Installation Instructions

for W10606694 L.P. (Propane and Butane)

Gas Conversion Kit

Converting 20,000 BTU/hr Gas Burners from Natural Gas

to Liqueed Petroleum (Bottled Gas)

Parts included in Kit:

1 Instruction Sheet

1 Blocking Pin

1 Orice, Burner-Butane No. .049

1 Orice, Burner-Propane No. 55

1 Label, Rating Plate Conversion (English)

1 Label, Rating Plate Conversion (French)

1 Label, Conversion Record (English)

1 Label, Conversion Record (French)

1 Label, Burner Baseplate (English/French)

Section 1 - Clothes Dryer with A Full-Front Panel & Front Mounted Console .... page 2

Section 2 - Dryers with Toe Panel ........................................................................... page 5

Section 3 - Dryers with A Full-Front Panel & Rear Mounted Console ................. page 5

Warning: This conversion kit shall be installed by a qualied

service agency in accordance with the manufacturer’s

instructions and all applicable codes and requirements of

the authority having jurisdiction. The information in these

instructions must be followed to minimize the risk of re or

explosion or to prevent property damage, personal injury,

or death. The qualied service agency is responsible for the

proper installation of this kit. The installation is not proper

and complete until the operation of the converted appliance

is checked as specied in the manufacturer’s instructions

supplied with this kit.

NOTE: A qualied service technician is any person or

representative of a company who is experienced or trained

in servicing gas equipment and is familiar with necessary

precautions.

Canada Only

THIS CONVERSION KIT SHALL BE CARRIED OUT IN

ACCORDANCE WITH THE REQUIREMENTS OF THE

PROVINCIAL AUTHORITIES HAVING JURISDICTION AND

IN ACCORDANCE WITH THE REQUIREMENTS OF THE

CAN-B49.1 AND CAN1-B149.2 INSTALLATION CODE.

NOTE: Read these instructions before proceeding.

IMPORTANT: The LP Conversion Kit you received is an

approved kit for converting your gas dryer from natural to LP

propane or butane gas. The kit no. shown on the Burner Data

Label located on the Burner Base may not match the kit you

receive due to kit consolidation.

This dryer has been manufactured for use with Natural Gas.

Installation of this conversion kit converts the dryer for use with

L.P. gas with supply pressure between 8" (203 mm) and

13" (330 mm) water column. If this dryer is converted for use

with L.P. gas by means of this kit, the input rating will be 20,000

BTU’s per hour, for altitudes up to 10,000 feet (3,048 m). For

installations above 2,000 feet (610 m), contact a qualied service

agency for derating instructions.

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

READ THOROUGHLY AND FOLLOW STEPS

1. Unplug dryer or disconnect power.

2. Turn off gas supply using the shut-off valve that supplies

the dryer.

3. Open dryer door and remove lint lter screen (on some

models).

4. Fill out information on the appropriate Conversion Record

Label (English or French) and apply in a conspicuous

location adjacent to model and serial tag located in the

door well. Go to section 1, 2, or 3 depending on your model.

W10607131A

SECTION 1 - CLOTHES DRYER WITH A FULL-FRONT PANEL

& FRONT MOUNTED CONSOLE

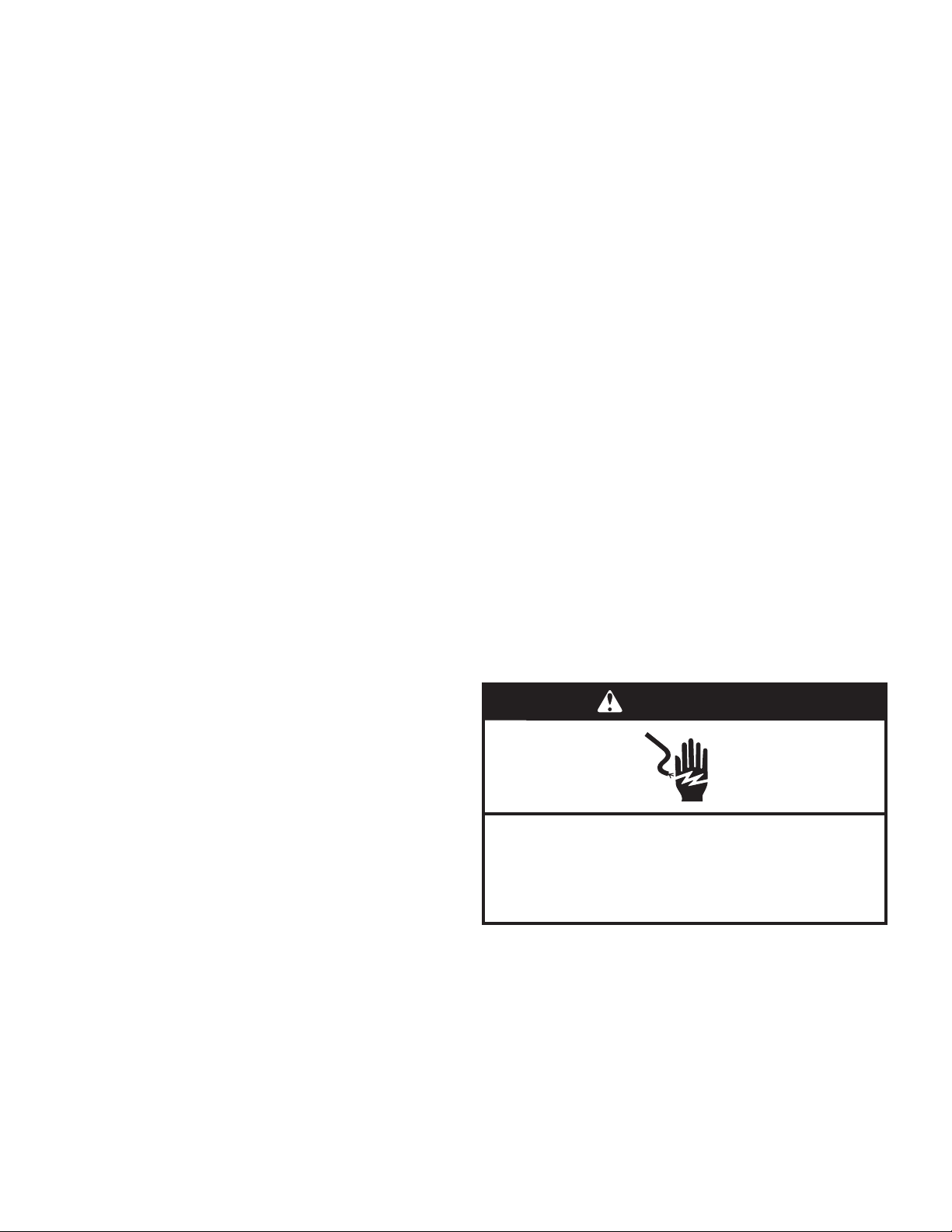

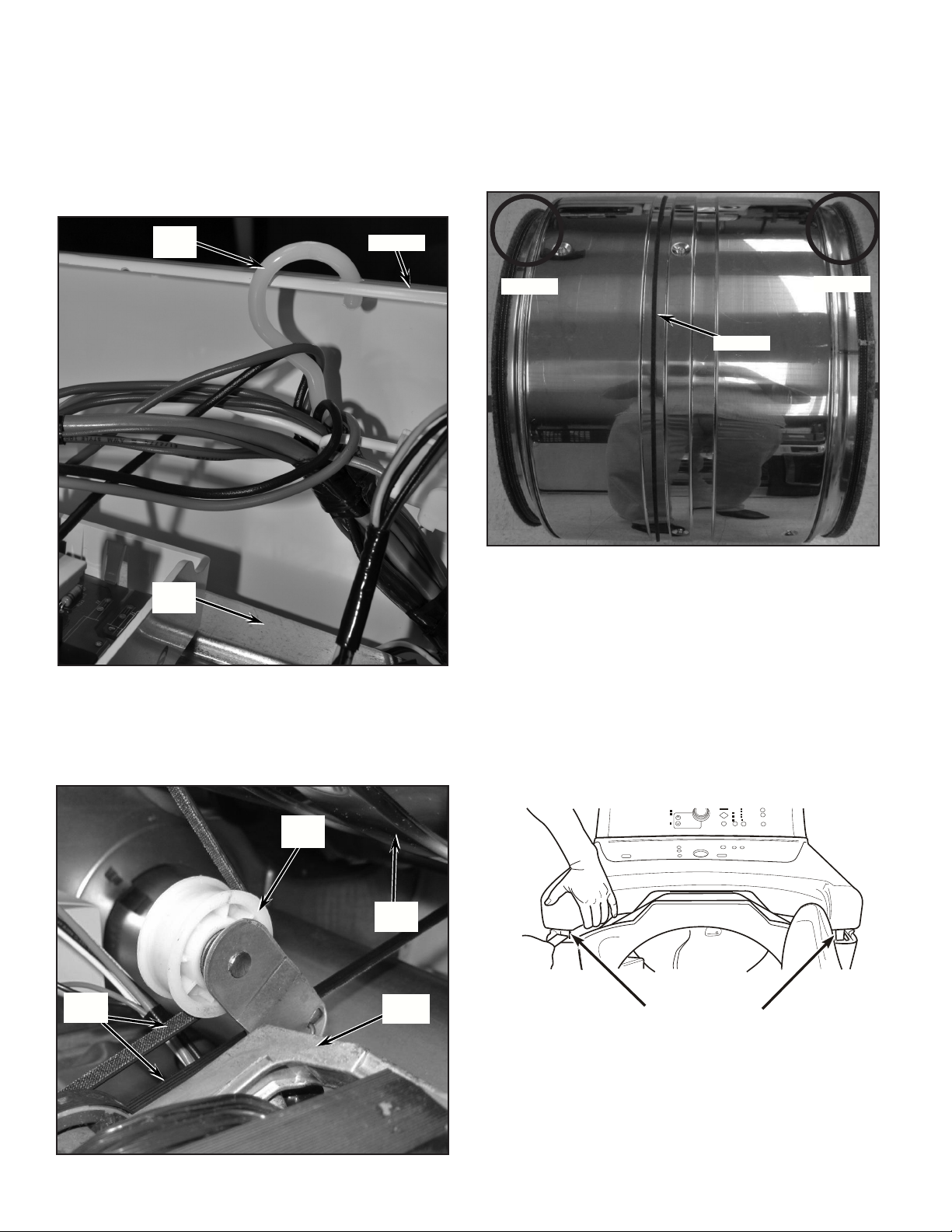

5. Remove dryer top by rst removing the two (2) screws

from the rear of the dryer. See Figure 1.

8. Disconnect drum light connector and main console

connector as shown in Figure 4. Lift up on console

and tilt assembly forward to remove console.

NOTE: Only on models with the CCU Bracket located on

the left side of the unit.

TOP - REAR

(2) SCREWS

FIGURE 1

6. Remove dryer top by sliding top toward rear of dryer and

lift to remove. See Figure 2.

FIGURE 2

7. Remove console by rst removing two (2) screws (one

from each side of console assembly) at location as shown

in Figure 3.

CCU

BRACKET

MAIN CONSOLE

CONNECTOR

FIGURE 4

9. Remove front panel assembly by opening door and

remove the two (2) screws as shown in Figure 5. After

removal of these screws, close door.

DRYER DOOR

(2) SCREWS

FIGURE 5

10. Disconnect door switch connector. See Figure 6.

DRUM LIGHT

CONNECTOR

FRONT

PANEL

CONSOLE

ASSEMBLY

DOOR

SCREW

FIGURE 3

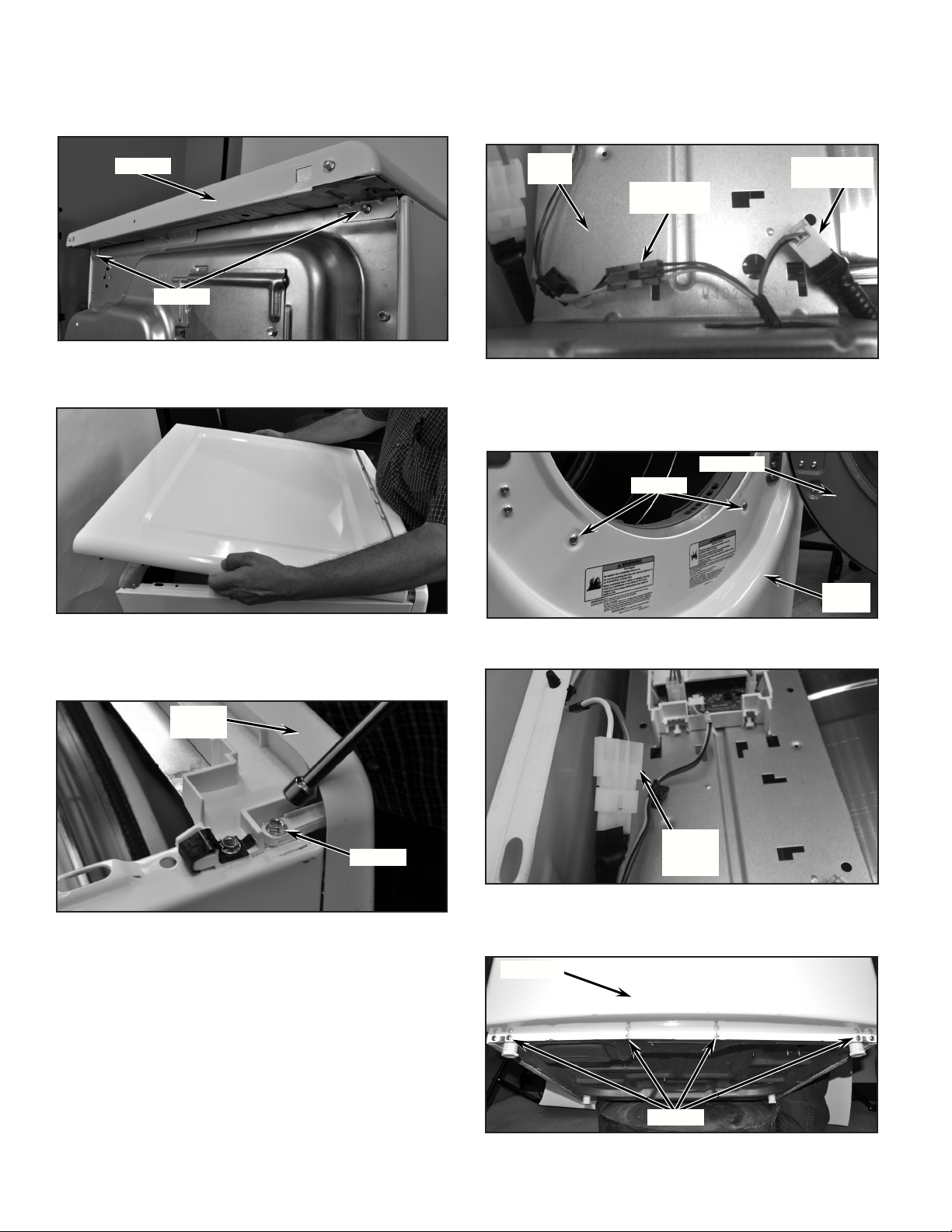

11. Remove front panel by rst removing four (4) screws from

bottom of front panel as shown in Figure 7.

FRONT PANEL

SWITCH

CONNECTOR

FIGURE 6

(4) SCREWS

FIGURE 7

2

12. Next remove the three (3) screws from the top of the front

panel as shown in Figure 8.

(3) SCREWS

FIGURE 8

13. Remove front panel assembly from dryer by lifting panel

assembly up and off tabs (one each side) as shown in

Figure 9.

TAB

NOTE: Only on models with the CCU Bracket located on the left

side of the unit.

CCU

BRACKET

(3) SCREWS

- RIGHT SIDE

FRONT

PANEL

FIGURE 9

14. Next remove console mounting bracket by removing two (2)

screws securing bracket to cabinet left side panels, two (2)

screws from right side panel and one (1) screw from central

control bracket. Slightly lift assembly and remove from dryer.

See Figure 10A and 10B.

(2) SCREWS -

LEFT SIDE

FIGURE 10B

15. Remove the bulkhead assembly from dryer by rst

removing lint screen from dryer lint duct. See Figure 11.

LINT

SCREEN

BULKHEAD

ASSEMBLY

FIGURE 11

LINT DUCT

FIGURE 10A

3

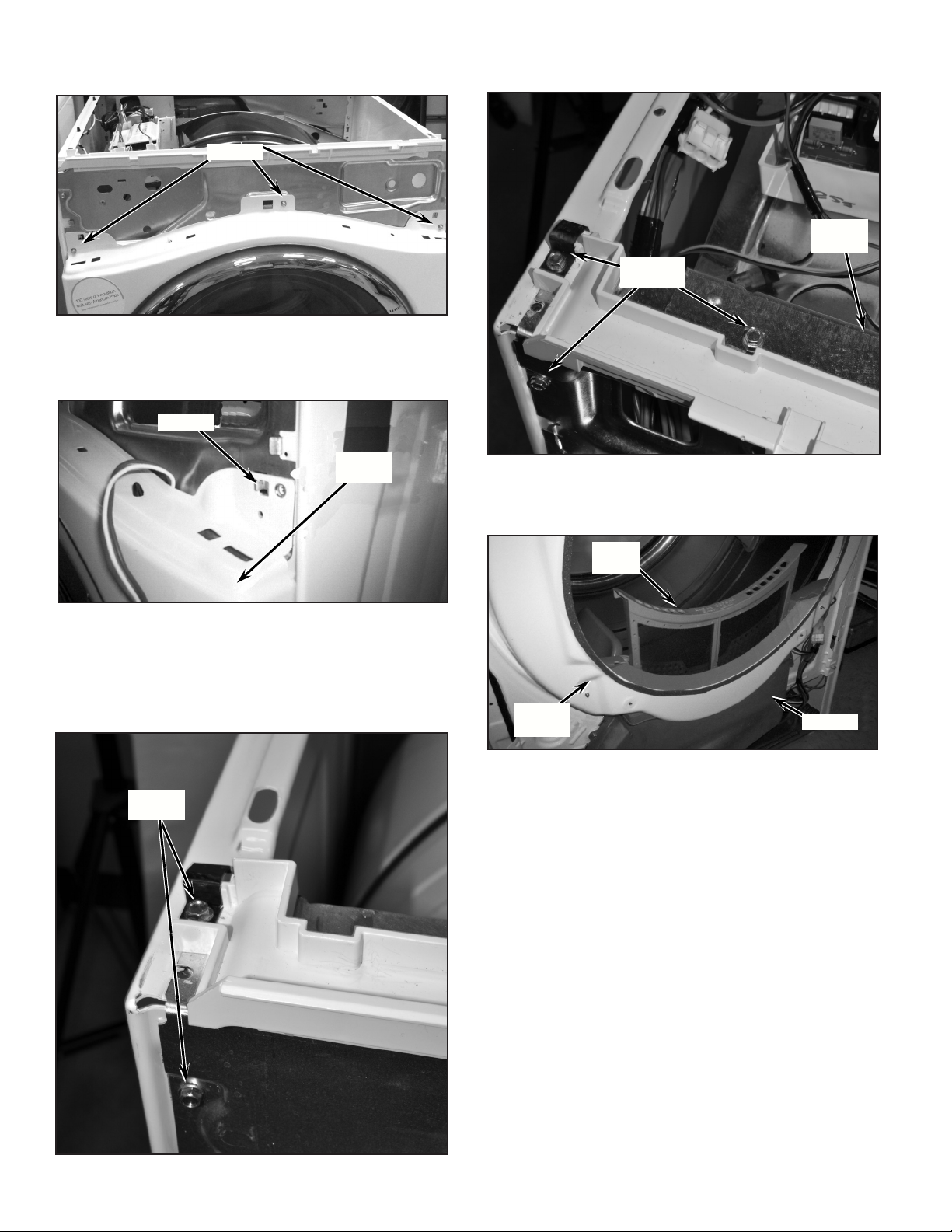

16. Disconnect moisture sensor disconnect block from main

harness disconnect block located at lower right side of

dryer. See Figure 12.

MOISTURE SENSOR

DISCONNECT BLOCK

MAIN HARNESS

DISCONNECT BLOCK

18. Remove bulkhead assembly by rst removing four (4)

screws securing the bulkhead assembly to cabinet.

Slightly lift up on bulkhead assembly and at the same

time pulling away from drum working rollers off drum.

See Figure 14.

NOTE: During removal of bulkhead, take special notice of the

Lower Protective Shield to assure proper orientation during

reassembly.

(4) SCREWS

LOWER

PROTECTIVE

SHIELD

FIGURE 12

17. Remove lint duct by removing the four (4) screws and clip

as shown in Figure13.

NOTE: Slide lint duct down and away from dryer to remove.

(3) SCREWS

SCREW

FIGURE 13

LINT DUCT

CLIP

FIGURE 14

19. Swing bulkhead assembly to side and remove two (2)

harness clips to disconnect harness from bulkhead.

See Figure 15.

NOTE: Only on models with the CCU Bracket located on

the right side of the unit.

CCU

BRACKET

BULKHEAD

(2) CLIPS - MAIN

HARNESS

4

FIGURE 15

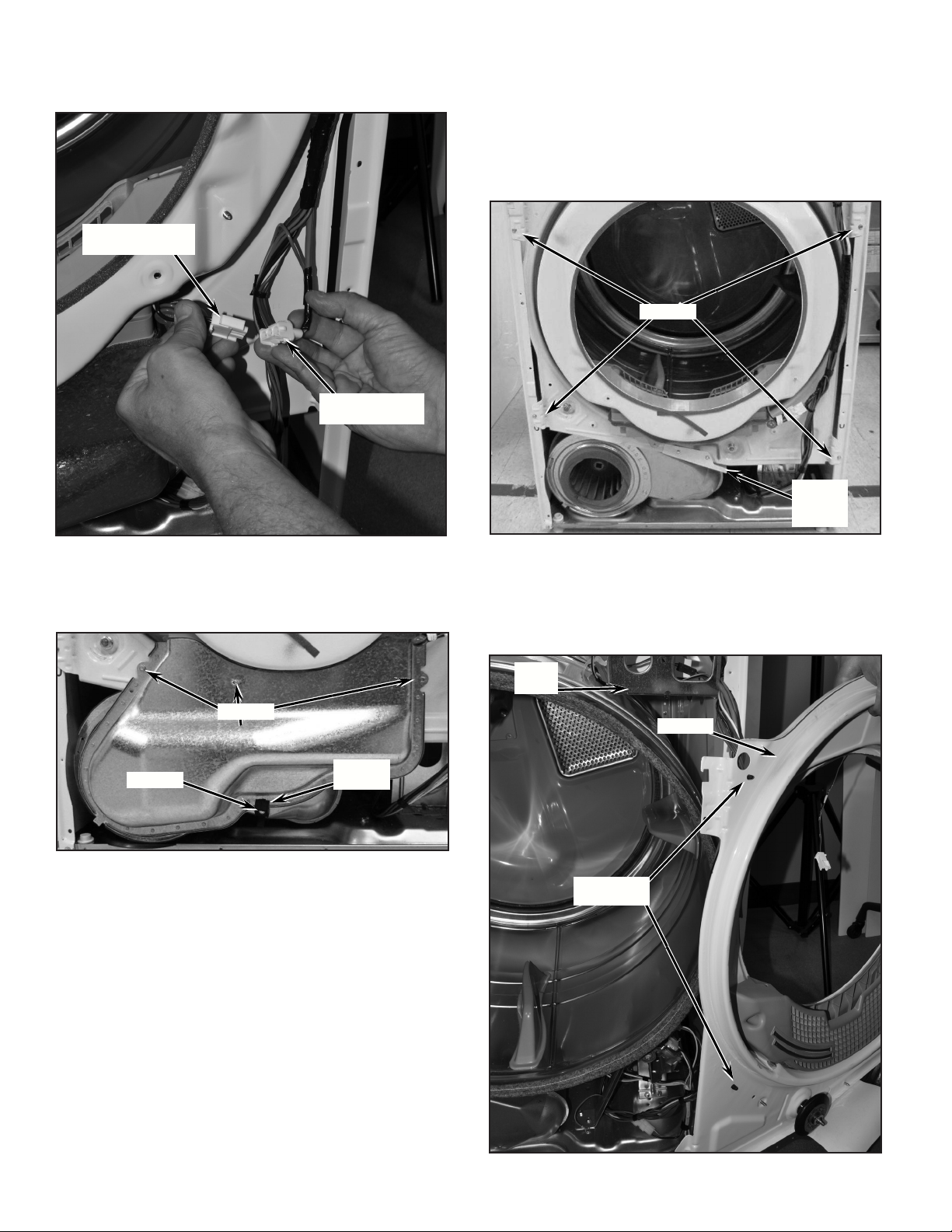

20. To gain further access to the burner assembly the drum

will need to be removed. Before removing drum from

dryer the CCU & bracket assembly must be secured in

position to side panel using the plastic hook attached to

the main harness. This will allow the CCU assembly to

hang in place rather than dropping down when the drum

is removed. See Figure 16.

NOTE: Only on models with the CCU Bracket located on

the right side of the unit.

22. Remove drum from dryer by grasping the drum belt and

front of drum and slide drum out of cabinet front.

IMPORTANT: Note position of drum belt, front and rear

orientation for reassembly. See Figure 18.

NOTE: When removing drum from cabinet be sure not to hit

the CCU & bracket assembly knocking it from its hanging

position. Continue to Step 23 “Changing the Orice.”

HOOK -

PLASTIC

CCU

BRACKET

FIGURE 16

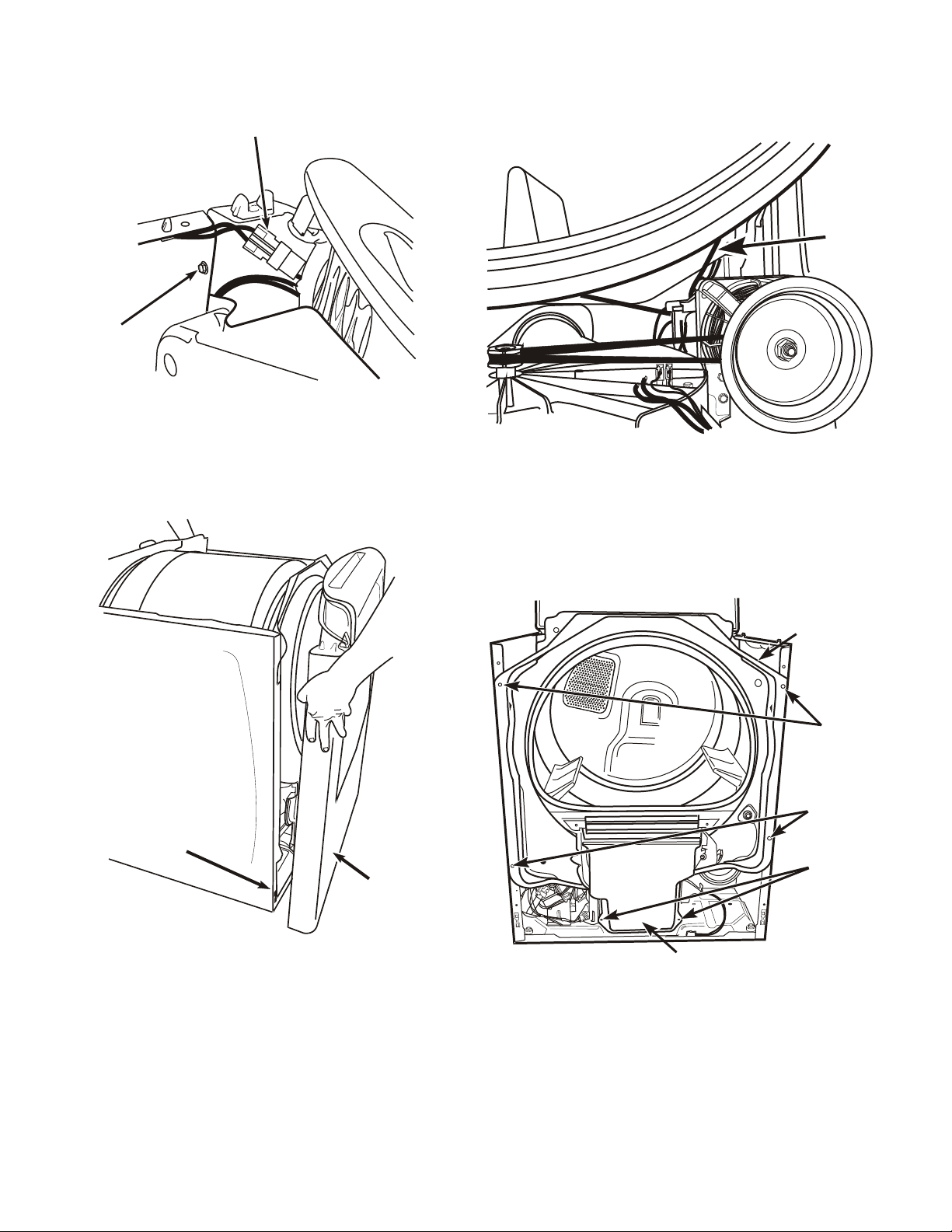

21. Remove drum from dryer by rst reaching into dryer just

under the drum, to back side of drive motor. Grasp idler

pulley and lift up to relieve tension from belt and remove

belt from motor pulley and idler pulley. Refer to Figure 17

for belt removal and reassembly.

SIDE PANEL

REAR

DRUM BELT

FIGURE 18

SECTION 2 - DRYERS WITH TOE PANEL

5. Remove toe panel. On some models, a small at-head

screwdriver is required to release the clips at the top of

the toe panel. Continue to Step 23 “Changing the Orice.”

SECTION 3 - DRYERS WITH A FULL-FRONT PANEL

AND REAR MOUNTED CONSOLE

5. Lift dryer top. Use a putty knife to press against the left

and right spring clips to release them from the top. Gently

lean dryer top toward the wall so as not to damage the

dryer top or wall. See Figure 1.

FRONT

IDLER

PULLEY

DRYER

DRUM

DRUM

BELT

DRIVE

MOTOR

SPRING CLIPS

FIGURE 1

FIGURE 17

5

6. Remove two (2) hex head screws from the cabinet front

panel. See Figure 2.

DOOR SWITCH CONNECTOR

CABINET FRONT

SCREW

FIGURE 2

7. Disconnect the door switch connector from the harness

connector. See Figure 2.

8. Lift the front panel, unhook it from the bottom two

hangers and remove the panel. See Figure 3.

9. Reach around the back of the drive motor and push the

idler wheel arm to relieve the spring tension on the belt,

then slide the belt off the idler and motor pulleys. See

Figure 4.

BELT

FIGURE 4

10. Loosen the top two (2) hex-head screws and remove the

bottom two (2) hex-head screws from the front bulkhead.

Remove the lower two (2) screws from the blower air duct.

Gently remove the bulkhead and blower air duct from the

front of the dryer. See Figure 5.

HANGER

FIGURE 3

FRONT

PANEL

BULKHEAD

TOP TWO (2)

SCREWS

BOTTOM TWO (2)

SCREWS

LOWER TWO (2)

SCREWS

BLOWER

AIR DUCT

FIGURE 5

11. Remove the drum from the dryer cabinet.

12. Disconnect ignitor wires from harness then remove

the burner tube by removing the two (2) screws securing

it to the burner base. See Figure 19B, then continue to

Step 23 “Changing the Orice”.

6

Loading...

Loading...