Page 1

INSTALLATION INSTRUCTIONS

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS.

FOR RESIDENTIAL USE ONLY.

IMPORTANT : LIRE ET CONSERVER CES INSTRUCTIONS.

POUR UTILISATION RÉSIDENTIELLE UNIQUEMENT.

LIB0100831A/W10708303A

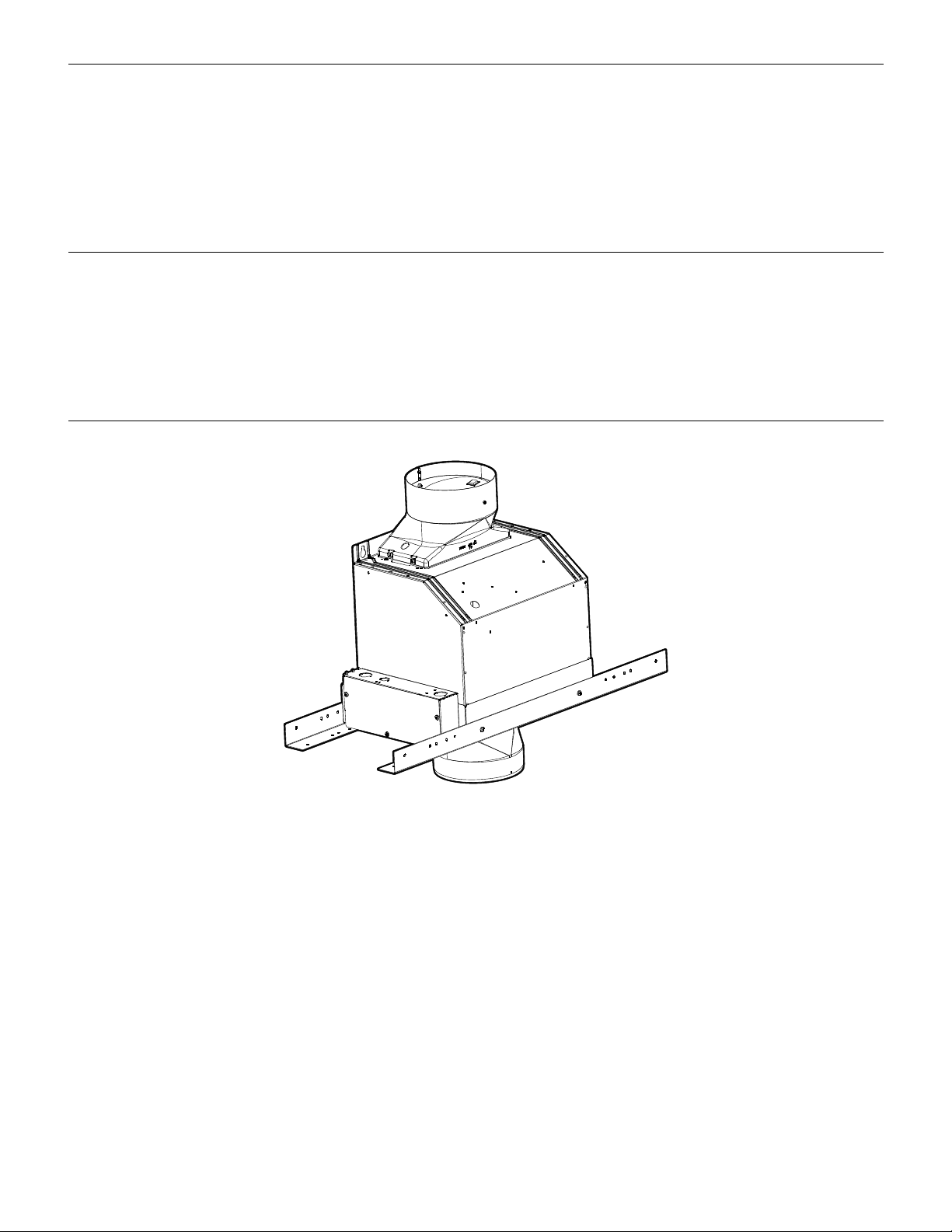

IN-LINE SMART KIT

Installation Instructions

For questions about features, operation/performance, parts, accessories or service, call: 1-800-253-1301

or visit our website at www.whirlpool.com

In Canada, call 1-800-807-6777 or visit our website at www.whirlpool.ca

INSTRUCTIONS D’INSTALLATION

VENTILATEUR DÉPORTÉ INTELLIGENT

Instructions d’installation

Au Canada, pour assistance, installation ou service, composer le 1-800-807-6777

Table of Contents/Table des matières.............................................................................2

ou visiter notre site Web à www.whirlpool.ca

Page 2

TABLE OF CONTENTS

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

TABLE DES MATIÈRES

RANGE HOOD SAFETY .................................................................2

INSTALLATION REQUIREMENTS................................................4

Tools and Parts ............................................................................4

Location Requirements................................................................4

Venting Requirements..................................................................5

Electrical Requirements ...............................................................6

INSTALLATION INSTRUCTIONS..................................................6

Prepare Location..........................................................................6

Prepare In-Line Smart Kit.............................................................6

Install In-Line Smart Kit

KVWB40DS Series Range Hoods................................................7

Complete Installation .................................................................10

Make Electrical Connection .......................................................11

Install In-Line Smart Kit

KVUB60DS Series Range Hoods ..............................................12

Complete Installation .................................................................16

Make Electrical Connection .......................................................17

Install In-Line Smart Kit

JXW85DS, JXI85DS, KVWB60DS, and KVIB60DS

Series Range Hoods ..................................................................18

Complete Installation .................................................................23

Make Electrical Connection .......................................................24

Install In-Line Smart Kit

WVW75UC and WV175UC Series Range Hoods......................25

Complete Installation .................................................................29

Make Electrical Connection .......................................................30

WIRING DIAGRAM .......................................................................31

SÉCURITÉ DE LA HOTTE DE CUISINIÈRE................................32

EXIGENCES D’INSTALLATION...................................................34

Outillage et pièces......................................................................34

Exigences d’emplacement.........................................................34

Exigences concernant l’évacuation ...........................................35

Spécifications électriques ..........................................................36

INSTRUCTIONS D’INSTALLATION.............................................36

Préparation de l’emplacement...................................................36

Préparation du ventilateur déporté intelligent............................36

Installation du ventilateur déporté intelligent

Hottes série KVWB40DS............................................................37

Achever l’installation ..................................................................40

Raccordement électrique...........................................................41

Installation du ventilateur déporté intelligent

Hottes série KVUB60DS.............................................................42

Achever l’installation ..................................................................46

Raccordement électrique...........................................................47

Installation du ventilateur déporté intelligent

Hottes série JXW85DS, JXI85DS,

KVWB60DS et KVIB60DS ..........................................................48

Achever l’installation ..................................................................53

Raccordement électrique...........................................................54

Installation du ventilateur déporté intelligent

Hottes série WVW75UC et WV175UC.......................................55

Achever l’installation ..................................................................59

Raccordement électrique...........................................................60

SCHÉMA DE CÂBLAGE...............................................................61

RANGE HOOD SAFETY

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

■ Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

■ Before servicing or cleaning the unit, switch power off at

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When

the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag,

to the service panel.

■ Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction.

■ Do not operate any fan with a damaged cord or plug.

Discard fan or return to an authorized service facility for

examination and/or repair.

■ Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer's guideline and safety

standards such as those published by the National Fire

Protection Association (NFPA), the American Society for

Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code

authorities.

■ When cutting or drilling into wall or ceiling; do not damage

electrical wiring and other hidden utilities.

■ Ducted fans must always be vented outdoors.

CAUTION: For general ventilating use only. Do not use

to exhaust hazardous or explosive materials and vapors.

CAUTION: To reduce risk of fire and to properly exhaust

air, be sure to duct air outside - do not vent exhaust air into

spaces within walls or ceilings, attics or into crawl spaces,

or garages.

WARNING: TO REDUCE THE RISK OF FIRE, USE ONLY

METAL DUCTWORK.

WARNING: TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE:

■ Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

■ Always turn hood ON when cooking at high heat or when

flambeing food (i.e. Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flambé).

■ Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

■ Use proper pan size. Always use cookware appropriate for

the size of the surface element.

WARNING: TO REDUCE THE RISK OF INJURY TO

PERSONS IN THE EVENT OF A RANGE TOP GREASE

FIRE, OBSERVE THE FOLLOWING:

a

■ SMOTHER FLAMES with a close fitting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out

immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

■ NEVER PICK UP A FLAMING PAN - you may be burned.

■ DO NOT USE WATER, including wet dishcloths or towels -

a violent steam explosion will result.

■ Use an extinguisher ONLY if:

– You know you have a class ABC extinguisher, and you

already know how to operate it.

– The fire is small and contained in the area where it

started.

– The fire department is being called.

– You can fight the fire with your back to an exit.

a

Based on "Kitchen Fire Safety Tips" published by NFPA.

■ WARNING: To reduce the risk of fire or electrical shock,

do not use this fan with any solid-state speed control

device.

3

Page 4

INSTALLATION REQUIREMENTS

†®TORX and T20 are registered trademarks of Acument Intellectual Properties, LLC.

6"

(15.2 cm)

4" (10.2 cm)

10¹¹⁄₁₆"

(27.1 cm)

4" (10.2 cm)

6" (15.2 cm)

9⁵⁄₈"

(24.5 cm)

26" (66.0 cm)

12"

(30.5 cm)

Tools and Parts

Gather the required tools and parts before starting installation. Read

and follow the instructions provided with any tools listed here.

Tools needed

■ Drill

■ 1¼" (3.0 cm) drill bit

■ ¹⁄₈" (3.0 mm) drill bit

■ Pencil

■ Wire stripper or utility knife

■ Tape measure or ruler

■ Pliers

■ Caulking gun and weatherproof caulking compound

■ Vent clamps

■ Metal duct tape

■ Jigsaw or keyhole saw

■ Flat-blade screwdriver

■ Metal snips

■ Phillips screwdriver

■ 10" (25.4 mm) driver extension

Parts needed

■ ½" (13 mm) UL listed or CSA approved wiring conduit and

connector. The length of the conduit is determined by the

distance between the In-Line Smart Kit and the range hood.

■ 8 - 14 AWG wires, one of each of the following colors:

black, white, red, blue, gray, brown, yellow and green/yellow

(ground). The lengths of the wires are determined by the

distance between the In-Line Smart Kit and the range hood.

■ 3 - UL listed strain relief ½" (13 mm)

■ 6" (15.2 cm) round vent duct

■ 1 - T10 Torx

■ 1 - T20

■ 1 - Plastic wire clip

■ 4 - 5 x 45 mm mounting screws

■ 3 - 2.9 x 13 mm mounting screws

■ 1 - UL listed or CSA approved plastic strain reliefs

■ 1 - in-line housing

■ 1 - in-line base

■ 1 - in-line mounting bracket

■ 1 - Cover plate

■ 1 - UL listed or CSA approved wire clamp

®†

adapter

®

Tor x® adapter

Location Requirements

IMPORTANT: Observe all governing codes and ordinances. Have

a qualified technician install the In-Line Smart Kit.

All openings in the ceiling and wall where the In-Line Smart Kit

will be installed must be sealed.

For Mobile Home Installations

The installation of this in-line blower system must conform to the

Manufactured Home Construction Safety Standards, Title 24

CFR, Part 328 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD, Part 280) or when such

standard is not applicable, the standard for Manufactured Home

Installation 1982 (Manufactured Home Sites, Communities and

Setups) ANSI A225.1/NFPA 501A, or latest edition, or with local

codes.

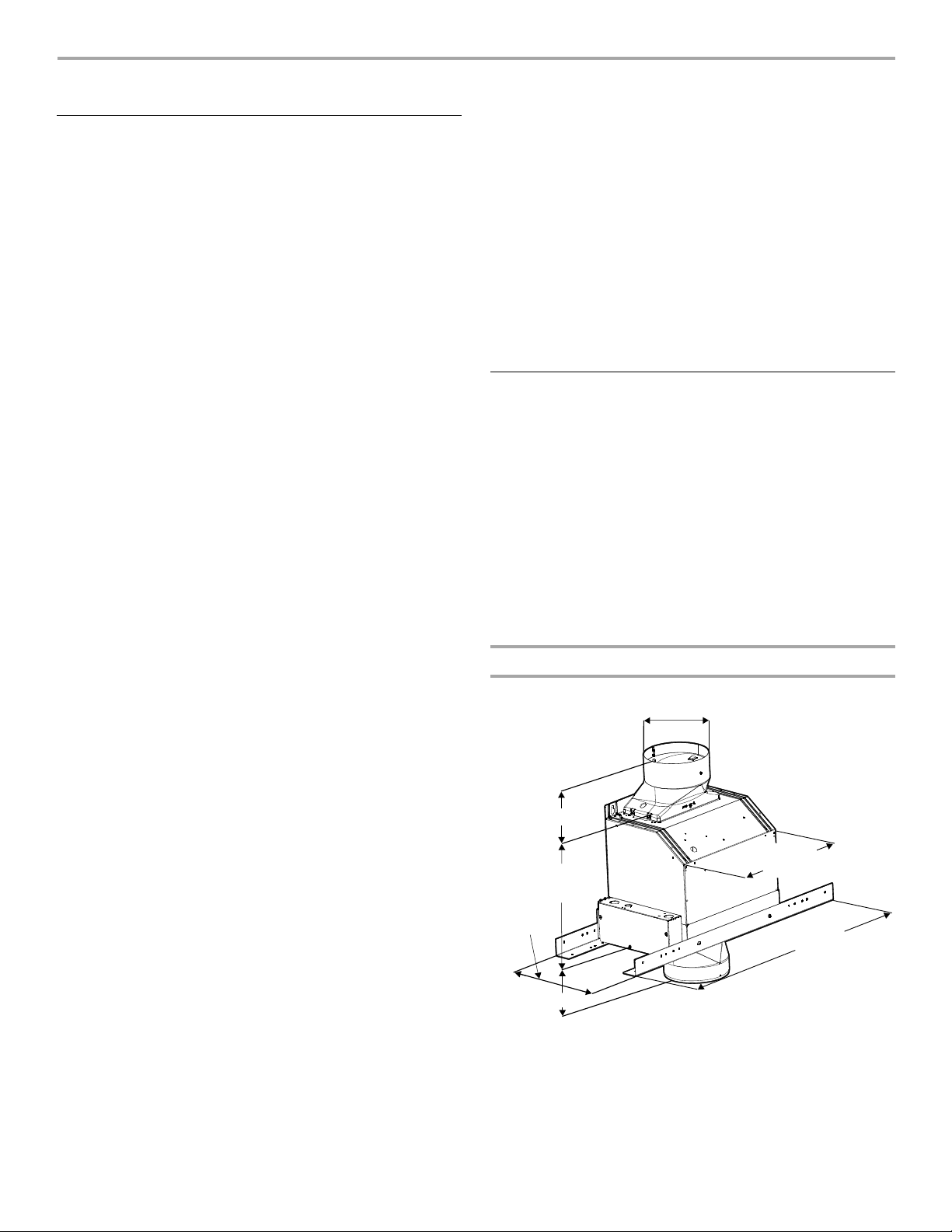

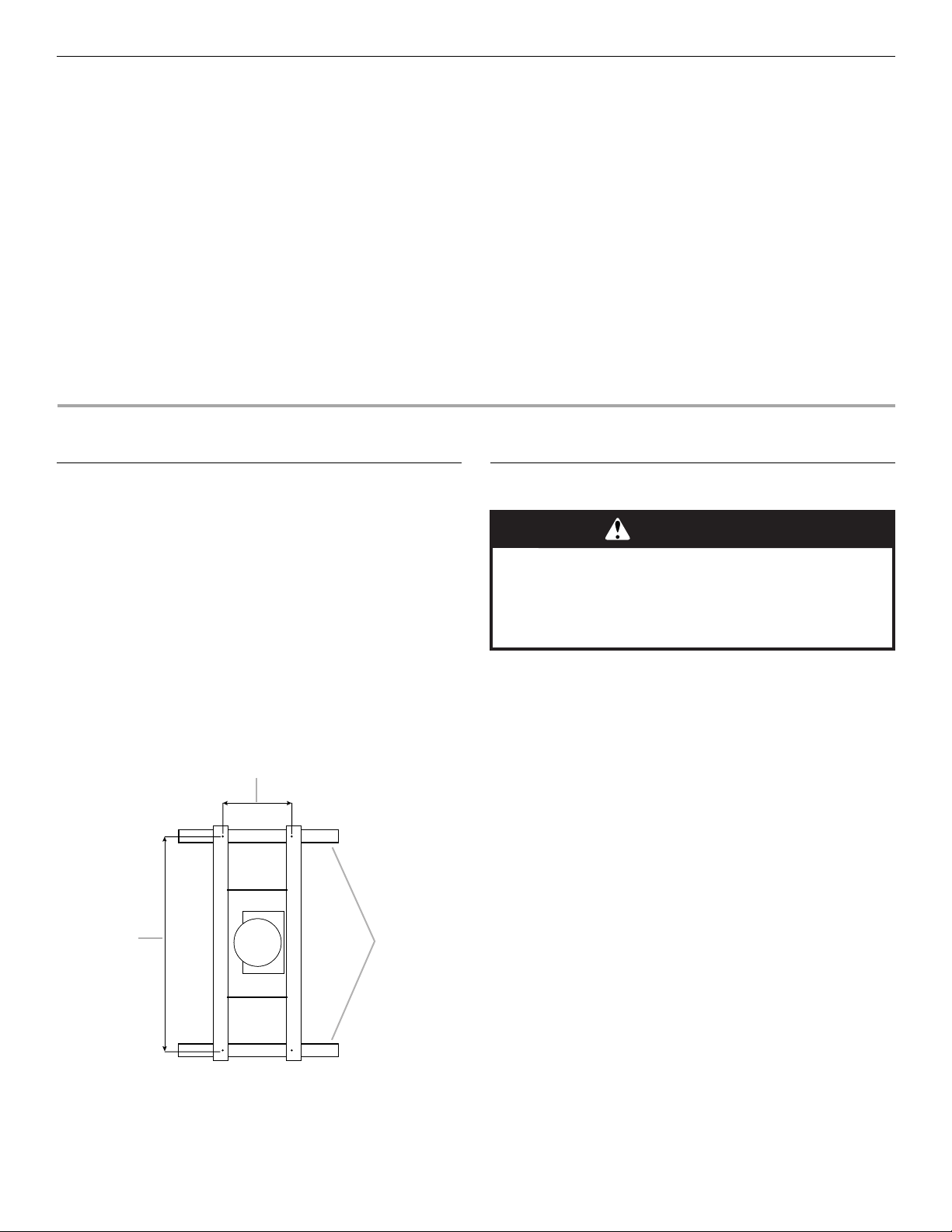

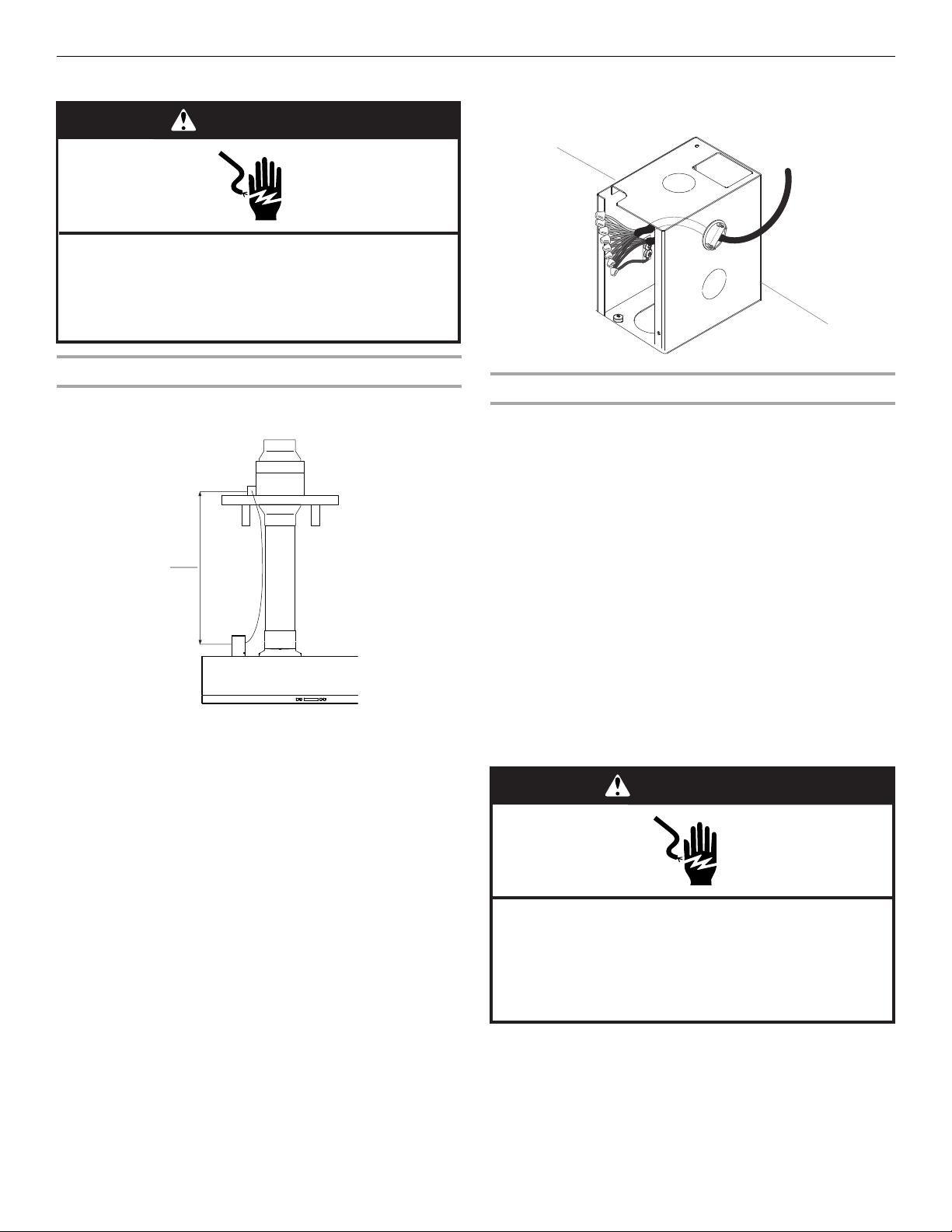

Product Dimensions

Parts supplied

Remove parts from packages. Check that all parts are included.

■ 1 - 6" (15.5 cm) vent transition without backdraft damper

■ 1 - 6" (15.5 cm) vent transition with backdraft damper

■ 4 - 3.5 x 6.5 mm mounting screws

■ 4 - 3.5 x 9.5 mm mounting screws

■ 1 - 9-pin pigtail electrical connector with 8 wire pigtail

■ 1 - Metal terminal box and cover

■ 16 - UL listed or CSA approved wire connectors

4

Page 5

Venting Requirements

A

B

90 elbow

6 ft (1.8 m)

2 ft

(0.6 m)

Wall cap

■ Vent system must terminate to the outdoors.

■ Do not terminate the vent system in an attic or other enclosed

area.

■ Do not use 4" (10.2 cm) laundry-type wall caps.

■ Use round, metal venting only. Rigid metal venting is

recommended. Plastic or metal foil venting is not

recommended.

■ The length of the vent system and the number of elbows

should be kept to a minimum to provide efficient

performance.

For the Most Efficient and Quiet Operation:

■ Use no more than three 90° elbows.

■ Make sure there is a minimum of 24" (61.0 cm) of straight

vent between the elbows if more than 1 elbow is used.

■ Do not install 2 elbows together.

■ Use clamps and metal duct tape to seal all joints in the vent

system.

■ The vent system must have a damper.

■ Use weatherproof caulking compound to seal the exterior

wall or roof opening around the cap.

■ The size of all venting should be uniform.

Cold Weather Installations

An additional back draft damper should be installed to minimize

backward cold air flow. A thermal break should be installed to

minimize conduction of outside temperatures as part of the vent

system. The damper should be on the cold air side of the thermal

break.

The break should be as close as possible to where the vent

system enters the heated portion of the house.

NOTE: Plywood may be used as a mounting base to span open

areas between ceiling joists and rafters. If used, be sure to use

plywood capable of supporting 25 Ib (11.3 kg).

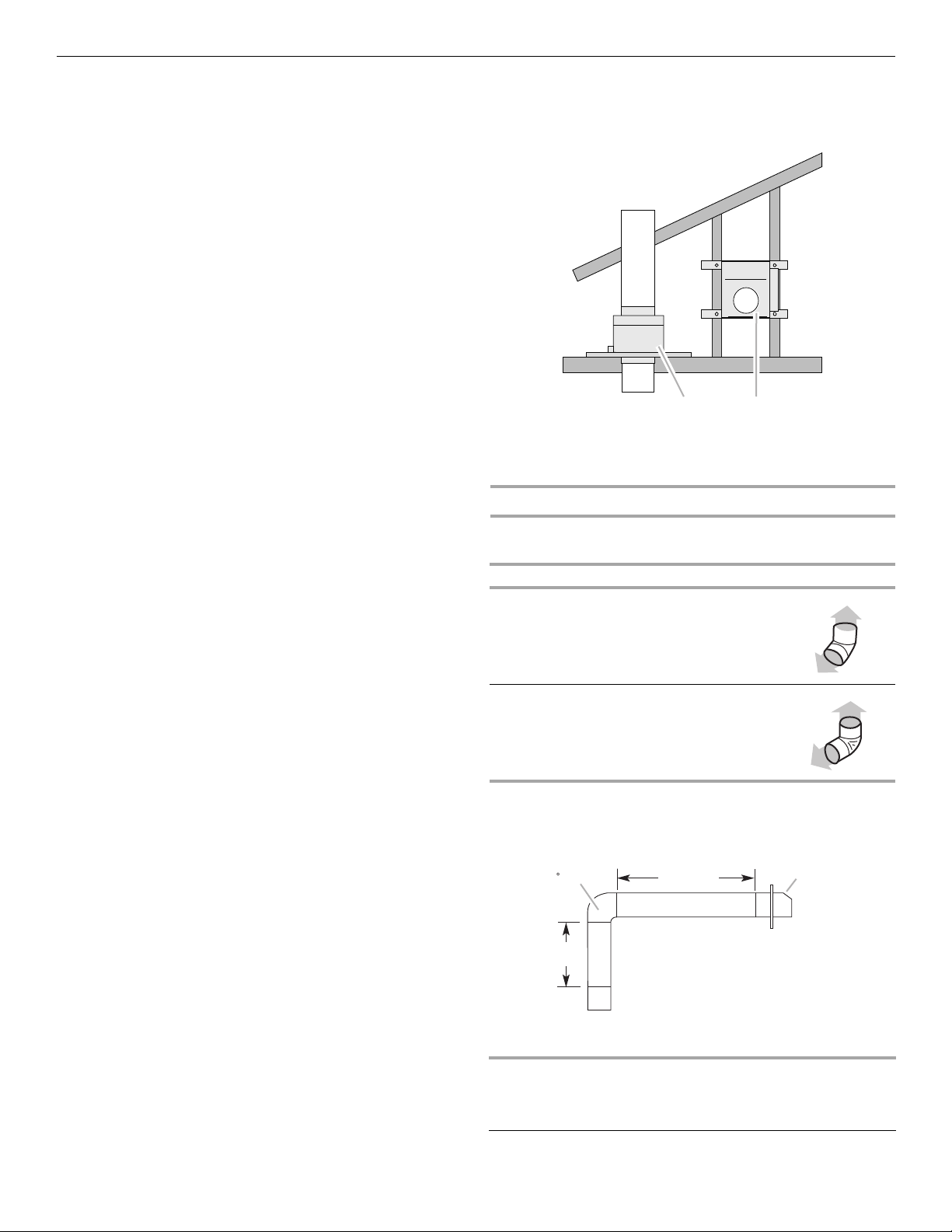

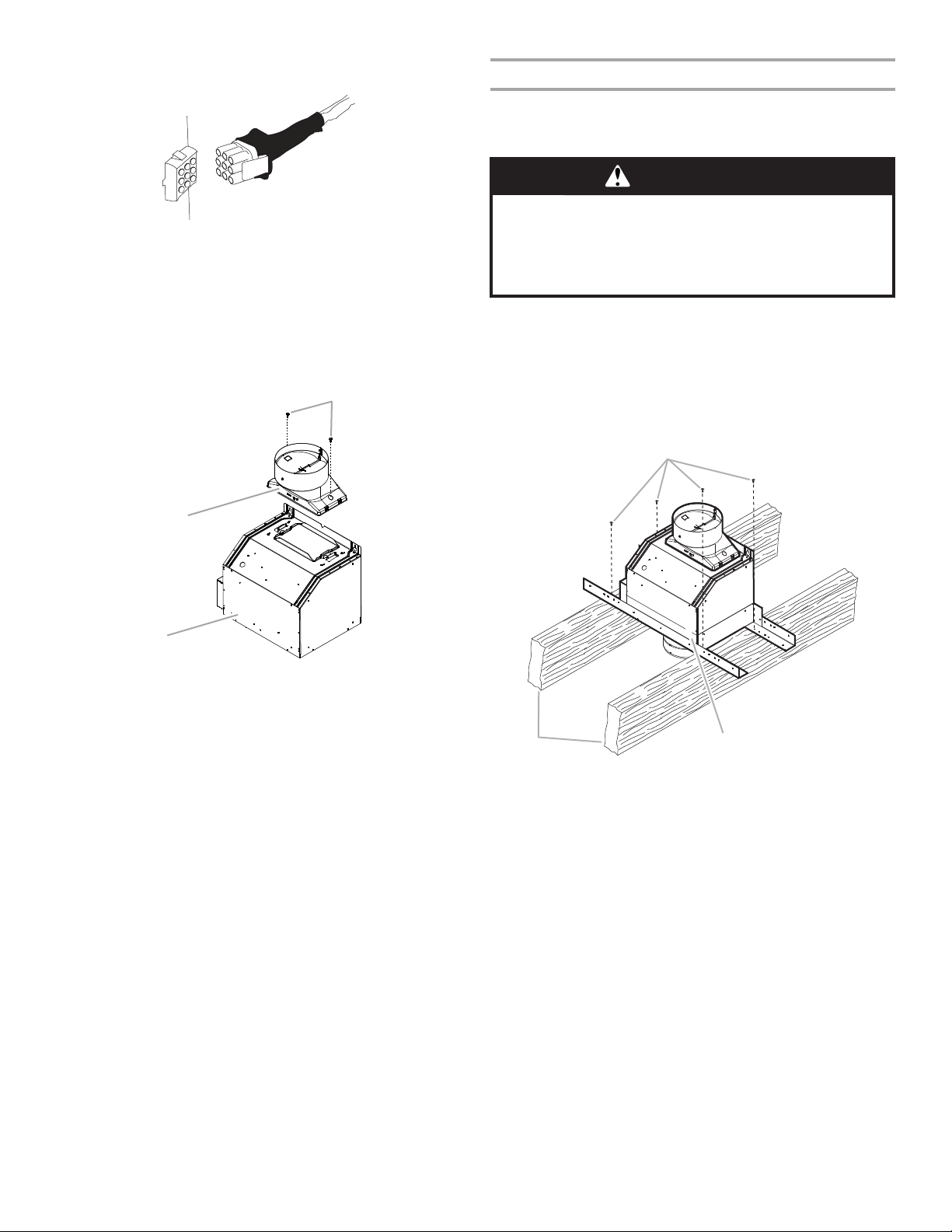

A. Mounted on top of ceiling joists (vertical duct)

B. Mounted to cross-members tied to trusses

(horizontal duct)

Calculating Vent System Length

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

Vent Piece 6" (15.2 cm) Round

45° elbow

2.5 ft

(0.8 m)

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements in your

area.

Typical In-Line Smart Kit Installations

A 6" (15.2 cm) round vent system is needed for installations (not

included).

The In-Line Smart Kit inlet and outlet openings are 6" (15.2 cm)

round. The exhaust (outlet) opening on the range hood must also

be 6" (15.2 cm) round.

NOTE: Flexible vent is not recommended. Flexible vents create

back pressure and air turbulence that can greatly reduce In-Line

Smart Kit performance.

The vent system may terminate either through the roof or wall.

90° elbow

5.0 ft

(1.5 m)

The maximum recommended equivalent vent length is 35 ft

(10.7 m).

Example Vent System

The following example falls within the maximum recommended

vent length of 35 ft (10.7 m).

1 - 90° elbow = 5.0 ft (1.5 m)

1 - wall cap = 0.0 ft (0.0 m)

8 ft (2.4 m) straight = 8.0 ft (2.4 m)

Length of system = 13.0 ft (3.9 m)

5

Page 6

Electrical Requirements

C

A

B

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

Observe all governing codes and ordinances.

Ensure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70 (latest

edition), or CSA Standards C22.1-94, Canadian Electrical Code,

Part 1 and C22.2 No. 0-M91 (latest edition) and all local codes

and ordinances.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

■ A 120 volt, 60 Hz., AC only, 15-amp, fused electrical circuit is

required.

INSTALLATION INSTRUCTIONS

■ If the house has aluminum wiring, follow the procedure

below:

1. Connect a section of solid copper wire to the pigtail

leads.

2. Connect the aluminum wiring to the added section of

copper wire using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer's recommended

procedure. Aluminum/copper connection must conform with

local codes and industry accepted wiring practices.

■ Wire sizes and connections must conform with the rating of

the appliance as specified on the model/serial rating plate.

The model/serial plate is located behind the filter on the rear

wall of the range hood.

■ Wire sizes must conform to the requirements of the National

Electrical Code, ANSI/NFPA 70 (latest edition), or CSA

Standards C22. 1-94, Canadian Electrical Code, Part 1 and

C22.2 No. 0-M91 (latest edition) and all local codes and

ordinances.

Prepare Location

CAUTION: To reduce the risk of fire and electrical shock, install

the In-Line Smart Kit only with the range hood model series listed

in these instructions.

■ Before cutting or drilling into the ceiling or walls, make sure

there is proper clearance within the ceiling or wall for the vent

system.

■ When cutting or drilling into the ceiling or wall, do not

damage electrical wiring on other hidden utilities.

■ Determine which venting method to use: roof, or wall.

■ The In-Line Smart Kit must be installed to a secure structure

of the roof, ceiling, wall, or floor. The In-Line Smart Kit may

also be installed into a new or existing frame construction.

The structure must be capable of supporting 25 Ib (11.3 kg).

The installation holes on the in-line mounting bracket to be

used to mount the In-Line Smart Kit to the structure.

Prepare In-Line Smart Kit

1. Using two or more people, move the In-Line Smart Kit and

the range hood to a workbench or work space.

2. Unpack all parts supplied with the In-line smart kit. Use the

“Tools and Parts” section of this manual to verify that all parts

have been included.

3. Remove the In-line-Smart assembly from the wooden

packaging material

NOTE: Do not move the In-Line Smart Kit to the mounting

location until the range hood blower motor has been installed in

the in-line housing. Do not install the range hood until the In-Line

Smart Kit and vent system have been installed.

IMPORTANT: Installation of the In-Line Smart Kit is model

specific. Before installing, determine the model number of the

range hood to be used with the In-Line Smart Kit. See the

appropriate “Install In-Line Smart Kit” section.

A. Distance between installation holes: 24" (61 cm),

19½" (49.2 cm), 18" (46.2 cm), and 14½" (36.8 cm)

6

B. Distance between installation holes: 7¾" (19.7 cm)

C. Mounting structure

Page 7

Install In-Line Smart Kit

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

C

B

A

A

C

B

A

B

C

D

D

KVWB40DS Series Range Hoods

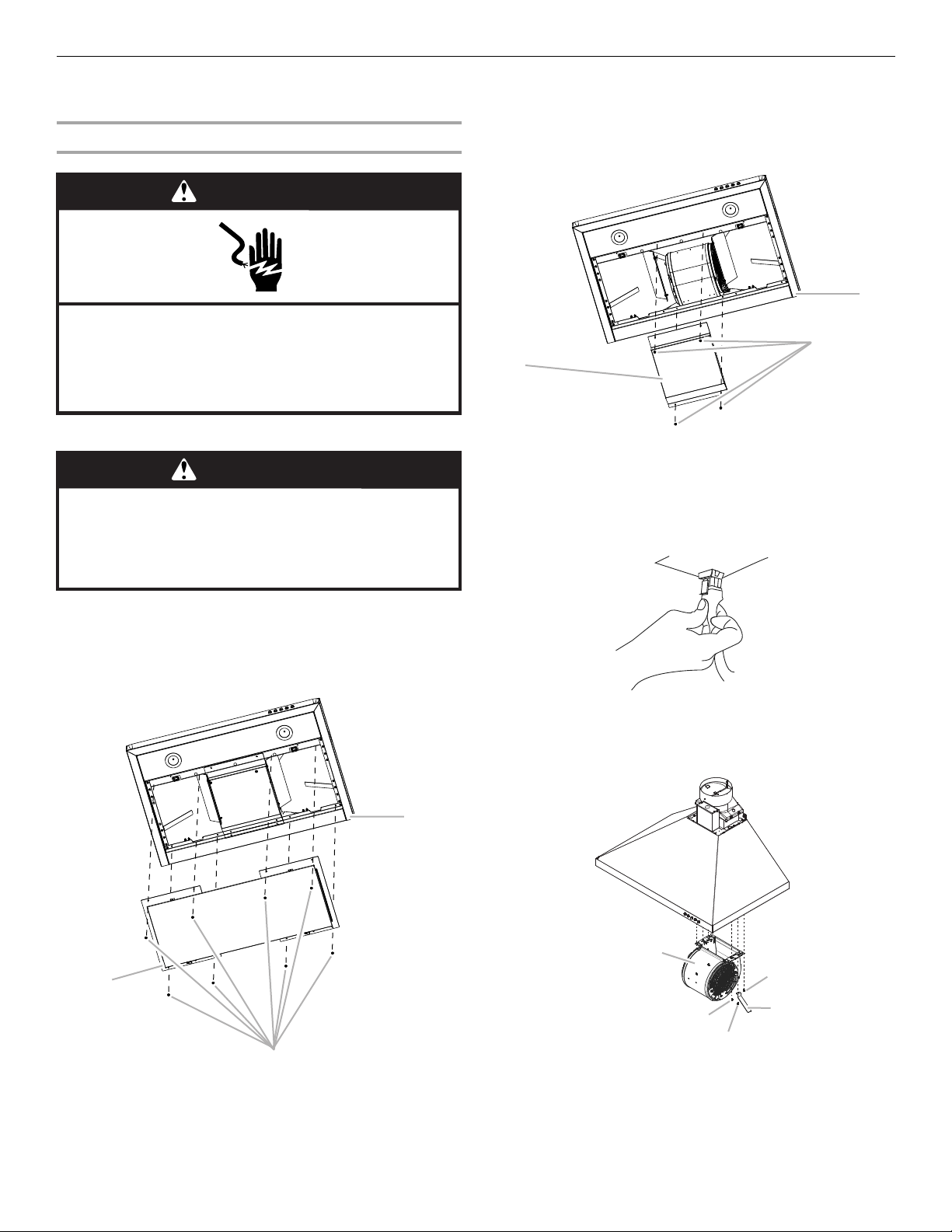

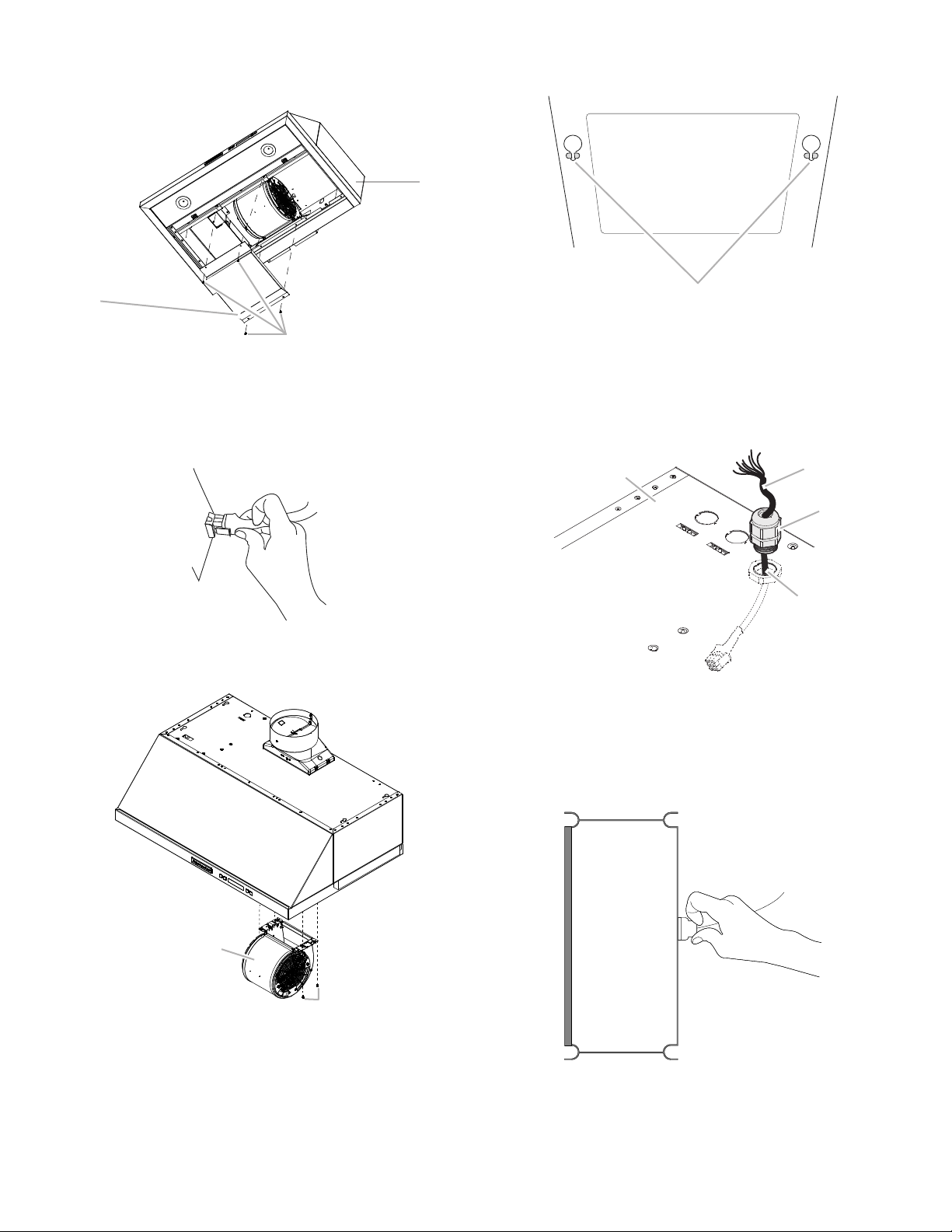

Remove Blower Motor from Range Hood Housing

4. Using the T10 Torx® adapter, remove the 4 screws from the

blower motor cover plate. Remove the cover plate from the

motor and set it aside.

1. Disconnect power.

2. Using two or more people, place the range hood on its back.

Be sure to set the range hood on a covered surface.

3. Using the T10 Torx® adapter, remove the 8 screws securing

the bottom panel to the range hood. Remove the bottom

panel and set it aside.

A. Blower motor cover plate

B. Screws (4)

C. Range hood

5.

Disconnect the blower motor from the range hood wiring. Press

the top and bottom clip of the 9-pin electrical connector to

disconnect.

6. Using the T20® Tor x® adapter with a long extension, remove

the 6 screws that secure the blower motor and insulation

retainers (2) to the range hood housing. Set the screws and

insulating retainers aside.

A. Bottom panel

B. Screws (8)

C. Range hood

A. Blower motor

B. Screws - insulation retainer (2)

C. Insulation retainers (2)

D. Screws - blower motor mounting (4)

7

Page 8

7. Push on the blower motor to disengage the two spring tabs

A

C

A

B

C

A

from the keyhole slots in the top of the range hood housing.

3. Install the vent transition without a backdraft damper to the

bottom of the in-line base. Use the T10 Torx

®

adapter and

install 2 - 3.5 x 9.5 mm mounting screws to secure the

transition to the base.

A. Keyhole slots

8. Remove the blower motor from the range hood housing and

set it aside.

9. Reinstall the 2 insulation retainers and 2 screws to the range

hood housing. Use the T20

®

Torx® adapter with a long

extension.

10. Reinstall the blower motor cover plate and bottom panel. Use

the T10 Torx

®

adapter and the screws previously removed.

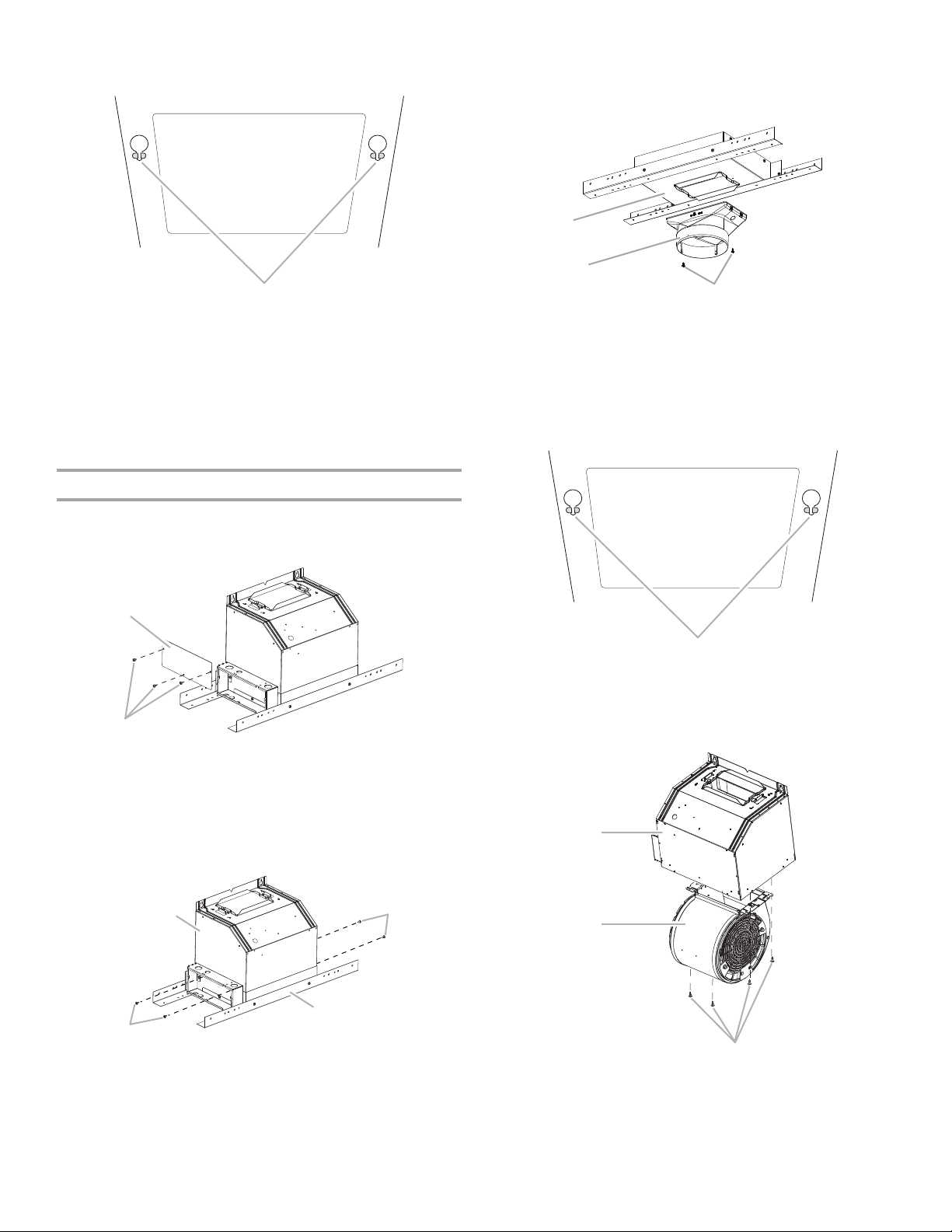

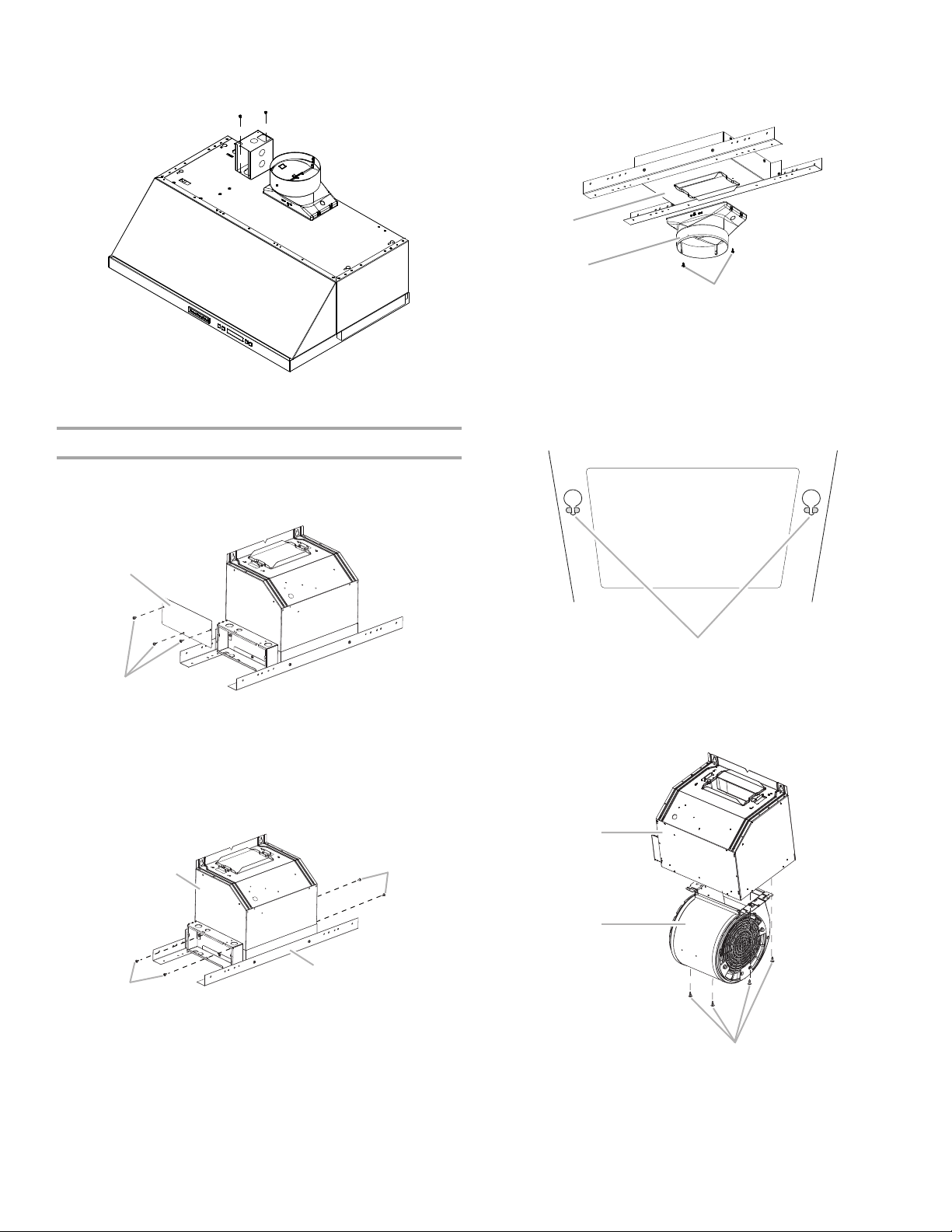

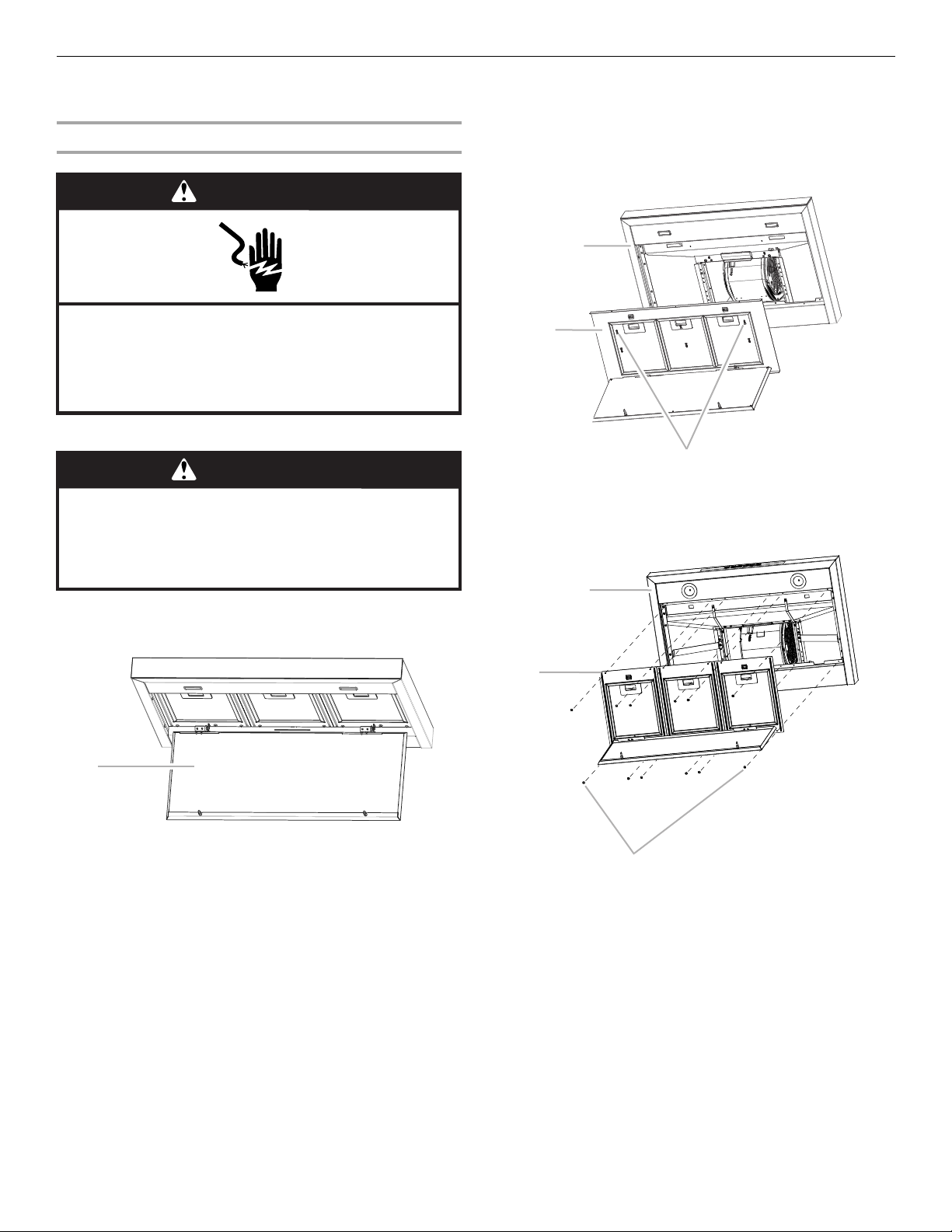

Assemble the In-Line Smart Kit

1. Using the T20® Tor x® adapter, remove the 3 screws from the

terminal box cover on the in-line housing. Set the screws and

cover aside.

A

B

A. Terminal box cover

B. Screws (3)

A. In-line base

B. Vent transition (without backdraft damper)

C. 3.5 x 9.5 mm screws (2)

4. Place the blower motor inside the in-line housing.

5.

Engage the blower motor spring tabs into the keyhole slots

located at the top of the in-line housing. Push the motor so the

spring tabs are secured into the small neck of the keyhole slots.

A. Keyhole slots

6. Locate the 4 screws removed from the blower motor. Use

these 4 screws to secure the motor to the in-line housing.

Tighten with the T20

®

Tor x® adapter.

2. Disassemble the in-line housing from the in-line base. Using

®

the T20

Torx® adapter, remove the 2 screws from inside the

terminal box near the top and the 2 screws located on the

opposite side. Lift the housing off the base and mounting

A

bracket.

A

B

B

C

A. In-line housing

B. In-line base

C. Screws (4)

A. In-line housing

B. Blower motor

C. Screws (4)

C

7. Place the in-line housing (with blower motor installed) near

8

the in-line base.

Page 9

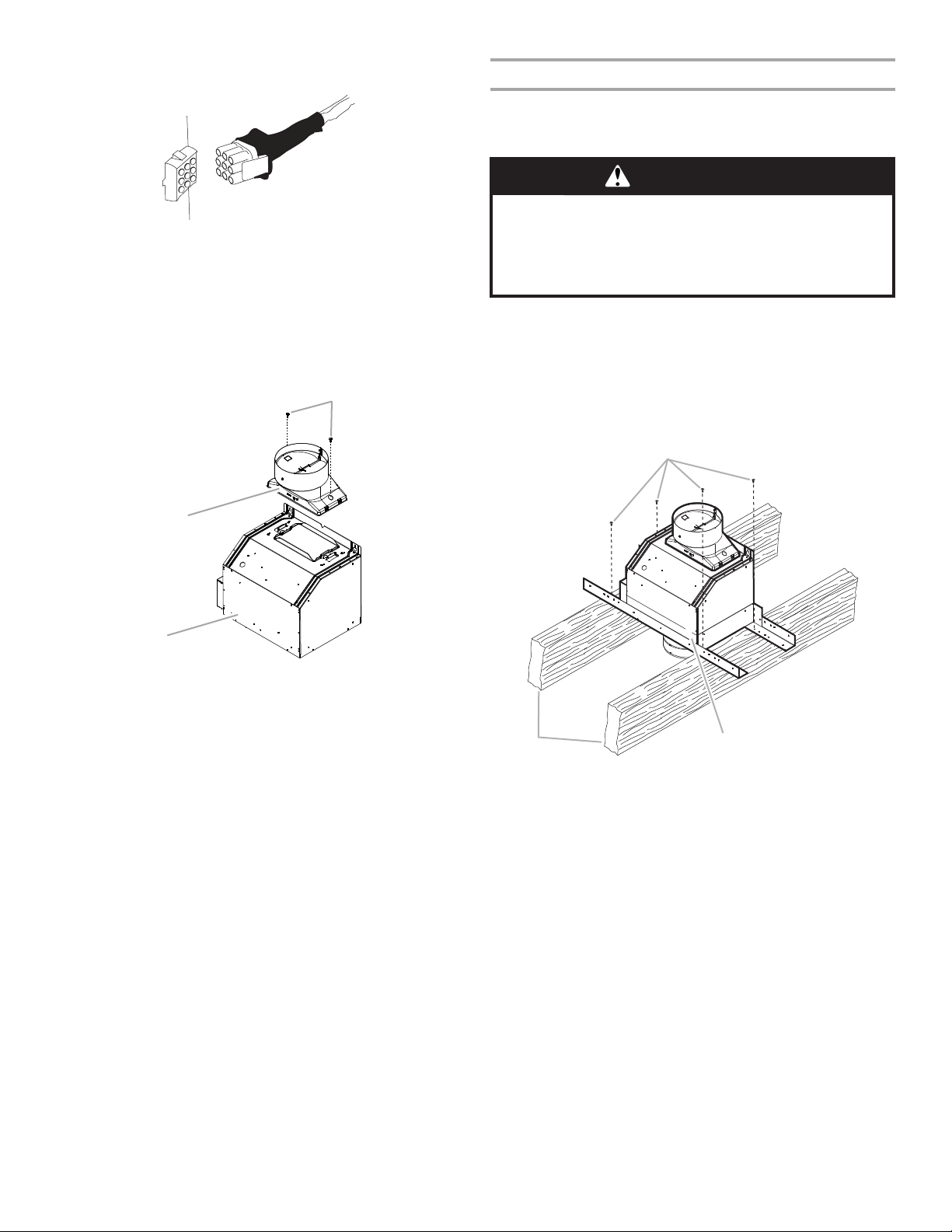

8. Connect the 9-pin connector from the blower motor to the

A

B

C

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

9-pin connector inside the in-line base.

9. Slide the in-line housing inside the in-line base. Align the

mounting holes in the in-line housing to the mounting holes in

the in-line base. Secure with the 4 screws removed when the

in-line housing was removed from the in-line base. Use the

®

T20

Tor x® adapter to secure the screws.

10. Install the vent transition with a backdraft damper to the top

of the in-line housing. Use the T10 Torx

®

adapter and install

2 - 3.5 x 9.5 mm mounting screws to secure the transition to

the housing

.

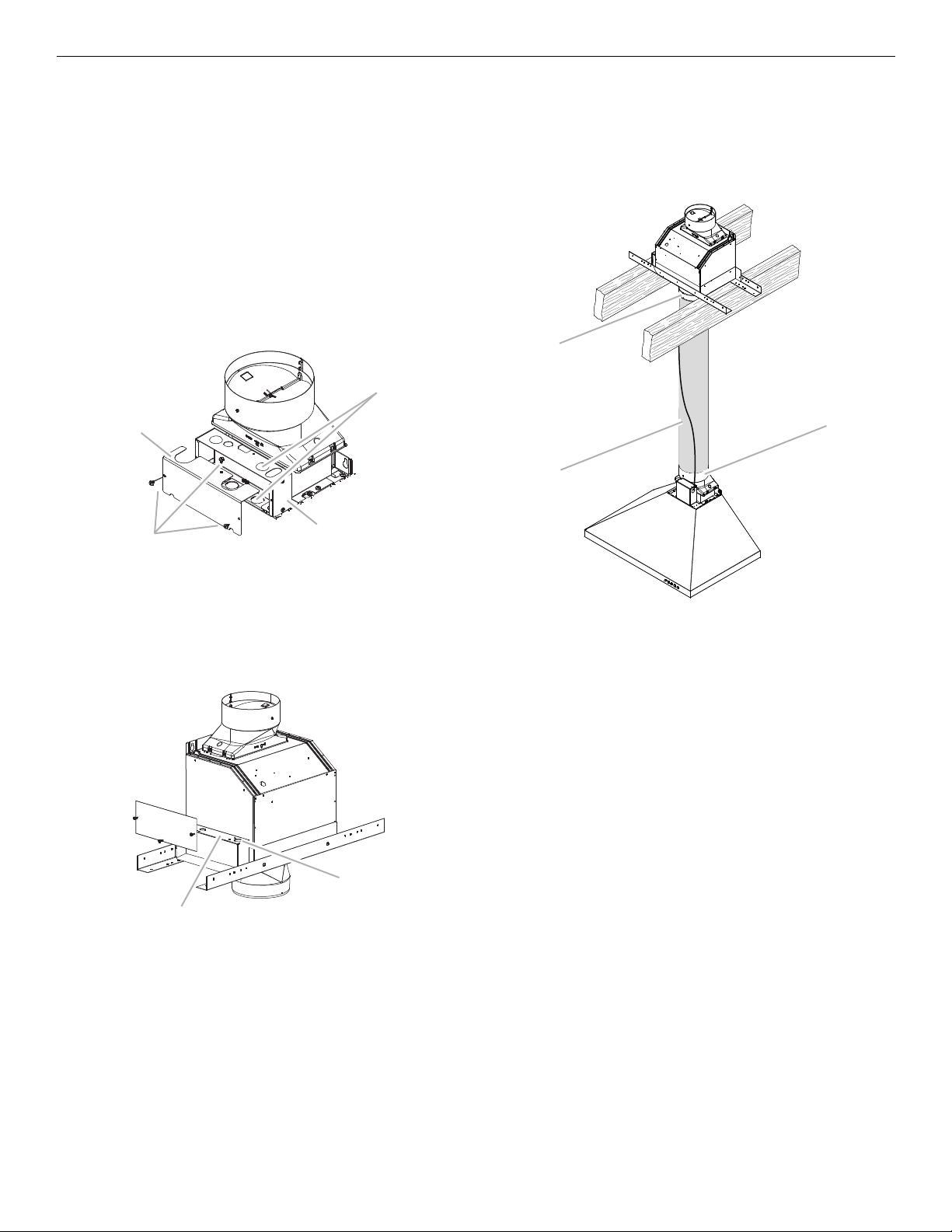

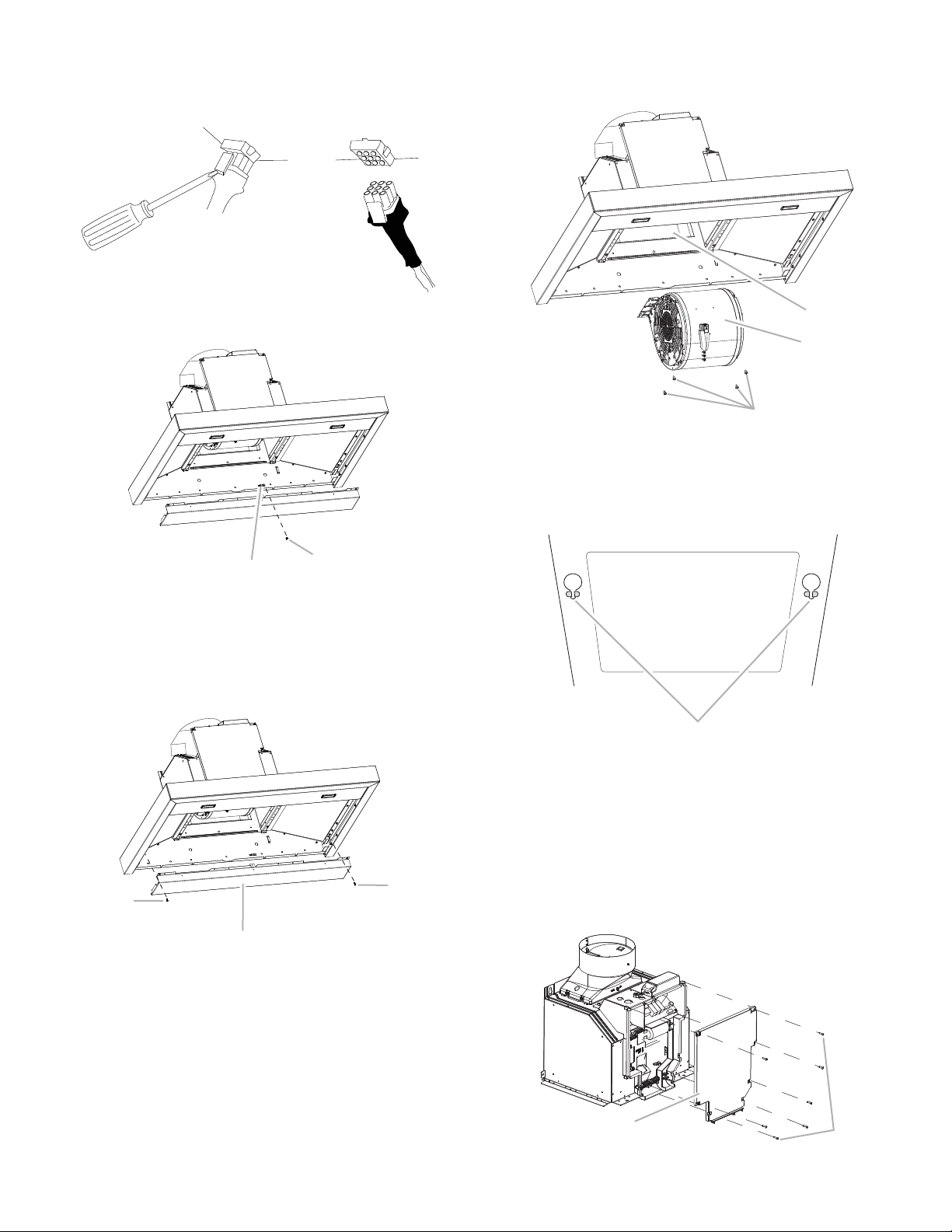

Install In-Line Smart Kit

The In-Line Smart Kit must be installed to a secure structure of

the roof, ceiling, wall, or floor. The In-Line Smart Kit may also be

installed into a new or existing frame construction.

1. Using two or more people, position the assembled In-Line

Smart Kit (housing, base and mounting bracket) in its final

mounting location.

2. Use a pencil to mark the location of the 4 mounting holes.

3. Drill 4 mounting pilot holes where marked.

4. Install the In-Line Smart assembly in its final location using

4 - 5 x 45 mm mounting screws mm screws.

A

A. In-line housing

B. Vent transition (with backdraft damper)

C. 3.5 x 9.5 mm screws (2)

B

A. 5 x 45 mm screws (4)

B. Secure structure (joist, rafters or trusses)

C. In-line smart assembly

C

9

Page 10

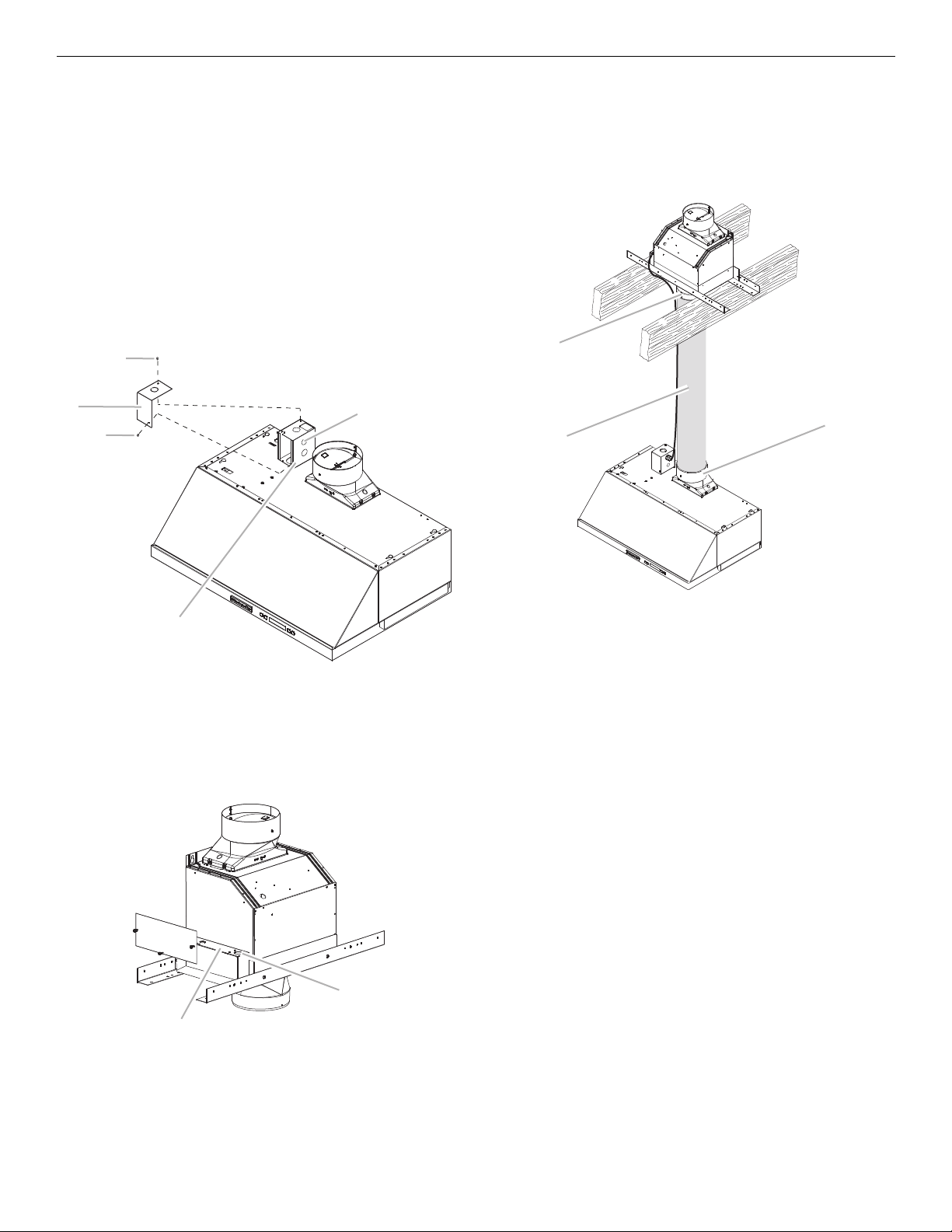

Complete Installation

A

D

C

B

A

B

A

B

C

Determine and make all necessary cuts and drill holes for the

vent system.

IMPORTANT: When cutting or drilling into the ceiling or wall, be

sure to not damage electrical wiring or other hidden utilities.

1. Install the range hood in its final location. Use the Installation

Instructions provided with the range hood.

2. Determine the location where the ¹⁄₂" (13 mm) wiring conduit

will be routed through the ceiling or wall to connect the InLine Smart Kit and the range hood.

3. Drill a 1¹⁄₄" (3.2 cm) hole(s) in this location.

4. Locate the terminal boxes on the In-Line Smart Kit and the

range hood.

5. Remove the terminal box cover on the range hood. Set the

cover and screws aside.

7. Install the UL listed or CSA approved strain reliefs (3) in the

range hood and In-Line Smart kit electrical knockouts.

8. Connect the vent system to the vent transition on the range

hood. Connect the vent system to the vent transition located

on the bottom In-Line Smart Kit. Use clamps and metal duct

tape to seal all joints.

A. Range hood terminal box cover

B. Electrical knockouts

C. Range hood terminal box

D. Screws (3)

6. Remove the electrical knockout from the In-Line Smart Kit (B,

see the following illustration) and the range hood terminal

A. Vent transition - in-line smart kit (bottom)

B. Vent system

C. Vent transition - range hood

box.

A. In-line smart kit terminal box

B. Electrical knockouts

10

Page 11

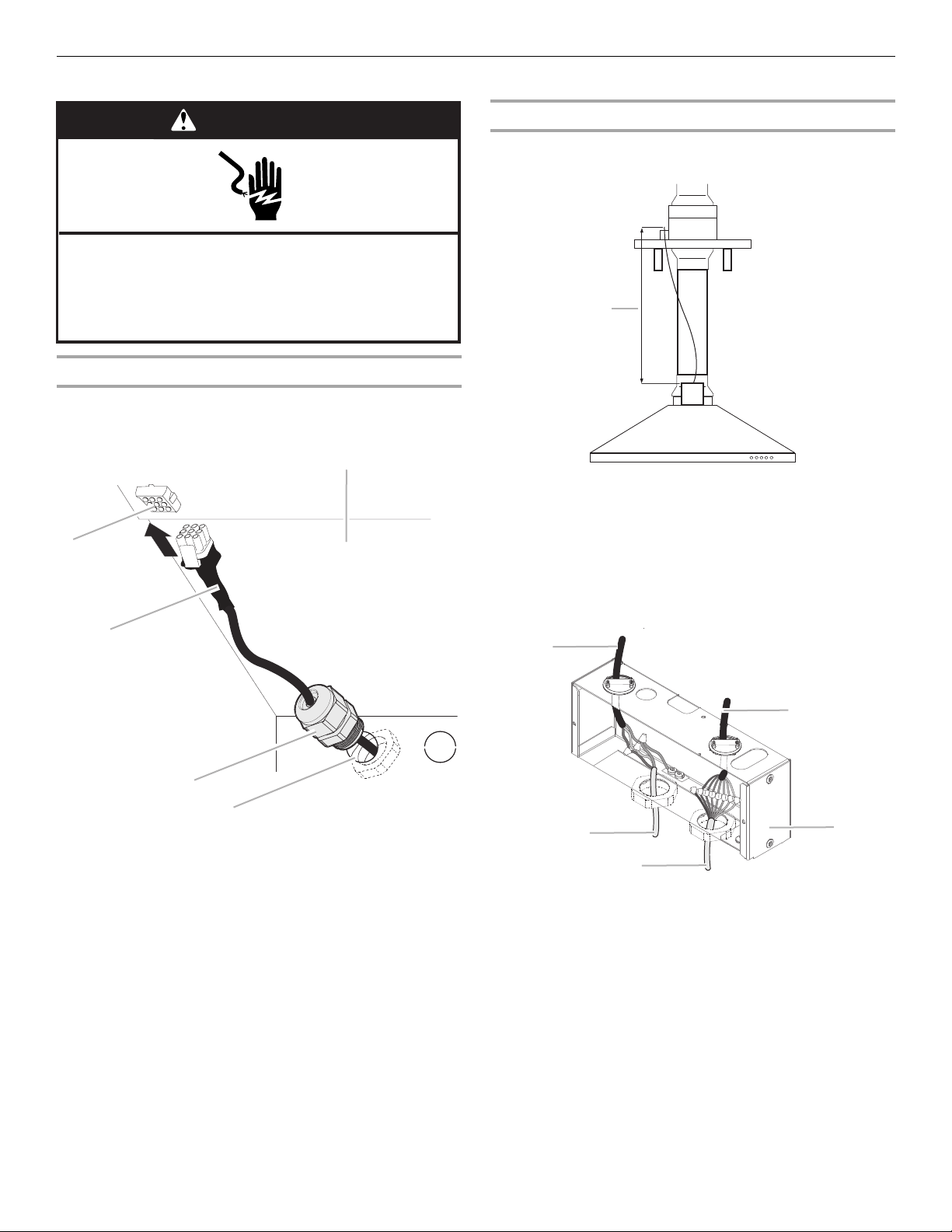

Make Electrical Connection

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

A

A

B

C

D

E

Connect Range Hood

1. Connect the 9-pin pigtail electrical connector provided with

the In-Line Smart Kit to the 9-pin electrical connector inside

the range hood.

E

A

B

Connect Range Hood and In-Line Smart Kit

1. Measure the distance between the In-Line Smart Kit and the

range hood terminal box.

A. Distance between in-line smart kit

and the range hood terminal box

2. Install 8 - 14 AWG wires with an insulating sleeve or conduit

between the terminal box and UL listed strain reliefs.

3. Connect together the set of 8 wires in the In-Line Smart Kit

terminal box.

4. Connect together the set of 8 wires in the range hood

terminal box.

C

D

A. 9-pin connector (range hood)

B. 9-pin pigtail electrical connector

C. Plastic strain relief

D. Electrical knockout

E. Range hood (inside)

A. Conduit and 8 - 14 AWG wires

B. Terminal box (range hood)

C. 9-pin pigtail electrical connector

D. Range hood power supply

E. Home power supply

11

Page 12

Connect In-Line Smart Kit

WARNING

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire

in terminal box.

Failure to do so can result in death or electrical shock.

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

B

C

A

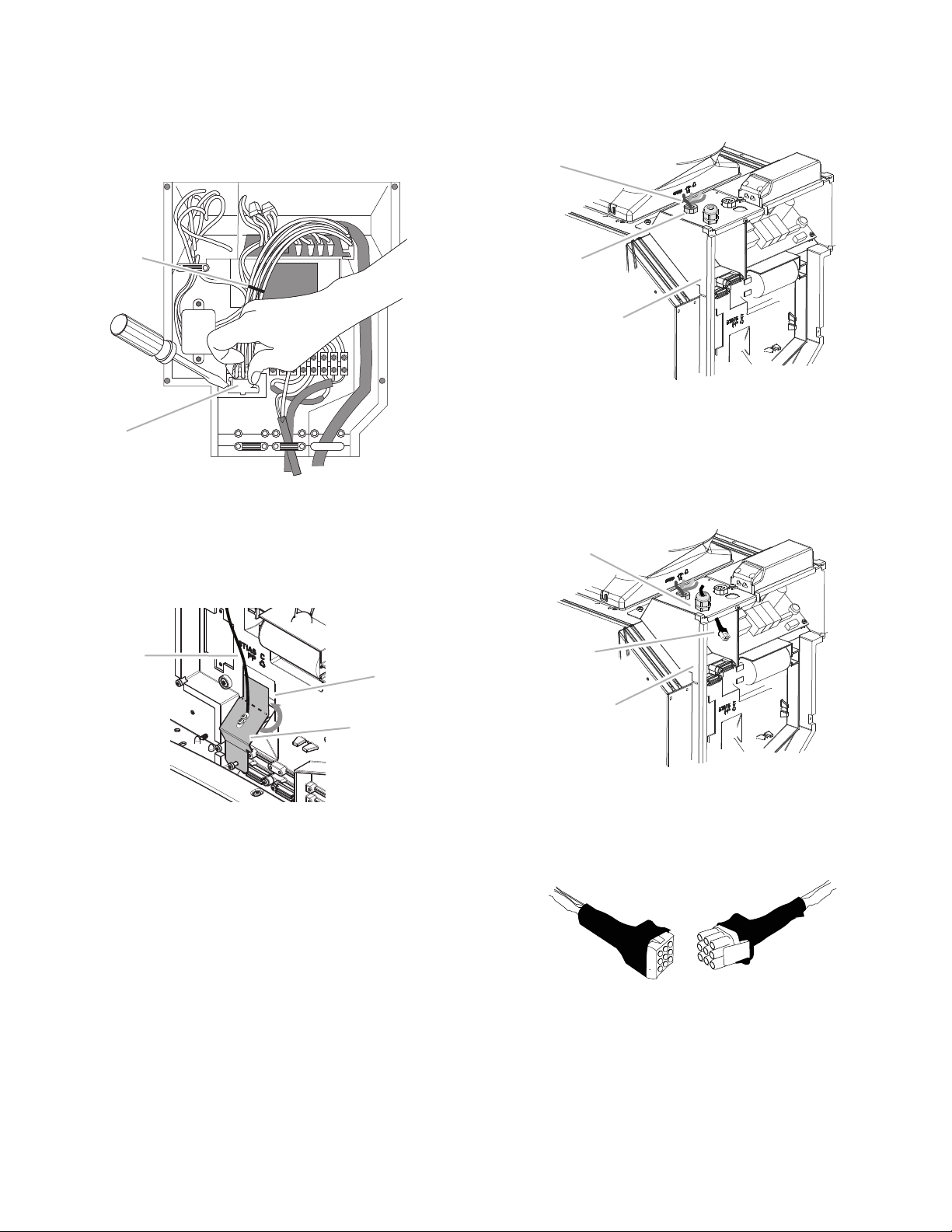

Electrical Connection In-Line Smart Kit

1. Use a UL listed or CSA approved wire connector to connect

the black wires together.

2. Use a UL listed or CSA approved wire connector to connect

the white wires together.

3. Use a UL listed or CSA approved wire connector to connect

the red wires together.

4. Use a UL listed or CSA approved wire connector to connect

the blue wires together.

5. Use a UL listed or CSA approved wire connector to connect

the gray wires together.

6. Use a UL listed or CSA approved wire connector to connect

the brown wires together.

7. Use a UL listed or CSA approved wire connector to connect

the yellow wires together.

8. Use a UL listed or CSA approved wire connector to connect

the green/yellow wires together.

9. Tighten the UL listed or CSA approved strain relief.

Install In-Line Smart Kit

KVUB60DS Series Range Hoods

NOTE: KVUB60DS series range hoods must be top vented for

installation with the In-Line Smart Kit.

Remove Blower Motor from Range Hood Housing

Electrical Connection Range Hood

10. Repeat all steps above to make the electrical connection in

the range hood terminal box.

11. Connect power supply wires together using the “Make

Electrical Connections” section in the range hood manual.

12. Reinstall the terminal box covers on the In-Line Smart Kit and

range hood.

13. Reconnect power.

3. Using the T10 Torx® adapter, remove the 8 screws securing

the bottom panel to the range hood. Remove the bottom

panel and set it aside.

1. Disconnect power.

2. Using two or more people, place the range hood on its back.

Be sure to set the range hood on a covered surface.

12

A. Bottom panel

B. Screws (8)

C. Range hood

Page 13

4. Using the T10 Torx® adapter, remove the 4 screws from the

C

B

A

B

A

A

C

blower motor cover plate. Remove the cover plate from the

motor and set it aside.

7. Push on the blower motor to disengage the 2 spring tabs

from the keyhole slots in the top of the range hood housing.

A. Keyhole slots

A. Blower motor cover plate

B. Screws (4)

C. Range hood

5.

Disconnect the blower motor from the range hood wiring. Press

the top and bottom clip of the 9-pin electrical connector to

disconnect.

6. Using the T20® Tor x® adapter with a long extension, remove

the 4 screws that secure the blower motor to the range hood

housing and set them aside.

8. Remove the blower motor from the range hood housing and

set it aside.

9. Remove the electrical knockout from the top of the range

hood and install 1 - UL listed or CSA approved plastic strain

relief. Run the 9-pin connector and pigtail wires through the

strain relief as shown.

A

B

D

A. Range hood (top)

B. 9-pin electrical connector (wires)

C. UL listed or CSA approved plastic

strain relief

D. Electrical knockout

10. Connect the 9-pin connector installed to the 9-pin connector

on the inside of the range hood electrical box.

A. Blower motor

B. Screws - blower motor mounting (4)

13

Page 14

11. Install the metal terminal box supplied with the In-Line Smart

C

A

B

C

A

Kit to the top of the range hood using 2 - 3.5 x 6.5 mm

mounting screws.

3. Install the vent transition without a backdraft damper to the

bottom of the in-line base. Use the T10 Torx

®

adapter and

install 2 - 3.5 x 9.5 mm mounting screws to secure the

transition to the base.

A. In-line base

B. Vent transition (without backdraft damper)

C. 3.5 x 9.5 mm screws (2)

12. Reinstall the blower motor cover plate and bottom panel. Use

the T10 Torx

®

adapter and the screws previously removed.

Assemble the In-Line Smart Kit

1. Using the T20® Tor x® adapter, remove the 3 screws from the

terminal box cover on the in-line housing. Set the screws and

cover aside.

A

B

A. Terminal box cover

B. Screws (3)

2. Disassemble the in-line housing from the in-line base. Using

®

the T20

Torx® adapter, remove the 2 screws from inside the

terminal box near the top and the 2 screws located on the

opposite side. Lift the housing off the base and mounting

bracket.

4. Place the blower motor inside the in-line housing.

5.

Engage the blower motor spring tabs into the keyhole slots

located at the top of the in-line housing. Push the motor so the

spring tabs are secured into the small neck of the keyhole slots.

A. Keyhole slots

6. Locate the 4 screws removed from the blower motor. Use

these 4 screws to secure the motor to the in-line housing.

Tighten with the T20

®

Tor x® adapter.

A

A

B

B

C

A. In-line housing

B. In-line base

C. Screws (4)

A. In-line housing

B. Blower motor

C. Screws (4)

C

7. Place the in-line housing (with blower motor installed) near

14

the in-line base.

Page 15

8. Connect the 9-pin connector from the blower motor to the

A

B

C

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

9-pin connector inside the in-line base.

9. Slide the in-line housing inside the in-line base. Align the

mounting holes in the in-line housing to the mounting holes in

the in-line base. Secure with the 4 screws removed when the

in-line housing was removed from the in-line base. Use the

®

T20

Tor x® adapter to secure the screws.

10. Install the vent transition with a backdraft damper to the top

of the in-line housing. Use the T10 Torx

®

adapter and install

2 - 3.5 x 9.5 mm mounting screws to secure the transition to

the housing

.

Install In-Line Smart Kit

The In-Line Smart Kit must be installed to a secure structure of

the roof, ceiling, wall, or floor. The In-Line Smart Kit may also be

installed into a new or existing frame construction.

1. Using two or more people, position the assembled In-Line

Smart Kit (housing, base and mounting bracket) in its final

mounting location.

2. Use a pencil to mark the location of the 4 mounting holes.

3. Drill 4 mounting pilot holes where marked.

4. Install the In-Line Smart assembly in its final location using

4 - 5 x 45 mm screws.

A

A. In-line housing

B. Vent transition (with backdraft damper)

C. 3.5 x 9.5 mm screws (2)

B

A. Mounting screws (4)

B. Secure structure (joist, rafters or trusses)

C. In-line smart assembly

C

15

Page 16

Complete Installation

A

B

B

C

D

A

B

A

B

C

Determine and make all necessary cuts and drill holes for the

vent system.

IMPORTANT: When cutting or drilling into the ceiling or wall, be

sure to not damage electrical wiring or other hidden utilities.

1. Install the range hood in its final location. Use the Installation

Instructions provided with the range hood.

2. Determine the location where the ¹⁄₂" (13 mm) wiring conduit

will be routed through the ceiling or wall to connect the InLine Smart Kit and the range hood.

3. Drill a 1¹⁄₄" (3.2 cm) hole(s) in this location.

4. Locate the terminal box on the In-Line Smart Kit and the

terminal box on the top of the range hood.

5. Remove the cover from the range hood terminal box. Set the

cover and screws aside.

7. Install the UL listed or CSA approved strain reliefs (3) in the

range hood and In-Line Smart kit electrical knockouts.

8. Connect the vent system to the vent transition on the range

hood. Connect the vent system to the vent transition located

on the bottom In-Line Smart Kit. Use clamps and metal duct

tape to seal all joints.

A. Vent transition - in-line smart kit (bottom)

B. Vent system

C. Vent transition - range hood

A. Terminal box cover

B. Screws (2)

C. Terminal box

D. Electrical knockout

6. Remove the electrical knockout from the In-Line Smart Kit (B,

see the following illustration) and the range hood terminal

box.

A. In-line smart kit terminal box

B. Electrical knockouts

16

Page 17

Make Electrical Connection

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

A

WARNING

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire

in terminal box.

Failure to do so can result in death or electrical shock.

Connect Range Hood and In-Line Smart Kit

1. Measure the distance between the In-Line Smart Kit and the

range hood terminal box.

A. Distance between in-line smart kit

and the range hood terminal box

2. Install 8 - 14 AWG wires with an insulating sleeve or conduit

between the terminal box and UL listed strain reliefs.

3. Connect together the set of 8 wires in the In-Line Smart Kit

terminal box.

4. Connect together the set of 8 wires in the range hood

terminal box.

Connect In-Line Smart Kit

Electrical Connection In-Line Smart Kit

1. Use a UL listed or CSA approved wire connector to connect

the black wires together.

2. Use a UL listed or CSA approved wire connector to connect

the white wires together.

3. Use a UL listed or CSA approved wire connector to connect

the red wires together.

4. Use a UL listed or CSA approved wire connector to connect

the blue wires together.

5. Use a UL listed or CSA approved wire connector to connect

the gray wires together.

6. Use a UL listed or CSA approved wire connector to connect

the brown wires together.

7. Use a UL listed or CSA approved wire connector to connect

the yellow wires together.

8. Use a UL listed or CSA approved wire connector to connect

the green/yellow wires together.

9. Tighten the UL listed or CSA approved strain relief.

Electrical Connection Range Hood

10. Repeat all steps above to make the electrical connection in

the range hood terminal box.

11. Connect power supply wires together using the “Make

Electrical Connections” section in the range hood manual.

12. Reinstall the terminal box cover on the In-Line Smart Kit and

range hood.

13. Reconnect power.

17

Page 18

Install In-Line Smart Kit

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

A

A

B

C

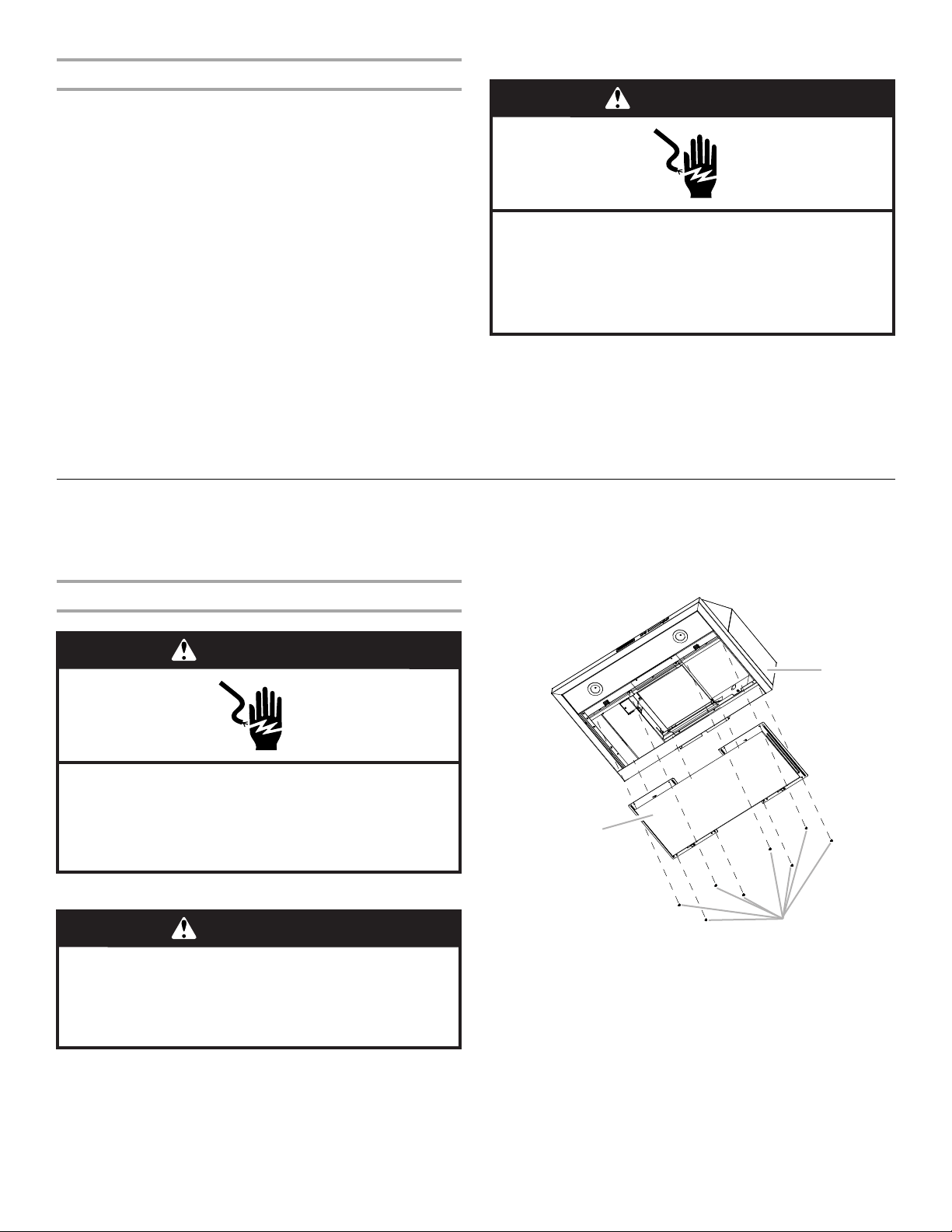

JXW85DS, JXI85DS, KVWB60DS, and KVIB60DS Series Range Hoods

Remove Blower Motor from Range Hood Housing

1. Disconnect power.

4. Using the T10 Torx® adapter remove the screws securing the

filter retainer panel to the range hood. See the following

illustrations for screw locations and numbers.

JXW85DS and JXI85DS Range Hoods

A

B

C

A. Range hood

B. Filter retainer panel

C. Screws (6)

2. Using two or more people, place the range hood on its back.

Be sure to set the range hood on a covered surface.

3. Open the stainless steel panel.

A. Stainless steel panel

KVWB60DS and KVIB60DS Range Hoods

A. Range hood

B. Filter retainer panel

C. Screws (12)

18

Page 19

5. Disconnect the blower motor from the range hood wiring.

B

A

A

A

B

A

B

C

A

A

B

Using a flat blade screwdriver, and press down on the top clip

of the 9-pin electrical connector while pressing the bottom

clip. Unplug the blower motor from the 9-pin connector.

6. Using the T10 Torx® adapter, remove the screw that secures

the temperature sensor to the bottom rear panel.

8. Using the T20® Tor x® adapter with a long extension, remove

the 4 screws that secure the blower motor to the range hood

housing and set them aside.

A. Range hood housing

B. Blower motor

C. Screws (4)

9. Push on the blower motor to disengage the 2 spring tabs

from the keyhole slots in the top of the range hood housing.

A. Temperature sensor

B. Sensor mounting screw

7. Using the T10 Torx® adapter, remove the 2 screws from the

bottom of the rear panel. Pull the bottom rear panel towards

the front of the range hood to disengage the spring tabs from

the bottom flange of the rear panel. Set the panel and screws

aside.

A. Bottom rear panel mounting screws

B. Bottom rear panel

A. Keyhole slots

10. Reinstall the bottom rear panel using the T10 Torx® adapter

and the 2 screws previously removed.

11.

Reinstall the temperature sensor to the bottom rear panel using

the T10 Torx

®

adapter and the screw previously removed.

12. Reinstall the filter retainer panel using the T10 Torx® adapter

and the screws previously removed.

13. Using the T10 Torx® adapter, remove the 7 screws securing

the plastic electrical box cover to the range hood. Remove

the cover and set it aside.

A. Plastic electrical box cover

B. Screws (7)

19

Page 20

14. Remove the 2 electrical knockouts from the top of the range

A

B

A

A

B

C

A

B

C

hood electrical box and install a UL listed or CSA approved

plastic strain relief into the front knockout.

15. Remove the 9-pin connector inside the range hood electrical

box. Insert a flat-blade screwdriver into the lateral clips while

removing the connector (see the following illustration).

16. Cut the wire tie that is closest to the 9-pin electrical connector.

A. Wire tie

B. 9-pin electrical connector (wires)

18. Run the 3 electrical power wires (black, white and green) and

the cover plate ground wire (green) through the small

electrical knockout in the top of the range hood electrical

box. Secure all 4 wires with 1 - UL listed or CSA approved

wire clamp. Snap the wire clamp into the electrical knockout.

A. Electrical power wires (4)

B. UL listed or CSA approved wire clamp

C. Range hood electrical box

19. Run the 9-pin pigtail electrical connector through the UL

listed or CSA approved strain relief.

NOTE: The 9-pin connector must be inside the range hood

electrical box.

17. Mount the cover plate supplied with the In-Line Smart Kit to

close the opening in the electrical box.

NOTE: Bend the cover plate along the perforation so it

conforms to the shape of the electrical box.

C

B

A. Opening

B. Cover plate

C. Cover plate ground wire

A. UL listed or CSA approved strain relief

B. 9-pin pigtail electrical connector

C. Range hood electrical box

20. Connect the 9-pin connector installed to the 9-pin connector

on the inside of the range hood electrical box.

20

21. Reinstall the plastic electrical box cover. Use the T10 Torx®

and the screws previously removed.

Page 21

22. Install the metal terminal box suppled with the In-Line Smart

A

B

C

C

A

B

C

A

Kit to the top of the range hood electrical box. Use

2 - 3.5 x 6.5 mm screws to secure the terminal box.

3. Install the vent transition without a backdraft damper to the

bottom of the in-line base. Use the T10 Torx

®

adapter and

install 2 - 3.5 x 9.5 mm mounting screws to secure the

transition to the base.

A. 3.5 x 6.5 mm screws (2)

B. Metal terminal box

C. Range hood electrical box

Assemble the In-Line Smart Kit

1. Using the T20® Tor x® adapter, remove the 3 screws from the

terminal box cover on the in-line housing. Set the screws and

cover aside.

A

B

A. Terminal box cover

B. Screws (3)

2. Disassemble the in-line housing from the in-line base. Using

®

the T20

Torx® adapter, remove the 2 screws from inside the

terminal box near the top and the 2 screws located on the

opposite side. Lift the housing off the base and mounting

bracket.

A. In-line base

B. Vent transition (without backdraft damper)

C. 3.5 x 9.5 mm screws (2)

4. Place the blower motor inside the in-line housing.

5.

Engage the blower motor spring tabs into the keyhole slots

located at the top of the in-line housing. Push the motor so the

spring tabs are secured into the small neck of the keyhole slots.

A. Keyhole slots

6. Locate the 4 screws removed from the blower motor. Use

these 4 screws to secure the motor to the in-line housing.

Tighten with the T20

®

Tor x® adapter.

A

B

A

B

C

A. In-line housing

B. In-line base

C. Screws (4)

A. In-line housing

B. Blower motor

C. Screws (4)

C

7. Place the in-line housing (with blower motor installed) near

the in-line base.

21

Page 22

8. Connect the 9-pin connector from the blower motor to the

A

B

C

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

9-pin connector inside the in-line base.

9. Slide the in-line housing inside the in-line base. Align the

mounting holes in the in-line housing to the mounting holes in

the in-line base. Secure with the 4 screws removed when the

in-line housing was removed from the in-line base. Use the

®

T20

Tor x® adapter to secure the screws.

10. Install the vent transition with a backdraft damper to the top

of the in-line housing. Use the T10 Torx

®

adapter and install

2 - 3.5 x 9.5 mm mounting screws to secure the transition to

the housing

.

Install In-Line Smart Kit

The In-Line Smart Kit must be installed to a secure structure of

the roof, ceiling, wall, or floor. The In-Line Smart Kit may also be

installed into a new or existing frame construction.

1. Using two or more people, position the assembled In-Line

Smart Kit (housing, base and mounting bracket) in its final

mounting location.

2. Use a pencil to mark the location of the 4 mounting holes.

3. Drill 4 mounting pilot holes where marked.

4. Install the In-Line Smart assembly in its final location using

4 - 5 x 45 mm screws.

A

A. In-line housing

B. Vent transition (with backdraft damper)

C. 3.5 x 9.5 mm screws (2)

B

A. Mounting screws (4)

B. Secure structure (joist, rafters or trusses)

C. In-line smart assembly

C

22

Page 23

Complete Installation

A

B

A

B

A

B

C

Determine and make all necessary cuts and drill holes for the

vent system.

IMPORTANT: When cutting or drilling into the ceiling or wall, be

sure to not damage electrical wiring or other hidden utilities.

1. Install the range hood in its final location. Use the Installation

Instructions provided with the range hood.

2. Determine the location where the ¹⁄₂" (13 mm) wiring conduit

will be routed through the ceiling or wall to connect the InLine Smart Kit and the range hood.

3. Drill a 1¹⁄₄" (3.2 cm) hole(s) in this location.

4. Locate the terminal box on the In-Line Smart Kit and the

electrical box on the range hood

5. Remove the electrical knockout from the In-Line Smart Kit (B,

see the following illustration) and the range hood terminal

box.

7. Connect the vent system to the vent transition on the range

hood. Connect the vent system to the vent transition located

on the bottom In-Line Smart Kit. Use clamps and metal duct

tape to seal all joints.

A. Vent transition - in-line smart kit (bottom)

A. In-line smart kit terminal box

B. Electrical knockouts

B. Vent system

C. Vent transition - range hood

6. Remove the 2 electrical knockouts on the side of the terminal

box installed on the range hood.

A. Metal terminal box (range hood)

B. Electrical knockouts (2)

23

Page 24

Make Electrical Connection

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire

in terminal box.

Failure to do so can result in death or electrical shock.

Connect Range Hood and In-Line Smart Kit

1. Install the UL listed or CSA approved strain reliefs (3) in the

range hood and In-Line Smart Kit electrical knockouts.

2. Measure the distance between the In-Line Smart Kit and the

range hood terminal box.

A

5. Connect together the set of 8 wires in the range hood

terminal box.

Connect In-Line Smart Kit

Electrical Connection In-Line Smart Kit

1. Use a UL listed or CSA approved wire connector to connect

the black wires together.

2. Use a UL listed or CSA approved wire connector to connect

the white wires together.

3. Use a UL listed or CSA approved wire connector to connect

the red wires together.

4. Use a UL listed or CSA approved wire connector to connect

the blue wires together.

5. Use a UL listed or CSA approved wire connector to connect

the gray wires together.

6. Use a UL listed or CSA approved wire connector to connect

the brown wires together.

7. Use a UL listed or CSA approved wire connector to connect

the yellow wires together.

8. Use a UL listed or CSA approved wire connector to connect

the green/yellow wires together.

9. Tighten the UL listed or CSA approved strain relief.

Electrical Connection Range Hood

A. Distance between in-line smart kit

and the range hood terminal box

3. Install 8 - 14 AWG wires with an insulating sleeve or conduit

between the terminal box and UL listed strain reliefs.

4. Connect together the set of 8 wires in the In-Line Smart Kit

terminal box.

24

10. Repeat all steps above to make the electrical connection in

the range hood terminal box.

11. Connect power supply wires together using the “Make

Electrical Connections” section in the range hood manual.

12. Reinstall the terminal box cover on the In-Line Smart Kit and

reinstall the electrical box cover on the range hood.

13. Reconnect power.

Page 25

Install In-Line Smart Kit

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

A

A

B

A

B

WVW75UC and WV175UC Series Range Hoods

Remove Blower Motor from Range Hood Housing

1. Disconnect power.

5. Remove the 2 screws securing the insulating retainer to the

blower motor and set them aside.

6. Disconnect the blower motor from the range hood wiring.

Using a flat blade screwdriver, and press down on the top clip

of the 9-pin electrical connector while pressing the bottom

clip. Unplug the blower motor from the 9-pin connector.

7. Using the T20® Tor x® adapter with a long extension, remove

the 4 screws, 4 steel washers and 4 rubber washers that

secure the blower motor to the range hood housing and set

them aside.

2. Using two or more people, place the range hood on its back.

Be sure to set the range hood on a covered surface.

3.

Open the stainless steel panel. Grasp panel at the left corners

and pull down to disengage the 2 catch pins from the spring

catches. The panel is attached at the right and will rotate down.

4. Remove the metal grease filter by pulling the spring release

handle and then pulling down the filter.

A. Blower motor

B. Screws, steel washers, and

rubber washers(4)

8. Using the T10 Torx® adapter, remove the 7 screws securing

the plastic electrical box cover to the range hood. Remove

the cover and set it aside.

A. Plastic electrical box cover

B. Screws (7)

A. Spring release handle

25

Page 26

9. Remove the 2 electrical knockouts from the top of the range

A

B

A

A

B

C

A

B

C

hood electrical box and install a UL listed or CSA approved

plastic strain relief into the front knockout.

10. Remove the 9-pin connector inside the range hood electrical

box. Insert a flat-blade screwdriver into the lateral clips while

removing the connector (see the following illustration).

11. Cut the wire tie that is closest to the 9-pin electrical connector.

A. Wire tie

B. 9-pin electrical connector (wires)

13. Run the 3 electrical power wires (black, white and green) and

the cover plate ground wire (green) through the small

electrical knockout in the top of the range hood electrical

box. Secure all 4 wires with 1 - UL listed or CSA approved

wire clamp. Snap the wire clamp into the electrical knockout.

A. Electrical power wires (4)

B. UL listed or CSA approved wire clamp

C. Range hood electrical box

14. Run the 9-pin pigtail electrical connector through the UL

listed or CSA approved strain relief.

NOTE: The 9-pin connector must be inside the range hood

electrical box.

12. Mount the cover plate supplied with the In-Line Smart Kit to

close the opening in the electrical box.

NOTE: Bend the cover plate along the perforation so it

conforms to the shape of the electrical box.

C

B

A. Opening

B. Cover plate

C. Cover plate ground wire

A. UL listed or CSA approved strain relief

B. 9-pin pigtail electrical connector

C. Range hood electrical box

15. Connect the 9-pin connector installed to the 9-pin connector

on the inside of the range hood electrical box.

26

16. Reinstall the plastic electrical box cover. Use the T10 Torx®

and the screws previously removed.

Page 27

17. Install the metal terminal box suppled with the In-Line Smart

A

B

C

C

A

B

C

A

Kit to the top of the range hood electrical box. Use

2 - 3.5 x 6.5 mm screws to secure the terminal box.

3. Install the vent transition without a backdraft damper to the

bottom of the in-line base. Use the T10 Torx

®

adapter and

install 2 - 3.5 x 9.5 mm mounting screws to secure the

transition to the base.

A. 3.5 x 6.5 mm screws (2)

B. Metal terminal box

C. Range hood electrical box

Assemble the In-Line Smart Kit

1. Using the T20® Tor x® adapter, remove the 3 screws from the

terminal box cover on the in-line housing. Set the screws and

cover aside.

A

B

A. Terminal box cover

B. Screws (3)

2. Disassemble the in-line housing from the in-line base. Using

®

the T20

Torx® adapter, remove the 2 screws from inside the

terminal box near the top and the 2 screws located on the

opposite side. Lift the housing off the base and mounting

bracket.

A. In-line base

B. Vent transition (without backdraft damper)

C. 3.5 x 9.5 mm screws (2)

4. Place the blower motor inside the in-line housing.

5.

Engage the blower motor spring tabs into the keyhole slots

located at the top of the in-line housing. Push the motor so the

spring tabs are secured into the small neck of the keyhole slots.

A. Keyhole slots

6. Locate the 4 screws removed from the blower motor. Use

these 4 screws to secure the motor to the in-line housing.

Tighten with the T20

®

Tor x® adapter.

A

B

A

B

C

A. In-line housing

B. In-line base

C. Screws (4)

A. In-line housing

B. Blower motor

C. Screws (4)

C

7. Place the in-line housing (with blower motor installed) near

the in-line base.

27

Page 28

8. Connect the 9-pin connector from the blower motor to the

A

B

C

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

9-pin connector inside the in-line base.

9. Slide the in-line housing inside the in-line base. Align the

mounting holes in the in-line housing to the mounting holes in

the in-line base. Secure with the 4 screws removed when the

in-line housing was removed from the in-line base. Use the

®

T20

Tor x® adapter to secure the screws.

10. Install the vent transition with a backdraft damper to the top

of the in-line housing. Use the T10 Torx

®

adapter and install

2 - 3.5 x 9.5 mm mounting screws to secure the transition to

the housing

.

Install In-Line Smart Kit

The In-Line Smart Kit must be installed to a secure structure of

the roof, ceiling, wall, or floor. The In-Line Smart Kit may also be

installed into a new or existing frame construction.

1. Using two or more people, position the assembled In-Line

Smart Kit (housing, base and mounting bracket) in its final

mounting location.

2. Use a pencil to mark the location of the 4 mounting holes.

3. Drill 4 mounting pilot holes where marked.

4. Install the In-Line Smart assembly in its final location using

4 - 5 x 45 mm screws.

A

A. In-line housing

B. Vent transition (with backdraft damper)

C. 3.5 x 9.5 mm screws (2)

B

A. Mounting screws (4)

B. Secure structure (joist, rafters or trusses)

C. In-line smart assembly

C

28

Page 29

Complete Installation

A

B

A

B

A

B

C

Determine and make all necessary cuts and drill holes for the

vent system.

IMPORTANT: When cutting or drilling into the ceiling or wall, be

sure to not damage electrical wiring or other hidden utilities.

1. Install the range hood in its final location. Use the Installation

Instructions provided with the range hood.

2. Determine the location where the ¹⁄₂" (13 mm) wiring conduit

will be routed through the ceiling or wall to connect the InLine Smart Kit and the range hood.

3. Drill a 1¹⁄₄" (3.2 cm) hole(s) in this location.

4. Locate the terminal box on the In-Line Smart Kit and the

electrical box on the range hood

5. Remove the electrical knockout from the In-Line Smart Kit (B,

see the following illustration) and the range hood terminal

box.

7. Connect the vent system to the vent transition on the range

hood. Connect the vent system to the vent transition located

on the bottom In-Line Smart Kit. Use clamps and metal duct

tape to seal all joints.

A. Vent transition - in-line smart kit (bottom)

B. Vent system

C. Vent transition - range hood

A. In-line smart kit terminal box

B. Electrical knockouts

6. Remove the 2 electrical knockouts on the side of the terminal

box installed on the range hood.

A. Metal terminal box (range hood)

B. Electrical knockouts (2)

29

Page 30

Make Electrical Connection

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire

in terminal box.

Failure to do so can result in death or electrical shock.

Connect Range Hood and In-Line Smart Kit

1. Install the UL listed or CSA approved strain reliefs (3) in the

range hood and In-Line Smart Kit electrical knockouts.

2. Measure the distance between the In-Line Smart Kit and the

range hood terminal box.

A

5. Connect together the set of 8 wires in the range hood

terminal box.

Connect In-Line Smart Kit

Electrical Connection In-Line Smart Kit

1. Use a UL listed or CSA approved wire connector to connect

the black wires together.

2. Use a UL listed or CSA approved wire connector to connect

the white wires together.

3. Use a UL listed or CSA approved wire connector to connect

the red wires together.

4. Use a UL listed or CSA approved wire connector to connect

the blue wires together.

5. Use a UL listed or CSA approved wire connector to connect

the gray wires together.

6. Use a UL listed or CSA approved wire connector to connect

the brown wires together.

7. Use a UL listed or CSA approved wire connector to connect

the yellow wires together.

8. Use a UL listed or CSA approved wire connector to connect

the green/yellow wires together.

9. Tighten the UL listed or CSA approved strain relief.

Electrical Connection Range Hood

A. Distance between in-line smart kit

and the range hood terminal box

3. Install 8 - 14 AWG wires with an insulating sleeve or conduit

between the terminal box and UL listed strain reliefs.

4. Connect together the set of 8 wires in the In-Line Smart Kit

terminal box.

30

10. Repeat all steps above to make the electrical connection in

the range hood terminal box.

11. Connect power supply wires together using the “Make

Electrical Connections” section in the range hood manual.

12. Reinstall the terminal box cover on the In-Line Smart Kit and

reinstall the electrical box cover on the range hood.

13. Reconnect power.

Page 31

WIRING DIAGRAM

BU

GY

BK

RD

WH

YL

BR

YL/GN

YL/GN

BU

GY

BK

RD

WH

YL

BR

YL/GN

M

SE14CA

1

2

3

4

5

6

7

8

9

31

Page 32

SÉCURITÉ DE LA HOTTE DE CUISINIÈRE

Risque possible de décès ou de blessure grave si vous ne

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

AVERTISSEMENT

DANGER

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Avertissements de la proposition 65 de l'État de Californie :

AVERTISSEMENT : Ce produit contient au moins un produit chimique connu par l’État de Californie pour être à l’origine de

cancers.

AVERTISSEMENT : Ce produit contient au moins un produit chimique connu par l’État de Californie pour être à l’origine de

malformations et autres déficiences de naissance.

32

Page 33

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ

LIRE ET CONSERVER CES INSTRUCTIONS

AVERTISSEMENT : POUR RÉDUIRE LE RISQUE

D'INCENDIE, CHOC ÉLECTRIQUE OU DOMMAGES

CORPORELS, RESPECTER LES INSTRUCTIONS

SUIVANTES :

■ Utiliser cet appareil uniquement dans les applications

envisagées par le fabricant. Pour toute question, contacter

le fabricant.

■ Avant d'entreprendre un travail d'entretien ou de nettoyage,

interrompre l'alimentation de la hotte au niveau du tableau

de disjoncteurs, et verrouiller le tableau de disjoncteurs

pour empêcher tout rétablissement accidentel de

l'alimentation du circuit. Lorsqu'il n'est pas possible de

verrouiller le tableau de disjoncteurs, placer sur le tableau

de di

sjoncteurs une étiquette d'avertissement proéminente

interdisant le rétablissement de l'alimentation.

■ Tout travail d'installation ou câblage électrique doit être

réalisé par une personne qualifiée, dans le respect des

prescriptions de tous les codes et normes applicables, y

compris les codes du bâtiment et de protection contre les

incendies.

■ Ne pas faire fonctionner un ventilateur dont le cordon ou la

fiche est endommagé(e). Jeter le ventilateur ou le retourner

à un centre de service agréé pour examen et/ou réparation.

■ Une source d'air de débit suffisant est nécessaire pour le

fonctionnement correct de tout appareil à gaz (combustion

et évacuation des gaz à combustion par la cheminée), pour

qu'il n'y ait pas de reflux des gaz de combustion. Respecter

les directives du fabricant de l'équipement de chauffage et

les prescriptions des normes de sécurité - comme celles

publiées

par la National Fire Protection Association (NFPA)

et l'American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), et les prescriptions des

autorités réglementaires locales.

■ Lors des opérations de découpage et de perçage dans un

mur ou un plafond, ne pas endommager les câblages

électriques et les canalisations qui peuvent s’y trouver.

■ Les ventilateurs d'évacuation doivent toujours décharger

l'air à l'extérieur.

MISE EN GARDE : Cet appareil est conçu uniquement

pour la ventilation générale. Ne pas l'utiliser pour l'extraction

de matières ou vapeurs dangereuses ou explosives.

MISE EN GARDE : Pour minimiser le risque d'incendie

et évacuer adéquatement les gaz, veiller à acheminer l'air

aspiré par un conduit jusqu'à l'extérieur - ne pas décharger

l'air aspiré dans un espace vide du bâtiment comme une

cavité murale, un plafond, un grenier, un vide sanitaire ou

un garage.

AVERTISSEMENT : POUR RÉDUIRE LE RISQUE

D'INCENDIE, UTILISER UNIQUEMENT DES CONDUITS

MÉTALLIQUES.

AVERTISSEMENT : POUR MINIMISER LE RISQUE

D'UN FEU DE GRAISSE SUR LA CUISINIÈRE :

■ Ne jamais laisser un élément de surface fonctionner à

puissance de chauffage maximale sans surveillance. Un

renversement/débordement de matière graisseuse pourrait

provoquer une inflammation et la génération de fumée.

Utiliser une puissance de chauffage moyenne ou basse

pour le chauffage d'huile.

■ Veiller à toujours faire fonctionner le ventilateur de la hotte

lors de la cuisson avec une puissance de chauffage élevée

ou lors de la cuisson d'un mets à flamber (à savoir crêpes

Suzette, cerise jubilée, steak au poivre flambé).

■ Nettoyer fréquemment les ventilateurs d'extraction. Veiller à

ne pas laisser la graisse s'accumuler sur les surfaces du

ventilateur ou des filtres.

■ Utiliser toujours un ustensile de taille appropriée. Utiliser

toujours un ustensile adapté à la taille de l'élément

chauffant.

AVERTISSEMENT : POUR RÉDUIRE LE RISQUE DE

DOMMAGES CORPORELS APRÈS LE DÉCLENCHEMENT

D'UN FEU DE GRAISSE SUR LA CUISINIÈRE, APPLIQUER

LES RECOMMANDATIONS SUIVANTES :

a

■ Placer sur le récipient un couvercle bien ajusté, une tôle à

biscuits ou un plateau métallique POUR ÉTOUFFER LES

FLAMMES, puis éteindre le brûleur. VEILLER À ÉVITER

LES BRÛLURES. Si les flammes ne s'éteignent pas

immédiatement, ÉVACUER LA PIÈCE ET APPELER LES

POMPIERS.

■ NE JAMAIS PRENDRE EN MAIN UN RÉCIPIENT

ENFLAMMÉ - vous risquez de vous brûler.

■ NE PAS UTILISER D'EAU, ni un torchon humide - ceci

pourrait provoquer une explosion de vapeur brûlante.

■ Utiliser un extincteur SEULEMENT si :

– Il s'agit d'un extincteur de classe ABC, dont on connaît le

fonctionnement.

– Il s'agit d'un petit feu encore limité à l'endroit où il s'est

déclaré.

– Les pompiers ont été contactés.

– Il est possible de garder le dos orienté vers une sortie

pendant l'opération de lutte contre le feu.

a

Recommandations tirées des conseils de sécurité en cas

d'incendie de cuisine publiés par la NFPA.

■ AVERTISSEMENT : Pour réduire le risque d'incendie

ou de choc électrique, ne pas utiliser ce ventilateur avec un

quelconque dispositif de réglage de la vitesse à

semi-conducteurs.

33

Page 34

EXIGENCES D’INSTALLATION

†®TORX et T20 sont des marques déposées de Acument Intellectual Properties, LLC

6"

(15.2 cm)

4" (10,2 cm)

10¹¹⁄₁₆"

(27,1 cm)

4" (10,2 cm)

6" (15,2 cm)

9⁵⁄₈"

(24,5 cm)

26" (66,0 cm)

12"

(30,5 cm)

Outillage et pièces

Rassembler les outils et pièces nécessaires avant d’entreprendre

l’installation. Lire et observer les instructions fournies avec chacun

des outils de la liste ci-dessous.

Outils nécessaires

■ Perceuse

■ Foret de 1¼" (3,0 cm)

■ Foret de ¹⁄₈" (3,0 mm)

■ Crayon

■ Pince à dénuder ou couteau utilitaire

■ Mètre-ruban ou règle

■ Pince

■ Pistolet à calfeutrage et composé de calfeutrage résistant

aux intempéries

■ Brides de conduit

■ Ruban adhésif pour conduits métalliques

■ Scie sauteuse ou scie à guichet

■ Tournevis à lame plate

■ Cisaille de ferblantier

■ Tournevis Phillips

■ Rallonge de 10" (25,4 mm) pour adaptateur de vissage

Pièces nécessaires

■ Conduit de câblage et raccord de ½" (13 mm) - homologation

UL ou CSA. La longueur du conduit est déterminée par la

distance entre le ventilateur déporté intelligent et la hotte.

■ 8 conducteurs de calibre 14 AWG, chacun d’une des

couleurs suivantes :

noir, blanc, rouge, bleu, gris, marron, jaune ou vert/jaune

(terre). La longueur des conducteurs est déterminée par la

distance entre le ventilateur déporté intelligent et la hotte.

■ 3 serre-câble de ½" (13 mm) (homologation UL)

■ Conduit de ventilation rond de dia. 6" (15,2 cm)

■ 1 adaptateur Torx

■ 1 adaptateur Torx

■ 1 attache-câble en plastique

■ 4 vis de montage de 5 x 45 mm

■ 3 vis de montage de 2,9 x 13 mm

■ 1 serre-câble plastique (homologation UL ou CSA)

■ 1 caisse pour ventilateur déporté

■ 1 base pour ventilateur déporté

■ 1 support de montage pour ventilateur déporté

■ 1 couvercle

■ 1 serre-fils (homologation UL ou CSA)

®†

®

T20

T10

®

Exigences d’emplacement

IMPORTANT : Observer les dispositions de tous les codes et

règlements en vigueur. Recourir à un technicien qualifié pour

installer le ventilateur déporté intelligent.

Assurer l’étanchéité au niveau de chaque ouverture découpée

dans le plafond ou le mur pour l’installation du ventilateur

déporté intelligent.

Installation dans une résidence mobile

L’installation de ventilateur déporté intelligent doit satisfaire aux

exigences de la norme Manufactured Home Construction Safety

Standards, Titre 24 CFR, partie 328 (anciennement Federal

Standard for Mobile Home Construction and Safety, titre 24,

HUD, partie 280); lorsque cette norme n’est pas applicable,

l’installation doit satisfaire aux critères de la plus récente édition

de la norme Manufactured Home Installation 1982 (Manufactured

Home Sites, Communities and Setups) ANSI A225.1/NFPA 501A,

ou des codes locaux.

Dimensions du produit

Pièces fournies

Retirer les pièces de leur emballage. Vérifier que toutes les

pièces sont présentes.

■ 1 raccord de transition de 6" (15,5 cm) sans clapet anti-reflux

■ 1 raccord de transition de 6" (15,5 cm) avec clapet anti-reflux

■ 4 vis de montage de 3,5 x 6,5 mm

■ 4 vis de montage de 3,5 x 9,5 mm

■ 1 connecteur de raccordement à 9 broches avec câble à 8

conducteurs

■ 1 boîtier de raccordement métallique avec couvercle

■ 16 connecteurs de fils (homologation UL ou CSA)

34

Page 35

Exigences concernant l’évacuation

A

B

Coude à 90˚

6 pi (1,8 m)

2 pi

(0,6 m)

Bouche de

décharge murale

■ Le système doit évacuer l’air à l’extérieur.

■ Ne pas terminer le circuit d’évacuation dans un grenier ou

dans un autre espace clos.

■

Ne pas utiliser une bouche de décharge murale de 4" (10,2 cm)

normalement utilisée pour un équipement de buanderie.

■

Utiliser un conduit métallique cylindrique uniquement. Un

conduit d’évacuation en métal rigide est recommandé. Ne pas

utiliser de conduit de plastique ou métallique souple extensible.

■

La longueur du circuit d’évacuation et le nombre de coudes

doit être réduit au minimum pour des performances optimales.

Pour un fonctionnement efficace et silencieux :

■ Ne pas utiliser plus de trois coudes à 90°.

■ Veiller à ce qu’il y ait une section droite de conduit d’un

minimum de 24" (61 cm) entre les raccords coudés, si on doit

en utiliser plus d’un.

■ Ne pas installer 2 coudes successifs.

■ Utiliser des brides et du ruban adhésif pour conduit

métallique afin d’assurer l’étanchéité de chaque jointure du

circuit d’évacuation.

■ Le circuit d’évacuation doit comporter un clapet anti-reflux.

■ À l’aide d’un produit de calfeutrage, assurer l’étanchéité

autour de la bouche de décharge à l’extérieur (à travers le

mur ou le toit).