Whirlpool RH8930XLS User Manual

VENTED KITCHEN RANGE HOOD

FOR 120 V. OPERATION

READ AND SAVE THESE INSTRUCTIONS

Before you begin, read the following instructions

completely and carefully. If followed, they will simplify

the installation job.

IMPORTANT: OBSERVE ALL GOVERNING CODES

AND ORDINANCES

SAVE THESE INSTRUCTIONS FOR THE LOCAL

I

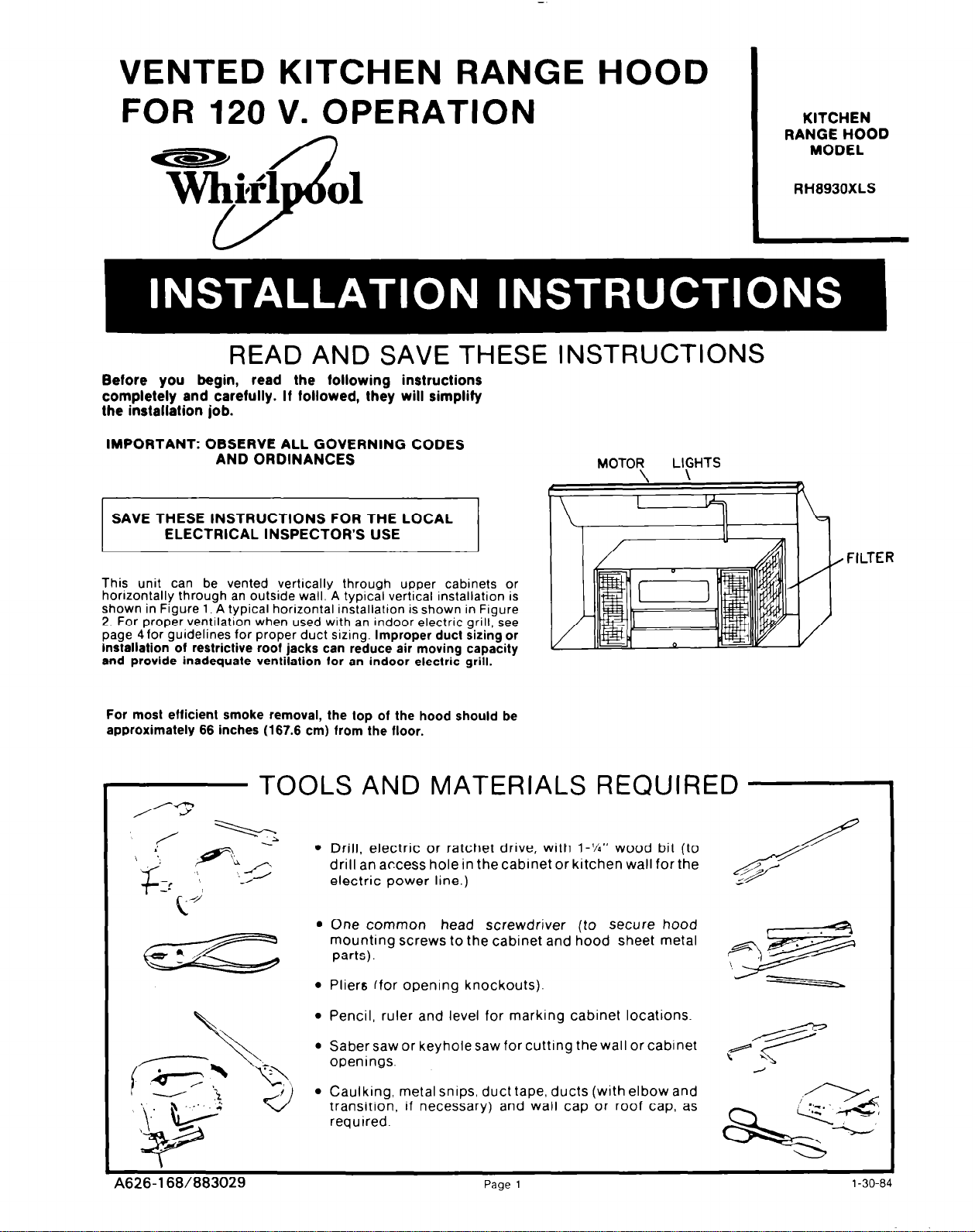

This unit can be vented vertically through upper cabinets or

horlzontally through an outside wall. A typical vertical installation is

shown in Figure 1. A typical horizontal installation is shown in Figure

2. For proper ventilation when used with an indoor electric grill, see

page 4for guidelines for proper duct sizing. Improper duct sizing or

lnsfallation of restrictive roof jacks can reduce air

and provide inadequate ventilation ior an indoor electric

ELECTRICAL INSPECTOR’S USE

moving

capacity

grill.

MOTOR

KITCHEN

RANGE HOOD

MODEL

RH8930XLS

LIGHTS

FILTER

For most

approximately 66 inches (167.6 cm) from the floor.

eflicient smoke removal, the top of the hood should be

TOOLS AND MATERIALS REQUIRED

/-T

/

;

1

J FL;

T

I+

bl

‘,-/

l

Drill, electric or ratchet drive, with l-‘/4” wood bit (to

drill

an access hole in the cabinet or kitchen wall for the

electric power line.)

l

One common head screwdriver (to secure hood

mounting screws to the cabinet and hood sheet metal

parts).

l

Pliers ffor opening knockouts).

l

Pencil, ruler and level for marking cabinet locations.

l

Saber saw or keyhole saw for cutting the wall or cabinet

openings.

l

Caulking, metal snips, duct tape, ducts (with elbow and

transitron. if necessary) and wall cap or roof cap, as

required.

/

29

A626-168/883029

Page

1

l-30-84

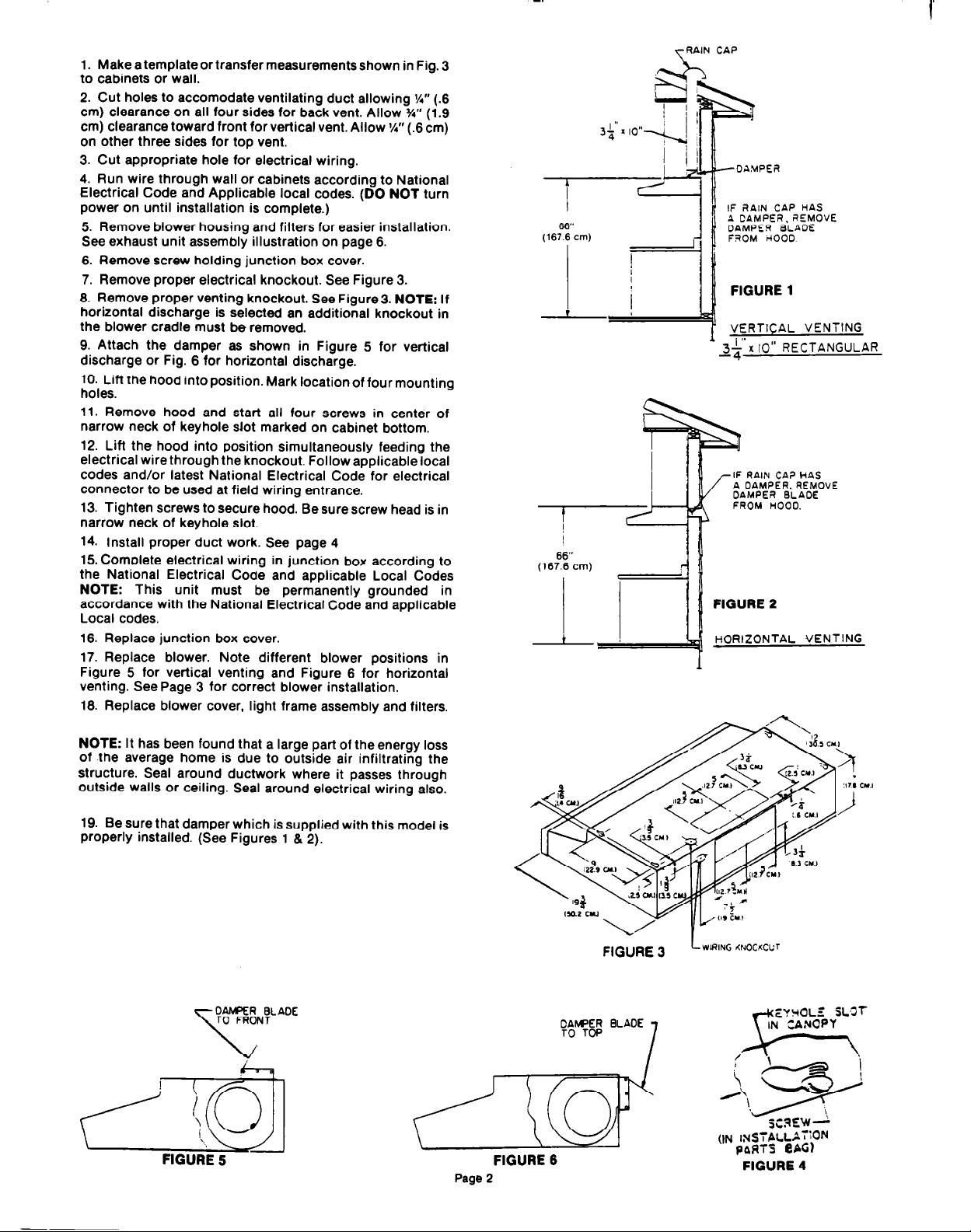

Make a template or transfer measurements shown in Fig. 3

1.

to cabinets or wall.

2. Cut holes to accomodate ventilating duct allowing W’ (.6

cm) clearance on all four sides for back vent. Allow J/4” (1.9

cm) clearance toward front for vertical vent. Allow %” (.6 cm)

on other three sides for top vent.

3. Cut appropriate hole for electrical wiring.

4. Run wire through wall or cabinets according to National

Electrical Code and Applicable local codes. (DO NOT turn

power on until installation is complete.)

5. Remove blower housing and filters for easier installation.

See exhaust unit assembly illustration on page 6.

6. Remove screw holding junction box cover.

7. Remove proper electrical knockout. See Figure 3.

8. Remove proper venting knockout. See Figure3. NOTE: If

horizontal discharge is selected an additional knockout in

the blower cradle must be removed.

9. Attach the damper as shown in Figure 5 for vertical

discharge or Fig. 6 for horizontal discharge.

10. Lift the hood into position. Mark location of four mounting

holes.

11. Remove hood and start all four screws in center of

narrow neck of keyhole slot marked on cabinet bottom.

12. Lift the hood into position simultaneously feeding the

electrical wire through the knockout. Follow applicable local

codes and/or latest National Electrical Code for electrical

connector to be used at field wiring entrance.

13. Tighten screws to secure hood. Be sure screw head is in

narrow neck of keyhole slot.

14. Install proper duct work. See page 4

15. Complete electrical wiring in junction box according to

the National Electrical Code and applicable Local Codes

NOTE: This unit must be permanently grounded in

accordance with the National Electrical Code and applicable

Local codes.

16. Replace junction box cover.

17. Replace blower. Note different blower positions in

Figure 5 for vertical venting and Figure 6 for horizontal

venting. See Page 3 for correct blower installation.

18. Replace blower cover, light frame assembly and filters.

TRAIN CAP

IF RAIN CAP HAS

A CAMPER, REMOVE

DAMPEF) BLADE

FROM rCOO0

FIGURE 1

VERTICAL VENTING

,a

3%. x IO” RECTANGULAR

IF RAIN CAP HAS

A DAMPER. REMOVE

DAMPER BLAOE

FROM HOOD.

FIGURE 2

HORIZONTAL VENTING

NOTE: It has been found that a large part of the energy loss

of the average home is due to outside air infiltrating the

structure. Seal around ductwork where it passes through

outside walls or ceiling. Seal around electrical wiring also.

Be sure that damper which is supplied with this model is

19.

properly installed. (See Figures 1 8 2).

6-1

c5mf

FIG&E 5

Page 2

FIGURE 6

FIGURE 4

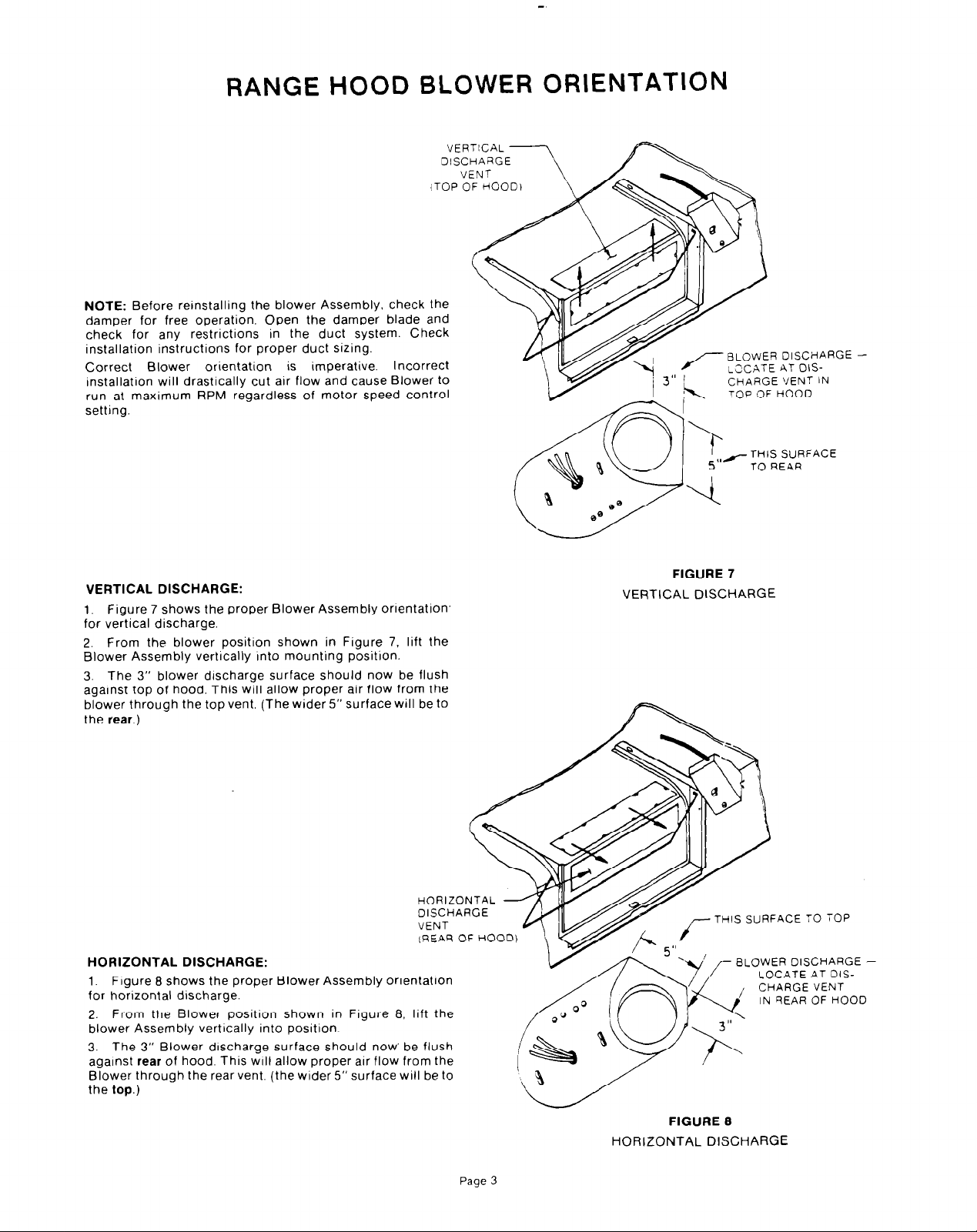

RANGE HOOD BLOWER ORIENTATION

(TOP OF HOOD1

NOTE:

damper for free operation. Open the damper blade and

check for any restrictions in the duct system. Check

installation instructions for proper duct sizing.

Correct Blower orientation is imperative. Incorrect

tnstallatron will drastically cut atr flow and cause Blower to

run at maximum RPM regardless of motor speed control

setting.

Before reinstalling the blower Assembly, check the

VERTICAL DISCHARGE:

1, Figure 7 shows the proper Blower Assembly ortentatton’

for vertical discharge.

2. From the blower position shown in Figure 7. lift the

Blower Assembly verttcally Into mounting position.

3. The 3” blower drscharge surface should now be flush

against top of hood. This will allow proper air flow from the

blower through the top vent. (The wider 5” surface will be to

the rear.)

BLOWER DISCHARGE ‘LXATE AT OIS-

CHARGE VENT IN

TOP OF HOOD

,,/ THIS SURFACE

TO REAR

FIGURE 7

VERTtCAL DISCHARGE

HORIZONTAL

DISCHARGE

VENT

(REAR OF HOOD)

HORIZONTAL DISCHARGE:

1. Figure 8 shows the proper Blower Assembly orientation

for horizontal discharge.

2. From the Blower position shown in Figure 8. lift the

blower Assembly vertrcally into position

3. The 3” Blower drscharge surface should now’ be flush

against rear of hood. This

Blower through the rear vent. (the wider 5” surface will be to

the top.)

will

allow proper air flow from the

Page 3

THIS

SURFACE TO TOI=

BLOWER DISCHARGE -

LOCATE AT DIS-

FIGURE 8

HORIZONTAL DISCHARGE

Loading...

Loading...