CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

SELF-CLEANING

SLIDE-IN GAS

RANGE

KR-35

Model: GW395LEP

JOB AID

Part No. 8178455

FORWARD

This Whirlpool Job Aid, “Self-Cleaning Slide-In Gas Range,” (Part #8178455), provides the

technician with information on the installation, operation, and service of the Self-Cleaning SlideIn Gas Range. It is to be used as a training Job Aid and Service Manual. For specific information

on the model being serviced, refer to the “Use and Care Guide,” or “Wiring Diagram” provided with

the gas range.

The Wiring Diagram and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Whirlpool Self-Cleaning Slide-In Gas Range.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the range to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2004, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Safety First......................................................................................................................... 1-1

Model & Serial Number Designations ................................................................................ 1-2

Model & Serial Number Label & Wiring Diagram Locations .............................................. 1-3

Specifications..................................................................................................................... 1-4

Whirlpool Gas Range Warranty ......................................................................................... 1-6

INSTALLATION INFORMATION ........................................................................................... 2-1

Gas Supply Requirements ................................................................................................. 2-1

Electrical Requirements ..................................................................................................... 2-3

L.P. Gas Conversion.......................................................................................................... 2-4

Adjusting For The Proper Flame........................................................................................ 2-8

Installing The Anti-Tip Bracket ........................................................................................... 2-9

THEORY OF OPERATION ..................................................................................................... 3-1

Electronic Oven Control System Functions ....................................................................... 3-1

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Control Panel And The Electronic Oven Control Board &

User Interface ................................................................................................................. 4-2

Removing The Ignition Switches, A Gas Valve,

And The Control And Cooling Fan TODs ....................................................................... 4-4

Removing The Door Latch Assembly And The Spark Module (DSI) ................................. 4-6

Removing The Cooktop, And A Surface Burner & Ignitor.................................................. 4-8

Removing The Rear Panel .............................................................................................. 4-10

Removing An Oven Light Socket Assembly .................................................................... 4-11

Removing The Broil Burner And Ignitor ........................................................................... 4-12

Removing The Bake Burner And Ignitor .......................................................................... 4-14

Removing The Oven Temperature Sensor ...................................................................... 4-16

Removing The Cooling Fan ............................................................................................. 4-17

Removing The Oven TOD ............................................................................................... 4-18

Removing The Gas Distribution Valve ............................................................................. 4-19

Removing The Power Supply Cord ................................................................................. 4-20

Removing A Side Panel ................................................................................................... 4-21

Removing & Reinstalling The Oven Door ........................................................................ 4-22

Removing The Oven Door Gasket................................................................................... 4-23

Removing The Decorative Glass And Oven Door Handle,

The Hinges, And The Oven Door Glass ...................................................................... 4-24

- iii -

Page

COMPONENT TESTING ........................................................................................................ 5-1

Control & Cooling Fan TODs ............................................................................................. 5-1

Ignition Switches ................................................................................................................ 5-2

Door Latch Assembly......................................................................................................... 5-3

Oven Temperature Sensor ................................................................................................ 5-3

Cooling Fan Motor ............................................................................................................. 5-4

Oven TOD.......................................................................................................................... 5-4

Gas Distribution Valve ....................................................................................................... 5-5

Gas Valve .......................................................................................................................... 5-5

Clock .................................................................................................................................. 5-6

Keypad Layout ................................................................................................................... 5-6

Display Board & Connector Pinouts .................................................................................. 5-7

DIAGNOSTICS & TROUBLESHOOTING .............................................................................. 6-1

Diagnostics ........................................................................................................................ 6-1

Failure/Error Display Codes........................................................................................... 6-1

Hidden EOC Functions ................................................................................................. 6-2

Temperature Adjustment ............................................................................................... 6-2

EZ354 ............................................................................................................................ 6-3

Troubleshooting Chart ....................................................................................................... 6-4

WIRING DIAGRAM & STRIP CIRCUITS ............................................................................... 7-1

Wiring Diagram .................................................................................................................. 7-1

Strip Circuits ...................................................................................................................... 7-2

- iv -

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always

read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

1-1

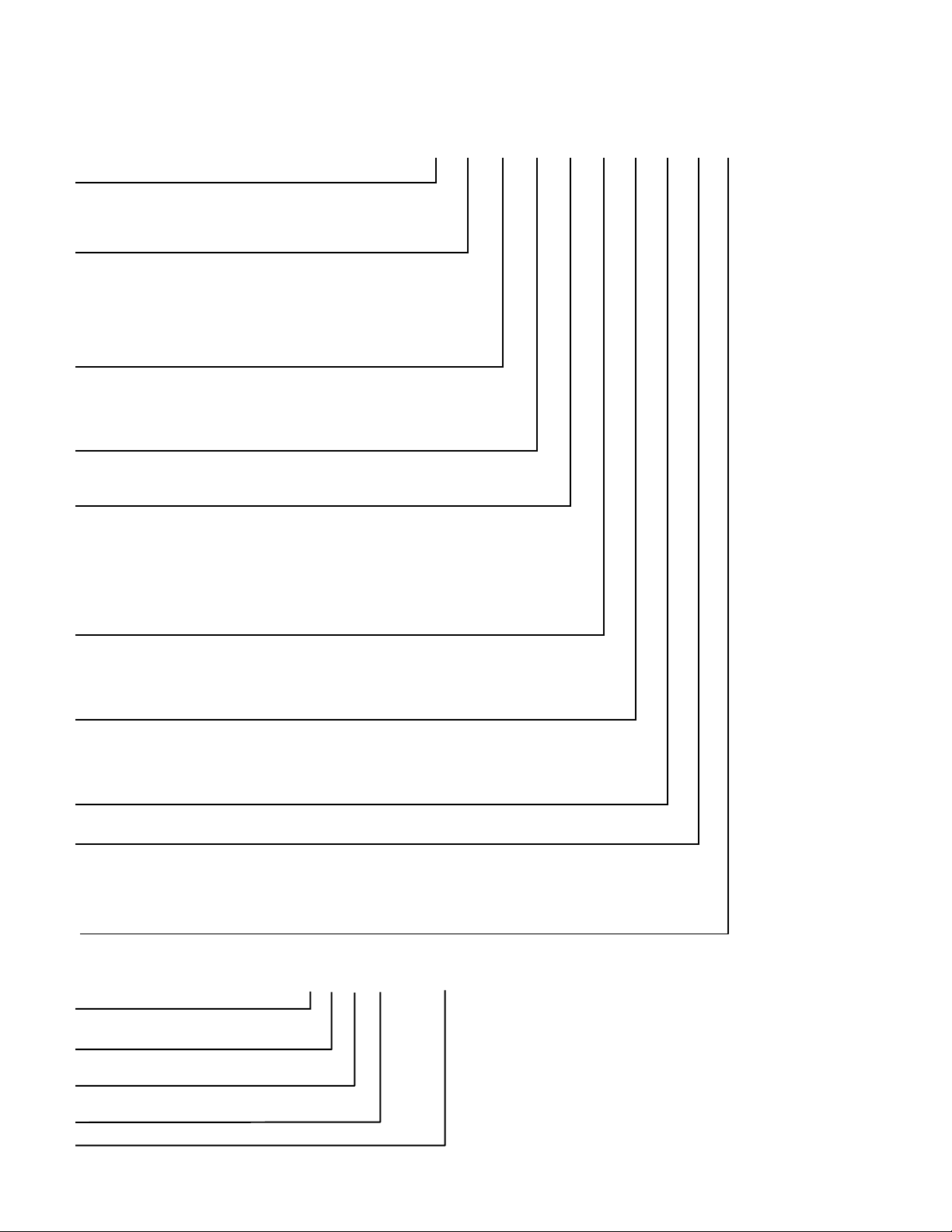

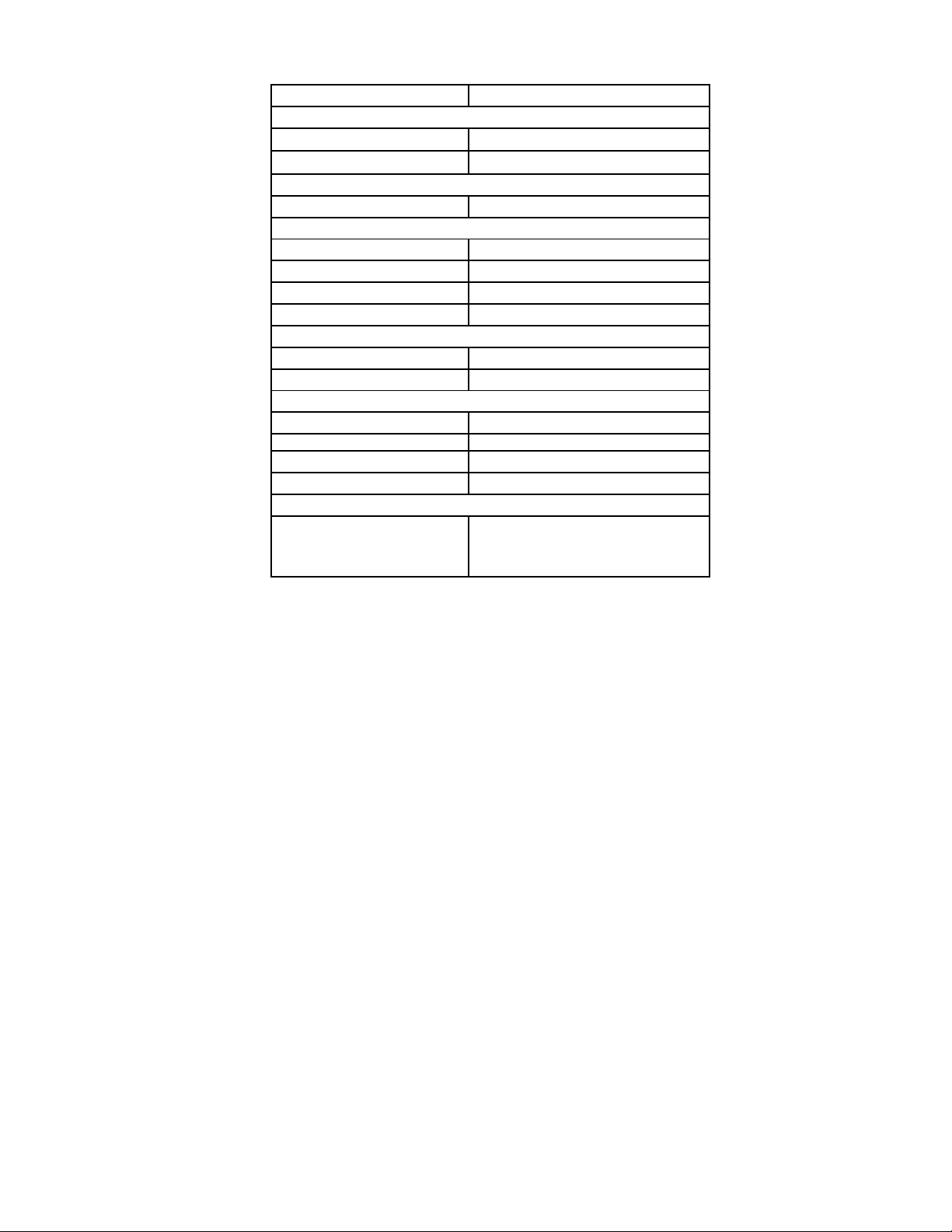

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER

PRODUCT GROUP

R = ELECTRIC RANGES

S = GAS RANGES

G = WHIRLPOOL GOLD RANGE

PRODUCT IDENTIFICATION

A = ACCESSORY K = KITS

B = BUILT-IN M = MV COMBO

C = COOKTOP S = SET-IN

E = EYE-LEVEL W = SLIDE-IN GAS

F = FREESTANDING Y = SLIDE-IN ELECTRIC

H = HOODS

MODEL SIZE

3 = 30" SLIDE-IN

4 = 40" SLIDE-IN

5 = 36" SLIDE-IN

6 = 30" SET-IN RANGES

OVEN TYPE

0 THRU 3 = STANDARD PORCELAIN

4 THRU 9 = PYROLYTIC SELF-CLEAN

FEATURE / VARIATIONS

ELECTRIC

0, 1, 2, 5, 7 = COIL ELEMENTS

4 = STANDARD PATTERN CERAMIC

6, 8, 9 = DELUXE PATTERN CERAMIC

GAS

0, 1, 2, 3, 4, 6 = OPEN BURNER

5 & 7 = SEALED BURNER

DOOR TYPE

B = SOLID BLACK GLASS

L = LARGE WINDOW

O = METAL OVEN DOOR

P = STANDARD WINDOW GLASS

FEATURE CODE

E = ELECTRONIC IGNITION (GAS ONLY)

S = STANDING IGNITION (GAS ONLY)

C = COLOR COORDINATED GLASS (BEFORE 1998)

X = NOT DEFINED

YEAR OF INTRODUCTION

P = 2004

COLOR CODE

B = BLACK

Q = WHITE ON WHITE

S = STAINLESS STEEL

T = BISCUIT

GW3 9 5 LEP Q

SERIAL NUMBER

SERIAL NUMBER

MANUFACTURING SITE

X = OXFORD, MS

YEAR OF PRODUCTION

R = 2004

WEEK OF PRODUCTION

(7th WEEK)

PRODUCT SEQUENCE NUMBER

X R 07 1 2 3 4 5

1-2

MODEL & SERIAL NUMBER LABEL

& WIRING DIAGRAM LOCATIONS

The Model/Serial Number label and Wiring Diagram locations are shown below.

Model/Serial Number Location

(Above Storage Drawer)

Storage Drawer

1-3

Wiring Diagram Location

(On Underside Of Drawer)

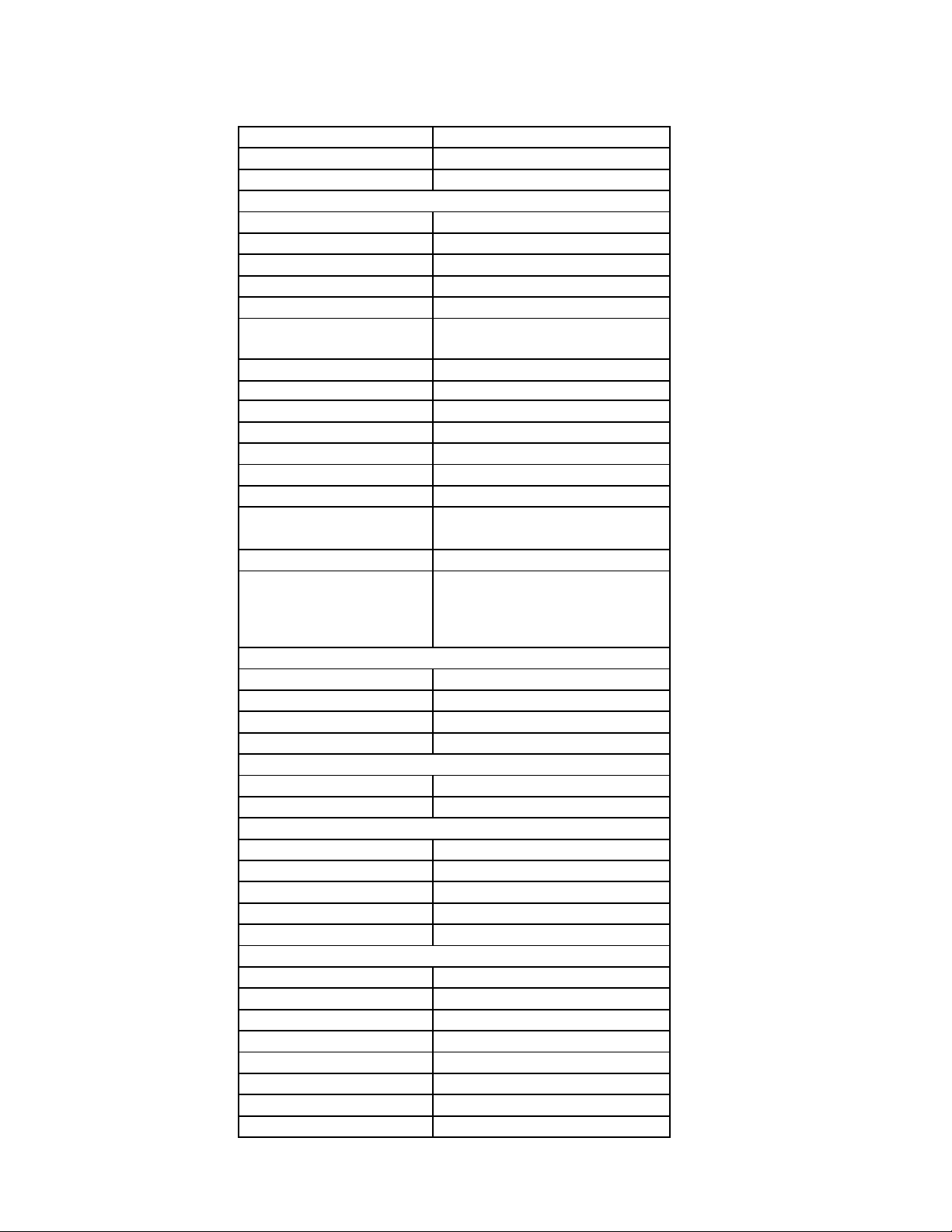

SPECIFICATIONS

Model # GW395LEP Q/B/T/S

Model Description Gas Self-Clean

Oven Control Type EZ354

OVEN CONTROL FUNCTIONS

Convect bake No

Bake Yes

Temperature range 170 to 500°F

Custom broil Yes

Temperature range 300 to 500°F

Temperature control

Self-clean Yes, variable time

Time set range 2:30 to 4:30 (15 min. increments)

Delay bake Yes (Cook time, Stop time buttons)

Timer Yes (up to 12hrs, 59 min. max.)

Oven light (manual) Yes

Control lockout Yes

Pre-heat countdown timer Yes

Control overlay color

Oven Heating Indicator Light In display

Hidden functions

CONSOLE FEATURES

Location Front

Burner "ON" Indicator Light No

Burner Controls Push to turn, infinite

Valve degrees of rotation 210 degrees

COOKTOP FEATURES

Burner Type Sealed

Ignition Electronic

Burner Configuration

Right Front Burner 6,000 btu

Left Front Burner 14,000 btu

Right Rear Burner 12,000 btu

Left Rear Burner 6,000 btu

Lift Top No

OVEN FEATURES

Oven cleaning type Self-clean

Accubake system Yes

Number of temperature sensors 1

Oven Capacity 4.3 Cu. Ft.

Broil Burner 10,000 btu

Door Position in Broil Closed

Bake Burner 15,500 btu

Oven Light Yes

Temperature up/down buttons

(5 degree increments)

Q=White/Nestle, B=Black/blk Divide,

T=Biscuit/dk biscuit, S=Black/blk Divide

Select F/C temperature, temperature

calibration offset, disable/enable timer

reminder signals, disable/enable cycle end

audible signals

1-4

Model # GW395LEP Q/B/T/S

OVEN DOOR FEATURES

Door Latch Yes-Motorized

Removable Door Yes

STORAGE/WARMING DRAWER

Storage Drawer Yes

LITERATURE

Use & Care Guide Yes (English + French)

Tech Sheets/Wiring Diagrams 9757668

Installation Instructions Yes (English + French)

Service Manual/Job Aid 8178455

DIMENSIONS

Height-Overall 35.9"

Width 29.875"

OTHER SPECIFICATIONS

LP Convertible Yes, conversion orifices included

Agency Approval CSA

Power cord Included

Anti-Tip Device w/ Unit Floor Bracket

ACCESSORIES

Included, matches body color, to close gap

Trim Kit

from rear of unit to wall (previous

freestanding installation)

1-5

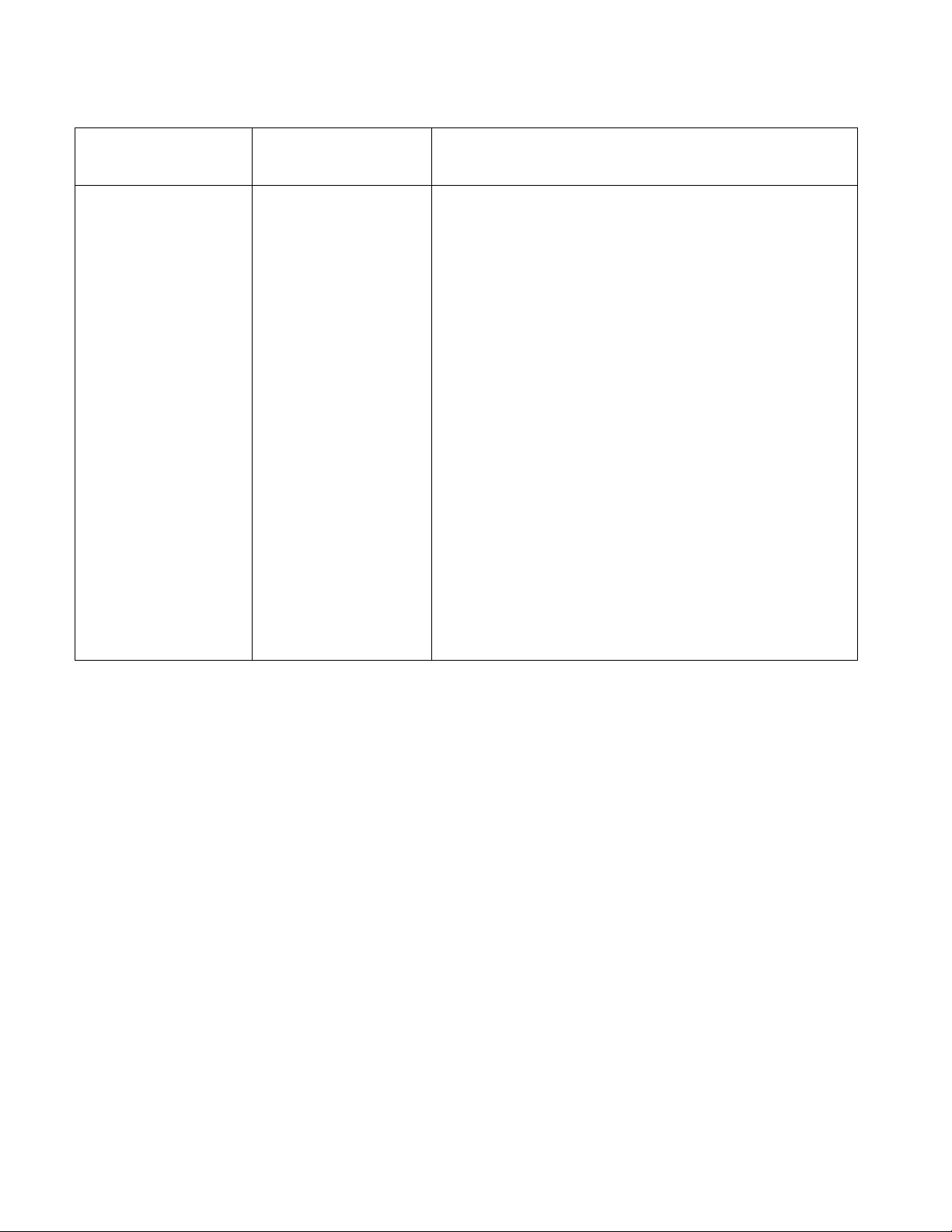

WHIRLPOOL GAS RANGE WARRANTY

LENGTH OF

WARRANTY:

ONE-YEAR FULL

WARRANTY

FROM DATE OF

PURCHASE.

WHIRLPOOL

WILL PAY FOR:

®

replacement

FSP

parts and repair

labor costs to

correct defects in

materials or workmanship. Service

must be provided

by an authorized

Whirlpool service

company.

WHIRLPOOL

WILL NOT PAY FOR:

A. Service calls to:

1. Correct the installation of the range.

2. Instruct you how to use the range.

3. Replace house fuses or correct house wiring.

4. Replace owner-accessible light bulbs.

5. Correct house plumbing.

B. Repairs when the range is used in other than

normal, single-family household use.

C. Pickup and delivery. The range is designed to

be repaired in the home.

D. Damage to the range caused by accident, alter-

ation, misuse, abuse, fire, flood, acts of God, or

use of products not approved by Whirlpool.

E. Repairs to parts or systems resulting from unau-

thorized modifications made to the appliance.

F. In Canada, travel or transportation expenses for

customers who reside in remote areas.

G. Replacement parts or repair labor costs for units

operated outside the United States and Canada.

WHIRLPOOL CORPORATION AND WHIRLPOOL CANADA INC.

SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states and provinces do not allow the exclusion or limitation of incidental or consequential damages

so this exclusion or limitation may not apply to you. This warranty gives you specific legal rights and you

may also have other rights which vary from state to state or province to province.

Outside the 50 United States and Canada, this warranty does not apply. Contact your authorized

Whirlpool dealer to determine if another warranty applies.

If you need service first see “Troubleshooting” in the “Use & Care Guide.” Additional help can be found by

checking “Assistance or Service” or call our Customer Interaction Center at 1-800-253-1301 from

anywhere in the U.S.A., or write: Whirlpool Brand Home Appliances, Customer Interaction Center, 553

Benson Road, Benton Harbor, MI 49022-2692. In Canada, call Whirlpool Canada Inc. at 1-800-807-6777.

1-6

INSTALLATION INFORMATION

GAS SUPPLY REQUIREMENTS

WARNING

Explosion Hazard

Use a new AGA or CSA approved gas

supply line.

Install a shutoff valve.

Securely tighten all gas connections.

If connected to L.P. gas, have a qualified

person make sure gas pressure does

not exceed 14″ water column.

Examples of a qualified person include

licensed heating personnel, authorized

gas company personnel, and

authorized service personnel.

Failure to do so can result in death,

explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: Range must be connected to

a regulated gas supply.

1. This installation must conform with local

codes and ordinances. In the absence of

local codes, installations must conform

with American National Standard, National

Fuel Gas Code ANSI Z223.1—latest edition* or CANI-B149—latest edition** installation codes.

Copies of the standards listed may be obtained

from:

2. Input ratings shown on the model/serial

rating plate are for elevations up to 2,000

feet (609.6 m). For elevations above 2,000

feet (609.6 m), ratings are reduced at a

rate of 4% for each 1,000 feet (304.8 m)

above sea level. (Not applicable for

Canada.)

3. This range is equipped for use with Natural gas. It is design-certified by AGA/CSA

for Natural and L.P. gas with appropriate

conversion. Conversion to L.P. gas can be

made using the kit included in the literature package. The model/serial rating plate

has information on the type of gas that can

be used. If this information does not agree

with the type of gas available, check with

your Whirlpool dealer.

4. Provide a gas supply line of 3/4″ (1.9 cm)

rigid pipe to the range location. A smaller

size pipe on long runs may result in insufficient gas supply. Pipe-joint compounds

appropriate for use with L.P. gas must be

used. With L.P. gas, piping or tubing size

can be 1/2″ (1.3 cm) minimum. L.P. gas

suppliers usually determine the size and

materials used on the system.

5. If local codes permit, a new AGA/CSA

design-certified, 4-5 foot (122 -152.4 cm)

long, 1/2″ (1.3 cm) or 3/4″ (1.9 cm) I.D.,

flexible metal appliance connector is recommended for connecting this range to

the gas supply line. Do Not kink or damage

the flexible tubing when moving the range.

A 1/2″ (1.3 cm) male pipe thread is needed

for connection to pressure regulator female pipe threads.

* American Gas Association

1515 Wilson Boulevard

Arlington, Virginia 22209

** CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

Flexible Gas Supply Line

Continued on the next page.

2-1

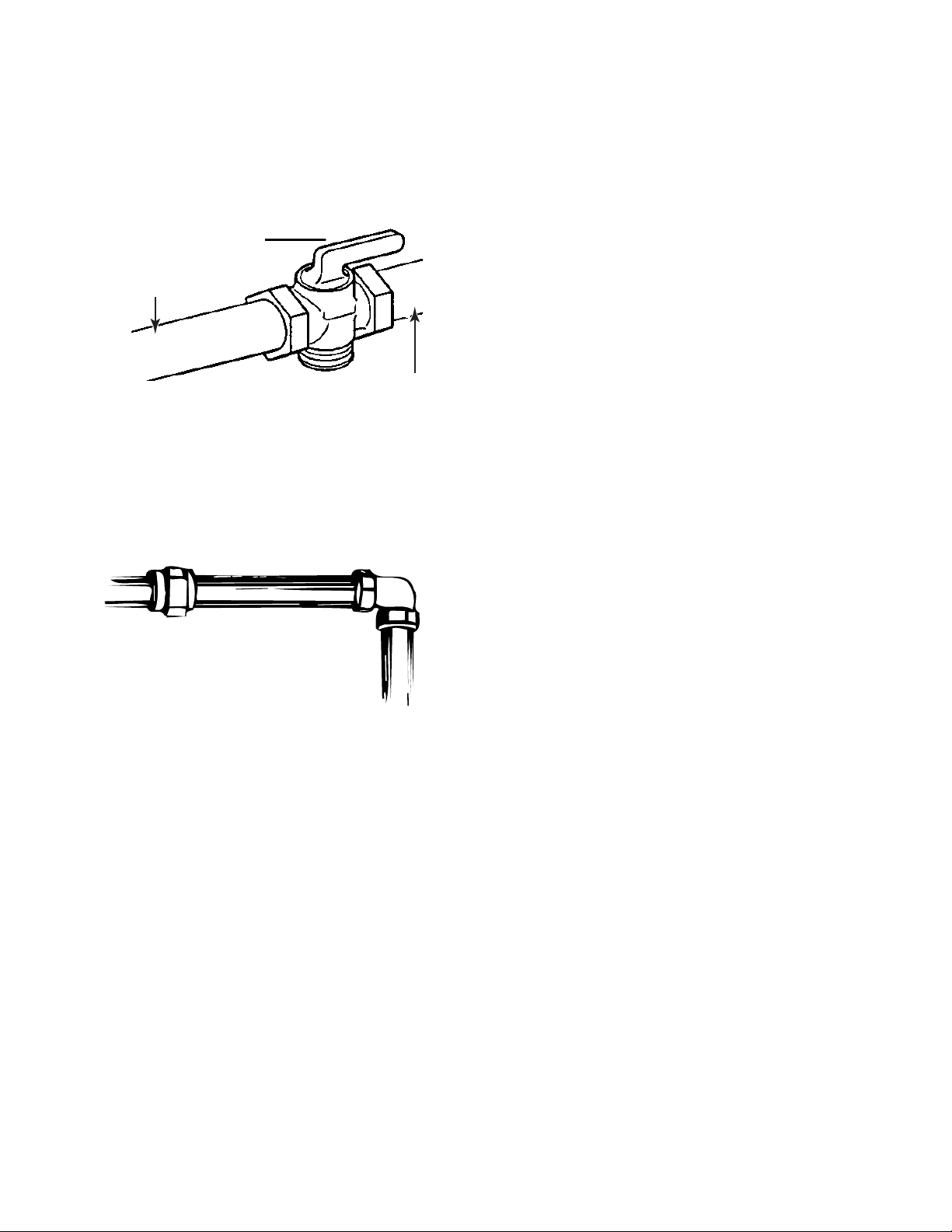

6. The supply line shall be equipped with an

approved shutoff valve. This valve should

be located in the same room, but external

to the range, and should be in a location

that allows ease of opening and closing.

Do Not block access to shutoff valve.

Manual Shutoff Valve

OPEN Position

To Range

8. The regulator setting must be checked at

a minimum of 1 inch water column above

the manifold pressure. The inlet pressure

to the regulator should be as follows for

operation:

Natural gas:

Manifold pressure—5 inches

Maximum pressure—14 inches

L.P. gas:

Manifold pressure—10 inches

Maximum pressure—14 inches

9. Line pressure testing:

Gas Supply Line

7. If rigid pipe is used as a gas supply line, a

combination of pipe fittings must be used

to obtain an in-line connection to the range.

All strains must be removed from the supply and fuel lines so the range will be level

and in line.

Rigid Pipe

Testing above 1/2 psi (gauge)

The range and its individual shutoff valve

must be disconnected from the gas supply

piping system during any pressure testing

of that system at test pressures greater

than 1/2 psig (3.5 kPa).

Testing at 1/2 psi (gauge) or lower

The range must be isolated from the gas

supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than

1/2 psig (3.5 kPa).

2-2

ELECTRICAL REQUIREMENTS

WARNING

NOTE: The metal chassis of the range MUST

be grounded in order for the control panel to

work. If the metal chassis of the range is not

grounded, NO keypads will operate. Check

with a qualified electrician if you are in doubt as

to whether the metal chassis of the range is

grounded.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

If codes permit and a separate ground wire

is used, it is recommended that a qualified

electrician determine that the ground path

is adequate.

Do Not ground to a gas pipe.

Check with a qualified electrician if you are

not sure range is grounded.

Do Not have a fuse in the neutral or ground

circuit.

A 120-volt, 60-Hz, AC-only, 15-ampere, fused

electrical circuit is required. A time-delay fuse

or circuit breaker is recommended. It is recommended that a separate circuit serving only this

range be provided.

Recommended ground method

For personal safety, this range is equipped with

a power supply cord having a 3-prong ground

plug. To minimize possible shock hazard, the

cord must be plugged into a mating 3-prong,

ground-type outlet, grounded in accordance

with the National Electrical Code, ANSI/NFPA

70—latest edition* or CSA Standard C22.1,

Canadian Electrical Code, Part 1,—latest edition** and all local codes and ordinances. If a

mating outlet is not available, it is the personal

responsibility and obligation of the customer to

have a properly grounded, 3-prong outlet installed by a qualified electrician.

Copies of the standards listed may be obtained

from:

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts, 02269

** CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

Electronic ignition systems operate within wide

voltage limits, but proper grounding and polarity are necessary. In addition to checking that

the outlet provides 120-volt power and is correctly grounded, the outlet must be checked by

a qualified electrician to see if it is wired with

correct polarity.

2-3

L.P. GAS CONVERSION

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

WARNING

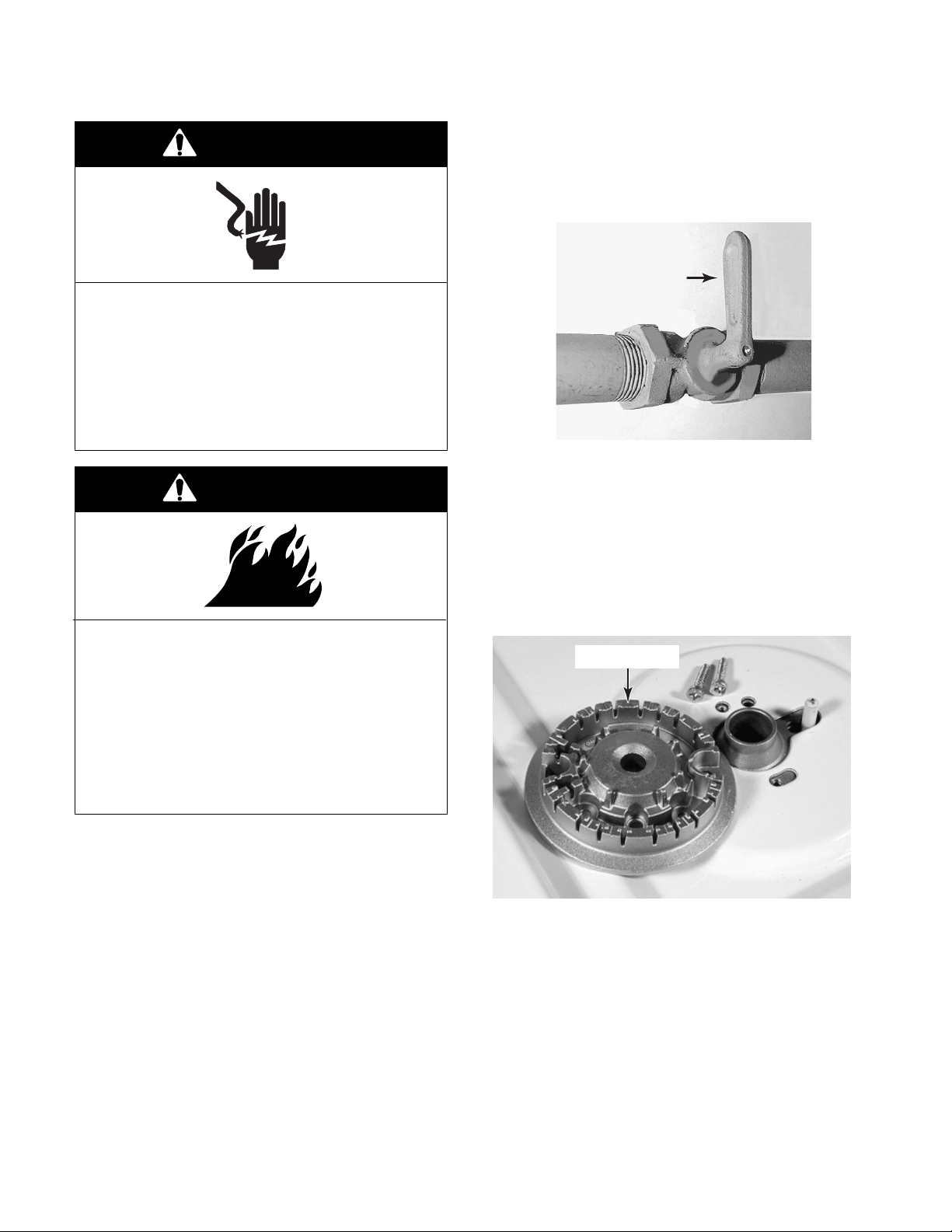

1. Check to make sure that the main gas

supply line to the range has been shut off,

and that the power supply cord is disconnected from the AC outlet.

Gas Valve Handle

To “Shutoff” Position

2. To convert the surface burners for use

with L.P. gas:

a)Remove the grates and burner caps

from the cooktop.

b)Remove the two screws from each of

the burner heads and lift the heads off

the cooktop.

Fire Hazard

Shut off gas supply line valve.

Make all conversions before turning

gas supply valve back on.

Failure to follow these instructions

could result in explosion, fire, or other

injury.

NOTE: Gas conversion from Natural to L.P.

gas must be done by a qualified installer.

Examples of a qualified installer include

licensed heating personnel, authorized gas

company personnel, and authorized service personnel.

L.P. gas must not be used unless the L.P.

conversion has been made using the kit that is

included with this range. See the “Gas Supply

Requirements” starting on page 2-1.

Burner Head

2-4

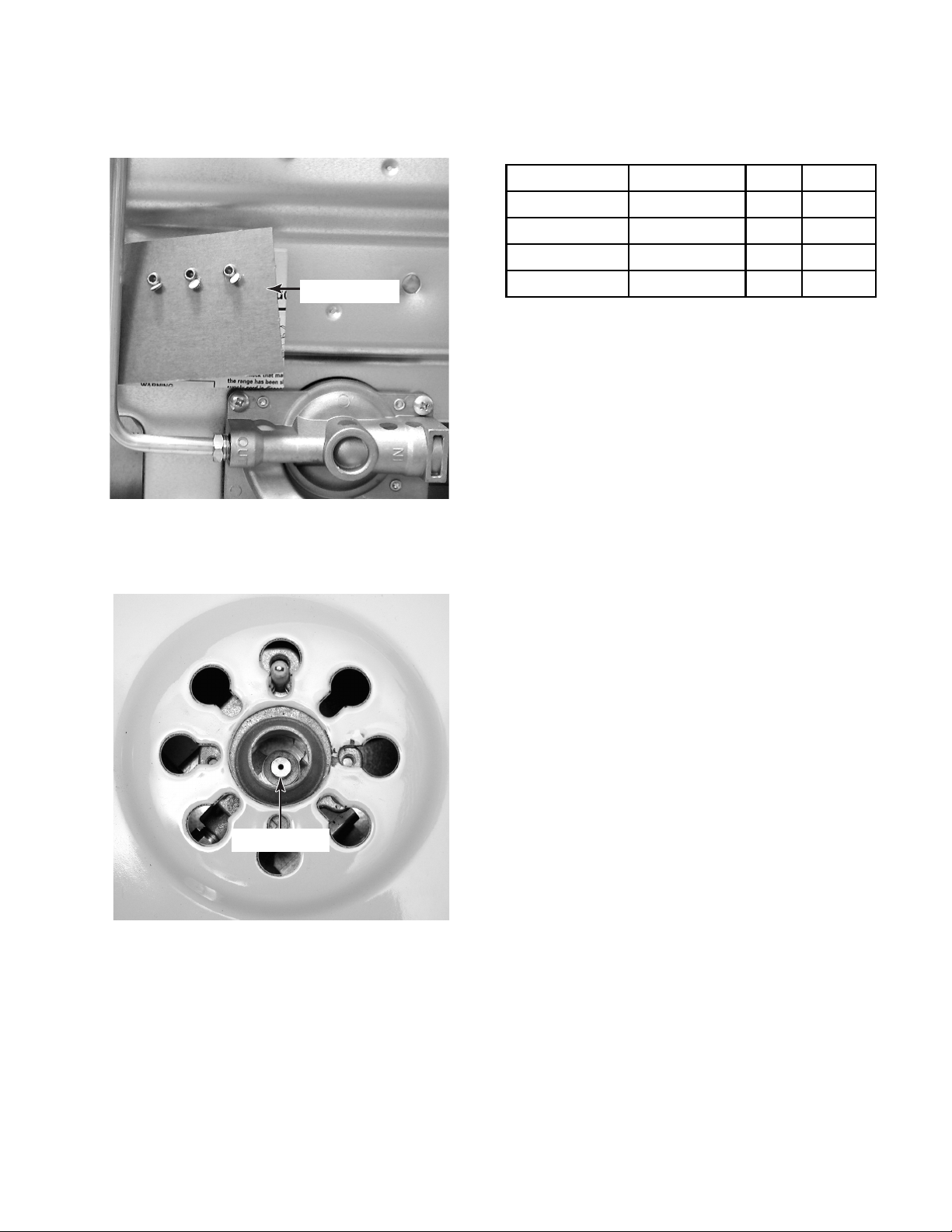

NOTE: The L.P. orifices are fastened to the

back of the range near the bottom on a cardboard form.

Orifice Card

c) Use an 8 mm socket and carefully re-

move the orifice spud from each of the

four burners.

d)Install the four L.P. gas orifices in the

burners, as shown in the following chart

(do not overtighten them):

Burner Location Burner Rating Color Size

Right Front 5,000 BTU Red 0.70 mm

Left Front 13,000 BTU Green 1.10 mm

Right Rear 10,000 BTU Blue 0.95 mm

Left Rear 5,000 BTU Red 0.70 mm

e)Place the natural gas orifices in the ori-

fice card holes.

3. To convert the broil burner for use with

L.P. gas:

a)Open the oven door and remove the

oven racks.

b)Use a 1/2″ open-end wrench and turn

the orifice hood down snug onto the pin

(approximately 2-1/2 turns). DO NOT

OVERTIGHTEN THE ORIFICE. The

burner flame cannot be properly adjusted if this conversion is not made.

c) Reinstall the oven racks and close the

oven door.

Orifice Spud

Continued on the next page.

2-5

Broil Burner Orifice

4. To convert the bake burner for use with

L.P. gas:

a)Remove the bake burner from the gas

distribution valve orifice (see page 4-14

for the procedure).

b)Use a 1/2″ open-end wrench and turn

the bake burner orifice hood down snug

onto the pin (approximately 2-1/2 turns).

DO NOT OVERTIGHTEN THE ORIFICE. The burner flame cannot be prop-

erly adjusted if this conversion is not

made.

Bake Burner Orifice Hood

Pin

Orifice

Hood

Natural Gas:

Increases Flame Size

In This Direction

L.P. Gas:

Increases Flame Size

In This Direction

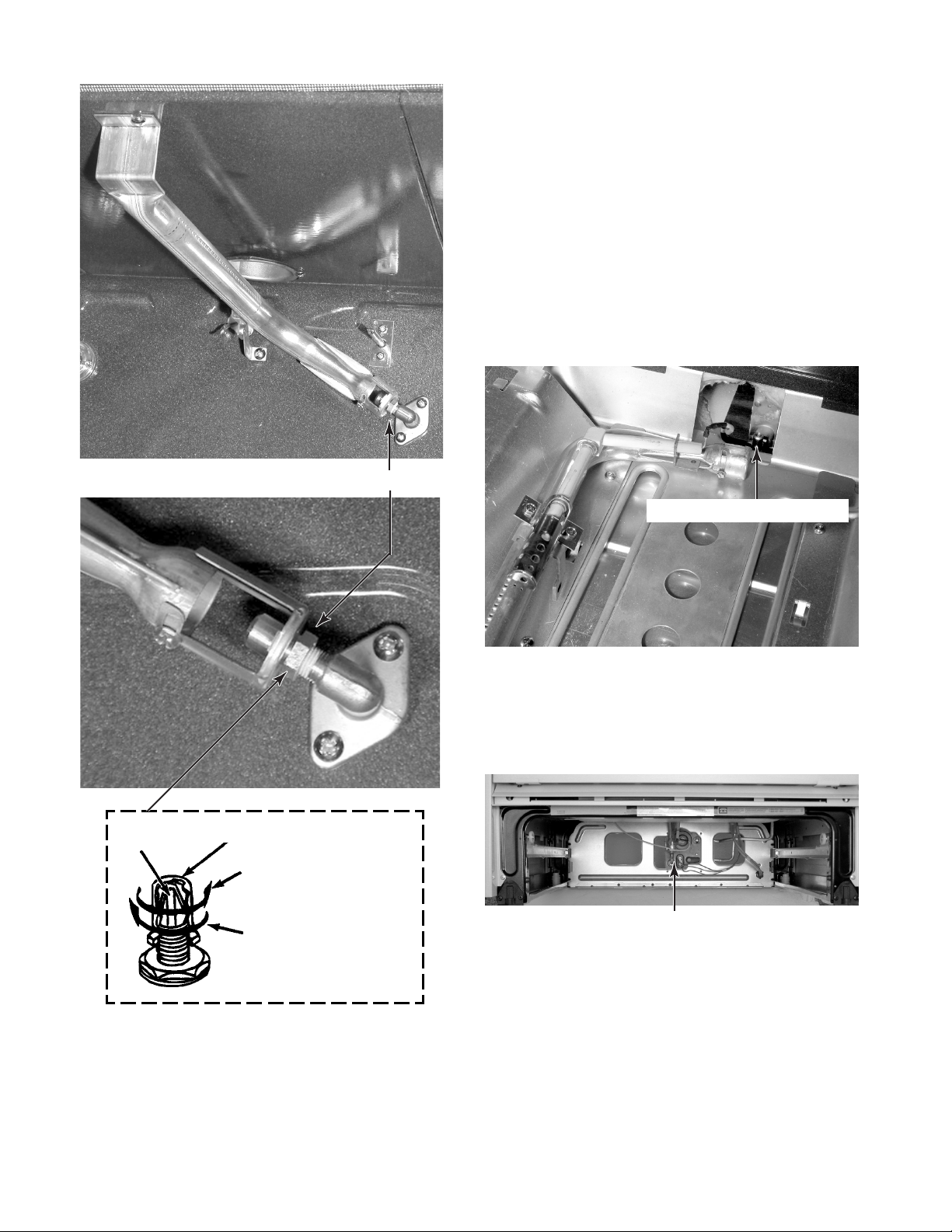

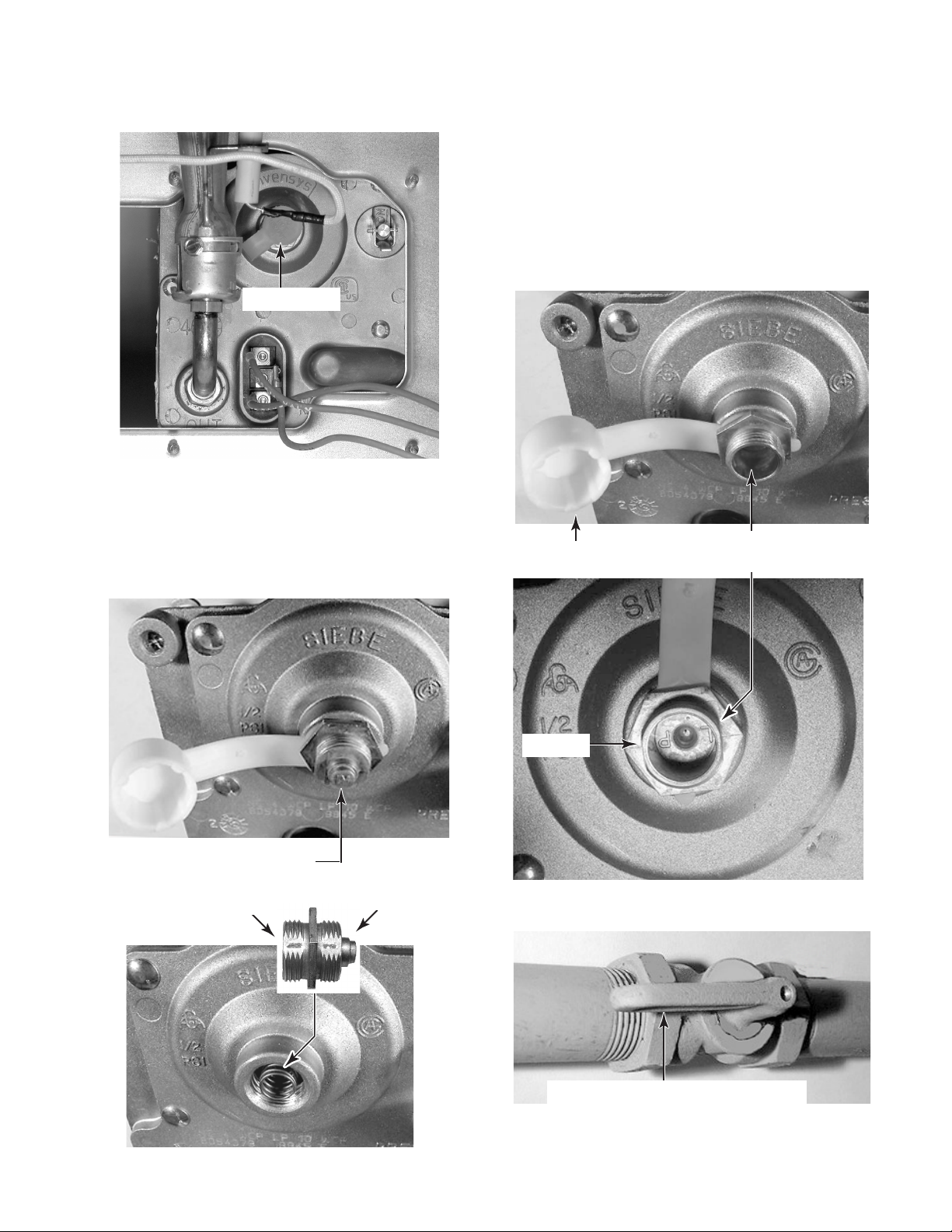

5. To convert the gas distribution valve

for use with L.P. gas:

a)Remove the storage drawer from the

range.

Gas Distribution Valve

2-6

b)Pull the plastic cap off the gas distribu-

tion valve conversion cap.

Plastic Cap

c) Unscrew the conversion cap from the

gas distribution valve and remove it and

the plastic cap. Note the difference between the L.P. and Natural gas ends of

the cap.

d)Install the loop on the plastic cap over

the natural gas side of the conversion

cap.

e)Install the plastic cap and the conver-

sion cap on the gas distribution valve

with the L.P. side facing up (you will see

“LP” stamped inside the cap, as shown

below).

f) Reinstall the storage drawer.

Plastic Cap

Conversion Cap Set

For Use With L.P. Gas

Conversion Cap Set For

Use With (N) Natural Gas

L.P. Gas

Natural Gas

L.P. Gas

6. Turn the gas supply valve handle on.

Gas Valve Handle To “On” Position

2-7

ADJUSTING FOR THE PROPER FLAME

SURFACE BURNERS

1. Turn on one of the surface burners and set

the flame to its lowest (LO) setting. The

flame should be steady and the inner cone

should be dark blue in color. The size

should be approximately 1/4″ (0.64 cm)

high.

2. If the low flame needs to be adjusted:

a)Remove the control knob.

b) Look inside the gas valve stem and note

the small screw. Insert a small screwdriver into the gas valve stem and fit it

in the screw slot.

Flame

Adjustment

Screw

BAKE & BROIL BURNERS

1. Remove the oven racks and oven bottom.

2. Light the bake and broil burners, then

check their flames. They should be approximately 1/2″ (1.3 cm) high.

3. If the bake or broil burner flame needs to

be adjusted:

a)Loosen the locking screw on the burner

air shutter. NOTE: For the bake burner,

you will have to remove the unit from

its mounting location to access the air

shutter.

Bake Burner

Air Shutter

c) Hold the gas valve stem with a pair of

pliers, and turn the screw in either direction until the flame size is approximately 1/4″ high.

d)Replace the control knob.

e)Turn the control knob from HI to LO and

check to make sure that it remains adjusted properly.

f) Check the other three burners, and ad-

just them, if necessary.

Broil Burner

Air Shutter

b)Adjust the air shutter until the flame is

the proper height. The inner cone

should be bluish-green, and the outer

mantle should be dark blue. There

should be no blowing or lifting of the

flame away from the burner ports.

NOTE: Natural gas flame does not have

a yellow tip.

c) Retighten the air shutter screw.

2-8

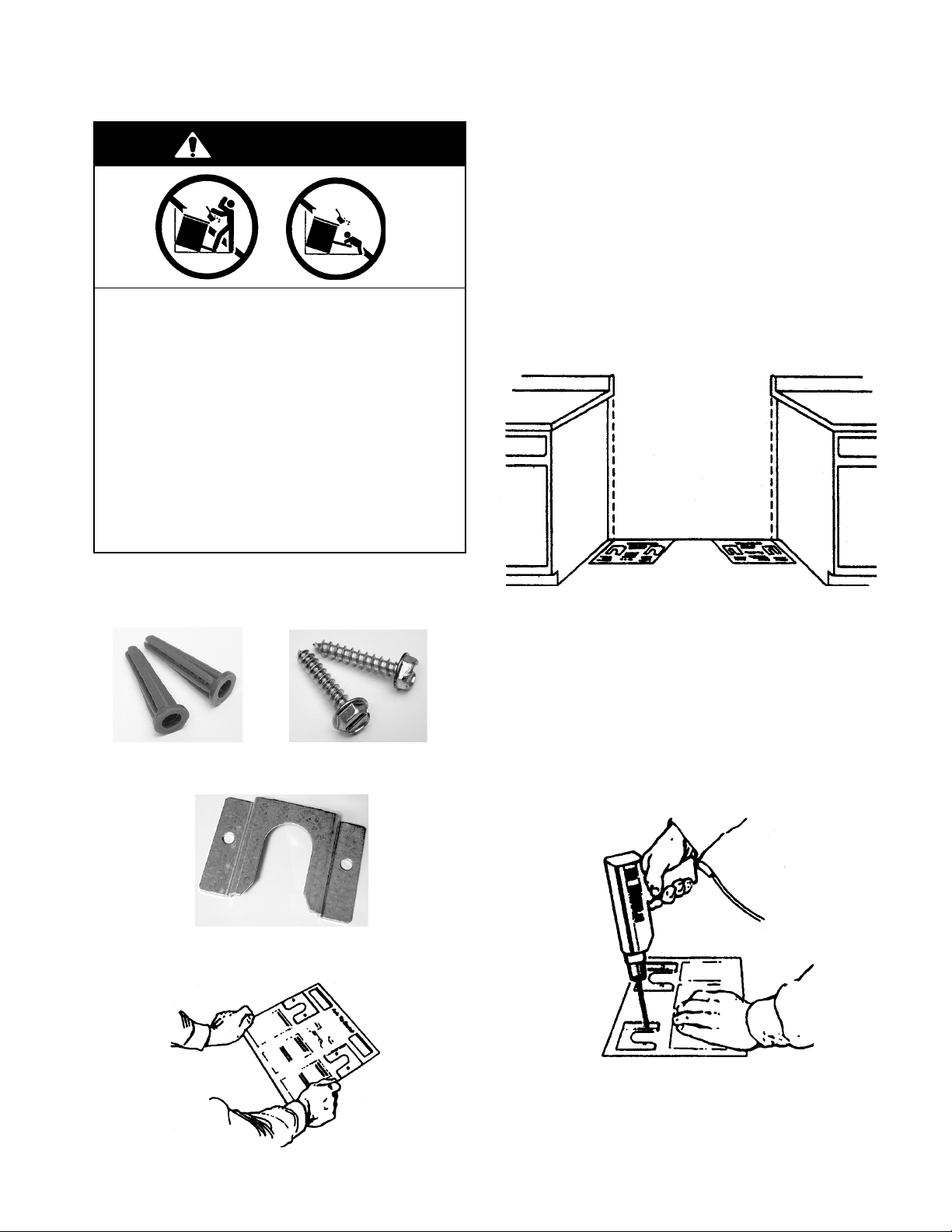

INSTALLING THE ANTI-TIP BRACKET

WARNING

Tip-Over Hazard

A child or adult can tip the range and

be killed.

Connect anti-tip bracket to rear range

foot.

Reconnect the anti-tip bracket, if the

range is moved.

Failure to follow these instructions can

result in death or serious burns to

children and adults.

NOTE: The anti-tip bracket can be installed to

hold either the right or left rear leg of the range.

1. Determine which leg you wish to anchor to

the floor.

2. Place the template on the floor in the

range opening so that the top edge is

against the wall, molding, or cabinet, and

the template is in the location where the

anti-tip bracket will be installed.

3. Tape the template to the floor.

PARTS SUPPLIED

(2) Plastic Anchors (2) Screws

(1) Anti-Tip Bracket

Template

NOTE: For mounting to a wood floor, proceed

with step 4. For concrete or ceramic floors,

proceed to step 5.

4. To mount the anti-tip bracket to a wood

floor:

a)Use the template to mark the hole loca-

tions to be drilled.

b) Use a 1/8″ drill bit and drill the two holes.

Continued on the next page.

2-9

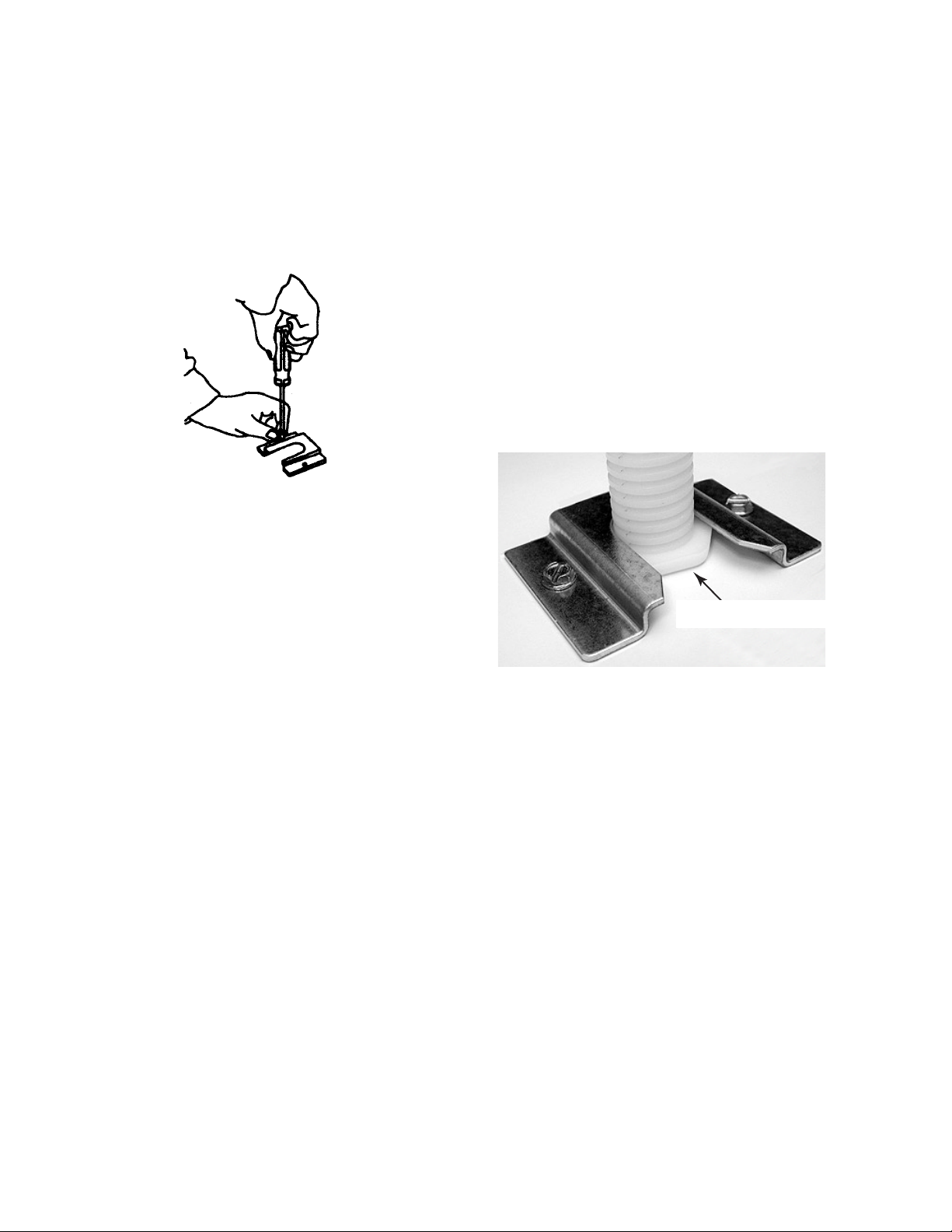

c) Remove the template from the floor.

c) Remove the template from the floor.

d)Line up the two mounting holes in the

anti-tip bracket with the two holes you

just drilled in the floor.

e)Use the two screws that were supplied

and fasten the anti-tip bracket to the

floor.

5. To mount the anti-tip bracket to a con-

crete or ceramic floor:

a)Use the template to mark the hole loca-

tions to be drilled.

d)Tap the two plastic anchors into the

mounting holes with a hammer.

e)Line up the two mounting holes in the

anti-tip bracket with the two holes you

just drilled in the floor.

f) Use the two screws that were supplied

and fasten the anti-tip bracket to the

floor.

6. Move the range close to the cabinet opening and plug the power supply cord into a

grounded outlet.

7. Move the range into position and make

sure that the rear leveling leg slides into

the anti-tip bracket, as shown.

b)Use a 3/16″ drill bit and drill the two

holes.

Slide Leg Into Bracket

2-10

THEORY OF OPERATION

ELECTRONIC OVEN CONTROL SYSTEM FUNCTIONS

BAKE PREHEAT

When the user presses the BAKE key, the control displays Pre in 3-digit display area during

preheat countdown. The BAKE and ON LEDs

are also lit.

If the user queries the set temperature, the

control displays the set temperature, a flashing degree symbol, and a solidly lit temperature scale.

If the user changes the set temperature during the preheat cycle, the countdown continues uninterrupted.

When the preheat countdown expires:

1. The control sounds the preheat end audible signal.

2. The control shows the set temperature in

the 3-digit display area, along with a solidly lit degree symbol.

3. The BAKE and ON LEDs remain lit. The

displayed temperature does not change

unless the user changes the set temperature.

Open Door Preheat

If the door is opened during the preheat cycle:

1. An open door display is shown (door LED).

2. Electric Models: Both bake and broil ele-

ments will turn off at the end of cycle.

3. Gas Models: The broil burner will turn off

as soon as the user opens the door, and

the bake burner will turn off after a 15second delay.

4. The preheat countdown continues in background.

BAKE

If the control receives the door-locked signal

during an active bake function, the control

should perform the following procedure:

1. Moves the door latch to the unlocked

position.

2. Waits for the door-unlocked signal from

the door switch.

3. If the door-unlocked signal is not received,

it terminates the bake function, and sounds

the audible failure signal.

4. If the door-locked signal is discontinued,

the control continues the Bake function.

3-1

Open Door Bake

If the door is opened during a bake cycle:

1. An open door display is shown (door LED).

2. Electric Models: Both bake and broil ele-

ments will turn off at the end of cycle.

3. Gas Models: The broil burner will turn off

as soon as the user opens the door, and

the bake burner will turn off after a 15second delay.

4. Both bake and broil burners will turn off

until the user closes the door, or presses

the OFF/CANCEL key.

CONVECTION BROIL

The convection broil default temperatures are:

• Electric 500°F (260°C)

• Gas HI (525°F) (292°C)

RECALL LAST FAILURE CODE

The oven control will provide visual identification of the last electronic control failure. The

user can recall the last failure code by pressing

and holding the OFF/CANCEL key for 5 seconds. The failure code display is terminated by

pressing the OFF/CANCEL key, unless it is the

OFF/CANCEL key itself that has failed.

BROIL

Electric ranges offer open-door broiling, and

gas ranges offer closed-door broiling.

If the control receives the door-locked signal

during an active broil function, the control

should perform the following procedure:

1. Moves the door latch to the unlocked

position.

2. Waits for the door-unlocked signal from

the door switch.

POWER FAILURE DURING CLEAN

The control will write the state of the clean cycle

to the EEPROM so that when powerup occurs,

the control can follow the cool-down sequence.

The door latch will stay latched.

COOLING FAN

The cooling fan will be on during all cook or

clean functions. In addition, the fan should

remain on after all cook or clean functions until

oven cavity temperature reaches 270°F

(132°F).

KEYBOARD LOCKOUT

Disabling All Cook And Clean Functions

The user disables/enables all oven functions

(Bake, Broil, Clean) by pressing and holding

the START key for 5 seconds. When the user

disables/enables the keyboard lockout, the

control sounds the Enable/Disable audible signal.

Clock and timer functions are still available

during keyboard lockout. The control illuminates the “lock” icon ( ) and the Loc LED

whenever the user has disabled the keyboard.

When the keyboard has been disabled, the

control prompts the user to press and hold the

Oven START key for 5 seconds by illuminating the START? LED whenever the user

presses an oven function key, a timed oven

function key, a temperature, or a time slew.

When the range has powered down, the control stores the status (enabled or disabled) of

the keyboard lockout function in the EEPROM.

Upon power up, the control recalls the keyboard lockout status from the EEPROM.

This feature can only be activated from the

“idle” mode.

3-2

POWER UP

HIDDEN FUNCTION SUMMARY

When the control is powered up, it checks the

oven temperature, the keytail connector and

keypad, illuminates the display, and allows one

minute for a complete oven test.

Power Up Membrane

Switch Connection Test

The keytail connector is checked on power up.

An “Invalid Entry Signal” sounds if the membrane switch tail is not connected.

Illumination At Power Up

The electronic display powers up with the entire vacuum display area illuminated for three

seconds.

The three second time period can be overridden by pressing any key.

Tulsa/Oxford Manufacturing

Test Sequence

This test is available for only the first minute

after power up.

The user activates all of the hidden functions

by pressing and holding the appropriate key

for 5 seconds. The following shows a list of all

the hidden features or functions.

KEY HIDDEN FUNCTION

BAKE Temperature Calibration Offset

BROIL Temperature Scale Selection (°F / °C)

OFF/CANCEL Recall Last Failure Code

START/ENTER* Software Revision Number

TIMER SET Disable / Enable Timer Reminder

Signals

COOK TIME Disable / Enable Cycle End Audible

Signals

STOP TIME Disable / Enable Valid Data Entry

Signals

TBD Audible Signal Pitch Control

* Recall last failure code function or failure mode.

The test is accessed by pressing the CANCEL,

CANCEL, and START keys. The routine will

present a blank display, then any system or

control failures will be detected in two seconds.

Exit the test sequence by pressing the OFF/

CANCEL key.

3-3

— NOTES —

3-4

COMPONENT ACCESS

This section instructs you on how to service each component inside the Self-Cleaning Slide-In Gas

Range. The components and their locations are shown below.

COMPONENT LOCATIONS

Not Shown: Electronic Oven Control

Gas Valves /

Ignition Switches

Spark Module

(DSI)

Cooktop Components

Control

TOD

Door Latch

Assembly

Cooling Fan

TOD

Oven & Rear Components

Surface Burner

& Ignitor (4 ea)

Gas Valves /

Ignition Switches

Broil Burner

& Ignitor

Oven Light

Bake Burner

& Ignitor

Cooling Fan

(Rear Of Unit)

Oven

Temperature

Sensor

Oven TOD

(Rear Of Unit)

Gas Distribution Valve

(Rear Of Unit)

4-1

REMOVING THE CONTROL PANEL AND THE ELECTRONIC

OVEN CONTROL BOARD & USER INTERFACE

4. To remove the control panel:

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

a) Pull the knobs off the gas valves.

b) Remove the two screws from the sides

of the end caps.

Screw

Right

End Cap

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Remove the two grates from the top of the

range.

Grates

c) Open the oven door and remove the six

screws from the bottom of the control

panel (two end cap screws and four

control panel screws).

End Cap Screw (2) Control Panel Screw (4)

d) Close the oven door.

e) Pull the control panel forward and re-

move the two end caps.

f) Disconnect the wire connectors from

the electronic oven control board at P2,

P3, and P4.

Electronic Oven

Control Board

4-2

P4

P3 P2

5. To remove the electronic oven control

board:

a) Remove the control panel (see step 4).

b) Disconnect the ribbon cable from con-

nector P1.

c) Remove the three screws from the elec-

tronic oven control board. Lift the bottom of the board slightly, slide the top

edge out from under the holders, and

remove the board.

d) Remove the four screws from the con-

trol panel bracket and remove the

bracket.

Control Panel Bracket Screws

e) Lift one of the corners, and peel the

user interface off the control panel.

3 Screws

Ribbon Cable P1

Holders

6. To remove the user interface:

a) Remove the control panel (see step 4).

b) Remove the electronic oven control

board (see step 5).

c) Remove the two screws from the elec-

tronic oven control board bracket and

remove the bracket.

Board Bracket Screws

Peel Off

User Interface

4-3

REMOVING THE IGNITION SWITCHES, A GAS VALVE,

AND THE CONTROL AND COOLING FAN TODS

1. Unplug range or disconnect power.

WARNING

2. Turn off gas supply to range.

3. Remove the two grates from the top of the

range.

4. Remove the control panel (see step 4 on

page 4-2 for the procedure).

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

L1

BK

BK

DOOR

SWITCH

OVEN

TEMP

SENSOR

COM

N.O.

t

Y

Y

V

°

V

OVEN CONTROL

P4-3

Y

P3-3

Y

P3-4

V

P3-6

V

P3-7

TRANSFORMER

OVEN LIGHT RELAY

K-4

LATCH RELAY

K-3

COOLING

FAN RELAY

K-8

Left Gas Valves &

Ignition Switches

Control TOD (N.C.)

Opens @ 96°C (205°F)

Resets @ 74°C (165°F)

P4-1

P4-4

P4-5

P4-7

W

CONTROL TOD

BK/W

LATCH DRIVE

BR

GY

96.1

(205

°±3°

°±6°

M

C

F)

OVEN LIGHT 1

OVEN LIGHT 2

Right Gas Valves &

Ignition Switches

Cooling Fan TOD (N.O.)

Resets @ 70°C (158°F)

Closes @ 60°C (140°F)

N

W

GND

WW

OVEN TOD

120

°

+10°-0°C

()

248

°

+18°-0°F

W

W

COOLING

FAN M OTO R

W

M

DOOR LATCH

SWITCH

N.O.

BU

P3-1

P3-2

BROIL RELAY

K-2

GND

P2-2

BAKE RELAY

G

K-1

BK

BK

P2-1

P2-4

BK

BK

SURFACE BURNER

IGNITION SWITCHES

BK

BK

BU

BU

R

COM

COOLING FAN TOD

°±3°

C

70

°±6°

(158

GY

F)

4-4

5. To remove the ignition switches:

NOTE: The ignition switches must be replaced

as an assembly. They cannot be replaced individually.

a) Pull the ignition switches and unsnap

them from the gas valves, then remove

them from the valve stems.

b) Disconnect the ignition switch wire con-

nector from the main harness and remove the switches.

Ignition Switch

Connector

7. To remove a control or cooling fan

TOD:

a) Remove the wires from the terminals.

b) Remove the mounting screw.

Control Or Cooling Fan TOD

REASSEMBLY NOTES:

Ignition Switches

6. To remove a gas valve:

a) Remove the ignition switch from the gas

valve you are servicing (see step 5).

b) Remove the 1/2″ gas line connector

from the gas valve.

c) Remove the 1/4″ hex-head gas valve

mounting screw and its rubber seal

from the front of the gas manifold.

1/2″ Gas Line

Connector

Gas Valve

• Before reinstalling the gas valve, make sure

that the rubber seals on the mounting screw,

and on the valve, are not cracked or damaged. If they are, replace them.

• Perform a leak check on the gas valve after

reinstalling it. Use a soap bubble method to

perform the check.

Seals

Gas Valve Screw

4-5

REMOVING THE DOOR LATCH ASSEMBLY

AND THE SPARK MODULE (DSI)

b) Remove the two top screws from the

WARNING

door latch assembly bracket.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Remove the two grates from the top of the

range.

4. Remove the control panel (see step 4 on

page 4-2 for the procedure).

Top Door Latch Screws

c) Pull the door latch assembly forward as

far as it will go, and disconnect the

wires from the terminals of the two

switches and the motor.

d) Remove the door latch assembly from

the unit.

Motor White Brown

Door Switch

(2 Yellow)

Spark Module Door Latch Assembly

5. To remove the door latch assembly:

a) Open the oven door and remove the

two front mounting screws from the air

vent.

Front Door Latch Screws

Latch Switch

(2 Blue)

4-6

6. To remove the spark module (DSI):

a) Remove the bracket mounting screw.

Spark Module Screw

b) Pull the spark module forward as far as

it will go and disconnect the wires from

the terminals, then remove the spark

module from the unit.

c) Remove the spark module mounting

screw from the bracket and remove the

module from the bracket.

J1

BU OR RD YL

Module Screw

GN WH BN

4-7

REMOVING THE COOKTOP, AND A

SURFACE BURNER & IGNITOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

5. Remove the control panel (see step 4 on

page 4-2 for the procedure).

6. Remove the two screws from each of the

burner heads and lift the heads off the

cooktop.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Pull the range out of its mounting location

so that you can access the rear of the unit.

4. Remove the grates, the vent cover, and

the burner caps from the top of the range.

Grates

Vent

Cover

Burner Cap (4)

Burner Head

W/2 Screws

7. To remove the cooktop:

a) Remove the three screws from the front

cooktop bracket and remove the

bracket.

3 Cooktop Bracket Screws

b) Remove the screws from the left, right,

and rear trim pieces and remove the

trim from around the cooktop.

4-8

Side Trim

Screws

Rear Trim

Screws

c) Lift the cooktop off the top of the unit

and set it aside.

e) Remove the two hex-head bracket

screws and remove the burner from the

bracket.

Bracket Screws

9. To remove an ignitor:

a) Remove the surface burner from the

burner box (see step 8).

b) Remove the screw from the ignitor.

8. To remove a surface burner:

a) Remove the cooktop (see step 7).

b) Remove the gas line.

c) Disconnect the ignitor wire from the

terminal.

d) Remove the two bracket screws from

the burner box.

Surface Burner

Ignitor Wire

Gas Line Nut

Bracket Screw (1 of 2)

Ignitor Screw

4-9

REMOVING THE REAR PANEL

WARNING

5. Remove the eleven screws from the rear

panel and remove the panel.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Pull the range out of its mounting location

so that you can access the rear of the unit.

4. From the rear of the unit, remove the four

screws from the top bracket and remove

the bracket.

Top Bracket

Screw

(1 of 11)

Rear Panel

4 Screws

4-10

REMOVING AN OVEN LIGHT SOCKET ASSEMBLY

5. Unscrew the lens and bulb from the oven

WARNING

Electrical Shock Hazard

light socket assembly and remove them.

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Open the oven door, remove the racks

from inside the oven, then close the oven

door.

4. Pull the range out of its mounting location

so that you can access the rear of the unit.

Oven Lights

Oven Lens & Bulb

6. Remove the rear panel from the unit (see

page 4-10 for the procedure).

7. Disconnect the two wire connectors from

the oven light socket terminals.

8. Move the insulation out of the way, and

press in on the two locking tabs of the oven

light socket, then push the socket out of

the liner opening.

Socket Tab

Oven Light Socket

4-11

Oven Light Socket

REMOVING THE BROIL BURNER AND IGNITOR

4. To remove the ignitor from the broil

WARNING

burner:

a) Remove the ignitor cover screw and

remove the cover from the liner.

b) Remove the two 5/16″ hex-head

screws from the ignitor bracket.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Open the oven door, remove the racks

from inside the oven, then close the oven

door.

Broil Burner & Ignitor

Ignitor Cover

Broil Ignitor Screws

c) Pull the ignitor into the oven and dis-

connect the wire from the terminal.

Ignitor Wire

Broil Ignitor

4-12

5. To remove the broil burner:

a) Remove the ignitor from the broil burner

(see step 4).

b) Remove the rear screw from the broil

burner.

c) Loosen the front broil burner screw,

slide the burner off the orifice, and

remove the burner.

Front Screw

Broil Burner

Orifice

Rear Screw

4-13

REMOVING THE BAKE BURNER AND IGNITOR

5. Remove the four screws from the flame

WARNING

spreader and remove the spreader.

Flame Spreader

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Open the oven door, remove the racks

from inside the oven, then close the oven

door.

Bake Burner &

Ignitor Location

2 Screws

6. To remove the bake burner:

a) Remove the screw from the bake burner

bracket.

b) Lift the bake burner off the gas orifice

and slide it back to remove the front

from the chassis slot. Position the burner

and ignitor so you can lift it out of the

lower section of the oven.

2 Screws

Screw

4. Lift the bake burner cover off the flame

spreader.

Bake Burner Cover

Bake Burner

4-14

c) Disconnect the wire from the ignitor

terminal.

Ignitor Wire

7. To remove the ignitor from the bake

burner:

a) Remove the bake burner from the unit

(see step 6).

b) Remove the two 5/16″ hex-head screws

from the ignitor bracket, and slide the

end of the ignitor out of the support.

Ignitor Screws

Support

4-15

REMOVING THE OVEN TEMPERATURE SENSOR

5. Remove the rear panel (see page 4-10 for

WARNING

Electrical Shock Hazard

the procedure).

6. Disconnect the oven temperature sensor

connector from the wiring harness.

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Open the oven door, remove the racks

from inside the oven, then close the oven

door.

4. Pull the range out of its mounting location

so that you can access the rear of the unit.

Oven Temperature Sensor

Sensor Connector

7. From inside the oven, remove the screws

from the temperature sensor and remove

the sensor.

Oven Temperature Sensor

4-16

Sensor Screws

REMOVING THE COOLING FAN

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

5. Use a 90° screwdriver, and remove the

two screws from each end of the cooling

fan cover, then remove the cover.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Pull the range out of its mounting location

so that you can access the rear of the unit.

4. Remove the rear panel (see page 4-10 for

the procedure).

Cooling Fan

Cooling Fan

Cover

6. Remove the four screws from the cooling

fan and remove the fan from the bracket.

Cooling Fan Screws

7. Disconnect the two cooling fan wires from

the motor terminals.

Screws

(2 of 4)

4-17

Motor Wires

REMOVING THE OVEN TOD

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Pull the range out of its mounting location

so that you can access the rear of the unit.

4. Remove the rear panel (see page 4-10 for

the procedure).

Wire Connector

Screw (1 of 2)

Wire Connector

Oven TOD

5. Remove the two wire connectors from the

oven TOD terminals.

6. Remove the two screws from the oven

TOD and remove it.

OVEN CONTROL

TRANSFORMER

4-3

OVEN LIGHT RELAY

K-4

3-3

LATCH RELAY

3-4

K-3

3-6

COOLING

FAN RELAY

K-8

3-7

P4-1

P4-4

P4-5

P4-7

W

CONTROL TOD

96.1

(205

BK/W

LATCH DRIVE

BR

GY

°±3°

°±6°

M

C

F)

N

GND

WW

OVEN LIGHT 1

OVEN LIGHT 2

OVEN TOD

120

°

+10°-0°C

()

248

°

+18°-0°F

COOLING

FA N M OT OR

M

W

W

W

W

4-18

REMOVING THE GAS DISTRIBUTION VALVE

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Pull the range out of its mounting location

so that you can access the rear of the unit.

4. Disconnect the gas lines from the gas

distribution valve.

5. Remove the four screws from the gas

distribution valve, pull it down to remove

the orifice from the bake burner, and lay it

down so you can access the wires.

Gas Outlet Lines

Screws (2 of 4)

Gas Inlet Line

Gas Distribution Valve

NOTE: For servicing the Gas Distribution System, refer to Job Aid KR-28, Part Number

8177893.

6. Disconnect the three wires from the gas

distribution valve terminals.

Red

Orange

Blue

4-19

Oven Shutoff Valve

REMOVING THE POWER SUPPLY CORD

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

5. Disconnect the power supply cord connector from the main harness connector.

6. Remove the green ground wire screw

from the power supply cord.

7. Release the strain relief from the power

cord and remove the cord from the unit.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Pull the range out of its mounting location

so that you can access the rear of the unit.

4. Remove the rear panel (see page 4-10 for

the procedure).

Power Supply Cord

Power Supply

Cord Connector

Green Ground Wire

Strain Relief

4-20

REMOVING A SIDE PANEL

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Pull the range out of its mounting location

so that you can access the rear of the unit.

5. Remove the bottom rear screw for the side

panel you are removing.

6. Pull the back of the side panel out so it

clears the mounting bracket, then slide the

panel back until the top and bottom brackets are in the panel cutouts, then remove

the panel.

Top Bracket

4. Remove the top bracket (see page 4-10

for the procedure).

Top Cutout

Bottom Cutout

Left Side

Panel Screw

Bottom Bracket

4-21

REMOVING & REINSTALLING THE OVEN DOOR

To remove the oven door:

1. Fully open the door.

2. Rotate the locking arm on the door hinge

from the locked “down” position, to the

unlocked “up” position.

Locking Arm In The

Locked “Down” Position

3. Close the door to within six to eight inches,

then pull out on the bottom of the door

while slowly closing the door, and remove

the hinge hangers from the slots in the

chassis.

Close

To Remove Door

Pull Out

Locking Arm In The

Unlocked “Up” Position

To reinstall the oven door:

1. While tilting the door back slightly from a

vertical position, insert the hinge hangers

into the chassis slots as far as they will go.

Continue to push in on the bottom, and

fully open the door.

2. Rotate the locking arm on the hinge hangers to the locked, or fully “down” position.

3. Open and close the oven door to make

sure that it operates and seals properly.

4-22

REMOVING THE OVEN DOOR GASKET

1. Fully open the oven door.

2. Remove the screw from the door gasket

cover and remove the cover.

Gasket Cover

3. Starting at one end of the door gasket, pull

the clips out of the liner holes, and remove

the gasket.

Pull Gasket Clips

Out Of Liner Holes

REASSEMBLY NOTE: After the door gasket

is installed, make sure that it is even along the

surface of the door when the door is closed.

4-23

REMOVING THE DECORATIVE GLASS AND OVEN DOOR

HANDLE, THE HINGES, AND THE OVEN DOOR GLASS

1. Remove the oven door from the range

(see page 4-22 for the procedure).

2. Place the oven door on a padded work

surface with the decorative glass and

handle facing up and the bottom edge

facing the front.

3. To remove the decorative glass and

handle:

a) Remove the screw from each of the two

decorative glass retainers, and remove

the retainers.

Decorative Glass Retainers

b) Turn the door 180° so the handle faces

the front.

c) Remove the two door handle bracket

screws.

d) Lift the bottom of the decorative glass

and slide it down so the top clears the

lip of the liner, then lift the glass and

handle off the door liner assembly.

e) Remove the two door handle screws

from each of the brackets and remove

the handle from the decorative glass.

Door Handle Bracket Screws

4. To remove a hinge:

a) Remove the decorative glass and

handle from the door liner (see step 3).

b) Position the oven door liner with the

inner glass facing up.

c) Remove the two screws from the hinge

you are servicing.

d) Lift the door liner and remove the hinge.

Inner Glass

Hinge Screws

Door Handle Bracket Screws

5. To remove the two pieces of outer oven

door glass:

a) Remove the decorative glass and

handle from the door liner (see step 3).

4-24

b) Position the door liner with the outer

oven glass facing up, as shown.

c) Remove the two screws from the lower

bracket for the outer oven glass.

d) Slide the lower bracket off the first piece

of outer oven glass, then slide the glass

out of the top retainer tabs.

Top Retainer Tabs

6. To remove the inner oven door glass:

a) Remove the decorative glass and

handle from the door liner (see step 3).

b) Remove the two hinges (see step 4).

c) Remove the first piece of outer door

glass (perform steps 5b through 5d).

d) Remove the two inner door liner screws

and lift the inner liner off the outer liner.

Inner Liner Screws

Outer Glass #1

Lower Outer Glass Bracket Screws

e) Remove the three screws from the top

retainer and remove the retainer from

the liner.

Top Retainer Screws

Outer Glass #2

Inner Glass

Inner Liner

e) Lift the inner oven door glass off the

outer liner.

Inner Glass

Outer Liner

f) For the second piece of outer oven

glass, remove the two screws from the

left bracket, then remove the bracket

and second piece of glass from the

door liner.

Outer Glass #2

Left Bracket Screws

4-25

— NOTES —

4-26

COMPONENT TESTING

Before testing any of the components, perform

the following checks:

• The most common cause for control failure is

corrosion on connectors. Therefore, disconnecting and reconnecting wires will be necessary throughout test procedures.

• All tests/checks should be made with a VOM

or DVM having a sensitivity of 20,000 ohmsper-volt DC, or greater.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

CONTROL & COOLING FAN TODs

• Check all connections before replacing components, looking for broken or loose wires,

failed terminals, or wires not pressed into

connectors far enough.

• Resistance checks must be made with power

cord unplugged from outlet, and with wiring

harness or connectors disconnected.

WARNING

Refer to page 4-4 for the procedure for servicing the control and cooling fan TODs.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Disconnect one of the wires from the TOD

under test.

4. Set the ohmmeter to the R x 1 scale.

5. For the control TOD (N.C.), touch the

ohmmeter test leads to the terminals. The

meter should indicate continuity (0 Ω).

6. For the cooling fan TOD (N.O.), touch

the ohmmeter test leads to the terminals.

The meter should indicate an open circuit

(infinite).

Control TOD (N.C.)

Opens @ 96°C (205°F)

Resets @ 74°C (165°F)

Cooling Fan TOD (N.O.)

Resets @ 70°C (158°F)

Closes @ 60°C (140°F)

5-1

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

IGNITION SWITCHES

Refer to page 4-4 for the procedure for servicing the ignition switches.

NOTE: The ignition switches are connected to

each other in a parallel circuit so that if one

switch fails, the others will still operate. To

check each of the ignition switches for proper

operation, perform the following steps.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Remove the control panel and access the

ignition switch connector (see page 4-2 for

the procedure).

4. Reinstall the knobs on the valve stems.

5. Disconnect the ignition switch connector

from the wire harness.

6. Set the ohmmeter to the R x 1 scale.

7. Connect the ohmmeter test leads to the

pins of the spark module connector.

8. Press and turn one of the gas valve knobs

to the LITE position. At that point, the

switch should close, and the meter should

indicate continuity.

9. Continue to turn the knob away from the

LITE position. The switch should open,

and the meter should indicate an open

(infinite ∞) circuit.

10. Repeat steps 8 and 9 for the other ignition

switches. If the readings are not as stated,

replace the entire ignition switch assembly. They are supplied as an assembly and

cannot be changed individually.

5-2

WARNING

(°F)

(°C)

(Ω)

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

DOOR LATCH ASSEMBLY OVEN TEMPERATURE SENSOR

Motor

Door Switch

Refer to page 4-16 for the procedure for servicing the oven temperature sensor.

1. Unplug range or disconnect power.

Latch Switch

Refer to page 4-6 for the procedure for servicing the door latch assembly.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Disconnect one of the wires from the door

latch assembly component under test.

4. Set the ohmmeter to the R x 1 scale.

5. To test the motor, touch the ohmmeter

test leads to the terminals. The meter

should indicate between 2.6K and 3K Ω.

6. To test the door switch & latch switch:

a) Touch the ohmmeter test leads to the

COM and N.O. terminals. The meter

should indicate an open circuit (infinite).

b) With the ohmmeter leads connected as

stated in the previous step, press the

switch actuator. The meter should indicate continuity (0 Ω).

2. Turn off gas supply to range.

3. Disconnect the oven temperature sensor

connector.

4. Set the ohmmeter to the R x 1K scale.

5. Touch the ohmmeter test leads to the

oven temperature sensor connector pins.

The meter should indicate as shown in the

chart below.

Temperatures

32 0 1000

7 5 2 5 1100

20 0 9 5 1350

250 120 1450

35 0 175 1650

4 5 0 23 0 1850

550 290 2050

650 350 2240

865 4 6 5 2630

900 4 8 0 2700

Temperatures

Resistance

5-3

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

COOLING FAN MOTOR

Refer to page 4-17 for the procedure for servicing the cooling fan motor.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Disconnect one of the wires from the cooling fan motor.

4. Set the ohmmeter to the R x 1 scale.

5. Touch the ohmmeter test leads to the

cooling fan motor terminals. The meter

should indicate between 3 and 6 Ω.

OVEN TOD

Refer to page 4-18 for the procedure for servicing the oven TOD.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Disconnect the wires to the oven TOD

terminals.

4. Set the ohmmeter to the R x 1 scale.

5. Touch the ohmmeter test leads to the

oven TOD terminals. The meter should

indicate a closed circuit (0 Ω).

5-4

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

GAS DISTRIBUTION VALVE

Blue

Orange

Red

Refer to page 4-19 for the procedure for servicing the gas distribution valve.

1. Unplug range or disconnect power.

2. Turn off gas supply to range.

3. Remove the storage drawer. NOTE: You

can access the gas distribution valve from

inside the drawer area.

GAS VALVE

Refer to page 4-4 for the procedure for servicing the gas valves.

To test a gas valve, use a low-pressure manometer, and measure the inlet and outlet pressure across the valve. There should be no pressure drop. If there is a pressure drop, the valve

should be replaced.

4. Disconnect the wires from the gas distribution valve terminals.

5. Set the ohmmeter to the R x 1 scale.

6. Touch the ohmmeter test leads to the

indicated gas distribution valve terminals.

The meter should read as follows:

Terminal 1 (red) to terminal 2 (orange)

= 216 Ω ±30.

Terminal 2 (orange) to terminal 3 (blue)

= 216 Ω ±30.

5-5

CLOCK

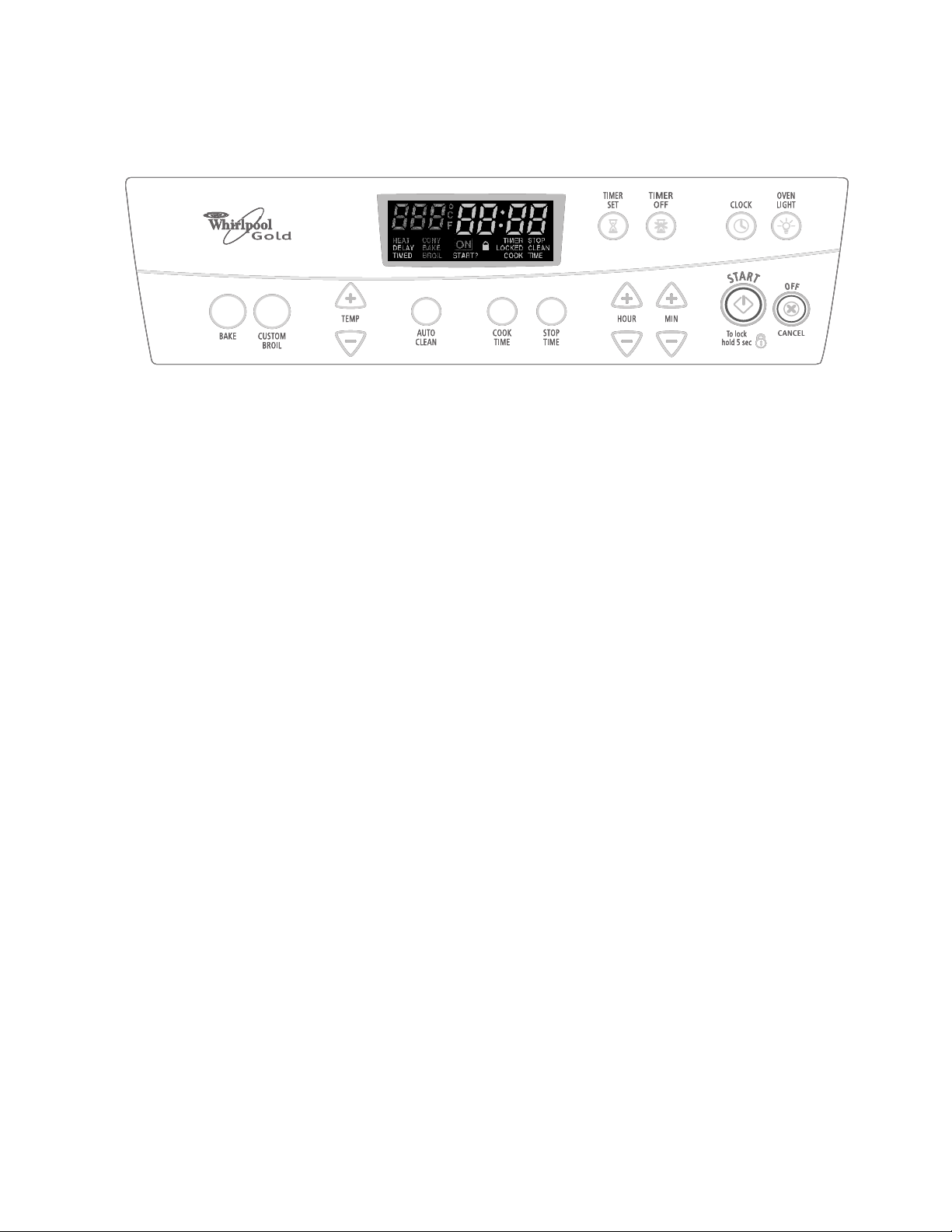

KEYPAD LAYOUT

BAKE

BROIL

CLEAN

TEMP UP

TEMP DOWN

COOK TIME

1234567891011121314151617181920

STOP TIME

TIMER SET

TIMER OFF

CLOCK

OVEN LIGHT

HOUR UP

MINUTE UP

HOUR DOWN

MINUTE DOWN

START

OFF/CANCEL

5-6

DISPLAY BOARD & CONNECTOR PINOUTS

5-7

— NOTES —

5-8

DIAGNOSTICS & TROUBLESHOOTING

DIAGNOSTICS

• All diagnoses of this range must begin with a

normal check of the line voltage, blown fuses,

and failed components.

FAILURE/ERROR DISPLAY CODES

• All units that have failed during the first few

days of use should be checked for loose

connections, or miswiring.

• All checks should be made with a meter

having a sensitivity of 20,000 ohms-per-volt,

or greater.

6-1

HIDDEN EOC FUNCTIONS

TEMPERATURE ADJUSTMENT

The user activates all hidden EOC functions by

pressing and holding the appropriate key for 5

seconds. The chart shows the hidden functions or features.

HIDDEN FUNCTIONS KEY

Temperature calibration offset Bake

°Fto°C Broil

Recall last failure code Off/Cancel

Disable/enable cycle end audible

signal

Cook Time

Disable/enable reminder signal Timer Set

Disable/enable valid data entry

signals

Stop Time

1. Press and hold the BAKE keypad for five (5)

seconds. The current offset, if any, will be

shown in the 3-digit display. CAL is shown

in the 4-digit display (3 digits on right).

2. Pressing the TEMP keypad “up” arrow (s)

adjusts the temperature in 5.6°C (10°F)

increments in the following sequence: Celsius: 0°, 5.6°, 11.1°, 16.7°,–16.7° –11.1°,

–5.6°, 0°, (Fahrenheit: 0°, 10°, 20°, 30°,

–30°, –20°, –10°, 0°), and so on.

3. Press the START/ENTER keypad to activate the desired temperature adjustment. If

the START/ENTER keypad is not pressed

within 5 minutes, the adjustment is ignored.

4. BAKE temperature adjustment cannot result in operating temperatures higher than

274°C (525°F), or lower than 77°C, (1 70°F),

as measured at oven cavity center.

5. Once the BAKE temperature has been adjusted, BROIL temperatures are automatically offset to the same degree.

6. The CLEAN temperature is also offset automatically when the BAKE temperature is

adjusted. If the BAKE temperature has been

raised, the CLEAN temperature is offset

+3°C (+5°F). If the BAKE temperature has

been lowered, the CLEAN temperature is

offset –3°C (–5°F).

6-2

EZ354

Test Mode: Available for the first 60 seconds after power up.

Enter the Test Mode by pressing:

CANCEL

CANCEL

START

Any system or control failures will be displayed within 2 seconds.

NORMAL DISPLAY ERROR DISPLAY

Exit the Test Mode by pressing the OFF/CANCEL key.

To recall the last error code, press the OFF/CANCEL key for 5 seconds.

Pressing the indicated keys will show the following displays:

Convection

Bake

Bake

Custom

Broil

Temp +

Temp –

Auto Clean

WILL CYCLE LATCH MOTOR

Min +

Clock

WILL CHECK BUZZER

OFF/CANCEL

EXIT TEST MODE

Hidden Functions

Holding the appropriate key for 5 seconds will activate the hidden function:

BAKE Temperature Calibration Offset

BROIL Temperature Scale Selection (°F / °C)

OFF/CANCEL Recalls The Last Failure Code

START/ENTER Software Revision Number

TIMER SET Disables/Enables Timer Reminder Signals

COOK TIME Disables/Enables Cycle End Signals

STOP TIME Disables/Enables Valid Date Entry Signals

6-3

TROUBLESHOOTING CHART

PROBLEM

Oven will not operate. Electronic oven control is not set prop-

Burner fails to light.

Burner flames are uneven. Burner ports are clogged. Clean burner ports with straight pin.

Burner flames lift off ports, are yellow, or are noisy when turned off.

on.

Burners spark.

Control knob will not turn. Press in on the knob before turning. If knob is still hard to turn, replace the

The self-clean cycle will not operate.

“PF” shows on the display. There has been a power failure.

A failure code (E3, F1, etc.) is showing on the display.

The keypads do not operate. The Control Lock has been set.

POSSIBLE CAUSE

erly.

A delay start has been programmed.

Range is not plugged in.

A household fuse or circuit breaker

has opened.

Burner ports are clogged.

The air-to-gas mixture is incorrect.

Burner is wet.Burner makes “popping” noise when

It is normal for all four burners to

spark briefly when:

• A draft is blowing on the burners.

• A very large pot on burner causes

flame to be unstable.

• The burner is turned on but has not

ignited.

Continuous sparking may be caused

when:

• A switch contact is wet.

• There is a faulty spark module.

• The wall outlet wiring is not

correct.

A delay start time has been programmed.

The cooling fan is not running.

Press the CANCEL/OFF keypad.

SOLUTION

Reset the oven control (see the Use &

Care Guide for instructions describing the function you are operating).

Wait for the start time to be reached.

Plug power cord into a live AC outlet.

Replace fuse or reset the breaker.

Clean burner ports with straight pin.

Adjust air shutters for bake or broil

burners.

Top burner ports are clogged. Clean

or replace burner.

Allow burner to dry.

Allow switch to dry.

Replace the spark module.

Rewire wall outlet.

gas valve.

Wait for the start time to be reached.

Check the cooling fan wiring.

Test the control panel shutdown switch.

Replace the motor.

Reset the clock.

If the code does not disappear, refer

to page 6-1, and identify the cause of

the error message to help you correct

the problem.

Press and hold the Control Lock keypad for 5-seconds to unlock the keypads.

The range is not properly grounded.

6-4

WIRING DIAGRAM & STRIP CIRCUITS

WIRING DIAGRAM

L1

BK

BK

BK

DOOR

SWITCH

OVEN

TEMP

SENSOR

COM

N.O.

t

N

W

GND

OVEN CONTROL

TRANSFORMER

P4-3

OVEN LIGHT RELAY

K-4

Y

Y

P3-3

Y

Y

V

°

V

P3-4

V

P3-6

V

P3-7

P2-2

LATCH RELAY

K-3

COOLING

FAN RELAY

K-8

BROIL RELAY

K-2

P4-1

P4-4

P4-5

P4-7

P3-1

P3-2

P2-1

W

CONTROL TOD

BK/W

LATCH DRIVE

BR

GY

BU

BU

BU

96.1

(205

N.O.

COM

°±3°

°±6°

M

C

F)

OVEN LIGHT 1

OVEN LIGHT 2

DOOR LATCH

SWITCH

WW

OVEN TOD

120

°

+10°-0°C

()

248

°

+18°-0°F

W

W

COOLING

FAN MO TOR

W

M

BK

BK

GND

BK

SURFACE BURNER

IGNITION SWITCHES

BK

DSI

G