Page 1

INSTALLATIONINSTRUCTIONS

30" (76.2 CM) FREESTANDINGGAS RANGES

INSTRUCCIONESDEINSTALACION

ESTUFASAUTONOMAS A GAS DE30" (76,2 CM)

Table of Contents/Indice

RANGE SAFETY ....................................................................................... 2

INSTALLATION REQUIREMENTS ......................................................... 3

Tools and Parts ..................................................................................... 3

Location Requirements ......................................................................... 3

Electrical Requirements ........................................................................ 5

Gas Supply Requirements .................................................................... 5

INSTALLATION INSTRUCTIONS ........................................................... 6

Unpack Range ...................................................................................... 6

Install Anti-Tip Bracket .......................................................................... 7

Verify Anti-Tip Bracket Location ........................................................... 8

Level Range .......................................................................................... 8

Make Gas Connection .......................................................................... 8

Check Operation ................................................................................... 9

Complete Installation .......................................................................... 10

GAS CONVERSIONS ............................................................................. 11

LP Gas Conversion ............................................................................. 11

Complete Conversion ......................................................................... 12

Natural Gas Conversion ...................................................................... 13

Complete Conversion ......................................................................... 14

SEGURIDAD DE LA ESTUFA ............................................................... 15

REQUISITOS DE INSTALACION .......................................................... 16

Piezas y herramientas ......................................................................... 16

Requisitos de ubicaci6n ..................................................................... 16

Requisitos electricos .......................................................................... 18

Requisitos del suministro de gas ....................................................... 18

INSTRUCCIONES DE INSTALACION .................................................. 20

Desempaque la estufa ........................................................................ 20

Instalaci6n del soporte anti-vuelco .................................................... 20

Verificaci6n de la ubicaci6n del soporte anti-vuelco ......................... 21

Nivelaci6n de la estufa ........................................................................ 21

Conexi6n del suministro de gas ......................................................... 22

Verifique el funcionamiento ................................................................ 23

Complete la instalaci6n ...................................................................... 24

CONVERSIONES DE GAS .................................................................... 25

Conversi6n de gas L.P ....................................................................... 25

Complete la conversi6n ...................................................................... 27

Conversi6n de gas natural .................................................................. 27

Complete la conversi6n ...................................................................... 28

iMPORTANT:

installer: Leave installation instructions with the homeowner.

Homeowner: Keep installation instructions for future reference.

IMPORTANTE:

Instaiador: Deje las instrucciones de instalaci6n con el propietario.

Propietario: Conserve las instrucciones de instalaci6n para referencia futura.

W10110358B

Page 2

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death,

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance,

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or

the gas supplier,

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

In the State of Massachusetts, the following installation instructions apply:

[] Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] If using a ball valve, it shall be a T-handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

2

Page 3

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

• Level

• 3/8"drive ratchet

• Tape measure

• Flat-blade screwdriver

• Phillips screwdriver

• Hand or electric drill

• Wrench or pliers

• 7 mm combination wrench

• Pipe wrench

• 1/8"(3.2 mm) drill bit (for wood floors)

• 3/16"(4.8 mm) carbide-tipped masonry drill bit (for concrete/

ceramic floors)

• Pipe-joint compound resistant to LP gas

• Noncorrosive leak-detection solution

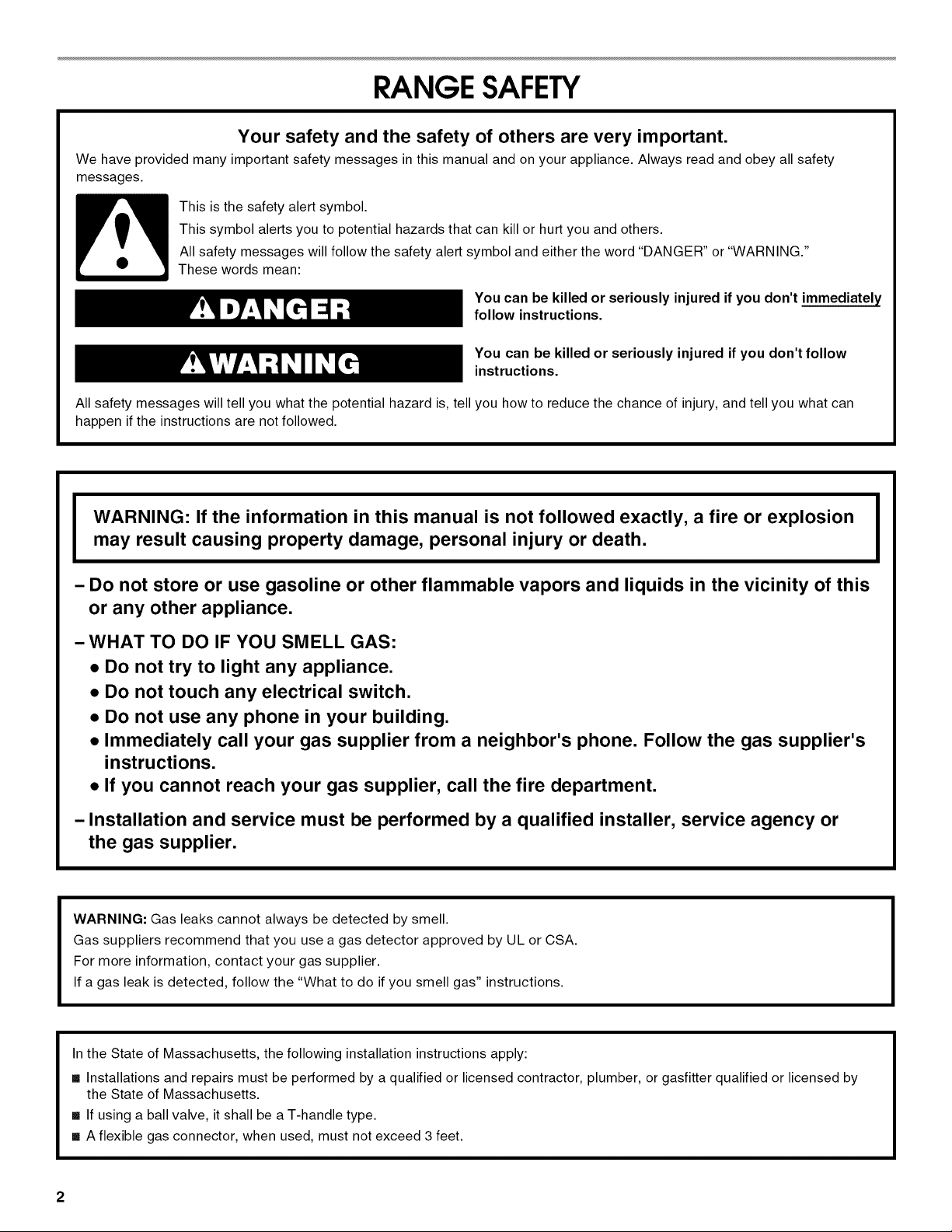

Parts supplied

Check that all parts are included.

A

B

,J

i i

C

A.Anti-tip bracket

B. Plastic anchors (2)

C. #10 x 1/=.screws (2)

• Bag containing literature.

• Conversion orifice spuds (inside bag containing literature).

• Anti-tip bracket must be securely mounted to subfloor.

Thickness of flooring may require longer screws to anchor

bracket to subfloor. Longer screws are available from your

local hardware store.

Parts needed

Check local codes and consult gas supplier. Check existing gas

supply and electrical supply. See "Electrical Requirements" and

"Gas Supply Requirements" sections.

IMPORTANT: Observe all governing codes and ordinances. Do

not obstruct flow of combustion and ventilation air.

It is the installer's responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located on the oven frame behind

the left side of the broiler door.

A. Model/serial rating plate location

The range should be located for convenient use in the kitchen.

Recessed installations must provide complete enclosure of

the sides and rear of the range.

To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood

that projects horizontally a minimum of 5" (12.7 cm) beyond

the bottom of the cabinets.

All openings in the wall or floor where range is to be installed

must be sealed.

Do not seal the range to the side cabinets.

Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

The floor anti-tip bracket must be installed. To install the anti-

tip bracket shipped with the range, see "Install Anti-Tip

Bracket" section.

Grounded electrical supply is required. See "Electrical

Requirements" section.

Proper gas supply connection must be available. See "Gas

Supply Requirements" section.

Contact a qualified floor covering installer to check that the

floor covering can withstand at least 200°F (93°C).

Use an insulated pad or 1¼,,(0.64 cm) plywood under range if

installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate or sustain other damage. This oven

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194°F (90°C).

Page 4

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD Part 280). When such standard is not

applicable, use the Standard for Manufactured Home

Installations, ANSI A225.1/NFPA 501A or with local codes.

Mobile home installations require:

• When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing the

range is adequate as long as it conforms to the standards

listed above.

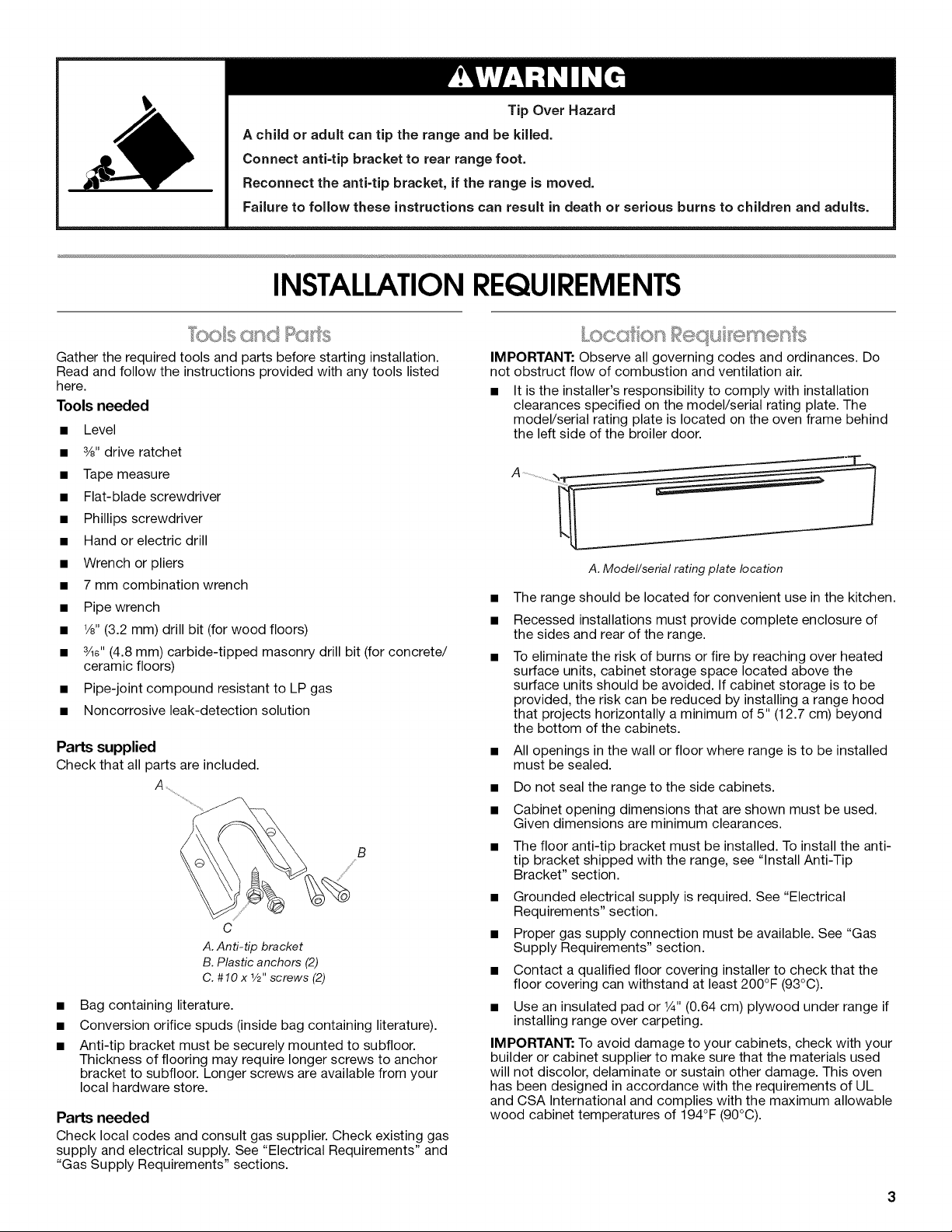

Product Dimensions

A

G

A

©© @@

/

C

E

;J

A. 26_" (67.9 cm)

B. 36" (91.4 cm)

C. 46¼" (117.5 cm)

D. 297/8" (75.9 cm)

E.24¼" (61.6 cm)

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and

36" (91.4 cm) countertop height.

If the cabinet depth is greater than 24" (61.0 cm), oven frame must

extend beyond cabinet fronts by 1/2"(13.0 mm) minimum.

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

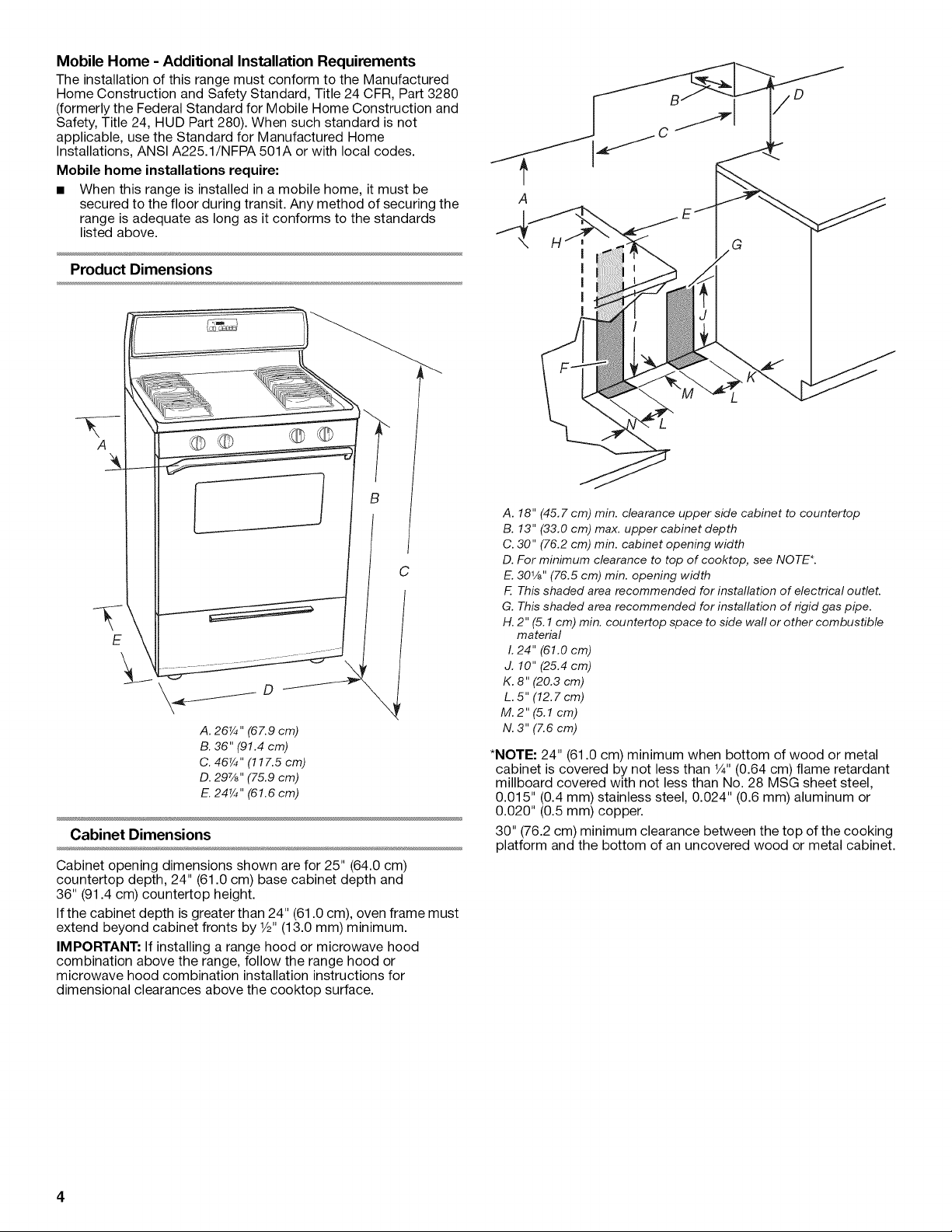

A. 18" (45.7 cm) min. clearance upper side cabinet to countertop

B. 13" (33.0 cm) max. upper cabinet depth

C. 30" (76.2 cm) min. cabinet opening width

D. For minimum clearance to top of cooktop, see NQTE*.

E. 30%" (76.5 cm) min. opening width

F. This shaded area recommended for installation of electrical outlet.

G. This shaded area recommended for installation of rigid gas pipe.

H. 2" (5.1 cm) min. countertop space to side wall or other combustible

material

I. 24" (61.0 cm)

J. 10" (25.4 cm)

K. 8" (20.3 cm)

L. 5" (12.7 cm)

M. 2" (5.1 cm)

N. 3" (7.6 cm)

*NOTE: 24" (61.0 cm) minimum when bottom of wood or metal

cabinet is covered by not less than 1/4"(0.64 cm) flame retardant

millboard covered with not less than No. 28 MSG sheet steel,

0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking

platform and the bottom of an uncovered wood or metal cabinet.

Page 5

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

IMPORTANT: The range must be electrically grounded in

accordance with local codes and ordinances, or in the absence of

local codes, with the National Electrical Code, ANSI/NFPA 70,

latest edition.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

• A 120 volt, 60 Hz., AC only, 15-amp fused, electrical circuit is

required. A time-delay fuse or circuit breaker is also

recommended. It is recommended that a separate circuit

serving only this range be provided.

• This range is equipped with a power supply cord having a

3 prong ground plug. To minimize possible shock hazard the

cord must be plugged into a grounded 3 prong outlet.

• Electronic ignition systems operate within wide voltage limits,

but proper grounding and polarity are necessary. Check that

the outlet provides 120-volt power and is correctly grounded.

This range is equipped with an electronic ignition system that

will not operate if plugged into an outlet that is not properly

polarized.

• The wiring diagram is located on the back of the range in a

clear plastic bag.

NOTE: The metal chassis of the range must be grounded in

order for the control panel to work. Ifthe metal chassis of the

range is not grounded, no keypads will operate. Check with a

qualified electrician if you are in doubt as to whether the metal

chassis of the range is grounded.

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1 - latest edition or CAN/CGA B149 - latest

edition.

IMPORTANT: Leak testing of the range must be conducted

according to the manufacturer's instructions.

Type of Gas

Natural gas:

This range is design-certified by CSA International for use with

Natural gas or, after proper conversion, for use with LP gas.

• This range is factory set for use with Natural gas. See "Gas

Conversions" section. The model/serial rating plate located

behind the storage drawer on the right-hand side oven door

frame has information on the types of gas that can be used. If

the types of gas listed do not include the type of gas available,

check with the local gas supplier.

LP gas conversion:

Conversion must be done by a qualified service technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier. See "Gas

Conversions" section.

Gas Supply Line

Provide a gas supply line of 3A"(1.9 cm) rigid pipe to the range

location. A smaller size pipe on longer runs may result in

insufficient gas supply. With LP gas, piping or tubing size can

be 1/2"(1.3 cm) minimum. Usually, LP gas suppliers determine

the size and materials used in the system.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON ®ttape.

1-®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

Page 6

Flexible metal appliance connector:

If local codes permit, a new CSA design-certified,

4 to 5 ft (122 to 152.4 cm) long, 1/2"(1.3 cm) or

34" (1.9 cm) I.D., flexible metal appliance connector may

be used for connecting range to the gas supply line.

• A 1/2"(1.3 cm) male pipe thread is needed for connection

to the female pipe threads of the inlet to the appliance

pressure regulator.

• Do not kink or damage the flexible metal tubing when

moving the range.

Rigid pipe connection:

The rigid pipe connection requires a combination of pipe

fittings to obtain an in-line connection to the range. The rigid

pipe must be level with the range connection. All strains must

be removed from the supply and fuel lines so range will be

level and in line.

Gas Pressure Regulator

The gas pressure regulator supplied with this range must be used.

The inlet pressure to the regulator should be as follows for proper

operation:

Natural gas:

Minimum pressure: 5" WCP

Maximum pressure: 14" WCP

LP gas:

Minimum pressure: 11" WCP

Maximum pressure: 14" WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

Burner Input Requirements

Input ratings shown on the model/serial rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced at a

rate of 4% for each 1,000 ft (304.8 m) above sea level (not

applicable for Canada).

Gas Supply Pressure Testing

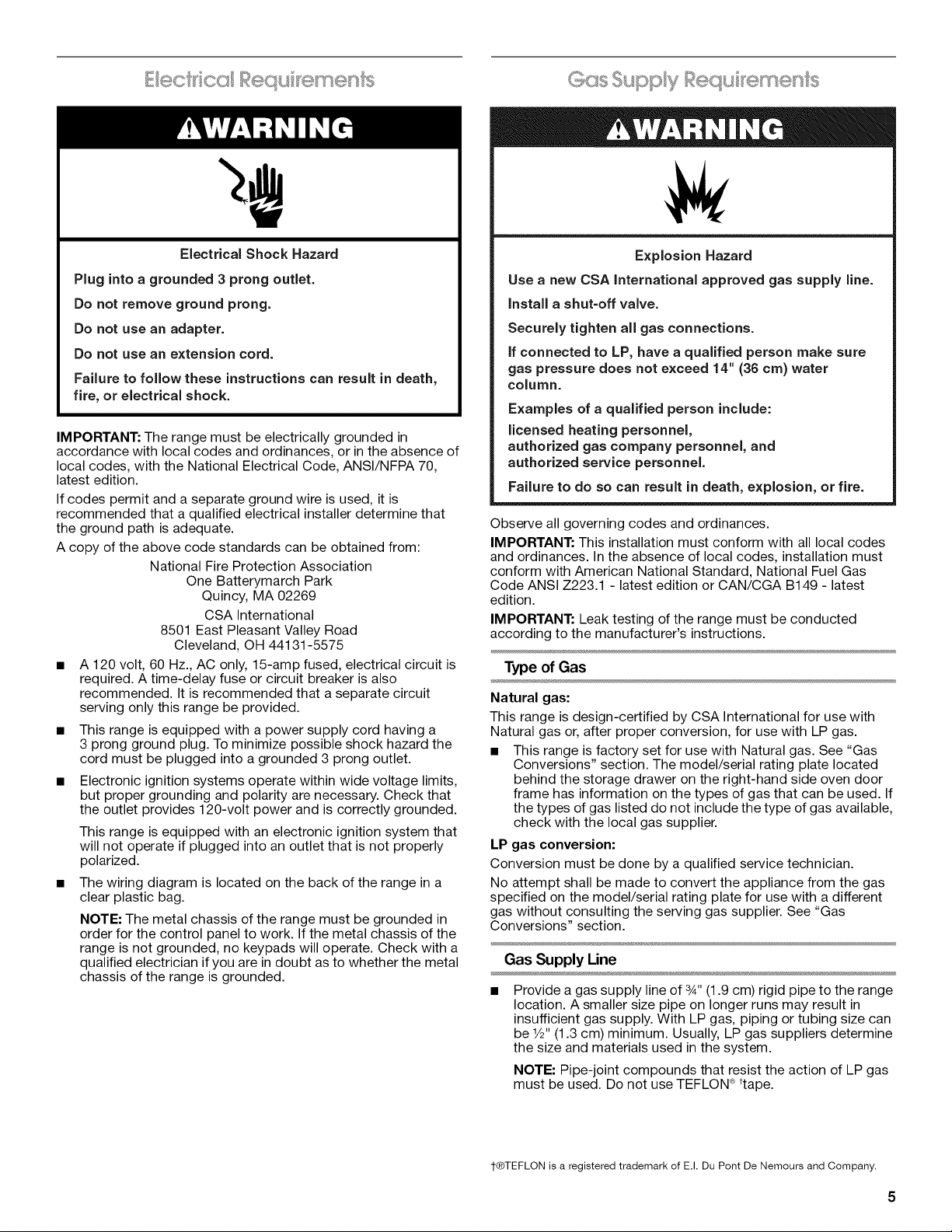

Must include a shutoff valve:

The supply line must be equipped with a manual shutoff valve.

This valve should be located in the same room but external to

the range opening, such as an adjacent cabinet. It should be

in a location that allows ease of opening and closing. Do not

block access to shutoff valve. The valve is for turning on or

shutting off gas to the range.

B

A

A. Gas supply line

B. Shutoff valve "open" position

C. To range

INSTALLATIONINSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Do not use oven door handle to lift or move the range

2. Remove shipping materials, tape and film from range. Keep

cardboard bottom under range.

3. Remove oven racks and parts package from inside oven.

4. To place range on its back, take 4 cardboard corners from the

carton. Stack one cardboard corner on top of another. Repeat

with the other 2 corners. Place them lengthwise on the floor

behind the range to support the range when it is laid on its

back.

Gas supply pressure for testing regulator must be at least

1" water column pressure above the manifold pressure shown on

the model/serial rating plate.

Line pressure testing above 1/2psi gauge (14" WCP)

The range and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2psi (3.5 kPa).

Line pressure testing at 1/2psi gauge (14" WCP) or lower

The range must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to

or less than 1/2psi (3.5 kPa).

5=

Using 2 or more people, firmly grasp the range and gently lay

it on its back on the cardboard corners.

6.

Pull cardboard bottom firmly to remove.

7.

Use an adjustable wrench to loosen the leveling legs. Adjust

the leveling legs to the correct height. Leveling legs can be

loosened to add up to a maximum of 1" (2.5 cm). A minimum

of 3_6'1(0.5 cm) is needed to engage the anti-tip bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, then tilt forward to

adjust the rear legs.

8=

Place cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto cardboard or

hardboard.

6

Page 7

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

Contact a qualified floor covering installer for the best procedure

for drilling mounting holes through your type of floor covering.

Before moving range, slide range onto shipping base, cardboard

or hardboard.

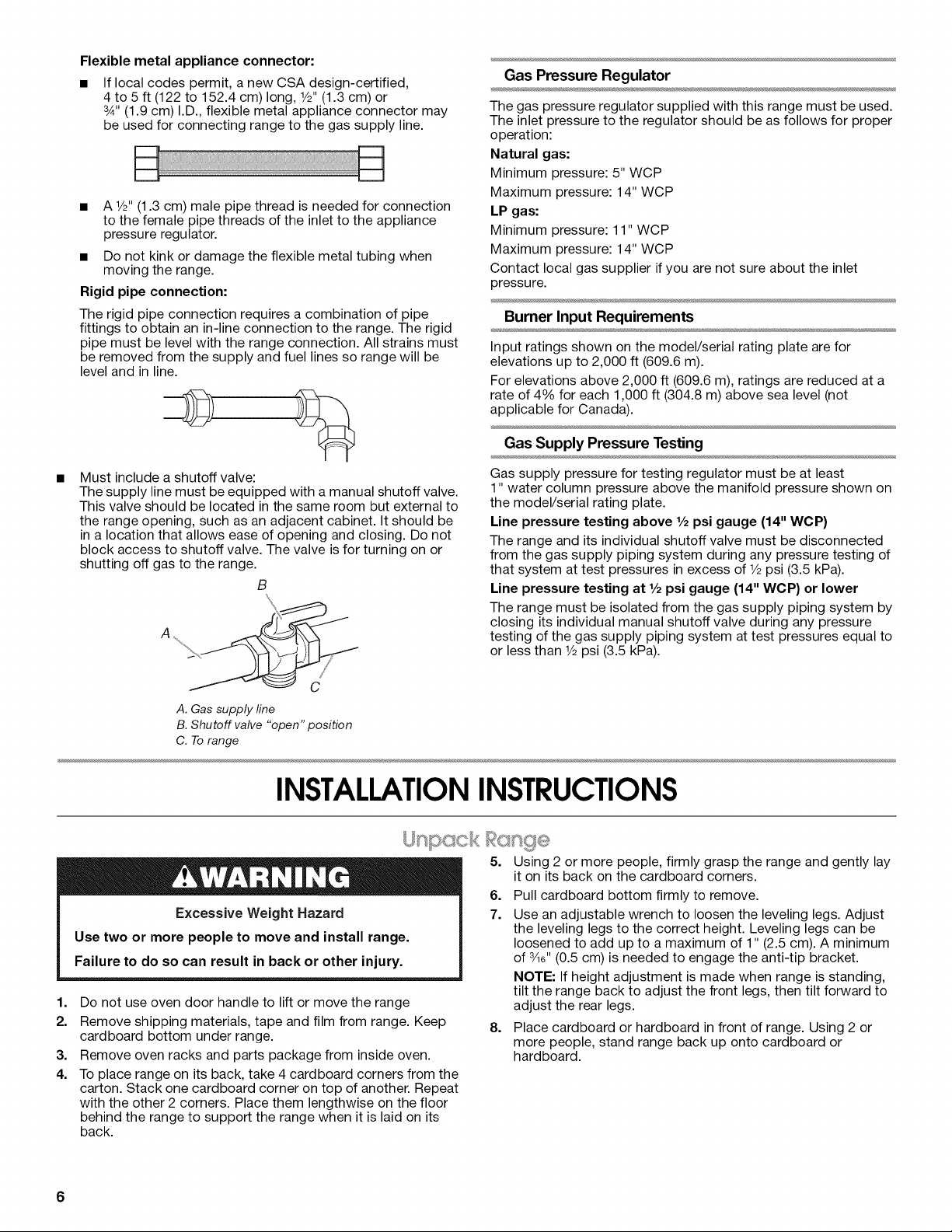

1. Remove template from the anti-tip bracket kit (found inside

the oven cavity).

2. Place template on the floor in cabinet opening so that the left

edge is against cabinet and top edge is against rear wall,

molding or cabinet.

3. Tape template into place.

4. If countertop is not flush with cabinet opening edge, align

template with overhang.

Align the anti-tip bracket holes with the holes in the floor.

Fasten the anti-tip bracket with the screws provided.

Depending on the thickness of your flooring, longer screws

may be necessary to anchor the bracket to the subfloor.

Longer screws are available from your local hardware store.

6. Move range close enough to the opening to allow for final

electrical connection. Remove shipping base, cardboard or

hardboard from under range.

7. Open the broiler door. Use a 3/8"drive ratchet to lower the rear

leveling legs one-half turn. Use a wrench or pliers to lower the

front leveling legs one-half turn.

If cabinet opening iswider than that specified in the "Location

Requirements" section, adjust template so range will be

centered in cabinet opening.

5=

To mount anti-tip bracket to wood floor, drill two 1/8"(0.32 cm)

holes at the positions marked on the bracket template.

Remove template from floor and move to Step 7.

To mount the anti-tip bracket to a concrete or ceramic floor,

use a 3/16"(0.5 cm) masonry drill bit to drill 2 holes at the

positions marked on the bracket template. Remove the

template from the floor. Tap plastic anchors into holes with a

hammer.

A. Rear leveling leg

B. Front leveling leg

8=

Adjust the leveling legs to the correct height. Leveling legs can

be loosened to add up to a maximum of 1" (2.5 cm). A

minimum of 3/le"(0.5 cm) is needed to engage the anti-tip

bracket.

g=

Move range into its final location making sure rear leveling leg

slides into anti-tip bracket.

10. If installing the range in a mobile home, you must secure the

range to the floor. Any method of securing the range is

adequate as long as it conforms to the standards in the

"Location Requirements" section.

11. Continue installing your range using the following installation

instructions.

Page 8

1. Checkthattheanti-tipbracketisinstalled:

• Lookfortheanti-tipbracketsecurelyattachedtothefloor.

• Slidetherangebacksotherearrangefootisundertheanti-

tipbracket.

1=

Place rack in oven.

2.

Place level on rack and check levelness of range, first side to

side; then front to back.

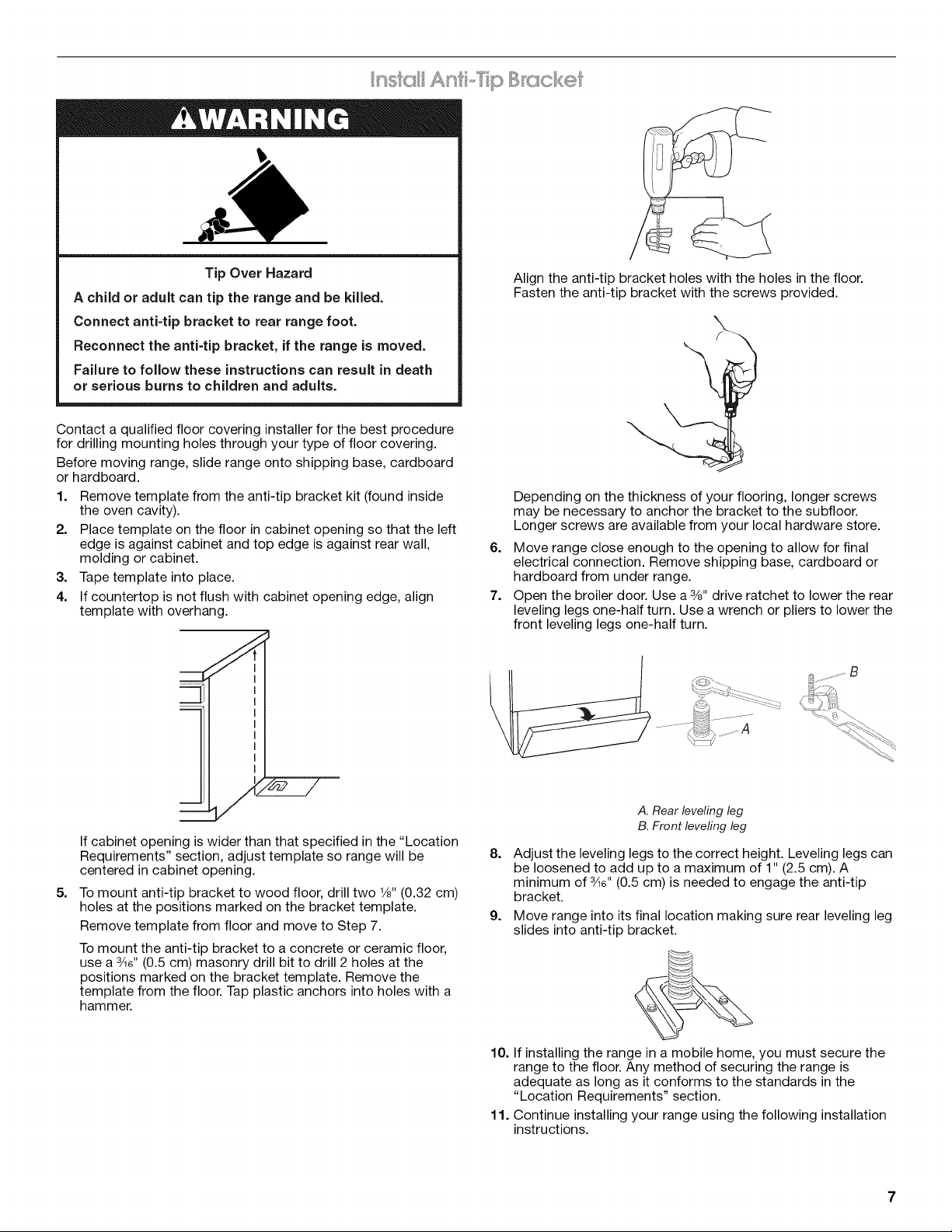

1. Apply pipe-joint compound made for use with LP gas to all

pipe thread connections.

2. Using a pipe wrench to tighten, connect the gas supply to the

range.

C

B

G ........................................

3.

If range is not level, pull range forward until rear leveling leg is

removed from the anti-tip bracket. Use 3/8"drive ratchet and

wrench or pliers to adjust leveling legs up or down until range

is level.

4. Push range back into position.

5. Check that rear leveling leg is engaged in anti-tip bracket.

NOTE: Range must be level for satisfactory baking performance.

Explosion Hazard

Use a new CSA (nternational approved gas supply line.

install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

A. Pressure regulator

connection fitting

B. 90 ° elbow

C. Black iron pipe

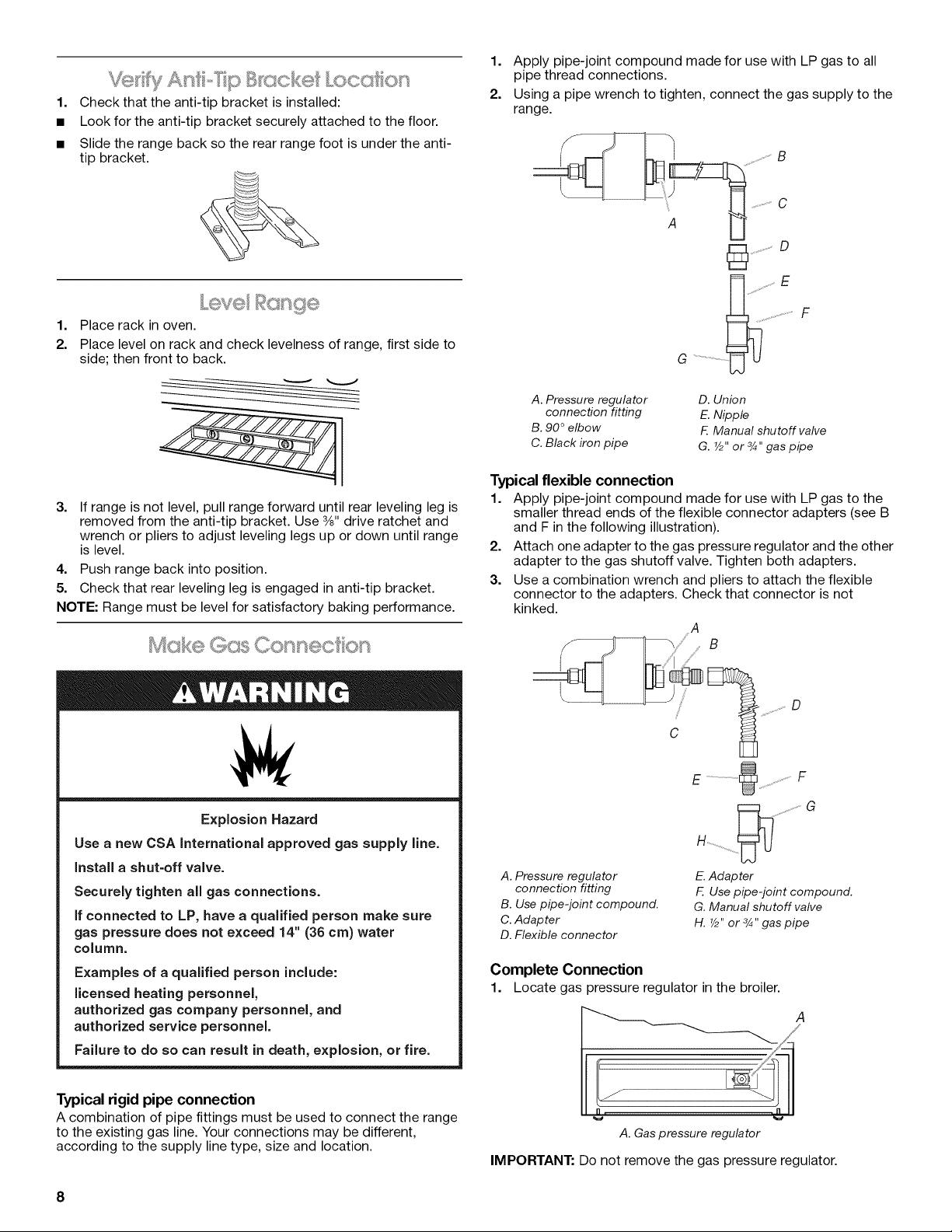

Typical flexible connection

1. Apply pipe-joint compound made for use with LP gas to the

smaller thread ends of the flexible connector adapters (see B

and F in the following illustration).

2. Attach one adapter to the gas pressure regulator and the other

adapter to the gas shutoff valve. Tighten both adapters.

3. Use a combination wrench and pliers to attach the flexible

connector to the adapters. Check that connector is not

kinked.

A. Pressureregulator E.Adapter

connection fitting F Usepipe-joint compound.

B.Use pipe-joint compound. G.Manual shutoff valve

C.Adapter H. Y2"or3/4"gas pipe

D.Flexible connector

D. Union

E.Nipple

F Manual shutoff valve

G. V2"or 3/4"gas pipe

A

......................D

E

............_ F

H ................................

G

Complete Connection

1. Locate gas pressureregulator in the broiler.

Typical rigid pipe connection

A combination of pipe fittings must be used to connect the range

to the existing gas line. Your connections may be different,

according to the supply line type, size and location.

8

A.Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

Page 9

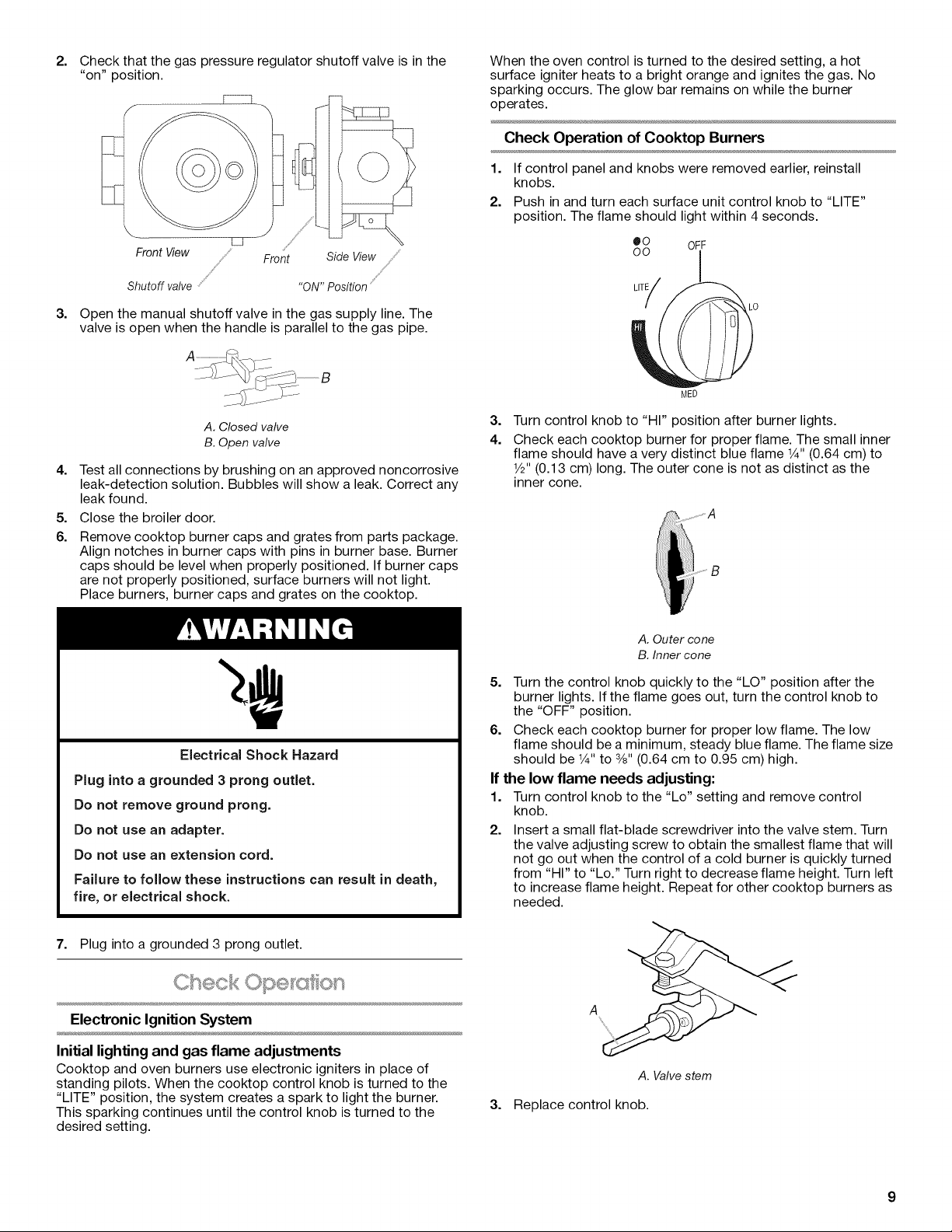

2=

Check that the gas pressure regulator shutoff valve is in the

"on" position.

f

LJ

Front View Front Side View

Shutoff valve "ON" Position ....

3=

Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

4=

Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leak found.

5=

Close the broiler door.

6.

Remove cooktop burner caps and grates from parts package.

Align notches in burner caps with pins in burner base. Burner

caps should be level when properly positioned. If burner caps

are not properly positioned, surface burners will not light.

Place burners, burner caps and grates on the cooktop.

When the oven control is turned to the desired setting, a hot

surface igniter heats to a bright orange and ignites the gas. No

sparking occurs. The glow bar remains on while the burner

operates.

Check Operation of Cooktop Burners

1=

If control panel and knobs were removed earlier, reinstall

knobs.

2.

Push in and turn each surface unit control knob to "LITE"

position. The flame should light within 4 seconds.

eo OF

O0

LIT/ LO

MED

3=

Turn control knob to "HI" position after burner lights.

4.

Check each cooktop burner for proper flame. The small inner

flame should have a very distinct blue flame 1¼,,(0.64 cm) to

1/2"(0.13 cm) long. The outer cone is not as distinct as the

inner cone.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

7. Plug into a grounded 3 prong outlet.

Electronic Ignition System

Initial lighting and gas flame adjustments

Cooktop and oven burners use electronic igniters in place of

standing pilots. When the cooktop control knob is turned to the

"LITE" position, the system creates a spark to light the burner.

This sparking continues until the control knob is turned to the

desired setting.

A. Outer cone

B. Inner cone

5. Turn the control knob quickly to the "LO" position after the

burner lights. If the flame goes out, turn the control knob to

the "OFF" position.

6. Check each cooktop burner for proper low flame. The low

flame should be a minimum, steady blue flame. The flame size

should be W' to 3/8"(0.64 cm to 0.95 cm) high.

If the low flame needs adjusting:

1. Turn control knob to the "Lo" setting and remove control

knob.

2= Insert a small flat-blade screwdriver into the valve stem. Turn

the valve adjusting screw to obtain the smallest flame that will

not go out when the control of a cold burner is quickly turned

from "HI" to "Lo." Turn right to decrease flame height. Turn left

to increase flame height. Repeat for other cooktop burners as

needed.

A. Valvestem

3. Replace control knob.

Page 10

Check Operation of Oven/Broil Burner

Electronic oven control (on some models):

1. Open broiler door.

2. Press the "BAKE" pad.

• The "BAKE" indicator will light.

• "350" will appear inthe display.

3. Press the START/ENTER pad.

• The "TEMP" and "ON" indicators will appear.

• The display will show the automatic countdown time

(10 minutes) needed to preheat the oven for selected

temperature.

The oven burner should light in 20-40 seconds; this delay

is normal. The oven valve requires a certain time before it

will open and allow gas to flow. The oven burner will burn

until oven temperature has reached 350°E After

20-40 seconds, the oven burner will begin to cycle on and

off to maintain the 350°F temperature.

Broil burner and oven burner are the same burner. Check the broil

function as follows:

1. Press the "BROIL" pad.

• "525" will appear in the display.

• The "BROIL" indicator will light.

2. Press the START/ENTER pad.

• The "TEMP" and "ON" indicators will appear.

The oven burner should light in 20-40 seconds; this delay

is normal. The oven valve requires a certain time before it

will open and allow gas to flow. To avoid damaging the hot

surface igniter, do not insert any object into the openings

of the shield that surrounds the igniter or clean that area.

3. Check the oven burner for proper flame. The flame should be

1/2"(0.13 cm) long, with inner cone of bluish-green. The outer

mantle should be dark blue and should be clean and soft in

character. No yellow tips (not enough air), blowing or lifting

(too much air) of flame should occur.

Manifold panel oven control (in some models):

1. Open broiler door.

2. Push and trun the oven control knob to 350°E The oven

burner should light in 20-40 seconds, this delay is normal. The

oven valve requires a certain time before itwill open and allow

gas to flow. The oven burner will burn until oven temperature

has reached 350°E After 20-40 seconds, the oven burner will

begin to cycle on and off to maintain the 350°F temperature.

Make this verification with the knob in the "BROIL" position.

To avoid damaging the hot surface igniter, do not insert any

object into the openings of the sheild that surrounds the

igniter or clean that area.

25o'.

3OO

350

OVENTEMP

3.

Check the oven burner for proper flame. The flame should be

1/2"(0.13 cm) long, with inner cone of bluish-green. The outer

mantle should be dark blue and should be clean and soft in

character. No yellow tips (not enough air), blowing or lifting

(too much air) of flame should occur.

If the flame needs adjusting:

1. Turn the oven off. Wait for the oven burner to cool down.

2. Open oven door and remove oven racks, oven tray, flame

spreader and set aside.

A ............

A

A. Oven tray (lift up at area shown to remove)

B. Screws

C. Flame spreader

3.

Locate the air shutter near the rear wall of oven and loosen the

shutter screw.

A. Shutter screw

B.Air shutter

4=

Adjust the air shutter.

5.

Turn the oven back on and check for proper flame. If the flame

is still not properly adjusted, turn the oven off, wait for the

oven burner to cool down and repeat Step 4 until flame is

properly adjusted.

6.

When the flame has been properly adjusted, turn the oven off,

wait for the burner to cool down.

7.

Tighten the shutter screw.

8.

Reinstall flame spreader and oven tray. Reinstall the oven

racks and close oven door.

9.

Close the broiler door.

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2, Check that you have all of your tools.

3, Dispose of/recycle all packaging materials.

4, Check that the range is level. See "Level Range."

5. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, see the

"Range Care" section of the Use and Care Guide.

6, Read the Use and Care Guide.

7, Turn on surface burners and oven. See the Use and Care

Guide for specific instruction on range operation.

If range does not operate, check the following:

• Household fuse is intact and tight, or circuit breaker has not

tripped.

• Range is plugged into a grounded 3 prong outlet.

• Electrical supply is connected.

• See "Troubleshooting" in the Use and Care Guide.

8. When the range has been on for 5 minutes, check for heat. If

the range is cold, turn off the range and check that the gas

supply line shutoff valve is open.

10

Page 11

• If the gas supply line shutoff valve is closed, open it, then If you need Assistance or Service:

repeat the 5-minute test as outlined above. Please reference the "Assistance or Service" section of the Use

• If the gas supply line shutoff valve is open, press the and Care Guide or contact the dealer from whom you purchased

CANCEL button on the oven control panel and contact a your range.

qualified technician.

GAS CONVERSIONS

Gas conversions from Natural gas to LP gas or from LP gas to

Natural gas must be done by a qualified installer.

Explosion Hazard

Use a new CSA International approved gas supply line.

instal a shut=off valve.

Securely tighten al gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 crn) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

2.

Unplug range or disconnect power.

...................S

A__ ........................C

A. To range

B. Manual shutoff valve "closed" position

C. Gas supply line

To Convert Gas Pressure Regulator

1. Open broiler door and remove broiler pan. The gas pressure

regulator is located in the back right hand corner of the broiler

compartment.

A

q

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

NOTE: Do not remove the spring beneath the cap.

2.

Remove the cap from the gas pressure regulator using a

flat-blade screwdriver.

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn manual shutoff valve to the "closed" position.

A.Cap

3. Turn the cap over so the LP is visible.

A. Cap

4. Reinstall the cap.

11

Page 12

To Convert Surface Burners

1. Remove burnergrate, burner caps and burners.

A

5. Place the Natural gas orifice spuds in the parts bag for future

use and keep with the bag containing literature.

6. Reinstall burners, burner caps and burner grates.

To Convert Oven Burner

1. Open the oven door and remove oven racks, oven tray, flame

spreader and set aside.

2. Lift oven burner. The orifice spud is behind the oven burner air

shutter.

3.

Locate LP gas orifice spud stamped "56" in the bag

containing literature supplied with the range.

A. Burner cap

B. Burner

C. Center burner

2=

Locate LP gas orifice spuds for top burners in the bag

containing literature included with the range. Three LP gas

spuds are stamped "78," and two are stamped "84."

3=

Remove Natural gas orifice spuds using a 7 mm combination

wrench.

4.

Install LP gas orifice spuds using a 7 mm combination

wrench.

©

A. Spud

B. Holder

NOTE: Depending on model, the range cooktop may be

equipped with 4 standard burners, 3 standard burners and

1 power burner, or 3 standard burners, 1 power burner and

1 center burner. Spud size/location remain the same.

A. Standard burner - LP gas orifice spud number 78

B. Power burner - LP gas orifice spud number 84

C. Center burner - LP gas orifice spud number 84

D. Standard burner - LP gas orifice spud number 78

E. Standard burner - LP gas orifice spud number 78

A

A. Oven burner

B. Air shutter

B

4. Use a 7 mm combination wrench and remove the Natural gas

orifice spud.

5. Install the number "56" LP gas spud.

IMPORTANT: Do not overtighten.

A

A. LP oven orifice spud stamped with "56"

6=

Place Natural gas oven burner spud in plastic parts bag along

with Natural gas cooktop burner spuds for future use and

keep with the bag containing literature.

7=

Reinstall oven burner.

8.

Reinstall oven racks, oven tray and flame spreader.

1. Refer to the "Make Gas Connection" section for properly

connecting the range to the gas supply.

2. Turn the manual shutoff valve in the gas supply line to the

open position.

3. Refer to the "Electronic Ignition System" section for proper

burner ingestion, operation and burner flame adjustments.

IMPORTANT: You may have to adjust the "LO" setting for

each cooktop burner.

Checking for proper cooktop and oven burner flames is very

important. The small inner cone should have a very distinct

blue flame 1¼,,to 1/2"(0.64 cm to 0.13 cm) long. The outer cone

is not as distinct as the inner cone. LP gas flames have a

slightly yellow tip.

4. Close the broiler door and press the CANCEL/OFF pad.

5. Refer to the "Complete Installation" section to complete this

procedure.

12

Page 13

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1,

Turn manual shutoff valve to the "closed" position.

2.

Unplug range or disconnect power.

...................S

A

...................................O

3. Turn the cap over so that N or NAT is visible.

A.Cap

4. Reinstall the cap.

To Convert Surface Burners

1. Remove burner grate, burner caps and burners.

C

A. Torange

B.Manual shutoff valve "closed" position

C.Gas supply fine

To Convert Gas Pressure Regulator

1. Open broiler door and remove broiler pan. The gas pressure

regulator is located in the back right hand corner of the broiler

compartment.

A.Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

NOTE: Do not remove the spring beneath the cap.

2. Remove the cap from the gas pressure regulator using a

flat-blade screwdriver.

A

A. Burner cap

B. Burner

C. Center burner

2,

Locate the Natural gas orifice spuds for top burners in the bag

containing literature included with the range. Three Natural

gas spuds are stamped "125," one is stamped "132" and one

"128."

3,

Remove the LP gas orifice spuds using a 7 mm combination

wrench.

4.

Install the Natural gas orifice spuds using a 7 mm combination

wrench.

o \

A. Spud

B. Holder

A

B

A. Cap

13

Page 14

NOTE: Depending on model, the range cooktop may be

equipped with 4 standard burners, 3 standard burners and

1 power burner, or 3 standard burners, 1 power burner and

1 center burner• Spud size/location remain the same.

A. Standard burner - Natural gas orifice spud number 125

B. Power burner - Natural gas orifice spud number 132

C. Center burner - Natural gas orifice spud number 128

D. Standard burner - Natural gas orifice spud number 125

E. Standard burner - Natural gas orifice spud number 125

5. Place LP gas orifice spuds in the parts bag for future use and

keep with the bag containing literature•

6. Reinstall burners, burner caps and burner grates•

To Convert Oven Burner

1. Open the oven door and remove oven racks, oven tray, flame

spreader and set aside•

2. Lift oven burner• The orifice spud is behind the oven burner air

shutter•

3.

Locate Natural gas orifice spud stamped "47" in the bag

containing literature supplied with the range.

4. Use a 7 mm combination wrench and remove the LP gas

orifice spud.

5. Install the number "47" LP gas spud.

IMPORTANT: Do not overtighten.

6.

Place LP gas oven burner spud in plastic parts bag along with

LP gas cooktop burner spuds for future use and keep with the

bag containing literature•

7.

Reinstall oven burner•

8.

Reinstall oven racks, oven tray and flame spreader•

P ................." ""_ " ......,0 d%.,_:;_:4OF_l

'_,,_.0I'@)_@E@p ',Is",+.@ ,,_A"'..

1.

Refer to the "Make Gas Connection" section for properly

connecting the range to the gas supply.

2.

Turn the manual shutoff valve in the gas supply line to the

open position.

3.

Refer to the "Electronic Ignition System" section for proper

burner ingestion, operation and burner flame adjustments.

IMPORTANT: You may have to adjust the "kO" setting for

each cooktop burner•

Checking for proper cooktop and oven burner flames is very

important• The small inner cone should have a very distinct

blue flame 1¼,,to 1/2"(0.64 cm to 0.13 cm) long. The outer cone

is not as distinct as the inner cone. Natural gas flames do not

have yellow tips.

4. Close the broiler door and press the CANCEL/OFF pad.

5. Refer to the "Complete Installation" section to complete this

procedure•

14

A. Oven burner

B. Air shutter

Page 15

SEGURIDADDELA ESTUFA

Su seguridad y la seguridad de los demos es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodomestico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el simbolo de advertencia de seguridad.

Este simbolo le llama la atenci6n sobre peligros potenciales que pueden ocasionar la muerte o una lesi6n a

usted y a los demas.

Todos los mensajes de seguridad iran a continuaci6n del simbolo de advertencia de seguridad y de la palabra

"PELIGRO" o "ADVERTENCIA". Estas palabras significan:

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesibn grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesibn grave.

Todos los mensajes de seguridad le diran el peligro potencial, le diran c6mo reducir las posibilidades de sufrir una lesi6n y Io que

puede suceder si no se siguen las instrucciones.

ADVERTENCIA: Si la informacion en este manual no se sigue con exactitud, podria

ocurrir un incendio o una explosion, Io que causaria dahos a propiedades, heridas

personales o la muerte.

- No almacene o use gasolina u otros liquidos y vapores inflamables cerca de este u otro

aparato electrodomestico.

- PASOS QUE USTED DEBE SEGUIR SI HUELE A GAS:

• No trate de encender ningun aparato electrodomestico.

• No toque ningun interruptor electrico.

• No use ningun telefono en su casa o edificio.

• Llame inmediatamente a su proveedor de gas desde el telefono de un vecino.

Siga las instrucciones de su proveedor de gas.

• Si usted no puede comunicarse con su proveedor de gas, Ilame al departamento

de bomberos.

- La instalacion y el servicio deben ser efectuados por un instalador calificado, una

agencia de servicio o por el proveedor de gas.

ADVERTENCIA: Las perdidas de gas no siempre se pueden detectar por el olfato.

Los proveedores de gas recomiendan que usted use un detector de gas aprobado por UL (Laboratorio de normalizaci6n) o

CSA (Asociaci6n canadiense de seguridad).

Para obtener mas informaci6n, p6ngase en contacto con su proveedor de gas.

Si se detecta una fuga de gas, siga las instrucciones de "Pasos que usted debe seguir si huele a gas".

15

Page 16

En el estado de Massachusetts se aplican las siguientes instrucciones de instalaci6n:

• Las instalaciones y reparaciones se deben efectuar por un contratista, plomero o gasista calificado o licenciado por el estado

de Massachusetts.

• Si se usa una valvula de bola, debe ser un tipo de manigueta T.

• Si se usa un conector de gas flexible no debe exceder de 3 pies.

Peligro de Vuelco

Un nJ_o o un aduito puede voicar aeeJdentaJmente Jaestufa y resuitar muerto.

Conecte el soporte anti=vuelco a la pata trasera de la estufa.

Si traslada de Jugar Jaestufa, vuelva a conectar el soporte anti=vuelco.

No seguir estas instrueeiones puede ocasionar la muerte o quemaduras graves en ni_os y

aduitos.

REQUlSlTOSDE INSTALACION

El soporte anti-vuelco debe estar montado en el contrapiso

RezGs y "" ...........

ReOna las herramientas y piezas necesarias antes de comenzar la

instalacion. Lea y siga las instrucciones provistas con cualquiera

de las herramientas enlistadas aqui.

Herramientas necesarias

• Nivel

• Trinquete de accionamiento de 3/8"

• Cinta para medir

• Destornillador de hoja plana

• Destornillador Phillips

• Taladro manual o electrico

• Llave de tuerca o pinzas

• Llave de combinacion de 7 mm

• Llave para tubes

• broca de 1/8"(3,2 mm) (para pisos de madera)

• broca para alba_ileria con punta de carburo de 3/le"(4,8 mm)

(para pisos de concreto/ceramica)

• Pegamento para tuberias resistente a gas L.R

• Solucion para detectar fugas, que no sea corrosiva

firmemente. SegOn el espesor del piso, es posible que sea

necesario utilizar tornillos mas largos para sujetar elsoporte al

contrapiso. Puede conseguir tornillos m4s largos en su

ferreteria local.

Piezas necesarias

Verifique los codigos locales y consulte con el proveedor de gas.

Verifique elsuministro de gas existente y el suministro electrico.

Vea las secciones "Requisites electricos" y "Requisites del

suministro de gas".

u_:;,;%,b CGC ONI,

IMPORTANTE: Observe todos los c6digos y reglamentos

aplicables. No obstruya el flujo de aire para la combusti6n y la

ventilaci6n.

Es la responsabilidad del instalador cumplir con los espacios

de instalacion especificados en la placa con la clasificacion

de modelo/serie. La placa indicadora de modelo/serie esta

ubicada en el marco del horno, detrAs del lade izquierdo de la

puerta del asador.

Piezas suministradas

Verifiqueque esten todas las piezas.

B

C

A. Soporte anti-vuelco

B. Taquetes de pl4stico (2)

C. Tornillos #10 x 1/2" (2)

• Bolsa con material impreso

• Espitas de los orificios para la conversion (dentro de la bolsa

con material impreso).

16

A. Ubicaci6n de la placa de clasificaci6n de modelo/serie

• Debera colocarse la estufa en un lugar conveniente de la

cocina para su use.

• Las instalaciones empotradas deberan proveer un recinto

completamente cerrado de los lades y la parte posterior de la

estufa.

Para eliminar el riesgo de quemaduras o incendio al tocar

unidades con lasuperficie caliente, deberA evitarse el uso de

armarios de almacenaje encima de las unidades. Si van a

proveerse armarios, puede reducir el riesgo instalando una

capota de ventilacion que se proyecte horizontalmente un

minimo de 5" (12,7 cm) sobresaliendo de la base de los

armarios.

Deberan sellarse todas las aberturas en la pared o en el piso

en donde se instalarA la estufa.

No selle la estufa a los armarios laterales.

Deben usarse las dimensiones de la abertura del armano que

se muestran. Las dimensiones proporcionadas son los

espacios minimos.

Page 17

• Debe instalarse el soporte anti-vuelco del piso. Para instalar el

soporte anti-vuelco enviado con la estufa, vea la seccion

"lnstalacion del soporte anti-vuelco".

• Se requiere un suministro electrico conectado a tierra. Vea la

seccion "Requisitos electricos".

• Debera haber una conexion adecuada del suministro de gas.

Vea la seccion "Requisitos del suministro de gas".

• Pongase en contacto con un instalador calificado de

revestimiento de pisos para cerciorarse de que el

revestimiento del piso puede soportar por Io menos 200°F

(93°C).

• Use una almohadilla aislante o una madera laminada de 1¼,,

(0,64 cm) debajo de la estufa siva a instalar la estufa sobre

una alfombra.

IMPORTANTE. Para evitar da_os a sus armarios, verifique con el

constructor o distribuidor de armarios para asegurarse de que los

materiales que se usen no se descoloren, astillen ni sufran ningOn

otro tipo de da_o. Este horno ha sido dise_ado de acuerdo a los

requisitos de UL y CSA International, y cumple con las

temperaturas mAximas permitidas para armarios de madera de

194°F (90°C).

Requisitos de instalaci6n adicionales para las casas

rodantes

La instalacion de esta estufa debe ajustarse al Estandar de

seguridad y construccion de casas fabricadas, Titulo 24 CFR,

Parte 3280 (anteriormente conocido como Estandar federal para

la seguridad y construccion de casas rodantes, Titulo 24, HUD

Parte 280). Cuando no sea aplicable ese estandar, use el Estandar

para instalaciones en casas fabricadas, ANSI A225.1/NFPA 501A

u obedezca los codigos locales.

Las instalaciones en casas rodantes necesitan"

Cuando se instale la estufa en una casa rodante, deberA

asegurarse al piso durante el transporte. Cualquier metodo de

fijacion es adecuado en tanto cumpla con las normas

indicadas arriba.

Medidas del armario

Las dimensiones de la abertura del armario que se muestran son

para una profundidad del mostrador de 25" (64,0 cm),

profundidad de la base del armario de 24" (61,0 cm) y una altura

del mostrador de 36" (91,4 cm).

Si la profundidad del armario es mayor de 24" (61,0 cm), debera

extenderse el marco del horno mas alia de los frentes del armario

por un minimo de 1/2"(13,0 mm).

IMPORTANTE" Siva a instalar una campana para estufa o una

combinacion microondas campana sobre la estufa, siga las

instrucciones de instalacion incluidas con la campana para estufa

o la combinacion microondas campana para las medidas de

espacio sobre la superficie de coccion.

G

I

I

I

I

Medidas del producto

A

E

A. 26¼" (67,9 cm)

B. 36" (91,4 cm)

C. 46¼" (117,5 cm)

D. 297/8'' (75,9 cm)

E.24¼" (61,6 cm)

A. 18" (45, 7 cm) de espacio mfnimo del lado superior del armario al

mostrador

B. 13" (33,0 cm) m#ximo de profundidad del armario superior

C. 30" (76,2 cm) de ancho mfnimo de la abertura del armario

D. Para ver el espacio mfnimo hasta la parte superior de la superficie

de cocci6n, vea la NOTA*.

E.301/8''(76,5 cm) de ancho mfnimo de la abertura

F. Se recomienda esta _rea sombreada para la instalaci6n del

tomacorriente.

G. Se recomienda esta #rea sombreada para la instalaci6n de la

tuberfa de gas rfgida

H. 2" (5,1 cm) de espacio mfnimo del mostrador a la pared lateral u

C

otro material combustible

I. 24" (61,0 cm)

J. 10" (25,4 cm)

K. 8" (20,3 cm)

L. 5" (12, 7 cm)

M. 2" (5,1 cm)

N. 3" (7,6 cm)

*NOTA: 24" (61,0 cm) minimo cuando la base del armario de

madera o de metal este protegida por carton retardante alas

llamas de no menos de 1/4"(0,64 cm), cubierto de lamina de

acero de no menos de N° 28 MSG, acero inoxidable de 0,015"

(0,4 mm), aluminio de 0,024" (0,6 mm) o cobre de 0,020"

(0,5 mm).

30" (76,2 cm) de espacio minimo entre la parte superior de la

plataforma de la superficie de coccion y la base de un armario de

madera o metal desprotegido.

17

Page 18

stos c® de

PelJgro de Choque El_ctrico

Conecte a un contacto de pared de conexi6n a tierra de

3 terminales.

No quite la terminal de conexi6n a tierra.

No use un adaptador.

No use un cable el_ctrico de extensi6n.

No seguir estas instrucciones puede ocasionar

la muerte, incendio o choque el_ctrico.

IMPORTANTE: La estufa debera estar conectada a tierra de

acuerdo con los codigos y ordenanzas locales, o en la ausencia

de codigos locales, con el Codigo Nacional Electrico (National

Electrical Code), ANSI/NFPA 70, Oltima edicion.

Si los codigos Io permiten y se emplea un alambre de conexion a

tierra separado, es recomendable que un instalador electrico

calificado determine si la trayectoria de conexion a tierra es

adecuada.

Usted puede obtener una copia de todas las normas arriba

indicadas en:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

Se necesita un circuito electrico de 120 voltios, 60 hertzios,

CA solamente, de 15 amperios y protegido con fusible. Se

recomienda tambien un fusible retardador o un cortacircuitos.

Asimismo se recomienda el uso de un circuito independiente

que preste servicio Onicamente a esta estufa.

Esta estufa viene equipada con un cable electrico dotado de

un enchufe con tres terminales y conexion atierra. Para

reducir al minimo el peligro de posibles choques electricos, el

cable debe ser enchufado en un contacto de pared de tres

terminales conectado a tierra.

Los sistemas de encendido electronico funcionan dentro de

amplios limites de voltaje, pero se debe tener la conexion a

tierra y polaridad correctas. Verifique que el contacto tenga

una capacidad para 120 voltios y que este debidamente

conectado a tierra.

Esta estufa esta equipada con un sistema de encendido

electronico que no funcionarA si se enchufa en un contacto

que no esta debidamente polarizado.

El diagrama de cableado esta ubicado en la parte posterior de

la estufa, en una bolsa de plastico transparente.

NOTA: El armazon de metal de la estufa debera conectarse a

tierra para que funcione el panel de control. Si no se conecta a

tierra el armazon de metal, ningOn boton funcionara. Verifique

con un electricista calificado si tiene dudas acerca de si esta

conectado a tierra el armazon de la estufa.

Peligro de Explosi6n

Use una I[nea de suministro de gas nueva con

aprobaci6n de CSA international.

Instale una v_lvula de cierre.

Apriete firmemente todas las conexiones de gas.

Si se conecta a un suministro de gas LP, la presi6n no

debe exceder una coiumna de agua de 36 cm (14") y

debe set verificada por una persona calificada.

Ejempios de una persona calificada incluyen:

personal de servicio del sistema de calefacci6n con

licencia,

personal autorizado de la compahia de gas, y

personal autorizado para dar servicio.

No seguir estas Jnstrucciones puede ocasionar

la muerte, explosi6n o incendio.

Observe todos los codigos y reglamentos aplicables.

IMPORTANTE: Esta instalacion debe hacerse de acuerdo con

todos los codigos y ordenanzas locales. Si no hay codigos

locales, la instalacion debera hacerse de acuerdo al C6digo

Nacional Estadounidense (American National Standard), el

Codigo Nacional de Gas Combustible (National Fuel Gas Code),

ANSI Z223.1- Qltima edicion o CAN/CGA B149 - Qltima edicion.

IMPORTANTE: La prueba de fugas de la estufa deberA

efectuarse segQn las instrucciones del fabricante.

Tipo de gas

Gas natural:

El dise_o de esta estufa esta certificado por CSA International

para gas natural o, despu6s de la conversi6n apropiada, para

usarse con gas L.P.

• Esta estufa esta preparada de fabrica para uso con gas

natural. Vea la secci6n "Conversiones de gas". La placa

con el nQmero de modelo/serie, ubicada en el marco, del

lado derecho, detras del caj6n de almacenamiento, tiene

informaci6n acerca de los tipos de gas que pueden

usarse. Si la lista de tipos de gas no incluye el tipo de gas

disponible, averigQe con el distribuidor de gas de su

Iocalidad.

Conversibn de gas L.P.:

La conversion deberA Ilevarla a cabo un tecnico de servicio

calificado.

No se debera hacer intento alguno para convertir el aparato

del gas especificado en la placa de clasificacion del modelo/

serie para utilizar un gas distinto sin consultar con el

abastecedor de gas. Vea la seccion "Conversiones de gas".

18

Page 19

Linea de suministro de gas

Regulador de la presi6n de gas

Provea una linea de suministro de gas de tuberia rigida de

%" (1,9 cm) hacia la ubicacion de la estufa. Una tuberia de

tama_o mas peque_o en tendidos mas largos puede traer

como consecuencia un suministro de gas insuficiente.

Con el gas LP, el tama_o de la tuberia puede ser de un

minimo de 1/2"(1,3 cm). Por Io general, los proveedores de

suministro de gas LP determinan el tama_o y los

materiales a usarse en el sistema.

NOTA: Deben usarse compuestos para uniones de tuberia

que sean resistentes a la accion del gas LR No utilice cinta

TEFLON®t.

Conector flexible de metal del aparato:

• Si los codigos locales Io permiten, puede usarse un

conector de metal flexible para aparatos nuevo, con

dise_o certificado de CSA, de 4 a 5 pies (122 a 152,4 cm)

de largo, diametro interno de 1/2"(1,3 cm) 6 3_,,(1,9 cm)

para conectar la estufa a la linea de suministro de gas.

Se necesita una rosca macho para tuberia de 1/2"(1,3 cm) para

conectar las roscas hembra de la entrada al regulador de

presion del aparato.

No tuerza ni da_e latuberia de metal flexible cuando mueva la

estufa.

Conexibn de tuberia rigida:

La conexion de tuberia rigida requiere una combinacion de

accesorios de tuberia para obtener una conexion en linea hacia la

estufa. Latuberia rigida deberA estar nivelada con la conexion de

la estufa. DeberAn quitarse todas las torceduras de las lineas de

suministro y de combustible para que la estufa este nivelada y

alineada.

Debe tener una valvula de cierre:

La linea de suministro debera equiparse con una valvula de

cierre manual. Esta valvula debera estar ubicada en la misma

habitacion pero fuera de la abertura donde se encuentra la

estufa, como un armario adyacente. Debera estar en una

ubicacion que permita un facil acceso para abrir y cerrar. No

bloquee el acceso a la valvula de cierre. La valvula es para

abrir o cerrar el suministro de gas a la estufa.

Debera usarse el regulador de la presion de gas suministrado con

esta estufa. Para el funcionamiento adecuado, la presion de

entrada al regulador deberA ser como se indica a continuacion:

Gas natural:

Presion minima: 5" WCP

Presion maxima: 14" WCP

Gas LP:

Presion minima: 11" WCP

Presion maxima: 14" WCP

Pongase en contacto con el proveedor de gas de su Iocalidad si

no esta seguro acerca de la presion de entrada.

Requisitos de entrada del quemador

Los rangos de entrada que se muestran en la placa de

clasificacion del modelo/serie son para elevaciones de hasta

2.000 pies (609,6 m).

Para elevaciones mayores de 2.000 pies (609,6 m), los rangos se

reducen a un ritmo de 4 % por cada 1.000 pies (304,8 m) por

encima del nivel del mar (no es aplicable para CanadA).

Prueba de presi6n del suministro de gas

La presion del suministro de gas para un regulador de prueba

debe ser de al menos 1" de la presion de la columna de agua

sobre la presion del mQItiple, que se muestra en la placa

indicadora del modelo/serie.

Prueba de presibn de la linea por encima de 1/2Ib/pulg 2

manom_trica (presibn de la columna de agua de 14")

La estufa y su valvula de cierre individual deberan ser

desconectadas del sistema de tuberia del suministro de gas

durante toda prueba de presion efectuada en dicho sistema a

presiones de prueba mayores de 1/2Ib/pulg 2 (3,5 kPa).

Prueba de presibn de la linea a 1/2Ib/pulg 2 (presibn de una

columna de agua de 14") o menor

La estufa debera aislarse del sistema de tuberia del suministro de

gas cerrando la valvula de cierre individual manual durante toda

prueba de presion efectuada en dicho sistema a presiones de

prueba iguales o menores de 1/2Ib/pulg 2 (3,5 kPa).

B

x

A

A. Lfnea de suministro de gas

B. V_lvula de cierre en posici6n "abierta"

C. A la estufa

1-®TEFLON es una marca registrada de E.I. Du Pont De Nemours and Company.

19

Page 20

INSTRUCCIONESDE INSTALACION

Peligro de peso excesivo

Use dos o m_s personas para mover e instalar

la estufa.

No seguir esta instrucci6n puede ocasionar una

lesi6n en la espalda u otro tipo de lesiones.

1. No use la agarradera de la puerta del horno para levantar o

mover la estufa.

2. Quite los materiales de envio, la cinta adhesiva y la pelicula de

la estufa. Mantenga la base de carton debajo de la estufa.

3. Saque las parrillas del horno y el paquete de piezas del

interior del horno.

4. Para colocar la estufa sobre su parte posterior, tome los 4

esquinales de carton de la caja. Apile un esquinal de carton

sobre el otro. Repita con los otros 2 esquinales. Coloquelos a

Io largo, sobre el piso, detras de la estufa para protegerla

cuando se coloque sobre su parte posterior.

5. Con la ayuda de 2 o mas personas, agarre la estufa con

firmeza y coloquela suavemente sobre su parte posterior, en

los esquinales de carton.

6. Jale la base de carton con firmeza para quitarla.

7. Use una Ilave de tuercas ajustable para aflojar las patas

niveladoras. Ajuste las patas niveladoras para corregir la

altura. Las patas niveladoras pueden aflojarse para agregar un

maximo de 1" (2,5 cm). Se necesita un minimo de 3_6"

(5,0 mm) para encajar el soporte anti-vuelco.

NOTA: Si se ajusta la altura cuando la estufa esta de pie, inclinela

hacia atras para ajustar las patas delanteras y luego inclinela

hacia delante para ajustar las patas traseras.

8. Coloque el cart6n o madera frente a la estufa. Con la ayuda

de 2 o mas personas, coloque la estufa de pie nuevamente

sobre el carton o madera.

Peligro de Vuelco

Un ni_o o un adulto puede volcar accidentalmente

la estufa y resultar muerto.

Conecte el soporte anti-vuelco a la pata trasera de

la estufa.

Si traslada de lugar la estufa, vuelva a conectar

el soporte anti-vuelco.

No seguir estas instrucciones puede ocasionar

la muerte o quemaduras graves en niSos y adultos.

Pongase en contacto con un instalador competente de

revestimiento de pisos para ver cual es el mejor procedimiento

para perforar orificios de montaje a traves del tipo de

revestimiento de pisos que usted tenga.

Antes de mover la estufa, deslicela sobre la base de transporte,

carton o madera.

1. Saque la plantilla del juego del soporte anti-vuelco (se

encuentra dentro de la cavidad del horno).

2. Coloque la plantilla sobre el piso, en la abertura del armario,

de manera que el extremo izquierdo este contra el armario y el

extremo superior este contra la pared, moldura o armario

posterior.

3. Pegue la plantilla con cinta adhesiva en el lugar.

4. Si el mostrador no esta alineado con el extremo de la abertura

del armario, alinee la plantilla con la saliente.

m

20

iL

Page 21

Si la abertura del armario es mas ancha que Io especificado en la

seccion "Requisitos de ubicacion", ajuste la plantilla de manera

que la estufa este centrada en la abertura del armario.

5. Para montar el soporte anti-vuelco al piso de madera, perfore

dos orificios de 1/8"(0,32 cm) en las posiciones marcadas en la

plantilla del soporte.

Saque la plantilla del piso y continQe con el paso 7.

Para montar el soporte anti-vuelco a un piso de hormigon o

de ceramica, use una broca de taladro de albafiileria de 3/le"

(0,5 cm), para taladrar 2 orificios en las posiciones marcadas

sobre la plantilla del soporte. Saque la plantilla del piso.

Martille los taquetes de plastico en los orificios.

Alinee los orificios del soporte anti-vuelco con los orificios en

el piso. Sujete el soporte anti-vuelco con los tornillos

provistos.

9. Mueva laestufa a su ubicacion final, asegurAndose de que la

pata niveladora trasera se desliza en el soporte anti-vuelco.

10. Si instala la estufa en una casa rodante, debera fijar la estufa

al piso. Cualquier metodo de fijacion es adecuado en tanto

cumpla con las normas indicadas en la seccion "Requisitos

de ubicacion".

11. ContinOe instalando la estufa siguiendo las instrucciones de

instalacion.

_t: f C(XC O_S _ " .........

....... c® ,Jbcc c o de sopo e

1.

AsegOrese de que el soporte anti-vuelco haya sido instalado.

Busque el soporte anti-vuelco ajustado firmemente al piso.

Deslice la estufa hacia atras de modo tal que la pata trasera

quede debajo del soporte anti-vuelco.

SegOn el espesor del piso, es posible que necesite tornillos

mas largos para sujetar el soporte al contrapiso. Puede

conseguir tornillos mas largos en su ferreteria local.

6. Mueva la estufa I0 suficientemente cerca de la abertura para

permitir que se hagan las conexiones electricas finales. Quite

la base de transporte, carton 0 madera que se encuentra

debajo de la estufa.

7. Abra la puerta del asador. Use un trinquete de accionamiento

de 3/8"para bajar las patas niveladoras traseras dando medio

giro. Use una Ilave de tuercas 0 unas pinzas para bajar las

patas niveladoras delanteras media vuelta.

A. Pata niveladora trasera

B. Pata niveladora delantera

1. Ponga la parrilla en el horno.

2. Coloque un nivel en la parrilla y verifique que la estufa este

nivelada, primero de lado a lado y despu6s de adelante hacia

atrAs.

3. Si la estufa no esta nivelada, jalela hacia adelante hasta quitar

la pata niveladora posterior del soporte anti-vuelco. Use un

trinquete de accionamiento de 3/8"y Ilave de tuercas o pinzas

para ajustar las patas niveladoras hacia arriba o hacia abajo

hasta que la estufa este nivelada.

4. Empuje la estufa a su posicion final.

5. Verifique que la pata niveladora trasera este enganchada en el

soporte anti-vuelco.

NOTA" La estufa debe estar nivelada para obtener un horneado

satisfactorio.

8.

Ajuste las patas niveladoras para corregir la altura. Las patas

niveladoras pueden aflojarse para agregar un maximo de 1"

(2,5 cm). Se necesita un minimo de 3/le"(0,5 cm) para encajar

el soporte anti-vuelco.

21

Page 22

C,onex de < de

3. Use una Ilave de combinaci6n y unas pinzas para ajustar el

conector flexible a los adaptadores. Cerci6rese de que el

conector no este torcido.

A

Peiigro de Expiosi6n

Use una linea de suministro de gas nueva con

aprobaei6n de CSA international.

[nstale una v_[vula de cierre.

Apriete firmemente todas las eonexiones de gas.

Si se conecta a un suministro de gas LP, la presi6n no

debe e×ceder una co[umna de agua de 36 cm (14") y

debe ser verificada por una persona calificada.

Ejemp[os de una persona calificada ineiuyen:

personal de servicio del sistema de caiefaeci6n con

licencia,

personal autorizado de la eompaffia de gas, y

personal autorizado para dar servicio.

No seguir estas instrueeiones puede ocasionar

la muerte, expiosi6n o ineendio.

Conexi6n tipica de la tuberia rigida

Se debe usar una combinacion de tubos de union para conectar

la estufa a la linea de suministro de gas existente. Sus conexiones

pueden ser distintas, de acuerdo con el tipo de linea de

suministro, tamafio y ubicacion.

1. Aplique compuesto para union de tuberia fabricado para

usarse con el gas LP en todas las conexiones con rosca de

tuberia.

2. Utilizando una Ilave de tuercas para tuberia para ajustar,

conecte el suministro de gas a la estufa.

i¸ .- ..............O

E

.........._ F

G

H ................................

A. Accesorio de conexi6n del

regulador de presi6n

B. Use compuesto para

uniones de tuberfa

C. Adaptador

D. Conector flexible

E. Adaptador

F. Use compuesto para uniones de

tuberfa

G. Wlvula de cierre manual

H. Tubo de gas de 7/2" 6 3/4"

Complete la conexi6n

1. Ubique el regulador de la presion de gasen el asador.

A

A. Regulador de la presi6n de gas

.........................................._ ..........B

........................e

A.Accesorio de conexidn D.Unidn

del regulador de E.Niple

presi6n F.V_lvulade cierre manual

B. Codo de 90° G. Tubode gas de V2"6 3/4"

C. Tuberfade hierro negro

Conexi6n flexible tipica

1. Aplique compuesto para union de tuberia hecho para usarse

con gas LP a los extremos mas pequefios de la rosca de los

adaptadores flexibles del conector (vea B y Fen la ilustracion

siguiente).

2. Fije un adaptador al regulador de la presion del gas y el otro

adaptador a la valvula de cierre de gas. Apriete ambos

adaptadores.

IMPORTANTE: No quite el regulador de la presion de gas.

2. Verifique que la valvula de cierre del regulador de la presion de

gas este en la posicion "ON" (Abierta).

'-- U

Vistafrontal Partefrontal Vistalateral .........

Valvulade cierre....... Posicidn"ON"(Abierto)

3=

Abra lavalvula de cierre manual de la linea de suministro de

gas. La valvula esta abierta cuando la manija esta paralela al

tubo de gas.

A. V_lvula cerrada

B. V_lvula abierta

22

Page 23

4,

Pruebe todas las conexiones aplicando con un cepillo una

solucion aprobada para deteccion de fugas que no sea

corrosiva. Se observarAn burbujas si hay fuga. Tape cualquier

fuga que encuentre.

5,

Cierre la puerta del asador.

6.

Saque las tapas de los quemadores de la superficie de

coccion y las parrillas del paquete de piezas. Alinee las

muescas que estan en las tapas de los quemadores con los

pasadores de la base del quemador. Las tapas del quemador

deberAn estar niveladas cuando se colocan en la posicion

correcta. Si las tapas de los quemadores no estan en la

posicion correcta, los quemadores de la superficie no se

encenderan. Coloque los quemadores, las tapas de los

quemadores y las parrillas sobre la superficie de coccion.

Peligro de Choque EI6ctrico

Conecte a un contacto de pared de conexi6n a tierra de

3 terminales.

No quite la terminal de conexi6n a tierra.

No use un adaptador.

No use un cable el_ctrico de extensi6n.

No seguir estas instrucciones puede ocasionar

la muerte, incendio o choque el6ctrico.

7. Conecte a un contacto de pared de conexi6n a tierra de 3

terminales.

que e nc onc m ento

Sistema de encendido electr6nico

Encendido inicial y ajustes de la llama de gas

Los quemadores de la superficie de cocci6n y el horno usan

encendedores electr6nicos en lugar de pilotos permanentes.

Cuando se gira la perilla de control de la superficie de cocci6n a la

posici6n "LITE" (Encendido), el sistema crea una chispa para

encender el quemador. Esta chispa continQa hasta que se gire la

perilla de control hacia el ajuste deseado.

Cuando el control del horno se gira hacia el ajuste deseado, un

encendedor caliente de la superficie se calienta hasta quedar con

un color naranja brillante, y enciende el gas. No se producen

chispas. Mientras funciona el quemador, la barra luminosa

permanecerA encendida.

2,

Empuje hacia adentro y gire cada perilla de control de la

superficie hacia la posici6n "LITE" (Encendido). La llama

deberA encenderse en menos de 4 segundos.

eo OF

O0

LIT/ LO

MED

3. Gire la perilla de control hacia la posici6n "HI" (Alto) despu6s

de que se encienda el quemador.

4. Fijese que cada quemador de la superficie de coccion tenga

la llama adecuada. El cono interior pequefio debera tener una

llama azul bien nitida de 1¼,,(0,64 cm) a 1/2"(1,3 cm) de largo.

El cono exterior no es tan nitido como el cono interior.

A. Cono exterior

B. Cono interior

5. Gire rapidamente la perilla de control hacia la posicion "LO"

(Bajo) despu6s de que el quemador se encienda. Si la llama

se apaga, gire la perilla de control hacia la posicion "OFF"

(Apagado).

6. Fijese que cada quemador de la superficie de coccion tenga

la llama baja adecuada. La llama baja debera ser una llama

azul minOscula y estable. La llama deberA tener una altura de

1_'1 a 3/8'1(0,64 cm a 0,95 cm).

Si la llama baja necesita ajustarse:

1. Gire la perilla de control hacia el ajuste "LO" (Bajo) y sAquela.

2. Inserte un destornillador pequefio de hoja plana en el vastago

de la valvula. Gire el tornillo de ajustar la valvula para obtener

la llama mas pequefia que no se apague cuando se gire el

control de un quemador frio de "HI" (Alto) a "LO" (Bajo). Gire

hacia laderecha para reducir la altura de la llama. Gire hacia la

izquierda para aumentar la altura de la llama. Repita el

procedimiento para los otros quemadores de la superficie de

coccion, segun sea necesario.