The location should

be easy to reach for opening and closing.

In Canada:

An individual manual shut-off valve must be installed in

accordance with the B149.1, Natural Gas and Propane

Installation Code. It is recommended that an individual

manual shut-off valve be installed within six (6)ft. (1.8 m)

of the washer/dryer. The location should be easy to reach

for opening and closing.

E

B

A. 3/8" flexible gas connector

B. 3/8" pipe to flare adapter fitting

C. 1/8" NPT minimum plugged tapping

D. 1/2" NPT gas supply line

E. Gas shut-off valve

This washer/dryer is equipped with its own permanent,

flexible gas connector, design-certified by CSA International,

for connecting the washer/dryer to the gas supply line.

DRYER GAS CONNECTION

Option 1

Rigid gas supply line:

[] Connect your washer/dryer to the rigid gas supply line using

an elbow and a 3/8" flare x 3/8" NPT adapter fitting between

the stainless steel gas connector and the washer/dryer gas

pipe, as needed to prevent kinking.

Option 2

Approved aluminum or copper tubing:

[] 3/8" approved aluminum or copper tubing is acceptable for

lengths under 20 ft. (6.1 m) if local codes and gas supplier

permit.

[] If you are using natural gas, do not use copper tubing.

[] Lengths over 20 ft. (6.1 m) should use larger tubing and

a different size adapter fitting.

[] If your washer/dryer has been converted to use LP gas, 3/8"

LP compatible copper tubing can be used. If the total length

of the supply line is more than 20 ft. (6.1 m), use larger pipe.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON_'*_ttape.

GAS SUPPLY CONNECTION REQUIREMENTS

[] Use an elbow and a 3/8" flare x 3/8" NPT adapter fitting

between the flexible gas connector and the washer/dryer gas

pipe, as needed, to avoid kinking.

[] Use only pipe-joint compound. Do not use TEFLON _'*_ttape.

BURNER INPUT REQUIREMENTS

Elevations up to 10,000 ft (3,048 meters):

[] The design of this washer/dryer is certified by CSA

International for use at altitudes up to 10,000 ft (3,048 m)

above sea level at the Btu rating indicated on the model/serial

number plate. Burner input adjustments are not required when

the washer/dryer is operated up to this elevation.

Elevations above 10,000 ft (3,048 meters):

[] When installed above 10,000 ft. (3,048 m) a 4% reduction of

the burner Btu rating shown on the model/serial number plate

is required for each 1,000 ft. (305 m) increase in elevation.

Gas supply pressure testing

[] The washer/dryer must be disconnected from the gas supply

piping system during pressure testing at pressures greater

than 1/2 psi.

12

Flexible gas connector

1®TEFLON is a registered trademark of E.I. Dupont De Nemours and Company.

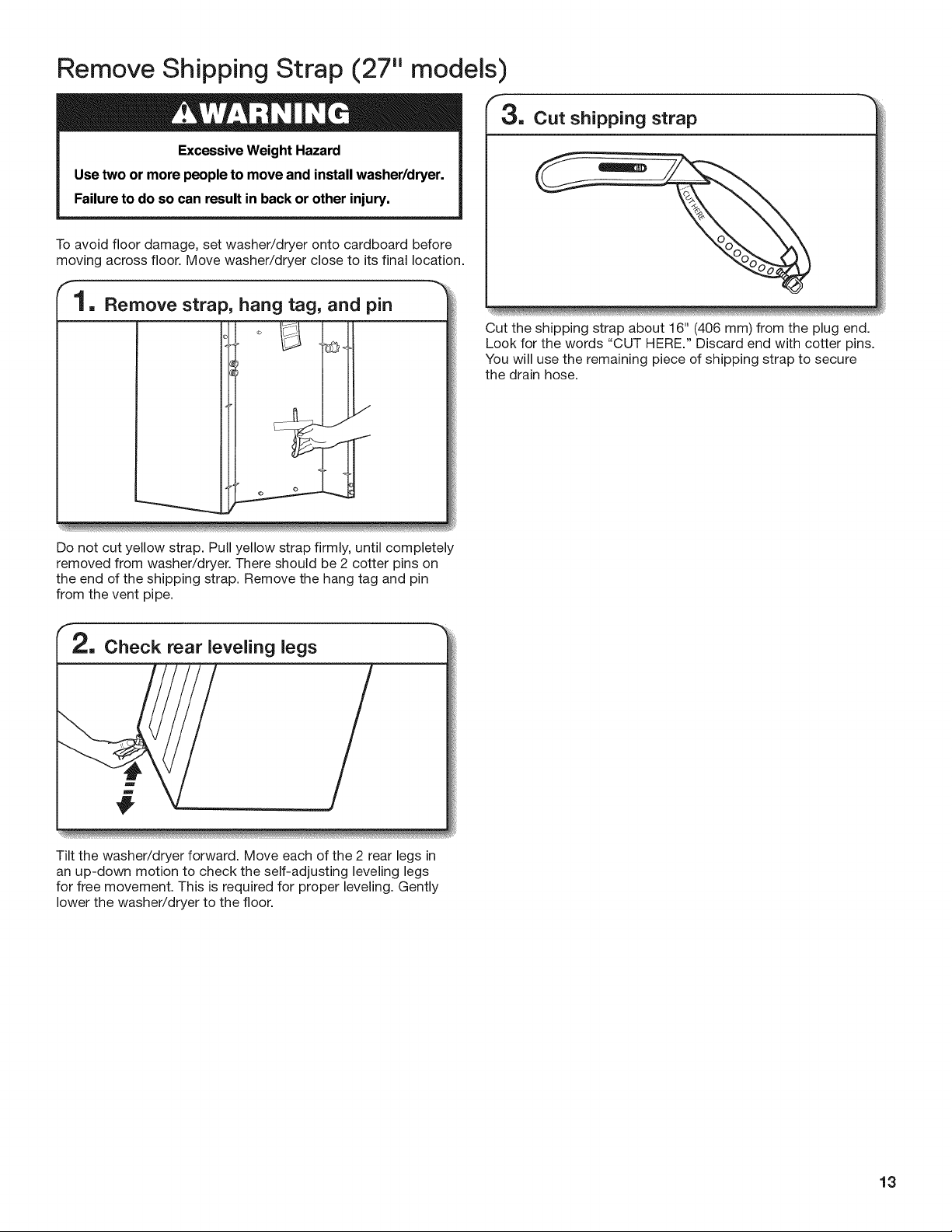

Remove Shipping Strap

Excessive Weight Hazard

Use two or more people to move and install washer/dryer.

Failure to do so can result in back or other injury.

To avoid floor damage, set washer/dryer onto cardboard before

moving across floor. Move washer/dryer close to its final location.

(27" models)

1. Remove strap, hang tag, and pin

3. Cut shipping strap

Cut the shipping strap about 16" (406 mm) from the plug end.

Look for the words "CUT HERE." Discard end with cotter pins.

You will use the remaining piece of shipping strap to secure

the drain hose.

Do not cut yellow strap. Pull yellow strap firmly, until completely

removed from washer/dryer. There should be 2 cotter pins on

the end of the shipping strap. Remove the hang tag and pin

from the vent pipe.

2. Check rear leveling legs

Tilt the washer/dryer forward. Move each of the 2 rear legs in

an up-down motion to check the self-adjusting leveling legs

for free movement. This is required for proper leveling. Gently

lower the washer/dryer to the floor.

13

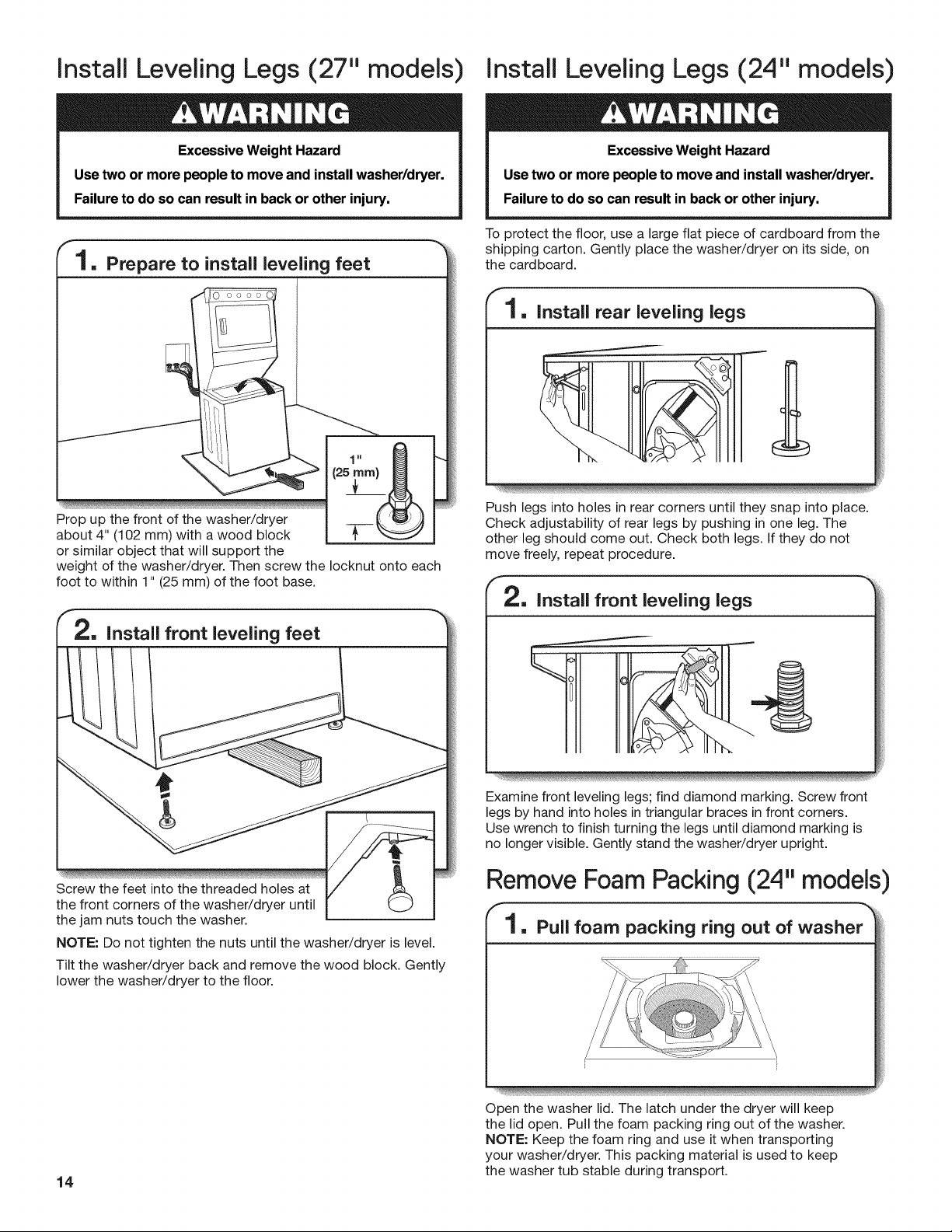

Install Leveling Legs (27" models)

Install Leveling Legs (24" models)

Excessive Weight Hazard

Use two or more people to move and install washer/dryer.

Failure to do so can result in back or other injury.

1. Prepare to install leveling feet

Prop up the front of the washer/dryer

about 4" (102 mm) with a wood block

or similar object that will support the

weight of the washer/dryer. Then screw the Iocknut onto each

foot to within 1" (25 mm) of the foot base.

Excessive Weight Hazard

Use two or more people to move and install washer/dryer.

Failure to do so can result in back or other injury,

To protect the floor, use a large flat piece of cardboard from the

shipping carton. Gently place the washer/dryer on its side, on

the cardboard.

F1, Install rear leveling legs

Push legs into holes in rear corners until they snap into place.

Check adjustability of rear legs by pushing in one leg. The

other leg should come out. Check both legs. If they do not

move freely, repeat procedure.

f2, Install front leveling legs

2, Install front leveling feet

Screw the feet into the threaded holes at

the front corners of the washer/dryer until

the jam nuts touch the washer.

NOTE: Do not tighten the nuts until the washer/dryer is level.

Tilt the washer/dryer back and remove the wood block. Gently

lower the washer/dryer to the floor.

1

Examine front leveling legs; find diamond marking. Screw front

legs by hand into holes intriangular braces in front corners.

Use wrench to finish turning the legs until diamond marking is

no longer visible. Gently stand the washer/dryer upright.

Remove Foam Packing (24" models)

f 1. Pull foam packing ring out of washer

14

Open the washer lid. The latch under the dryer will keep

the lid open. Pull the foam packing ring out of the washer.

NOTE: Keep the foam ring and use it when transporting

your washer/dryer. This packing material is used to keep

the washer tub stable during transport.

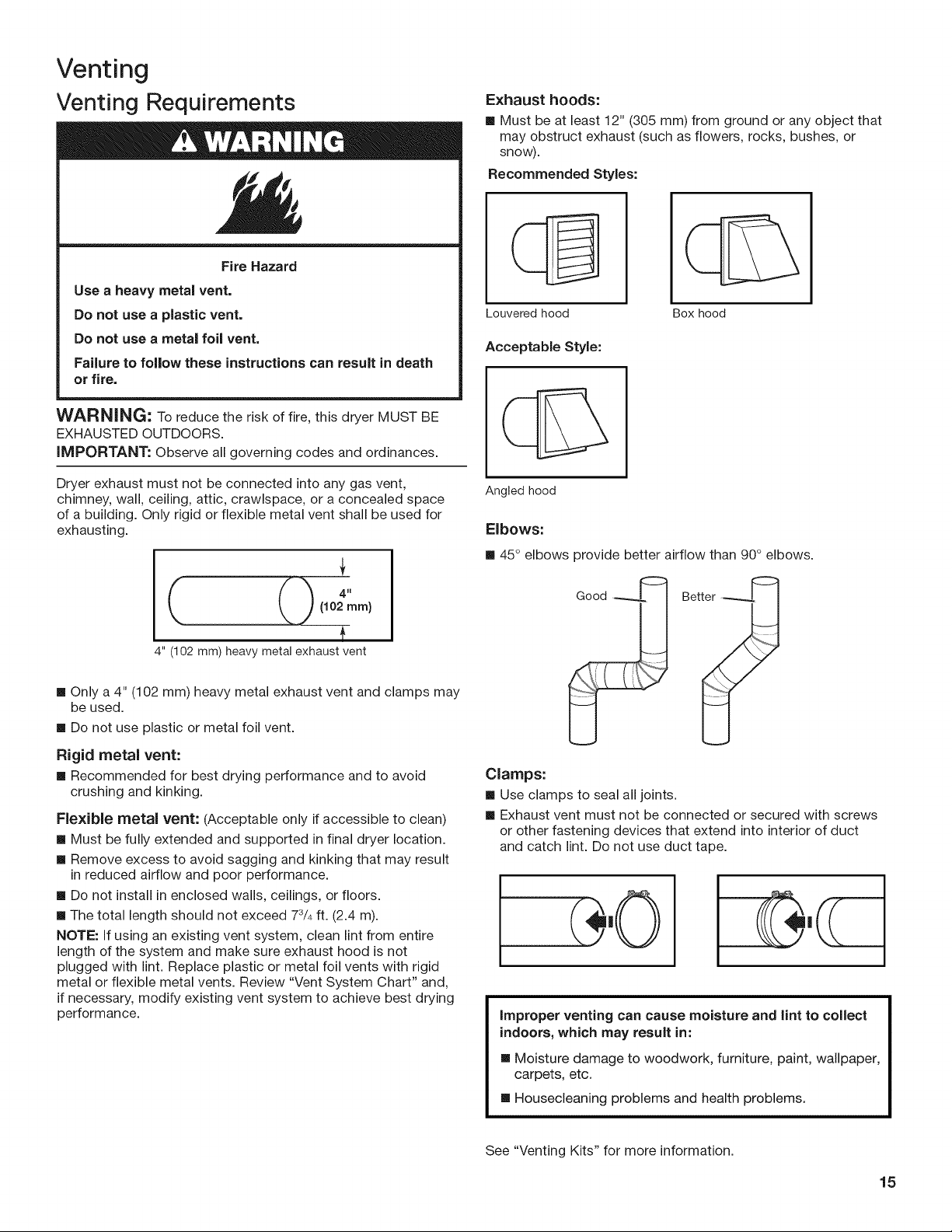

Venting

Venting Requirements

Fire Hazard

Use a heavy metal vent,

Do not use a plastic vent.

Do not use a metal foi vent,

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Exhaust hoods:

[] Must be at least 12" (305 mm) from ground or any object that

may obstruct exhaust (such as flowers, rocks, bushes, or

snow).

Recommended Styles:

Louvered hood

Acceptable Style:

Box hood

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or flexible metal vent shall be used for

exhausting.

(

4" (102 mm) heavy metal exhaust vent

[] Only a 4" (102 mm) heavy metal exhaust vent and clamps may

be used.

[] Do not use plastic or metal foil vent.

Rigid metal vent:

[] Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

[] Must be fully extended and supported in final dryer location.

[] Remove excess to avoid sagging and kinking that may result

in reduced airflow and poor performance.

[] Do not install in enclosed walls, ceilings, or floors.

[] The total length should not exceed 73/4ft. (2.4 m).

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not

plugged with lint. Replace plastic or metal foil vents with rigid

metal or flexible metal vents. Review "Vent System Chart" and,

if necessary, modify existing vent system to achieve best drying

performance.

(102 ram)

Angled hood

Elbows:

[] 45° elbows provide better airflow than 90° elbows.

Bet

Clamps:

[] Use clamps to seal all joints.

[] Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct

and catch lint. Do not use duct tape.

improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

See "Venting Kits" for more information.

15

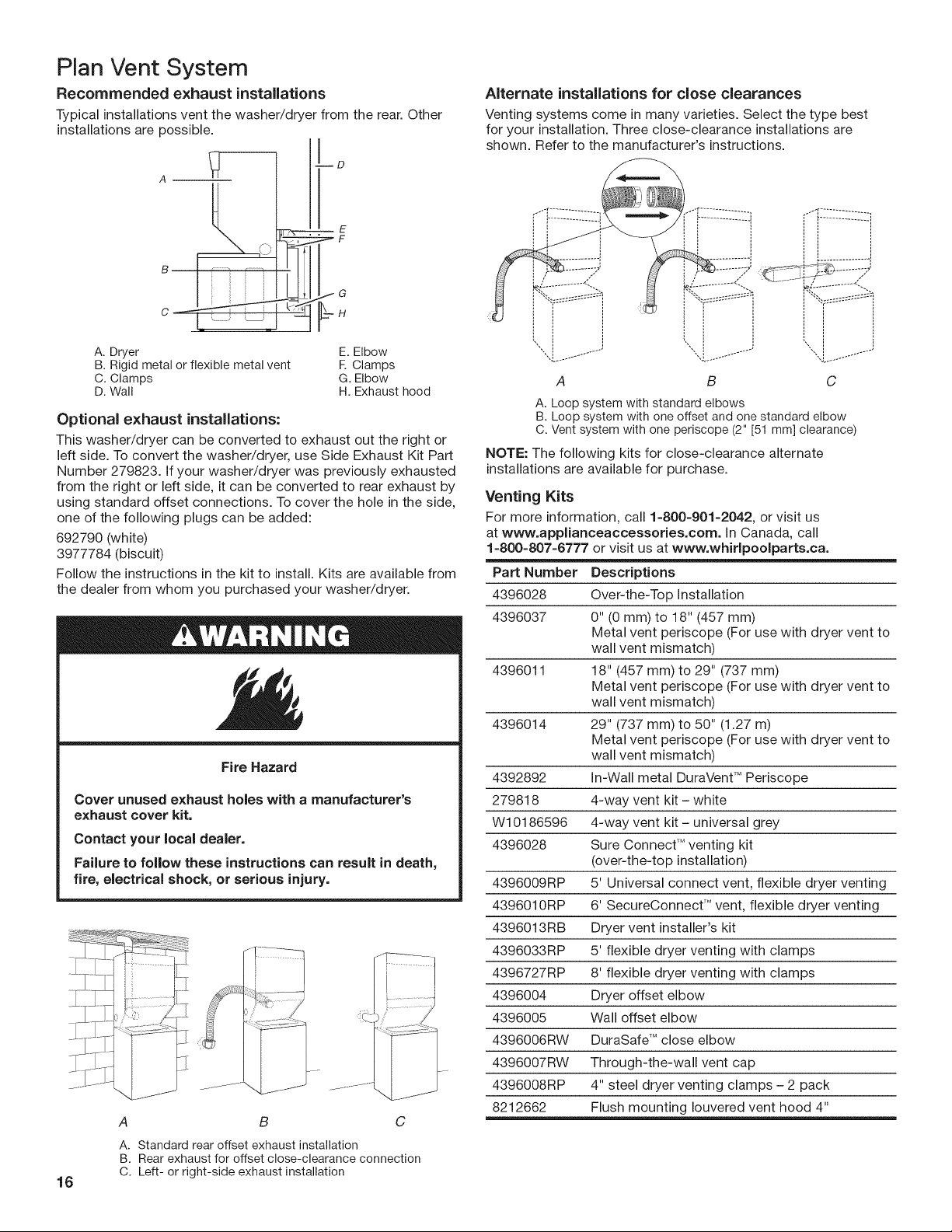

Plan Vent System

Recommended exhaust installations

Typical installations vent the washer/dryer from the rear. Other

installations are possible.

A. Dryer E. Elbow

B. Rigid metal or flexible metal vent E Clamps

C. Clamps G. Elbow

D. Wall H. Exhaust hood

Optional exhaust installations:

This washer/dryer can be converted to exhaust out the right or

left side. To convert the washer/dryer, use Side Exhaust Kit Part

Number 279823. if your washer/dryer was previously exhausted

from the right or left side, it can be converted to rear exhaust by

using standard offset connections. To cover the hole in the side,

one of the following plugs can be added:

692790 (white)

3977784 (biscuit)

Follow the instructions in the kit to install. Kits are available from

the dealer from whom you purchased your washer/dryer.

Fire Hazard

Cover unused exhaust holes with a manufacturer's

exhaust cover kit.

Contact your local dealer.

Failure to follow these instructions can result in death,

fire, electrical shock, or serious injury.

A B C

A. Standard rear offset exhaust installation

B. Rear exhaust for offset close-clearance connection

16

C. Left- or right-side exhaust installation

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best

for your installation. Three close-clearance installations are

shown. Refer to the manufacturer's instructions.

.-r.......... .--'r ................ , .... r.................

:4

L . ..... ......

A B C

A. Loop system with standard elbows

B. Loop system with one offset and one standard elbow

C. Ventsystem with one periscope (2" [51 mm] clearance)

NOTE: The following kits for close-clearance alternate

installations are available for purchase.

Venting Kits

For more information, call 1-800-901-2042, or visit us

at www.applianceaccessories.com, in Canada, call

1-800-807-6777 or visit us at www.whirlpoolparts.ca.

Part Number Descriptions

4396028 Over-the-Top installation

4396037 0" (0 mm) to 18" (457 mm)

Metal vent periscope (For use with dryer vent to

wall vent mismatch)

4396011 18" (457 mm) to 29" (737 mm)

Metal vent periscope (For use with dryer vent to

wall vent mismatch)

4396014 29" (737 mm) to 50" (1.27 m)

Metal vent periscope (For use with dryer vent to

wall vent mismatch)

4392892 In-Wall metal DuraVent TM Periscope

279818 4-way vent kit - white

W10186596 4-way vent kit - universal grey

4396028 Sure Connect TM venting kit

(over-the-top installation)

4396009RP 5' Universal connect vent, flexible dryer venting

4396010RP 6' SecureConnect TM vent, flexible dryer venting

4396013RB Dryer vent installer's kit

4396033RP 5' flexible dryer venting with clamps

4396727RP 8' flexible dryer venting with clamps

4396004 Dryer offset elbow

4396005 Wall offset elbow

4396006RW DuraSafe TM close elbow

4396007RW Through-the-wall vent cap

4396008RP 4" steel dryer venting clamps- 2 pack

8212662 Flush mounting Iouvered vent hood 4"

Special provisions for mobile home installations:

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

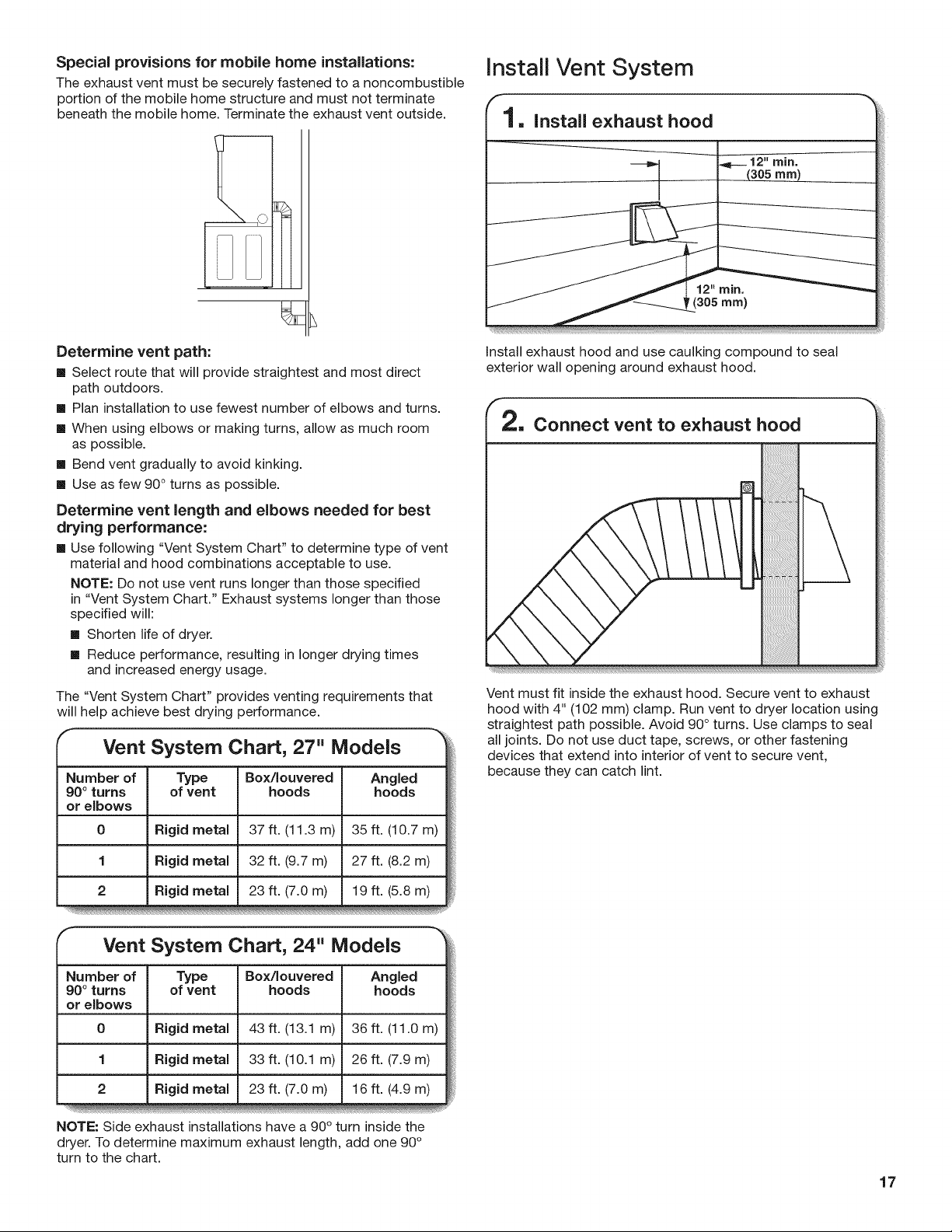

Install Vent System

Determine vent path:

m Select route that will provide straightest and most direct

path outdoors.

m Plan installation to use fewest number of elbows and turns.

m When using elbows or making turns, allow as much room

as possible.

m Bend vent gradually to avoid kinking.

m Use as few 90° turns as possible.

Determine vent length and elbows needed for best

drying performance:

m Use following "Vent System Chart" to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified

in "Vent System Chart." Exhaust systems longer than those

specified will:

m Shorten life of dryer.

m Reduce performance, resulting in longer drying times

and increased energy usage.

The "Vent System Chart" provides venting requirements that

will help achieve best drying performance.

Vent System Chart, 27" Models

Number of Type Box/Iouvered Angled

90 ° turns of vent hoods hoods

or elbows

0 Rigid metal 37 ft. (11.3 m) 35 ft. (10.7 m)

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

f

2. Connect vent to exhaust hood

Vent must fit inside the exhaust hood. Secure vent to exhaust

hood with 4" (102 mm) clamp. Run vent to dryer location using

straightest path possible. Avoid 90° turns. Use clamps to seal

all joints. Do not use duct tape, screws, or other fastening

devices that extend into interior of vent to secure vent,

because they can catch lint.

1 Rigid metal 32 ft. (9.7 m) 27 ft. (8.2 m)

2 Rigid metal 23 ft. (7.0 m) 19 ft. (5.8 m)

Vent System Chart, 24" Models

Number of Type Box/Iouvered Angled

90 ° turns of vent hoods hoods

or elbows

0

1

2

NOTE: Side exhaust installations have a 90 ° turn inside the

dryer. To determine maximum exhaust length, add one 90°

turn to the chart.

Rigid metal

Rigid metal

Rigid metal

43ft. (13.1 m)

33ft. (10.1 m)

23 ft. (7.0 m)

36 ft. (11.0 m)

26 ft. (7.9 m)

16 ft. (4.9 m)

17

Connect Drain Hose

Proper connection of the drain hose protects your floors

from damage due to water leakage. To keep the drain hose

from coming off or leaking, it must be installed according

to the following instructions:

IMPORTANT: To ensure proper installation, this procedure

must be followed exactly.

1. Attach clamp to drain hose

Check the drain hose to see whether it is the proper length.

Wet the inside of the straight end of the drain hose with tap

water.

IMPORTANT: Do not use any lubricant other than water.

Squeeze ears of the silver double-wire clamp with pliers to

open. Place clamp over the straight end of the drain hose 1/4"

(6.4 mm) from the end.

Place drain hose in standpipe

Place hose into standpipe (shown in picture) or over side of

laundry tub.

IMPORTANT: 4.5" (114 mm) of drain hose should be inside

standpipe; do not force excess hose into standpipe or lay

on bottom of laundry tub. Drain hose form must be used.

(floor drain installations only)

(27" model shown)

Open clamp. Twist hose back and forth while pushing onto

drain connector on the side of the washer/dryer. Continue until

hose contacts the ribbed stops on the cabinet. Place clamp

over the area marked "CLAMP." Release clamp.

For floor drain installations, you will need to remove the drain

hose form from the end of the drain hose. You may need

additional parts with separate directions. See "Tools and Parts."

18

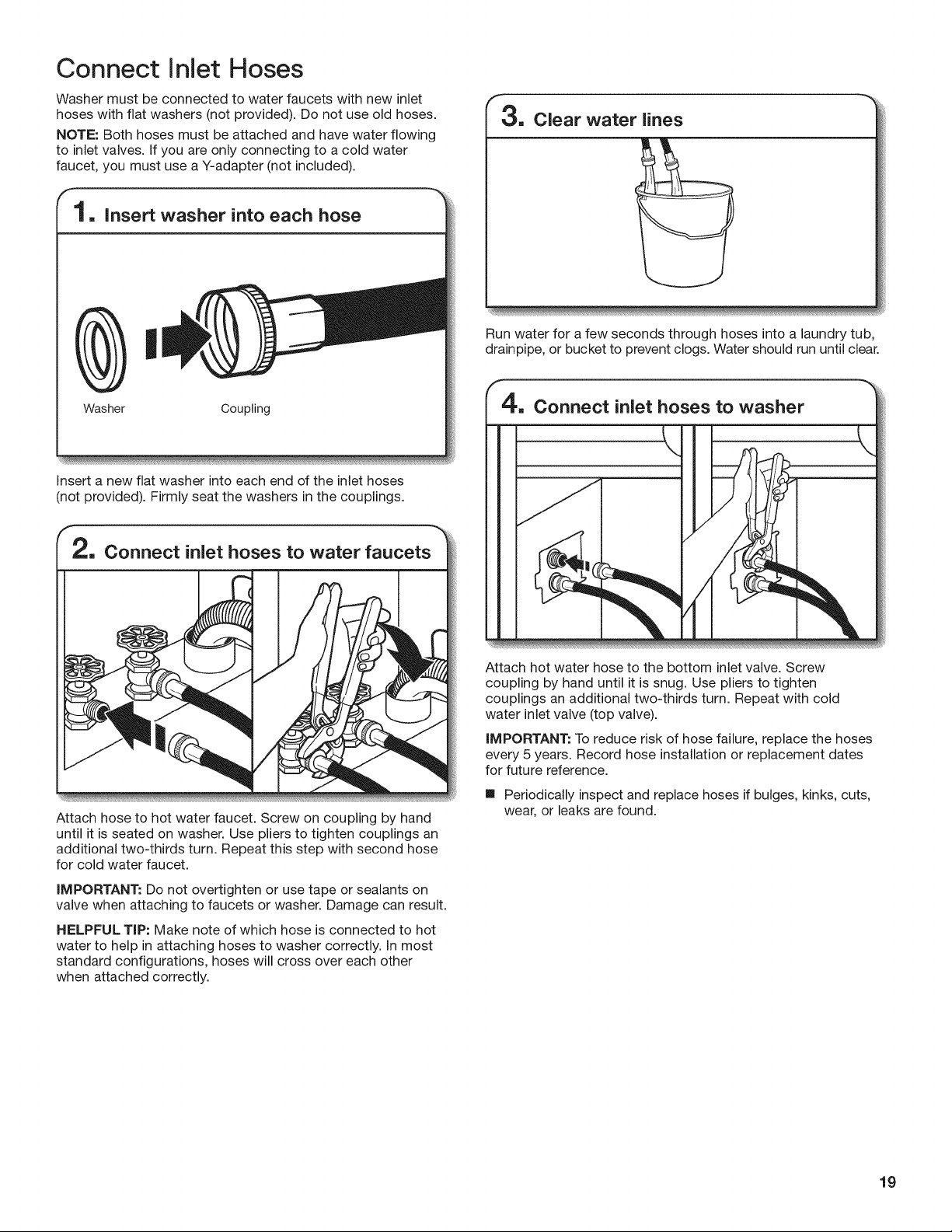

Connect Inlet Hoses

Washer must be connected to water faucets with new inlet

hoses with flat washers (not provided). Do not use old hoses.

NOTE: Both hoses must be attached and have water flowing

to inlet valves. If you are only connecting to a cold water

faucet, you must use a Y-adapter (not included).

1, Insert washer into each hose

3. Clear water lines

Run water for a few seconds through hoses into a laundry tub,

drainpipe, or bucket to prevent clogs. Water should run until clear.

Washer Coupling

Insert a new flat washer into each end of the inlet hoses

(not provided). Firmly seat the washers in the couplings.

Attach hose to hot water faucet. Screw on coupling by hand

until it is seated on washer. Use pliers to tighten couplings an

additional two-thirds turn. Repeat this step with second hose

for cold water faucet.

IMPORTANT: Do not overtighten or use tape or sealants on

valve when attaching to faucets or washer. Damage can result.

NELPFUL TIP: Make note of which hose is connected to hot

water to help in attaching hoses to washer correctly. In most

standard configurations, hoses will cross over each other

when attached correctly.

K 4, Connect inlet hoses to washer

Attach hot water hose to the bottom inlet valve. Screw

coupling by hand until it is snug. Use pliers to tighten

couplings an additional two-thirds turn. Repeat with cold

water inlet valve (top valve).

IMPORTANT: To reduce risk of hose failure, replace the hoses

every 5 years. Record hose installation or replacement dates

for future reference.

m Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

19

5. Move washer/dryer to final location

fT, Secure drain hose

Outer Access Panel j Inner Access Panel

(27" model shown) I- (27"models only)

If you are working in a closet or recessed area: move the

washer/dryer into its final location and remove cardboard

from under washer/dryer. Remove the outer access panel

by removing 2 (24" models) or 3 (27" models) Phillips-head

screws and one bumper (27" models only), located at the top

of the access panel. Remove inner access panel (27" models

only) by removing clip, cover, and 2 screws. Set panels,

screws, clip, inner access panel cover, and bumper aside.

Complete hookup of water hoses and vent. Replace access

panels upon completion of washer/dryer installation.

6. Check for leaks

C

Laundry Tub Standpipe

4.5"

(114 rnm)

Secure drain hose to laundry tub leg, drain standpipe, or inlet

hoses for wall standpipe with shipping strap removed earlier

(27" models) or plastic strap included in the parts package

(24" models).

Turn on water faucets to check for leaks. A small amount of

water may enter washer. It will drain later.

2O

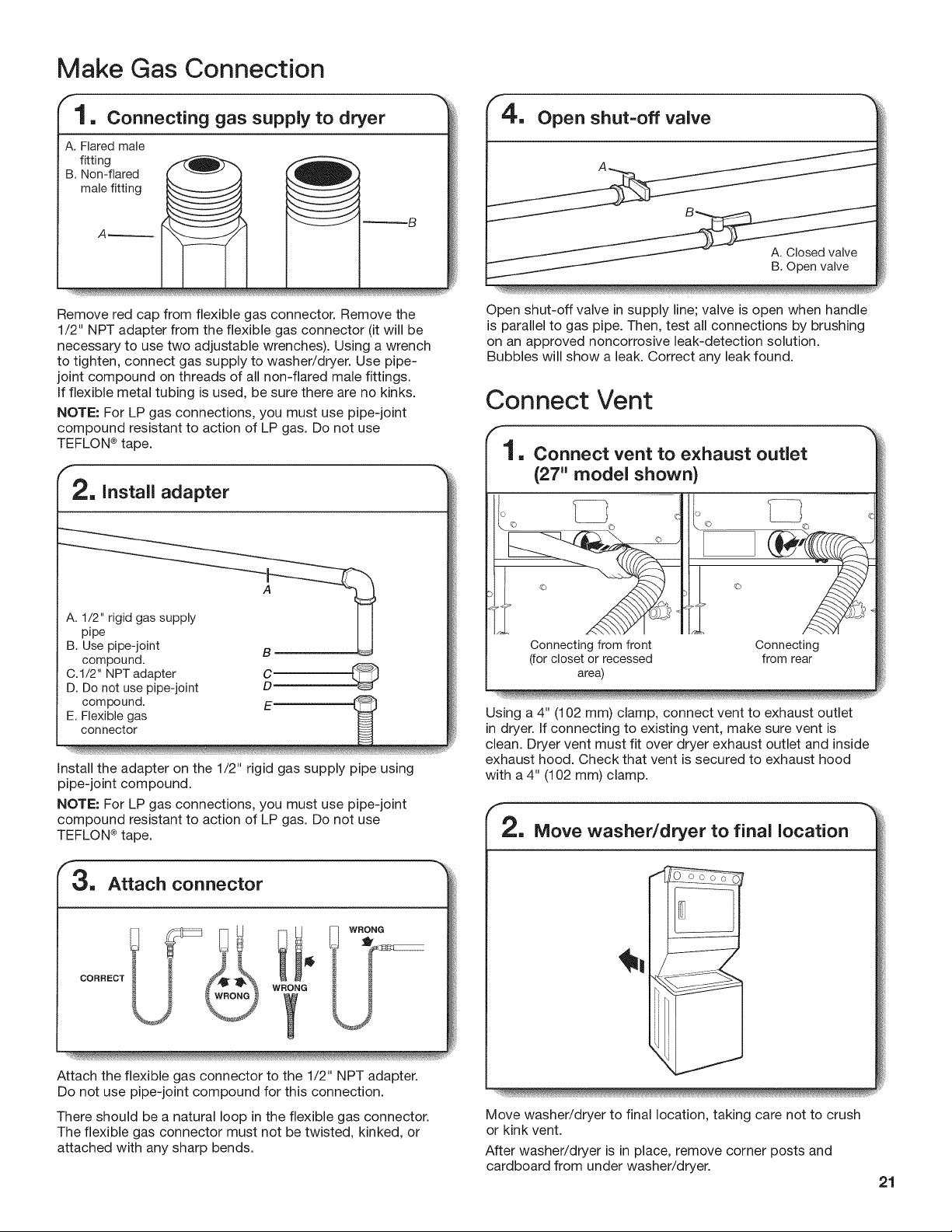

Make Gas Connection

r "1, Connecting gas supply to dryer "_

A. Flared male

fitting ___)--_

B. Non-flared

male fitting

_B

m

Remove red cap from flexible gas connector. Remove the

1/2" NPT adapter from the flexible gas connector (it will be

necessary to use two adjustable wrenches). Using a wrench

to tighten, connect gas supply to washer/dryer. Use pipe-

joint compound on threads of all non-flared male fittings.

If flexible metal tubing is used, be sure there are no kinks.

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to action of LP gas. Do not use

TEFLON ®tape.

_=,

:2, Install adapter

4, Open shut=off valve

A. Closed valve

B. Open valve

Open shut-off valve in supply line; valve is open when handle

is parallel to gas pipe. Then, test all connections by brushing

on an approved noncorrosive leak-detection solution.

Bubbles will show a leak. Correct any leak found.

Connect Vent

"1, Connect vent to exhaust outlet

(27" model shown)

A. 1/2" rigid gas supply

pipe

B. Use pipe-joint

compound.

C.1/2" NPT adapter

D. Do not use pipe-joint

Install the adapter on the 1/2" rigid gas supply pipe using

pipe-joint compound.

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to action of LP gas. Do not use

TEFLON ®tape.

©

3. Attach connector

©

Connecting from front Connecting

(for closet or recessed from rear

area)

Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure vent is

clean. Dryer vent must fit over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood

with a 4" (102 mm) clamp.

2, Move washer/dryer to final location

Attach the flexible gas connector to the 1/2" NPT adapter.

Do not use pipe-joint compound for this connection.

There should be a natural loop in the flexible gas connector.

The flexible gas connector must not be twisted, kinked, or

attached with any sharp bends.

Move washer/dryer to final location, taking care not to crush

or kink vent.

After washer/dryer is in place, remove corner posts and

cardboard from under washer/dryer.

21

Loading...

Loading...