Whirlpool WED97HEXL1 Parts Diagram

FOR SERVICE TECHNICIAN’S USE ONLY

Voltage Measurement Safety Information

When performing live voltage measurements, you must do the following:

Verify the controls are in the off position so that the appliance does not start when energized.

Allow enough space to perform the voltage measurements without obstructions.

Keep other people a safe distance away from the appliance to prevent potential injury.

Always use the proper testing equipment.

After voltage measurements, always disconnect power before servicing.

IMPORTANT: Electrostatic Discharge (ESD) Sensitive Electronics

ESD problems are present everywhere. Most people begin to feel an ESD discharge at

approximately 3000V. It takes as little as 10V to destroy, damage, or weaken the main control

assembly. The new main control assembly may appear to work well after repair is finished,

but a malfunction may occur at a later date due to ESD stress.

Use an anti-static wrist strap. Connect wrist strap to green ground connection point or

unpainted metal in the appliance

-OR Touch your finger repeatedly to a green ground connection point or unpainted metal

in the appliance.

Before removing the part from its package, touch the anti-static bag to a green ground

connection point or unpainted metal in the appliance.

Avoid touching electronic parts or terminal contacts; handle electronic control assembly

by edges only.

When repackaging main control assembly in anti-static bag, observe above instructions.

This service data sheet is intended for use by persons having electrical, electronic, and

mechanical experience and knowledge at a level generally considered acceptable in the

appliance repair trade. Any attempt to repair a major appliance may result in personal injury

and property damage. The manufacturer or seller cannot be responsible, nor assume any

liability for injury or damage of any kind arising from the use of this data sheet.

Contents

IMPORTANT SAFETY NOTICE — “For Technicians only”

Whirlpool Control Panel ........................................ 2

Diagnostic Guide .................................................. 3

Service Diagnostics ............................................. 3

Error Diagnostic ................................................... 4

Component Activation .......................................... 5

System Info ......................................................... 5

Fault/Error Codes .................................................7

PART NO. W10319757B

DO NOT REMOVE OR DESTROY

Troubleshooting Guide .......................................... 8

Troubleshooting Tests........................................... 9

Strip Circuits ...................................................... 23

Dryer Disassembly Instructions .......................... 24

Wiring Diagrams ..........................................26, 27

Component Locations ........................................ 28

Specifications ....................................................28

PAGE 1

FOR SERVICE TECHNICIAN’S USE ONLY

3rd

2nd

1st

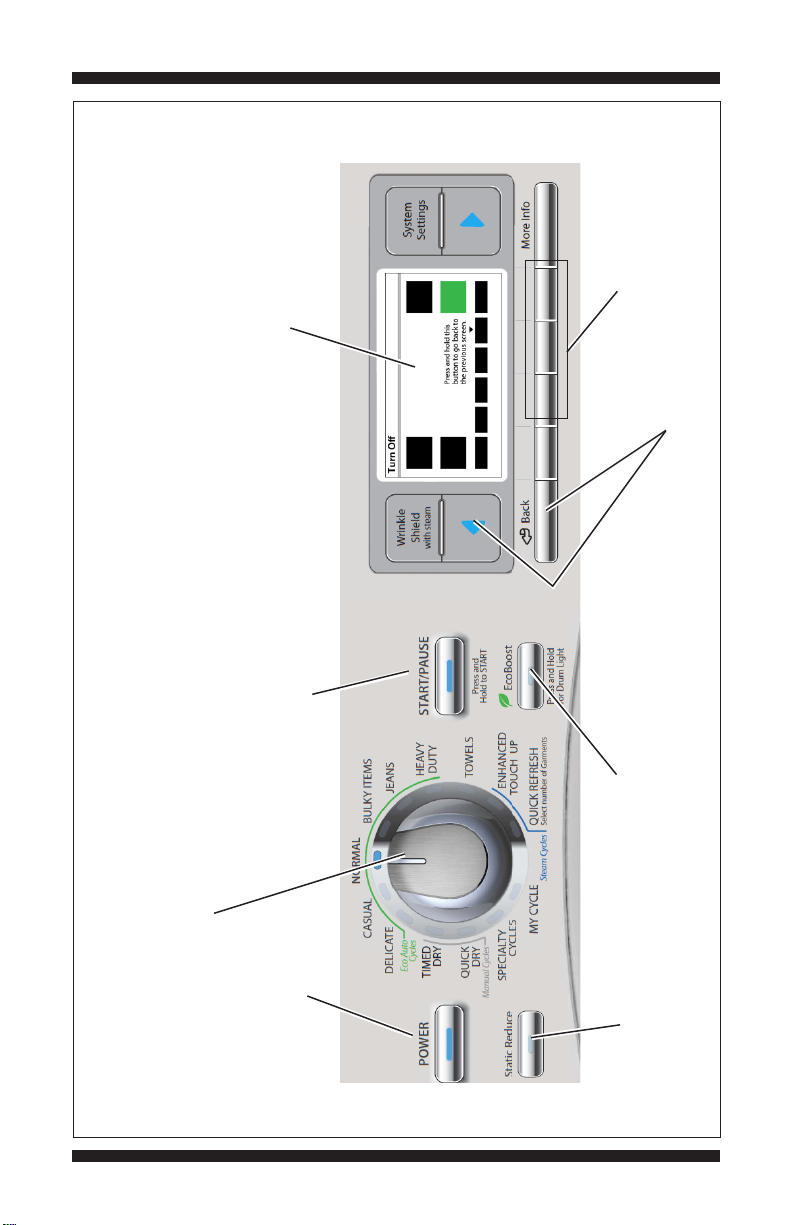

System Information are accessed via Service Menus.

changes their on-screen representations from black to

green. UI Component Test, Error Codes, Diagnostics, and

Color LCD Screen – pressing the buttons around the screen

Begin or continue test.

“START/PAUSE” button:

press once to turn off indicator.

to access Diagnostic Mode.

(1st, 2nd, 3rd) Recommended buttons

t

times to exit Diagnostic Mode.

“Back & ( )” buttons: press one or more

to turn off indicator

(not available on all models).

“EcoBoost” button: press once

Rotating the cycle selector knob turns off each

WHIRLPOOL CONTROL PANEL (features and appearances may vary between models)

PAGE 2

appearances vary between models).

corresponding cycle indicator. (Features and

to turn off indicator.

“POWER” button: press once

“Static Reduce” button:

(not available on all models).

press once to turn off indicator

Figure 1 - UI Component Test

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

DIAGNOSTIC GUIDE

Before servicing, check the following:

Make sure there is power at the wall outlet.

Has a household fuse blown or circuit breaker

tripped? Was a regular fuse used? Inform

customer that a time-delay fuse is required.

Is dryer vent properly installed and clear

of lint or obstructions?

All tests/checks should be made with a

VOM (volt-ohm-milliammeter) or DVM

(digital-voltmeter) having a sensitivity of

20,000 Ω per volt DC or greater.

Resistance checks must be made with

dryer unplugged or power disconnected.

IMPORTANT: Avoid using large

diameter probes when checking harness

connectors as the probes may damage

the connectors upon insertion.

Check all harnesses and connections before

replacing components. Look for connectors

not fully seated, broken or loose wires and

terminals, pin insertion, or wires not pressed into

connectors far enough to engage metal barbs.

A potential cause of a control not

functioning is corrosion or contamination on

connections. Use an ohmmeter to check for

continuity across suspected connections.

SERVICE DIAGNOSTICS

These tests allow factory or service personnel

to test and verify all inputs to the machine control

electronics. You may want to do a quick and

overall checkup of the dryer with these tests

before going to specific troubleshooting tests.

ACTIVATING SERVICE DIAGNOSTICS

1. Be sure the dryer is in standby mode

(plugged in with all indicators off).

2. Select any three buttons (except POWER)

and follow the steps below, using the same

buttons. Remember the buttons and the order

that the buttons were pressed. (Recommended

button selections shown in figure 1):

Within 8 seconds,

• Press and Release the 1st selected button,

• Press and Release the 2nd selected button,

• Press and Release the 3rd selected button;

• Repeat this 3 button sequence 2 more times.

3. If the key sequence was entered successfully,

the language selection screen is displayed.

4. Select the desired language—choices are:

English, French, and Spanish.

5. The following screen warns that this area is

for service technicians only.

• Pressing “Exit” returns to original screen.

• Pressing “Enter” continues to DIAGNOSTIC

HOME screen.

NOTE: Service Diagnostics will time out and

return to standby after 5 minutes of user inactivity.

EXITING SERVICE DIAGNOSTICS

Use either of the two methods below to exit

Service Diagnostics.

• Select “Exit Diagnostics” on the

Diagnostics Home Screen.

• Press the “Back” button one or more times,

depending on location in Service Diagnostics.

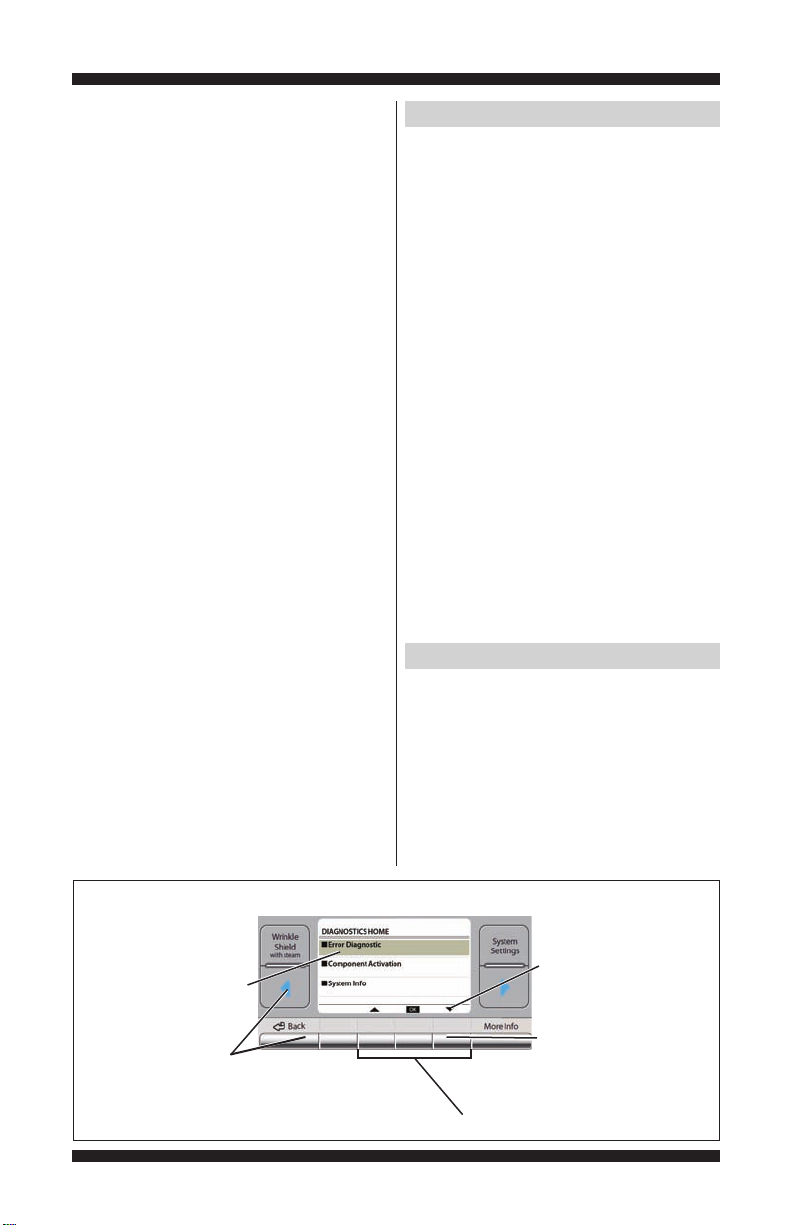

DIAGNOSTICS HOME SCREEN

LCD Navigation (See figure 2)

The menu is displayed as a list of

selectable items on separate rows.

Each menu item may contain several

lines.

As user navigates over elements with

additional information, the highlight

extends the length of the screen. All

non-selectable items will display a

short gray highlight preceding the

item.

Pressing the Left or Back button

returns user to previous screen.

The last item after System Info is

“Exit Diagnostics”.

Figure 2 - LCD Navigation

DO NOT REMOVE OR DESTROY

When an invalid item is selected, an

invalid key-press beep is generated.

Pressing the corresponding buttons

for the arrows moves highlight up and

down. Pressing the corresponding

button for OK selects the highlighted

option.

The navigation buttons have press and

hold functionality. If the button is held

for longer than 1 second, the navigation

will automatically move one row

every 0.5 seconds.

These buttons are used for navigation and selection.

PAGE 3

FOR SERVICE TECHNICIAN’S USE ONLY

DIAGNOSTICS HOME SCREEN

The “Diagnostics Home” screen (see figure

2, page 3) displays the following service

diagnostic items:

• Error Diagnostic – Access Error Codes,

Error History, Quick Diagnostic Test, and

Clear All Errors

• Component Activation – Activation and

functional testing of system components

and sensors (page 5)

• System Info – Displays model #, serial

#, hardware info, and other system

variables (page 5)

• Exit Diagnostics – Exits Service

Diagnostics and returns to standby mode

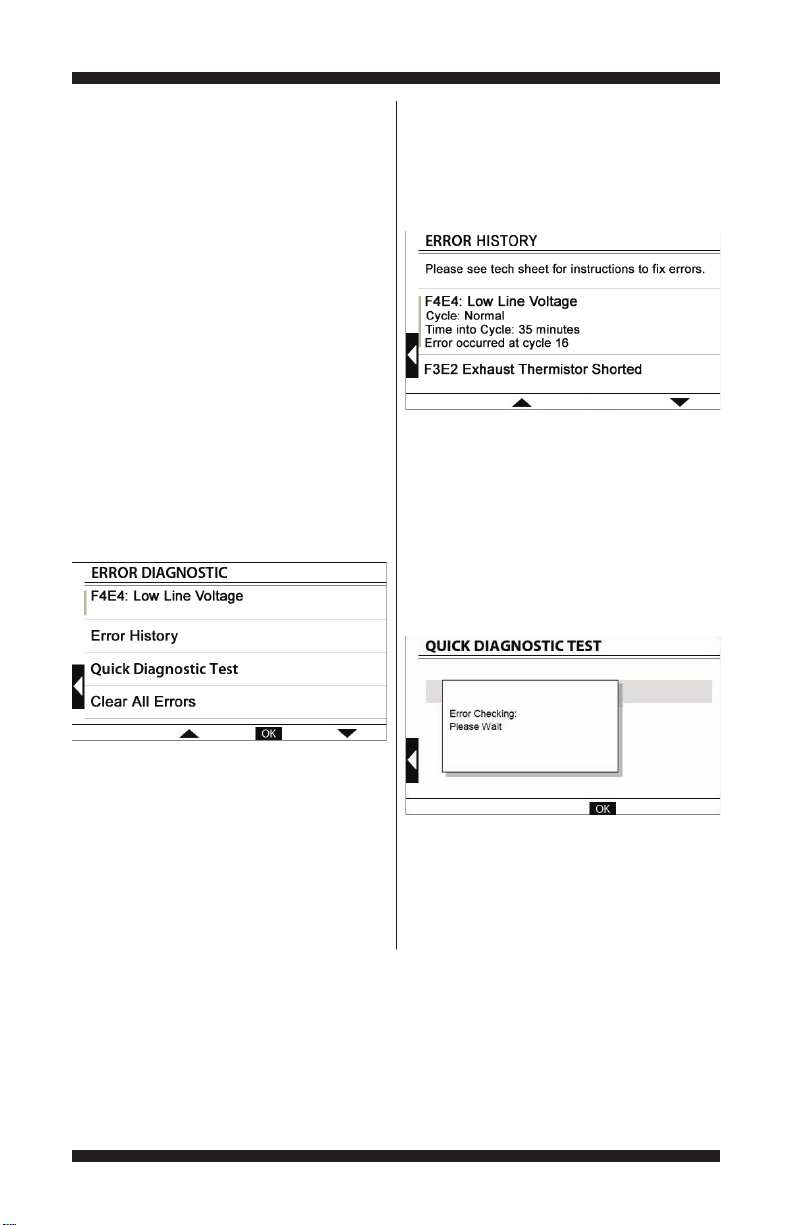

ERROR DIAGNOSTIC

Access Error Codes, Error History,

Quick Diagnostics, and Clear All Errors

NOTE: If no saved error exists, the only menu

item displayed is “Quick Diagnosic Test”.

• Error History – Displays the last four

saved fault/error codes (if no saved error

exists, this item is NOT shown). Provides

error code and description, time of error,

and cycle information when error occurred

(see figure 4).

Figure 4 - Error History Screen

• Quick Diagnostic Test – Performs a quick

system level test of the dryer and displays

error results in a dialog box (see figure 5).

Tests drum motor and heater(s), exhaust

and inlet thermistors, air flow (AF), and

low line voltage (L2). Test stops on first

error detected. Use this test to check for

errors and verify repairs. NOTE: Door

must be closed to perform test.

Figure 3 - Error Diagnostic Screen

• Error Codes – Displays most recent saved

fault/error code (if no saved error exists,

this item is NOT shown). Refer to Fault/

Error Code chart on page 7.

PAGE 4

Figure 5 - Quick Diagnostic Test

• Clear All Errors – Clears all stored fault/

error codes (if no saved error exists,

this item is NOT shown). NOTE: Once

the errors are cleared, they cannot be

recovered again.

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

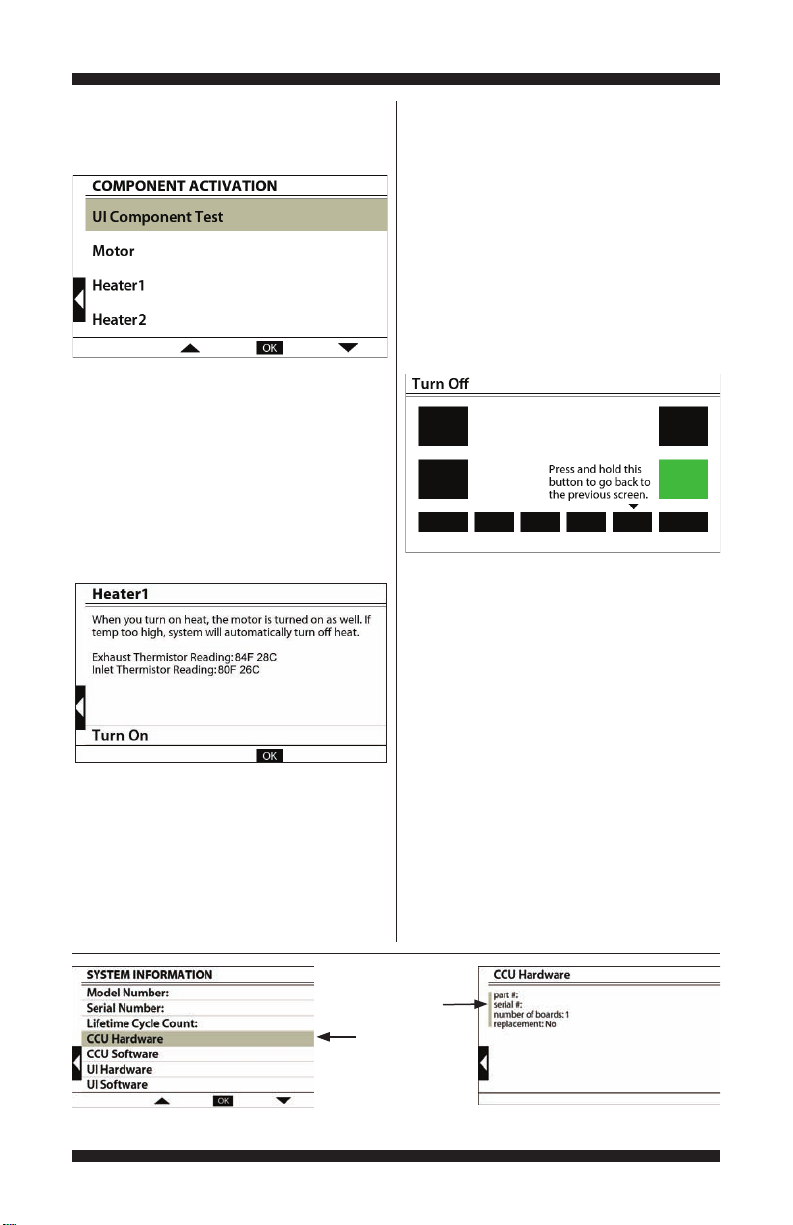

COMPONENT ACTIVATION

Activation and functional testing of system

components and sensors (see Figure 6).

Figure 6 - Component Activation Menu

• Component Activation – When a

component is selected from the

Component Activation menu (see Figure

6), a screen appears providing component

information, and if available, attributes

related to the component (see figure

7). Many of the components listed can

be turned on and off. By default, the

component is off. (See chart on page 6.)

Figure 7 - Component Screen

• UI Component Test – Upon activation,

all LEDs are turned on. Pressing each

button turns off its LED, rotating the cycle

selector knob turns off each LED, and

pressing the ATM buttons changes their

on-screen representations from black to

green (see figure 8). Press and hold the

right-most navigation key to return to

previous screen.

If indicators do not turn off and beep after

pressing buttons and rotating the cycle

selector, go to TEST #6: Buttons

& Indicators, page 20.

Figure 8 - UI Component Test

SYSTEM INFO

Displays model and serial number, hardware

information, and other system variables (if

provided).

NOTE: Missing system information does not

indicate a problem. The system information

screens are common across various

platforms; therefore, information provided on

one dryer may not be available on another. If

uncertain about the information, check with

technical support.

NOTE: All non-selectable items will display a

short gray highlight preceding the selection;

however, as the highlight of the screen moves

over items with more information, it displays

regular background length. (see Figures 9 & 10.)

Non-selectable items

Items with more info.

Figure 9 - System Information Screen Figure 10 - Hardware Information Details

DO NOT REMOVE OR DESTROY

PAGE 5

FOR SERVICE TECHNICIAN’S USE ONLY

Output On/Off Details

UI Component Test N/AUpon activation, all LEDs are turned on. Pressing each button turns off

its LED. Rotating the cycle selector knob turns off each LED. Pressing

the ATM buttons changes their on-screen representations from black

to green.

Motor YES Status (On/Off) NOTE: Door must be closed.

If the motor does not turn on, go to TEST #3, page 13.

Heater1 (Electric)/ Heat On (Gas) YES Status (On/Off) NOTE: Door must be closed.

Attributes: Exhaust & Inlet Thermistor Reading.

When you turn on heat, the motor is turned on as well. If temp is

too high, system will automatically turn off heat.

• If the motor does not turn on, go to TEST #3, page 13.

• If no heat is detected, go to TEST #4, page 14.

Heater2 (Electric Only) YES Status (On/Off) NOTE: Door must be closed.

Attributes: Exhaust & Inlet Thermistor Reading.

When you turn on heat, the motor is turned on as well. If temp is

too high, system will automatically turn off heat.

• If the motor does not turn on, go to TEST #3, page 13.

• If no heat is detected, go to TEST #4, page 14.

Heater 1 & 2 (Electric Only) YES Status (On/Off) NOTE: Door must be closed.

Attributes: Exhaust & Inlet Thermistor Reading.

When you turn on heat, the motor is turned on as well. If temp is

too high, system will automatically turn off heat.

• If the motor does not turn on, go to TEST #3, page 13.

• If no heat is detected, go to TEST #4, page 14.

Inlet ThermistorN/A Status (F°, C°, and Resistance)

If inlet thermistor reading is out of range, go to TEST #4a, page 17.

Exhaust ThermistorN/A Status (F°, C°, and Resistance)

If exhaust thermistor reading is out of range, go to TEST #4a, page 17.

Moisture Sensor N/AStatus (Open/Closed)

• Place finger over both sensor strips. If sensor status does not change,

go to TEST #5, page 19.

Door Status N/AStatus (Open/Closed)

• If opening the door does not change status, go to TEST #7, page 21.

CCU Line Voltage 1N/A Status (L1 Voltage Measurement) NOTE: Door must be closed.

When measuring L1, the motor and heater are activated.

• If L1 is absent, go to TEST #1, page 9.

CCU Line Voltage 2 (Electric Only)N/A Status (L2 Voltage Measurement) NOTE: Door must be closed.

When measuring L2, the motor and heater are activated.

• If L2 is absent, go to TEST #1, page 9.

Air Flow N/AStatus (Normal/Restricted) NOTE: Door must be closed.

• If air flow does not turn on, go to TEST #4, page 14.

Drum Light YES Status (On/Off)

• If drum light does not turn on, go to TEST #1, page 9.

Buzzer YES Status (On/Off)

• If buzzer does not sound, go to TEST #6, page 20.

Myst Valve YES Status (On/Off) After being turned on, the myst valve automatically

deactivates after 30 seconds if not turned off.

• If myst valve does not turn on, go to TEST #9, page 22.

COMPONENT ACTIVATION CHART

Component Activation Chart

PAGE 6

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

CODE DESCRIPTION EXPLANATION AND RECOMMENDED PROCEDURE

Indicates that a power failure occurred while the dryer was running. Press START to continue the

cycle, or press POWER to clear the display.

Indicates low air flow that may affect dryer performance.

Confirm that airflow system is not blocked. Check lint screen, exhaust duct, exhaust fan.

• Refer to Fault/Error Code “F4E3” below for recommended procedure.

Indicates low L2 voltage (less than 30 V) is detected at the CCU.

• Refer to Fault/Error Code "F4E4" below for recommended procedure.

F1E1 Cycle Control Unit (CCU) Problem

Indicates a CCU problem.

• Verify all connections to and from the CCU.

• See TEST #1: Machine Control Power Check, page 9.

F2E1 User Interface (UI) Problem (stuck button)

Indicates a stuck button (depressed for over 20-seconds) or UI mismatch. This fault code

will ONLY appear in the service diagnostic mode. See TEST #6: Buttons and Indicators, page 20.

F2E2 User Interface Software Error 1

Appears if UI cannot read EEPROM software from UI.

• Verify all connections between CCU and UI.

• Replace the UI.

F2E3 User Interface Software Error 2

Appears if main control EEPROM is not programmed correctly.

• Replace the UI.

F3E1

Exhaust Thermistor Open

See TEST #4a: Thermistors, page 17.

Indicates that the exhaust thermistor is open. Temperature drops below 18° F (> 50k ohms).

F3E2

Exhaust Thermistor Shorted

Indicates that the exhaust thermistor has shorted. Temperature above 250° F (< 500 ohms).

See TEST #4a: Thermistors, page 17.

F3E3

Inlet Thermistor Open

Indicates that the Inlet Thermistor is open. Temperature drops below 18° F (>245k ohms).

See TEST #4a: Thermistors, page 17.

F3E4

Inlet Thermistor Shorted

Indicates that the Inlet Thermistor is shorted. Temperature above 391° F (< 328 ohms).

See TEST #4a: Thermistors, page 17.

F3E5

Inlet and Exhaust Thermistor Open

Indicates that the Inlet and Exhaust Thermis tor are open. Will occur if the P14 connector is not

plugged into the CCU.

F3E6 Moisture Sensor Open

Indicates that the moisture sensor strip is open. This fault code will ONLY appear in the service

diagnostic mode. See TEST #5: Moisture Sensor, page 19.

F3E7 Moisture Sensor Shorted

Indicates that the moisture sensor strip has shorted. This fault code will ONLY appear in the service

diagnostic mode. See TEST #5: Moisture Sensor, page 19.

F4E1 Heater Relay or Connector Problem

Indicates no voltage detected at the heater relay. This fault code will ONLY appear in the service

diagnostic mode.

• Unplug dryer or disconnect power and check that the wires are plugged into the heater element(s)

F4E3 Restricted Air Flow

Indicates low air flow that may affect dryer performance.

• Confirm that airflow system is not blocked, check lint screen, exhaust duct, exhaust fan.

• See TEST #4a: Thermistors, page 17.

F4E4

L2 Line Voltage Error

L2 indicates low L2 voltage (less than 30 V) is detected at the CCU.

• Check to see if a household fuse has blown or a circuit breaker has tripped.

• Confirm the power cord is properly installed and plugged into the power outlet.

• Check the relay connections on the CCU.

• Gas Models Only: Check the P14 connection on the CCU. (Ha rness Loopback on pins 4 & 5)

F6E1

F6E2

Communication Error UI to CCU

Communication Error CCU to UI

Communication between the CCU and UI has not been detected.

• Check the harnres continuity and connections between the CCU and UI.

• Check AC and DC supplies. See TEST #1: Machine Control Power Check, page 9.

• Replace the User Interface.

• Replace the CCU.

SERVICE FAULT/ERROR CODES

CUSTOMER FAULT/ERROR CODES

Power Failure / Interruption

Restricted Air Flow

Low Line Voltage

and the relay(s) on the CCU.

Fault/Error Code Chart

The fault codes below may be indicated under various conditions and can be accessed through Service Diagnostic Mode.

DO NOT REMOVE OR DESTROY

PAGE 7

TROUBLESHOOTING GUIDE

PROBLEMPOSSIBLE CAUSE CHECKS & TESTS

No power to dryer. Check power at outlet, check circuit breaker,

fuses, or junction box connections.

Connection problem between AC plug and dryer.See Te st #2: Supply Connections, page 11.

Connection problem between CCU and UI,

or between Power Cube and UI.

Check connections and continuity between

CCU, Power Cube, and UI.

Power supplies not present at machine electronics. See Test #1: Machine Control Power Check,

page 9.

User Interface problem. See Test #6: Buttons & Indicators, page 20.

Door not fully closed or striking the door latch.Be sure the door is completely closed,

then press and hold the START button.

Door Switch problem. See Test #7: Door Switch, page 21.

Drive Belt / Belt Switch problem. See Test #3: Motor Circuit, page 13.

Thermal Fuse / Motor problem. See Test #3: Motor Circuit, page 13.

User Interface problem. See Test #6: Buttons & Indicators, page 20.

CCU problem. See Test #1: Machine Control Power Check,

page 9.

Poor airflow.Check lint screen and exhaust vent. Clean

if necessary.

Check the Pause/Cancel button. Perform UI Component Test under

Component Activation.

Moisture Sensor problem. See Test #5: Moisture Sensor, page 19.

Thermistor problem. See Te st #4a: Thermistors, page 17.

User Interface problem. See Test #6: Buttons & Indicators, page 20.

CCU problem. See Test #1: Machine Control Power Check,

page 9.

User selects invalid option. Refer customer to “Use and Care Guide”.

User Interface problem. See Test #6: Buttons & Indicators, page 20.

Drive Belt / Belt Switch problem. See Test #3: Motor Circuit, page 13.

Thermal Fuse (elect. Only). See Te st #4b: Thermal Fuse, page 18.

Door switch problem. See Test #7: Door Switch, page 21.

Motor problem. See Test #3: Motor Circuit, page 13.

CCU problem. See Test #1: Machine Control Power Check,

page 9.

Check installation. Verify proper dryer installation.

Check for L1 and L2. Perform CCU, L1, and L2 tests in Service

Diagnostics.

Heater system malfunction or open heater coil. See Test #4: Heat System, page 14.

CCU problem. See Test #1: Machine Control Power Check,

page 9.

Heater coil shorted. See Test #4: Heat System, page 14.

Heater relay shorted. See Test #4: Heat System, page 14.

Heater system problem. See Test #4: Heat System, page 14.

Dryness setting for auto cycles.Increase drying times for one or more

Lint screen full. Clean if necessary. Refer customer

to “Use and Care Guide”.

Heater vent clogged. Clean if necessary. Refer customer

to “Use and Care Guide”.

Moisture Sensor problem. See Test #5: Moisture Sensor, page 19.

Adjust Customer Focused Dryness Level. See Test #5a: Adjusting Customer-

Focused Dryness Level, page 20.

Steam cycle not selected. Refer customer to “Use and Care Guide”.

No water to valve. Verify water supply is turned on.

No water from valve. See Test #9: Myst Valve, page 22.

WATER VALVE NOT DISPENSING

(

Water valve is activated intermittently

during the steam cycle.)

WILL NOT HEAT

HEATS IN AIR CYCLE

SHUTS OFF BEFORE CLOTHES

ARE DRY

DRUM WILL NOT SPIN

CONSOLE WON’T ACCEPT

SELECTIONS

WILL NOT POWER UP

- No operation

- No keypad response

- No LED's or display

WILL NOT START CYCLE

(No response when Start button

is pressed.)

WILL NOT SHUT OFF

WHEN EXPECTED

auto cycles.

Some tests will require accessing components (see page 28).

PAGE 8

FOR SERVICE TECHNICIAN’S USE ONLY

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

TROUBLESHOOTING TESTS

IMPORTANT: The following procedures

may require the use of needle probes

to measure voltage. Failure to use needle

probes will damage the connectors.

TEST #1: Machine Control Power Check

This test is used to determine if power is present at

the machine control electronics. This test assumes

that proper voltage is present at the outlet.

1. Unplug dryer or disconnect power.

2. Check for appropriate line voltages at the

outlet: 240VAC (electric 2-phase), 208VAC

(electric 3-phase), or 120VAC (gas).

If line voltage is present, go to step 3.

If line voltage is not present, check for

tripped circuit breaker or blown household

fuse. If CB (circuit breaker) is not tripped,

have customer check with qualified

electrician.

3. Remove top panel to access the machine

electronics.

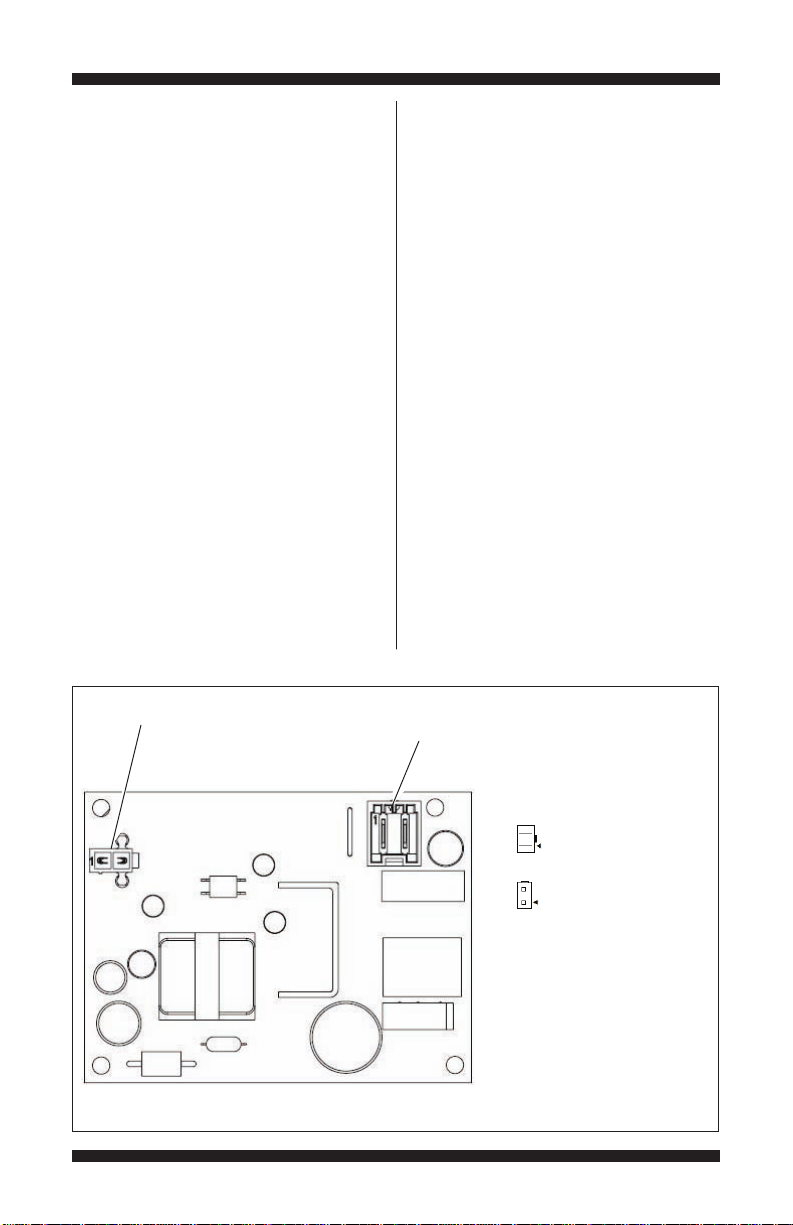

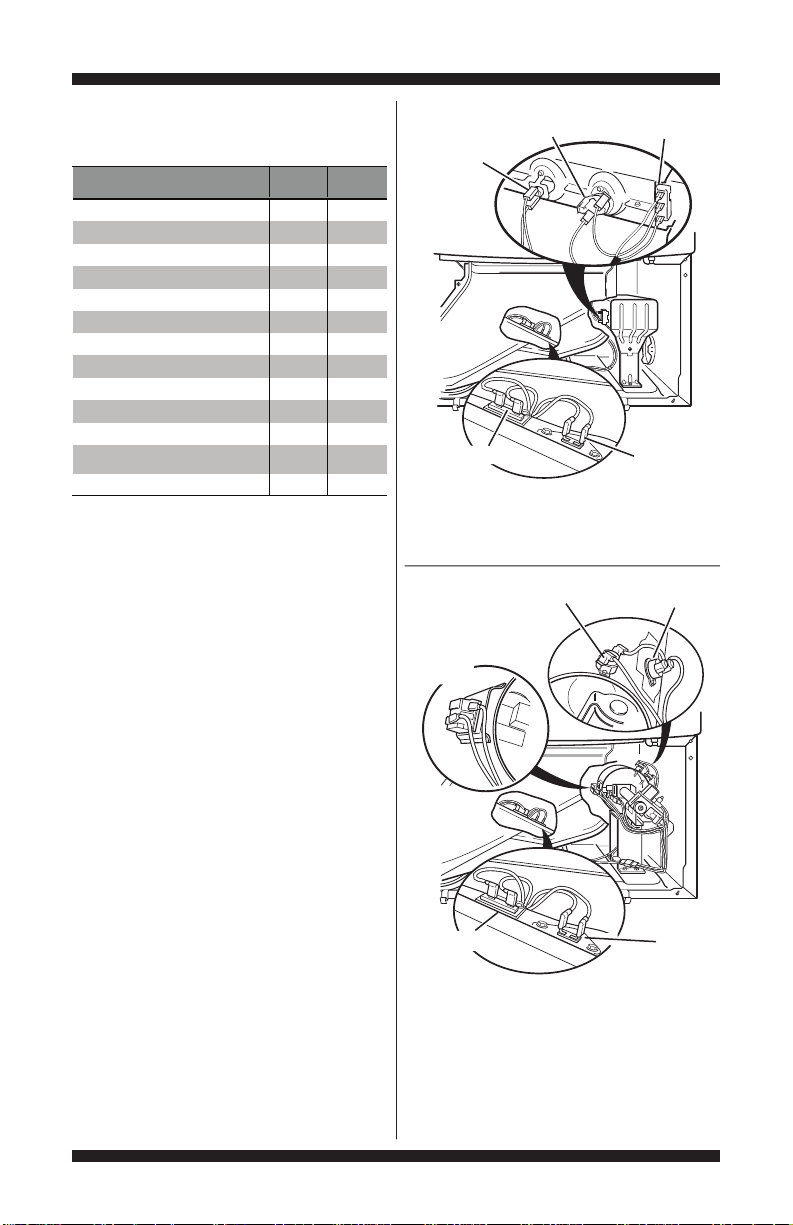

POWER CUBE:

4. Plug in dryer or reconnect power.

5. Power Cube VAC – With voltmeter set

to AC, connect red probe to P1-1 (L1) and

black probe to P1-2 (N). (See Figure 11.)

If 120VAC is present, go to step 6.

If 120VAC is not present, perform TEST

#2: Supply Connections, page 11.

6. Power Cube +5VDC – With voltmeter set

to DC, connect black probe to P2-1 (ground)

and red probe to P2-2 (+5VDC).

If +5VDC is present, go to step 8.

If +5VDC is not present, go to step 7.

7. Unplug dryer or disconnect power. Unplug

P2 from the Power Cube. Plug in dryer or

reconnect power and repeat step 6. Perform

voltage check inside header P2—DO NOT

SHORT PINS TOGETHER.

If +5VDC returns, check harnesses and

connections between the Power Cube and

UI. If acceptable, replace the UI. NOTE: 5V

is used to provide power to the UI and drum

light.

If +5VDC is not present, replace the Power

Cube.

Wide to UI

t

Figure 11 - Power Cube Connectors & Pinouts

DO NOT REMOVE OR DESTROY

L1/Neutral

t

P1 – L1/NEUTRAL

P1-2 WHT NEUTRAL

P1-1 BLK L1

P2 – WIDE TO UI (+5VDC)

P2-2 RED VDD (+5VDC)

P2-1 GRAY VSS (GND)

t = pin-1

PAGE 9

FOR SERVICE TECHNICIAN’S USE ONLY

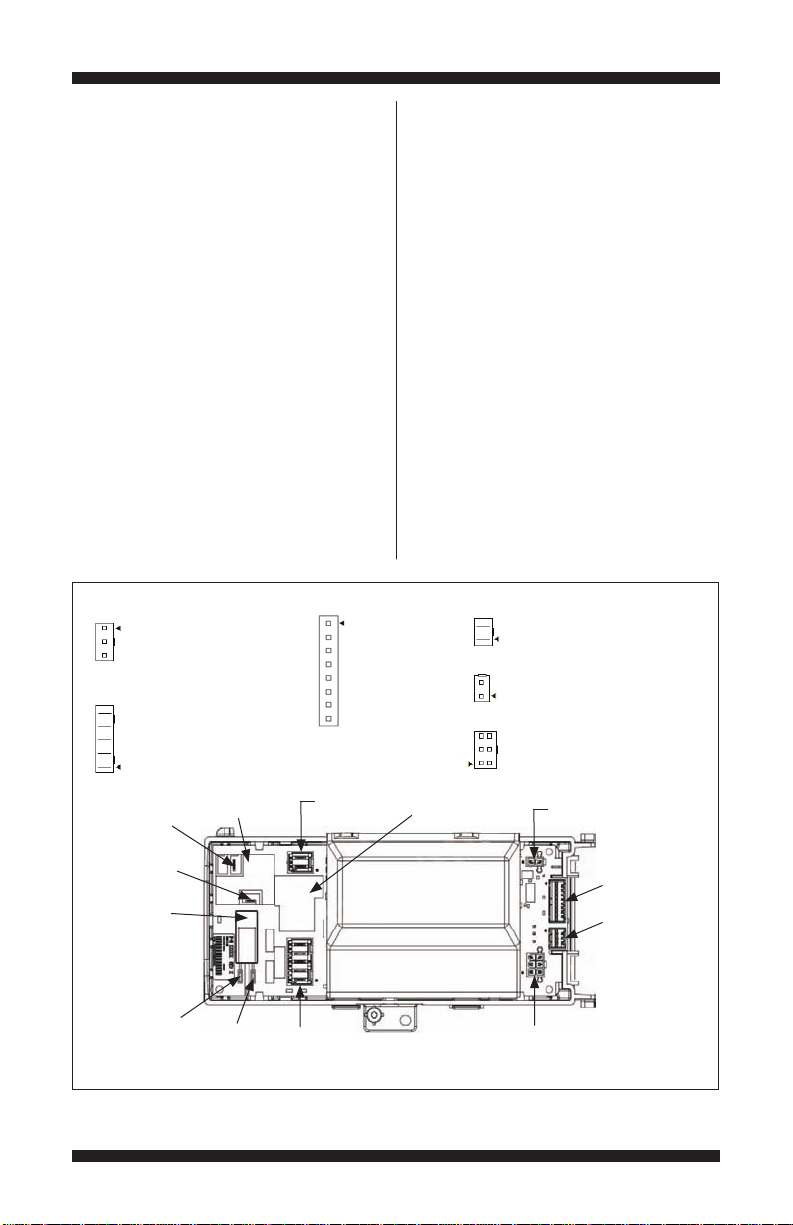

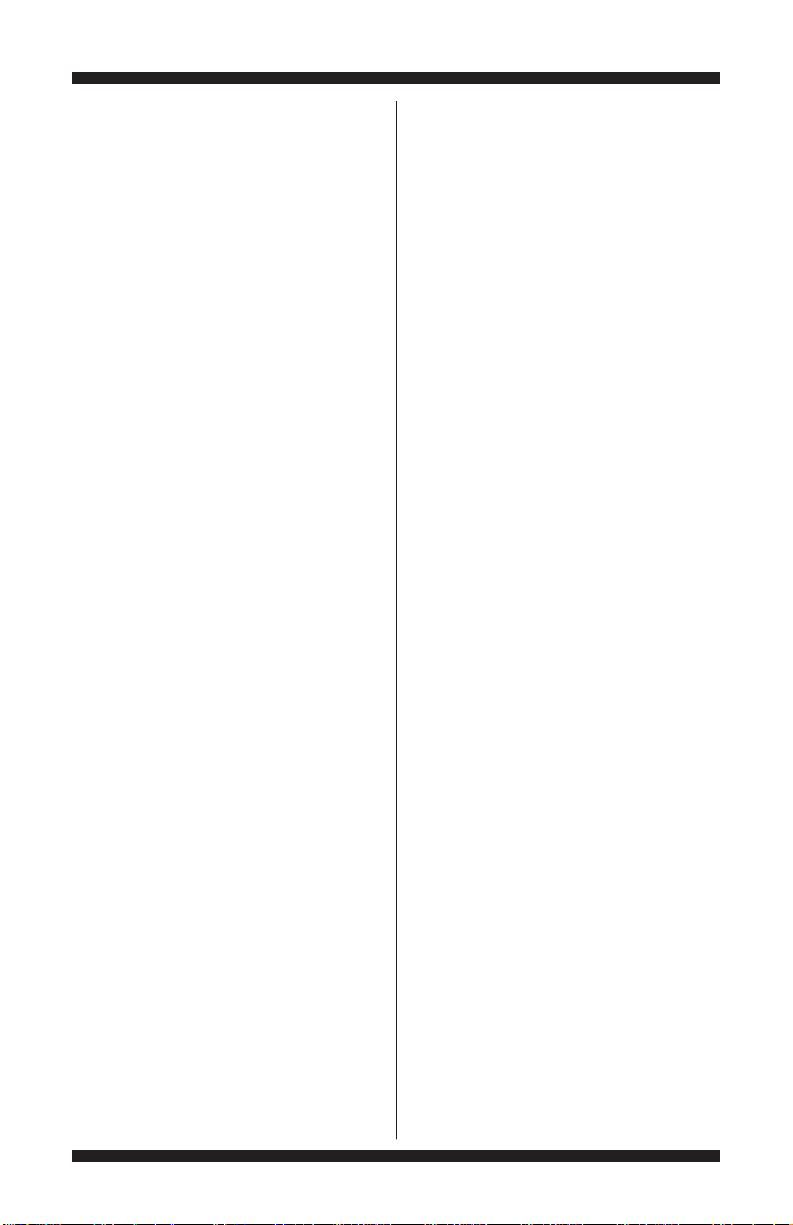

CCU (Cycle Control Unit):

8. CCU VAC – With voltmeter set to AC,

connect black probe to CCU P8-3 (N) and

red probe to P9-2 (L1). (See Figure 12.)

If 120VAC is present, go to step 9.

If 120VAC is not present, perform TEST

#2: Supply Connections, page 11.

9. CCU +5VDC – With voltmeter set to DC,

connect black probe to CCU P2-3 (ground)

and red probe to P2-1 (+5VDC).

If +5VDC is present, go to step 12.

If +5VDC is not present, go to step 10.

10. Unplug dryer or disconnect power. Unplug

P14 from the CCU. Plug in dryer or reconnect

power and repeat step 9.

If +5VDC returns, one of the thermistors

have shorted. To diagnose thermistors,

see TEST #4a, page 17.

If +5VDC is not present, go to step 11.

P2 – WIDE TO UI (+5 VDC)

P2-1 BLK +5VDC

P2-2 BLU DATA

P2-3 YEL 5V GND

P8 – MYST VALVE/DOOR SWITCH

P8-5 OPEN

P8-4 TAN DOOR SWITCH

P8-3 WHT NEUTRAL

P8-2 G/Y CHASSIS GND

P8-1 RED MYST VALVE

Heater Relay #1

L1 – BLK

(Gas & Elect.)

P5 – +12VDC

P5-1

P5-2

P5-3 12V GND

P5-4

P5-5

P5-6

P5-7

P14-3 RED OUTLET THERMISTOR

P14-2 RED INLET THERMISTOR

P14-1 RED INLET THERMISTOR

P5-8 +12VDC

P9

11. Unplug dryer or disconnect power.

Reconnect P14 to the CCU and unplug P2 from

the CCU. Plug in dryer or reconnect power and

repeat step 9. Perform voltage check inside

header P2 on CCU, between pins 1 & 3—DO

NOT SHORT PINS TOGETHER.

If +5VDC is still missing, replace the CCU.

If +5VDC returns, check harnesses and

connections between the CCU and user

interface (UI). If acceptable, replace the UI.

12. CCU +12VDC – with voltmeter set to DC,

connect black probe to CCU P5-3 (ground)

and red probe to P5-8 (+12VDC).

If +12VDC is present, go to step 13.

If +12VDC is not present, replace the CCU.

NOTE: 12V is used to actuate the 120VAC

relays, triacs, and switches.

13. Unplug dryer or disconnect power.

14. Reassemble all parts and panels.

15. Perform the “Quick Diagnostic Test”

through Service Diagnostics to verify repair.

P9 – MOTOR/L1

P9-2 BLK L1

P9-1 LT BLU MOTOR

P13 – MOISTURE SENSOR

P13-2 RED MOISTURE SENSOR

P13-1 BLK MOISTURE SENSOR

P14 – THERMISTORS

P14-6 RED OUTLET THERMISTOR

P14-5 RED MODEL RTN (GAS MODEL)

P14-4 RED MODEL (GAS MODEL)

Motor Relay

P13

Heater (E) – VLT

Heater (G) – RED

Heater Relay #2

(Elect. Only)

L1 – BLK

PAGE 10

K3

Heater – VLT

K2

K1

P8

Figure 12 - CCU Connectors & Pinouts

P5

P2

= pin-1

•

P14

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

COM

N

L1

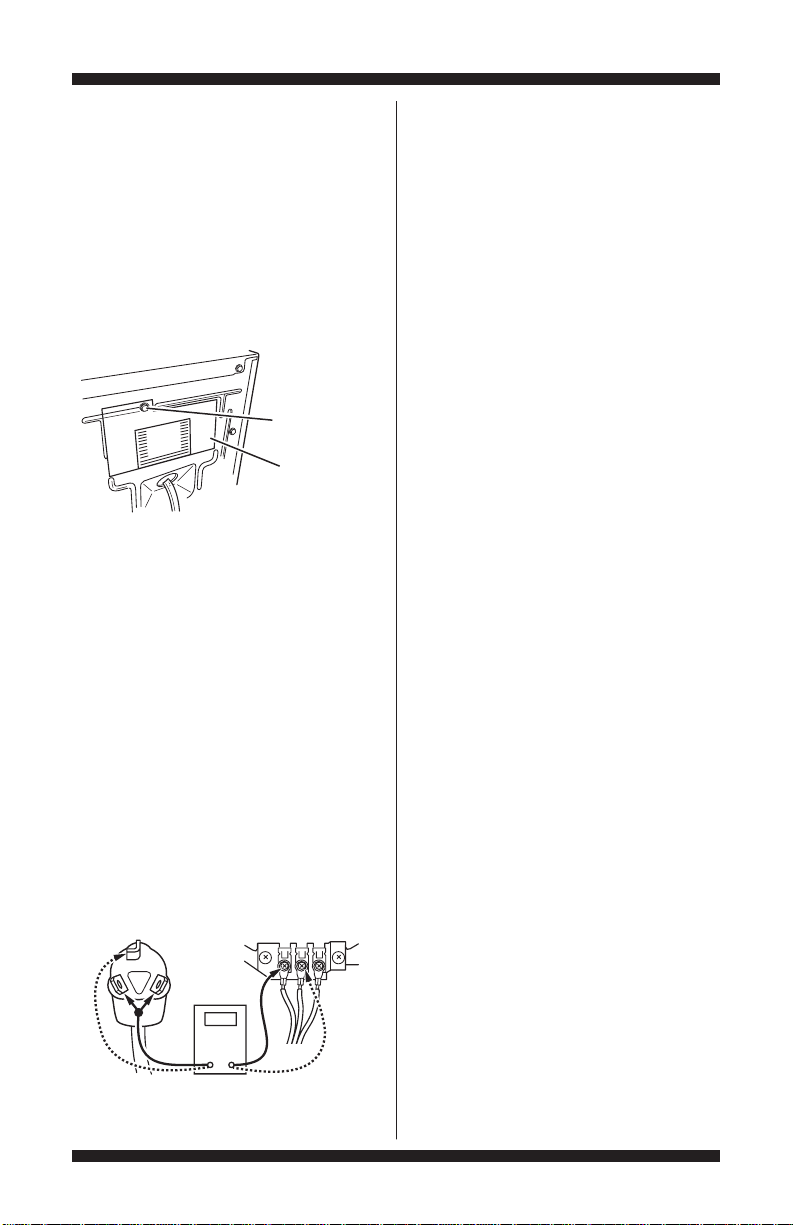

TEST #2: Supply Connections

This test assumes that proper voltage is

present at the outlet, and for U.S. installations,

a visual inspection indicates that the power

cord is securely fastened to the terminal block

(electric dryer) or wire harness connection

(gas dryer).

ELECTRIC DRYER (U.S. Installations):

1. Unplug dryer or disconnect power.

2. Remove the cover plate from the top right

corner of the back of the dryer. See figure 13.

Figure 13 - Remove the cover plate.

3. With an ohmmeter, check for continuity

between the neutral (N) terminal of the plug

and the center contact on the terminal block.

See figure 14a.

If there is no continuity, replace the power

cord and test the dryer.

If there is continuity, go to step 4.

4. In a similar way, check which terminal of

the plug is connected to the left-most contact

on the terminal block and make a note of

it. This will be L1 (black wire) in the wiring

diagram. See figure 14a.

When this is found, go to step 5.

If neither of the plug terminals have

continuity with the left-most contact of the

terminal block, replace the power cord and

retest dryer.

Power Cord

Plug

Figure 14a - Plug-to-terminal connections

for electric dryer.

Terminal Block

Remove Screw

Cover Plate

5. Access the machine electronics without

disconnecting any wiring to the CCU (See

Dryer Disassembly Instructions, page 24).

6. With an ohmmeter:

a. check for continuity between the L1

terminal of the plug (found in step 4) and

P9-2 (black wire) on the CCU.

b. check for continuity between the L1

terminal of the plug and P1-1 (black wire)

on the Power Cube.

If both show continuity, go to step 7.

If there is no continuity, check that wires to

the terminal block are mechanically secure.

If so, replace the main wire harness in the

dryer and retest.

7. With an ohmmeter:

a. Check for continuity between the neutral

(N) terminal of the plug and P8-3 (white wire)

on the CCU.

b. check for continuity between the neutral

(N) terminal of the plug and P1-2 (white wire)

on the Power Cube.

If both show continuity, go to step 8.

If there is no continuity, and the mechanical

connections of the wire are secure, replace

the main wire harness in the dryer and

retest.

8. Visually check that ALL connectors are

fully inserted into the CCU and Power Cube.

9. Reassemble all parts and panels.

10. Plug in dryer or reconnect power.

11. Perform the “Quick Diagnostic Test”

through Service Diagnostics to verify repair.

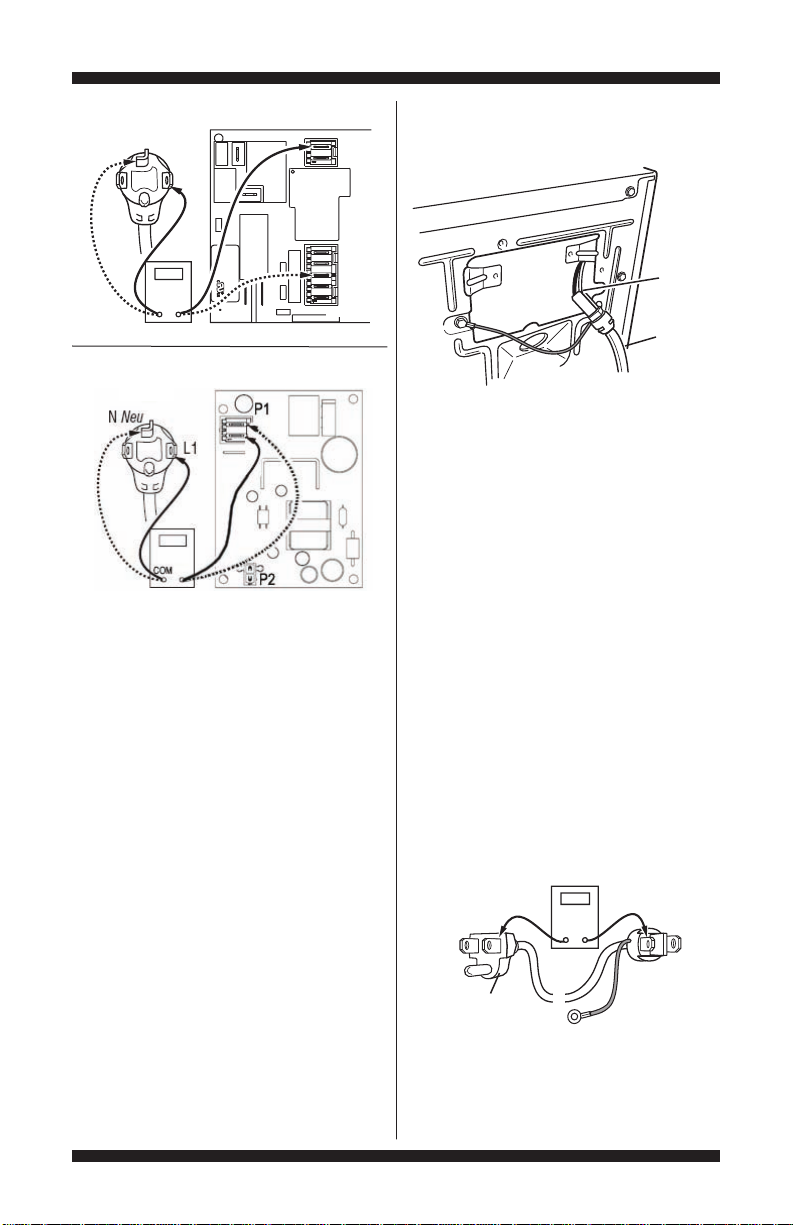

ELECTRIC DRYER (Canadian Installations):

1. Unplug dryer or disconnect power.

2. Remove the cover plate from the top right

corner of the back of the dryer. See figure 13.

3. Access the machine electronics

without disconnecting any wiring (see Dryer

Disassembly Instructions, page 24).

4. With an ohmmeter:

a. check the continuity from L1 and N plug

terminals of the power cord to the terminals

for L1 and N on the CCU. See figure 14b,

page 12.

b. check the continuity from L1 and N plug

terminals of the power cord to the terminals

for L1 and N on the Power Cube.

DO NOT REMOVE OR DESTROY

PAGE 11

FOR SERVICE TECHNICIAN’S USE ONLY

COM

Neu

G

L1

L1

Masse

N

Neu

N

G

Masse

P9

1

5

1

P/N XXXXXX Rev X

Date Code YDDD-xx

XXXX-XXX

MADE IN COO

L1

COM

P8

L1

N

Neu

N

Neu

Power Cord

Plug

Power Cord

Plug

Figure 14b - Plug-to-terminal connections

Cycle Control Unit

Power Cube

for electric dryer.

If continuity exists for all connections,

go to step 6.

If an open circuit is found, check the integrity

of the connections of the power cord to the

harness in the dryer; harness to the CCU and

Power Cube; and the integrity of the power

cord itself.

5. If it is necessary to replace the power

cord, remove the retaining clip that secures

the cord to the back panel. Disconnect the

cord from the main harness and the ground

wire from the rear panel, then pull out the

power cord.

6. Visually check that ALL connectors are

fully inserted into the CCU and Power Cube.

7. Reassemble all parts and panels.

8. Plug in dryer or reconnect power.

9. Perform the “Quick Diagnostic Test”

through Service Diagnostics to verify repair.

GAS DRYER (U.S. and Canadian Installations):

1. Unplug dryer or disconnect power.

2. Remove the cover plate from the top right

corner of the back of the dryer. See figure 13.

PAGE 12

3. Check that the power cord is firmly

connected to the dryer’s wire harness.

See figure 15.

Wire

Harness

Power

Cord

Figure 15 - Power cord-to-wire harness

connection for gas dryer.

4. Access the machine electronics without

disconnecting any wiring (See Dryer

Disassembly Instructions, page 24).

5. With an ohmmeter:

a. check for continuity between the neutral (N)

terminal of the plug and P8-3 (white wire) on the

CCU. The left-hand side of figure 16 shows the

position of the neutral terminal (N) on the power

cord plug. Also see figure 12, page 10.

b. check for continuity between the neutral (N)

terminal of the plug and P1-2 (white wire) on the

Power Cube.

If both show continuity, go to step 6.

If there is no continuity, disconnect the

white wire of the main harness from the

power cord at the location illustrated in

figure 15. Test the continuity of the power

cord neutral wire as illustrated in figure 16.

If an open circuit is found, replace the

power cord. Otherwise, go to step 6.

Power Cord

Plug

Figure 16 - Power cord terminals, gas dryer.

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

Part of Motor System

Electric

Dryer

Gas

Dryer

Drum belt

��

Door switch

��

Harness/connection

��

Thermal fuse

�

no

Drive motor

��

Belt switch

��

Centrifugal switch

��

Machine control electronics

��

6. In a similar way, with an ohmmeter:

a. check for continuity between the L1 terminal

of the plug and P9-2 (black wire) on the CCU.

b. check for continuity between the L1 terminal

of the plug and P1-1 (black wire) on the Power

Cube.

If both show continuity, go to step 8.

If there is no continuity, check the continuity

of the power cord in a similar way to that

illustrated in figure 16, but for power cord’s

L1 wire. If an open circuit is found, replace

the power cord. Otherwise, go to step 7.

If an open circuit is found, replace the power

cord. Otherwise, replace the main harness.

7. If the power cord passes the continuity check,

replace the main harness.

8. Visually check that ALL connectors are fully

inserted into their circuit boards.

9. Reassemble all parts and panels.

10. Plug in dryer or reconnect power.

11. Perform the “Quick Diagnostic Test”

through Service Diagnostics to verify repair.

TEST #3: Motor Circuit

3 Quick Check: Motor activation and related

attributes are provided in “Service Diagnostics

> Component Activation > Motor”. This test

will check the wiring to the motor and the

motor itself. The following items are part of

this motor system:

3. Check for loose, worn, or damaged drum

belt—repair as necessary.

4. Door Switch problems can be uncovered

by following procedure under TEST #7: Door

Switch, page 21; however, if this was not

done, the following can be performed without

applying power to the dryer. Connect an

ohmmeter across CCU P8-3 (neutral, white

wire) and P8-4 (door, tan wire).

With the door properly closed, the ohmmeter

should indicate a closed circuit (0–2 Ω).

If not, check harnesses and connections

between CCU and door switch. If good,

replace the door switch assembly.

5. Motor Circuit Check - Access the CCU and

measure the resistance across P8-4 and P9-1.

If resistance across P8-4 and P9-1 is in

the range of 1 to 6 Ω, the motor circuit is

acceptable. Replace the CCU.

Otherwise, continue to step 6.

6. Check the wiring and components in the path

between these measurement points by referring

to the appropriate wiring diagram (gas or electric)

on pages 26 or 27. NOTE: To access motor

system components, refer to Dryer Disassembly

Instructions, page 24.

ELECTRIC DRYER ONLY: Check the thermal fuse.

See TEST #4b: Thermal Fuse, page 18.

ALL DRYERS: Continue with step 7 below to test

the remaining components in the motor circuit.

7. Check the drive motor and belt switch.

Slowly remove the drum belt from the springloaded belt switch pulley, gently letting the belt

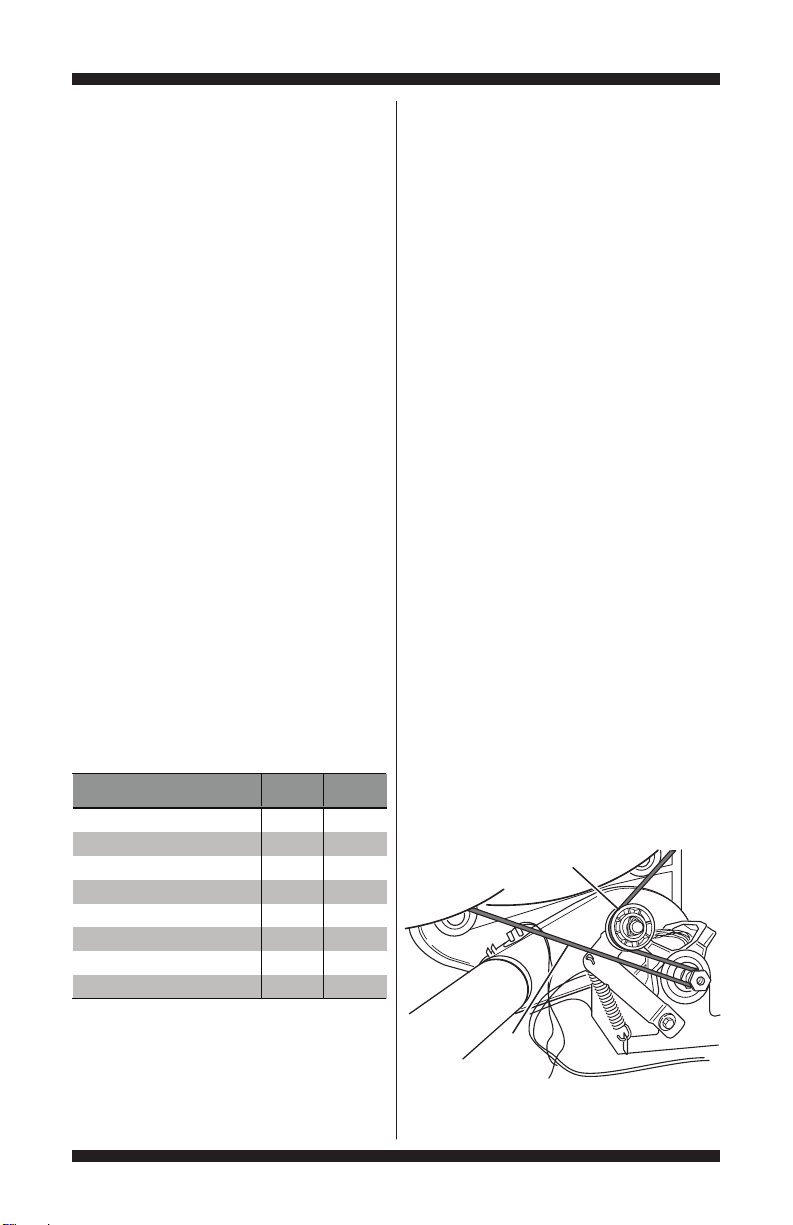

switch pulley down. See figure 17.

NOTE: Refer to strip circuit on page 23

to diagnose drive motor.

1. Unplug dryer or disconnect power.

2. Remove top panel to access the machine

electronics.

DO NOT REMOVE OR DESTROY

Belt Switch Pulley

Drum

Belt

Figure 17 - Slowly remove drum belt.

PAGE 13

FOR SERVICE TECHNICIAN’S USE ONLY

1

5

3

4

6

2

Winding

Resistance

in ohms

Contact Points

of Measurement

MAIN3.3–3.6

Lt. blue wire in back at pin 4

and bare copper wire terminal

removed from pin 5 of black

drive motor switch

START2.7–3.0

Lt. blue wire in back at pin 4

and bare copper wire terminal

on pin 3 of black drive

motor switch

1

5

3

4

6

2

1

5

3

4

6

2

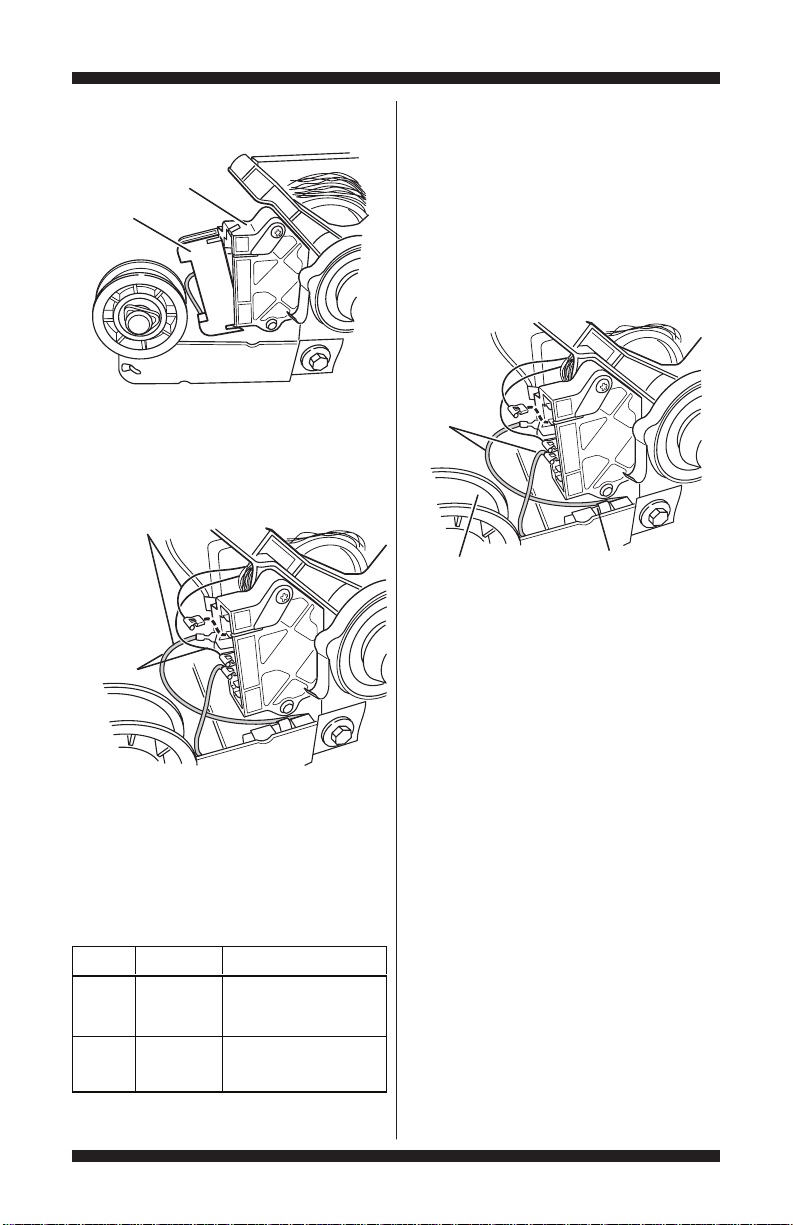

8. Remove the white connector from the drive

motor switch. See figure 18.

White

Connector

9. Remove the bare copper wire terminal from

pin 5 of black drive motor switch. See figure 19.

Main Winding:

Lt. Blue Wire in Back

and Bare Copper Wire

Start

Winding:

Lt. Blue Wire

in Back and

Bare Copper

Figure 19 - Main and start winding measure points.

10. Using figure 19 and the strip circuit on

page 23, check for the resistance values of

the motor’s Main and Start winding coils as

shown in the following table.

NOTE: Main and Start winding coils must be

checked at the motor.

PAGE 14

Drive Motor

Switch

Figure 18 - Remove white connector.

Wire

If the resistance at the motor is correct,

there is an open circuit between the motor

and CCU. Go to step 11 to check for belt

switch problem.

If the Start winding resistance is much

greater than 3 ohms, replace the motor.

11. Check the belt switch by measuring

resistance between the two light blue wires,

as shown in figure 20, while pushing up the

belt switch pulley.

Lt. Blue

Wires

Belt Switch Pulley

Belt Switch

Figure 20 - Checking the belt switch.

If the resistance reading goes from open to a

few ohms as pulley arm closes the switch, belt

switch is good. If not, replace the belt switch.

If belt switch is good and there is still an open

circuit, check and repair the main wiring harness.

12. Reassemble all parts and panels.

13. Plug in dryer or reconnect power.

14. Perform the “Quick Diagnostic Test”

through Service Diagnostics to verify repair.

TEST #4: Heat System

3 Quick Check: Motor activation and related

component attributes are provided in “Service

Diagnostics > Component Activation >

Heater 1, Heater 2, and Heater 1+2” for

electric, or “Heat On” for gas. This test is

performed when either of the following

situations occurs:

3Dryer does not heat

3Heat will not shut off

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

Part of Heating System

Electric

Dryer

Gas

Dryer

Harness/connection

��

Heater relay

��

Thermal cut-off

��

Thermal fuse no

�

High limit thermostat

��

Heat element assembly

�

no

Gas valve assembly no

�

Centrifugal switch

��

Outlet thermistor

��

Inlet thermistor

��

Machine control electronics

��

Console electronics and housing

assembly

��

Gas supply no

�

This test checks the components making up

the heating circuit. The following items are

part of this system:

NOTE: On the gas dryer, the inlet thermistor

is located below the CCU bracket at the drum

inlet vent. Refer to strip circuit on page 23 to

diagnose heater system.

Dryer does not heat:

Locate the components using figures 21a and

21b. To access heater system components, see

Dryer Disassembly Instructions, page 24.

ELECTRIC DRYER ONLY:

3Quick Check: Perform the “CCU Line

Voltage 1” check under Component

Activation. If L1 is present, the thermal

cutoff is functional.

3Quick Check: Perform the “CCU Line

Voltage 2” check under Component

Activation. If L2 is present, the centrifugal

switch, high limit thermostat, and the side

of the heater connected to heater relay 1

are functional.

1. Unplug dryer or disconnect power.

2. Remove top panel to access the machine

electronics.

3. Check Heaters—on the CCU, use an

ohmmeter to measure the resistance between

the violet wire terminal on heater relay #1

and the violet wire terminal on heater relay #2.

If the resistance is ≤ 50 Ω, go to step 5.

If an open circuit is detected, go to step 4.

DO NOT REMOVE OR DESTROY

Inlet Thermistor/High Limit

Thermostat Assembly

Thermal

Cut-Off

Thermal Fuse

Figure 21a - Thermal components,

electric dryer, viewed from front.

High Limit Thermostat

Flame

Sensor

Thermal Fuse

Figure 21b - Thermal components,

gas dryer, viewed from front.

Heater

Element

Outlet

Thermistor

Electric Dryer

Thermal

Cut-Off

Outlet

Thermistor

Gas Dryer

PAGE 15

FOR SERVICE TECHNICIAN’S USE ONLY

4. Visually check the wire connections between

each relay and their respective heaters. If the

connections look good, check for continuity

across each heater (violet wire to center red

wire). Refer to strip circuit on page 23.

Replace the heater if it is electrically open.

5. Check Thermal Cut-off—on the CCU, use

an ohmmeter to measure continuity between

P9-2 (L1) and the black wire terminal on heater

relay #1. Then, measure continuity between P9-2

(L1) and the black terminal on heater relay #2.

If there is continuity, go to step 7.

If an open circuit is detected, go to step 6.

6. Visually check the wire connections

between each relay (black wire) and the

thermal cut-off. If the connections look good,

check for continuity across the thermal cut-off.

Replace the thermal cut-off if it is

electrically open.

7. Check High Limit Thermostat—visually

check the wire connections from the heaters

and centrifugal switch to the high limit

thermostat. If the connections look good, check

for continuity across the high limit thermostat.

Replace the high limit thermostat if it is

electrically open.

8. If no open circuit is detected, remove P14

from the CCU and measure the outlet thermistor

resistance between P14-3 and P14-6 at the

connector.

If 5–15 k ohms are measured, go to step 9.

If the resistance is less than 1 k ohm,

replace the outlet thermistor.

9. If the preceding steps did not correct the

problem and L1 and L2 were both detected,

replace the CCU. If L2 was not detected,

suspect the centrifugal switch before

replacing the CCU.

10. Reassemble all parts and panels.

11. Plug in dryer or reconnect power.

12. Perform the “Quick DIagnostic Test”

through Service Diagnostics to verify repair.

GAS DRYER ONLY:

1. Verify that the gas supply to the dryer

is turned on.

2. Unplug dryer or disconnect power.

3. Perform TEST #4b: Thermal Fuse on page

18. If the thermal fuse is OK, go to step 4.

4. Perform TEST #4c: Thermal Cut-Off on

page 18. If the thermal cut-off is OK, go to

step 5.

5. Locate the high limit thermostat (see

figures 21a & 21b, page 15). Measure the

continuity through it by connecting the meter

probes to the red and black wire terminals.

If there is an open circuit, replace both the

high limit thermostat and the thermal cut-off.

Otherwise, go to step 6.

6. Perform TEST #4d: Gas Valve on page

18. If the gas valve is OK, go to step 7.

7. If the preceding steps did not correct

the problem, suspect the centrifugal switch

before replacing the CCU.

8. Reassemble all parts and panels.

9. Plug in dryer or reconnect power.

10. Perform the “Quick Diagnostic Test”

through Service Diagnostics to verify repair.

Heat will not shut off:

ALL DRYERS:

1. Unplug dryer or disconnect power.

2. Remove top panel to access the machine

electronics.

3. Remove connector P14 from the CCU and

measure the resistance between P14-3 and

P14-6 at the connector.

If 5–15 k ohms are measured, the outlet

thermistor is OK.

If the resistance is less than 1 k, replace

the thermistor; if open, repair as necessary.

4. Check heater coil(s) for a short to ground

(usually inside the heater box). Repair or

replace if necessary.

5. Plug in dryer or reconnect power.

6. Run an “AIR” only timed dry cycle (no

heat). Check heater relay output(s) on CCU.

With a voltmeter set to AC, measure the

voltage across terminals 1 & 2 for heater

relay #1. If equipped, repeat procedure

with heater relay #2.

If voltage is present (~240VAC for electric,

~120VAC for gas), the relay is open and

working normally.

PAGE 16

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

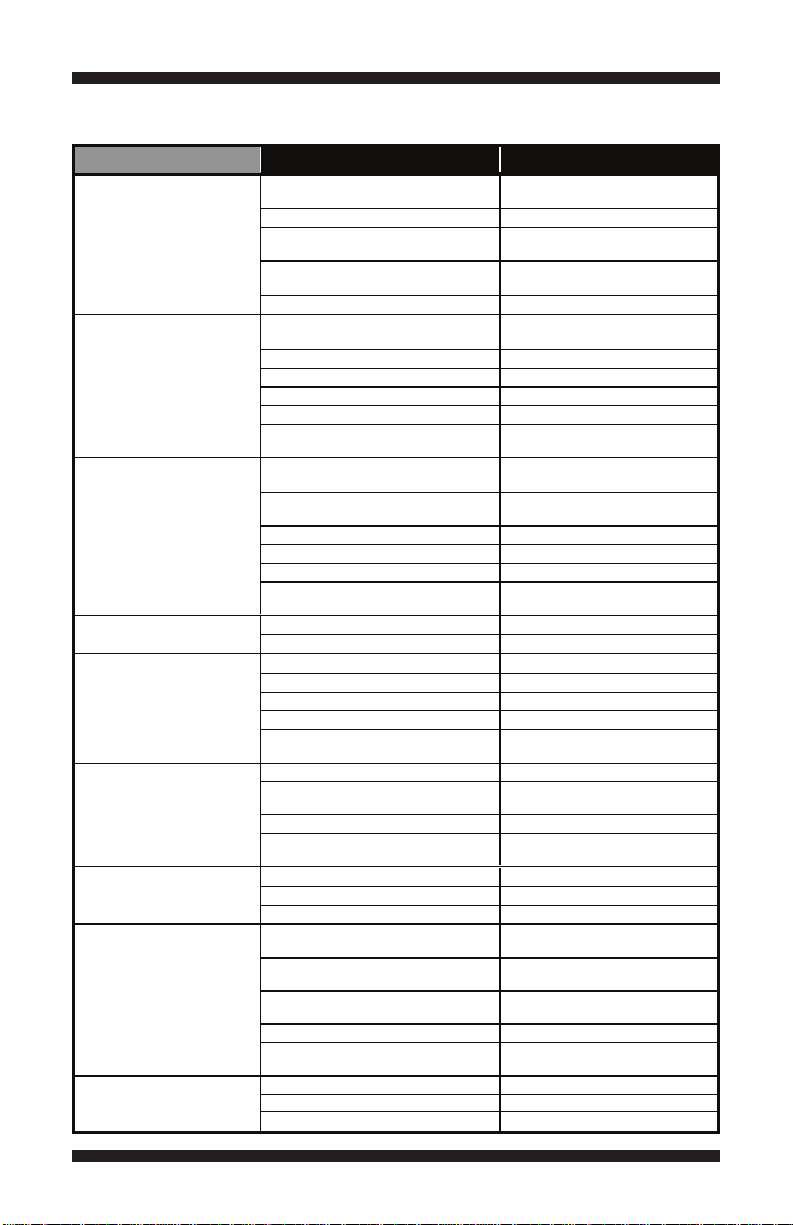

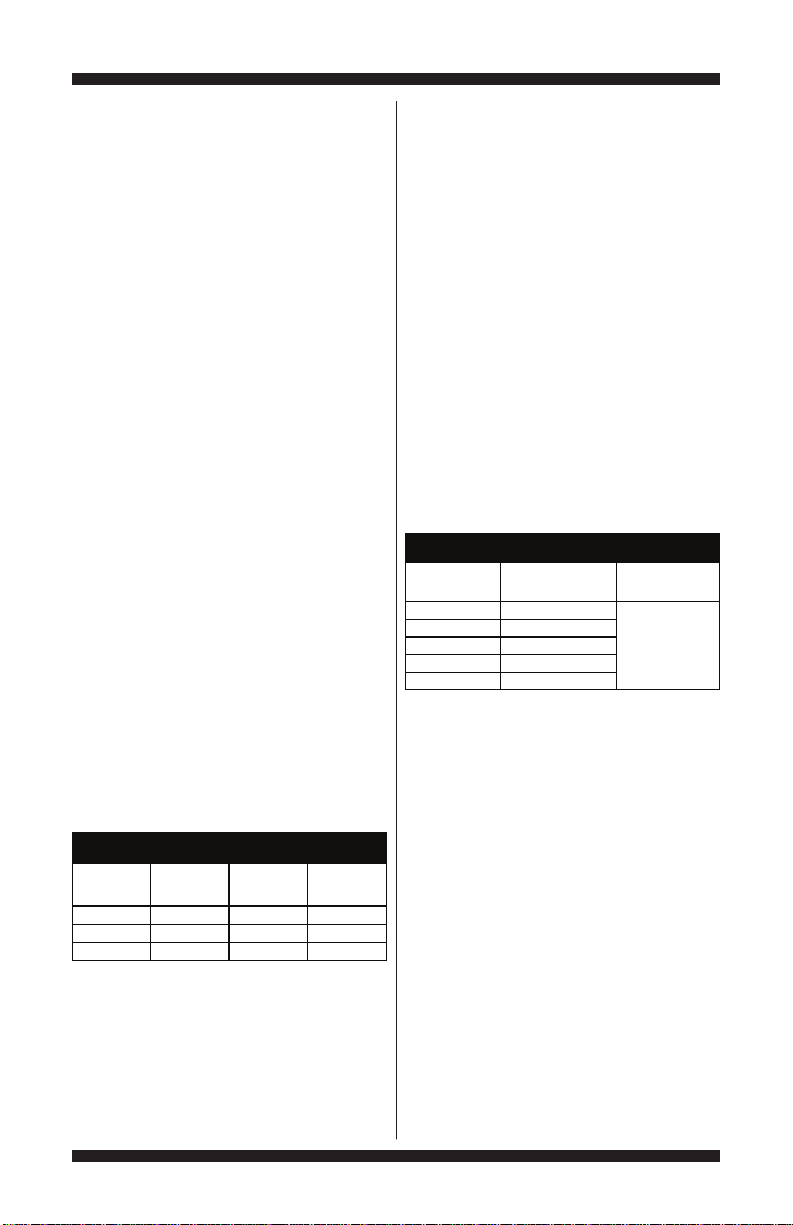

TEMP.

°F (°C)

RES.

RANGE

k ohms

TEMP.

°F (°C)

RES.

RANGE

k ohms

50° (10°) 19.0–22.0 80° (27°)8.5–10.5

60° (16°) 14.8–16.8 90° (32°)6.8–8.8

70° (21°)11.5–13.5 100° (38°)5.0–7.0

OUTLET THERMISTOR RESISTANCE

TEMPERATURE

SETTING

HEAT TURNS OFF*

°F (°C)

HEAT TURNS ON

°F (°C)

High 155° ± 5° (68° ± 3°)

Medium 140° ± 5° (60° ± 3°)

Low 125° ± 5° (52° ± 3°)

Extra Low 105° ± 5° (41° ± 3°)

EXHAUST TEMPERATURES

10–15° (6–8°)

below the

heat turn off

temperature

Medium High 150° ± 5° (65° ± 3°)

If little or no voltage is present, the relay

is closed and heater is activated. Replace

the CCU.

7. Unplug dryer or disconnect power.

8. Reassemble all parts and panels.

9. Plug in dryer or reconnect power.

10. Perform the “Quick Diagnostic Test”

through Service Diagnostics to verify repair.

TEST #4a: Thermistors

NOTE: Refer to strip circuit on page 23 to

diagnose outlet and inlet temperature thermistors.

Outlet (Exhaust) Thermistor

The CCU monitors the exhaust temperature

using the outlet thermistor, and cycles the

heater relay on and off to maintain the desired

temperature. NOTE: Begin with an empty dryer

and a clean lint screen.

3Quick Check: Exhaust thermistor readings

in °F, °C, and resistance are provided

in “Service Diagnostics > Component

Activation > Exhaust Thermistor.”

1. Unplug dryer or disconnect power.

2. Remove top panel to access the machine

electronics.

3. Remove connector P14 from the CCU

and measure the resistance between P14-3

and P14-6 at the connector. The following

table gives temperatures and their associated

resistance values.

NOTE: All thermistor resistance measurements

must be made while dryer is unplugged and

connector removed from CCU.

If the resistance is OK, the outlet thermistor

is good. Proceed to step 4.

If the thermistor resistance does not agree

with the table, replace the outlet thermistor.

4. Check P14-3 and P14-6 to dryer cabinet

ground. If either pin indicates continuity

otherwise, proceed to step 5.

DO NOT REMOVE OR DESTROY

to ground (short), replace wiring harness;

5. If the preceding steps did not correct the

problem, replace the CCU.

Temperature Levels Incorrect – If no error code

is displayed and the connections to the thermistor

are good, check the exhaust temperature value

at any or all of the temperature levels in question,

using the Timed Dry cycle. IMPORTANT: Be

sure EcoBoost (if available) is turned OFF before

testing.

1. Remove load from dryer and disconnect

external vent.

2. Plug in dryer or reconnect power.

3. Run a TIMED DRY cycle of at least 2

minutes in duration. Select High, Medium

High, Medium, Low, or Extra Low. Turn off

EcoBoost.

4. Using a calibrated temperature probe,

take a temperature measurement in the

center of the exhaust outlet. The correct

exhaust temperatures are as follows:

If the temperature is not reached within

~7 minutes, check voltage level and vent

blockage, and then retest.

If the temperature probe does not agree

with temperature setting, replace the outlet

thermistor.

If the temperature probe confirms the

temperature setting, retest at a different

temperature setting.

5. If the preceding steps did not correct the

problem, replace the CCU.

Inlet Thermistor

The CCU monitors the inlet temperature using

the inlet thermistor. The inlet thermistor (along

with the outlet thermistor) is used to detect

air flow, and assists in calculating load size.

NOTE: On the electric dryer, the inlet thermistor

is part of the high thermostat assembly (see

figures 21a & 21b). On the gas dryer, the inlet

thermistor is located below the CCU bracket

at the drum inlet duct (see figure 29, page 28).

PAGE 17

Loading...

Loading...