Whirlpool KUIA15NRH'11, KUIA18NNJ'11, KUIA15PLL'11, KUIA18PNL'11, KUIA15NLH'11 User Manual

...

KAR-19

TECHNICAL EDUCATION

2007 DESIGN

15q & 18q AUTOMATIC

ICE MAKERS

KUIA15NRH*11

KUIA15PRL*11

KUIA15NLH*11

KUIA15PLL*11

* Denotes Color Designation

KUIA18NNJ*11

KUIA18PNL*11

Intoductory Models

JOB AID 4317408

FORWARD

This KitchenAid Job Aid “2007 Design 15" & 18" Automatic Ice Makers” (Part No. 4317408),

provides the In-Home Service Professional with information on the installation, operation, and

service of the 2007 Design 15" & 18" Automatic Ice Makers. For specifi c information on the model

being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the ice maker.

The Wiring Diagram and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only . Always use the Wiring Diagram supplied with the product when servicing

the ice maker.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the In-Home Service

Professional to properly diagnose malfunctions and repair the KitchenAid 2007 Design 15" & 18"

Automatic Ice Makers.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the ice maker to its proper operational status.

WHIRLPOOL CORPORA TION assumes no responsibility for any repairs made

on our products by anyone other than In-Home Service Professionals.

Copyright © 2007, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

Page

GENERAL .............................................................................................................................. 1-1

Ice Maker Safety ................................................................................................................ 1-1

KitchenAid Model & Serial Number Designations .............................................................. 1-2

Model & Serial Number Label Location.............................................................................. 1-3

Specifi cations ..................................................................................................................... 1-4

INSTALLATION INFORMATION ............................................................................................ 2-1

Electrical Supply Requirements ......................................................................................... 2-1

Water Supply And Drain Connections ................................................................................ 2-2

THEORY OF OPERATION .................................................................................................... 3-1

Operating Systems............................................................................................................. 3-1

Operational Modes ............................................................................................................. 3-5

Models With Internal Drain Pumps..................................................................................... 3-8

COMPONENT ACCESS ........................................................................................................ 4-1

Component Locations ........................................................................................................ 4-1

Removing The Bin Thermistor, Cutter Grid, Evaporator Thermistor,

& Water Distributor ......................................................................................................... 4-2

Removing The Electronic Control Housing Components ................................................... 4-5

Removing The Water Recirculation Pump ......................................................................... 4-7

Removing The Reservoir Drain Pump & Water Level Sensor............................................ 4-8

Removing The Condenser Fan Motor ................................................................................ 4-9

Removing The Evaporator ............................................................................................... 4-12

Removing The Measured Fill Water Valve ....................................................................... 4-16

Removing The Hot Gas Valve & Solenoid ....................................................................... 4-17

Removing The Condenser ............................................................................................... 4-18

Removing The Compressor ............................................................................................. 4-19

Removing The Internal Drain Pump ................................................................................. 4-21

Removing The Ice Maker Door & Gasket (15" Models) ................................................... 4-22

Removing The Ice Maker Door & Gasket (18" Models) ................................................... 4-23

COMPONENT TESTING ........................................................................................................ 5-1

Bin Thermistor .................................................................................................................... 5-1

Evaporator Thermistor ....................................................................................................... 5-1

Cutter Grid.......................................................................................................................... 5-2

Dual Transformer ............................................................................................................... 5-2

Water Recirculation Pump ................................................................................................. 5-3

Reservoir Drain Pump ........................................................................................................ 5-3

Water Level Sensor ............................................................................................................ 5-4

Condenser Fan Motor ........................................................................................................ 5-4

Measured Fill Water Valve ................................................................................................ 5-5

Hot Gas Valve Solenoid ..................................................................................................... 5-5

Compressor, Overload Protector, & Relay ......................................................................... 5-6

- iii -

Page

DIAGNOSTICS & TROUBLESHOOTING ............................................................................. 6-1

Water And Its Effect On Making Ice ................................................................................... 6-1

Troubleshooting Chart ........................................................................................................ 6-2

Diagnostic Flow Chart For Ice Maker Control Board ......................................................... 6-5

WIRING DIAGRAM & STRIP CIRCUITS ............................................................................... 7-1

Wiring Diagram .................................................................................................................. 7-1

Strip Circuits ....................................................................................................................... 7-2

TECH TIPS ............................................................................................................................. 8-1

Cleaning The Ice Maker ..................................................................................................... 8-1

Cleaning The Evaporator Plate ....................................................................................... 8-1

- iv -

GENERAL

WARNING

DANGER

ICE MAKER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on the appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

WARNING

DANGER

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

1-1

KITCHENAID MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER K UI A 15 NR H S 0

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

K = KITCHENAID

PRODUCT IDENTIFICATION

UI = UNDERCOUNTER ICE MAKER

MERCHANDISING SCHEME

A = ARCHITECT C = CULINARY & ARCHITECT II

S = STANDARD O = OUTDOOR

V = SIGNATURE SERIES

CAPACITY / SIZE / SERIES / CONFIGURATION

15 = 15" WIDE

18 = 18" WIDE

FEATURES

PR = PUMP, RIGHT HAND DOOR SWING

PL = PUMP, LEFT HAND DOOR SWING

PN = PUMP, NON-REVERSIBLE DOOR SWING

NR = NON-PUMP, RIGHT HAND DOOR SWING

NL = NON-PUMP, LEFT HAND DOOR SWING

NN = NON-PUMP, NON-REVERSIBLE DOOR SWING

YEAR OF INTRODUCTION

H = 1999, J = 2000, K = 2001, L = 2002, S = 2006, T = 2007

COLOR CODE

B = BLACK, W = WHITE, S = STAINLESS

T = BISCUIT, M = METEORITE

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER E T 04 54321

DIVISION RESPONSIBILITY

E = EVANSVILLE, IN

YEAR OF PRODUCTION

T = 2006, U = 2007

WEEK OF PRODUCTION

04 = 4th WEEK

PRODUCT SEQUENCE NUMBER

MODEL NUMBER

SERIAL NUMBER

1-2

MODEL & SERIAL NUMBER LABEL LOCATION

The Model/Serial Number label location is shown below.

Model & Serial

Number Location

1-3

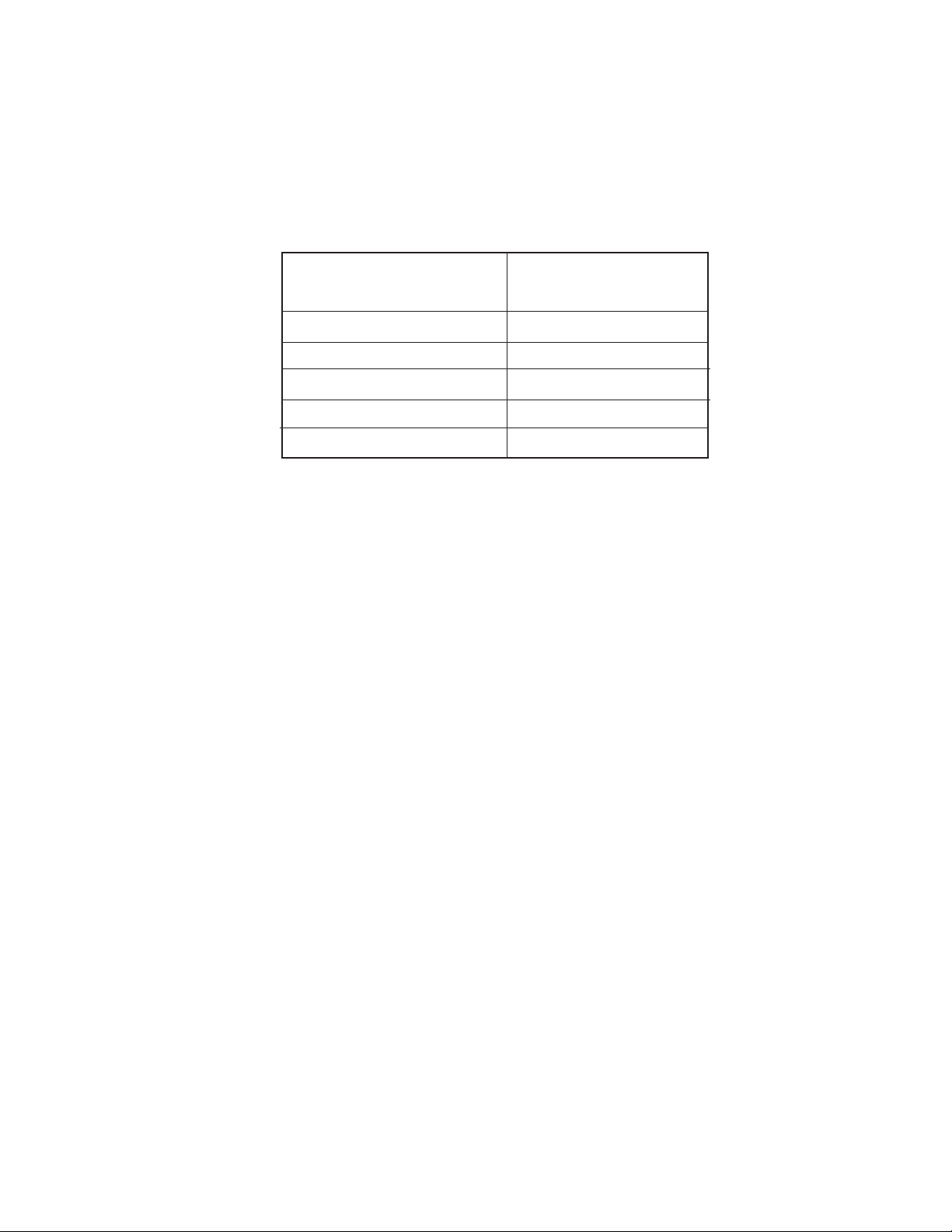

SPECIFICATIONS

AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97 to 127 VAC (rated 115VAC), 60 Hz

Amperage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.5 Amps (max)

Minimum Circuit Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 Amps

Ice Production per 24 hours (Approximate)

Water Temperature

Ambient Temperature

60⋅F (15⋅C)

70⋅°F (21°C) 46 lbs (21 kg)

80⋅°F (27°C) 47 lbs (21 kg)

90⋅°F (32°C) 40 lbs (18 kg)

100⋅°F (38°C) 40 lbs (18 kg)

110⋅°F (43°C) 38 lbs (17 kg)

Ice Shape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4" x 3/4" Square

Ice Thickness @ Normal Setting (Approximate) . . . . . . . . . . . . . . . . . . . . . . . . .0.32" (8.1 mm)

Ice Thickness @ Thin Setting (Approximate) . . . . . . . . . . . . . . . . . . . . . . . . . . .0.28" (7.0 mm)

Ice Thickness @ Thick Setting (Approximate) . . . . . . . . . . . . . . . . . . . . . . . . . . 0.39" (9.9 mm)

15 Inch Storage Capacity (Approximate). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 lbs. (11.3 kg)

18 Inch Storage Capacity (Approximate). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 lbs. (15.9 kg)

Exterior Dimensions (W x D x H) . . . 15" or 18" x 24" x 34" (381 or 457.2 x 609.6 x 863.6 mm)

Exterior Finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stainless Steel or Painted Steel

Net Weight . . . . . . . . . . . . . . . . . . . . . . . . . . 15" = 94 lbs. (42.6 kg) 18" = 123 lbs. (55.8 kg)

Cube Thickness Control . . . . . . . . . . . . . . . . . . . Water Level Sensor & Control Board Setting

Harvest Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Thermistor under Evaporator

Bin Ice Level Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Thermistor on side of Bin

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R134a

Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 to 100⋅F

Water Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 to 120 psig

Water Consumption (Dependent On Water Pressure) . . . . . . . . . . 6 to 10 gallons per 4 hours

1-4

INSTALLATION INFORMATION

WARNING

ELECTRICAL SUPPLY REQUIREMENTS

IMPORTANT: If this product is connected to

WARNING

a GFCI (Ground Fault Circuit Interrupter) protected outlet, nuisance tripping of the power

supply may occur, resulting in the loss of cooling. Ice quality may be affected. If nuisance

tripping has occurred, and if the condition of

the ice appears poor, dispose of it.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fi re, or electrical shock.

Before you move the ice maker into its fi nal

location, it is important to make sure you have

the proper electrical connection:

• A 115 Volt, 60 Hz, AC only 15- or 20- amp electrical supply , properly grounded in accordance

with the National Electrical Code and local

codes and ordinances, is required.

• It is recommended that a separate circuit,

serving only the ice maker, be provided. Use

a receptacle which cannot be turned off by

a switch or pull chain.

Recommended Grounding Method

For personal safety, this appliance must be

grounded. This appliance is equipped with a

power supply cord having a 3-prong grounding

plug. To minimize possible shock hazard, the

cord must be plugged into a mating, 3- prong,

grounding-type wall receptacle, grounded in

accordance with the National Electrical Code

and local codes and ordinances. If a mating

wall receptacle is not available, it is the personal responsibility of the customer to have

a properly grounded, 3-prong wall receptacle

installed by a qualifi ed electrician.

2-1

WATER SUPPLY AND DRAIN CONNECTIONS

CONNECTING THE WATER LINE

1. Turn off the main water supply.

2. Turn on the nearest faucet and allow it to

run long enough to clear line of water.

3. Find a 1/2"(12.70 mm) to 1-1/4" (3.18

cm) vertical cold water pipe near the ice

maker.

NOTE: A horizontal pipe will work, but drill on

the top side of the pipe, not the bottom. This

will keep water away from the drill motor, and

also keeps normal sediment from collecting in

the valve.

4. Using a grounded drill, a 1/4" (6.35 mm)

hole in the cold water pipe you have selected.

5. Fasten a shutoff valve to the cold water

pipe with a pipe clamp. Make sure that the

outlet end is fi rmly in the 1/4" (6.35 mm)

drilled hole, and that the washer is under

the pipe clamp.

IMPORTANT: Do not use a piercing-type, or

a 3/16" (4.76 mm) saddle-type valve. These

can reduce water fl ow and easily become

clogged.

8. Use 1/4" (6.35 mm) O.D. copper tubing

for the cold water supply and:

a) Measure from the connection at the

back of the ice maker to the cold water

pipe.

b) Add an extra 36" (91.4 cm) to ensure

that you have the proper length. Make

sure both ends of the copper tubing are

cut square.

c) Slip a compression sleeve and com-

pression nut over the ends of the copper

tubing.

d) Insert the end of tubing into the water

shutoff outlet as far as it will go, and

screw the compression nut onto the

outlet. Tighten the compression nut

with an adjustable wrench, but do not

overtighten it.

9. Place the free end of the copper tubing into

a container or sink, and turn on the main

water supply. Flush the tubing until water

is clear, and then turn of f the shutoff valve

on the water pipe. NOTE: Always drain the

water line before making the fi nal connec-

tion to the inlet of the water valve to avoid

a possible water valve malfunction.

6. Tighten the packing nut.

7. Tighten the pipe clamp screws carefully

and evenly so that the washer makes a

watertight seal. Do not overtighten the

pipe clamp. If the water line is soft copper

tubing, you could crush it.

10. Bend the copper tubing to meet the water

line inlet, located on the back of the ice

maker cabinet, as shown below.

2-2

11. Thread the nut onto the coupling at the

end of the copper tubing. Tighten the nut

by hand. Then tighten it with a wrench two

more turns. Do not overtighten.

CONNECTING THE DRAIN

SIDE VIEW

15" Models

Gravity Drain System

Connect the ice maker drain to your drain

in accordance with all state and local codes

and ordinances. If the ice maker is provided

with a gravity drain system, use the following

guidelines when installing the drain lines. This

will avoid water from fl owing back into the ice

maker storage bin and potentially fl owing onto

the fl oor, causing water damage.

• Drain lines must have a minimum of 5/8"

(15.88 mm) inside diameter.

• Drain lines must have a 1" drop per 48"

(2.54 cm drop per 122 cm) of run, or 1/4"

drop per 12" (6.35 mm per 30.48 cm) and

not have any low points where water can

settle.

• The fl oor drains must be large enough to

accommodate drainage from all drains.

• The ideal installation has a standpipe with a

1-1/2" (3.81 cm) to 2" (5.08 cm) PVC drain

reducer installed directly below the outlet of

the drain tube, as shown. Y ou must maintain

a 1" (2.54 cm) air gap between the drain hose

and the standpipe.

18" Models

1. Drain Hose

2. 1" (2.54 cm) Air Gap

3. PVC Drain Reducer

4. Center of drain should be 20" (50.8 cm) back on

15" models from front of door and 23" (58.4cm)

back on 18" models from front of door, with or

without the 3/4" (1.91 cm) panel on the door.

• It may be desirable to insulate the drain line

up to the drain inlet.

2-3

Drain Pump System (On Some Models)

WARNING

WARNING

Connect the ice maker drain to your drain in

accordance with the International Plumbing

Code and any local codes and ordinances.

NOTE: If the drain hose becomes twisted and

water cannot drain, the ice maker will not operate.

Connecting the Drain

After ensuring that the drain system is adequate, follow these steps to properly place

the ice maker:

WARNING

1. Plug in ice maker or reconnect power.

WARNING

Excessive Weight Hazard

Use two or more people to move and

install ice maker.

Failure to do so can result in back or

other injury.

2. Style 1 - For gravity drain system, push

the ice maker into position so that the ice

maker drain tube is positioned over the

PVC drain reducer. Style 2 - For drain

pump system connect the drain pump

outlet hose to the drain. See “Drain Pump

System” earlier in this section.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fi re, or electrical shock.

3. Recheck the ice maker to be sure that it

is level.

4. If it is required by your local sanitation

code, seal the cabinet to the fl oor with

an approved caulking compound after

all water and electrical connections have

been made.

2-4

THEORY OF OPERATION

OPERATING SYSTEMS

There are three operating systems in the ice

maker:

• Refrigeration System

• Water System

• Electrical System

REFRIGERATION SYSTEM

The refrigeration system in the ice maker is

very similar to the system used in other refrigeration appliances. The refrigerant used in this

unit is R134a.

There are two very important additions to the

refrigeration system in the ice maker: the Hot

Gas Valve, and the Condenser Accumulator

Tube. The components operate as follows:

• Hot Gas Valve - Allows high pressure

refrigerant gas to bypass the condenser

and fl ow through the condenser accu-

mulator tube.

• Condenser Accumulator T ube - Hot gas

pushes liquid refrigerant through the

accumulator tube into the evaporator,

helping to evenly heat the evaporator plate so that the ice slab releases

quickly and evenly.

3-1

WATER SYSTEM

The water system provides:

• Fresh water for ice production

• Water recirculation as ice is produced

• Water removal after ice is produced

The water system circulates water to freeze

into ice on the evaporator during the freeze

cycle. During the harvest cycle, it drains away

minerals and contaminates. During the clean

cycle, cleaning solution is circulated to clean

the system of minerals and contaminates.

The hardness of the water supplied to the ice

maker will affect the quality of the ice that is

produced. It may also affect the operation of

the water system.

A water softener , or poly phosphate feeder , will

not cure all of the problems associated with hard

water, but they can be used to reduce scale

buildup in the ice maker. NOTE: Some poly

phosphate feeders will cause a slime buildup

in the water system when the water supply has

a low mineral content.

The ice maker’s water system is shown on

next page.

3-2

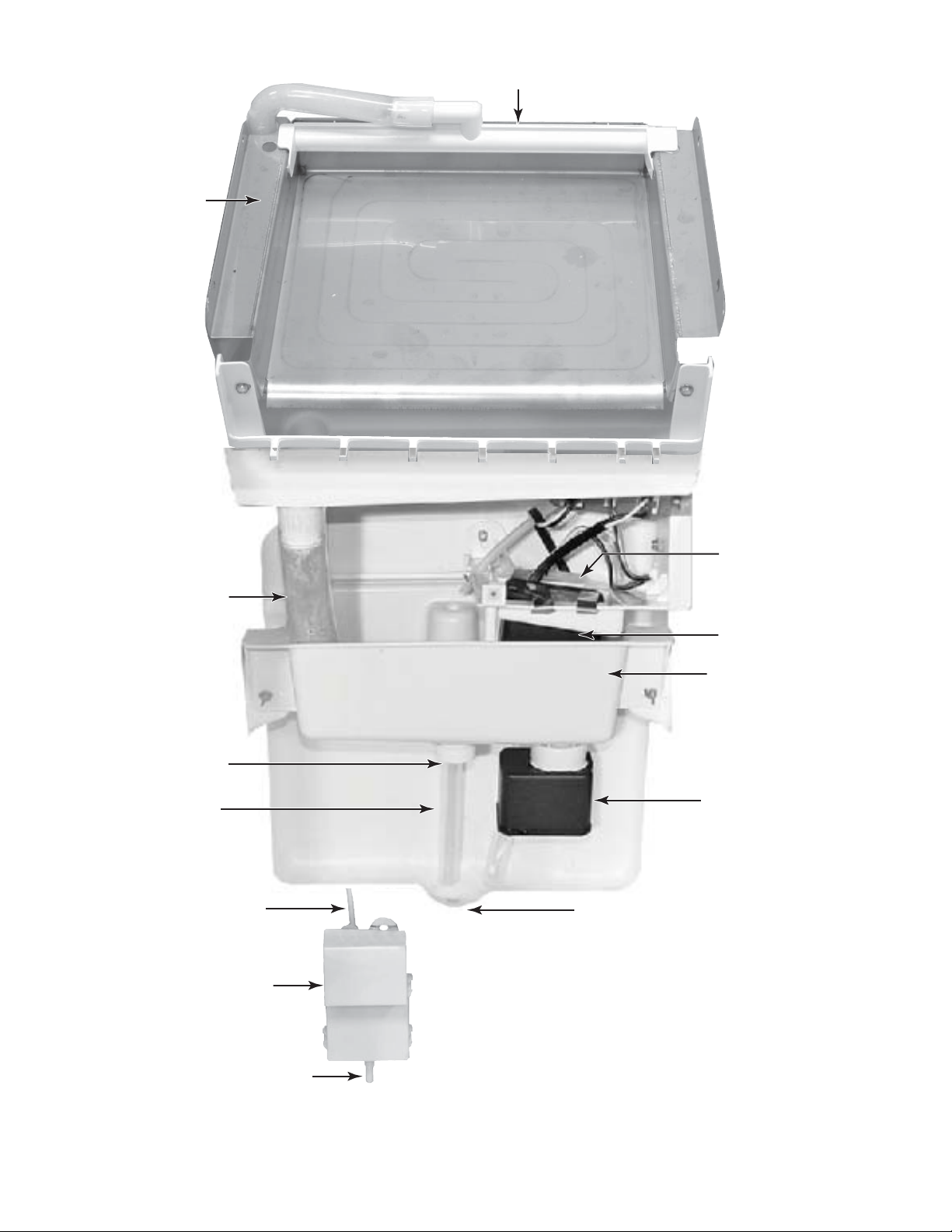

Evaporator

WATER SYSTEM COMPONENT LOCATIONS

Water Distributor

Water Return Tube

Manual Drain

Drain Overfl ow

Water Valve Outlet Tube

Measured Fill

Water Inlet Valve

Water Level Sensor

Water Recirculation

Pump

Reservoir Pan

Reservoir Drain Pump

Bin Drain

From Water Supply

3-3

ELECTRICAL SYSTEM

The ice maker’s electrical system provides power for the refrigeration and water systems, and

controls the operation of each component.

3-4

OPERATIONAL MODES

There are four main operational modes for the

ice maker (more detailed operation is found in

the fl ow chart on page 6-5):

• Freeze

• Harvest

• Clean

• Service (Diagnostics)

ICE MAKING CYCLE

In addition, there are three possible “Off” cycles

for the ice maker. They occur when:

1. The bin is full of ice and the LED is il-

luminated “ON/OFF” (Idle mode).

2. The "On/OFF” control switch has been

held for three seconds. The ON/OFF

LED will go out.

3. The Holiday Mode.

Electrical System

Line Voltage is supplied to the electrical control

switches and the primary side of the step-down

dual transformer. The dual transformer reduces

120 VAC to 8.75 VAC for the cutter grid and

the bin light and 12 V AC for the drain and recirculating pumps. The electronic control board

directs 12 VAC to the water recirculating and

reservoir drain pumps, and 120 VAC to the

hot gas solenoid, condenser fan motor, and

compressor. The measured fi ll water valve will

always have 120 V AC on the BK and WH wires

and 14 VDC on the OR/WH and BK/RD wires.

An evaporator thermistor supplies temperature

information to the electronic control to determine

when to terminate the harvest cycle.

Refrigeration System

The hot gas refrigerant, under high pressure, is

forced through the condenser, where it changes

into a liquid, and fl ows through the drier and

capillary tube into the evaporator. Under low

pressure in the evaporator, the liquid refrigerant

absorbs heat from the water fl owing over the

evaporator as the refrigerant evaporates into

a gas. As a low pressure gas, the refrigerant

fl ows back through the suction line of the heat

exchanger, to the compressor.

During the Freeze mode, some of the hot gas

that is in the condenser accumulating tube,

condenses to a liquid, and remains in the accumulating tube.

During the later stages of the Freeze mode, as

the ice slab forms on the evaporator freezing

plate, some of the refrigerant passing through

the evaporator will not evaporate into a gas, but

will remain a liquid. This liquid refrigerant will

settle in the accumulator, while the refrigerant

vapor is sucked off through the suction tube at

the top of the accumulator. This accumulated

liquid refrigerant will eventually be directed to

the evaporator to quickly warm the evaporator

plate during the Harvest mode.

NOTE: It is very important that the accumulator

is not tilted out of a horizontal position. If moved,

it could cause compressor failure.

Water System

The water recirculating pump moves the water

from the reservoir pan up to the distributor,

where it fl ows out over the evaporator freez-

ing plate.

Water that does not freeze on the evaporator

plate runs off the front edge, and falls back into

the reservoir, where it is recirculated back to

the water distributor.

As the ice slab forms, the minerals in the water

are on the surface of the ice. The water fl ow-

ing over the top of the ice slab washes these

minerals back into the water reservoir pan. The

water continues to recirculate until the water

level in the reservoir drops to the bottom of the

water level sensor. When the water level in the

reservoir drops below the sensor, the control

terminates the freeze mode and initiates the

harvest mode.

The control signals the measured fi ll valve to fi ll

to the selected water level setting. The measured fi ll valve uses a fl ow meter to accurately fi ll

to the correct volume. Thin Ice uses 32 ounces

(954cc), Normal Ice 37 ounces (1106cc), and

Thick Ice 42.5 ounces (1258cc).

3-5

HARVEST MODE

Electrical System

When the water level in the reservoir drops

below the water level sensor it signals the

electronic control to terminate power to the

condenser fan, and then the water recirculating

pump. The reservoir drain pump is activated

to fully drain the reservoir. Power is then supplied to the hot gas valve and a fi ll request is

sent to the measured fi ll valve. The fi ll valve

fi lls to the requested volume while the hot gas

valve is energized for the balance of the harvest mode.

If the evaporator thermistor is unplugged, the

evaporator defaults to a timed 4 minute harvest.

If the water level sensor is disconnected or

open, the control defaults to 25 minutes of

freeze time. The cleaning indicator LED feature will not function if the water level sensor

is disconnected.

Refrigeration System

The hot gas valve opens, allowing high pressure refrigerant gas to bypass the condenser,

and fl ow through the condenser accumulating

tube. The hot gas pushes the liquid refrigerant

that has accumulated in the accumulator tube

up into the evaporator. The hot liquid refrigerant

evenly heats the evaporator plate so that the

ice slab releases quickly and evenly.

The ice slab, when released, slides off of the

evaporator plate onto the cutter grid.

Water System

The electronic control board sends a signal to

the water valve. The signal tells the water valve

how much water to be fi lled, allowing water to

fl ow into the water reservoir pan. The water

fi ll volume is determined by the ice thickness

setting.

As a result of the hot gas fl ow and the ice sliding

off the evaporator plate, the evaporator temperature begins to rise. When the evaporator

thermistor reaches the set temperature (52°F),

the unit switches to the Freeze mode. This cycling between Freeze and Harvest, continues

until the ice bin is full.

The electronic control board operates the various components and systems in the ice maker

for each of the Freeze and Harvest modes.

CLEAN MODE

Electrical System

The electronic control board operates the

various components and systems during the

Clean mode.

For the order of the components cycled, see

the fl ow chart on page 6-13.

Water System

When the service control switch is in the “Clean”

position, the water recirculating pump circulates

the cleaning solution that has been added to the

reservoir, up to the water distributor , across the

evaporator, and back into the reservoir, where

it is recirculated. The compressor and hot gas

valve operate to heat the evaporator.

DIAGNOSTIC MODE

1. Do not continue with the diagnosis of the ice

maker if a fuse is blown, a circuit breaker

is tripped, or if there is less than a 120 volt

power supply at the wall outlet.

2. All units that have failed during the fi rst few

days of use should be checked for loose

connections or miswiring.

Entering and Navigating — Manual

Diagnostics

• Turn the product on. Within 10 seconds of

Power On, press and hold the On and the

Clean buttons. Release both buttons when

all user interface LEDs begin to fl ash.

• Within 5 seconds of all LEDs fl ashing, push

any other button on the user interface. This

begins manual diagnostics.

• If no button is pressed within 5 seconds, the

product goes into the automatic diagnostic

mode used at the assembly plant. Each

component is cycled for 5 seconds.

• The Service button (or Off button on some

models) is used to advance through each

step.

• T o exit manual diagnostics, press the Power

button (or On button on some models)

3-6

Diagnostic Chart

After pressing any button to enter manual diagnostics all LEDs will illuminate for 5 seconds. The

controls will then automatically move to the fi rst component.

Order Component On/Off LED

1 Entry intoTest

2 Bin Thermistor ON Solid--OK

3 Evaporator

4a Water Valve

4b Water Level

5 Recirculation

6 Reservoir Drain

7 Compressor and

8 Compressor and

9 Twice Ice OFF OFF ON Solid--No delay

10 Ice Thickness OFF 2 Blinks--Thin

Mode

Thermistor

4 min time out

Service button

press will advance

to step 6

Sensor

Pump

Pump

Condenser Fan

Motor

Hot Gas Valve

(On for some

models)

ON ON ON ON

2 blinks--Open

4blinks--Short

OFF OFF ON Solid--OK

OFF ON Solid--reservoir full

OFF ON Solid--reservoir full

ON ON ON OFF

ON OFF OFF OFF

ON Solid while cooling Blinking when evap

ON Solid while heating ON Solid while heating

Service LED

(Off for some

models)

OFF OFF OFF

Blinking--reservoir

empty

Blinking--reservoir

empty

thermistor reaches

4.5ºF; full frost pattern

should be visible

Blinking when evap

thermistor reaches 52ºF

4 Blinks--Normal

6 Blinks--Thick

Press Clean button to

cyclebetween settings

Clean LED Feature Light (for

2blinks--Open

4blinks--Short

ON OFF

ON OFF

ON OFF

ON Solid while heating OFF

Blinking--10 min delay

between cycles

Press Clean button to

cyclebetween settings

OFF OFF

some models)

OFF

OFF

ERROR DISPLAYS

These errors will occur at any time during normal operation if a thermistor fails.

2 Blinks — Service Light is blinking twice in repeating intervals – This signifi es a bin thermistor

failure. Check that the bin thermistor is plugged in to the control box. Check that the bin thermistor is not open or shorted. Replace the thermistor if it is open or shorted.

3 Blinks — Service Light is blinking three times in repeating intervals – This signifi es a harvest

failure. Check that the evaporator thermistor is connected to the sealed system tubing. If the

thermistor is plugged in, ensure that it is fully connected to the control box. (The ice maker will

operate on a timed cycle if the evaporator thermistor is unplugged.) Check the resistance of the

thermistor. If the thermistor checks good, then look for a frost pattern on the evaporator plate.

The unit may be low on refrigerant.

HOLIDAY MODE

The Holiday Mode feature is designed for the traveler or for those whose religious observances

require turning off the lights and the ice maker. By selecting this feature, ice production and the

interior lights will be disabled. Press and hold the Holiday Mode button to turn on the Holiday

Mode feature. Press and hold the button again to turn off the feature.

The Holiday mode LED is lite constantly in this mode.

3-7

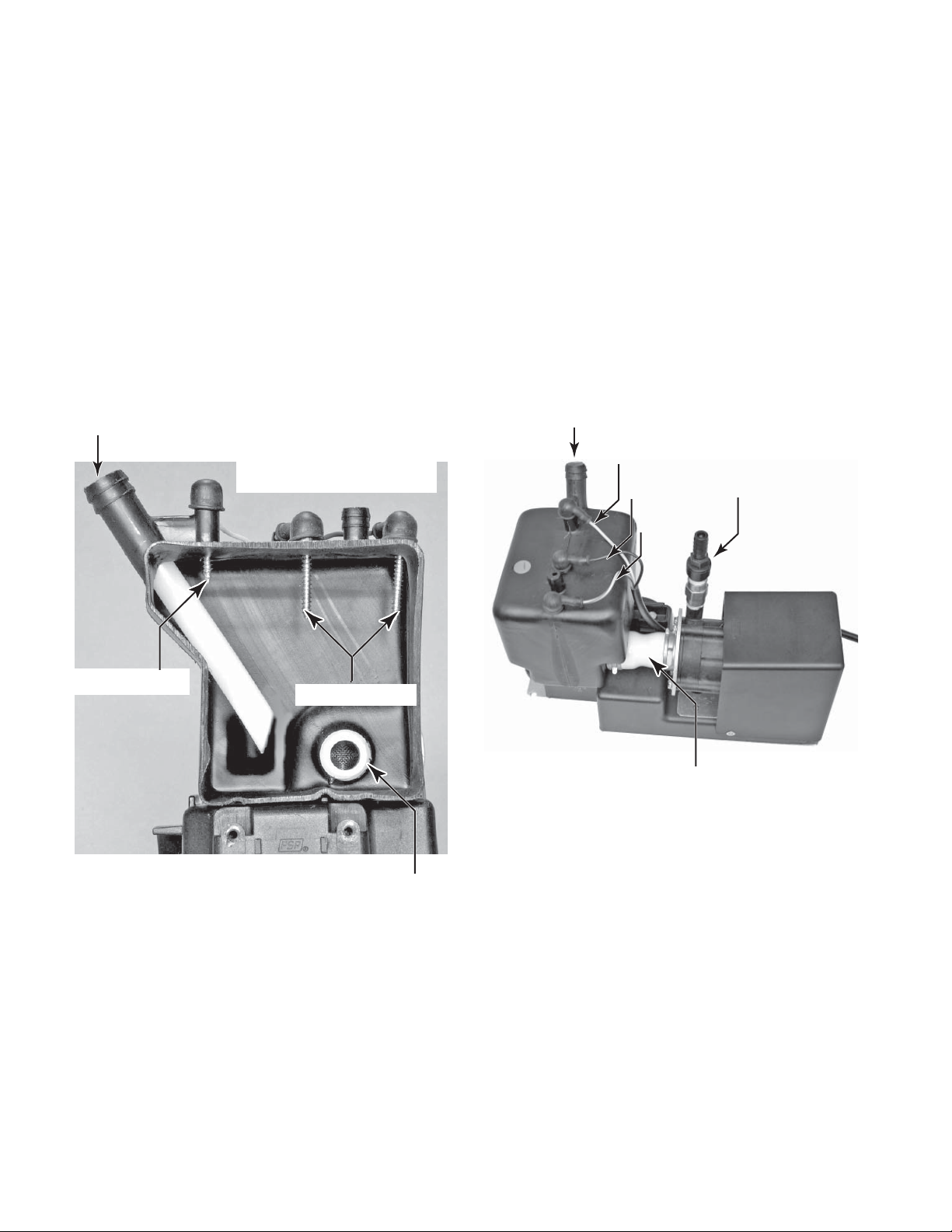

MODELS WITH INTERNAL DRAIN PUMPS

The power cord on the internal drain pump is

connected to a 120 VAC wall outlet. The ice

maker is then connected to the 120 V AC outlet

on the drain pump. If the drain pump fails, or if

the drain becomes blocked, power is shut off

to the 120 VAC outlet on the drain pump.

When the unit is fi rst plugged in, the drain

pump will run for 20 seconds. The power can

be disconnected and reconnected to verify that

the pump is operating properly.

Water from the ice maker reservoir, or melting

ice from the bin, drains down the bin drain tube

Pump Inlet

Contacts Sense Continuity

Through The Water

into the pump inlet, and then into the drain pump

chamber. As the water level rises, it bridges the

“full” contacts, and the pump starts to run. The

pump discharges the water through the outlet

and the check valve. When the “full” connection

is removed, the pump runs for an additional 12

seconds to empty the tank.

If the water level in the drain pump continues

to rise, due to a slow or blocked drain, or a

blocked vent hose, and touches the “overfi ll”

contact, power will be turned off to the drain

pump’s 120 V AC outlet, causing the ice maker

to turn off.

Vent Outlet

White

Black

Green

Pump Outlet &

Check Valve

Overfi ll Contact

Full Contacts

Connector Hose

(Contains Screen Washer)

Screen

Washer

3-8

COMPONENT ACCESS

This section instructs you on how to service each component inside the 2007 Design 15” & 18”

Automatic Ice Makers. The components and their locations are shown below.

COMPONENT LOCATIONS

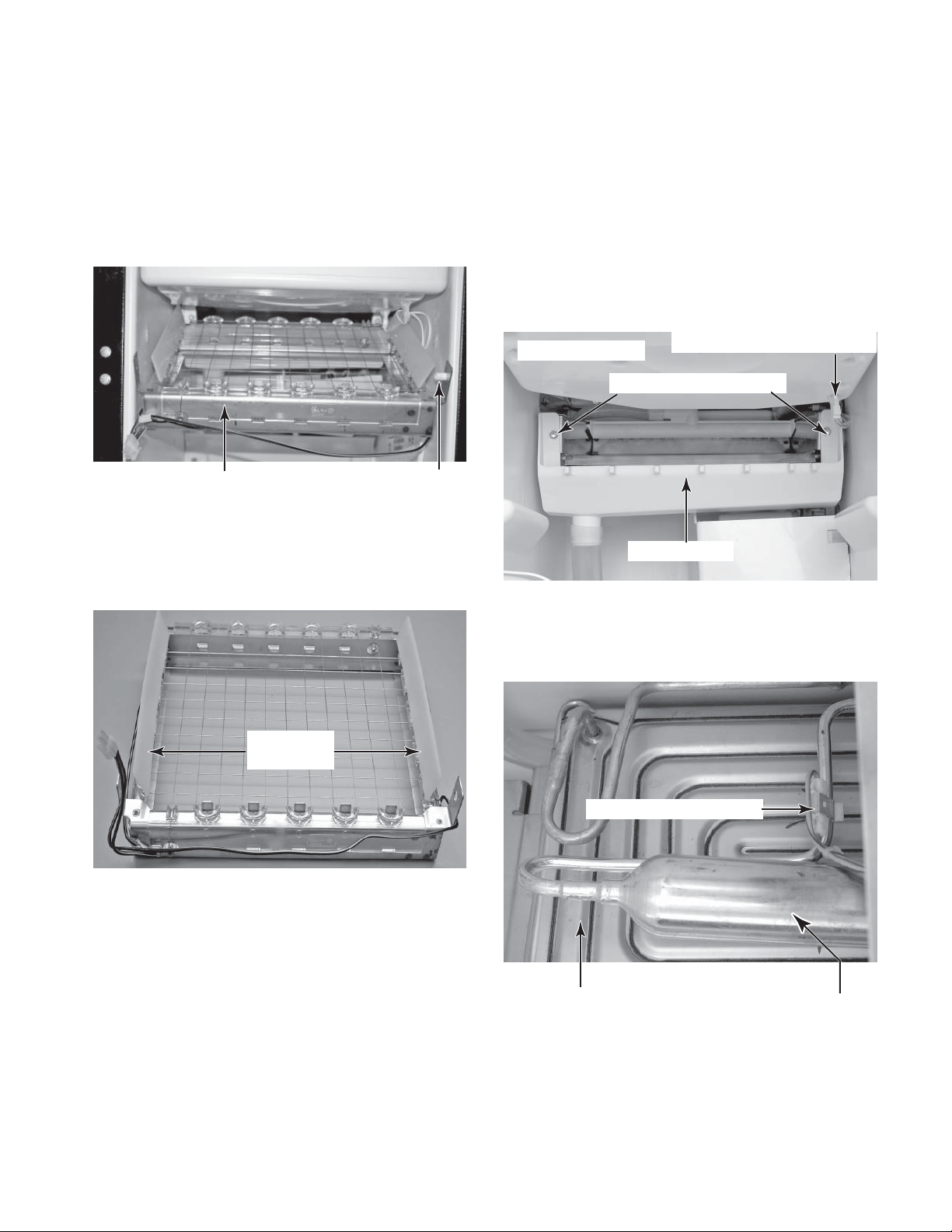

Evaporator

NOTE: The Evaporator

Thermistor Is Located On

Tubing Below Evaporator

Cutter Grid

Compressor

Condenser

Fan Motor

Dual Transformer

Light Switch

Electronic Control Board

Push-button

Switch

Bin

Thermistor

Water Level

Sensor

Water

Recirculation

Pump

Reservoir

Drain Pump

Hot Gas Valve &

S o l e n oi d ( B e hi n d

Condenser)

Measured Fill

Water Valve

Condenser

Condenser Accumulator Tube

4-1

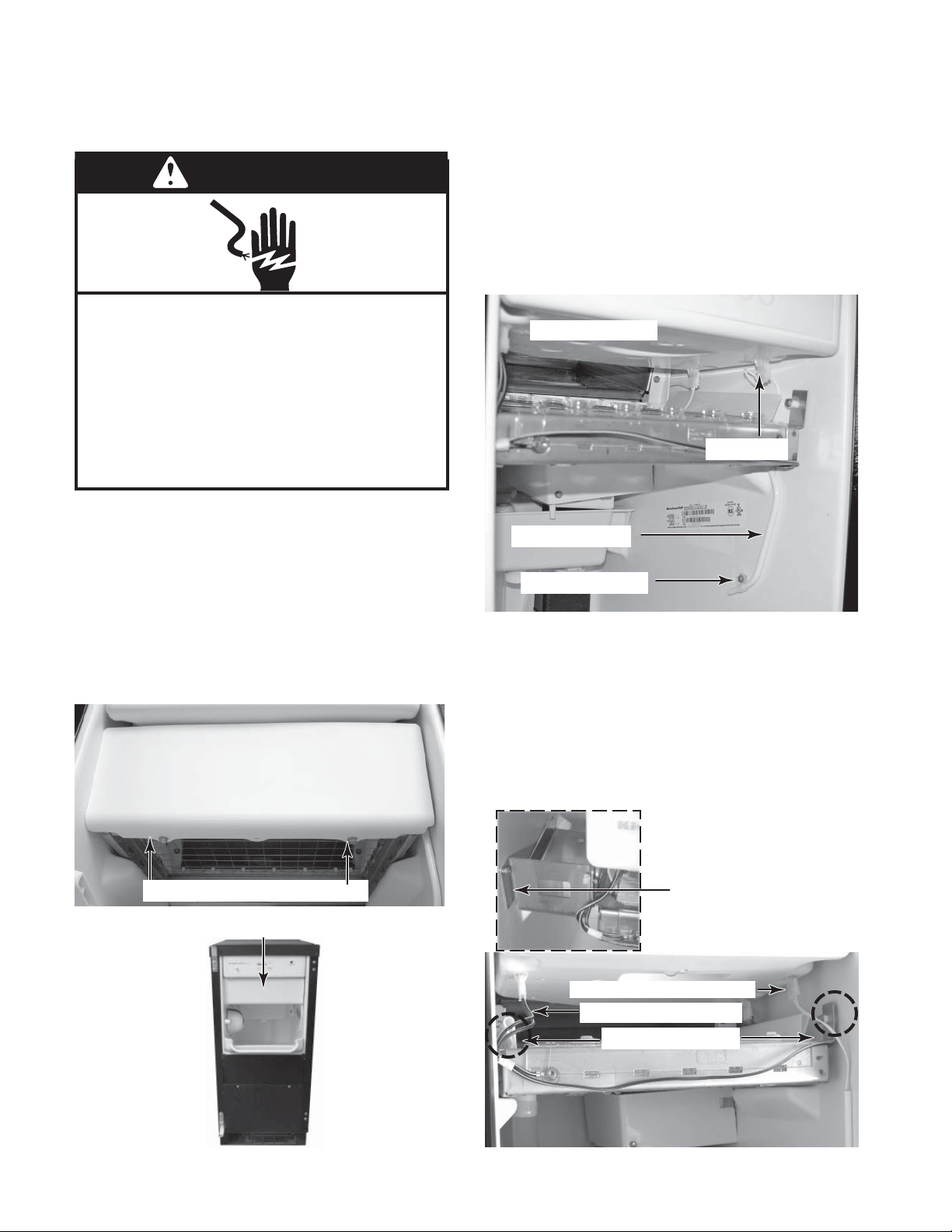

REMOVING THE BIN THERMISTOR, CUTTER GRID,

WARNING

EVAPORATOR THERMISTOR, & WATER DISTRIBUTOR

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fi re, or electrical shock.

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Cover or remove the ice from the storage

bin.

4. Place a cloth in the drain hole to avoid

hardware from falling inside.

5. Remove the two hex-head screws from the

cutter grid cover and remove the cover.

Cutter Grid Cover

6. To remove the bin thermistor:

a) Disconnect the bin thermistor connector

from the bottom of the control housing.

b) Pull the bin thermistor out of the retain-

ing clamp and remove it.

Control Housing

Connector

Bin Thermistor

Retaining Clamp

7. To remove the cutter grid:

a) Disconnect the cutter grid and bin

thermistor connectors from the bottom

of the control housing.

b) Remove the two hex-head screws from

both sides of the cutter grid. The longer

screw and white spacer are on the right

side.

Cutter Grid Cover Screws

Cutter Grid Cover

4-2

Spacer Bracket (Left Side)

˝ Models

18

Bin Thermistor Connector

Cutter Grid Connector

Cutter Grid Screws

c) Slide the cutter grid forward and out of

the unit and place it on a work surface.

Be careful not to scratch the ice maker

liner.

d) Remove the spacer from the right cutter

grid bracket tab.

8. To remove the evaporator thermistor:

a) Remove the cutter grid from the unit

(see step 7 on page 4-2 for the procedure).

b) Disconnect the evaporator thermistor

connector from the bottom of the control

housing.

c) Remove the two hex-head mounting

screws from the water trough and pull

the trough from the unit.

Cutter Grid

Spacer

e) Unsnap the two ice guides from the

cutter grid tabs. There should be a

slight outward tilt after the guides are

installed. Bend the metal tabs outward

if necessary.

Cutter Grid

Ice Guides

Control Housing

Water T rough Screws

Evap Thermistor Connector

Water T rough

d) Reach behind the accumulator, and

unclip the evaporator thermistor from

the evaporator tubing and remove it.

Evaporator Thermistor

Bottom Of The Evaporator

4-3

Accumulator

Continued on the next page.

Loading...

Loading...