Whirlpool WHP43, WGHP43, WGHP44, WGHP46, WGHP48 Installation Instructions Manual

...

HEAT PUMP INSTALLATION INSTRUCTIONS

Table of Contents

HEAT PUMP UNIT SAFETY...........................................................1

INSTALLATION REQUIREMENTS................................................ 2

Tools and Parts ............................................................................2

System Requirements..................................................................2

Location Requirements................................................................3

Electrical Requirements ...............................................................3

INSTALLATION INSTRUCTIONS..................................................4

Inspect Shipment.........................................................................4

Flush Refrigerant Lines ................................................................4

HEAT PUMP UNIT SAFETY

System Installation .......................................................................4

Connect Refrigerant Lines ...........................................................5

Make Electrical Connections .......................................................6

Charge Refrigerant Lines .............................................................8

Complete Installation..................................................................11

TROUBLESHOOTING ..................................................................12

SYSTEM MAINTENANCE ............................................................16

ASSISTANCE OR SERVICE.........................................................16

Accessories ................................................................................16

Recognize this symbol as a safety precaution.

Recognize Safety Symbols, Words and Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards.It is the

owner’s responsibility to read and comply with all safety

information and instructions accompanying these symbols.

Failure to heed safety information increases the risk of serious

personal injury or death, property damage and/or product

damage.

WARNING

Hazards or unsafe practices could result in property

damage, product damage, severe personal injury or death.

Goodman 1

CAUTION

Hazards or unsafe practices may result in property

damage, product damage, personal injury or death.

CAUTION

Hazards or unsafe practices may result in property

or product damage.

Goodman 9

WARNING

Installation and repair of this unit should

be performed ONLY by individuals meeting

the requirements of an “Entry Level Technician”

as specified by the Air-Conditioning, Heating and

Refrigeration Institute (AHRI). Attempting to

install or repair this unit without such background may

result in product damage, personal injury or death.

Goodman 7

WARNING

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

Goodman 6

WARNING

Scroll equipped units should never be used to evacuate

the air conditioning system. Vacuums this low can cause

internal electrical arcing resulting in a damaged or failed

compressor.

Goodman 32

Whirlpool® and Whirlpool Gold® Models WHP43, WHP44, WGHP43, WGHP44, WGHP46 and WGHP48

WPIO-259G

IMPORTANT: The United States Environmental Protection

Agency (EPA) has issued various regulations regarding the

introduction and disposal of refrigerants in this unit. Failure to

follow these regulations may harm the environment and can lead

to the imposition of substantial fines. These regulations may vary

by jurisdiction. A certified technician must perform the installation

and service of this product. Should questions arise, contact your

local EPA office.

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only for use by

qualified persons and do not supersede any national or local

codes in any way. The installation must comply with all state and

local codes as well as the National Electrical Code.

■ The heat pump is designed and approved for outdoor use

only.

■ The heat pump must be installed with no ductwork in the

airstream. The outdoor fan is not designed to operate against

any additional static pressure.

WARNING

Goodman 12

To avoid possible injury, explosion or death, practice safe

handling of refrigerants.

WARNING

Goodman 13

Refrigerants are heavier than air. They can "push out"

the oxygen in your lungs or in any enclosed space. To

avoid possible difficulty in breathing or death:

• Never purge refrigerant into an enclosed room or

space. By law, all refrigerants must be reclaimed.

• If an indoor leak is suspected, throughly ventilate the

area before beginning work.

• Liquid refrigerant can be very cold. To avoid possible

frostbite or blindness, avoid contact and wear gloves

and goggles. If liquid refrigerant does contact your

skin or eyes, seek medical help immediately.

• Always follow EPA regulations. Never burn refrigerant,

as poisonous gas will be produced.

This product is designed and manufactured to permit installation

in accordance with national codes. It is the installer’s

responsibility to install this unit in accordance with national codes

and/or prevailing local codes and regulations.

WARNING

Goodman 15

To avoid possible explosion, use only returnable (not

disposable) service cylinders when removing refrigerant

from a system.

• Ensure the cylinder is free of damage which could lead

to a leak or explosion.

• Ensure the hydrostatic test date does not exceed 5 years.

• Ensure the pressure rating meets or exceeds 400 lbs.

When in doubt, do not use cylinder.

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools Needed

■ To rc h

■ ¹⁄₄" (6.4 mm) nut driver

■ Vacuum pump

■ Micron gauge

Parts Needed

Check local codes and HVAC supplier. Check existing electrical

supply, and read “Electrical Requirements,” “Location

Requirements,” “System Requirements” and “Connect

Refrigerant Lines.”

NOTE: Some condensing units do not contain a factory-installed

filter dryer. With those units, a properly sized filter dryer must be

field installed in the liquid (high pressure) line set between the

outdoor condensing unit and indoor evaporator unit.

■ ⁵⁄₁₆" (7.6 mm) nut driver

■ Gauge set for R-410A

refrigerant

■ Nitrogen system

WARNING

Goodman 14

To avoid possible explosion:

• Never apply flame or steam to a refrigerant cylinder. If

you must heat a cylinder for faster charging, partially

immerse it in warm water.

• Never fill a cylinder more than 80% full of liquid

refrigerant.

• Never add anything other than R-22 to an R-22 cylinder

or R-410A to an R-410A cylinder. The service

equipment used must be listed or certified for the type

of refrigerant used.

• Store cylinders in a cool, dry place. Never use a cylinder

as a platform or a roller.

2

System Requirements

Heat pump system matches are derived from actual laboratory

testing of matched systems. It is recommended that only

matching equipment be used to ensure proper operation and

efficient performance.

■ The designed system matches are listed in the heat pump

specification sheets and on the heat pump refrigerant

charging instructions located on the back of the service

access panel.

■ Refrigerant charging instructions include a list of matching

indoor equipment with the proper thermal expansion device

size and amount of refrigerant charge required.

■ This heat pump has been factory charged with a quantity of

refrigerant (R-410A) sufficient for a matched indoor coil and a

maximum 15 ft (4.6 m) of refrigerant line.

Indoor System Thermal Expansion Device

■ Check the indoor coil thermal expansion device to see

whether it matches the required thermal expansion device for

the indoor coil and heat pump combination being installed.

■ Refer to the refrigerant charge label located on the inside of

the heat pump access panel for the correct thermal

expansion device size required.

■ Replace the thermal expansion device with the correct size if

this size is not already installed in the indoor coil. Instructions

for replacing the thermal expansion device are provided with

the indoor coil.

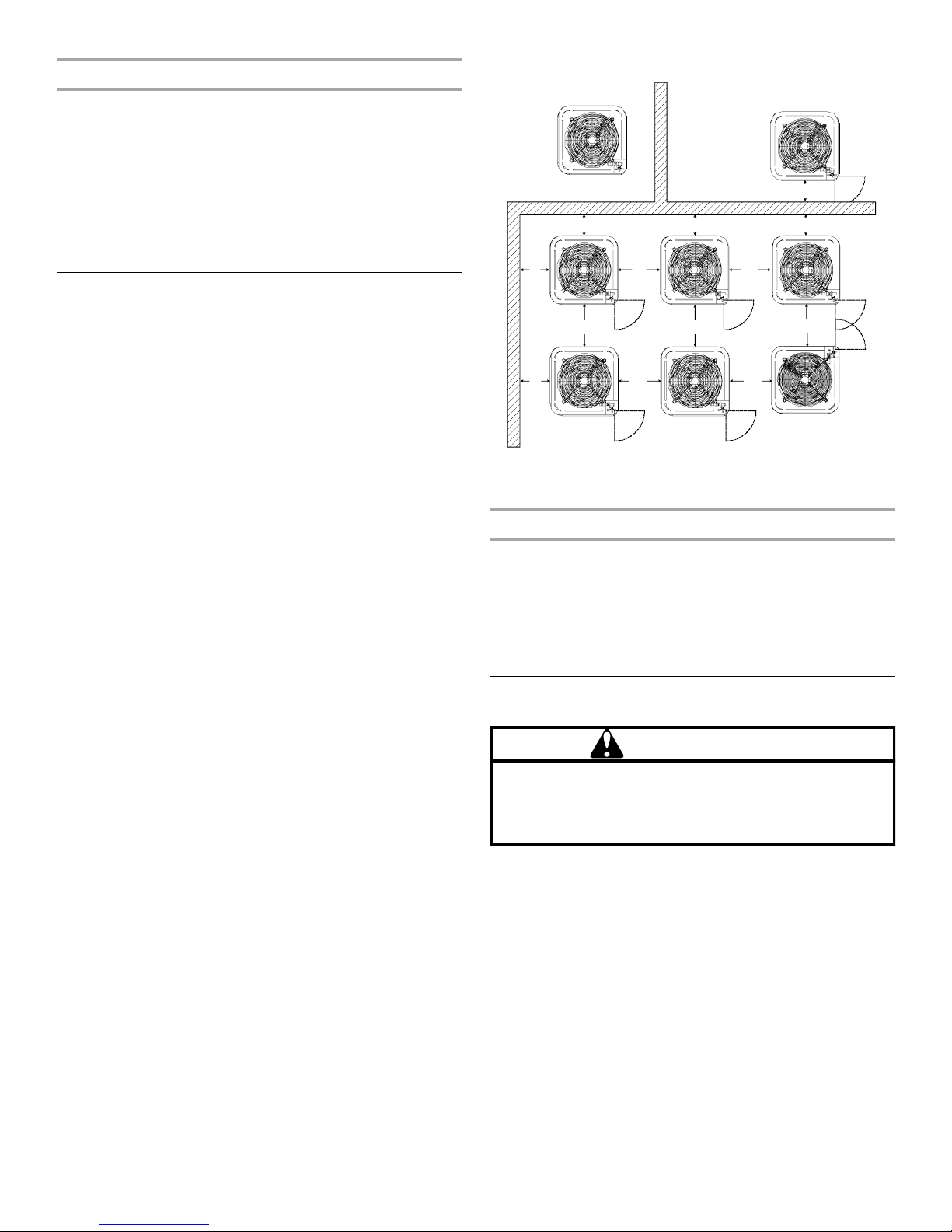

Installation Clearances—Single or Multiple Unit Installation

A

B

B

D D

B B

C

B

OK!

Location Requirements

■ This heat pump is designed to be located outdoors with

sufficient clearance for free entrance to the inlet and

discharge air openings. The location must also allow for

adequate service access. See “Installation Clearances.”

■ Where possible, select a location for the heat pump which is

shaded from the direct rays of the sun most of the time. North

or east locations are usually most desirable. Position the heat

pump to avoid direct contact with water, snow or ice from a

roofline overhead.

■ The heat pump must be installed on a solid, level mounting

pad that will not settle or shift. Isolate the pad from the

building structure to avoid possible transmission of sound or

vibration from the heat pump into the conditioned space.

■ The heat pump foundation should be raised to a minimum of

3" (7.6 cm) above finish grade. In areas which have prolonged

periods of temperatures below freezing, and/or snowfall, the

heat pump should be elevated above the average snow line.

If heat pump is to be installed on a flat roof, it should be on a

platform or other support which will raise the inlet air opening

12" (30.5 cm) minimum above the surface of the flat roof.

■ Avoid ice accumulation by ensuring free drainage of

condensate from defrost cycles. The heat pump should be

located away from walkways to avoid possible icing from

defrost condensate.

■ Avoid placing the heat pump near areas such as sleeping

quarters or study rooms. Normal operating sound levels may

be objectionable if the heat pump is placed near certain

rooms. A shift in sound type does occur during the defrost

mode. The defrost mode generally lasts no longer than

10 minutes.

■ Where possible, the top of the condensing unit should be

completely unobstructed.

■ If vertical conditions require placement beneath an

obstruction, there should be a minimum of 5 ft (1.5 m)

between the top of the condensing unit and the obstruction.

NOTE: The specified dimensions meet requirements for air

circulation only. Consult all appropriate regulatory codes prior

to determining final clearances.

■ Avoid corner installations if possible.

■ Either side adjacent to the valves can be placed toward the

structure provided the side away from the structure maintains

minimum service clearance.

C

D

B

D

C

D

D

C

D

OK!

OK!

C

CC

A. Not recommended

B. 10" (25.4 cm)

C. 18" (45.7 cm)

D. 20" (50.8 cm)

Rooftop Installation

■ Check that the roof structure can support the weight of the

condensing unit.

■ Keep the weather-tight integrity of the roof during and after

installation.

■ Vibration-absorbing pads or springs can be installed between

the condensing unit legs or frame and the roof mounting

assembly to reduce noise vibration.

Electrical Requirements

WARNING

To avoid the risk of injury, electrical shock or death, the

furnace must be electrically grounded in accordance with

local codes or, in their absence, with the latest edition of the

National Electric Code (NEC).

IMPORTANT: The United States Environmental Protection

Agency (EPA) has issued various regulations regarding the

introduction and disposal of refrigerants in this unit. Failure to

follow these regulations may harm the environment and can lead

to the imposition of substantial fines. These regulations may vary

by jurisdiction. A certified technician must perform the installation

and service of this product. Should questions arise, contact your

local EPA office.

This product is designed and manufactured to permit installation

in accordance with national codes. It is the installer’s

responsibility to install this unit in accordance with national codes

and/or prevailing local codes and regulations.

Goodman 31

3

NOTE: All outdoor wiring must be suitable for outdoor use. Use

copper conductors only.

■ All field wiring must be done in accordance with National

Electrical Code requirements, applicable requirements of UL,

or local codes, where applicable.

INSTALLATION INSTRUCTIONS

■ Electrical wiring, disconnect means and over-current

protection are to be supplied by the installer. Refer to the

rating plate for the maximum over-current protection,

minimum circuit ampacity, and operating voltage. See the

wiring diagrams in “Make Electrical Connections.”

Inspect Shipment

This heat pump is shipped in one package, completely

assembled and wired. The thermostat is shipped in a separate

carton when ordered.

■ Check the heat pump rating plate to confirm specifications

are as ordered.

■ Upon receipt of equipment, inspect it for possible shipping

damage. Examine the heat pump inside the carton if the

carton is damaged.

■ If damage is found, it should be noted on the carrier’s freight

bill. Damage claims should be filed with the carrier

immediately. Claims of shortages should be filed with the

seller within 5 days.

NOTE: If any damages are discovered and reported to the carrier,

do not install the heat pump, because your claim may be denied.

Flush Refrigerant Lines

Refrigerant lines must be flushed by a licensed, EPA certified

refrigerant technician in accordance with established procedures.

NOTES:

■ R-410A outdoor systems are not recommended for use with

indoor systems that have used R-22 as the refrigerant.

However, if this condensing unit is being matched with an

approved line set which was previously charged with R-22

refrigerant, the line set must be flushed prior to installation.

See your local distributor for an appropriate flushing kit.

■ Check the refrigerant lines for size and length. See “Connect

Refrigerant Lines.”

■ Polyol ester (POE) oils are used in Whirlpool units charged

with R-410A refrigerant. Residual mineral oil from the R-22

system can act as an insulator, inhibiting proper heat transfer.

It can also clog the thermal expansion device, reducing

system performance and capacity.

■ Where possible, drain as much residual compressor oil from

the existing systems, lines, and traps. Pay close attention to

low areas where oil may collect.

System Installation

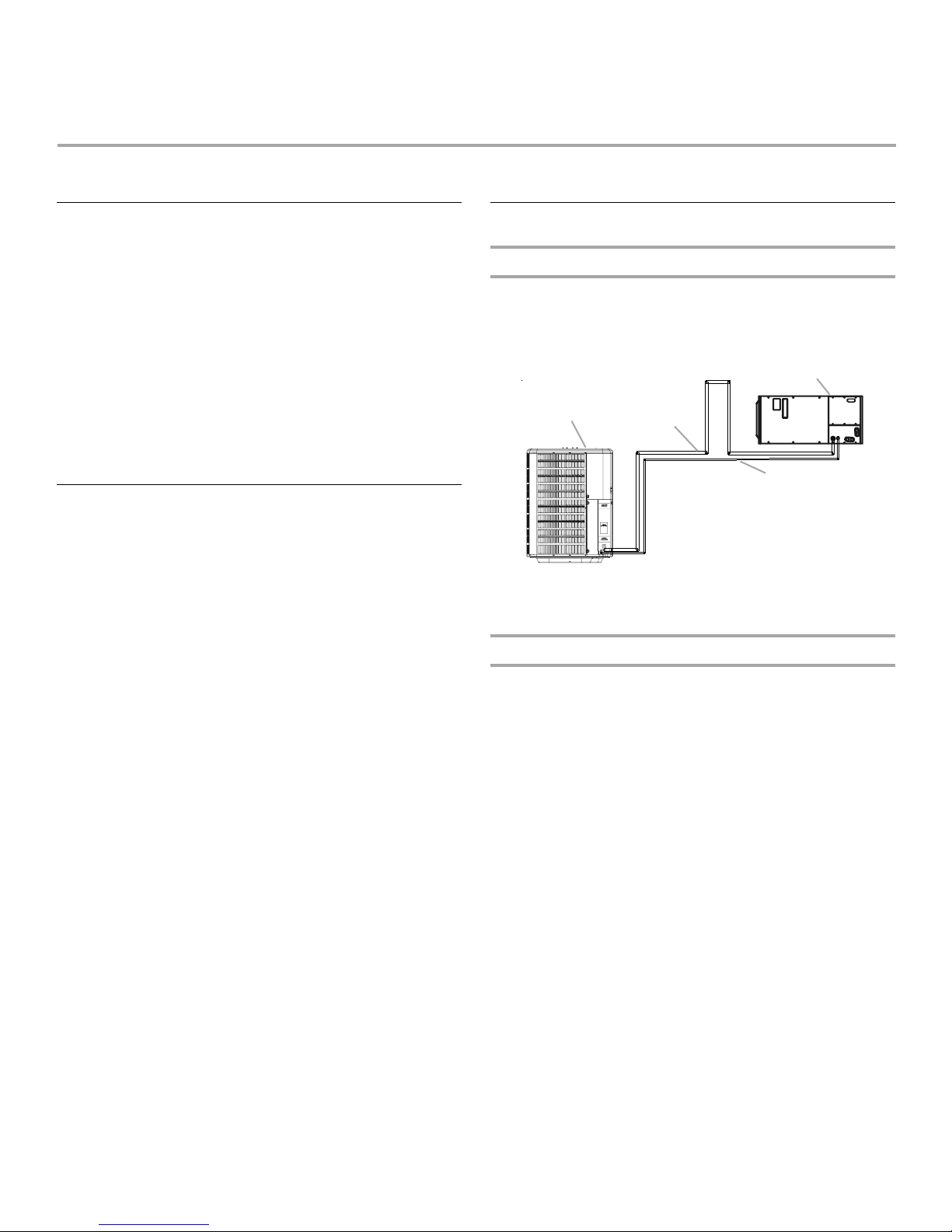

Mounting Evaporator Coil Above Condensing Unit

When mounting the evaporator coil above the condensing unit,

an inverted loop in the suction line adjacent or near the

connection to the evaporator coil is required. The top of the loop

must be slightly higher than the top of the evaporator coil.

C

A

A. Condensing unit

B. Suction line

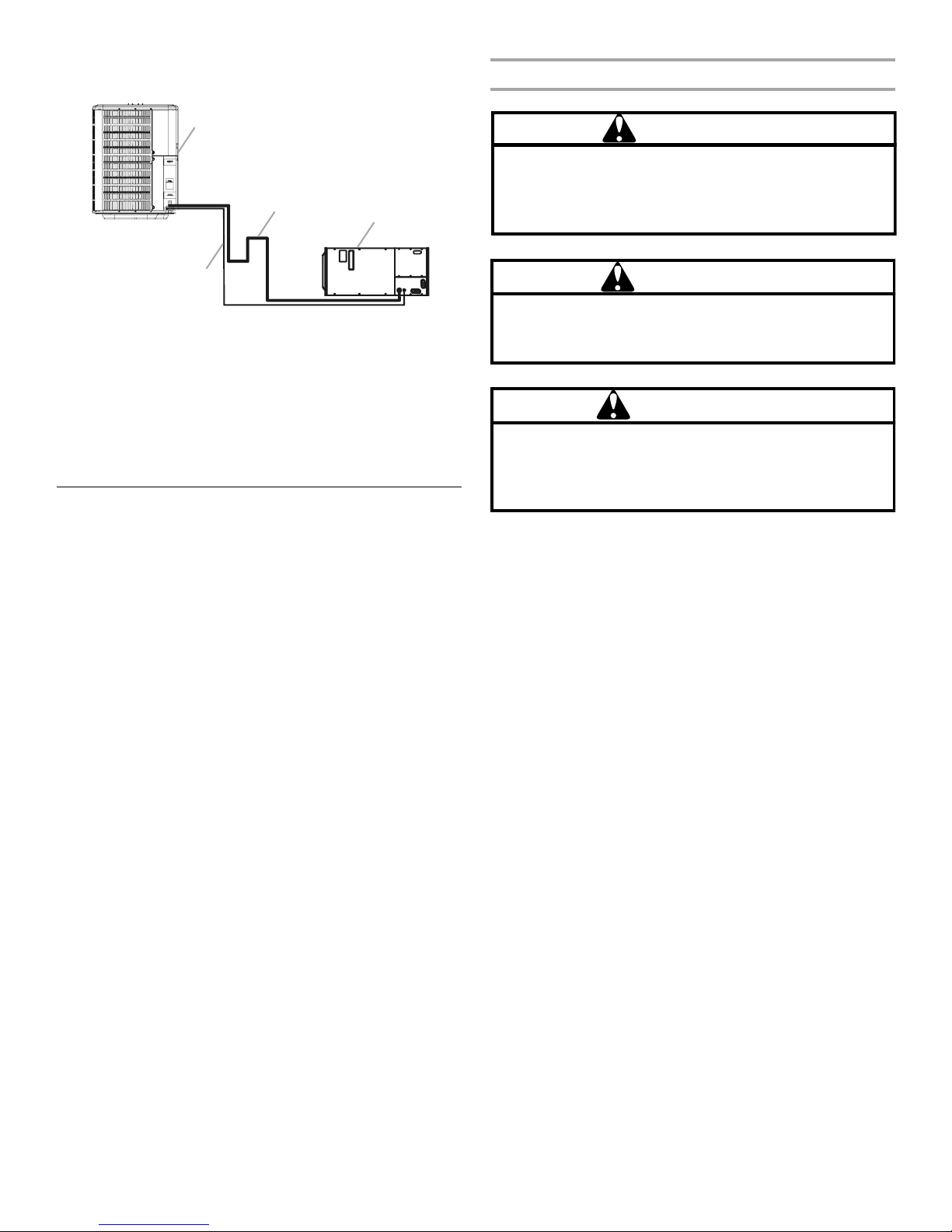

Mounting Condensing Unit Below Evaporator Coil

When mounting the condensing unit above the evaporator coil,

oil traps are required at equal intervals along the suction line.

■ Install 1 oil trap for a height difference of 15 ft to 25 ft (4.6 m

to 7.6 m) between indoor and outdoor units.

■ Install 2 oil traps for a height difference of 26 ft to 50 ft (7.9 m

to 15.2 m) between indoor and outdoor units.

■ Install 3 oil traps for a height difference of 51 ft to 100 ft

(15.5 m to 30.5 m) between indoor and outdoor units.

B

D

C. Evaporator coil

D. Liquid line

4

■ Install 4 oil traps for a height difference of 101 ft to 150 ft

(30.8 m to 45.7 m) between indoor and outdoor units.

Connect Liquid and Suction Lines

A

C

B

A. Condensing unit

B. Liquid line

Insulation is necessary to avoid condensation from forming and

dropping from the suction line. Armflex (or satisfactory

equivalent) with ³⁄₈" (1 cm) minimum wall thickness is

recommended. In severe conditions (hot, high humidity areas),

¹⁄₂" (1.3 cm) insulation may be required. Insulation must be

installed in a manner which keeps tubing from damage and

contamination.

C. Suction line

D. Evaporator coil

D

Connect Refrigerant Lines

Refrigerant lines must be connected by a licensed, EPA certified

refrigerant technician in accordance with established procedures.

IMPORTANT:

■ Connecting refrigerant lines must be clean, dehydrated,

refrigerant-grade copper lines. Heat pumps should be

installed only with specified line sizes for approved system

combinations with elevation differences up to 15 ft (4.6 m)

and total length of up to 50 ft (15.2 m). See the Suction Line

Sizes and Liquid Line Sizes charts.

■ Sharp bends or possible kinking in the lines will cause a

reduction in performance.

■ To avoid contamination of the refrigerant system, do not

remove the caps from the lines or system connection points

until connections are ready to be completed.

CAUTION

Goodman 16

The compressor POE oil for R-410A units is extremely

susceptible to moisture absorption and could cause

compressor failure. Do not leave system open to

atmosphere any longer than necessary for installation.

Goodman 17

WARNING

To avoid the risk of fire or explosion, never use oxygen,

high pressure air or flammable gases for leak testing of a

refrigeration system.

WARNING

Goodman 18

To avoid possible explosion, the line from the nitrogen

cylinder must include a pressure regulator and a pressure

relief valve. The pressure relief valve must be set to open at

no more than 150 psig.

1. Route the suction and liquid lines from the fittings on the

indoor coil to the fittings on the heat pump. Run the lines in

as direct a path as possible, avoiding unnecessary turns and

bends.

2. For product efficiency, be sure that the suction line is

insulated over the entire exposed length and that both

suction and liquid lines are not in direct contact with floors,

walls, ductwork, floor joists, or other piping.

3. Remove valve cores.

4. Wrap the service valves with a wet rag or an approved

thermal trap.

5. If a filter dryer is not provided, install a filter dryer in the liquid

line between the outdoor condensing unit and the indoor

evaporator coil.

NOTE: To reduce oxidation from forming and contaminating

the system, purge the line set/coil with nitrogen (1 to 2 psig)

during the brazing process.

5

Loading...

Loading...