Whirlpool LMA1053LQ, LMA1053LT Installation Instructions

DRYING CABINET INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION DE

L’ARMOIRE SÉCHEUSE

Table of Contents Table des matières

DRYING CABINET SAFETY...........................................................1

INSTALLATION INSTRUCTIONS..................................................2

Tools and Parts ............................................................................2

Location Requirements................................................................2

Electrical Requirements ...............................................................3

Venting Requirements..................................................................4

Unpack Drying Cabinet................................................................5

Install and Level Drying Cabinet ..................................................5

Connect Vent................................................................................6

Reverse Door Swing ....................................................................6

Install Door Slider Kit....................................................................7

Complete Installation ...................................................................8

®

SÉCURITÉ DE L’ARMOIRE SÉCHEUSE ......................................9

INSTRUCTIONS D'INSTALLATION...............................................9

Outillage et pièces........................................................................9

Emplacement d'installation........................................................10

Spécifications électriques ..........................................................11

Exigences du système d'évacuation d’air.................................12

Déballage de l'armoire sécheuse...............................................12

Installation et mise d'aplomb de l'armoire.................................13

Raccordement au conduit d'évacuation....................................14

Inversion du sens d'ouverture de la porte .................................14

Installation des coulisseaux et tringles ......................................15

Achever l'installation ..................................................................16

DRYING CABINET SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or

“WARNING.” These words mean:

You can be killed or seriously injured if you don't

immediately follow instructions.

can be killed or seriously injured if you don't

You

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can

happen if the instructions are not followed.

8537102B

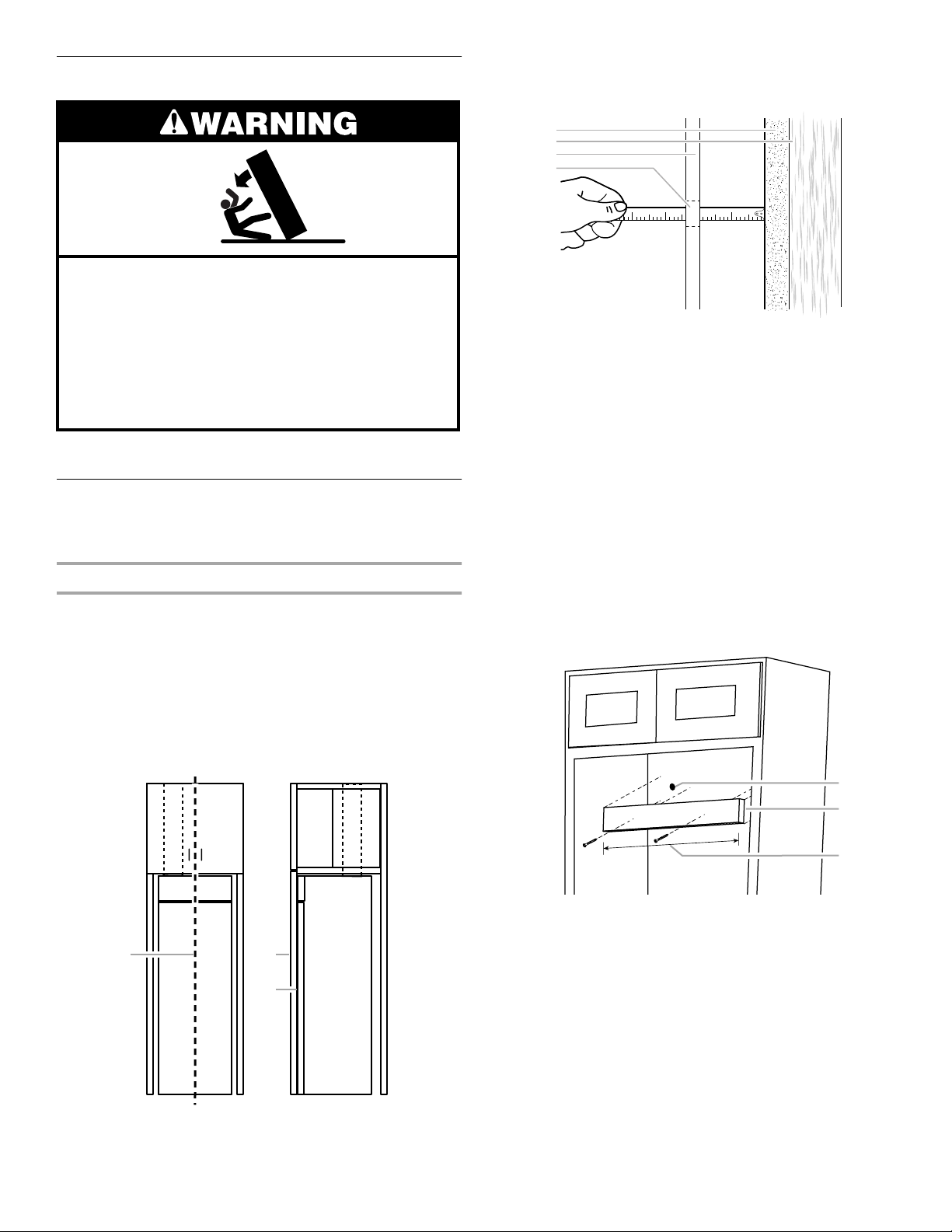

Tip Over Hazard

Drying cabinet is top heavy and tips easily when

not completely installed.

Use two or more people to move and install

drying cabinet.

Failure to do so can result in serious injury

or cuts.

INSTALLATION

INSTRUCTIONS

Tools and Parts

Assemble the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Too ls n eeded

■ Torpedo or pocket level

■ Tape measure

■ Drill (electric recommended)

■ Phillips screwdriver

■ ⁹⁄₃₂ in. drill bit (wall anchor)

Parts supplied

■ Allen wrench

■ Screws (2)

■ Plastic hole plugs (4)

■ ⁷⁄₆₄ in. drill bit (pilot hole)

■ ¹⁄₈ in. drill bit (attaching to

shim)

■ Marker or pencil

■ Gloves (optional)

■ Door Trim Kits (1)

■ Washers (2)

Alternate parts you may need

■ Shim

■ Panel trim kit (part numbers

4396494-white, 4396499biscuit)

Check local codes. Check existing electrical supply and venting.

See “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

■ Screws for securing shim

Location Requirements

You will need

■ A location that allows for proper exhaust installation. See

“Venting Requirements.”

■ A separate 15 or 20 amp circuit.

■ A grounded electrical outlet located within 5 ft. (152.4 cm) of

the drying cabinet. The drying cabinet has a 5 ft. (152.4 cm)

cord located on the top of the cabinet. Locate the power

outlet close enough to the top of the drying cabinet for the

plug to reach the outlet without using an extension cord. The

outlet should be easily accessible after the drying cabinet

installation. Adjust the outlet location if the drying cabinet is

installed inside custom cabinetry. See “Electrical

Requirements.”

■ A sturdy floor to support the total drying cabinet weight of

123 lbs (55.8 kg).

■ A level floor with a maximum slope of 1 in. (2.5 cm) under the

entire drying cabinet.

■ Ceiling must be a minimum of 12 in. (30.5 cm) from the top of

the cabinetry (see “Installation clearances”) or from the top of

the heavy metal vent if not installed in cabinetry.

■ The drying cabinet is designed for operation indoors in a dry

environment at a temperature above 32ºF (0ºC).

■ Check code requirements. Contact your local building

inspector.

Installation clearances

The location must be large enough to allow the drying cabinet

door to be opened fully.

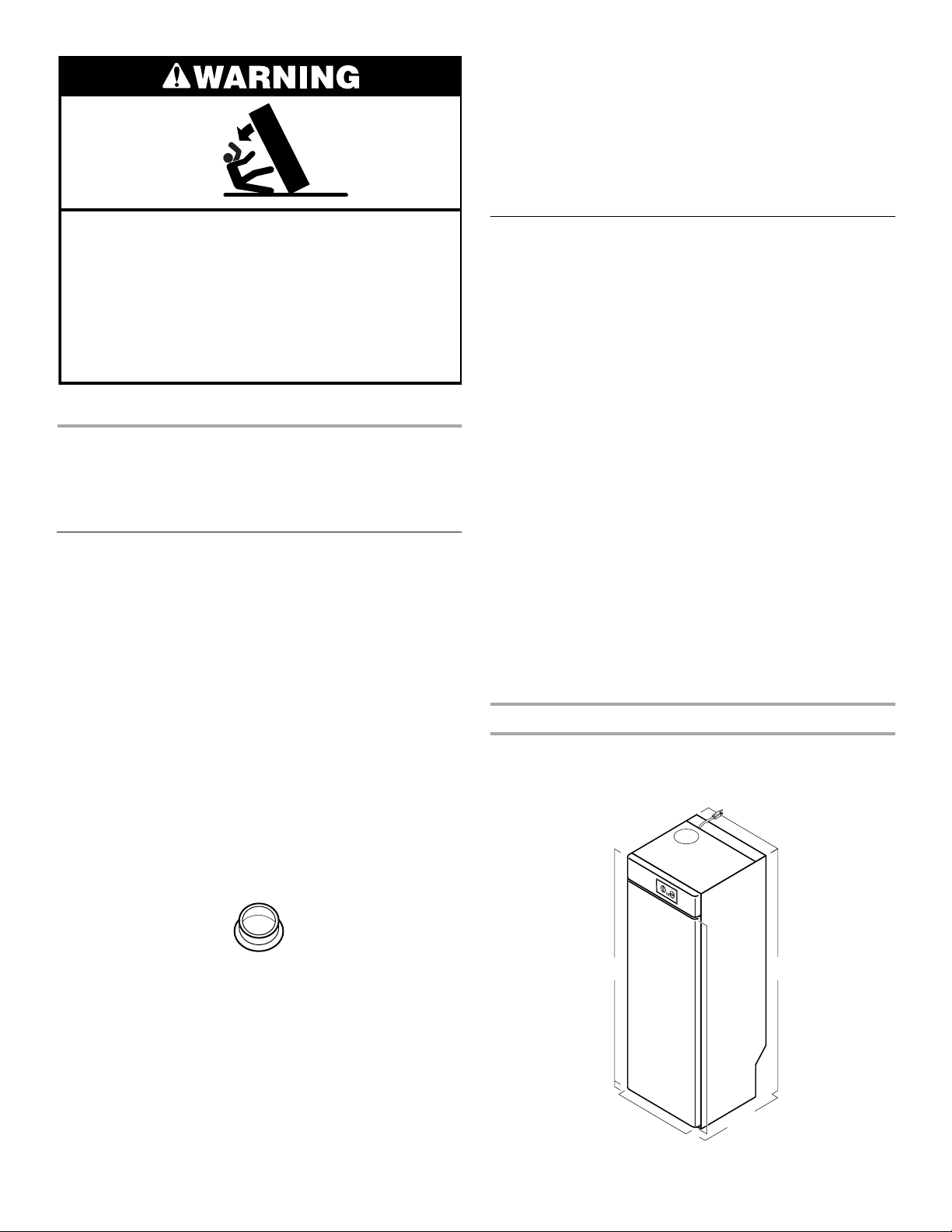

Drying Cabinet Dimensions

23.4"

(59.4 cm)

Hole plug

Parts needed

■ 4 in. (10.2 cm) heavy metal

exhaust vent (3 ft. [91.4 cm]

maximum length)

■ Handle for door trim

2

67"

(170.2 cm)

1"

(2.5 cm)

(door only)

23.4"

(58.4 cm)

60.25"

(153 cm)

24"

(61 cm)

68"

(172.7 cm)

Drying Cabinet Door Swing Dimensions

46.5"

(118.1 cm)

90˚

Minimum installation spacing for custom cabinetry or trim

kit installation

The dimensions shown following are for the minimum spacing

allowed.

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door and

floor moldings.

■ For built-in installation, minimum ventilation openings in the

top are required.

3

12" (30.5 cm) min.

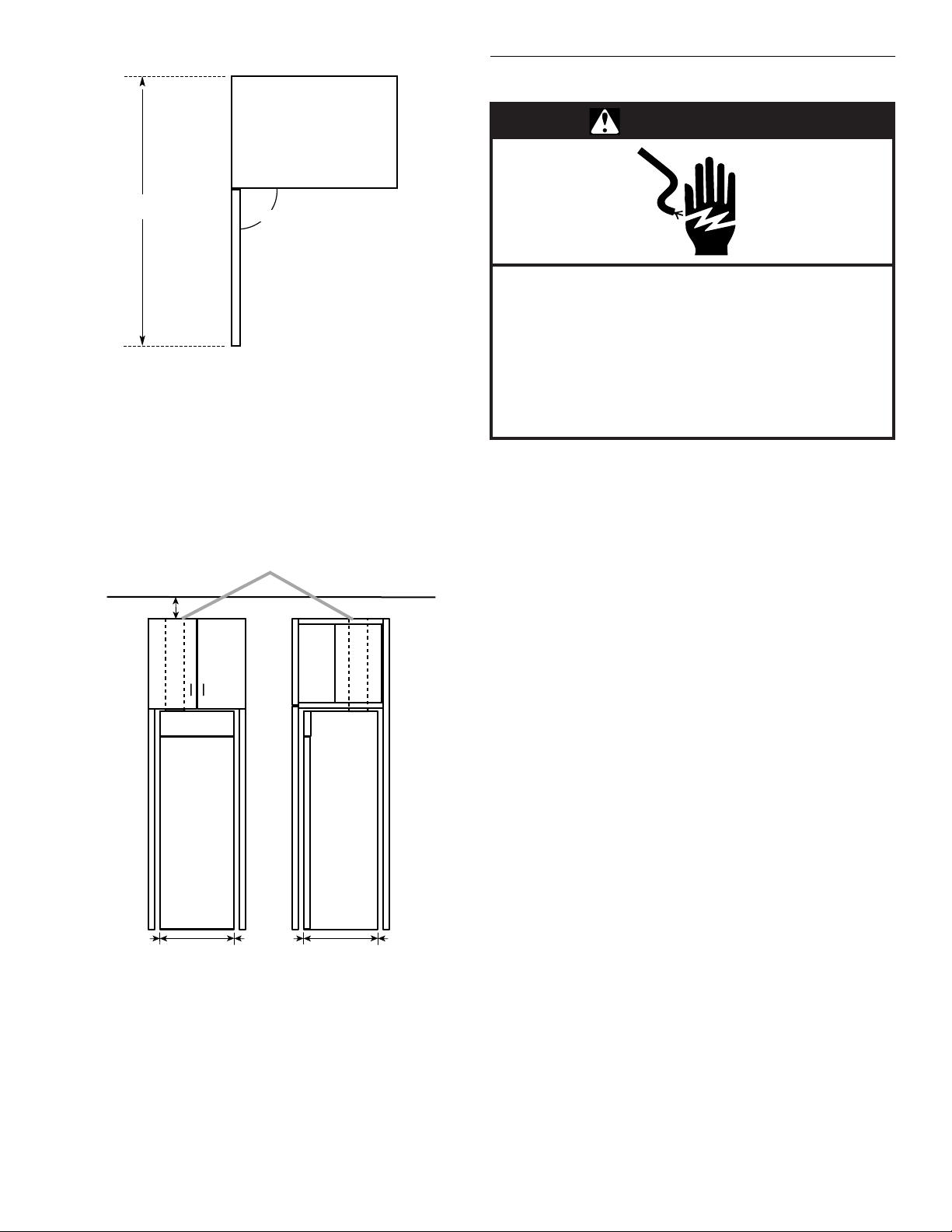

Electrical Requirements

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in

death, fire, or electrical shock.

It is your responsibility

■ To contact a qualified electrical installer if an electrical outlet

is not currently available.

■ To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSI/NFPA

70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association, Batterymarch Park,

Quincy, MA 02269.

(59.4 cm)

0"

0" 24"

(61 cm)

0"0" 23.4"

12

1. Front view

2. Side view

3. Open to the outside of the enclosure for

airflow (see “Venting Requirements”)

Electrical Connection

To properly install your drying cabinet, you must determine the

type of electrical connection you will be using and follow the

instructions provided for it here.

■ The drying cabinet should be connected to a 120 V 60 Hz

3 prong grounded outlet.

■ The drying cabinet is ready for connection with a 5 ft.

(152.4 cm) long cable with a grounded plug. Use only the

supplied cable and plug.

■ The outlet should be located for easy plug removal.

If using a replacement power supply cord, it is recommended

that you use Power Supply Cord Replacement Part Number

8181928. For further information, please call the Customer

Interaction Center at 1-800-253-1301. In Canada, call

1-800-461-5681.

3

For a grounded, cord-connected drying cabinet:

This drying cabinet must be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk of

electric shock by providing a path of least resistance for

electric current. This drying cabinet is equipped with a cord

having an equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate outlet that

is properly installed and grounded in accordance with all

local codes and ordinances.

1

2

WARNING:

Improper connection of the equipmentgrounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the drying cabinet

is properly grounded. Do not modify the plug provided with

the drying cabinet: if it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

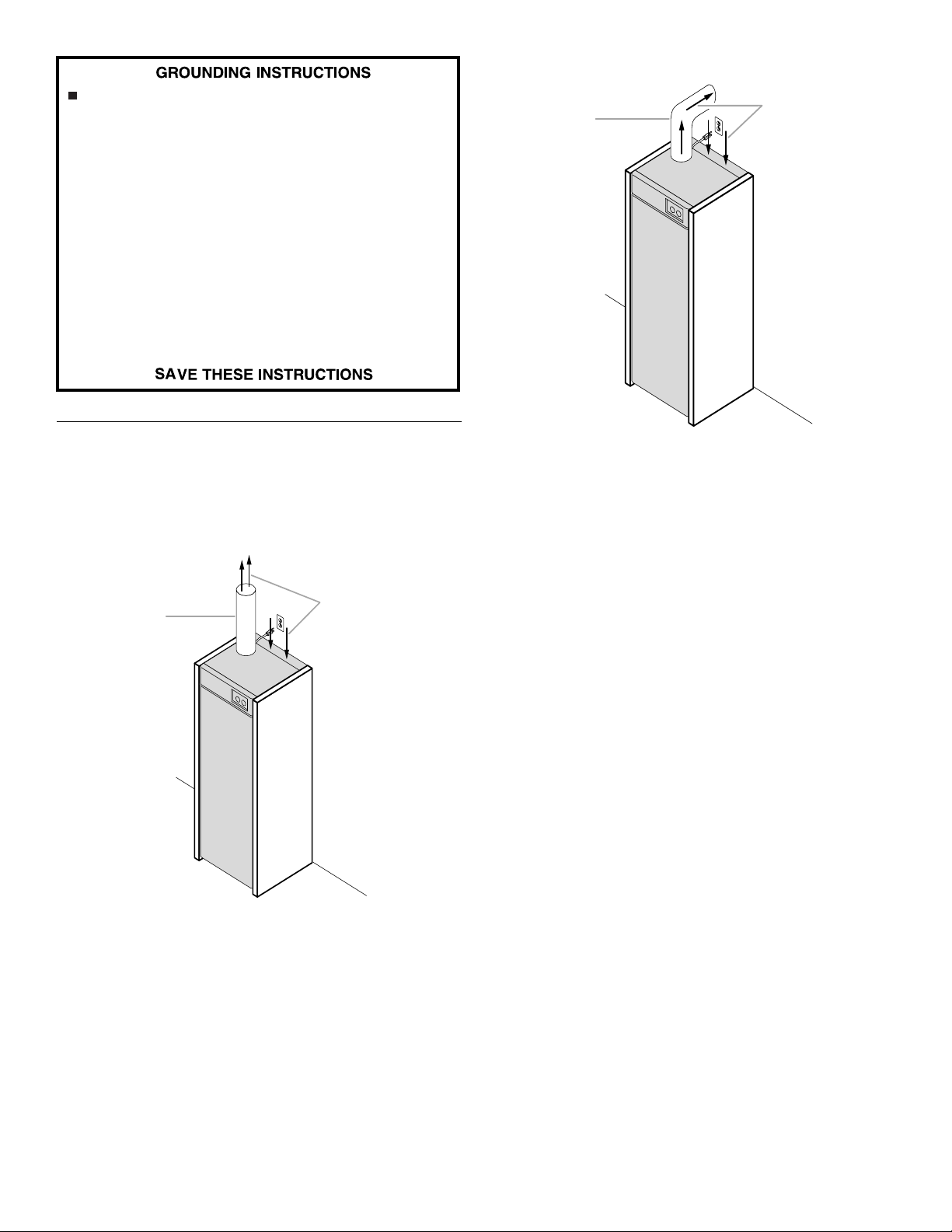

Venting Requirements

■ The drying cabinet should not be vented into a chimney, wall,

attic, ceiling or concealed space of a building.

■ The drying cabinet should vent into the room where the

drying cabinet is installed or into an adjacent room.

1

2

1. Venting into an adjacent room

2. Airflow in and out of the drying cabinet

■ Opening a door or window in the room where the drying

cabinet is installed is suggested for ventilation.

■ 4 in. (10.2 cm) heavy metal vent and clamps must be used.

Metal vent should not exceed 3 ft. (91.4 cm) in length.

■ If vented into the room where the drying cabinet is installed, a

minimum spacing of 12 in. (30.5 cm) from the metal vent to

the ceiling is suggested.

■ The drying cabinet must vent outside of the enclosure in

which it is installed.

■ Do not use an exhaust vent hood on the drying cabinet vent.

■ If custom cabinetry is built to enclose the top of the drying

cabinet, leave the venting area open to allow for airflow.

1. Venting into the same room

2. Airflow in and out of the drying cabinet

4

Unpack Drying Cabinet

2

3

Tip Over Hazard

Drying cabinet is top heavy and tips easily when

not completely installed.

Use two or more people to move and install

drying cabinet.

Failure to do so can result in serious injury

or cuts.

■ To prevent floor damage, set the drying cabinet onto the

cardboard prior to installation.

Install and Level Drying Cabinet

The drying cabinet may be installed with a panel trim kit or inside

custom cabinetry.

Move drying cabinet into position

1. Decide on the final location for the drying cabinet. Locate

existing wiring and plumbing to prevent drilling into or

severing wiring or plumbing during installation.

2. Keep the door taped closed until the drying cabinet is in its

final location.

3. As you slide the drying cabinet in so that it is flush and

centered with the cabinetry facing, route the power cord to

the 3 prong grounded outlet to avoid pinching the power

cord.

4. Remove tape and open the drying cabinet door. Slide out the

upper rack. Measure and note the distance from the drying

cabinet to the back panel or wall as shown.

1

2

3

4

1. Wall or panel behind drying cabinet

2. Wall stud

3. Back of drying cabinet

4. Mounting hole

5. Using a pencil, mark the location of the mounting holes on

the wall or back panel of the custom cabinetry. This will show

you the placement of the wood shim.

6. Slide the upper rack back and close the door. Keep the door

taped closed while it is being moved. Slide the drying cabinet

out.

7. Use a wood shim the thickness of the distance measured in

Step 4. The width of the shim cannot exceed 22 in. (55.9 cm)

or be less than 18 in. (45.7 cm). Attach the shim with the

appropriate length screws as shown.

NOTE: When attaching the shim, check to be sure that the

shim is attached solidly to the wall or custom cabinetry and

that the screws do not obstruct the drying cabinet mounting

holes.

1 2

3

1. Drying cabinet centered

2. Cabinetry door

3. Drying cabinet flush with cabinetry facing

1

1. Mounting hole markings

2. Wood shim

3. 18 in. (45.7 cm) Minimum/

22 in. (55.9 cm) Maximum width of shim

8. Slide the drying cabinet back into its final location. Remove

the door tape. Check to be sure that the shim is against the

back of the drying cabinet. If it is installed inside the custom

cabinetry, check that the front edge of the drying cabinet is

flush with the front of the custom cabinetry.

5

Loading...

Loading...