whirlpool R-92 Service Manual

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

R-92

WHIRLPOOL & KITCHENAID

IN-DOOR ICE SYSTEM

JOB AID

Part No. 4322658A

FORWARD

This Job Aid, “Whirlpool & KitchenAid In-Door Ice System,” (Part No. 4322658A), provides the

technician with information on the operation and service of the Whirlpool & KitchenAid In-Door

Ice System. It is to be used as a training Job Aid and Service Manual. For specific information on

the model being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the

Refrigerator/Freezer.

The Wiring Diagrams used in this Job Aid are typical and should be used for training purposes

only. Always use the Wiring Diagram supplied with the product when servicing the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the In-Door Ice System.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the In-Door Ice System to proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2002, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONENTS

Page

GENERAL............................................................................................................................... 1-1

Safety First......................................................................................................................... 1-1

PRODUCT INTRODUCTION .................................................................................................. 2-1

Overview ............................................................................................................................ 2-1

THEORY OF OPERATION ..................................................................................................... 3-1

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Ice Maker & The Water Fill Tube............................................................... 4-2

Removing The Emitter & Receiver Modules ...................................................................... 4-5

Removing & Reinstalling The Motor .................................................................................. 4-6

Accessing The Selector Switch Pack & Dispenser Switches ............................................ 4-9

DIAGNOSTICS & TROUBLESHOOTING .............................................................................. 5-1

Diagnostics ........................................................................................................................ 5-1

Optics Diagnostics Mode ............................................................................................... 5-1

Optics Diagnostics For Original Design Boards ............................................................. 5-2

Optics Diagnostics For 2002 Design Boards ................................................................. 5-4

Component Diagnostics Mode ....................................................................................... 5-5

Optics Diagnostics Mode Charts .................................................................................... 5-6

Component Diagnostics Mode Chart ............................................................................. 5-7

Troubleshooting Chart A—Original Optics Design ............................................................ 5-8

Troubleshooting Chart B—2002 Optics Design ................................................................. 5-9

Troubleshooting Chart C—Component Diagnostics Mode .............................................. 5-10

Troubleshooting The Motor.............................................................................................. 5-11

WIRING DIAGRAMS & STRIP CIRCUITS ............................................................................. 6-1

Whirlpool Wiring Diagram .................................................................................................. 6-1

KitchenAid Wiring Diagram ................................................................................................ 6-2

Strip Circuits ...................................................................................................................... 6-3

CONFIRMATION OF LEARNING EXERCISES ..................................................................... 7-1

- iii -

— NOTES —

- iv -

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always

read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

ELECTRICAL POWER SUPPLY &

GROUNDING REQUIREMENTS

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all panels before operating.

Failure to do so can result in death or

electrical shock.

WARNING

Electrical Shock Hazard

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

1-1

WARNING

Electrical Shock Hazard

Connect green ground wire to ground

screw.

Failure to do so can result in death or

electrical shock.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere.

ESD may damage or weaken the electronic control assembly. The new control

assembly may appear to work well after

repair is finished, but failure may occur at

a later date due to ESD stress.

• Use an antistatic wrist strap. Connect the

wrist strap to the green ground connection point, or to an unpainted metal surface in the appliance.

- OR -

• Touch your finger repeatedly to a green

ground connection point, or to an unpainted metal surface in the appliance.

• Before removing the part from its package, touch the antistatic bag to a green

ground connection point, or to an unpainted metal surface in the appliance.

• Avoid touching electronic parts, or terminal contacts. Handle the electronic control assembly by the edges only.

• When repackaging the failed electronic

control assembly in an antistatic bag,

observe the previous instructions.

1-2

PRODUCT INTRODUCTION

OVERVIEW

The primary objective of the In-Door Ice System is to increase the usable space in the

freezer compartment of the current freestanding side-by-side refrigerator/freezer. The solution is to relocate the ice maker, the ice container, and drive mechanism, and replace this

eye-level volume with a cantilever shelving system. The following description is intended to

relate the changes that have been made from

the current side-by-side ice & water dispenser

configuration. The description is divided into

three categories: Ice Making, Ice Storage, &

Ice Dispensing.

ICE MAKING

The ice maker module and mold have not been

changed from the current models. However,

the location, mounting method, air delivery,

water delivery, ice stripper, and ice level shutoff

have all been redesigned.

Location & Mounting

Air Delivery

Air is delivered to the ice maker mold through

a duct. This duct hooks onto the rear air duct

at the back of the liner, and is secured to the

top of the liner with two screws. The duct directs approximately 50% of the freezer air forward to the ice maker mold. The mounting

bracket, mentioned in the previous section,

also serves as an air director, and directs the

air that is delivered by the duct, under the mold,

and allows it to escape just under the ice stripper.

The ice maker has been relocated to the top

front of the freezer liner, and has been rotated

90˚. Due to code requirements, the ice maker

heater area is now protected by a plastic (PVC)

mounting bracket. The bracket is attached to

the ice maker with three mounting screws, and

is held in place by grooved tracks on either

side of the freezer liner.

Grooved

Track

Screw

(1 of 3)

Mounting

Bracket

Grooved

Track

Air Duct

2-1

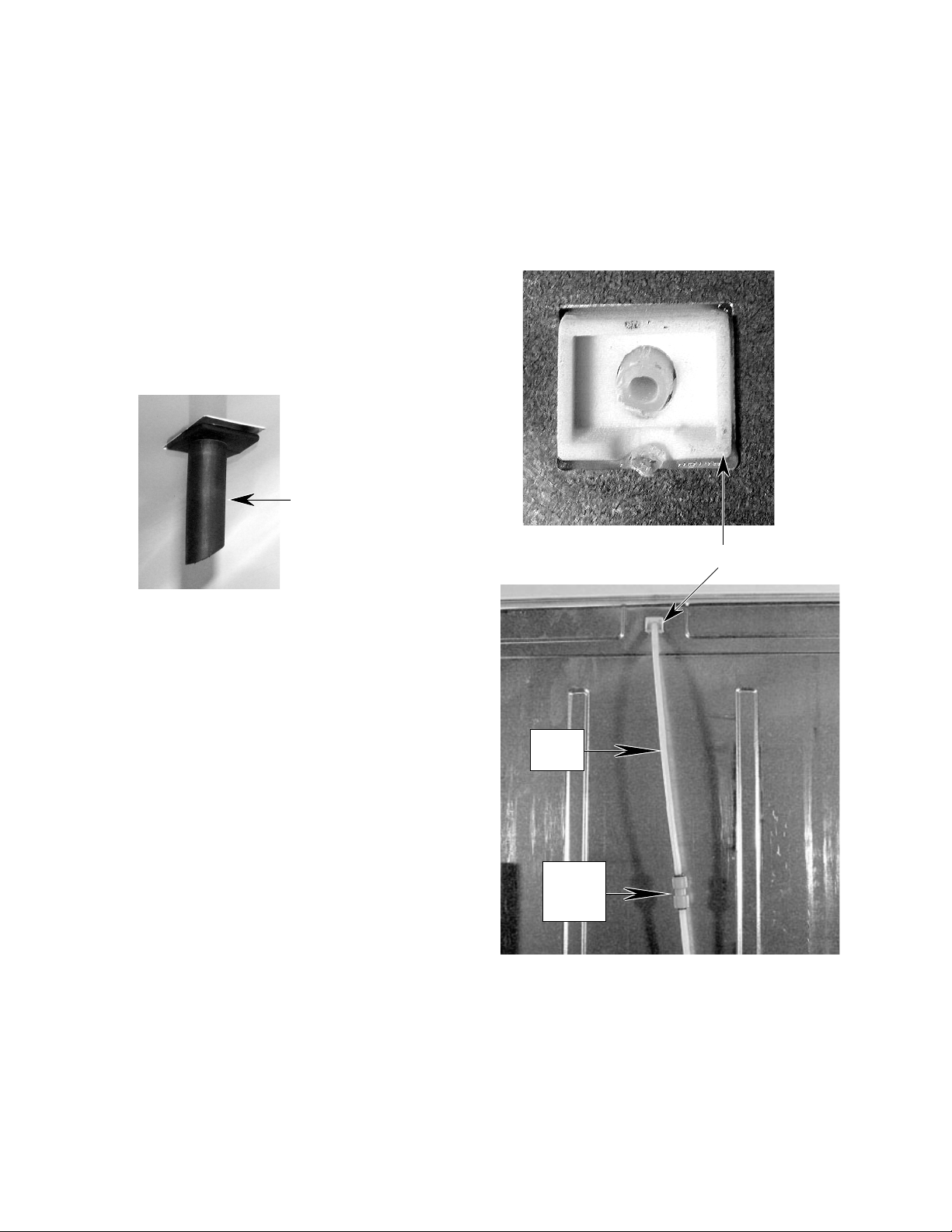

Water Delivery

Water is delivered to the ice maker mold by

means of a “tube-within-a-tube” design. A conduit system consisting of three separate pieces

(liner fitting, conduit, back panel fitting) is

foamed into place in the cabinet.

This conduit provides a pathway from the

freezer liner to the back panel. The majority of

this system is routed above the refrigerator liner

to prevent the water tubing from freezing. The

tubing that delivers the water is routed through

the conduit, and is secured by snapping into

place at the freezer liner fitting.

Water Nozzle

The water tube is made of polypropylene with

an overmolded santoprene nozzle. Due to the

rigid nature of the polypropylene, this tube is

mated to a more flexible polyethylene tube with

a John Guest fitting high on the back panel.

This change of material is necessary to prevent kinking when the tubing is attached to the

water valve.

Water

Tube

John

Guest

Fitting

Back Panel Fitting

2-2

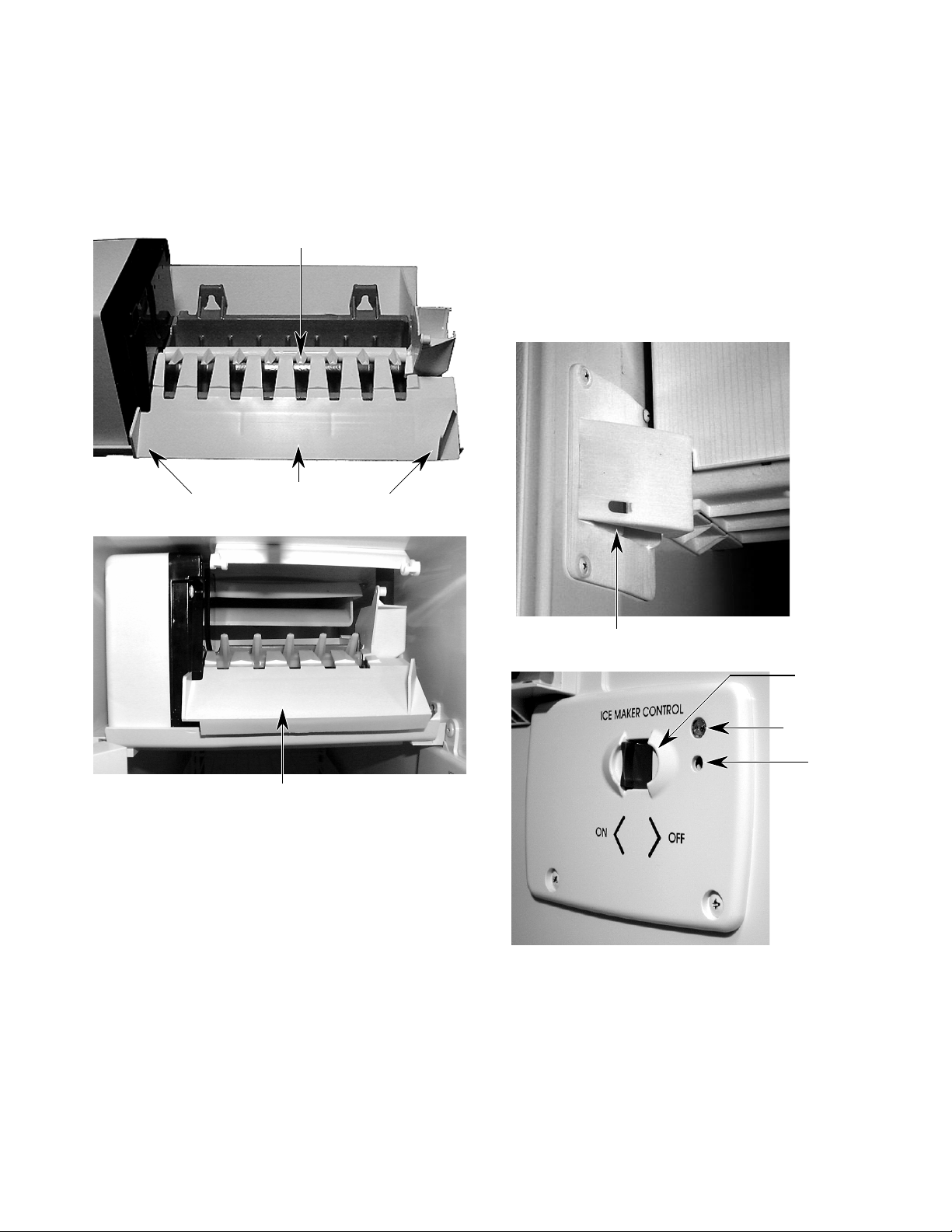

Ice Stripper

Ice Level Shutoff

The ice stripper has been modified in order to

direct ice into the new ice container. The main

differences from the current stripper are: an

increased ramp, and a directing wall at the fill

cup end.

Ejector Blades

Ice Stripper & Ramp

The mechanical shutoff arm on the older ice

makers has been replaced with an electronic

ice level control system. This system is located

on either side of the freezer liner and utilizes

infrared light technology to sense the level of

ice in the door-mounted ice container. A manual

shutoff option is still available on the right side

of the freezer liner. This feature consists of a

plastic slide that covers the receiver sensor and

blocks the infrared beam.

5-Cavity Ice Maker For

22 Cu. Ft. Models

Infrared Emitter

Manual

Shutoff

Status LED

Infrared

Receiver

2-3

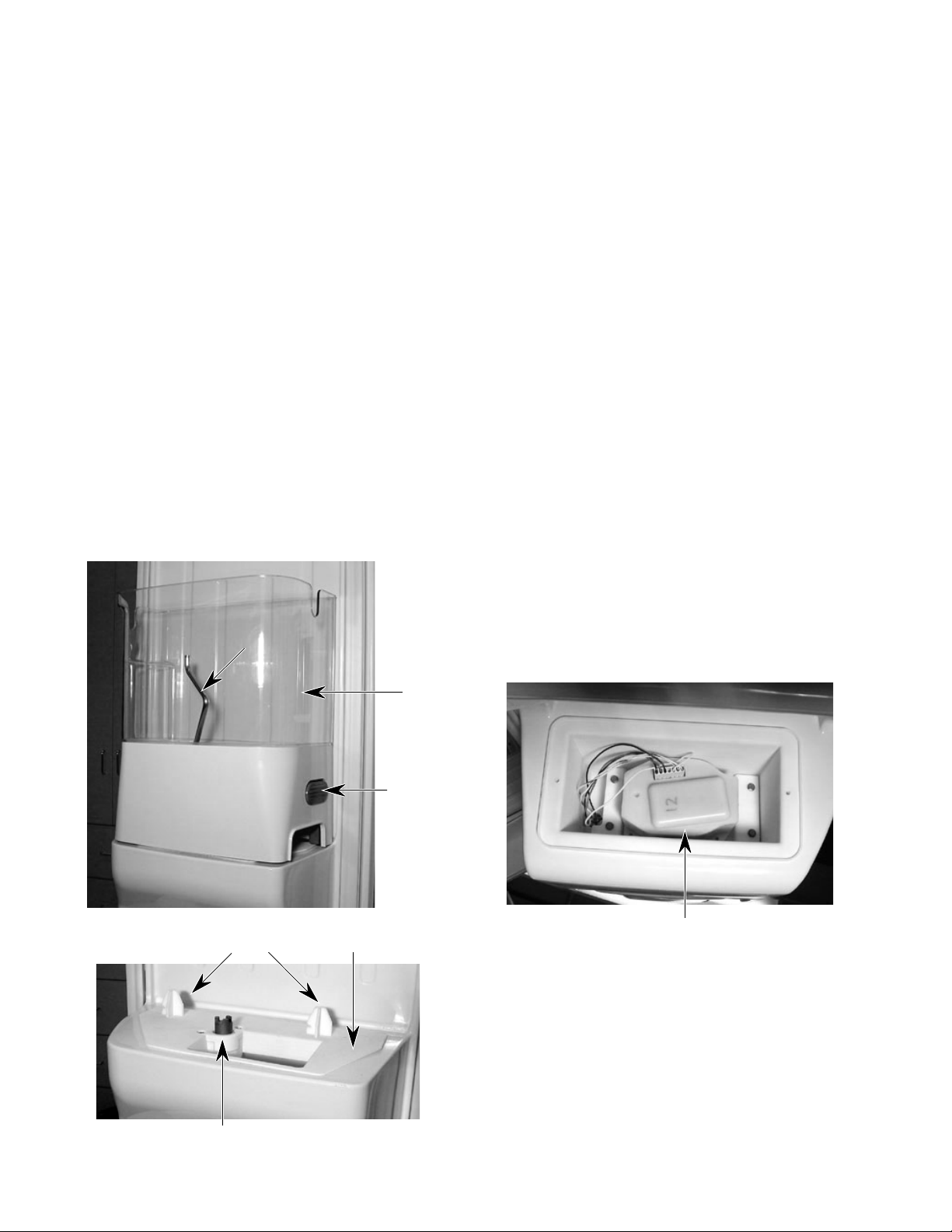

ICE STORAGE

ICE DISPENSING

The ice container has been redesigned and

relocated to the freezer door. It is secured in

place on the door liner with a sliding springloaded latch, mounted to a plate with two pins.

The mounting plate is foamed-in-place on the

door. The ice container is easily removed and

replaced on the door regardless of the auger

orientation.

The ice container is removed by pressing a

release button on the right side and lifting.

Removal instructions are printed on the container.

Other changes to the ice container consist of

a vertical rod ice auger, and a clear polycarbonate upper section. The vertical orientation

of the bin helps prevent “stale ice” areas, because the ice is a “first in—first out” system

which helps keep the ice fresher. Also, the ice

container can be completely emptied.

Major changes have been made to the power

train. The motor has been redesigned and relocated to the freezer door. The cube/crush

selector solenoid and its related linkage have

been eliminated, and a drive shaft/springloaded coupling have been added.

Motor

The motor is now located on the freezer door

in a foamed-in-place enclosure under the “dispenser bubble” area of the inner door panel.

The motor is mounted to a plastic mounting

bracket, which, in turn, is mounted to the enclosure with four mounting screws.

The motor operates on 115 volts DC (115 volts

AC is delivered to the motor, where it is converted within the motor assembly to DC). This

gives the motor a higher RPM than the earlier

dispenser motors, and results in a faster ice

delivery rate in both the cubed and crushed

modes.

Ice

Auger

Pins Plate

Crushed ice is delivered by turning the motor

in a clockwise direction, and cubed ice is delivered when the motor turns in a counterclockwise direction.

Ice

Container

Release

Button

Motor

Auger Coupling

2-4

Drive Shaft / Coupling

The drive shaft / coupling connects the motor

to the ice container auger. The coupling at the

top of the motor drive shaft is spring-loaded to

allow replacing the ice container without having to orient its coupling with the motor drive

shaft coupling. If the two couplings do not en-

Spring-Loaded Pin

Spring

gage when the container is placed on the door,

the motor drive shaft coupling will be depressed. The next time ice is dispensed, the

motor drive shaft coupling will spring up, and

engage the ice container coupling.

The original designed units use a pin that rests

on a spring, located inside the drive shaft. The

newly designed units have only the spring,

which rests in a shallower opening at the top

of the drive shaft, and eliminates the need for

the pin.

On newly designed models, the hex drive shaft

coupling has a skirt around it to prevent any

pieces of a damaged coupling from falling down

the chute.

Hex Drive Shaft

Top of Original Design

Hex Drive Shaft

Original Hex Drive

Shaft Coupling

Top of Newly Designed

Hex Drive Shaft

Newly Designed

Hex Drive Shaft

Coupling Skirt

Motor

2-5

— NOTES —

2-6

THEORY OF OPERATION

The new ice making system consists of the following: an ice maker with an integrated control module, an electronic ice level sensor, an

external water valve, and a freezer door compartment-mounted ice storage bin.

The ice maker control module is a stamped

circuit that provides power and control for the

ice making loads, which consist of the motor,

heater, and water valve.

The ice harvesting process begins when the

ice maker thermostat closes and signals that

the harvest temperature has been reached.

The closed thermostat applies power to the ice

maker motor and to the heater. As the heater

melts the outer layer of the ice, the motor rotates a rake, which sweeps the ice cubes out

of the mold, and into the storage bin.

Due to the placement of the storage bin on the

freezer door instead of on the cabinet, the

sensing of the ice level is quite different from

the earlier mechanical (bail arm) contact

method. The mechanical arm has been replaced by an electronic control that performs

this function, and two additional functions. It

controls power to the ice maker, and performs

system diagnostics, which includes optics diagnostics and component diagnostics.

The electronic control consists of two separate printed circuit boards mounted on opposite sides of the freezer liner just inside the

door. The board mounted on the freezer door

hinge-side of the cabinet is referred to as the

“emitter board,” and the board mounted on the

mullion side is referred to as the “receiver

board.”

When the ice maker thermostat closes and signals that ice is ready to be harvested, the emitter board sends out an infrared (IR) pulse. If

the path of the pulse is unobstructed to the

receiver board, the phototransistor on the receiver board will “sense” the pulse. The control will then energize a relay, which applies

power to the ice maker, and a harvest begins.

The ice maker loads, the motor, heater, and

water valve, are still controlled by the stamped

circuit module, which is part of the ice maker.

The electronic control will check periodically

to see if the ice maker is at the home position,

(when the ejector stops at the 2 o’clock position). If the ejector is at the home position, the

relay will deenergize, and remove power from

the ice maker until the next harvest.

To improve functionality and reliability, some

important differences exist between the new

In-Door Ice system, and the earlier mechanical-type ice making systems.

The first is that a harvest can only begin if the

freezer door is closed, and previous harvest

conditions are also met (ejector at home). If

the bin is full, and ice is removed, which lowers the ice level, it may take up to 5 minutes

before a harvest starts.

To prevent an early harvest from occurring after the last harvest is completed, a minimum

of 50 minutes must pass before another harvest will be initiated. Closing the receiver’s

shutoff slide covers the sensor and prevents

the ice maker from harvesting ice.

The In-Door Ice control contains two diagnostic routines. One is an optics test, and the other

is a component test. There are two optics tests:

one for the original style optics, and the other

for the 2002 design optics:

1.a) Original Optics—An optics circuit test is

run when the freezer door switch is actuated three times, and the freezer door

is closed to allow a path for the optics

beam to reach the receiver.

b) 2002 Design Optics—An optics circuit

test is run any time the freezer door is

opened.

2. Component Test—A component test is

run on power-up when the freezer door

is closed.

Both routines provide visual feedback as to the

result of the diagnostic. All other system enhancements are transparent during the ice

making system operation.

3-1

— NOTES —

3-2

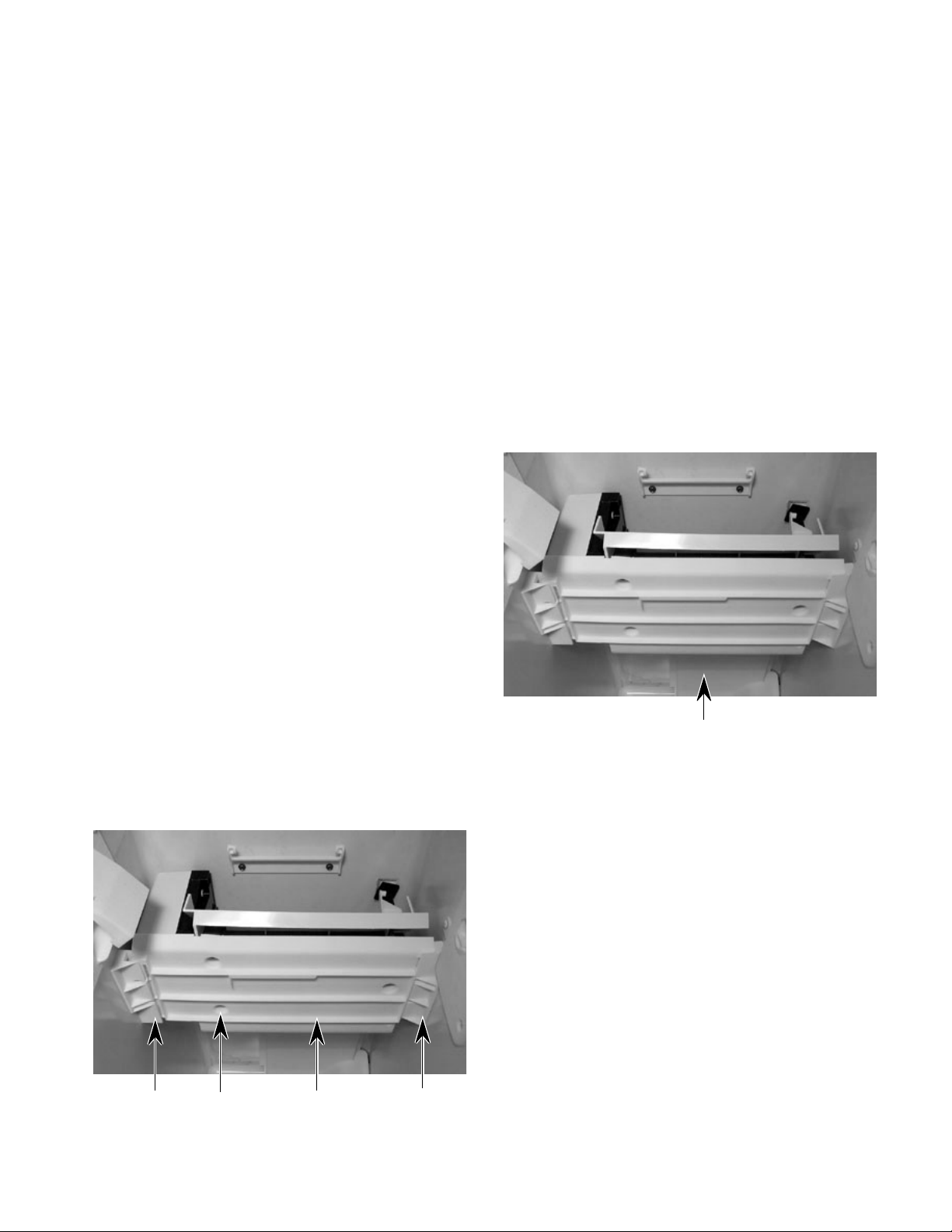

COMPONENT ACCESS

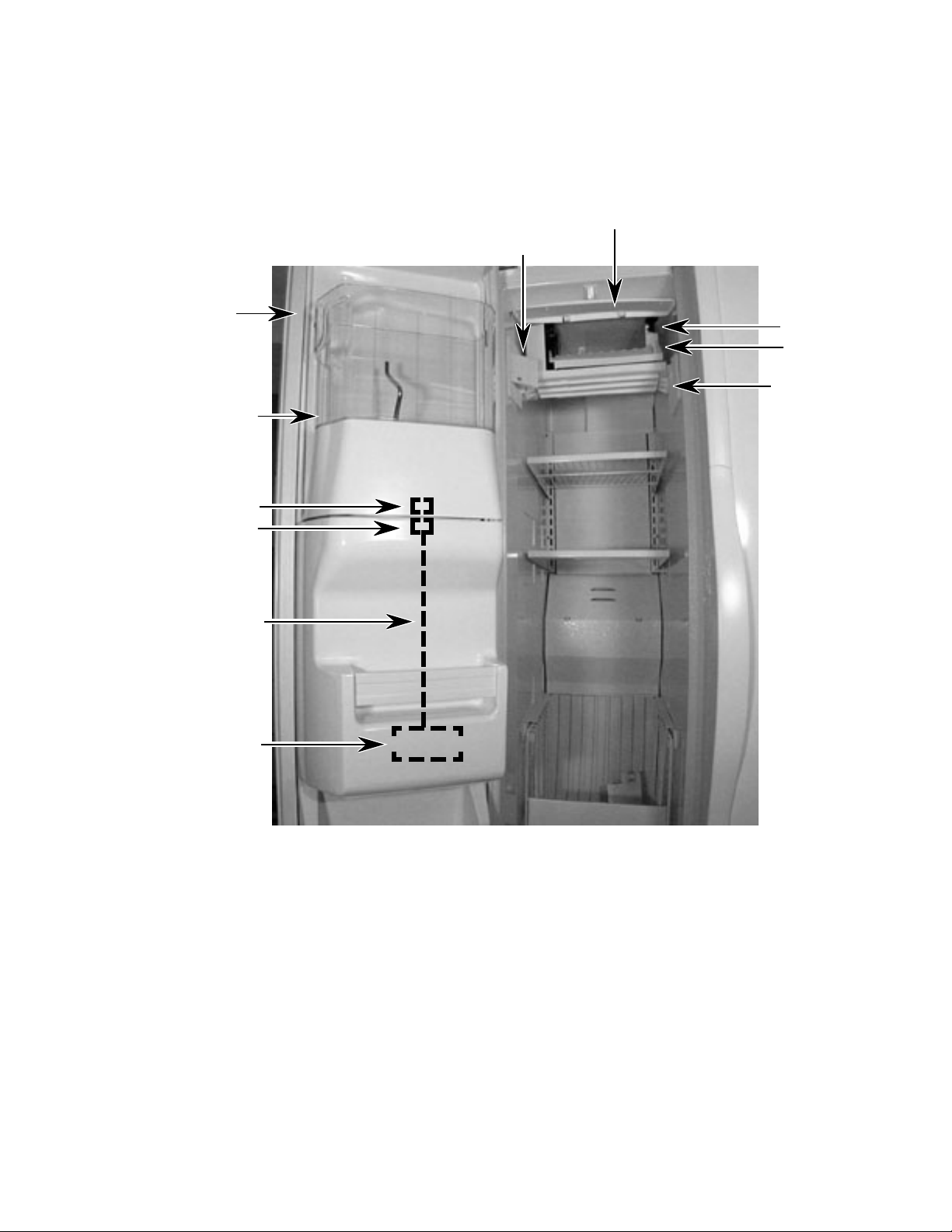

COMPONENT LOCATIONS

Ice Maker Door

Infrared Emitter

Freezer Door

Ice Bin

Ice Container

Auger Coupling

Motor Drive

Coupling

Hex Drive Shaft

Water Fill

Nozzle

Ice Maker

Infrared

Receiver

Motor

4-1

Loading...

Loading...