CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

R-106

TRAINING MANUAL

Part No. 8178689

ICEMAKER FAMILIARIZTION

AND TROUBLESHOOTING

FORWARD

The following training manual information is provided to make you more knowledgeable

about icemaker familiarization and troubleshooting.

Training manual information is designed for the experienced service specialist. It keeps

you advised of the most recent improvements and product changes, and allows you to

service these products more efciently.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on

our products by anyone other than authorized In-Home Service Professionals.

Copyright © 2007, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

Icemaker Familiarization and Troubleshooting

Ice Makers ............................................................................................................... Page 1

New Generation Compact Icemaker ........................................................................... Page 1

Removing Storage Bin and Cover .......................................................................... Page 2

Bin and Cover Removed ......................................................................................... Page 2

Mid South ................................................................................................................ Page 3

Operation ................................................................................................................. Page 4

New Generation Schematic ..................................................................................... Page 7

Removing Cover ...................................................................................................... Page 8

Cover Removed ....................................................................................................... Page 8

Water Fill Adjustment ............................................................................................... Page 9

Manual Cycle Initiation ............................................................................................ Page 9

Starting a Harvest Cycle ........................................................................................ Page 10

Releasing Wire Harness Cover ..............................................................................Page 11

Cover Release ........................................................................................................Page 11

Removing Icemaker ............................................................................................... Page 12

Disconnect Electrical ............................................................................................. Page 13

Slide Out Assembly ............................................................................................... Page 13

Whirlpool Modular Icemaker ...................................................................................... Page 14

Water Adjustment .................................................................................................. Page 15

Test Points ................................................................................................................. Page 15

Operation ................................................................................................................... Page 16

Resistance Checking ............................................................................................. Page 17

Jumper Wire .......................................................................................................... Page 18

Initiating a Harvest Cycle ....................................................................................... Page 19

Troubleshooting ..................................................................................................... Page 20

Whirlpool Ice Production ........................................................................................ Page 21

Amana Iceland Refrigerators ................................................................................. Page 22

Low Ice Production .................................................................................................... Page 23

Saddle Valves ........................................................................................................ Page 25

Checking Water Charge ............................................................................................ Page 26

Checking Water Fill ................................................................................................ Page 26

No Ice Production Safety Interlock ........................................................................ Page 27

No Ice Production .................................................................................................. Page 28

- iii -

— NOTES —

- iv -

Icemaker Familiarization and Troubleshooting

New Generation Compact Ice Maker

French Door Ice2o

To access, depress

release button

Mid-South

Ice Makers

New Generation Compact – AKA, Mid South used on French Door Refrigerators (Iceland) Ice and Water in the Door

Modular Ice Maker – AKA, Whirlpool used on just about everything else

1

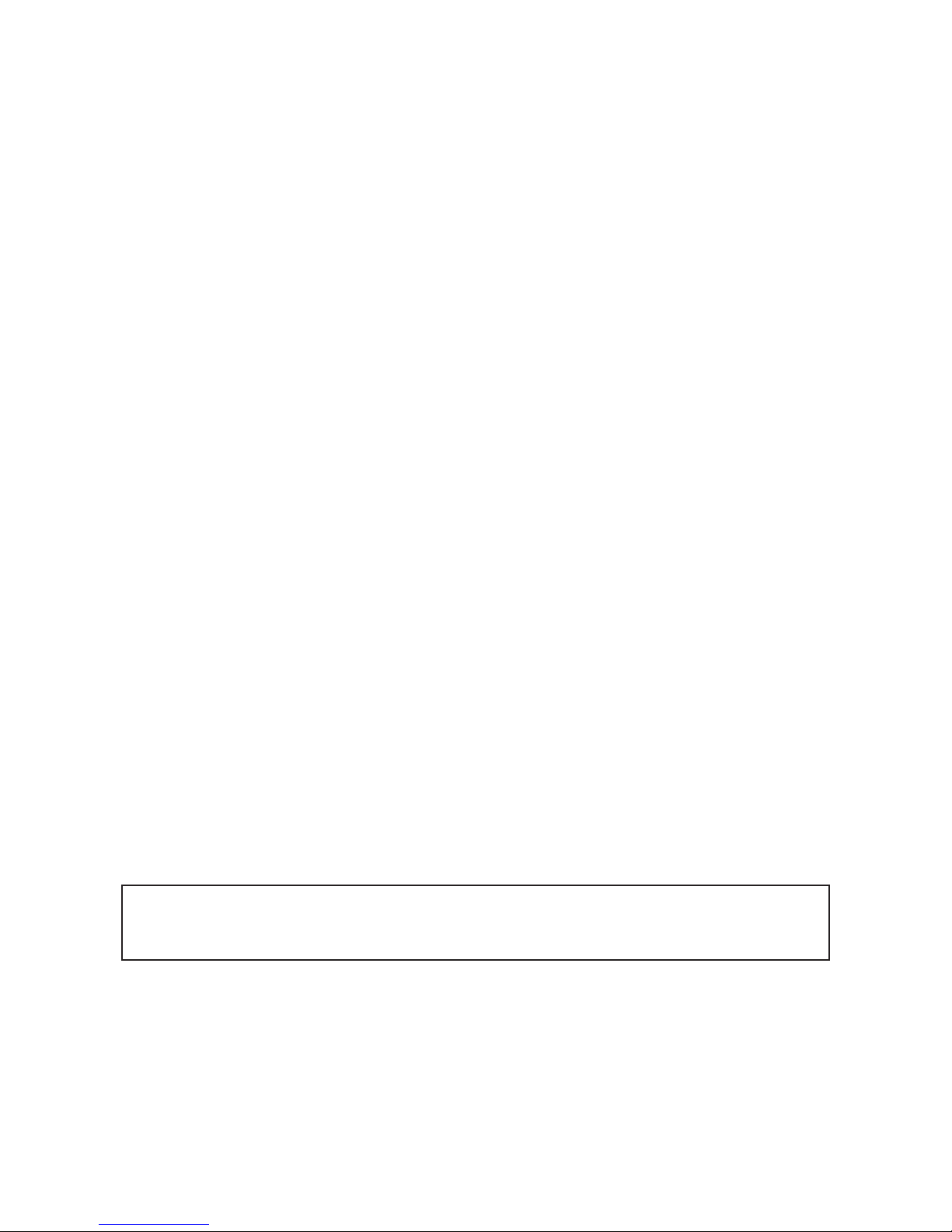

Removing Storage Bin and Cover

Slide Out Bin

Mid-South

To remove storage bin and cover, with the release button depressed slide out the

Bin and Cover Removed

Mid-South

assembly.

With the ice bin removed, the icemaker can be accessed.

2

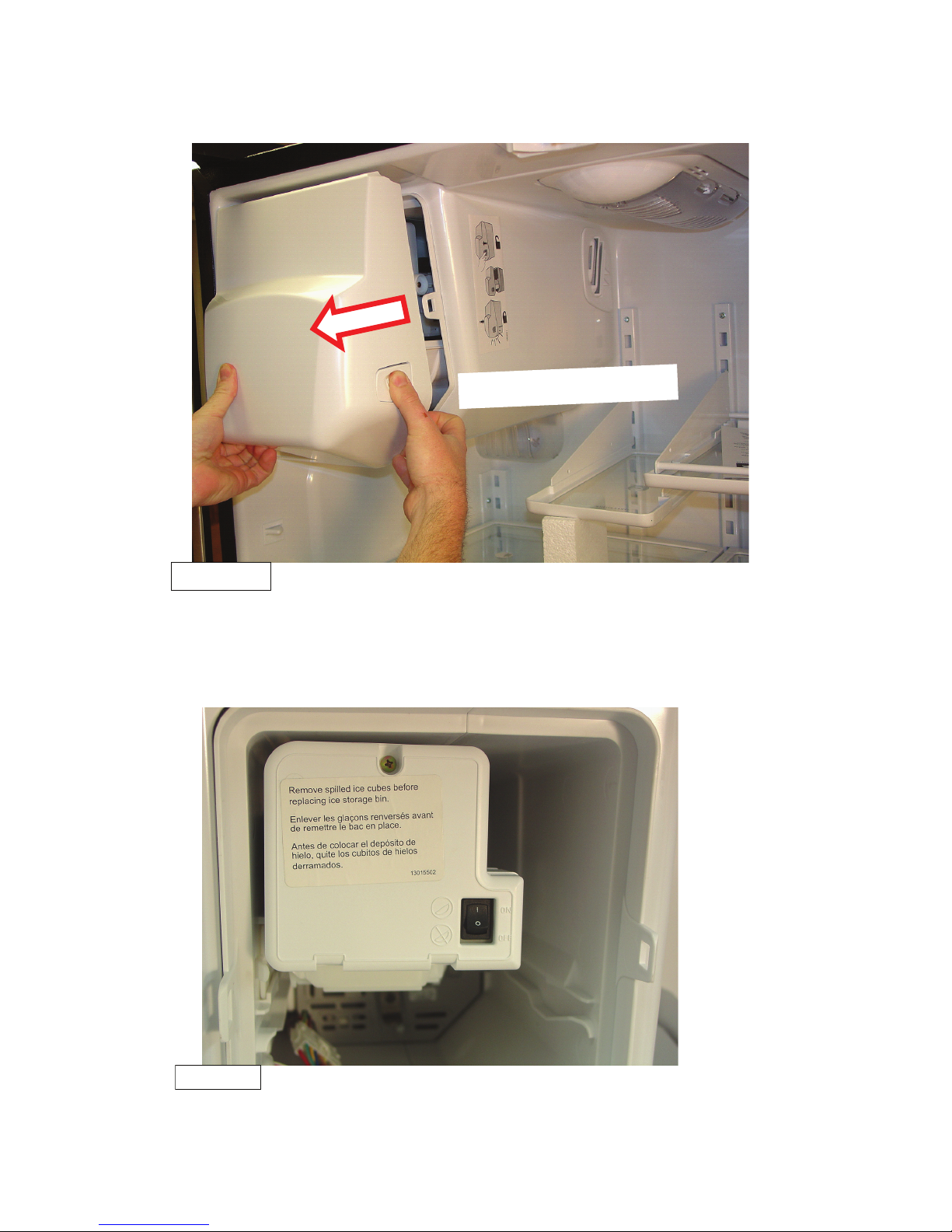

ON/OFF

Switch

Shut-off Arm

Mid-South

Mid-South

Mid South - This compact design is a variation of previous designs. Operation is

identical except for the following:

The metal feeler arm has been replaced with a plastic paddle that moves up and

down on a cam.

During the ice ejection cycle, the paddle lifts in the same manner as the feeler arm

and automatically turns the icemaker off if it senses that the bucket is full (while on its

downward movement).

3

Operation

Operation

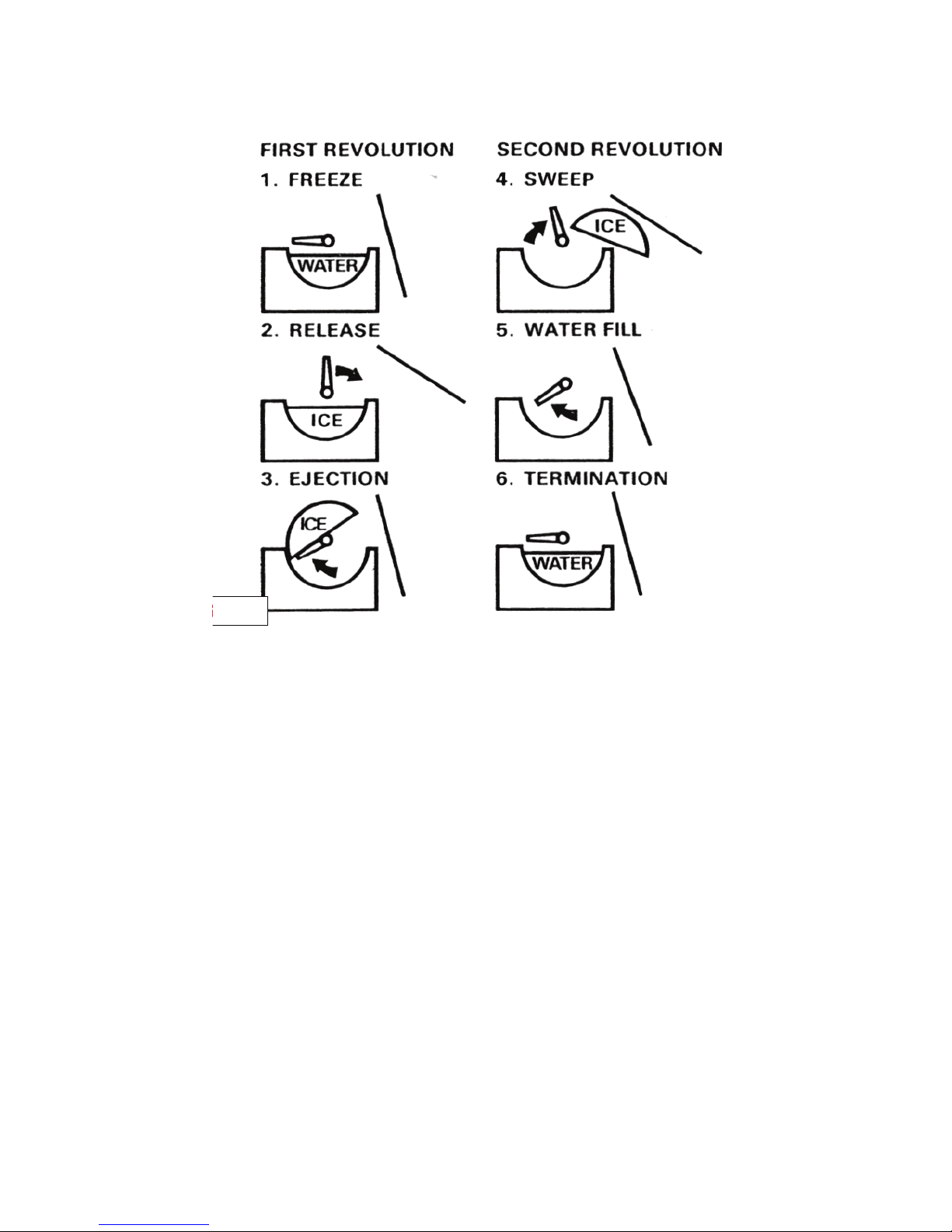

Icemaker Operational Cycle

Both the Compact and the Modular icemakers rely on a combination of electrical and

mechanical functions to create and eject ice. The complete ice cycle for the Compact

icemaker is described below and is divided into six major functions. The Modular icemaker cycle is also divided into the same six functions but requires only one revolution to complete the ejection of the ice. The six major functions are:

Freeze- Water enters the icemaker and is deposited in an ice mold. While the evaporator fan runs, part of the sub zero air that enters the freezer compartment is directed

across the top of the mold. Heat is removed from the water and the water freezes in

the mold.

Release- The temperature of the ice continues to drop until a thermostat in the icemaker closes. The thermostat is in contact with the mold and senses the temperature

of the mold and, thus, the ice within the mold. Designs vary but the mold temperature

must drop to around 15°F before the thermostat closes. This assures that the water

is completely frozen before the icemaker attempts to eject the ice. The closing of the

thermostat energizes a mold heater and starts the icemaker motor. The purpose of

the heater is to raise the temperature of the mold above 32°F.

Eject- With the mold heater energized, the ice in the mold begins to melt, freeing the

ice from the mold. At the same time, the icemaker motor turns an ejector blade which

lifts the ice out of the mold and dumps it into the ice bucket.

Sweep- The icemaker motor continues to rotate the ejector blade for another revolu-

tion. Any ice that might have not ejected during the rst sweep will be ejected.

4

Water ll- At the end of the second revolution, an internal cam in the icemaker ener-

gizes a ll switch. The switch turns on the icemaker water valve and water is allowed

to enter the icemaker.

Terminate- Once lled with water, the icemaker cycle terminates. The icemaker is

now ready to repeat the cycle.

Electrical Operation

Ejector Blade Shut off Arm

Freeze cycle

Immediately after the icemaker lls with water, the freezer air begins to cools the ice

mold. Since the mold and water are essentially at the same temperature, the mold

thermostat will remain open until the ice and mold reach a predetermined temperature

(15°F, ±3°). Notice that the ejector blades are at approximately the 9:00 o’clock position at the start of the cycle. This is known as the “home” position.

Thermostat Closes

When the mold and ice reach the set temperature, the thermostat closes. The mold

heater is energized through a parallel circuit which also energizes the motor.

First Three Seconds of Operation

All the while the icemaker is in the freeze cycle, the hold switch contact sits in a notch

on the icemaker cam. As soon as the motor begins to rotate the cam, the hold switch

contacts transfer and the switch closes. The hold switch contacts remain in this position until the cam has traveled a full 360° and the switch contact falls into the notch

again.

At the same time, the feeler arm begins to raise. Since the shut-off switch is mechanically coupled to the feeler arm, movement of the arm causes the shut-off switch

contacts to transfer. The transfer of both these switches creates a parallel current

path for the mold heater and the icemaker motor. The heater begins to thaw the ice

in the mold and the motor advances the ejector blades until they come in contact with

the ice.

Blade Contacts Ice

Upon contacting the ice, the motor stalls since the mold heater has not had sufcient

time to melt the ice enough to free it from the mold. The heater continues to warm

the mold until the ice is free and the blades can dislodge the ice and continue their

sweep.

Once free of the mold, the ice loosens and the blades resume their rotation towards

the home position (9:00 o’clock). The ice is ejected.

Water Switch Closes

Just before the blades reach their home position, the cam closes the water ll switch

for approximately 7 seconds. Since the thermostat has not yet opened and is shunting the water valve solenoid, the water valve doesn’t open at this time.

Start of the Second Revolution

Once the cam reaches the home position, the hold switch momentarily goes back to

its normally closed position. While the mold has heated sufciently to loosen the ice,

the mold has not yet reached the temperature required to open the mold thermostat.

The motor and heater continue to operate through the closed thermostat.

5

After Three Seconds

(Second Revolution)

Just as before, the cam continues its rotation and the hold switch contacts transfer to

the normally open position. The feeler arm begins to raise. The shut-off switch contacts transfer and the ejector blades resume their sweep.

If the bucket is full, the feeler arm will come to rest on top of the ice and prevent the

shut–off switch from resetting. This will keep the icemaker from producing any more

ice until the customer removes some of the ice from the bucket.

Thermostat Opens

Some time during the second revolution, the mold warms enough to open the thermostat and the heater is taken out of the circuit. The motor continues to get its power

through the normally open contacts of the hold switch.

Water Switch Closes

Just before the cam returns to the home position, the water switch is closed for the

second time. This time, the thermostat is open, eliminating the shunt to the water

valve. The water valve is energized for about 7 seconds. Current path for the valve is

from L1, through the heater and water switch.

Back to the Freeze Cycle

Once the motor advances the cam back to its home position, the hold and shut-off

switches transfer back to their normal positions and the icemaker is now ready for the

next freeze cycle. Once the mold gets down to temperature, the icemaker thermostat

closes and the ice harvest cycle repeats.

Water Fill Adjustment

Many of compact icemakers used today are equipped with a water ll adjustment.

Turning the ll adjustment screw changes the alignment between the cam and switch

and alters the amount of time the ll switch is energized. One full turn of the screw in

either direction changes the ll ±20 cc’s (approximate).

Manual Cycle Initiation

As we learned, the icemaker ejection cycle is initiated by the thermostat. If, however,

the icemaker is not ejecting, it will be necessary to manually initiate an ice ejection

cycle.

After removing the front cover, turn the motor shaft (small gear) ½ turn in the counterclockwise direction. This will rotate the cam enough to transfer the hold switch and

provide power to the motor. If the thermostat is closed at this time, the heater will

likewise be energized and the icemaker will complete the cycle.

After manual initiation, carefully feel the bottom of the mold. It should begin to heat. If

it doesn’t, either the thermostat has not yet closed or the heater is open.

Before manually initiating a cycle, check the position of the ejector arm. Assuming

the problem is in the icemaker, the position of the ejector arm will give you an indication of the failed component.

If the ejector blades are still in the home position (9 o’clock) the thermostat is most

likely at fault.

If the ejector blades stopped between the 9 and 10 o’clock positions, the hold switch

is most likely at fault.

An ejector at the 4 o’clock position normally indicates an open heater.

Any position other than the 9 or 4 o’clock positions may indicate motor problems or

broken, stripped or missing parts in the housing.

6

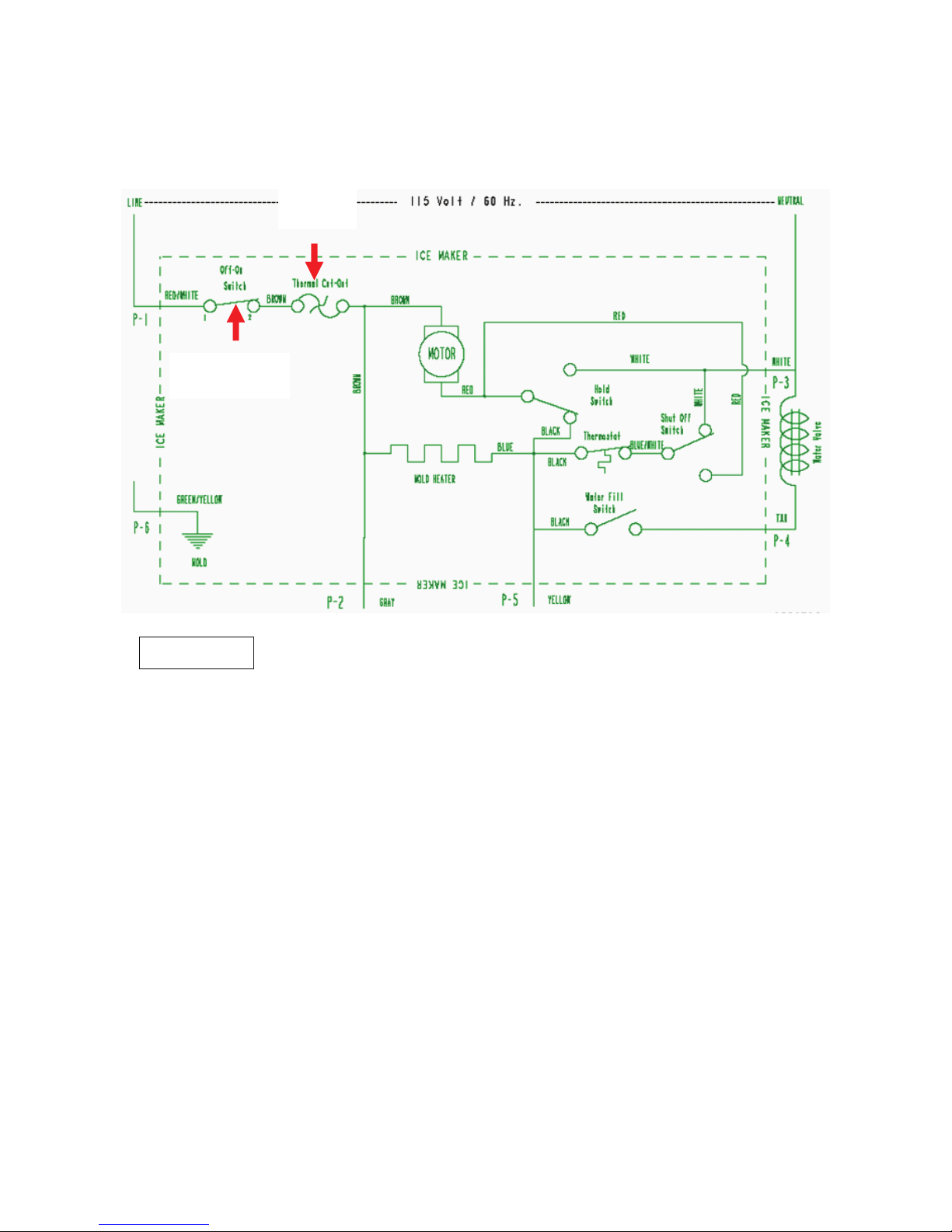

New Generation Schematic

120 Volt 60 Cycles

TCO

(New)

On/Off

Switch (New)

Mid-South

Mid South design incorporates an ON/OFF switch and Thermal Cut out. These features were not on the original Whirlpool compact design.

7

Loading...

Loading...