Whirlpool KR-28 User Manual

KR-28

WHIRLPOOL GAS RANGE

DIRECT SPARK

IGNITION SYSTEM

JOB AID

Part No. 8177893

FORWARD

This Job Aid, “Whirlpool Gas Range Direct Spark Ignition System,” (Part No. 8177893), provides

the technician with information on the operation and service of the Direct Spark Ignition System.

It is to be used as a training Job Aid and Service Manual.

The Wiring Diagrams used in this Job Aid are typical and should be used for training purposes

only. Always use the Wiring Diagrams supplied with the product when servicing the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Direct Spark Ignition System.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the Direct Spark Ignition System to the proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repair

made on our products by anyone other than Authorized Factory Service

Technicians.

Copyright 2000, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

Table of Contents

PAGE

SECTION 1 ................................................................................................................................ 1

THEORY OF OPERATION ........................................................................................................ 1

Introduction ........................................................................................................................... 1

Gas Distribution Valve ..........................................................................................................2

Manual Oven Shutoff Valve .............................................................................................. 3

Bake & Broil Solenoid-Activated Ports.............................................................................. 4

L.P. Gas Conversion.............................................................................................................5

Direct Spark Ignition Control ................................................................................................. 7

Electronic Spark Ignition .......................................................................................................8

Cooktop Burner Operation ................................................................................................ 8

Oven Burner Operation..................................................................................................... 9

SECTION 2 .............................................................................................................................. 11

COMPONENT ACCESS .......................................................................................................... 11

Removing The Direct Spark Ignition Control ...................................................................... 11

Removing The Gas Distribution Valve ................................................................................ 12

SECTION 3 .............................................................................................................................. 13

COMPONENT TESTING ......................................................................................................... 13

Direct Spark Ignition Control ............................................................................................... 13

Gas Distribution Valve ........................................................................................................ 17

SECTION 4 .............................................................................................................................. 19

WIRING DIAGRAM & STRIP CIRCUITS ................................................................................. 19

Wiring Diagram ................................................................................................................... 19

Strip Circuits ....................................................................................................................... 20

SECTION 5 .............................................................................................................................. 23

TECH TIPS .............................................................................................................................. 23

Diagnostic Flow Charts ....................................................................................................... 23

- iii -

IMPORTANT SAFETY INFORMATION

Your safety and the safety of others is very important.

Important safety messages have been provided in this Job Aid. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will be preceded by the safety alert symbol and the word

“WARNING.”

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell

you what can happen if the instructions are not followed.

GENERAL INFORMATION

IMPORTANT MODEL & SERIAL

NUMBER INFORMATION

The Direct Spark Ignition System is used on

Whirlpool gas ranges produced, beginning

January 3, 2000, Serial Code RK02. The Model

number of these units will be a “-5” version of

the current G-line gas range.

Example: SF365PEGQ5

This Direct Spark Ignition System will only be

available on self-cleaning gas ranges.

ELECTRICAL REQUIREMENTS

The supply voltage is critical for proper operation of the Direct Spark Ignition (DSI) System.

The requirements are 102 to 132 VAC with the

proper polarity and ground. If the electrical supply is less than 102 VAC, sparking will not be

reliable. If the system is over 132 VAC, permanent damage to the DSI can occur.

Proper polarity must also be supplied. If the

supply polarity is reversed, the DSI control will

not be able to detect the presence of a flame.

Reverse polarity will not affect the cooktop operation, but the Bake and Broil burners will fail

to remain lit.

A proper ground is also required. The DSI control generates a significant amount of electrical noise. This noise is minimized by clamping the noise to ground. If a proper ground is

not connected, the ERC may periodically display “PF,” which means that a reset has occurred in the ERC.

GAS REQUIREMENTS

Gas supply pressure should be a minimum of

7˝ water column pressure for natural gas, and

11˝ water column pressure for L.P. gas. However, the gas distribution valve should maintain 4˝ water column pressure for natural gas,

and 10˝ water column pressure for L.P. gas.

NOTE TO TECHNICIAN: Improper polarity will cause the direct spark ignition

system to malfunction. Always check for

proper polarity at the wall outlet before

replacing parts.

- iv -

SECTION 1SECTION 1

SECTION 1

SECTION 1SECTION 1

THEORY OF OPERATION

INTRODUCTION

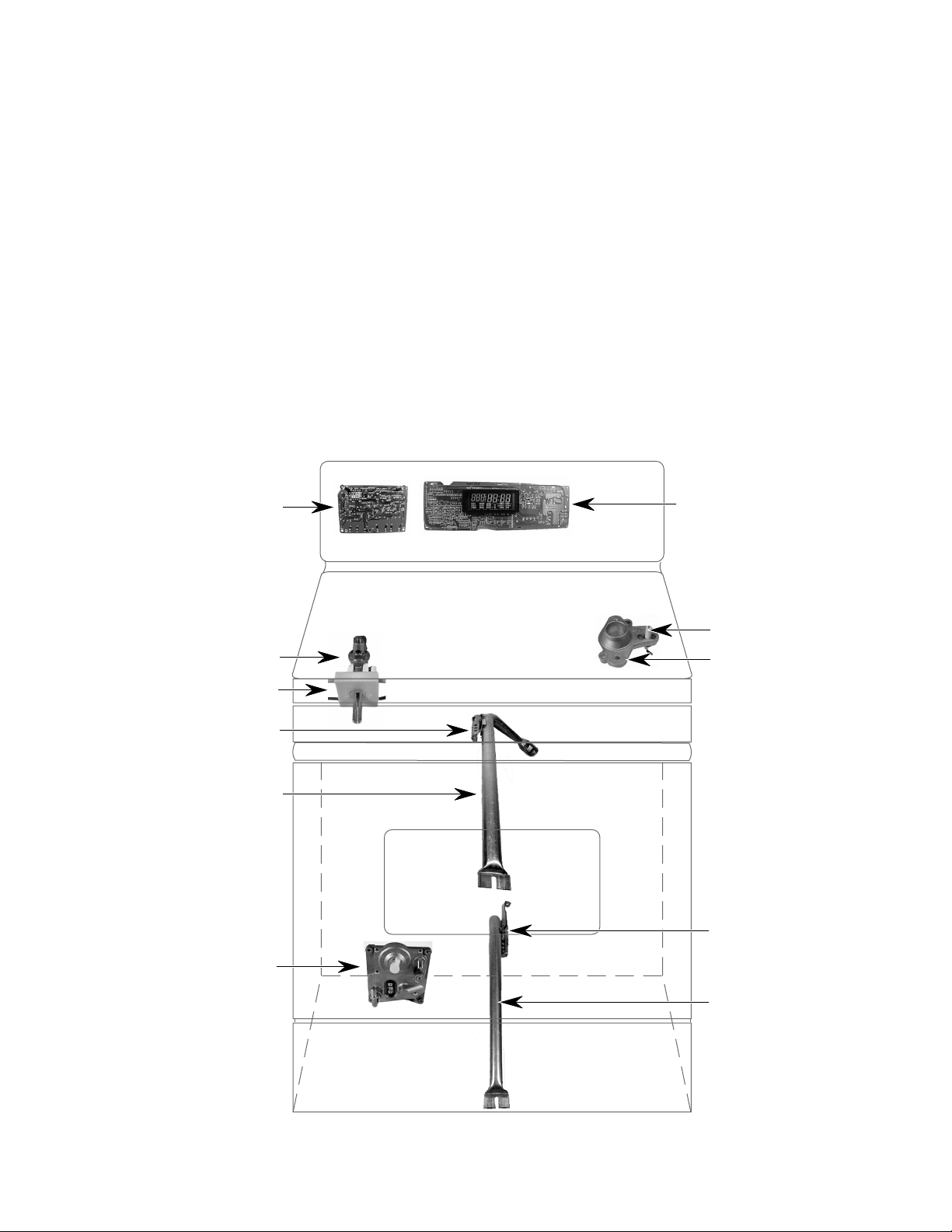

The Direct Spark Ignition System contains a

Gas Distribution Valve and a Direct Spark Ignition (DSI) Control that interfaces with the

Electronic Oven Control, and spark electrodes.

This provides the direct spark ignition and gas

distribution for Whirlpool self-cleaning gas freestanding ranges.

A proper ground and the correct polarity is necessary for the DSI control to sense the pres-

Direct Spark

Ignition Control

Gas Valve /

ence of a flame. If the polarity is reversed, or

in some cases if there is a poor ground, the

control will appear to operate normally. However, after an oven burner ignites, the spark

will continue to occur at the burner, and the

valve will then shut off after 4 seconds. This is

because the DSI control does not recognize

the presence of a flame when one is present

(see “Monitoring System,” on page 9).

Gas Distribution Valve

Ignitor &

Cooktop Burner

Ignition Switch

Broil Burner Ignitor

Broil Burner

Gas Distribution Valve

Bake Burner Ignitor

Bake Burner

- 1 -

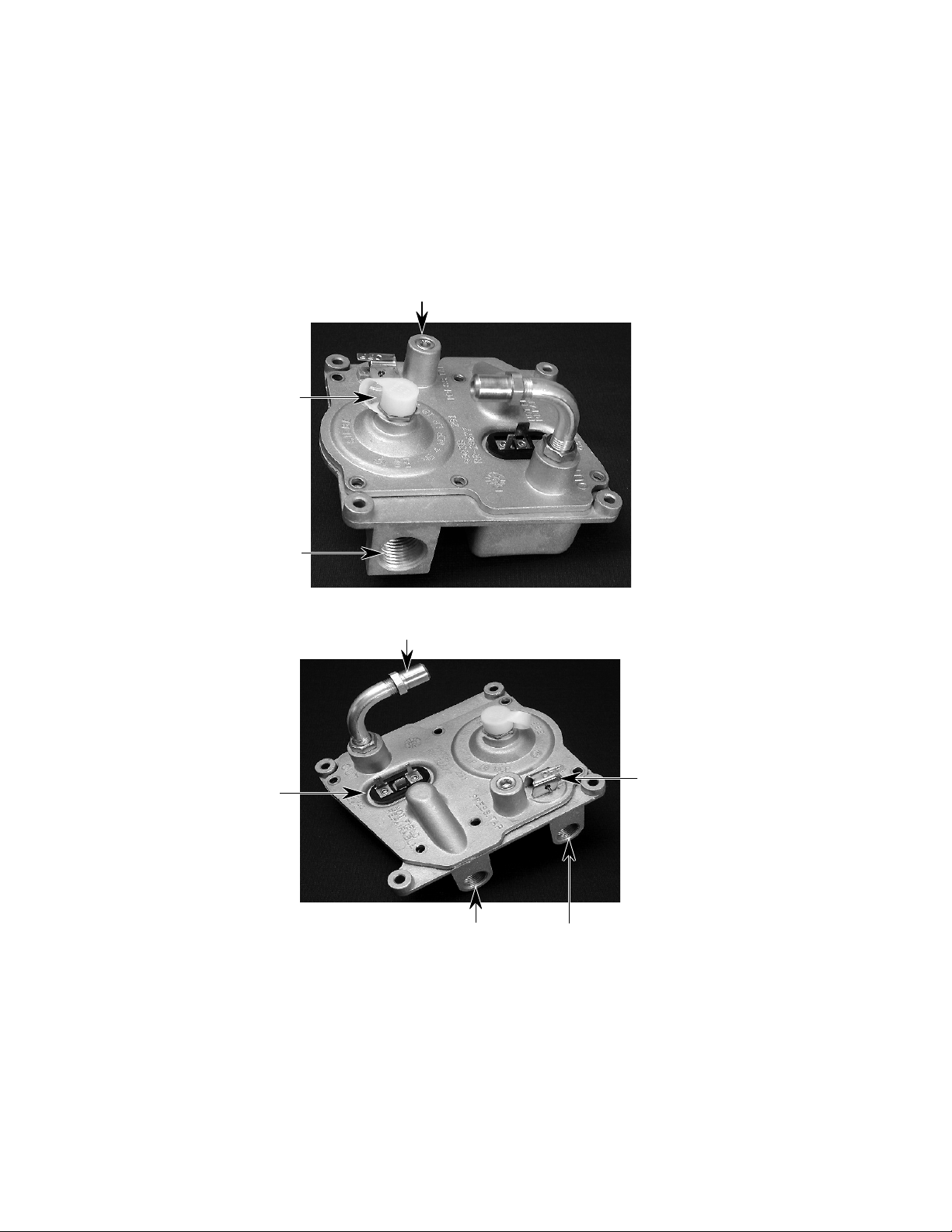

GAS DISTRIBUTION VALVE

The gas distribution valve can be converted to

L.P. gas, when necessary. It regulates the distribution of gas to the cooktop and both oven

burners. The gas distribution valve is non-serviceable.

Pressure Tap

(1/8˝ - 27 N.P.T.)

L.P. Conversion Cap

Gas Inlet (1/2˝

Female Threads)

The gas distribution valve is made up of the

following features:

• Natural & L.P. gas regulator

• Manual oven shutoff valve

• Bake & broil solenoids

• Pressure tap - To measure gas outlet

pressure

Electrical

Terminals

To Bake Burner

To Broil Burner

Gas Distribution Valve

Manual Oven

Shutoff Valve

To Cooktop

- 2 -

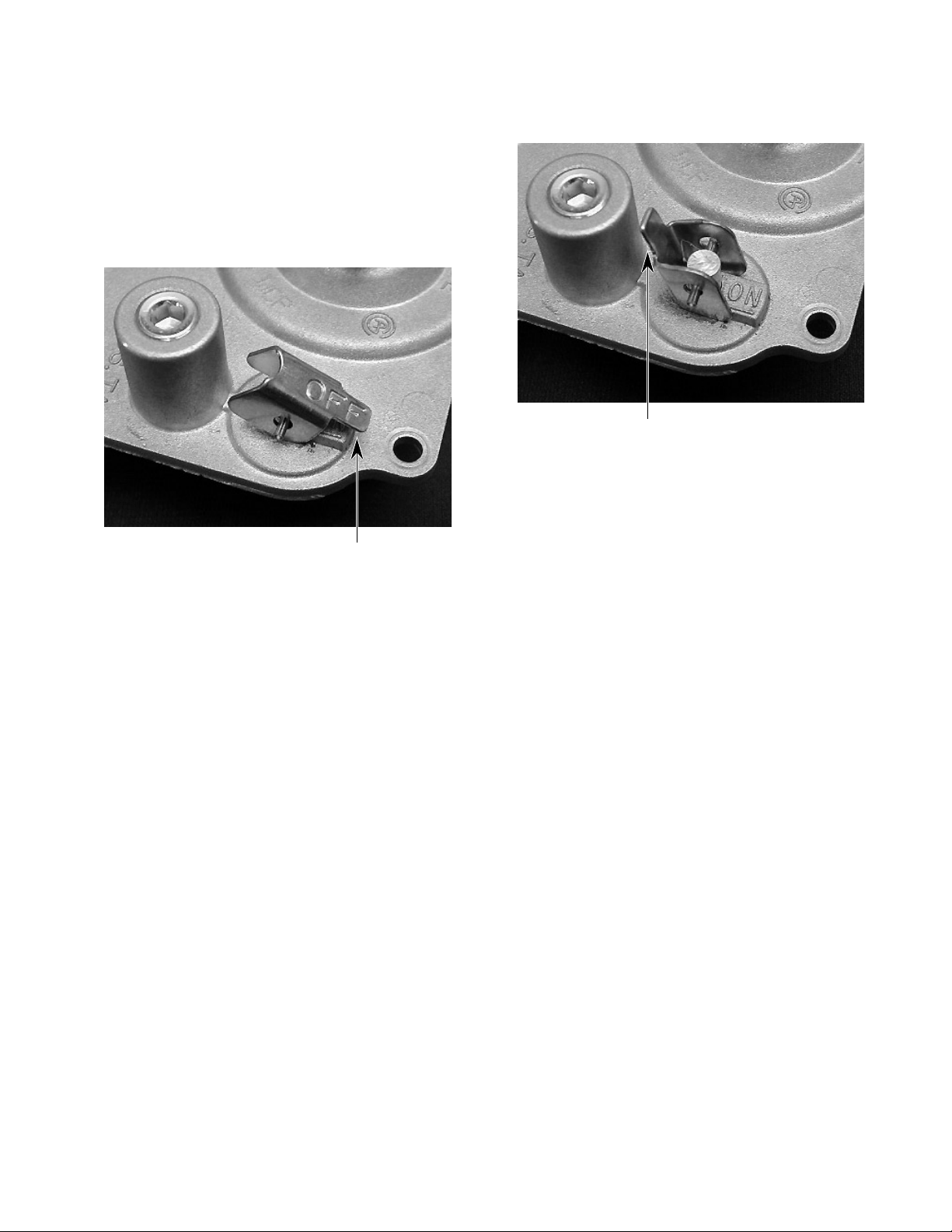

MANUAL OVEN SHUTOFF VALVE

A manual oven shutoff valve is available on

the gas distribution valve to shut off the gas to

the oven burners. This valve will not affect the

operation of the cooktop burners. When the

lever is down, the gas to the oven burners is

turned off.

When the lever is raised, the gas to the oven

burners is turned on.

Manual Valve Lever

Raised (Gas On)

Manual Valve Lever

Down (Gas Off)

- 3 -

BAKE & BROIL SOLENOIDACTIVATED PORTS

The bake and broil gas supply ports are opened

and closed by electrically-operated solenoids.

When voltage is received from the spark

ignition control for the bake or broil function,

(8-18 VDC), the solenoid for that function is

activated, and the valve opens to allow gas

Electrical Terminals:

Broil = 1/8˝ wide

Common = 1/4˝ wide

Bake = 3/16˝ wide

flow to the burner. The electrical connections

at the valve consist of three terminals, each

one sized differently to prevent incorrect wiring (see below).

The solenoids require special voltage/current

(8 - 18 VDC) from the direct spark ignition control to operate properly. IMPORTANT: Do not

attempt to operate the solenoids with any

other voltage supply.

Manual Oven

Shutoff Valve

216 Ω Resistance Across

Each Solenoid Terminal

8 to 18 VDC

NOTE: Always check

both solenoids. If either

solenoid is defective,

neither one will operate.

- 4 -

L.P. GAS CONVERSION

The range is manufactured to use natural gas.

To convert the range to use L.P. gas, the following steps are performed:

1. Turn off the gas and electrical supplies to

the range.

2. Remove the storage drawer from the

range.

3. Locate the gas distribution valve at the

rear of the range. To convert the gas

distribution valve:

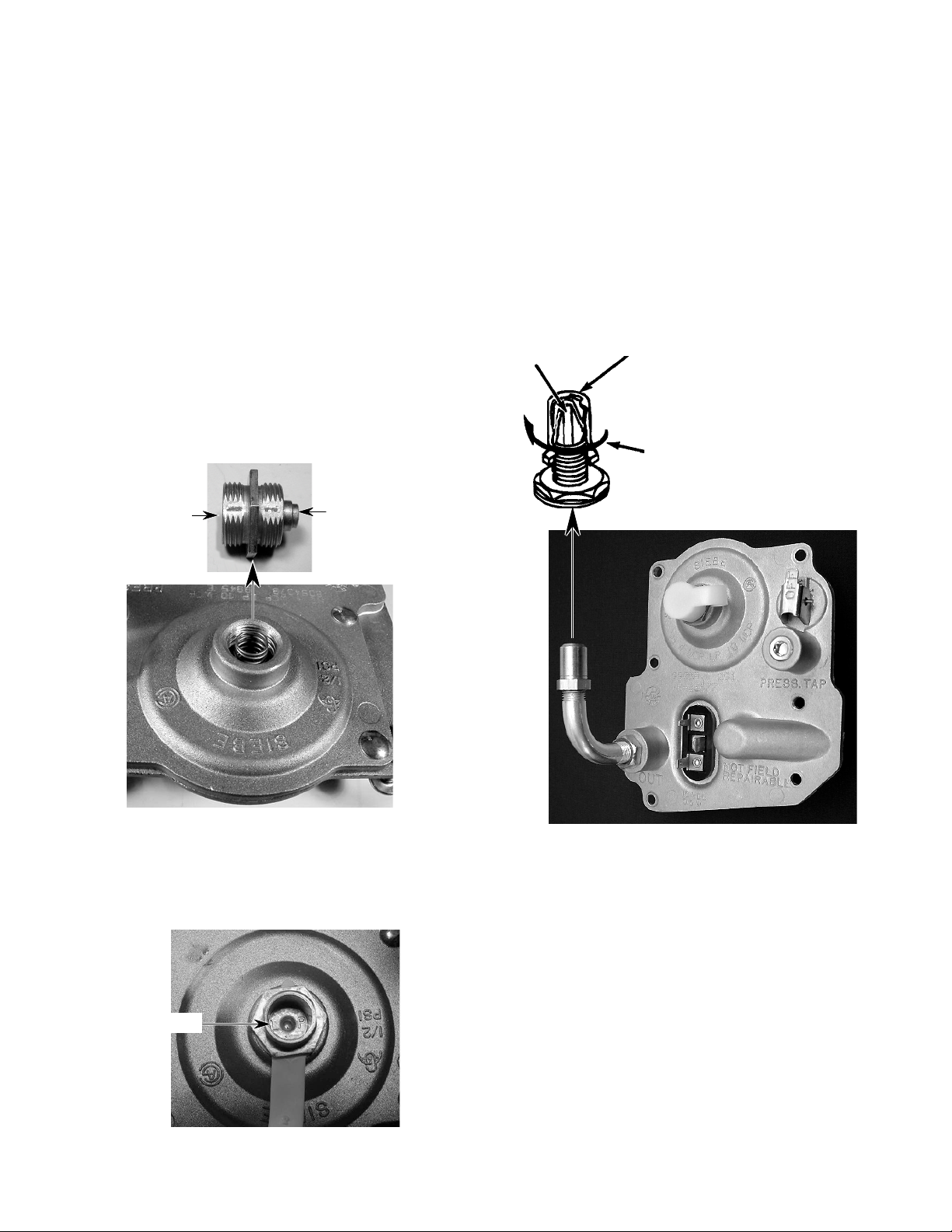

a)Unscrew the conversion cap from the

gas distribution valve. Note the difference between the L.P. and natural gas

ends of the cap.

L.P. Gas

Natural Gas

4. To convert the bake burner:

a)Open the oven door and remove the

oven racks.

b)Use a 1/2" open-end wrench and turn

the orifice hood down snug onto the pin

(approximately 2-1/2 turns). DO NOT

OVERTIGHTEN THE ORIFICE. The

burner flame cannot be properly adjusted if this conversion is not made.

Pin

Orifice Hood

Natural Gas:

Unit is manufactured

for natural gas

L.P. Gas:

Turn down 2-1/2 turns in

this direction

b)Install the conversion cap on the gas

distribution valve with the L.P. side facing up (you will see L.P. stamped inside

the cap, as shown).

L.P. Gas

- 5 -

Loading...

Loading...