Whirlpool WBM, 470 User Manual

Whirlpool of India Limited

SERVICE AND PARTS MANUAL

Document No. WOI/GNF/………………….

GLOBAL NO FROST

DOUBLE DOOR REFRIGERATORS

Sap code

9160

9161

9162

This document is intended only for qualified technicians who are aware of the respective safety

Model

WBM 470

WBM 480

WBM 490

regulations

Description

220L Thailand 4G

250L Thailand 4G

285L Thailand 4G

1

CONTENTS

Introduction 3

Safety precautions & warnings 4-5

Special Features 6

Technical Specifications 6

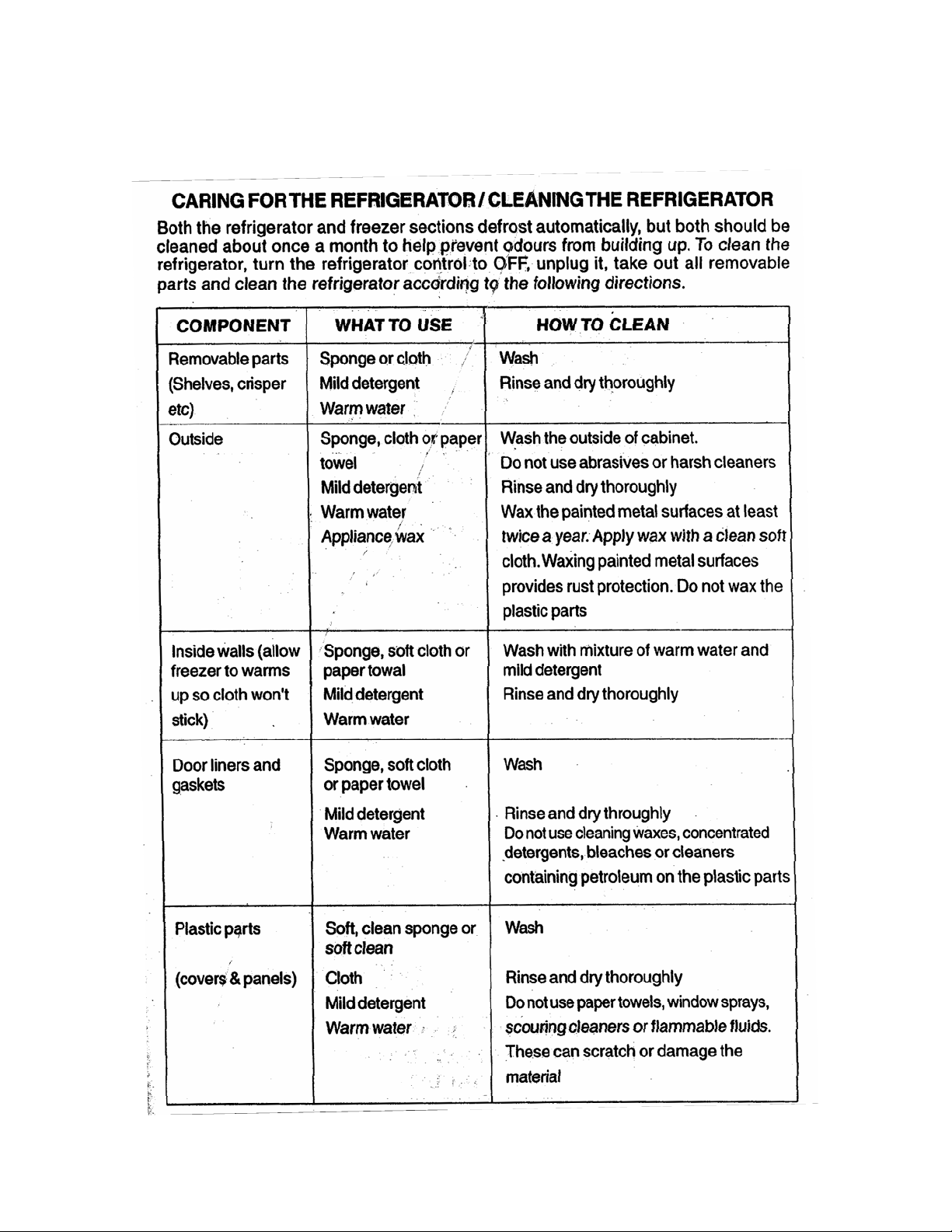

Care & Cleaning 7

GNF Refrigerator Parts Identification 8

Energy-Saving Tips 9

Refrigerator Sounds 9-10

Trouble-shooting General 10

Changing Control Settings 10-11

RI 34a Service Consideration 11

Service Instructions 12-17

(1) Procedure for R134a Sealed System (1) R134a Sealed System Service (2) Sweep

Charging Procedure (3) Contaminated R134a Sealed System Repairs (4) Freezer

Compartment (5) Refrigerator Compartment

Sealed System Diagnosis Review 18

Wiring Diagram 19

Trouble diagnosis chart 20-23

Sealed System Schematic Layout 24

Trouble Check For Cooling Cycle 25

Diagnostics & Flow Charts 26-33

(1) Refrigerator Does Not Operate (2) Defrosting Mechanism Does Not Work

(3) Purging The System (4) High Side Leaks & Noisy Compressor

(5) Burnouts & Compressor Replacement (6) Restricted System, High & Low Side

Leaks, Excessive Moisture

(7) Back Flushing PF (8) Sweep Charging & Final Charging

Procedure

Diagrams & Assembly Drawings 34-38

(1) Cabinet...……………………................ 34

(3) Freezer Compartment……..............15/36

(5) Compressor……………..………………38

(7) Wiring Diagram …….............………….19

Parts List 39-42

(2) Shelves……………………………….35

(4) Control Box………...…………….16/37

(6) GNF Refrigerator Parts ……………..8

(8) Sealed System Schematic Layout..24

2

I N T R 0 D U C T I 0 N

CFC Free

Manufacturing of a refrigerator includes certain operations like foaming, gas charging of the

sealed system etc. This involves the use of certain refrigerants, which are released in the

atmosphere, that contain chlorine. These are termed as CFCs (Chlorofluorocarbon).

CFC's when released in the atmosphere affect the ozone layer. It leads to the depletion of the

Ozone layer. The ozone layer acts as shield against the ultra violet sun rays, which are harmful to

us and cause skin diseases.

Whirlpool has responded to this required change by introducing refrigeration products that use

R134a, a Hydroflorocarbon (HFC) refrigerant that is chlorine- free. This refrigerant satisfies the

challenge of producing an environmentally friendly refrigeration product while meeting current

energy-efficiency standards.

Whirlpool to continue their response to produce environmentally friendly refrigeration product in

global level, have started producing in India “The Global No-frost “(GNF) refrigerator which is the

first CFC FREE of its kind.

A new plant is set up at Pune to manufacture the environmentally friendly refrigerators in India by

Whirlpool. All the refrigerators manufactured in this plant will use refrigerant R134a, which is a

CFC FREE refrigerant. R134a refrigerant is, in some ways, similar to R12. There are some very

important and critical differences that must be recognized. These differences require changes to

some sealed system repair procedures which we will see further in this manual.

3

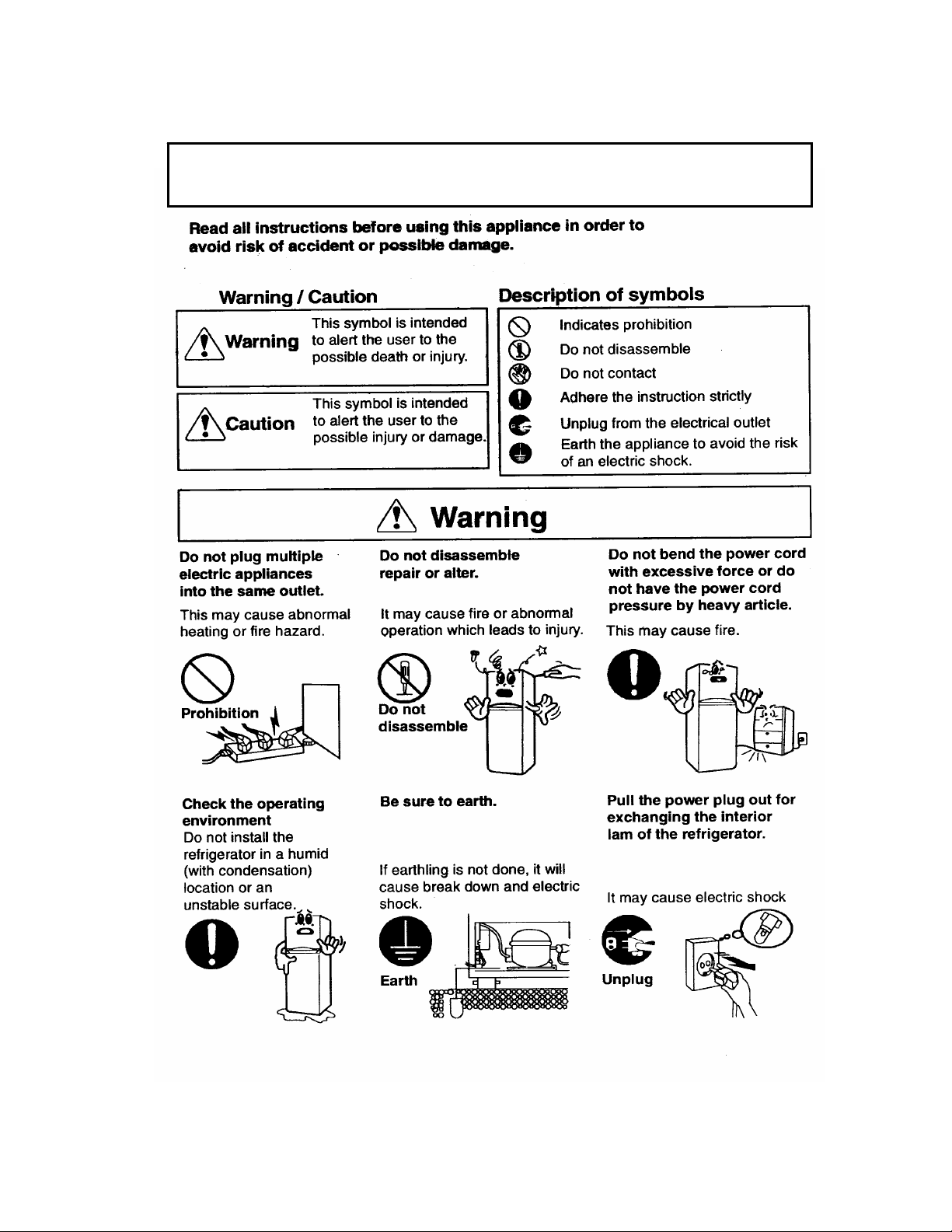

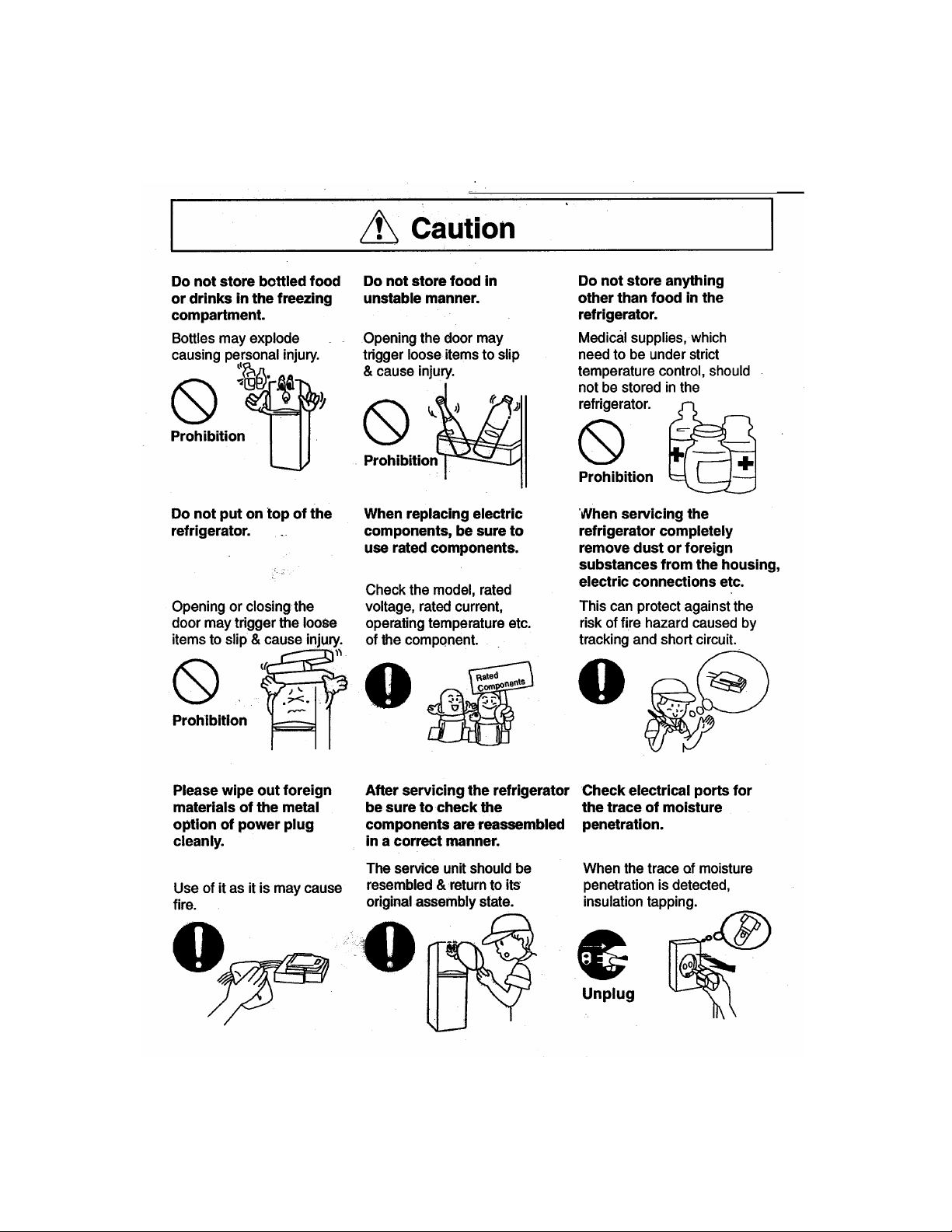

Safety Precautions & Warnings

4

5

SPECIAL FEATURES

The special features of these refrigerators compared to the existing refrigerators are as

follows:

1. Clean back refrigerator

2. CFC Free, No frost

3. Double door

4. Quick freeze compartment

5. Quick chiller compartment in refrigerator compartment

6. Heat loop for anti-condensation

7. Easy to handle crisper tray

8. Foamed in gasket and liners

9. Energy efficient compressor

10. Wheels for easy mobility

11. Galvanized and painted Steel body

TECHNICAL SPECIFICATIONS

MODEL

12NC

DESIGN SPECS

Capacity(L)total Net 220L 250L 285L

Capacity(L)total gross 240L 280L 320L

Refrigerator/Freezer 150 / 70 L 180 / 70 L 215 / 70 L

Tropicalized YES YES YES

ELECTRICAL

Voltage / Hz 220-240V/50-60Hz 220-240V/50-60Hz 220-240V/50-60Hz

Voltage Range 160-260V 160-260V 160-260V

Power Consumption 245W 245W 245W

REFRIGERANT

Type R134a R134a R134a

Quantity 96 gms. 96 gms. 96 gms

COMPRESSOR

Type Reciprocating Reciprocating Reciprocating

Motor Type RSIR RSIR RSIR

Compressor Cooling Static Static Static

WBM 470 WBM 480 WBM 490

6

7

GNF - REFRIGERATOR PARTS IDENTIFICATION

8

ENERGY - SAVING TIPS

You can help your refrigerator use less electricity by

1. Making sure the gaskets are clean and are making good contact with the cabi net.

2. Opening the refrigerator and freezer doors as little as possible. Keep food well organized

and remove all of what you need at one time.

3. Not overfilling the compartments so that air cannot circulate properly.

4. Not setting the refrigerator and freezer sections to at temperature higher than necessary. If

ice cream is firm and drinks are as cold as you like them, which is cold enough.

5. Keeping the refrigerator away from heat sources, such as a cooking range, water heater,

furnace, radiator or direct sunlight.

VACATION AND MOVING CARE SHORT VACATIONS

No need to shut off refrigerator if you will be away for less than four weeks.

LONG VACATIONS

Remove all the food if you are going for a month or more. Unplug the refrigerator and clean

it, rinse well and dry.

Tape rubber or wood blocks to the top of both doors, keeping them open far enough for air

to get in. This will keep odor and mold from building up.

MOVING

Remove all food. Pack frozen food in dry ice. Unplug the refrigerator and clean it

thoroughly. Take out all removable parts. Wrap all parts well and tape them together so

they don't shift and rattle. Screw in the leveling rollers and foot. Tape the doors shut and

tape the electric cord to the cabinet.

When you get to your new home, put everything back. Reconnect the water supply line if

you have an ice maker.

POWER INTERRUPTIONS

If electricity goes off, call the electricity dept. Ask how long will be off.

1. If service is to be interrupted 24 hours or less, keep both doors closed. This

will help frozen food stay frozen.

2. If service is to be interrupted longer 'than 24 hours, remove all frozen food and store in

frozen food locker.

3. A full freezer will stay cold longer than a partly filled one. A freezer full of meat will stay cold

longer than a freezer full of baked goods. If food contains ice crystals, it may be safely

refrozen, although the quality and flavor may be affected. If the condition of the food is poor

or if you feel it is unsafe, dispose of it.

REFRIGERATOR SOUNDS

Your new refrigerator may make sounds that your old one didn't. Because these sounds

are new, you may become concerned. However, these new sounds are normal. Hard

surfaces can make the sounds seem even louder. Some of the sounds you may hear are

RUNNING SOUNDS - caused by the high efficiency compressor and motor.

A SLIGHT HUM OR A SOFT HISS - caused by the refrigerator's fan motor and moving air.

9

CLICKING OR SNAPPING - caused by thermostat when the refrigerator stops on starts

operating. The defrost timer will click when the defrost cycle begins and ends.

WATER SOUNDS / GURGLING NOISE - caused by liquid settling in the tubing when the

refrigerator stops operating. You may also hear defrost water dripping into the defrost water

pan.

TROUBLE SHOOTING - GENERAL

HEAVY WARM LOAD - The amount of warm food placed in the refrigerator affects running time

and power consumption. Ordinarily, when a supply of food is placed in a refrigerator, it will

operate continuously until the food is down to the desired storage temperature. This

continuous operation is normal. In high ambient, an excessive warm load may cause

overload cycles.

EXCESSIVE DOOR OPENINGS - The length of time the door is left open and the number of

times the door is opened should be held to a minimum. Excessive door openings will

greatly increase running time, power consumption and frost build-up.

IMPROPER STORAGE - Uncovered foods and improper packaging materials and methods

cause food to dry out. This reduces the flavor of foods and results in excessive frost build- up.

WARM ROOM -

1. A warm room or other large source of heat (such as a cooking range, heater, hot air duct,

sunny window) can affect performance.

2. In general, the warmer the room, the greater the running time and power consumption.

EXTERIOR SWEATING - Refrigerators are designed to prevent "run off” moisture at 90 deg F

and 90% relative humidity ambient. There may be a thin film of moisture on some areas at

a lower temperature and relative humidity. This is within design specifications and is not a

fault of construction.

Relocating the refrigerator in a less humid, better ventilated area will normally eliminate

most moisture problems.

CHANGING THE CONTROL SETTINGS

Allow several hours for the refrigerator and freezer compartments to reach their operating

temperatures, before adding food items. If the milk or juices in the refrigerator section is as

cold as desired, then the thermostat is set correctly. The freezer section is set correctly

when ice cream remains firm. If the refrigerator and the freezer temperatures need to be

readjusted, make sure that you

1. Adjust the refrigerator compartment temperature first.

2. Wait at, least 24 hours before you make any further changes

3. When the refrigerator section is at the desired temperature, adjust the freezer section, as

desired.

The reasons for certain temperature problems are given below, accordingly set the

refrigerator section and freezer section

S.No. SYMPTOMS REASON

1. If the refrigerator section is TOO WARM Door opened often

Large amount of food added

Room temperature too warm

2. If freezer section is TOO WARM Door opened often

Large amount of food added

Very cold room temperature

3. If refrigerator section is TOO COLD Controls not set correctly for your conditions

10

4. If ICE isn't made fast enough Heavy ice usage

Very cold room temperature

5. If both sections are too warm Door opened often

Large amount of food added

Very warm or very cold room temperature

R134a SERVICE CONSIDERATIONS

R134a systems cannot tolerate (compared to other refrigerants) even trace amounts of

foreign substances, chemical contamination or moisture.

Examples of detrimental substances are wax or paraffin, silicon, greases, oils, rust

preventatives, lubricants, leak detection dye or any other additives.

Do not use R12 or R22 servicing equipment to repair an R134a system.

Use new servicing equipment. Old equipment (hoses, coupler/valve seals and 0-rings) are

not compatible with R134a.

Oil in R134a compressors is very sensitive and capable of absorbing large quantities of

moisture. Moisture cannot be removed from the compressor oil in a service workshop.

Service replacement compressor should be checked to make sure the studs seals are in

place and not tampered with.

Compressor studs should not remain open for more than ten minutes.

In any repair of R134a sealed system failure the filter-drier should always be replaced. And

in any compressor failure in R134 a system always replace with a new compressor.

11

SERVICE INSTRUCTIONS

The GNF refrigerators 285L, 250L, and 220L all are clean back refrigerators. A clean back

refrigerator incorporates the following parts foamed between the main liner and the cabinet.

1. The skin condenser - The condenser assembly is placed on the three sid es of the cabinet.

2. Heat loop - The heat loop is placed along the front side of the cabinet.

3. Suction & Capillary - The suction & capillary is placed on the backside of the cabinet. The

serviceable joints are available one for the Evaporator assembly in the Freezer

compartment and the other to the compressor and the drier.

4. Water drainage system - The defrost water drainage gets collected on the tray kept over

the compressor through the tube which is again formed at the backside of the cabinet.

5. Wiring Harness Assembly - The wiring assembly is foamed at the back side of the

refrigerator in such a way providing serviceable wiring connector in three places such as (1)

in the freezer compartment for the fan motor, defrost heater and bi-metal, (2) in the

refrigerator compartment for the thermostat, bulb holder, timer motor and (3) in the back

side dome area for the compressor, relay, overload protection and power cord. Each

compartment will have small wiring assembly for connecting the electrical parts available as

mentioned.

As these above mentioned parts are foamed in they become non-serviceable parts.

Great care on quality is taken to make these parts free from failure as any failure on

the above parts may lead for the unit replacement as a whole.

The other parts in the freezer compartment, refrigerator compartment and the door

assemblies except the liners are serviceable and the procedures for the same are given in

the following pages.

Procedure for repair of sealed system failures of

R134a systems.

This section has been specially introduced to explain in detail the precautions and care to

be taken in repair of refrigerators, which use R134a as the refrigerant (as in the GNF

refrigerator). It also explains in detail the "SWEEP CHARGING PROCEDURE" which is the

recommended procedure for repair of sealed system failures.

R134a sealed system service

R134a is used as a refrigerant in the Global No Frost refrigerators to make it more

environments friendly and comply with Environmental Protection Agency rules. R134a is a

Hydroflorocarbon refrigerant (Non - CFC) which is chlorine free and it makes it non ozone

layer depleting unlike other refrigerants like R12 which is a Chloroflorocarbon (CFC).

R134a is in some way similar to R12 in refrigerating properties but there are some

important and critical differences that should be always remembered.

The main Points to be remembered while servicing a R134a refrigerant based refrigerator

are

i) R134a is more sensitive to contamination and it can not tolerate moisture, traces of other

chlorine-based refrigerants and other chemical substances. Hence use only the tubing,

equipment which is compatible with R134a and maintained exclusive for R134a and do not

mix it with the other equipment meant for R12 based systems.

ii) The lubricant (Easter oil) used in R134a systems can absorb large amounts of moisture

and cause contamination. Hence never open the replacement compressor stubs ends to

12

moisture and keeps them plugged with the right plug till it is required to be used in the

repair.

iii) Do not use lubricating oil or refrigerant from chlorine based sealed system into R134a

system.

iv) Use sweep charging method (explained in detail in the next section) for charging of R134a

based systems after repair as it is more effective in removing the contaminants from the

sealed system.

v) Always replace the filter-drier in all sealed system repairs of R134a based systems

vi) Do not use the replacement compressor if its stubs are not plugged properly and do not

remove the plugs till it is time to braze the tubing to the stubs.

vii) Do not use manifold gauges during purging and charging of system.

CAUTION

If the above precautions are not followed it will result in the

premature compressor failure or complete system failure.

SWEEP CHARGING PROCEDURE FOR SEALED SYSTEM

REPAIR OF GNF REFRIGERATOR

The following are the main steps in the sweep charging of GNF refrigerator sealed system.

1) One or two access valves are attached to the sealed system. (The number of valves

depend on whether the compressor is operational or not.

2) The existing refrigerant charge is purged from sealed system in to a recovery bag.

3) Repairs are made to the sealed system taking all the precautions as required in repair of a

R134a refrigerant based sealed system.

4) The filter drier is replaced by a new filter drier.

5) The brazed joints on the high side are visually inspected for leaks.

6) The high side components are back flushed.

7) Four ounces of liquid refrigerant are metered into the sealed system.

8) A leak check is performed on the newly brazed joints in the high side of the system.

9) The compressor is run to circulate the sweep charge throughout the system

10) The refrigerant containing the contaminants is purged form the high side access valve in to

a recovery bag.

11) The system is finally charged with the prescribed amount of new refrigerant.

The sweep charging method is superior to other charging methods in removing the

contaminants (moisture and non condensable matter) from the sealed system.

The details of the sweep charging procedure is given in the flow charts No. 1 to 10

REPLACING R134a COMPRESSORS

1. CAUTION: Never open replacement compressor studs to the air for longer than 10

minutes.

2. Carefully inspect rubber plugs in the service replacement compressor studs. If the plug

appears to have been removed or tampered with, DO NOT USE THE COMPRESSOR. Get

another one.

3. Clean compressor studs with plugs still in them.

4. Install into system last. Braze into system within ten minutes.

13

Loading...

Loading...