Whirlpool RH9330XL User Manual

CONVERTIBLE KITCHEN RANGE HOOD

FOR 120 V. OPERATION

READ AND SAVE THESE INSTRUCTIONS

Before you begin,

completely and carefully. If followed, they will simplify

the installation job.

IMPORTANT: OBSERVE ALL GOVERNING CODES

SAVE THESE INSTRUCTIONS FOR THE LOCAL

ELECTRICAL INSPECTOR’S USE

read the following instructions

AND ORDINANCES

FOR VENTLESS INSTALLATION

USE DUCTLESS KIT RCH 9600

KITCHEN

RANGE HOOD

MODEL

RH9330XL

WAYS TO INSTALL VENTILATING DUCT:

There are three ways to install the ventilating duct.

Select the most practical method for your particular

installation.

Figure 7: 7” dia. round venting through the roof.

Figure 8: Transition, from the 7” dia. stack provided

on the hood to a 3 l/4 x 10 rectangular duct, for roof

venting.

Figure 9: 7” dia. elbow, for horizontal venting, with

a wall cap.

The duct, wall cap and roof cap shown in Figure 7,8

and 9 are not included with your range hood

These Items can be purchased separately.

TOOLS AND MATERIALS REQUIRED

F

A---

-;*/

:r

C”

l

Drill, electric or ratchet drive, with 3/8”, 3/16” and l/8”

wood brt (for drlllrng starter holes) and l-1/4” wood bit

(to drill an access hole in the cabinet or kitchen wall for

the electrrc power line.)

l

One common and one ohllllps head screwdriver (to

secure hood mounting screws to the cabinet and hood

sheet metal parts).

l

Pliers (for opening knockouts).

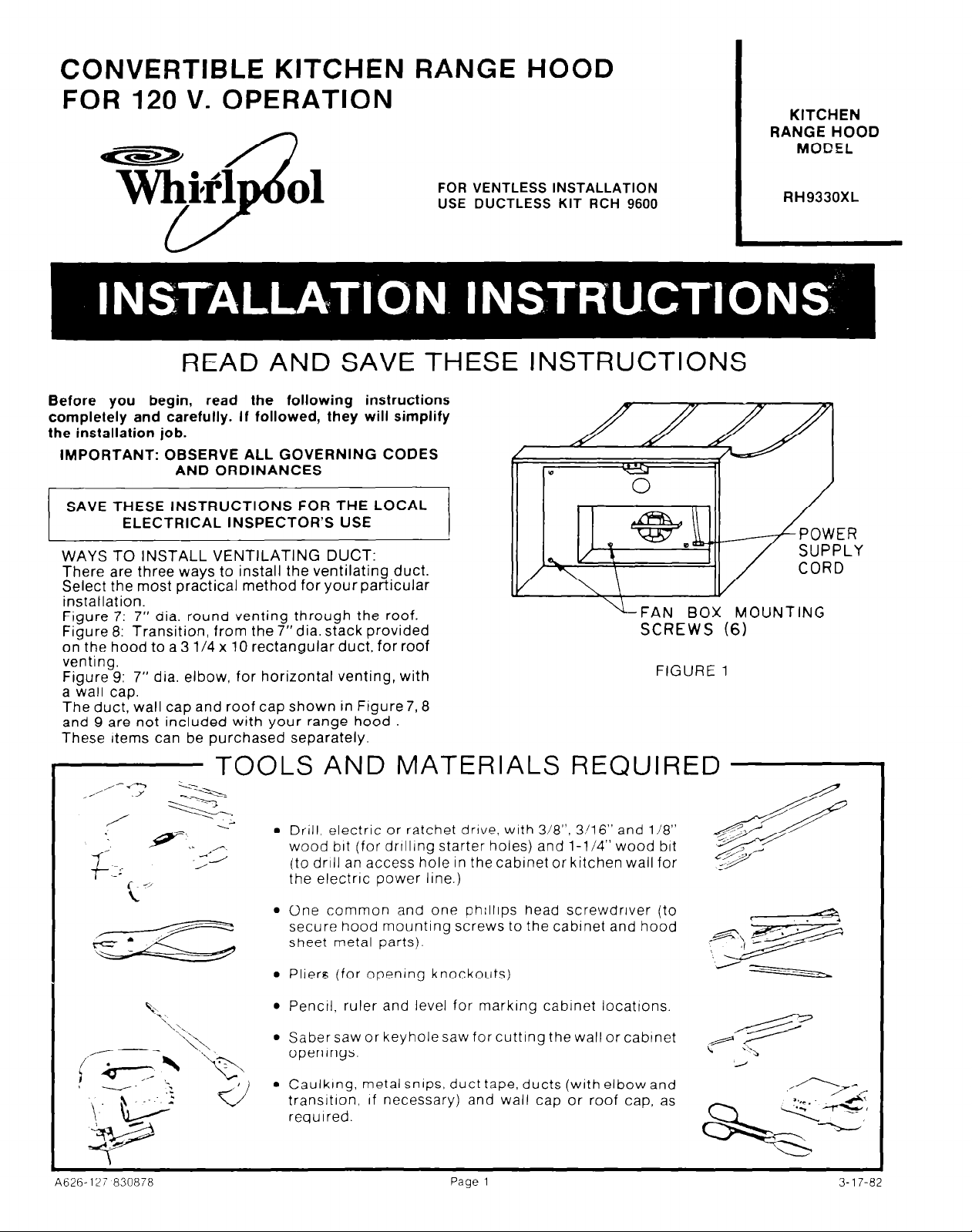

\FAN BOX MOUNTING

SCREWS (6)

FIGURE 1

A626-127 830878

l

Pencil, ruler and level for marking cabinet locattons.

l

Saber saw or keyholesaw for cutting the wall or cabinet

openings.

l

Caulkrng, metal snips, duct tape, ducts (with elbow and

transitron, If necessary) and wall cap or roof cap, as

required.

Page 1

3-17-82

INSTALLATION IJNDEQ KITCHEN F’JFQ ‘I)O’i’!Y

For easy, one man I-staliation hood should be

1.

disassembled.

First, remove the aluminum filter from fan box

assembly by pulling tab toward opposite end of

filter.

Remove two mount ng screws fcund in fan box

near back. (Figure :.)

Unplug power supply cord connection near

back.

Remove additional four screws from fan box

assembly and lift assembly out.

iisrnode tour scret.cs nolcrng top to canopy

assem biy

Fa3R TOP VENTING:(Figures 2, 7 8 8)

2.

Using the canopy ?oo as a hole !ocating pattern,

make a 7’/4” diameter hole. If the optional

rectangular transition is to be used, make a

3’b”xlO’;;” rectz:.juirar hole. Mark an- c*: ,.;;e

for wrring.Flanged hole is provided in canopy

for wiring entrance

FOR WALL VENTING: (Figures 2 & 9) Establish

center line for the hole pattern by measur’ng

half the width of the canopy and 10%” from the

top of the canopy. Make a 7%” diameter hole

through the wall. Mark and cut hole for wlrlng

F!anged hole is provided in canopy top for

wiring entrant

FCP DUCTLfSS , INSTALLATION: Refer to

InstructIons found in ductless kit RCH 9600 for

remarnrng installation procedure.

Install canopy top to kitchen furr down with four

3.

screws provided in installation pack, Fig. 5.

4. Install canopy assembly by sliding top flanges

of canopy assembly onto mating flanges on

canopy top, Figure 5. Secure with 4 screws

prevrously removed.

Hang hood on mounting screws and mark

4.

location for venting and wiring. Remove canopy

to cut holes.

FOR TOP VENTING: Mark venting hole

locations through the ceiling or other

obstructions between hood top and attic. Cut a

7’6” diameter hole for round venting (Fig. 7) or

a 3;;” x 10’,q” h~,e for rectanglr,a-,,~nili:g, Fig. 8.

FOR WALL VENTING: Establish the center for

the back vent hole bv measurina half the width

of the hood and down 1 O-1/4” from canopy top.

See Figures 2 and 9.

FOR DUCTLESS INSTALLATION: Refer to

instructions found in ductless kit RCH 9600 for

remaining installation procedure.

Replace hood and tighten screws

5.

6.

Make electrical connection at wiring at box on

back of canopy according to Figures 3 & 6.

7.

Witn nec?ssar:/ duct tn place (see Figure 4; ‘*rt

fan box assembly into posrtion and secure >,*ylth

six screws.

8. Plug hood power supply into receptacle.

Replace filter.

9.

FUAR DOWN ~-

F

CANOPY TOP ~-\

DOORS ~

-~ HOLE PATTERN FOR

TOP VENTING ONLY

5.

Make electrical connection at wiring box on

back of canopy assembly according to Figures

3&6

With necessary duct work in place (see Fig. 4),

6.

lift fan box assembly into position and secure

with 6 screws.

Plug hood power supply into receptacle.

7.

8. Replace filter.

FREE STANDING WALL INSTALLATION:

1. For easy, one man Installation, hood should be

:+sassnm5ls<

First, remove the aluminum tilter from tne fan

box assembly by pulling tab toward opposite

end of filter. Remove two mounting screws

found in fan box near back. (Figure 1)

Unplug power supply cord connection near

back Remove additional four screws from fan

box assembly and lift assembly out.

? I *I

i. -

y,pTr“,, “C’T-!hli, ,ap.-J

:r;OainiI:-.g

4)

no,55 dt r ii;’ c: <(t-y I1oie -,3is. i,i!;Jre

mark lorytion for 2

3. Insert screws Into n-arkea location leaving l/l6

to l/8 inch between wall and screw head.

NOTE:lf hollow sheetrock wall

IS

encountered,

molly bolts should be used instead of those

provided In installation packet. AddItional

support should be provided after canopy is in

place, when hollow wall molly bolts are used.

Page 2

7;‘TO 7;‘lNCH DIA

HOLE FOR BACK

VENTING ONLY

7” ROUND DUCT

1

CENTER LINE

OF HOOD

FIGURE 2

--4 ‘-1” WIDE

LIZ

KEYHOLE

MOUNTING

HOLE

HOOD

WIRING

FLANGE ON

HOOD BACK

FIGURE 3

ELECTRICAL GROUNDING:

Permanently ground this unit in accordance with

the latest National Electrical Code and applicable

local codes and ordrnances. It is recommended that

a permanent ground connection be made to the untt

using a conductor of appropriate size from a

grounded continuous metalltc cold water pipe, a

grounded lead in the service panel or a properly

driven and electrically grounded ground rod. Do not

ground to a gas supply pipe.

Loading...

Loading...