Whirlpool WGGE45 Installation Instructions Manual

PACKAGE GAS ELECTRIC FURNACES

INSTALLATION INSTRUCTIONS

Table of Contents

GAS FURNACE SAFETY................................................................1

INSTALLATION REQUIREMENTS................................................4

Tools and Parts ............................................................................4

Location Requirements................................................................4

Ductwork Requirements ..............................................................6

Filter Requirements......................................................................6

Electrical Requirements ...............................................................7

Gas Supply Requirements...........................................................7

INSTALLATION INSTRUCTIONS..................................................7

Inspect Shipment.........................................................................7

Place Unit in Final Location .........................................................7

Airflow Conversion .......................................................................7

Hood Installation ..........................................................................8

Connect Condensate Drain .........................................................8

Install Ductwork............................................................................8

Make Electrical Connections .......................................................9

Make Gas Connections..............................................................10

Start-up, Adjustments and Checks ...........................................14

Gas Manifold Pressure Measurement and Adjustment.............15

Blower Speed Adjustments........................................................17

Blower Performance Data..........................................................17

Unit Shutdown............................................................................19

Cooling Start-Up ........................................................................19

SEQUENCE OF OPERATION ......................................................20

Heating System ..........................................................................20

Cooling System ..........................................................................20

Fan Only .....................................................................................21

Cooling Start-Up ........................................................................21

MAINTENANCE ............................................................................22

TROUBLESHOOTING ..................................................................23

Unit Fails to Operate Properly....................................................23

Ignition Control Error Codes ......................................................23

Abnormal Operation—Heating...................................................24

Abnormal Operation—Cooling...................................................25

ASSISTANCE OR SERVICE.........................................................28

Accessories ................................................................................28

GAS FURNACE SAFETY

Recognize this symbol as a safety precaution.

Please adhere to the following warnings and cautions when installing, adjusting, altering, servicing or operating the furnace.

WARNING

Hazards or unsafe practices could result in property

damage, product damage, severe personal injury or death.

Goodman 1

CAUTION

Hazards or unsafe practices may result in property

damage, product damage, personal injury or death.

Placeholder

for

Bar

Code

Whirlpool Gold® Models

WGGE45

Whirlpool® Home Cooling and Heating

14610 Breakers Drive

Jacksonville, FL 32258

Hazards or unsafe practices may result in property

or product damage.

CAUTION

Goodman 9

WPIO-325C

IMPORTANT SAFETY INSTRUCTIONS

Use only with type of gas approved for this furnace.

■

Refer to the furnace rating plate.

Install this furnace only in a location and position

■

as specified in the “Location Requirements” section

of these instructions.

Provide adequate combustion and ventilation air to

■

the furnace space as specified in the “Venting

Requirements” section of these instructions.

■

Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system

only, as specified in the “Venting Requirements”

section of these instructions.

Never test for gas leaks with an open flame. Use a

■

commercially available soap solution made

specifically for the detection of leaks to check all

connections, as specified in the “Make Gas

Connections” section of these instructions.

Adequate clearance must be provided around the

■

vent-air intake terminals.

ANSI Box Install G 2009 in Goodman Folder

Always install furnace to operate within the furnace’s

■

intended temperature-rise range with a duct system

which has an external static pressure within the

allowable range, as specified in the “Complete

Installation” section of these instructions. See

furnace rating plate.

■

When a furnace is installed so that supply ducts

carry air circulated by the furnace to areas outside

the space containing the furnace, the return air

shall also be handled by duct(s) sealed to the

furnace casing and terminating outside the space

containing the furnace.

A gas-fired furnace for installation in a residential

■

garage must be installed as specified in the

“Location Requirements” section of these

instructions.

The furnace shall be installed so the electrical

■

components are protected from water.

■ Furnaces for indoor installation on combustible

flooring shall not be installed directly on carpeting,

tile or other combustible material other than wood

flooring.

SAVE THESE INSTRUCTIONS

To the Installer

Before installing this unit, please read this manual thoroughly to

familiarize yourself with specific items which must be adhered to,

including but not limited to: unit maximum external static

pressure, gas pressures, Btu imput rating, proper electrical

connections, circulating air temperature rise, minimum or

maximum CFM and motor speed connections and venting.

These furnaces are designed for Category I venting only.

WARNING

If the information in these instructions is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Goodman 42

WARNING

Should overheating occur or the gas supply fail to shut

off, turn off the manual gas shutoff valve external to the

furnace before turning off the electrical supply.

Goodman 43

WARNING

Do not connect to or use any device that is not designcertified for use with this unit. Serious property damage,

personal injury, reduced unit performance and/or hazardous

conditions may result from the use of such non-approved

devices.

Goodman 36

WARNING

This product contains or produces a chemical or

chemicals which may cause serious illness or death and

which are known to the State of California to cause

cancer, birth defects or other reproductive harm.

Goodman 45

2

WARNING

WARNING

Heating unit should not be utilized without reasonable,

routine inspection, maintenance and supervision. If the

building in which any such device is located will be

vacant, care should be taken that such device is

routinely inspected, maintained and monitored. In the

event that the building may be exposed to freezing

temperatures and will be vacant, all water-bearing pipes

should be drained, the building should be properly

winterized and the water source closed. In the event

that the building may be exposed to freezing

temperatures and will be vacant, any hydronic coil units

should be drained as well, and, in such case, alternative

heat sources should be utilized.

Goodman 47

WARNING

To avoid property damage, personal injury or death, do

not use this furnace if any part of the furnace has been

under water. Immediately call a qualified service technician

to inspect the furnace and to replace any part of the

control system and any gas control having been under

water.

Goodman 81

WARNING

This unit must not be used as a “construction heater”

during the finishing phases of construction on a new

structure. This type of use may result in premature failure

of the unit due to extremely low return air temperatures

and exposure to corrosive or very dirty atmospheres.

Goodman 79

WARNING

HIGH VOLTAGE!

Goodman 6

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

To prevent the risk of property damage, personal injury, or

death, do not store combustible materials or use gasoline

or other flammable liquids or vapors in the vicinity of this

unit.

Goodman 37

WARNING

Installation and repair of this unit should

be performed ONLY by individuals meeting

the requirements of an “Entry Level Technician”

as specified by the Air-Conditioning, Heating and

Refrigeration Institute (AHRI). Attempting to

install or repair this unit without such background may

result in product damage, personal injury or death.

Goodman 7

DANGER

Goodman 38

CARBON MONOXIDE POISONING HAZARD

Special Warning for Installation of Furnace or Air Handling

Units in Enclosed Areas such as Garages, Utility Rooms or

Parking Areas.

Carbon monoxide producing devices (such as an

automobile, space heater, gas water heater, etc.) should

not be operated in enclosed areas such as unventilated

garages, utility rooms or parking areas because of the

danger of carbon monoxide (CO) poisoning resulting from

the exhaust emissions. If a furnace or air handler is

installed in an enclosed area such as a garage, utility room

or parking area and a carbon monoxide producing device is

operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO

poisoning which can occur if a carbon monoxide producing

device continues to operate in the enclosed area. Carbon

monoxide emissions can be (re)circulated throughout the

structure if the furnace or air handler is operating in any

mode.

CO can cause serious illness including permanent brain

damage or death.

3

INSTALLATION REQUIREMENTS

WARNING

To prevent property damage, personal injury or death,

due to fire, explosions, smoke, soot, condensation,

electric shock or carbon monoxide, this unit must be

properly installed, repaired, operated and maintained.

These instructions are intended as a general guide only for use by

qualified persons and do not supersede any national or local

codes in any way. Compliance with all local, state, or national

codes pertaining to this type of equipment should be determined

prior to installation.

Read this entire instruction manual, as well as the instructions

supplied in separate equipment, before starting the installation.

The installation of the unit, wiring, warm air ducts, venting, etc.

must conform to the requirements of the National Fire Protection

Association; the National Fuel Gas Code, ANSI Z223.1/NFPA No.

54 (latest edition) and the National Electrical Code, ANSI/NFPA

No. 70 (latest edition) in the United States, and any state laws,

local ordinances (including plumbing or wastewater codes), or

local gas utility requirements. Local authorities having jurisdiction

should be consulted before installation is made. Such applicable

regulations or requirements take precedence over the general

instructions in this manual.

Tools and Parts

Gather the required tools before starting installation. Read and

follow the instructions provided with any tools listed here.

Tools Needed

■ Pipe wrench

■ Screwdriver

■ Tape measure

■ Thread sealant

■ Noncorrosive leak detection solution

■ Test gau ge wi th ¹⁄₈" NPT connection

(for measuring gas supply pressure)

■ To avoid possible corrosion of the heat exchanger, do not

locate the unit in an area where the outdoor air (for example,

combustion air for the unit) will be frequently contaminated by

compounds containing chlorine or fluorine. Common sources

of such compounds include swimming pool chemicals and

chlorine bleaches, paint stripper, adhesives, paints,

varnishes, sealers, waxes (which are not yet dried) and

solvents used during construction and remodeling. Various

commercial and industrial processes may also be sources of

chlorine/fluorine compounds.

■ To avoid possible illness or death of the building occupants,

do not locate outside air intake device (economizer, manual

fresh air intake, motorized fresh air intake) too close to an

exhaust outlet, gas vent termination or plumbing vent outlet.

For specific distances required, consult local codes.

■ Allow minimum clearances from the enclosure for fire

protection, proper operation, and service access. These

clearances must be permanently maintained.

■ The combustion air inlet and flue outlet hoods on the unit

must never be obstructed. If used, do not allow the

economizer/manual fresh air damper/ motorized fresh air

damper to become blocked by snow or debris. In some

climates or locations, it may be necessary to elevate the unit

to avoid these problems.

■ When the unit is heating, the temperature of the return air

entering the unit must be between 50°F and 100°F (10ºC and

37.8ºC).

Ground Level Installations Only

■ When the unit is installed on the ground adjacent to the

building, a level concrete (or equal) base is recommended.

Prepare a base that is 3" (7.6 cm) larger than the package unit

footprint and a minimum of 3" (7.6 cm) thick.

■ The base should also be located where no runoff of water

from higher ground can collect in the unit.

Parts Needed

Check local codes and with gas supplier. Check existing gas

supply, electrical supply, and venting, and read “Ductwork

Requirements,” “Electrical Requirements” and “Gas Supply

Requirements” before purchasing parts.

Location Requirements

All Installations

WARNING

To prevent possible equipment damage, property damage,

personal injury or death, the following bullet points must

be observed when installing the unit.

■ For proper flame pattern within the heat exchanger and

proper condensate drainage, the unit must be mounted level.

■ The flue outlet hood must be at least 12" (30.5 cm) from any

opening through which flue gases could enter a building, and

at least 36" (91.4 cm) above any forced air inlet located within

10 ft (3 m). The economizer/manual fresh air intake/motorized

fresh air intake and combustion air inlet mounted on the unit

are not affected by this restriction.

Goodman 50

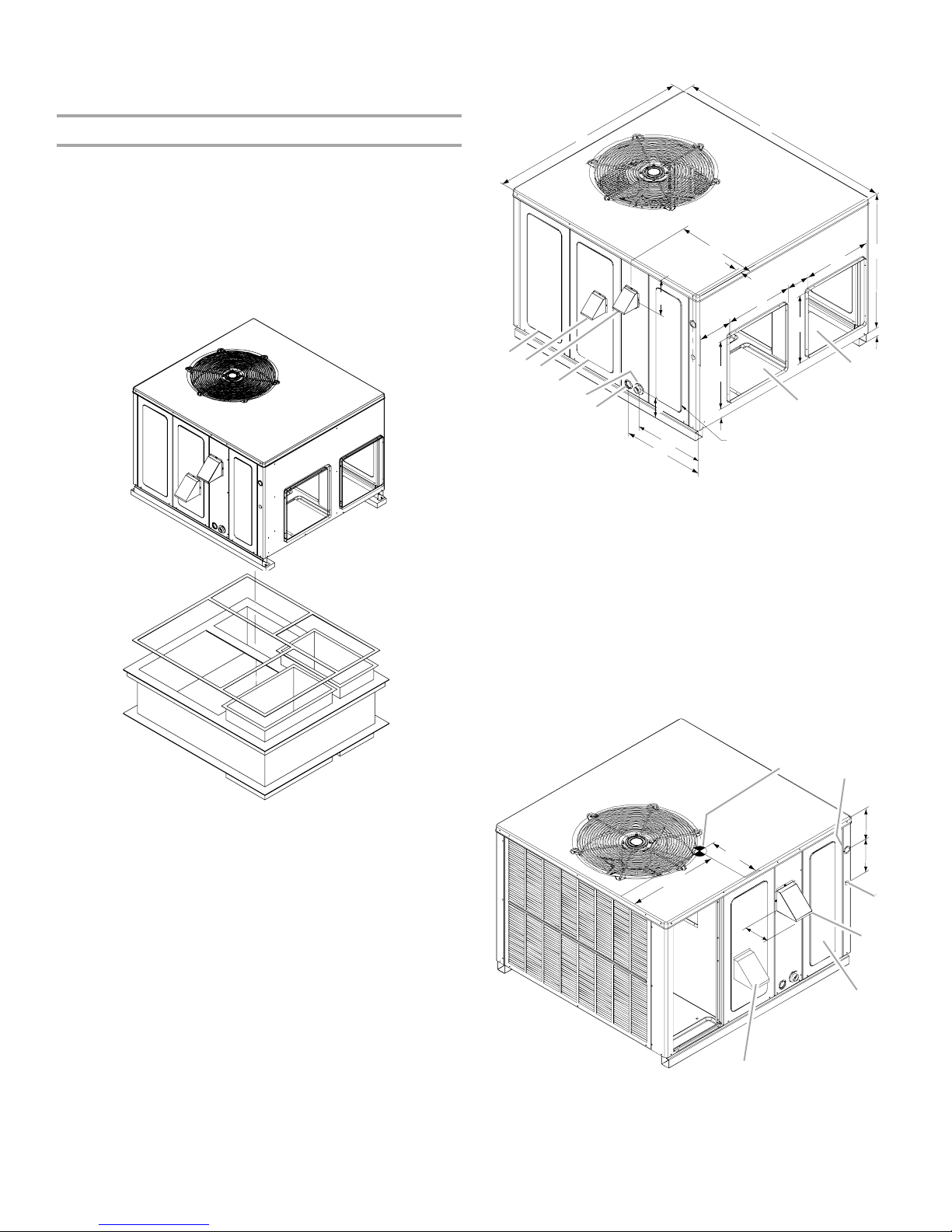

Rooftop Installations Only

■ The roof must have sufficient structural strength to carry the

weight of the unit(s) and snow or water loads as required by

local codes. Consult a structural engineer to determine the

weight capabilities of the roof.

Rooftop Installation

4

■ The unit may be installed directly on wood floors or on Class

A, Class B, or Class C roof covering material.

■ A safe, flat surface for service personnel should be provided.

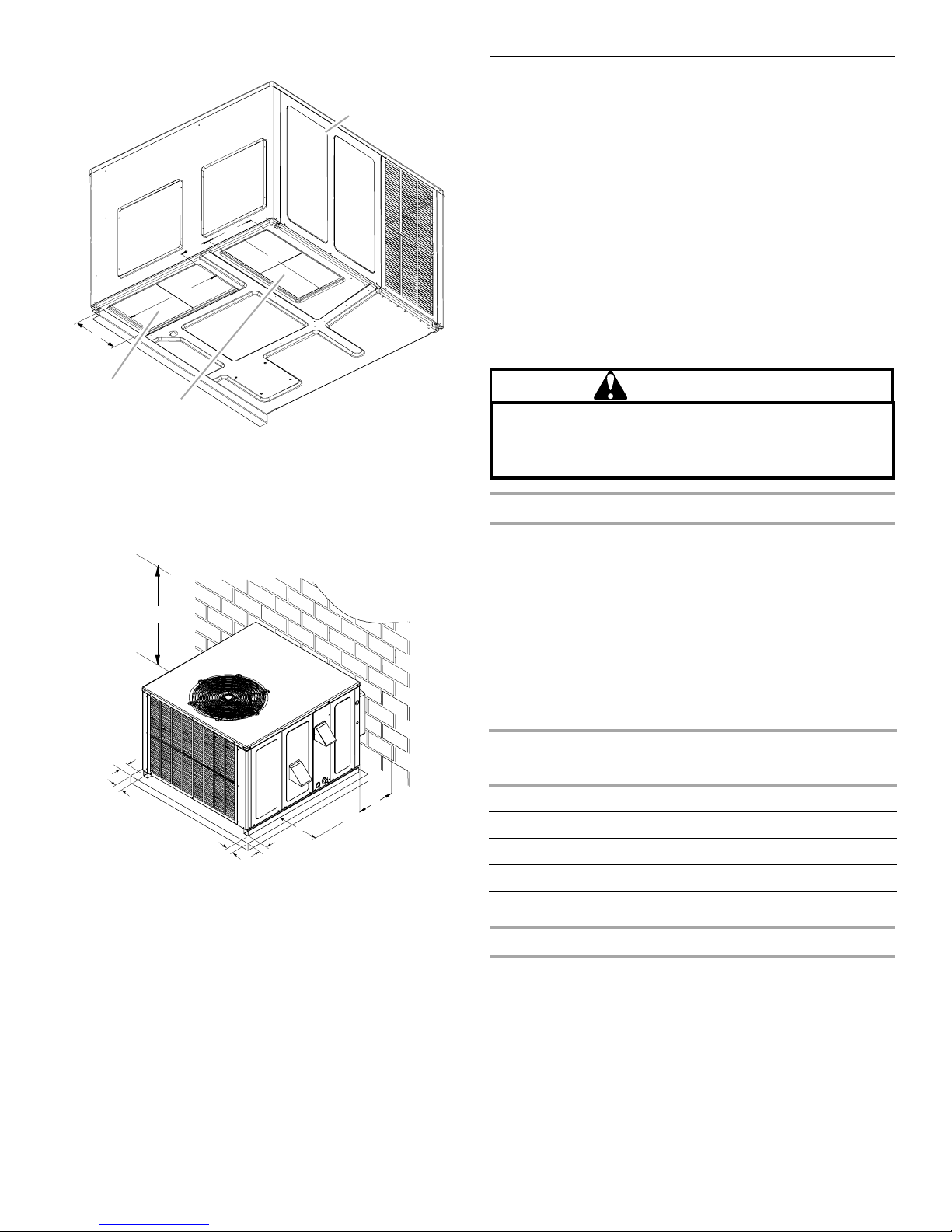

Unit Dimensions—Rear

Roof Curb Installations Only

■ Sufficient structural support must be determined prior to

locating and mounting the curb and package unit.

■ Ductwork must be constructed using industry guidelines. The

ductwork must be placed into the roof curb before mounting

the package unit.

■ Curb insulation, cant strips, flashing and general roofing

material are furnished by the contractor.

Roof Curb Installation

A

X

W

V

U

T

S

A. 47" (119.4 cm)

B. 51" (129.5 cm)

C. 18

⁷⁄₁₆

" (46.8 cm)

¹⁄₂

D. Medium: 9

(24.2 cm), large: 14"

(35.6 cm)

E. 7

¹⁵⁄₁₆

F. 16" (40.6 cm)

³⁄₈

" (3.5 cm)

G. 1

H. 5

¹⁄₂

" (14 cm)

I. Medium: 32" (81.3 cm ),

large: 40" (101.6 cm)

"

" (20.2 cm)

C

D

E

L

R

P

Q

³⁄₄

" (7 cm)

J. 2

K. Air return

L. Medium: 16"

(40.6 cm), large:

18" (45.7 cm)

M. Air supply

N. 3" (7.6 cm)

O. Evaporator/

control panel

access panel

P. 1 6

¹⁄₈

" (40.9 cm)

¹⁄₈

" (48.6 cm)

Q. 19

B

H

G

F

L

M

N

O

³⁄₄

" (12.1 cm)

R. 4

S. Gas supply entrance

T. Condensate drain

connection—

(1.9 cm) NPT female

U. Heat exchange

access panel

V. Flue exhaust hood

W. Combustion air inlet

X. Suction/liquid

pressure ports

behind compressor

access panel

I

F

J

K

³⁄₄

"

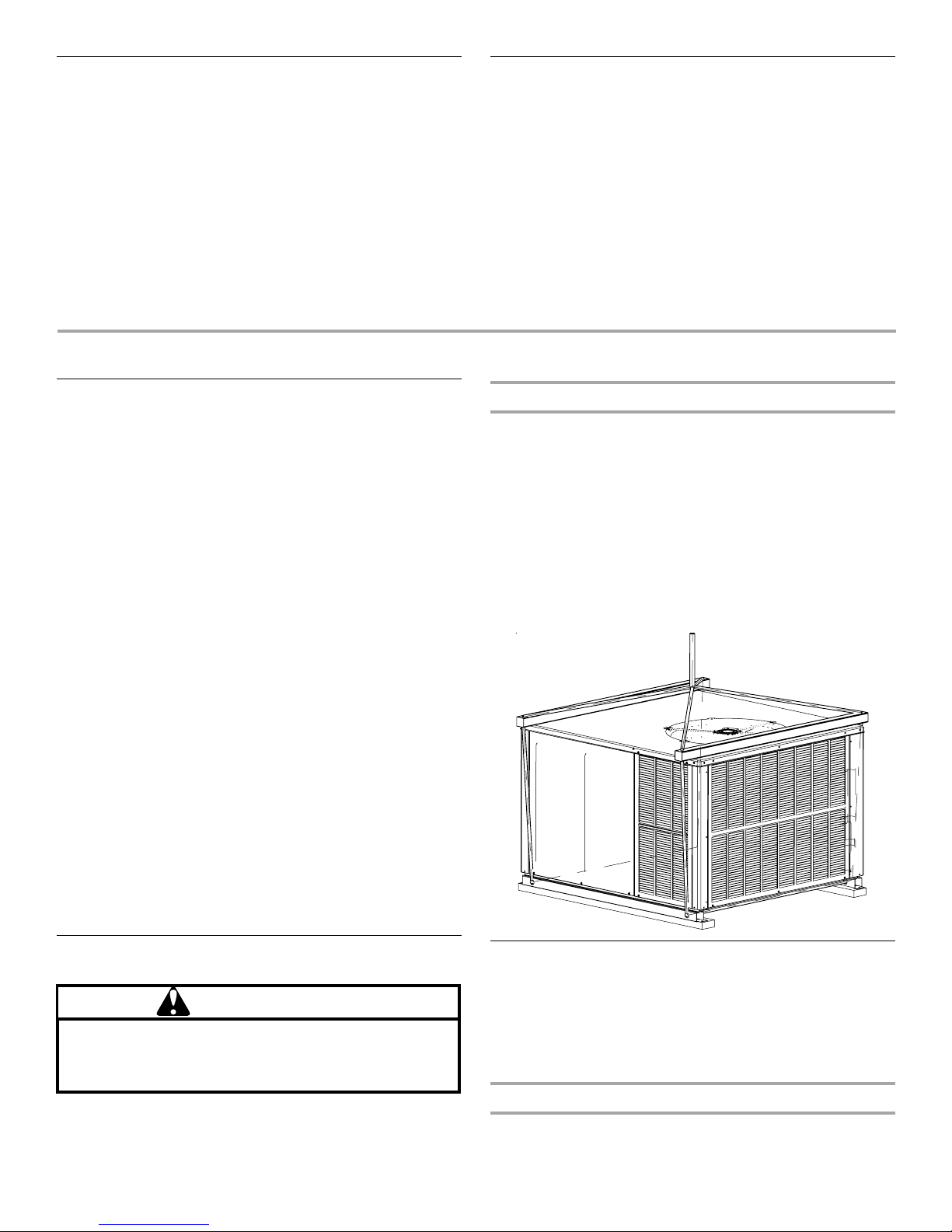

Unit Dimensions—Side

A. Center of gravity

B. 20" (50.8 cm)

C. 24" (61 cm)

D. Power supply wire

entrance

E. 7

F. 7

G. Control wire entrance

H. Flue exhaust hood

C

⁵⁄₁₆

" (17.6 cm)

⁷⁄₈

" (30 cm)

A

D

E

B

F

G

J

H

I

K

I. Control access

panel

¹⁄₄

" (13.3 cm)

J. 5

K. Combustion air

intake

5

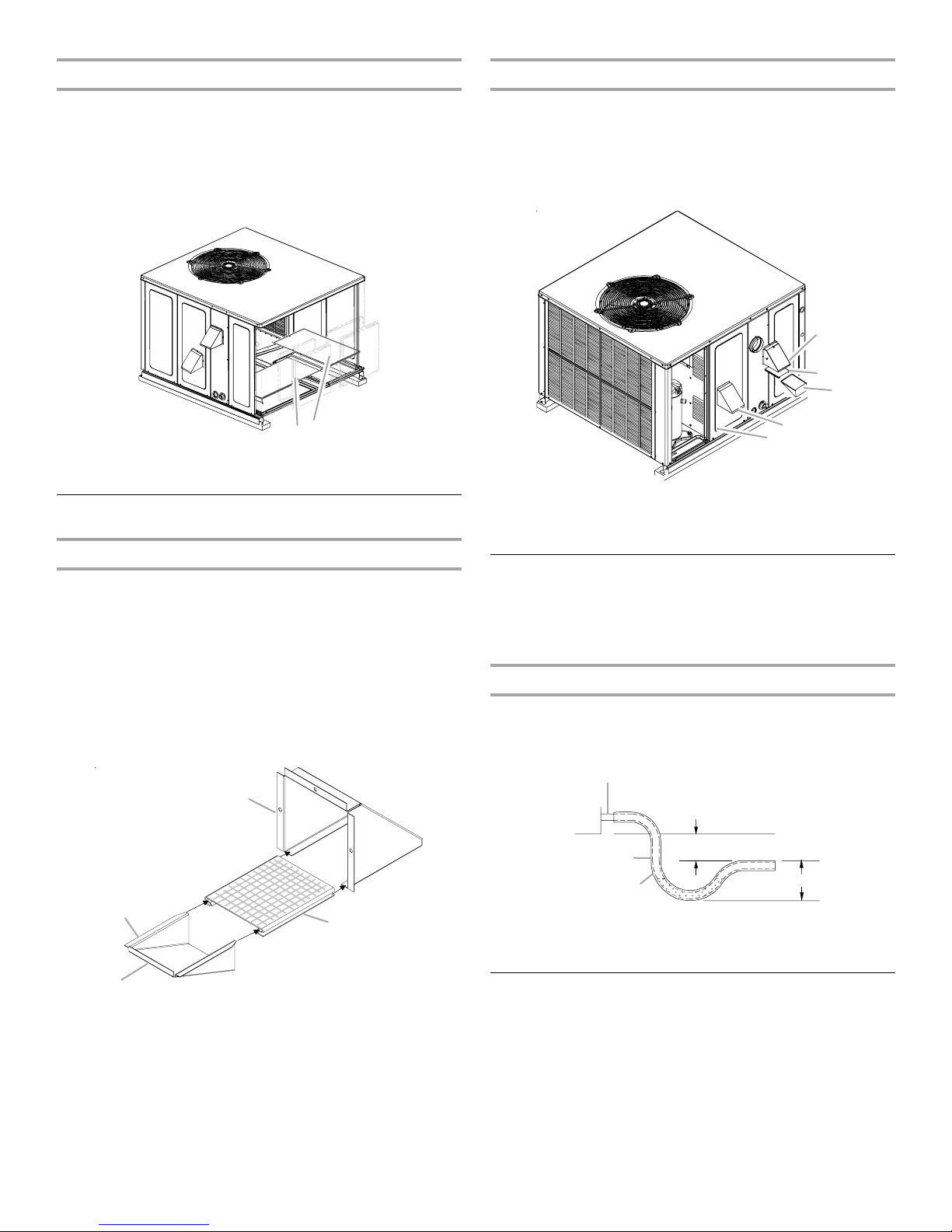

Unit Dimensions—Inside

F

B

Ductwork Requirements

A

E

B

■ Install all conditioned air plenums, ducts and air filters (if not

provided on the unit) in accordance with NFPA 90B Standard

for the Installation of Warm Air Heating and Air-Conditioning

Systems (latest edition).

■ The unit is provided with flanges for the connection of the

plenum and ducts.

■ All air filters must be listed as Class 2 furnace air filters.

■ All ductwork must be made of materials and insulated to

meet local, state and national codes. Ductwork installed

outdoors must be sealed and be weatherproof to avoid

physical damage. Caulking, flashing or other means of

adequately providing a permanent weather seal should be

used where duct penetrates a building or structure opening.

E

D

C

A. Blower access panel

B. 22" (55.9 cm)

C. Air return

D. Air supply

E. 11" (27.9 cm)

F. 5

³₄

" (14.6 cm)

Minimum Clearances

NOTE: Roof overhang should be no more than 36" (91.4 cm).

A

B

D

C

B

A. 48" (121.9 cm) minimum

B. 12" (30.5 cm) minimum

C. 36" (91.4 cm) minimum service access

D. 3" (7.6 cm) minimum

Filter Requirements

CAUTION

To prevent property damage due to fire and loss of

equipment efficiency or equipment damage due to dust

and lint build up on internal parts, never operate unit

without an air filter installed in the return air system.

Filters

Filters are not supplied with these units; however, filters must be

used. It is the installer’s responsibility to install a filter rack with

the ductwork and to install properly sized filters in accordance

with the Minimum Required Surface Area for Disposable Filters

chart.

All return air must pass through a filter before entering the unit.

An electronic air cleaner, filter rack or other accessible filter

arrangement must be installed in the return air ductwork.

Minimum recommended filter areas are listed in the Minimum

Required Surface Area for Disposable Filters chart, and are

based on a face velocity of 325 ft (99.1 m) per min. for disposable

filters and 525 ft (160 m) per min. for cleanable filters

Filter Sizes

Unit Minimum Filter Size

2 ton 20 x 20 x 1 (1)

2.5 ton 20 x 25 x 1 (1)

3 ton 25 x 25 x 1 (1)

3.5 to 4 ton 20 x 20 x 1 (2)

5 ton 20 x 25 x 1 (2)

Goodman 93

6

Filter Installation

IMPORTANT: When installing a filter, the airflow arrows on the

filter must point toward the circulator blower.

Electrical Requirements

NOTE: All outdoor wiring must be suitable for outdoor use. Use

copper conductors only.

■ All field wiring must be done in accordance with National

Electrical Code requirements, applicable requirements of UL,

or local codes, where applicable.

■ Electrical wiring, disconnect means and over-current

protection are to be supplied by the installer. Refer to the

rating plate for the maximum over-current protection,

minimum service ampacity, and operating voltage. See the

wiring connection diagrams in “Troubleshooting.”

■ This unit must be electrically grounded in accordance with

National Electric Code (ANSI/NFPA 70) requirements,

applicable requirements of UL, or local codes, where

applicable.

INSTALLATION INSTRUCTIONS

Gas Supply Requirements

This unit is equipped for use with Natural gas. A conversion kit is

required for use with propane. To order the correct conversion kit,

see your local distributor.

■ Gas supply piping should be installed in accordance with

local, state and national codes and the regulations of the

utility. Piping must be of adequate size to prevent undue

pressure drop. Consult the local utility or gas supplier for

complete details on special requirements for sizing gas

piping.

■ If local codes allow the use of a flexible gas appliance

connector, use a CSA design-certified outdoor flexible

stainless steel appliance connector or rigid gas supply line as

needed.

Inspect Shipment

Check the carton upon arrival for external damage. If damage is

found, a request for an inspection by the carrier agent should be

made in writing immediately.

Inspect the unit for damage including damage to the cabinetry.

Any bolts or screws which may have loosened in transit must be

retightened.

In the event of damage, the receiver should:

■ Make a notation on the delivery receipt of any visible damage

to the shipment or container.

■ Notify the carrier promptly and request an inspection.

■ In case of concealed damage, the carrier should be notified

as soon as possible—preferably within 5 days.

■ File the claim with the following supporting documents:

a) Original Bill of Lading, certified copy, or indemnity bond.

b) Original paid freight bill or indemnity in lieu thereof.

c) Original invoice or certified copy thereof, showing trade

and other discounts or reductions.

d) Copy of the inspection report issued by the carrier

representative at the time damage is reported to the

carrier. The carrier is responsible for making a prompt

inspection of the damage and for a thorough investigation

of each claim. The distributor or manufacturer will not

accept claims from dealers for transportation damage.

NOTES:

■ When inspecting the unit for transportation damage, remove

all packaging materials.

■ Recycle/dispose of the packaging material according to local

codes

■ If any damages are discovered and reported to the carrier, do

not install this unit, because your claim may be denied.

Hoisting

IMPORTANT: If using the bottom discharge with the roof curb,

the ductwork should be attached to the curb prior to installing the

unit. Ductwork dimensions are shown in the roof curb installation

instructions.

See “Roof Curb Installations Only” in “Location Requirements”

for the proper curb installation. Curbing must be installed in

compliance with the National Roofing Contractors Association

Manual.

Lower the unit onto the roof mounting curb. While rigging the

unit, the center of gravity will cause the condenser end to be

lower than the supply air end.

Rigging

Place Unit in Final Location

WARNING

To prevent property damage, the unit should remain in an

upright position during all rigging and moving operations.

To facilitate lifting and moving when a crane is used,

place the unit in an adequate cable sling.

IMPORTANT: Place the unit in the final location and position it in

the proper orientation to the house so that connecting ducts,

electrical and gas supplies is easily done. Hoisting may be

required.

Goodman 88

Airflow Conversion

Units can easily be converted from horizontal to downflow airflow

delivery. In downflow or high-static installations, the installer

should measure the total external static and review the blower

performance charts before performing the installation. In some

installations, it will be necessary to change the blower speed to

provide proper airflow.

Horizontal Application

This unit is shipped ready for horizontal application.

7

Downflow Application

C

Install Combustion Air Intake Hood

For downflow applications, horizontal supply and return duct

cover kits must be ordered from your distributor. Kit number

20464501PDGK is for the medium chassis and kit number

20464502PDGK is for the large chassis.

Cut insulation around the bottom openings and remove the

panels from the bottom of the unit, saving the screws holding the

panels in place.

B

A

A. Return air panel

B. Supply air panel

Hood Installation

Install Flue Exhaust Hood

Install the flue exhaust hood, screen and lower flue hood prior to

operation of the unit.

To install the flue hood, screen and lower flue hood:

1. Remove the flue exhaust hood assembly box from the blower

compartment.

2. Slide the screen over the flanges of the lower flue hood.

3. Slide the screen and lower flue hood assembly into the flue

exhaust hood.

Flue Exhaust Hood Assembly

1. Locate the second hood.

2. Using the 3 screws provided, attach the combustion air

intake hood, with the opening facing down, to the heat

exchanger access door.

Hood Attachment

A

B

D

E

A. Flue exhaust hood

B. Screen

C. Lower flue hood

D. Combustion air intake hood

E. Heat exchanger door

Connect Condensate Drain

The condensate drain outlet is a ³⁄₄" threaded PVC fitting located

at the bottom on the side of the unit. A ³⁄₄" drain line with trap

must be installed on all applications to avoid accumulation of

condensate under or around the unit.

Condensate Drain Connection

A ³⁄₄" (1.9 cm) NPT drain connection is supplied for condensate

piping. An external trap must be installed for proper condensate

drainage.

A

D

C

A. Flue exhaust hood

B. Screen

C. Lip

D. Lower flue hood

4. Using the 3 screws provided, attach the flue exhaust hood

assembly, with the opening facing down, over the flue

exhaust opening in the utility panel. See “Hood Attachment”

illustration.

8

A

F

E

D

B

A. Drain connection

B. 2" (5.1 cm) minimum

C. 3" (7.6 cm) minimum

B

C

D. Positive liquid seal (required)

E. Flexible tubing, hose or pipe

F. U n it

Install Ductwork

■ Install ductwork in accordance with NFPA 90B and any local

codes.

■ The use of flexible, noncombustible connectors between the

main trunk ducts and the supply and return air plenums is

recommended to minimize vibration transmission.

■ Plenums must be individually sealed to the unit casing with

ducts terminating inside the structure.

■ Flashing used to cover ductwork must permit removal of

access panels and top. See “Minimum Clearances” in the

“Locations Requirements” section.

Make Electrical Connections

WARNING

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

Thermostat

Thermostat Location

Mount the thermostat approximately 5 ft (1.5 m) above the floor,

in an area that has an inside, vibration-free wall and has good air

circulation.

Movement of air must not be obstructed by furniture, door,

draperies, etc. The thermostat must not be mounted where it will

be affected by drafts, hot or cold water pipes or air ducts in walls,

radiant heat from fireplace, lamps, the sun, television, etc.

Consult the Instruction Sheet packaged with the thermostat for

mounting instructions.

NOTE: WGGE4524, WGGE4530, WGGE4537 and WGGE4542

units have 1 stage of mechanical cooling and 2 stages of heating.

All other units have 2 stages of heating and 2 stages of

mechanical cooling. Units which will have economizers may use

thermostats with 2 or 3 stages of cooling. All units can use

single-stage or multistage thermostats. Refer to the following

thermostat illustrations for wiring.

All units have 1 stage of heating and one stage of mechanical

cooling. Units which will have economizers may use thermostats

with 1 or 2 stages of cooling.

The units are designed for operation on 60 hertz current and at

voltages as shown on the rating plate. All internal wiring in the

unit is complete. It is necessary to bring in the power supply to

the contactor as shown on the unit wiring diagram which is

supplied with each unit. Twenty-four volt wiring must be

connected between the unit control panel and the room

thermostat.

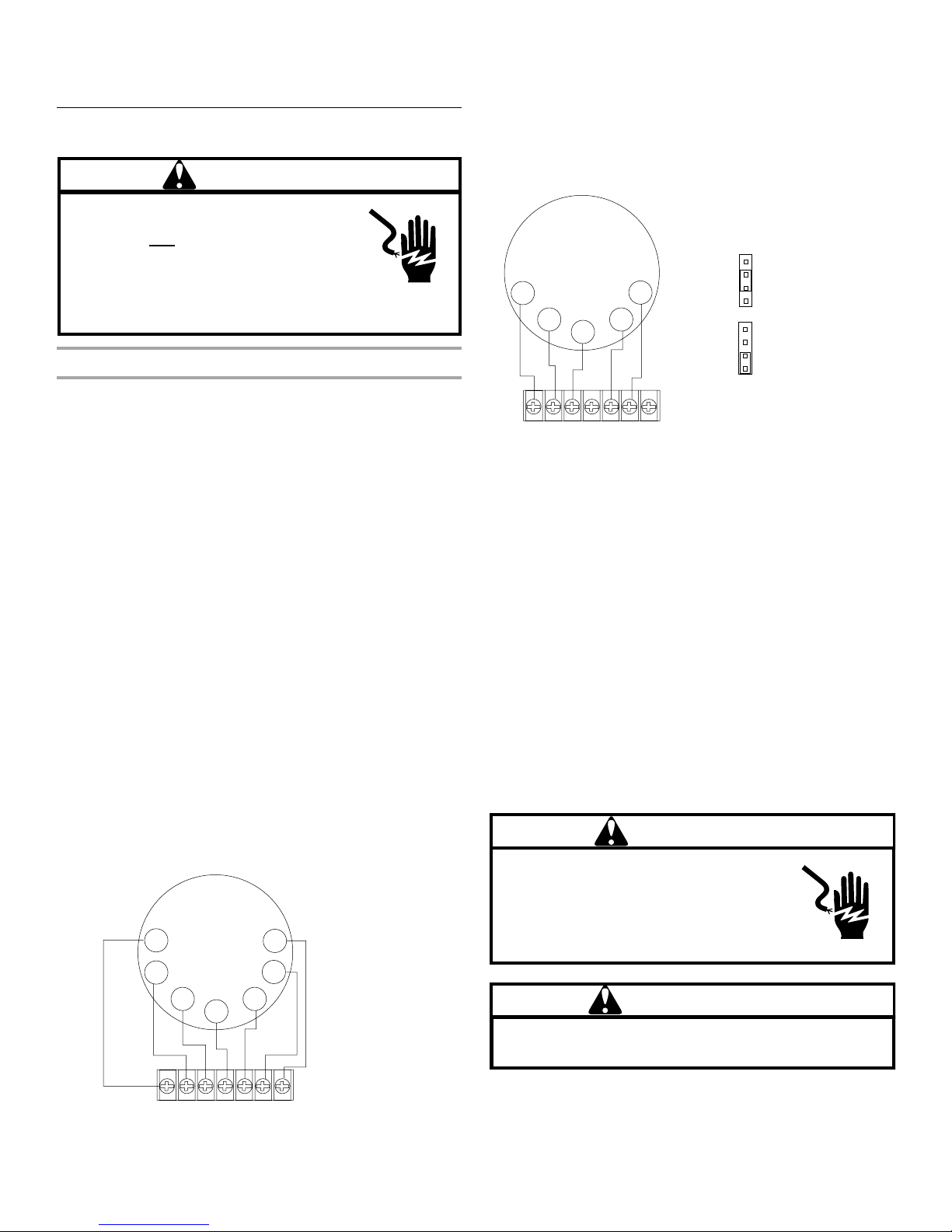

2-Stage Heating with 2-Stage Cooling Thermostat

Goodman 6

C

Y2

Y1

Single-Stage Thermostat

To use a single-stage thermostat, move the jumper located to the

left of the terminal strip labeled “Stage Delay” from “NONE” to

“5 MIN” or “10 MIN.” This selection will cause the control to run

on low stage for the selected time (5 or 10 minutes), and then

shift to high stage. This option controls both cooling and heating

modes. If the jumper is not moved, only low-stage cool and

low-stage heat will operate.

NONE

5 MIN

Y

C

RRC

IMPORTANT:

■ Electrical wiring, disconnect means and over-current

protection are to be supplied by the installer. Refer to the

rating plate for the maximum over-current protection,

minimum circuit ampacity and operating voltage. See the

wiring connection diagrams in “Troubleshooting.”

■ Install an adequate sized branch circuit disconnect,

according to the NEC, within sight of and readily accessible

to the unit.

■ The cable or conduit and fittings connected from the

disconnect switch to the unit wiring connections shall be

rated for outdoor use.

■ Check the unit rating plate to determine whether the system

is rated single phase or three phase and follow the

appropriate instructions for connecting the pigtail leads.

■ Plug unused side entry holes with field-supplied plugs to

keep moisture from entering the unit.

■ Low voltage wiring must be separated from line voltage

wiring.

G

W

Y2Y1GW2W1

10 MIN

NONE

5 MIN

10 MIN

5-Minute Delay

Period With Jumper

In This Position

10-Minute Delay

Period With Jumper

In This Position

Line Voltage Connections

WARNING

To avoid the risk of injury, electrical shock

or death, the furnace must be electrically

grounded in accordance with local codes or

in their absence, with the latest edition of the

National Electric Code (NEC).

HIGH VOLTAGE!

Goodman 60

W1

RRC

G

W2

Furnace Integrated

Control Module

Y2Y1GW2W1

WARNING

To avoid the risk of electrical shock, wiring to the unit

must be polarized and grounded.

Goodman 70

9

Loading...

Loading...