Whirlpool Thin Twin User Manual

Thin Twin

Ì2IF

■ Appli,

IMPORTANT:

Read and save

Washer»Dryer 230 Volt, 50 Hz

' ' lléC

Installation Instructions

tnese instructions.

IMPORTANT:

homeowner.

Homeowner; Keep Installation Instructions

for future reference ^^"'->'>5

Save Instaltation Instructions for local

electrical inspector's use

Part No. 3397516

Before yoti start...

Check location where washer/dryer will be

installed. Proper installation is your

responsibility. The washer/dryer must not be

installed or stored in an area where it will be

exposed to water and/or weather. Make

sure you have everything necessary for

correct installation.

Important: Observe all governing

codes and ordinances.

Check code requirements. Some codes limit

or do not permit the installation of clothes

dryers in garages, closets, mobile homes and

sleeping quarters. Contact your local

building inspector.

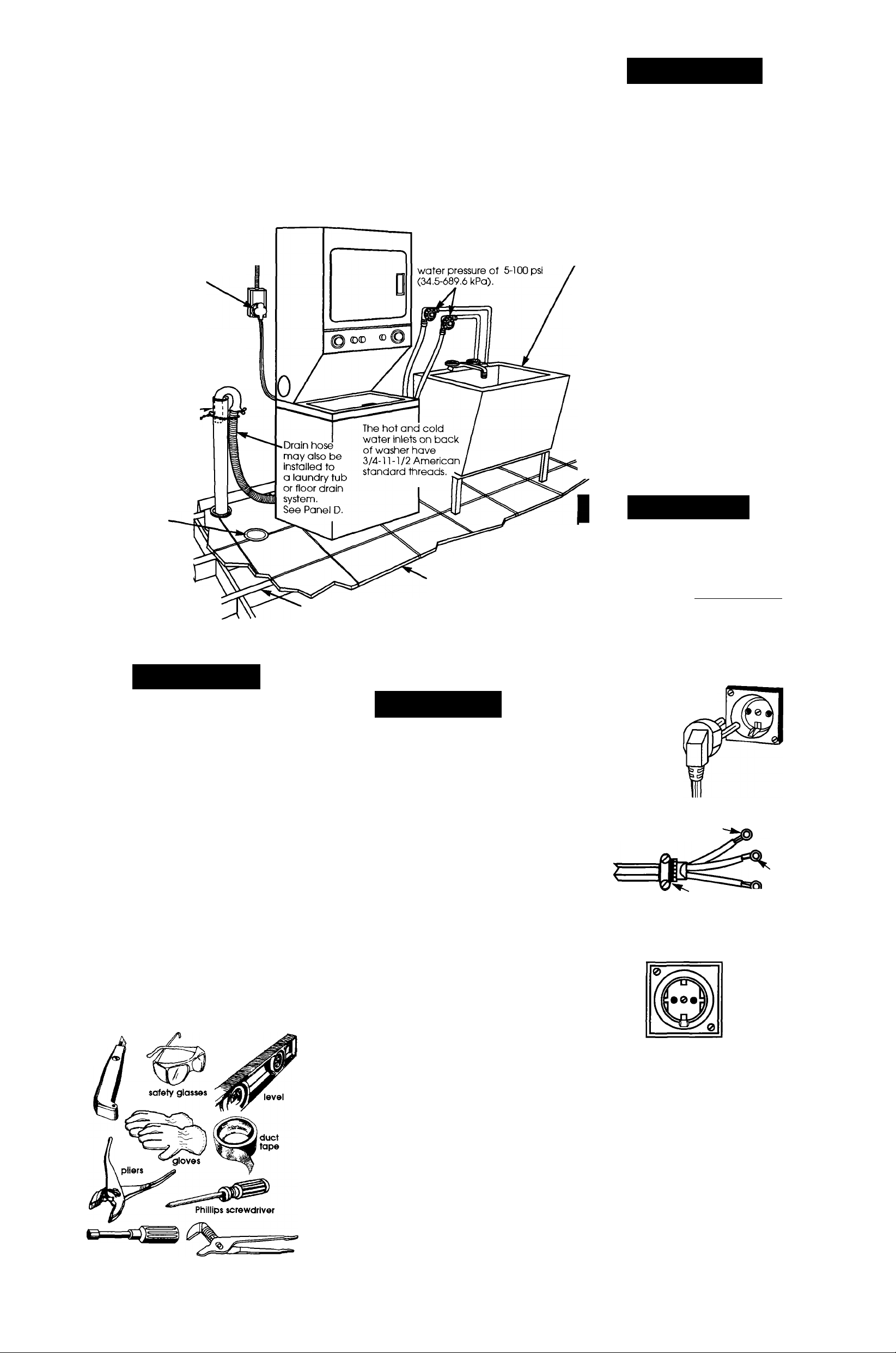

Check utilities: Proper electrical supply must

be available. See "Electrical requirements,"

Panel A.

^WARNING

Electric Shock Hazard

It Is the customer's responsibility:

• To contact a qualified electrical

Installer.

• To assure that the electrical Installation

Is adequate and In conformance with

all local codes and ordinances.

Failure to follow these Instructions could

result In death or serious Injury.

Earthed electrical outlet is

required. See "Electrical

requirements," Panel A.

Standpipe drain system needs a

two-inch (5 cm) diameter

standpipe with a minimum carryaway capacity of

17 gallons (64 liters) per

minute. Top of standpipe

must be at least ~

28 inches (71 cm) high

and no higher than

48 inches (122 cm) from

floor.

Floor drain system

requires a siphon break.

Part No. 285320,

available from your

authorized parts

distributor.

Location should be

large enough to fully

open dryer door 90°.

See "Recessed and

closet installation

instructions" and "Product

dimensions," Panel E.

Hot and cold water faucets

must be within 4 feet

(122 cm) of the back of the

washer/dryer and provide

Level floor: Maximum

slope under washer/dryer,

1 inch (2.5 cm).

. Support: Floor must be sturdy enough to

support washer/dryer weight with water

and clothes of 375 pounds (170 kilograms).

Water heater: Set to deliver 140°F (60°C)

water to the washer.

Laundry tub drain system needs a 20-gallon

(76 liters) laundry tub. Top of laundry tub

must be at least 28 inches (71 cm) high and

no higher than 48 inches (122 cm) from floor.

If a longer drain hose is needed, drain hose.

Part No. 388423, and hose connection kit.

Part No. 285442, are available from your

authorized parts distributor.

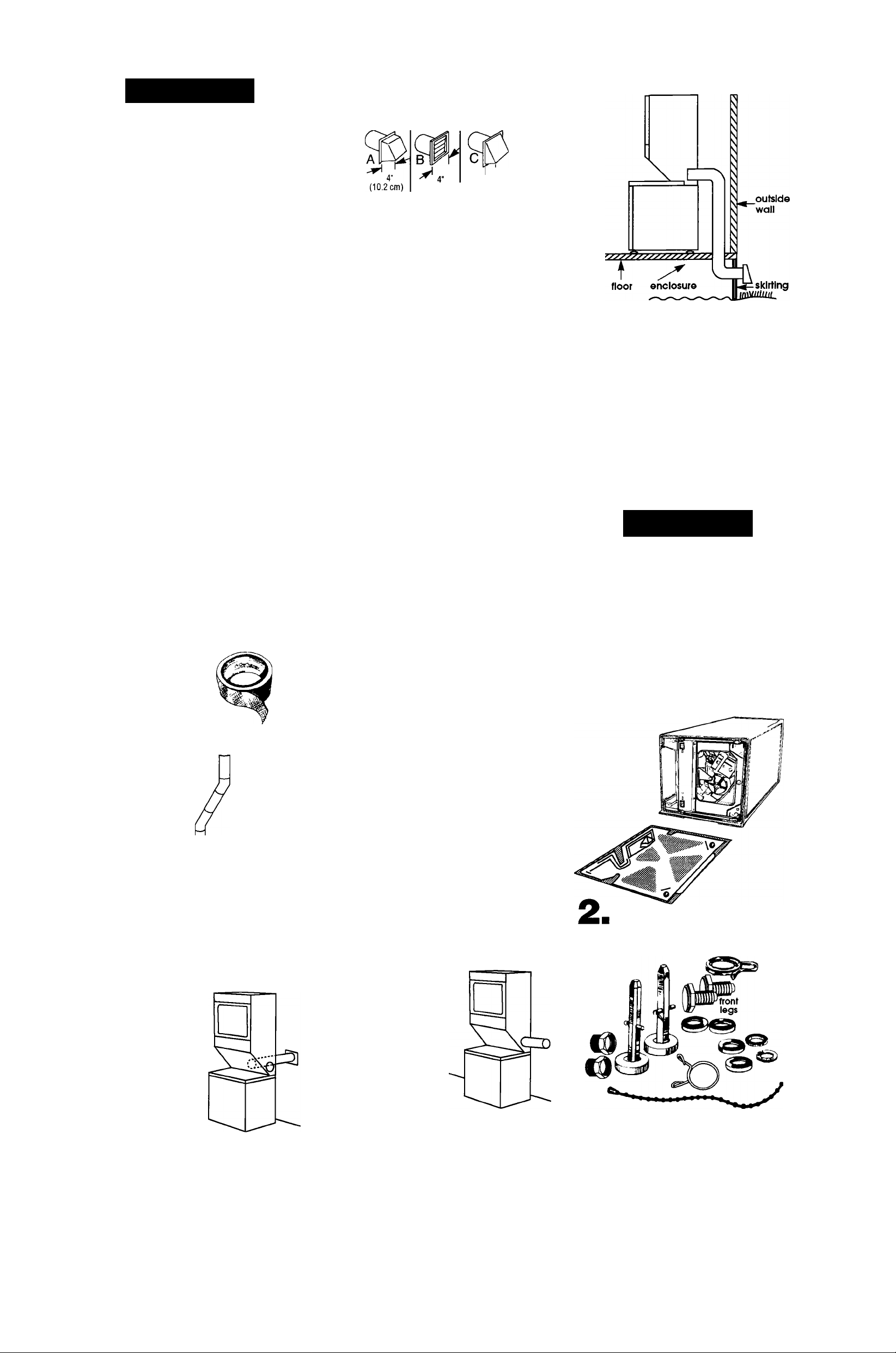

Dryer may be exhausted from rear or left or

right side. Exhausting through the side

requires side exhaust kit Part No. 279823. See

"Exhaust requirements," Panel B.

Four-Inch (10.2-cm) metal exhaust duct Is

required.

SEE RECESSED AND CLOSET INSTALLATION

INSTRUCTIONS ON PANEL E.

Acaution

Product Damage

Do Not store or operate washer/dryer

below 32°F (0°C) (some water may

remain In washer). Proper operation of

dryer cycles requires temperatures

above 45°F (7°C). See Use & Care Guide

for “Winterizing” Information.

Failure to follow these Instructions may

result In damage from freezing.

Awarning

Personal Injury Hazard

More than one person Is required to lift,

tilt, or move this washer/dryer because of

Its weight and size.

Failure to follow these Instructions may

result In personal Injury.

Fire Hazard

• Do Not use or store gasoline, paint,

thinners and other flammable materials

near washer/dryer. Fumes from such

materials could result In fire or

explosion.

• Never Install washer/dryer up against

draperies or curtains or on carpet. To

do so may result In a fire.

• Keep any and all Items from falling or

collecting behind the washer/dryer.

Failure to do so may result In a fire.

• Replace all access panels before

operating washer/dryer.

Failure to follow these Instructions may

result In a fire, explosion or electrical

shock.

Tools and materials

Electrical requirements Power supply cord

This appliance is equipped

Awarning

Electrical Shock Hazard

• Electrical earth Is required on this

appliance.

• Do Not earth to a gas pipe.

• Do Not modify the power supply cord

plug. It It will not fit the outlet, have a

proper outlet Installed by a qualified

electrician.

• Do Not reuse an old power supply cord.

Possible electrical shock or fire hazard

could occur If old power supply cord Is

used.

• Do Not hove a fuse In the neutral or

earthing circuit. A fuse In the neutral or

earthing circuit could result In an

electrical shock.

• Do Not use an extension cord with this

appliance.

• Check with a qualified electrician as to

whether the appliance Is properly

earthed.

Failure to follow these Instructions could

result In death or serious Injury.

with a 15-amp-rated Schuko

type power supply cord.

Two-wire power supply cord

earthing ■

wire

"strain reiief

Figure 1

nng

terminals

needed for installation:

utility

knife

1/4" socket wrench

or nut driver

Panel A

slip-joint pliers

that open to

1-1/2" minimum

If codes permit and a separate earthing wire

Is used. It Is recommended that a qualified

electrician determine that the earthing path

Is adequate.

A two-wire, plus earthing wire, single-phase,

230-volt 50-Flz, AC-only, 15-ampere electrical

supply is required on a separate circuit. A

time-delay fuse or circuit breaker is

recommended.

Recommended earthing

method

For your personal safety, this appliance must

be earthed, This appliance is equipped with

a Schuko-type power supply cord. To

minimize possible shock hazard, the cord

must be plugged into a mating wall

receptacle. See Figures 1 and 2,

two-wire

receptacie

Figure 2

If your electrical requirements are different,

contact your authorized service center or a

qualified electrician.

Direct wire

The dryer can be connected directly to the

fused, disconnect or circuit breaker box with

two-wire or fhree-wire flexible, armored or

non-metallic sheathed copper cable (with

earthing wire). Do Not use two-wire with

bare earthing wire. All current carrying wires

must be insulated.

A conduit connector must be installed at the

junction box. USE ONLY 10-GAUGE SOLID

COPPER WIRE. DO NOT USE ALUMINUM WIRE.

Allow four feet of slack in the line so the

dryer can be moved if servicing is ever

necessary.

Exhaust requirements

^WARNING

Fire Hazard

• Do Not use non-metal, flexible duct.

• Do Not use metal duct smaller than

4 Inches (10.2 cm) In diameter.

• Do Not use exhaust hoods with

magnetic latches.

• Check that exhaust system Is not longer

than specified. Exhaust systems longer

than specified will:

— Accumulate lint.

— Shorten the life of the product.

— Reduce performance and result In

longer drying times and Increased

energy usage.

Failure to follow specifications may result In

a fire.

• Do Not exhaust the dryer Into a

chimney, furnace cold air duct, attic or

crawl space, or any other duct used for

venting.

• Clean the exhaust system every year.

Accumulated lint could be fuel for a fire or

cause moisture damage.

• Exhausting your dryer Indoors Is Not

recommended. The moisture and lint

Indoors may cause:

— Lint to gather Inside and around the

dryer and be a fuel for fire.

— Moisture damage to woodwork,

furniture, paint, wallpaper, carpet, etc.

— Housecleaning problems and possible

health problems.

Failure to follow these Instructions could

result In fire damage, personal Injury or

health problems.

If using an existing exhaust system, clean lint

from entire length of exhaust system. Make

sure exhaust hood Is not plug^d with lint.

The exhaust system should be Inspected and

cleaned yearly.

Replace any vinyl or metallized plastic foil

exhaust duct with rigid metal or flexible

metal duct.

Use duct tape to seal all

joints. Do Not use screws

to secure duct.

exhaust air flow

better

Four-Inch (10.2 cm) rigid

metal pipe is preferred.

Plan installation to use

the fewest number of

eibows and turns.

Metal flexible duct must be fully extended

and supported when the dryer is in its final

position. DO NOT KINK OR CRUSH THE DUCT.

The metal flexible duct must be fully

extended to allow adequate exhaust air to

flow.

Allow as much room as possible when using

elbows or making turns. Bend duct gradually

to avoid kinking. Remove excess flexible

duct to avoid sagging and kinking that may

result in reduced air flow.

The exhaust duct can

be routed up, down,

left, right or straight out

the back of the

washer/dryer. Space

requirements are

provided on Panel E

and on the rear panel

of the washer/dryer. Use

the straightest path

possible to avoid 90° '

turns.

good

n

Maximum length of the exhaust system

depends upon the type of duct used,

number of elbows and the type of exhaust

hood. The maximum length for both rigid

and flexible duct is shown in the chart.

Number

ot90°

turns

2-V2"

(10.2 cm)

43 ft (13.1 m)

33tt(10m)

23 ft (7.0 m)

18 ft (5.5 m)

30 ft (9.1 m)

24 ft (7.3 m)

16 ft (4.9 m)

10 It (3.0 m)

The maximum length using a 2" x 6" rectangular

duct with 2 elbows and a 2-1/2" (TYPE C) exhaust

hood is 8 ft (2.4 m).

41ft(12.5m)

31 ft (9.4 m)

21 ft (6.4 m)

18 ft (5.5 m)

29 ft (8.8 m)

23 ft (7.0 m)

15ft(4.6m)

9 ft (2.1 m)

(6.4 cm)

36 ft (11.0m)

26 ft (7.9 m)

16 ft (4.9 m)

Not

recommended

24 ft (7.3 m)

18 ft (5.5 m)

10 ft (3.0 m)

Not

recommended

Maximum

length

of 4"

(10.2 cm)

diameter

rigid

metal

duct

flexible

metal

duct

For exhaust configurations other than those

listed in chart the back pressure MUST not

exceed 0.2 inches water column at the back

of the washer/dryer. The back pressure should

be checked by a qualified technician.

For exhaust systems not covered by the

exhaust length chart, check with your dealer

or distributor for information.

Service check: The back pressure in any

exhaust system used must not exceed

0.2 inches of water column measured with an

inclined manometer at the point that the

exhaust duct connects to the dryer.

Exhausting the dryer outside is recommended.

Recessed installation that is not exhausted

outside must use Exhaust Deflector Kit Part

No. 694609, available from your authorized

parts distributor. See "Recessed and closet

installation instructions," Panel E, for

unobstructed air opening requirements.

If the washer/dryer Is Installed In a confined

area such as a bedroom, bathroom or closet.

It must be exhausted to the outside and

provision must be made for enough air for

ventilation. Check governing codes and

ordinances. Also refer to the "Recessed and

closet installation instructions" on Panel E.

An exhaust hood should cap the exhaust duct

to prevent exhausted air

___

from returning into dryer. —

The outlet of the hood —

must be at least —

12 inches (30.5 cm) from —

the ground or any object

that may be in the path "

of the exhaust.

(30.5 cm)

minimum

Four-Inch (10.2-cm) outlet hood Is preferred.

However, a 2-1 /2 inch (6.4 cm) outlet hood

may be used with short systems only.

A 2-1/2 inch (6.4 cm) outlet hood can result in

ionger drying times than other hood types. For

permanent Installation, a stationary exhaust

system Is required.

Exhausting the dryer through the side of the

washer/dryer requires the use of Side Exhaust

Kit, Part No. 279823,

available from your

authorized parts distributor.

Follow kit Installation

Instructions for proper

exhaust installation.

Mobile home installation

This appliance Is suitable for mobile home

Installations.

Mobile home exhaust requirements: The

washer/dryer must have an outside exhaust.

If the dryer is exhausted through the floor

and the area under the mobile home is

enclosed, the exhaust system must terminate

outside the enclosed area. Extension

beyond the enclosure will prevent lint and

moisture buildup under the mobile home.

Now start...

With washer/dryer In laundry area.

^WARNING

Personal Injury Hazard

More than one person Is required to lift, tilt

or move the washer/dryer because of Its

weight and size.

Failure to follow this Instruction may result

In personal Injury.

Truck only from the rear to prevent produce

damage.

I Put on safety glasses and gloves.

Remove cardboard shipping base.

rear legs

4 legs

1 drain hose clamp

1 plastic beaded

strap

4 large, water-

hose washers

• 2 small water-hose

washers

• 1 small clamp

• 2 faucet adapters

• drain hose adapter

and clamp

(not shown)

Panel B

Remove parts from plastic package.

Check that all parts were included.

Loading...

Loading...