MICROWAVE

OVEN HOOD

COMBINATION

KM-30

8178573

i

FORWARD

This Job Aid, “Whirlpool Microwave Oven Hood Combination,” (Part No. 8178573), provides the

In Home Service Professional with information on the operation and service of the Whirlpool Micro-

wave Oven Hood Combination. It is to be used as a training Job Aid and Service Manual. For specic

information on the model being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided

with the microwave oven.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the In Home Service Professional to properly diagnose malfunctions and repair the Microwave Oven Hood Combination.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the microwave oven to proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized In Home Service Professionals.

Copyright © 2006, Whirlpool Corporation, Benton Harbor, MI 49022

ii

TABLE OF CONTENTS

GENERAL ................................................................................................................................. 1-1

Important Safety Information ............................................................................................1-1

Warning to In Home Service Professionals ...................................................................... 1-2

Precautions To Be Observed Before and During Servicing

to Avoid Possible Exposure to Excessive Microwave Energy .......................................... 1-3

R.F. Leakage Test ............................................................................................................. 1-4

Whirlpool Model Number Designations ............................................................................1-5

Whirlpool Serial Number Designations ............................................................................. 1-6

Model & Serial Number Label and Tech Sheet Locations ................................................ 1-6

Specications .................................................................................................................... 1-7

Whirlpool Microwave Oven Warranty ................................................................................1-10

INSTALLATION INFORMATION ...............................................................................................

Hood Fan Motor Mounting Positions ................................................................................2-1

THEORY OF OPERATION ........................................................................................................ 3-1

Air Flow Paths ................................................................................................................... 3-1

COMPONENT ACCESS ...........................................................................................................

Component Locations ....................................................................................................... 4-1

Removing the Turntable Motor & Hood (Cooktop) Lamp Assembly ................................. 4-2

Removing the Control Panel & Control Board .................................................................. 4-4

Removing the Motor Capacitor and Line Fuse ................................................................. 4-6

Removing the Door Switches ...........................................................................................4-6

Removing the Oven Cavity Lamp and Charcoal Filter ...................................................... 4-8

Removing the Oven Rack Retainers ................................................................................4-9

Removing the Outer Cabinet ............................................................................................ 4-10

Removing the Thermostats and Thermistor ...................................................................... 4-11

Removing the Magnetron .................................................................................................4-12

Removing the High-Voltage Transformer .......................................................................... 4-13

2-1

4-1

Removing the High-Voltage Diode and Capacitor ............................................................ 4-14

Removing the Oven Cavity Lamp Socket ......................................................................... 4-15

Removing the AC Line Filter ............................................................................................. 4-16

Removing the Hood Fan Motor and Humidity Sensor ...................................................... 4-17

Removing the Fuse Holder & Mounting Bracket ............................................................... 4-18

Removing the Door and Door Disassembly ...................................................................... 4-19

COMPONENT TESTING ...........................................................................................................

H.V. Transformer ............................................................................................................... 5-1

Magnetron ......................................................................................................................... 5-2

H.V. Capacitor ................................................................................................................... 5-2

H.V. Diode ......................................................................................................................... 5-3

iii

5-1

TABLE OF CONTENTS - CONTINUED

Turntable Motor ................................................................................................................. 5-3

Humidity Sensor ...............................................................................................................5-4

Hood Exhaust Fan Motor .................................................................................................. 5-4

AC Line Filter .................................................................................................................... 5-5

Thermostats ...................................................................................................................... 5-5

DIAGNOSIS & TROUBLESHOOTING ..................................................................................... 6-1

Interlock Switch Checkout Procedures ............................................................................. 6-1

Touch Panel and Electronic Control Test .......................................................................... 6-2

Microwave Oven Power Output Test ................................................................................ 6-3

Failure Codes Indications ................................................................................................. 6-3

WIRING DIAGRAM & STRIP CIRCUITS ..................................................................................

Wiring Diagram - 8205889 - Sensor Model ......................................................................7-1

Wiring Diagram - 8205660 - Non Sensor Model ............................................................... 7-2

Strip Circuits .....................................................................................................................7-3

Microwave Cooking ..................................................................................................... 7-3

Hood Exhaust Fan On High Automatically .................................................................. 7-3

Hood Exhaust Fan On Low Speed.............................................................................. 7-3

Hood Exhaust Fan On High / Medium ........................................................................ 7-4

Microwave Oven Plugged In—Time of Day Displayed ............................................... 7-4

Door Open—Oven Cavity Light Is On ......................................................................... 7-4

Cooktop Light On High ................................................................................................ 7-4

Cooktop Light On Low (Night Light) ............................................................................ 7-4

7-1

iv

GENERAL

IMPORTANT SAFETY INFORMATION

ELECTROSTATIC DISCHARGE

(ESD) SENSITIVE ELECTRONIC

ESD problems are present everywhere. ESD

may damage or weaken the electronic control

assembly. The new control assembly

may appear to work well after repair is nished,

but failure may occur at a later date

due to ESD stress.

IMPORTANT SAFETY

INSTRUCTIONS

Before touching any oven component or wiring,

always unplug the oven from its power

source and discharge the capacitor by using a

20,000 ohm discharge resistor or use an insulated plastic handle screwdriver to short across

the capacitor terminals.

Check that the unit is grounded before troubleshooting. Discharge any static charge from your

body by touching ground before handling any part

of the circuitry on the control board. Electrostatic

discharge may damage the control circuit.

Do not touch oven components or wiring during

operation. Attach meter leads with alligator

clips when making operational tests.

For continued protection against radiation

emission, replace only with these types of

switches: Primary (Interlock) Switch: SZM-V16FA-63 or VP-533A-OF; Secondary (Interlock)

Switch: SZM-V01-FA-32; Interlock (Monitor)

Switch: SZM-VI6-FA-62 or VP-532A-OF; Oven

Lamp Switch: SZM-V6-FA-31 or VP-331 AOD.

• Use an antistatic wrist strap. Connect

the wrist strap to a green ground connection

point or unpainted metal in the

appliance; or touch your nger repeatedly

to a green ground connection point

or unpainted metal in the appliance.

• Before removing the part from its package,

touch the antistatic bag to a green

ground connection point or unpainted

metal in the appliance.

• Avoid touching electronic parts or terminal

contacts. Handle the electronic

control assembly by the edges only.

• When repackaging the failed electronic

control assembly in an antistatic bag,

observe the above instructions.

It is neither necessary nor advisable to attempt

measurement of high voltage.

Attaching the adaptor ground terminal to the

wall receptacle cover screw does not ground

the appliance unless the cover screw is metal

and not insulated and the wall receptacle is

grounded through the house wiring.

1-1

WARNING TO IN HOME SERVICE PROFESSIONALS

To avoid possible exposure to microwave

radiation or energy, visually check the oven for

damage to the door and door seal before

operating any oven. Use a microwave survey

meter to check the amount of leakage before

servicing. In the event the R.F. Ieakage exceeds

4 mw/cm2 at 5 cm, appropriate repair

must be made before continuing to service the

unit. Check interlock function by operating the

door latch. The oven cook cycle should cut off

before the door can be opened.

The door and latching assembly contains the

radio frequency energy within the oven. The

door is protected by three safety interlock

switches. Do not attempt to defeat them.

Under no circumstances should you try to

operate the oven with the door open.

• Proper operation of microwave ovens requires

that the magnetron be properly

assembled to the waveguide and cavity.

Never operate the magnetron unless it is

properly installed.

• Be sure the “RF” seal is not damaged and

is assembled around the magnetron dome

properly when installing the magnetron.

• Routine service safety procedures should

be exercised at all times.

• Untrained personnel should not attempt

service without a thorough review of test

procedures and safety information contained

in this Job Aid.

Whirlpool microwave ovens have a monitoring

system designed to ensure proper operation of

the safety interlock systems.

The interlock monitor switch will immediately

cause the oven fuse to blow if the door is

opened and the primary door interlock switch

and/or the secondary interlock switch contacts

fail in a closed position.

CAUTION: Replace a blown fuse with a 20

ampere class H fuse only.

Test the upper and lower door interlock

switches, cook relay and interlock monitor

switch (middle switch) for proper operation as

described in the component test procedures,

before replacing the blown oven fuse.

Do not attempt to repair sticking contacts

of any interlock switch, safety switch, or

Cook (Latch) relay. The components must

be replaced.

Any indication of sticking contacts during component tests requires replacement of that component to ensure reliability of the safety interlock

system.

NOTE: If the fuse is blown, the monitor, primary,

and secondary interlock switches must be replaced. Be sure they are properly connected.

1-2

PRECAUTIONS TO BE OBSERVED BEFORE AND

DURING SERVICING TO AVOID POSSIBLE EXPOSURE

TO EXCESSIVE MICROWAVE ENERGY

A. Do not operate or allow the oven to be

operated with the door open.

B. Make the following safety checks on all

ovens to be serviced before activating the

magnetron or other microwave source,

and make repairs as necessary:

1) Interlock operation

2) Proper door closing

3) Seal and sealing surfaces (arcing,

wear, and other damage)

4) Damage to or loosening of hinges and

latches

5) Evidence of dropping or abuse

C. Before turning on the microwave power

for any service test or inspection within the

microwave generating components, check the

magnetron, wave guide or transmission

line, and cavity for proper alignment,

integrity, and connections.

D. Any defective or misadjusted components

in the interlock, monitor, door seal, and

microwave generation and transmission

systems shall be repaired, replaced, or

adjusted, using procedures described in

this Job Aid, before the oven is released to

the owner.

E. A microwave leakage check to verify compli-

ance with Federal Performance Standard

should be performed on each oven

prior to release to the owner.

F. Do not attempt to operate the oven if the

door glass is broken.

1-3

R.F. LEAKAGE TEST

EQUIPMENT

• Electromagnetic energy leakage monitor

(NARDA 81 00B, HOLADAY H 1501 ).

• 275 ±15 ML glass beaker.

TEST

On every service call, checks for microwave

energy emission must be made according to

the following manner.

1. Remove the cooking rack from the oven

cavity, if the microwave oven is so equipped.

2. Place a 275 ±15 ML (9.3 oz.) glass of

water in the center of the oven bottom.

3. Select “HIGH” cook power, turn the microwave

oven on, and test for R.F. Ieakage at

the following locations:

a) Around the cabinet at the front.

b) Around the door.

c) Across the console panel.

d) Horizontally across the door.

e) Vertically across the door.

f) Diagonally across the door.

g) Across the air vents.

h) Across the rear air vent.

i) All lockseams.

j) Weld at bottom.

k) Bottom plate.

I) Oven feet.

4. The scan speed is one inch per second.

When checking for R.F. Ieakage, use an approved R.F. measuring device to ensure less

than 4 mw/cm2 emission at 5 cm distance with

a maximum scan rate of 2.54 cm/second, in

compliance with U.S. Government Department

of Health, Education and Welfare 21CFR1030,

performance Standard for Microwave Ovens.

A properly operating door and seal assembly

will normally register small emissions, but they

must be no greater than 4 mw/cm2 to allow for

measurement uncertainty.

NOTE: Enter leakage readings in BEFORE and

AFTER spaces on the service document.

All microwave ovens exceeding the emission

level of 4 mw/cm2 must be reported to Dept. of

Service for microwave ovens immediately and

the owner should be told not to use the microwave oven until it has been repaired completely.

If a microwave oven is found to operate with the

door open, report to Dept. of Service, the

manufacturer and CDRH* immediately. Also

tell the owner not to use the oven.

The interlock monitor switch acts as the nal

safety switch protecting the customer from

microwave radiation. If the interlock monitor

switch operated to blow the fuse when the

interlocks failed, you must replace all interlock

switches with new ones, because the contacts

of those interlock switches may be melted and

welded together.

If safety interlock/monitor switch replacement,

or adjustment, is required, you must reconnect

the circuit, and perform a continuity check on

the monitor circuit.

All repairs must be performed in such a manner

that microwave energy emissions are minimal.

Address for CDRH is:

Ofce of Compliance (HFZ-342) Center for

Devices and Radiological Health

2098 Gaither Road

Rockville, MD 20850

* CDRH: Center for Devices and Radiological

Health, Food and Drug Administration.

1-4

WHIRLPOOL MODEL NUMBER DESIGNATIONS

MODEL NUMBER M H 2 17 5 X S T 0

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

G = WHIRLPOOL GOLD

M = MICROWAVE

PRODUCT IDENTIFICATION

B = BROWNER

C = CONVECTION

G = GRILL / CRISPER

H = OTR HOOD COMBO

K = KITS

M = GOLD CONVECTION

S = STIRRER FAN

T = TURNTABLE

MODEL VARIATIONS

0 - 9

CUBIC FEET

04 = .4 CU. FT. 09 = 0.9 CU. FT. 15 = 1.5 CU. FT.

06 = .6 CU. FT. 10 = 1.0 CU. FT. 16 = 1.6 CU. FT.

07 = .7 CU. FT. 12 = 1.2 CU. FT. 17 = 1.7 CU. FT.

08 = .8 CU. FT. 14 = 1.4 CU. FT.

FEATURE LEVEL

0 = 30” KIT (IF KIT)

2 = 22” KIT (IF KIT)

4 = 24” KIT (IF KIT)

5 = SENSORED MODEL

7 = 27” KIT (IF KIT)

FEATURE CODE

C = CSA APPROVED

S = CARRY IN WARRANTY (EFFECTIVE 02/96)

X = IN HOME WARRANTY (EFFECTIVE 02/96)

YEAR OF INTRODUCTION

S = 2006, T = 2007, V = 2008

COLOR CODE

B = BLACK, Q = WHITE, T = BISCUIT

ENGINEERING CHANGE (0, 1, 2, 3, ETC.)

1-5

WHIRLPOOL SERIAL NUMBER DESIGNATIONS

SERIAL NUMBER TR T 06 10001

MANUFACTURING SITE

TR = Shunde

YEAR OF PRODUCTION

T = 2006

WEEK OF PRODUCTION

06 = 6th week of the year

PRODUCT SEQUENCE NUMBER

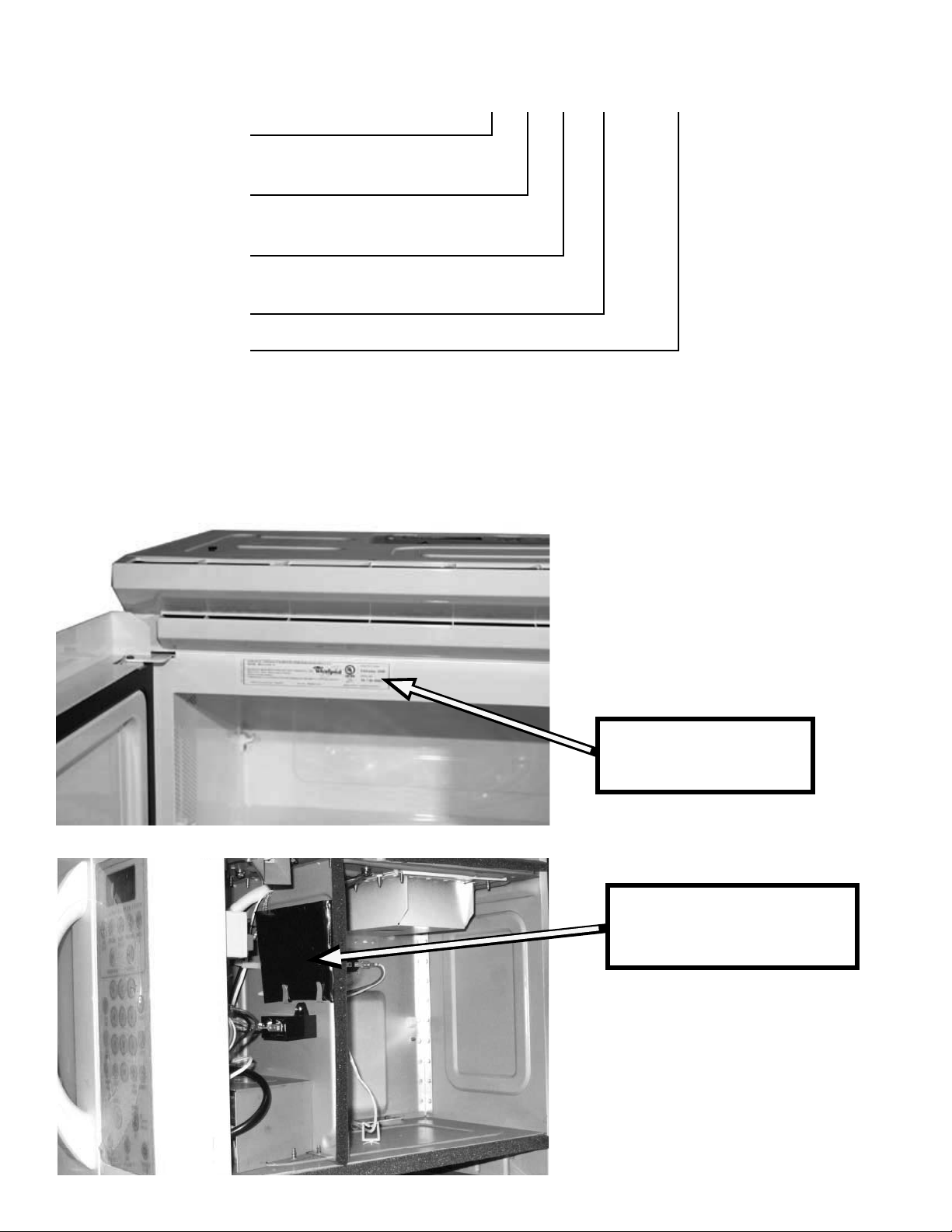

MODEL & SERIAL NUMBER LABEL AND

TECH SHEET LOCATIONS

Model & Serial

Number Location

1-6

Tech Sheet Location

(In black poly bag)

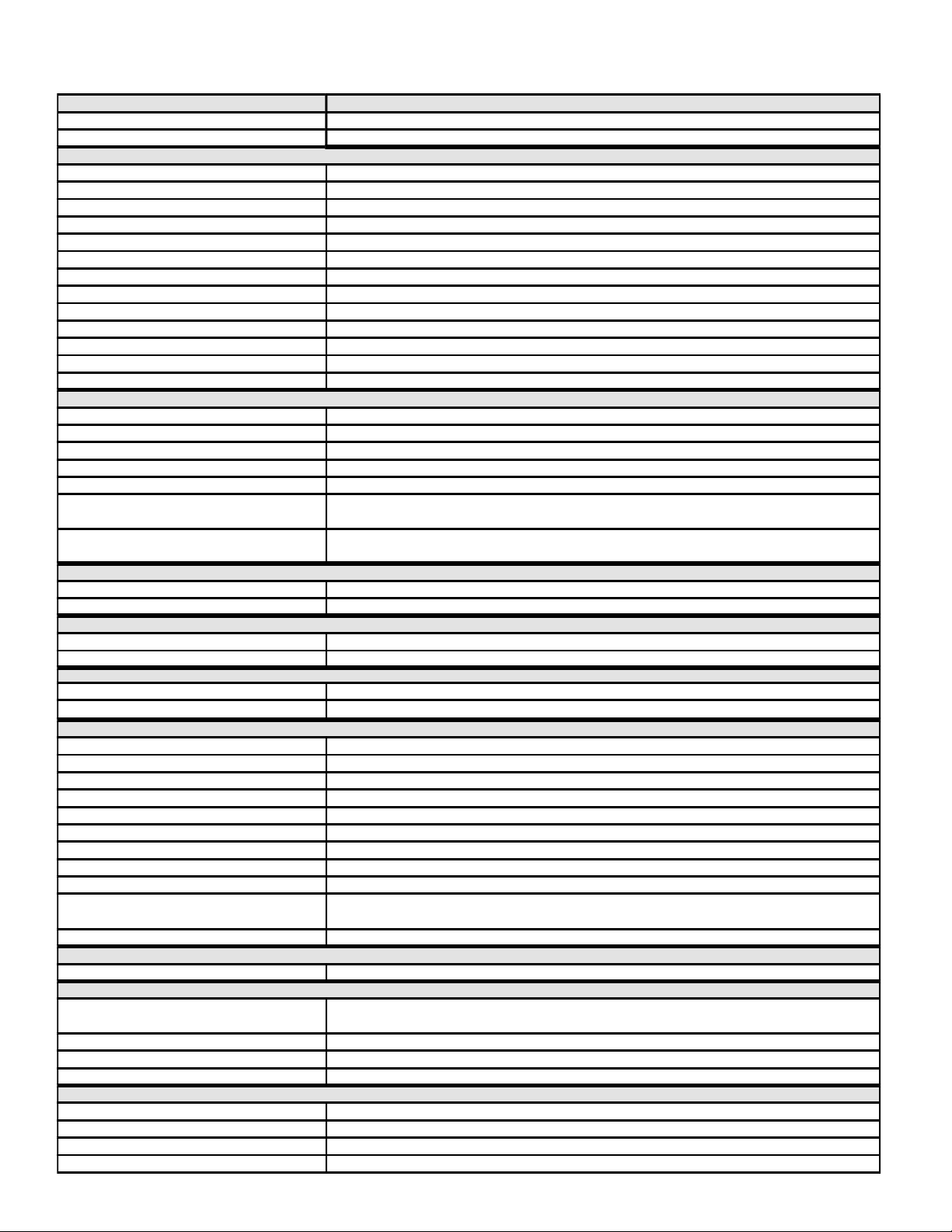

SPECIFICATIONS

MO DEL MH 2175XS

Fea tur e Level/Series SENSOR Cooking

Color s

White, Black, Biscuit and Stainless

CONTROL SYSTE M

Timer Electronic

Limits 99 Min. 99 Sec.

Operation TOUCH CONTROL, 30 Pads

Display Blue Green with scrolling text

Convection Cooking Cycles No

Keypad Disable / Child Lockout Mode Yes - Press "Cancel" Key for 3 Seconds

Cooktop Light Wattage One Incandescent 40 Watt bulb

Settings 3 levels (High, Night/Low, Off)

Fan Speed Indication "Low - Medium - High" -Scrolling Text

Power Failure Indication Yes - ' ' Displayed Flashing

Invalid Data Entry "BEEP"

Technical Error Indication "F-" With Error Number

Diagnostic System Yes

OVE N I NTERIOR F EATURES

Capacity 1.7 cu. ft.

Size W x H x D (inches)

21" W x 9 1/2" H x 14" D

Size W x H x D (mm)

535 x 240 x 355 mm

Cooking Power 1000 Watts (IEC-705 Rating)

Turn Table Yes, Sunken Flush

Cooling Fan Automatic - On if oven is operating,

Off if door open

Oven Light Automatic - Turns on when oven

door is open or oven is operating. (30 Watt)

DOOR F E ATURES

Handle/Latch Yes/Pull to open

Seals Two Stage (Capacitive and Reflective)

MICROWAVE SYSTE M

Distribution Top Feed w/ Stirrer

Magnetron One standard

SAFE TY F EATURES

Interlock

Three Door/Latch Operated (Primary, secondary and monitor)

Thermal Protectors

Four - 1 Magnetron, 1 Oven Cavity, 1 Hood, 1 Wave Guide

VENTILATION SYSTEM

Type Convertible Recirculation or Exhaust Vertical/Horizontal

Duct Outlet Size 3 1/4"H x 10"W

Recirculation CF M

112

Exhaust CFM

221

Touch Control 4 Speed

Exhaust Fan 'Auto ON - High Speed YES : 60° C, 140°F

Noise Level Recirculation (Acc. to IEC 704) 67dBA

Grease Filter Yes (2)-low cost

Charcoal Filter Yes (2)

Blower Type

Two Squirrel Cage Blower. Left fan wheel for hood airflow and cavity ventilation.

Right fan for cooling airflow

Shipped Recirculation mode

EXTERI OR F EATURES

Power Cord Length 3 Feet

OTHE R SP ECIF ICATIONS

Electrical 120V, Single Phase, 60 Hz

1800 Watts, For Use With 15 - 20 Amp Circuit

Domestic Use Only Yes

Agency Approvals FCC, DHHS, U.L. Listed, CSA

Approx. Net Weight - Lb 57 lbs.

LITE RATURE

Use & Care Guide 8205887

Installation Instructions 8206433

Warranty In Use & Care Guide

Tech Sheet 8205889

1-7

M O DEL M H 1160XSB/Q

Feature Level/Series Basic Non Sensor

Colors Black, White

CONTROL SYSTEM

Timer Electronic

Limits 99 Min. 99 Sec.

Operation TOUCH CONTROL, 25 Pads

Display Blue Green with scrolling text--Dual Language English and French

Convection Cooking Cycles No

Keypad Disable / Child Lockout Mode Yes - Press "Cancel" Key for 3 Seconds

Cooktop Light Wattage One Incandescent 40 Watt bulb

Fan Speed Indication "Low-Medium-High"-Scrolling Text

Power Failure Indication Yes - ':' Displayed Flashing

Invalid Data Entry "BEEP"

Technical Error Indication "F-" With Error Number

Diagnostic System Yes

OVEN INTERIOR FEATURES

Capacity 1.6 cu. ft.

Interior Dimensions W x H x D 21" W x 9 1/2" H x 14" D

Interior Dimensions W x H x D (mm) 535 x 240 x 355 mm

Cooking Power 950 Watts (IEC-705 Rating)

Turn Table Yes, Sunken Flush

Cooling Fan Automatic - On if oven is operating,

Off if door open

Oven Light Automatic - Turns on when oven

door is open or oven is operating. (30 Watts)

DOOR FEA TURES

Seals Two Stage (Capacitive and Reflective)

MICROWAVE SYSTEM

Distribution Top Feed w/o Stirrer

Magnetron One standard

SAFETY FEATURES

Interlock Three Door/Latch Operated

Primary, secondary and monitor

Thermal Protectors Four - 1 Magnetron, 1 Oven Cavity, 1 Hood, 1 Wave Guide

VENTIL A TION SYSTEM

Type Convertible Recirculation or Exhaust Vertical/Horizontal

Duct Outlet Size 3 1/4"H x 10"W

Recirculation CFM Out

112

Exhaust CFM Out

221

Touch Control 2 Speed

Exhaust Fan Auto ON - High Speed YES : 60° C, 140°F

Noise Level Recirculation (Acc. to IEC 704) Sound Power Level: 70 dB(A)

Grease Filter Yes (2)

Charcoal Filter Yes (1)

Blower Type/ Ventilation

Twin Squirrel Cage Blower: Left fan wheel for hood airflow and cavity ventilation.

Right fan for cooling airflow.

Shipped Recirculation mode

EXTERIOR FEA TURES

Power Cord Length 3 Feet

OTHER SPECIFICA TIONS

Electrical 120V, Single Phase, 60 Hz

1800 Watts, For Use With 15 - 20 Amp Circuit

Domestic Use Only Yes

Agency Approvals FCC, DHHS, UL, CUL

Approx. Net Weight - Lb 57 lbs.

LITERA TURE

Use & Care Guide 8205884

Installation Instructions 8205870

Warranty In Use & Care Guide

Tech Sheet 8205886

JobAid

8178573

1-8

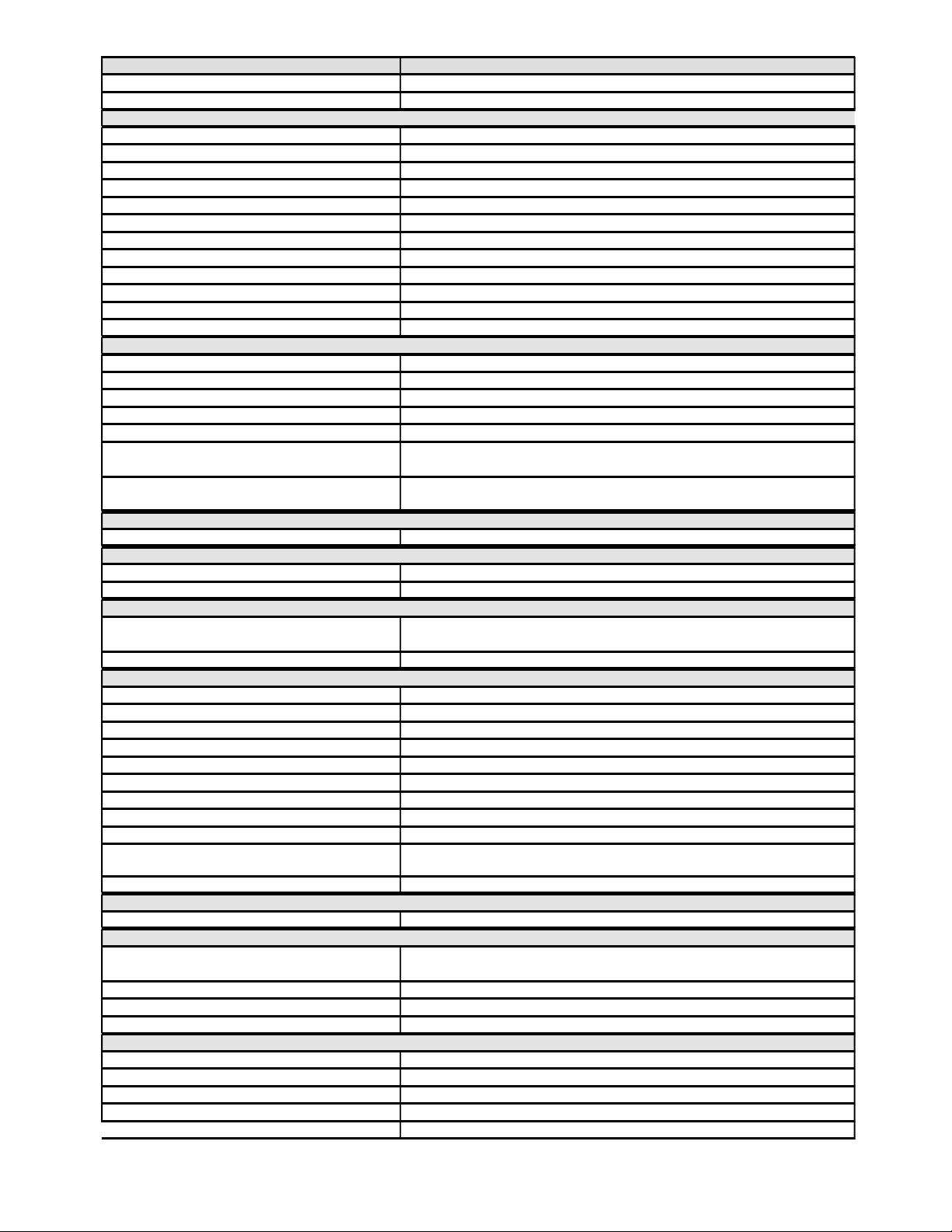

MH 1170XS TM H16XS

Basic Non Sensor Basic Non Sensor

Black, White, Biscuit and Stainless (B)Black, (Q)White, (D)Silver

Electronic Electronic

99 Min. 99 Sec. 99 Min. 99 Sec.

TOUCH CONTROL, TOUCH CONTROL,

Blue Green scrolling text--Dual Language English and French Blue Green with scrolling text--Dual Language English and French

No No

Yes - Press "Cancel" Key for 3 Seconds Yes - Press "Cancel" Key for 3 Seconds

One Incandescent 40 Watt bulb One Incandescent 40 Watt bulb

"Low-Medium-High"-Scrolling Text "Low-Medium-High"-Scrolling Text

Yes - ':' Displayed Flashing Yes - ':' Displayed Flashing

"RETRY"-Scrolling Text "RETRY"-Scrolling Text

"F-" With Error Number "F-" With Error Number

Yes Yes

1.7 cu. ft. 1.6 cu. ft.

21" W x 9 1/2" H x 14" D 21" W x 9 1/2" H x 14" D

535 x 240 x 355 mm 535 x 240 x 355 mm

1000 Watts (IEC-705 Rating) 1000 Watts (IEC-705 Rating)

Yes, Sunken Flush, Stoppable Yes, Sunken Flush

Automatic - On if oven is operating, Automatic - On if oven is operating,

Off if door open Off if door open

Automatic - Turns on when oven Automatic - Turns on when oven

door is open or oven is operating. (30 Watts) door is open or oven is operating. (30 Watts)

Two Stage (Capacitive and Reflective) Two Stage (Capacitive and Reflective)

Top Feed w/o Stirrer Top Feed w/o Stirrer

One standard One standard

Three Door/Latch Operated (Primary, secondary and monitor) Three Door/Latch Operated (Primary, secondary and monitor)

(Primary, secondary and monitor) (Primary, secondary and monitor)

Four - 1 Magnetron, 1 Oven Cavity, 1 Hood, 1 Wave Guide Four - 1 Magnetron, 1 Oven Cavity, 1 Hood, 1 Wave Guide

Convertible Recirculation or Exhaust Vertical/Horizontal Convertible Recirculation or Exhaust Vertical/Horizontal

3 1/4"H x 10"W 3 1/4"H x 10"W

112 112

221 221

2 Speed 2 Speed

YES : 60° C, 140°F YES : 60° C, 140°F

Sound Power Level: 70 dB(A) Sound Power Level: 70 dB(A)

Yes (2) Yes (2)

Yes (1) Yes (1)

Twin Squirrel Cage Blower: Left fan wheel for hood airflow and cavity ventilation.

Right fan for cooling airflow.

Twin Squirrel Cage Blower: Left fan wheel for hood airflow and cavity ventilation.

Right fan for cooling airflow.

Recirculation mode Recirculation mode

3 Feet 3 Feet

120V, Single Phase, 60 Hz 120V, Single Phase, 60 Hz

1800 Watts, For Use With 15 - 20 Amp Circuit 1800 Watts, For Use With 15 - 20 Amp Circuit

Yes Yes

FCC, DHHS, UL, CUL FCC, DHHS, UL, CUL

57 lbs. 57 lbs.

8205884 8205884

8205870

8205870

In Use & Care Guide In Use & Care Guide

8205880

8178573 8178573

1-9

WHIRLPOOL MICROWAVE OVEN WARRANTY

WHIRLPOOL CORPORATION MAJOR APPLIANCE WARRANTY

ONE YEAR LIMITED WARRANTY

For one year from the date of purchase, when this major appliance is operated and maintained according to instructions attached to or

furnished with the product, Whirlpool Corporation or Whirlpool Canada LP (hereafter “Whirlpool”) will pay for FSP

®

replacement parts

and repair labor to correct defects in materials or workmanship. Service must be provided by a Whirlpool designated service company.

ITEMS WHIRLPOOL WILL NOT PAY FOR

1. Service calls to correct the installation of your major appliance, to instruct you how to use your major appliance, to replace or repair

house fuses or to correct house wiring or plumbing.

2. Service calls to repair or replace appliance light bulbs, air filters or water filters. Those consumable parts are excluded from warranty

coverage.

3. Repairs when your major appliance is used for other than normal, single-family household use.

4. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation, installation not in

accordance with electrical or plumbing codes, or use of products not approved by Whirlpool.

5. Any food loss due to refrigerator or freezer product failures.

6. Replacement parts or repair labor costs for units operated outside the United States or Canada.

7. Pickup and delivery. This major appliance is designed to be repaired in the home.

8. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

9. Expenses for travel and transportation for product service in remote locations.

10. The removal and reinstallation of your appliance if it is installed in an inaccessible location or is not installed in accordance with

published installation instructions.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

Outside the 50 United States and Canada, this warranty does not apply. Contact your authorized Whirlpool dealer to determine if

another warranty applies.

If you need service, first see the “Troubleshooting” section of the Use & Care Guide. After checking “Troubleshooting,” additional help

can be found by checking the “Assistance or Service” section or by calling Whirlpool. In the U.S.A., call 1-800-253-1301. In Canada,

call 1-800-807-6777.

8/05

Keep this book and your sales slip together for future

reference. You must provide proof of purchase or installation

date for in-warranty service.

Write down the following information about your major appliance

to better help you obtain assistance or service if you ever need it.

You will need to know your complete model number and serial

number. You can find this information on the model and serial

number label located on the product.

Dealer name ____________________________________________________

Address ________________________________________________________

Phone number __________________________________________________

Model number __________________________________________________

Serial number __________________________________________________

Purchase date __________________________________________________

8205884

© 2005 Whirlpool Corporation.

.A.S.U,looplrihWfokramedarTMT/kramedarTderetsigeR®.devresersthgirllA

4619-652-68351

11/05

Printed in China

1-10

INSTALLATION INFORMATION

HOOD FAN MOTOR MOUNTING POSITIONS

RECIRCULATING AIR

REAR VENTED AIR

Airow towards front of unit.

Note: this is the way the

unit is shipped.

Airow towards rear of unit. Unplug

wire, turn fan motor over, and plug

wire back into the quick disconnect

socket over the top of the fan motor.

TOP VENTED AIR

Airow towards top of unit.

2-1

---- NOTES ----

2-2

THEORY OF OPERATION

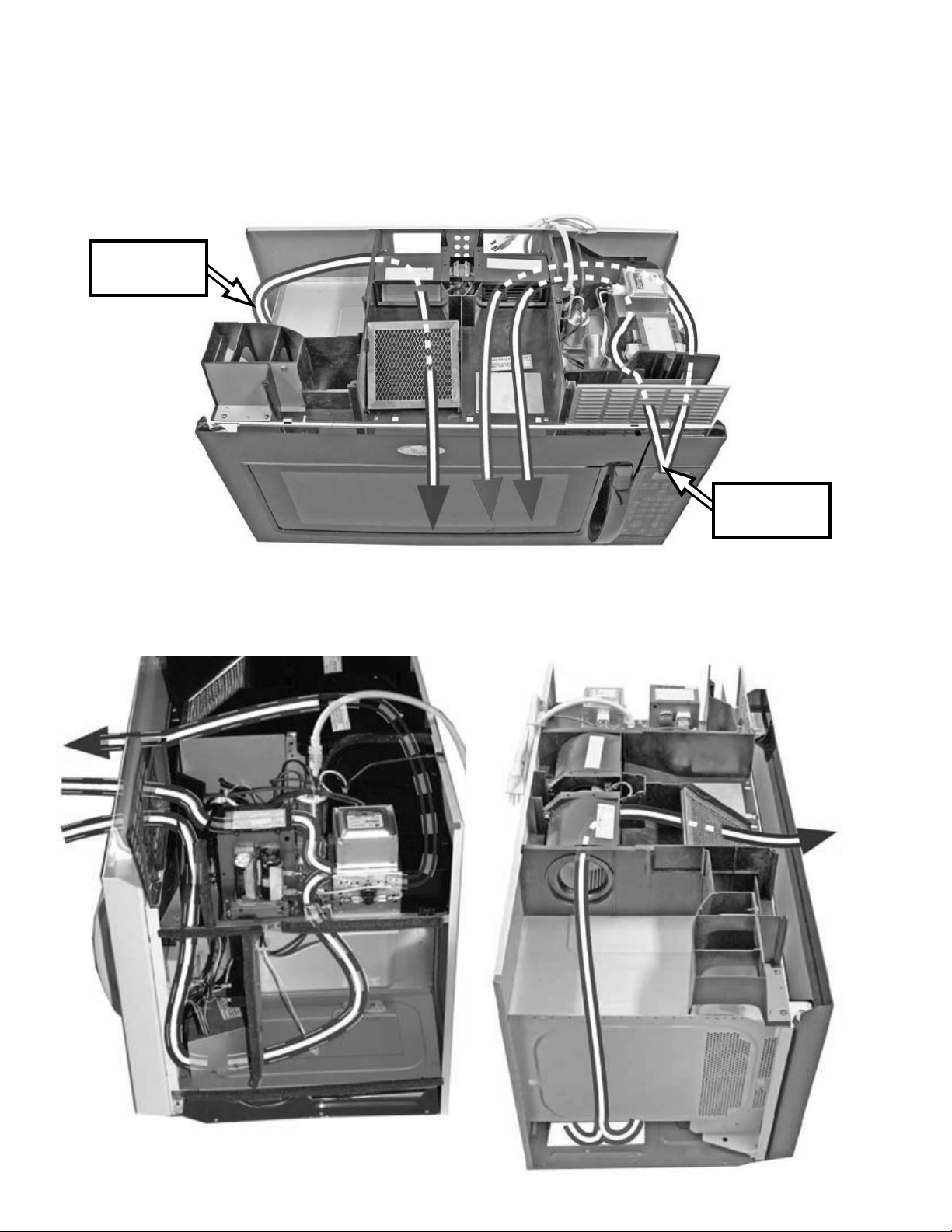

AIRFLOW PATHS

The microwave uses the exhaust blower motor to remove vapors from the cooking area below the

unit, it also circulates air within the unit to assist cooking performance and cool the operating components.

Cooktop

Venting

Component

cooling

This process is accomplished by using one side

of the blower motor assembly to pull ambient air

into the unit to cool the working components,

and the remaining side of the blower for exhausting steam and cooking odors.

3-1

Loading...

Loading...