Whirlpool LGV4634JT0, LGV4634JQ0 Installation Guide

Havequestionsaboutyourdryer?

Check your Use and Care Guide for a toll-free number to call, or call your

dealer. The dealer islisted in the Yetlow Pages of your phone directory

under "Appliances -- Household -- Major -- Service and Repair."

When you call, you will need the dryer model number and serial number.

Both numbers are on the model/serial rating plate located in the door well

b_hind the dryer door and on front of opening.

Record the numbers here for handy reference:

Model No.

Serial No.

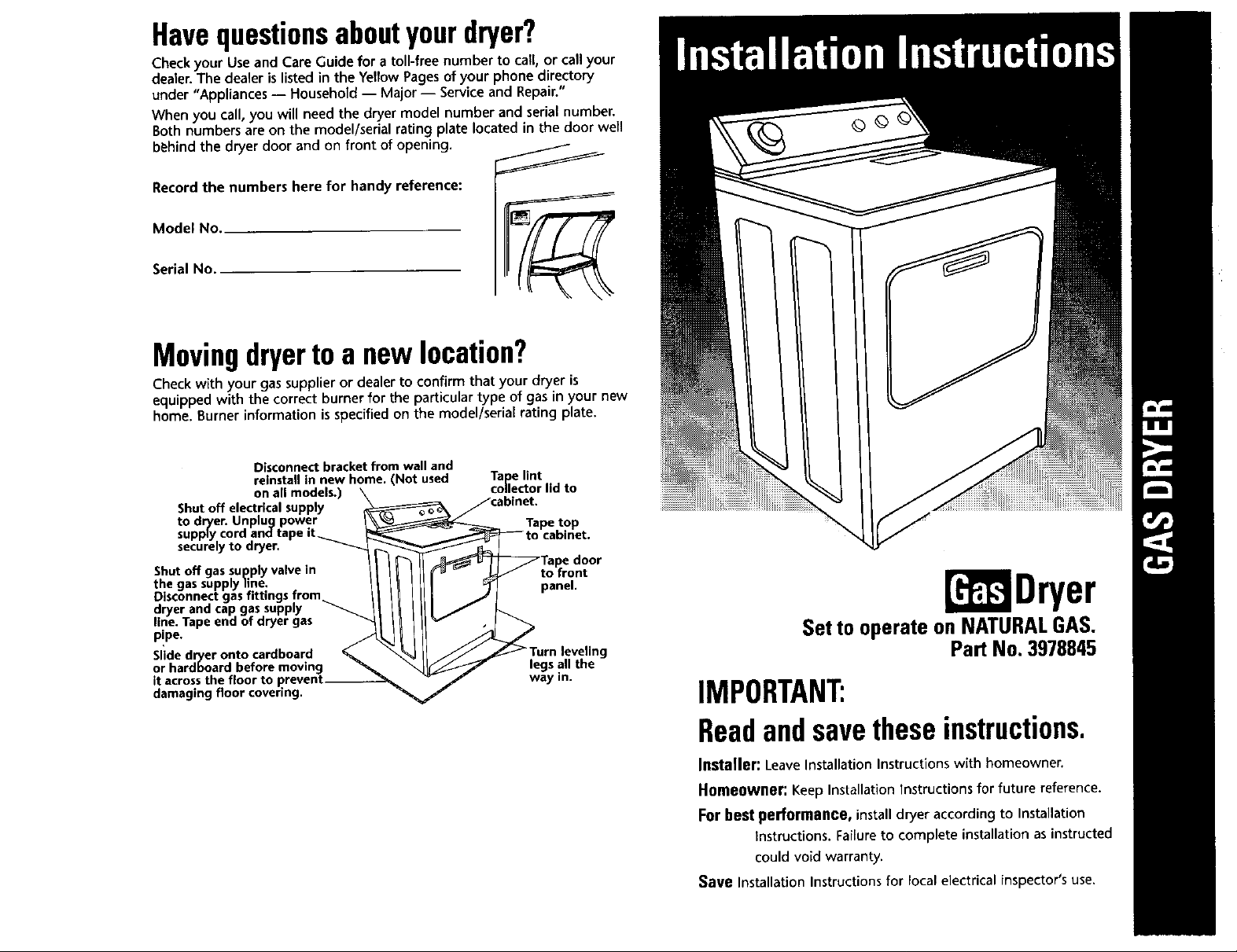

Movingdryerto a newlocation?

Check with your gas supplier or dealer to confirm that your dryer is

equipped with the correct burner for the particular type of gas in your new

home. Burner information is specified on the model/serial rating plate.

Disconnect bracket from wall and

reinstall in new home. (Not used

on all models.)

Shut off electrical supply

securely to dryer.

Shut off gas supply valve in

the gas supply fine.

Disconnect gas fittings from

dryer and cap gas supply

line. Tape end of dryer gas

pipe.

Slide dryer onto cardboard

or hardboard before moving

it across the floor to prevent--

damaging floor covering.

Tape lint

collector lid to

font

panel.

legs all the

way in.

[' Dryer

Set to operate on NATURALGAS.

Part No. 3978845

IMPORTANT:

Readandsavetheseinstructions.

Jnsta|Jer: Leave Installation Instructions with homeowner.

Hfimeowller: Keep Installation Instructions for future reference.

For best performance, install dryer according to Installation

Instructions. Failure to complete installation as instructed

could void warranty.

Save Installation Instructions for local electrical inspector's use.

-- Donotstoreorusegasoline,

--WHAT TODOIFYOUSMELL

r inlet "-.

_e connection

*from floor with _ 'Most installations will

dryer feet require at least S'inch

extended 1 inch dryer for the dryer vent.

clearance behLnd the

Forproperdryingperformance:

The location must provide:

I/Protection from weather and water: Do not

store or use dryer where it will be exposed to

water and weather.

I/Room temperature above 4S°F: If room

temperature is below 4S°F, automatic cycles

may not shut off.

I/Level floor: Maximum slope under entire dryer

shouid not be more than 1 inch. (If slope is

greater than 1 inch, install Extended Dryer Feet

Kit, Part No. 279810.) Clothes may not tumble

propeby and automatic sensor cyclesmay not

operate correctly if dryer is not level.

Itisyourresponsibilityto:

I/Observe all governing

codes and ordinances.

I/Check code requirements:

Some codes limit or do not

permit installation of clothes

dryers in garages, closets,

mobile homes or sleeping

quarters. Contact your local

building inspector.

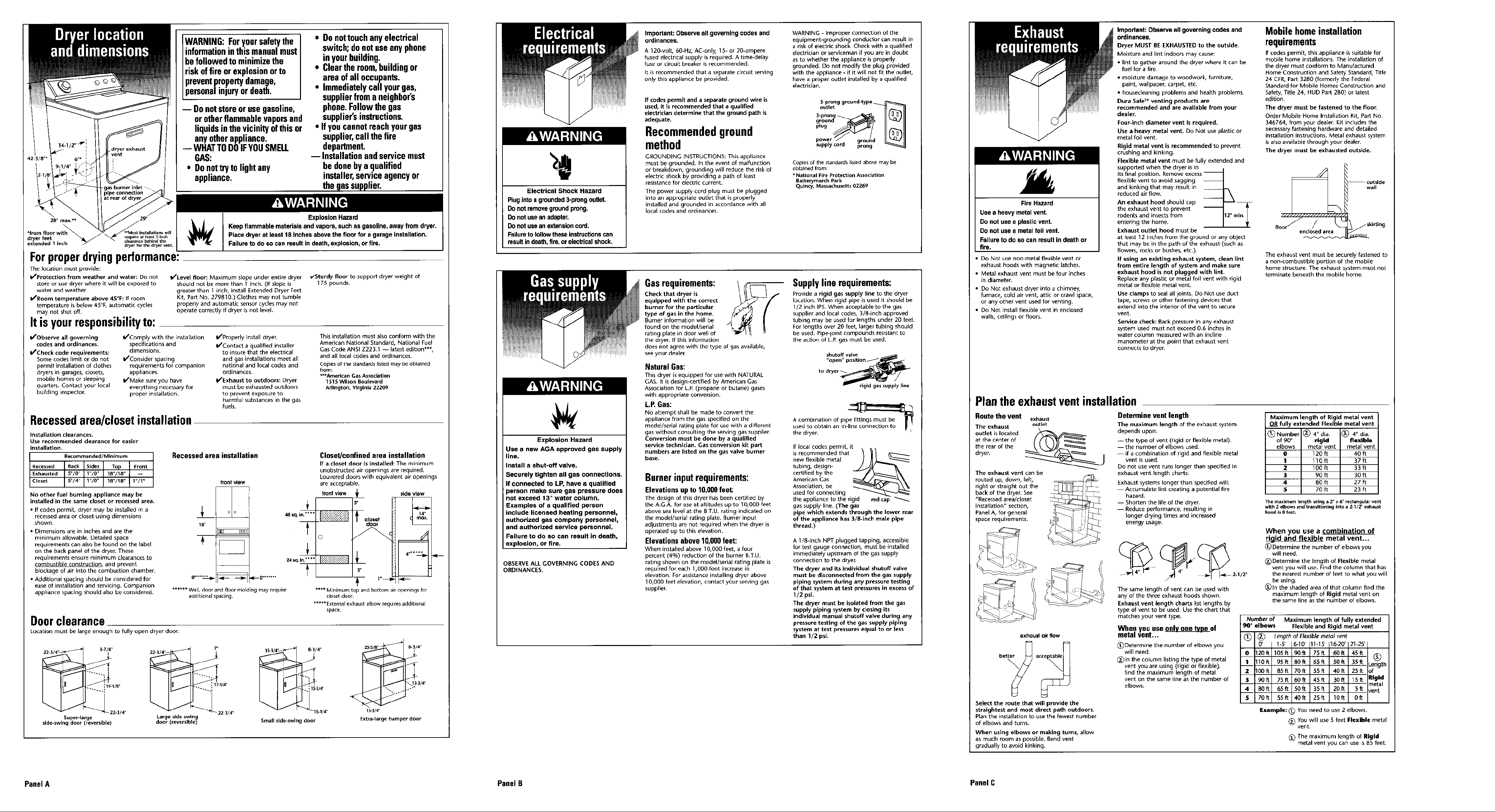

Recessedarea]closetinstallation

Installation clearances.

Use recommended clearance for easier

installation.

Exhausted

Recessed

Closet

No other fuel burning appliance may be

installed in the same closet or recessed area.

• If codes permit, dryer may be installed in a

recessed area or closet using dimensions

shown.

• Dimensions are in inches and are the

minimum allowable. Detailed space

requirements can also be found on the label

on the back panel of the dryer. These

requirements ensure minimum clearances to

combustible construction, and prevent

blockage of air into the combustion chamber.

• Additional spacing should be considered for

ease of installation and servicing. Companion

appliance spacing should also be considered.

Doorclearance

Location must be large enough to fully open dryer door.

I/Comply with the installation

specifications and

dimensions.

I/Consider spacing

requirements for companion

appliances.

I/Make sure you have

everything necessary for

proper installation.

Recessed area installation

****** Wall, door and floor molding may require

WARNING:Foryoursafetythe

informationinthismanualmust

befollowedto minimizethe

riskoffireorexplosionorto

preventpropertydamage,

personalinjuryordeath.

orotherflammablevaporsand

liquidsinthevicinityofthisor

anyotherappliance.

GAS:

• Donottrytalightany

appliance.

Keep flammable materials and vapors, such as gasoline, away from dryer.

Place dryer at least 18 inches above the floor for a garage installation.

Failure to do so can result in death, explosion,or fire.

I/Properly install dryer.

I/Contact a qualified installer

to insure that the electrical

and gas installations meet all

national and local codes and

ordinances.

I/Exhaust to outdoors: Dryer

must be exhausted outdoors

to prevent exposure to

harmful substances in the gas

fuels.

frontview

18"

additional spacing.

• Donottouchanyelectrical

switch;donotuseanyphone

inyourbuilding.

• Cleartheroom,buildingor

areaofalloccupants.

• Immediatelycallyourgas,

supplierfromaneighbor's

phone.Followthegas

suppliersinstructions.

• Ifyoucannotreachyourgas

supplier,callthefire

department.

-- Installationandservicemust

bedonebyaqualified

installer,serviceagencyor

the9assupplier.

Explosion Hazard

v'Sturdy floor to support dryer weight of

175 pounds.

This installation must also conform with the

American National Standard, National Fuel

Gas Code ANSI Z223,1 -- latest edition***,

and all local codes and ordinances.

Copies of the standards listed may be obtained

from:

***American Gas Association

1515 Wilson Boulevard

Arlington, Virginia 22209

Closel]confined area installation

If a closetdoor isinstalled: The minimum

unobstructedair openings are required.

Louvered doors with equivalent air openings

are acceptable.

front view

closet d mdx

dOOr

3"

**** Minimum top and bottom air openings for

closet door.

*****External exhaust elbow requires additional

space.

8.1/4"

,., ,,

side view

I 14"

Electrical Shock Hazard

Pluginto a grounded3-prong outlet.

Do not removegroundprong.

Do not usean adapter.

Do not usean extensioncord.

Failureto followtheseinstructionscan

resultin neath,fire,or electricalshock.

Explosion Hazard

Use a new AGA approved gas supply

line.

Install a shut-off valve.

Securely tighten all gas connections.

U connected to LP, have a qualified

person make sure gas pressure does

not exceed 13" water column.

Examples of a qualified person

include licensed heating personnel,

authorized gas company personnel,

and authorized service personnel.

Failure to do so can result in death,

explosion, or fire.

OBSERVE ALL GOVERNING CODES AND

ORDINANCES.

Important: Observe all governing codes and

ordinances.

A 120-volt, 6O-Hz, AC-only, 15- or 2B-ampere

fused electrical supply is required. A time-delay

fuse or circuit breaker is recommended.

It is recommended that a separate circuit serving

only this appliance be provided.

If codes permit and a separate ground wire is

used, it is recommended that a qualified

electrician determine that the ground path is

adequate,

WARNING - Improper connection of the

equipment-grounding conductor can result in

a risk of electric shock. Check with a qualified

electrician or serviceman it you are in doubt

as to whether the appliance is properly

grounded. Do not modify the plug provided

with the appliance - if it will not fit the outlet,

have a proper outlet installed by a qualified

electrician.

3 prong ground-type

3-pron

groun_

Recommendedground

power

method

GROUNDING INSTRUCTIONS: This appliance

must be grounded. In the event of malfunction

or breakdown, grounding will reduce the risk of

electric shock by providing a path of least

resistance for electric current,

The power supply cord plug must be plugged

into an appropriate outlet that is properly

installed and grounded in accordance with all

local codes and ordinances.

Gasrequirements: Supplyline requirements:

Check that dryer is

equipped with the correct

burner for the particular

type or gas in the home.

Burner information will be

found on the model/serial

rating plate in door well of

the dryer. If this information

does not agree with the type of gas available,

see your dealer.

Natural Gas:

This dryer is equipped for use with NATURAL

GAS. It is design-certified by American Gas

Association for L.R (propane or butane) gases

with appropriate conversion.

L,R Gas:

No attempt shall be made to convert the

appliance from the gas specified on the

model/serial rating plate for use with a different

gas without consulting the serving gas supplier.

Conversion must be done by a qualified

service technician. Gas conversion kit part

numbers are listed on the gas valve burner

base.

Burnerinputrequirements:

Elevations up to 10,000 feet:

The design of this dryer has been certified by

the A.G.A. for use at altitudes up to 10,000 feet

above sea level at the B.T.U. rating indicated on

the model/serial rating plate. Burner input

adjustments are not required when the dryer is

operated up to this elevation.

Elevations above 10,000 feet:

When installed above 10,OO0feet_ a four

percent (4%) reduction of the burner B.T.U.

rating shown on the model/serial rating plate is

required for each 1,000 foot increase in

elevation. For assistance installing dryer above

10,0go feet elevation, contact your serving gas

supplier.

Copies of the standards listed above may be

obtained from:

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

Provide a rigid gas supply line to the dryer

location. When rigid pipe is used it should be

IJ2 inch IPS.When acceptable to the gas

supplier and local codes, 318-inch approved

tubing may be used for lengths under 20 feet.

For lengths over 20 feet, larger tubing should

be used. Pipe-joint compounds resistant to

the action of L.P.gas must be used.

As__tmbinl_ttia°_ a(fn,PI.I_

the dryer.

If local codes permit, it

isrecommendedthat

new flexible metal

certified by the

American Gas

Association, be

tubing, design-

used for connecting

the appliance to the rigid red cap

gas supply line. (The gas

pipe which extends through the lower rear

of the appliance has 3/8-inch male pipe

thread.)

A 1/8-inch NPT plugged tapping, accessible

for test gauge connection, must be installed

immediately upstream of the gas supply

connection to the dryer.

The dryer and its individual shutoff valve

must be disconnected from the gas supply

piping system during any pressure testing

or that system at test pressures in excess of

1/2 psi.

The dryer must be isolated from the gas

supply piping system by closing its

individual manual shutoff valve during any

pressure testing of the gas supply piping

system at test pressures equal to or less

than 1/2 psi.

supply cord prong

shutoff valve

"open" position

to dryer _

Important: Observe all governing codes and

ordinances.

Dryer MUST BE EXHAUSTED to the outside,

Moisture and lint indoors may cause:

• lint to gather around the dryer where it can be

fuel for a fire.

• moisture damage to woodwork, furniture,

paint, wallpaper, carpet, etc,

• housecleaning problems and health problems.

Dura SafeTM venting products are

recommended and are available from your

dealer.

Fourdnch diameter vent is required.

Use a heavy metal vent. Do Not use plastic or

metal foil vent.

Rigid metal vent is recommended to prevent

crushing and kinking.

Flexible metal vent must be fully extended and

supported when the dryer is in

its final position. Remove excess --

flexible vent to avoid sagging

and kinking that may result in __

reduced air flow.

Fire Hazard

Use e heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to do so can _esult in death or

fire.

DO Not use non metal flexible vent or

exhaust hoods with magnetic latches.

Metal exhaust vent must be four inches

in diameter.

Do Not exhaust dryer into a chimney,

furnace, cold air vent, attic or crawl space,

or any other vent used for venting.

Do Not install flexible vent in enclosed

walls, ceilings or floors,

An exhaust hood should cap

the exhaust vent to prevent

rodents and insects from

entering the home.

Exhaust outlet hood must be

at least 12 inches from the ground or any object

that may be in the path of the exhaust (such as

flowers, rocks or bushes, etc,),

If using an existing exhaust system, clean lint

from entire length of system and make sure

exhaust hood is not plugged with lint.

Replace any plastic or metal foil vent with rigid

metal or flexible metal vent.

Use clamps to seal all joints. Do Not use duct

tape, screws or other fastening devices that

extend into the interior of the vent to secure

vent.

Service check: Back pressure in any exhaust

system used must not exceed 0.6 inches in

water column measured with an incline

manometer at the point that exhaust vent

connects to dryer.

Plantheexhaustventinstallation

Route the vent

The exhaust

outlet is located

at the center of

the rear of the

dryer.

The exhaust vent can be

routed up, down, left,

right or straight out the

back of the dryer. See

"Recessedarea/closet

installation" section,

Panel A, for general

space requirements.

exhaust

outlet

exhoust tar flow

Determine vent length

The maximum length of the exhaust system

depends upon:

-- the type of vent (rigid or flexible metal).

-- the number of elbows used.

-- if a combination of rigid and flexible metal

vent is used.

Do not use vent runs longer than specified in

exhaust vent length charts.

Exhaust systems longer than specified will:

Accumulate lint creating a potential fire

hazard.

-- Shorten the life of the dryer.

-- Reduce performance, resulting in

longer drying times and increased

energy usage.

The same length of vent can be used with

any of the three exhaust hoods shown,

Exhaust vent length charts list lengths by

type of vent to be used. Use the chart that

matches your vent type.

When you use _of

metal vent...

_Determine the number of elbows you

will need.

(_ln the column listing the type of metal

vent you are using (rigid or flexible),

find the maximum length of metal

vent on the same line as the number of

elbows.

Mobile homeinstallation

requirements

If codes permit, this appliance is suitable for

mobile home installations. The installation of

the dryer must conform to Manufactured

Home Construction and Safety Standard, Title

24 CFR,Part 3280 (formerly the Federal

Standard for Mobile Homes Construction and

Safety, Title 24, HUD Part 280) or latest

edition.

The dryer must be fastened to the floor.

Order Mobile Home Installation Kit, Part No.

346764, from your dealer. Kit includes the

necessaryfastening hardware and detailed

installation instructions. Metal exhaust system

isalso available through your dealer.

The dryer must be exhausted outside.

wall

enclosed area

The exhaust vent must be securely fastened to

a non-combustible portion of the mobile

home structure. The exhaust system must not

terminate beneath the mobile home.

Maximum length of Rigid metal vent

OR fully extended Flexible metal vent

Number _ 4" din. @ 4" dia.

of 90° dboId flexible

elbows metal vent metal vent

O 120ft 4fill

1 110ff 37ft

2 1O0ft 33f_

3 90 ft 3Oft

4 80 ft 27 ft

$ 70 ft 23 ft

The maximum length using a 2" x 6" p_ctangular vent

with 2 elbows and transitioning into a 2-1/2" exhaust

hood is 8 feet.

When you use a combination of

rigid and flexible metal vent...

_)Determine the number of elbows you

will need.

_)Determine the length of Flexible metal

vent you will use. Find the column that has

the nearest number of feet to what you will

be using.

(_ln the shaded area of that column find the

maximum length of Rigid metal vent on

the same line as the number of elbows.

Number of Maximum length of fully extended

900 elbows Flexible and Rigid metal vent

O' 1-5' 6-10' 11-15' 16-20' 21-25'

2oft lOSft 9Oft 75R 6Oft 4Sft

i _l_l_d_O0ft 8Sff 70_ SSft 40ff 25ff of _"

80ft 6Sft SOft 35ft 2Oft 5ft vent

.... _ metal

Select the route that will provide the

straightest and most direct path outdoors.

Plan the installation to use the fewest number

of elbows and turns.

When using elbows or making turns, allow

as much room as possible, gend vent

gradually to avoid kinking,

side-swing door (reversible)

Super-large Large side swin

door (reverslble_

Small side-swing door

_15.1/4"

13-3/4 n

Extra-large hamper door

Panel A Panel B Panel C

Example: (_ You need to use 2 elbows.

(_ You will use S feet Flexlble metal

vent.

(_) The maximum length of Rlgld

metal vent you can use is 85 feet.