Whirlpool GU1200XT, GU1500XT User Manual

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

POINT VOYAGER DISHWASHER

KD-12

MODEL NUMBERS:

GU1200XT

GU1500XT

JOB AID

Part No. 8178022

I

INTRODUCTION

This Job Aid, POINT VOYAGER DISHWASHER, Part No. 8178022 provides specific information on

the operation, diagnosis and repair of the Whirlpool Point Voyager series Undercounter Dishwasher.

POINT VOYAGER DISHWASHER has been compiled to provide the most recent information on design, features, operation, troubleshooting, and repair procedures.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Point Voyager dishwasher.

The objectives of the Job Aid are:

The service technician will -

• Understand proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the dishwasher to proper operational status.

WHIRLPOOL CORPORATION ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS BY ANYONE

OTHER THAN AUTHORIZED SERVICE TECHNICIANS.

© 2000 Whirlpool Corp., Benton Harbor, MI 49022

PB

TABLE OF CONTENTS

MODEL/SERIAL NUMBER DESIGNATORMODEL/SERIAL NUMBER DESIGNATOR

MODEL/SERIAL NUMBER DESIGNATOR

MODEL/SERIAL NUMBER DESIGNATORMODEL/SERIAL NUMBER DESIGNATOR

Section One

INSTALLATION CONSIDERATIONSINSTALLATION CONSIDERATIONS

INSTALLATION CONSIDERATIONS

INSTALLATION CONSIDERATIONSINSTALLATION CONSIDERATIONS

GENERAL CONSIDERATIONS...............................................................1

SPECIFICA-SPECIFICA-

SPECIFICA-

SPECIFICA-SPECIFICA-

TIONS....................................................................................TIONS....................................................................................

TIONS....................................................................................

TIONS....................................................................................TIONS....................................................................................

22

2

22

Section Two

THEORY OF OPERATIONTHEORY OF OPERATION

THEORY OF OPERATION

THEORY OF OPERATIONTHEORY OF OPERATION

CONTROL PANEL ...................................................................................3

Model: GU1200XTK

Cycle Selection Chart .................................................................. 3

Option Selection ..........................................................................5

Cycle Status Indicators ...............................................................6

CONTROL PANEL ...................................................................................7

Model: GU1500XTK

Cycle Selection Chart .................................................................. 7

FUNCTION DESCRIPTION......................................................................9

............................................................................

......................................

............................................................................

....................................................

..........................

....................................................

............................................................

..............................

............................................................

iviv

iv

iviv

11

1

11

33

3

33

Section Three

COMPONENT ACCESSCOMPONENT ACCESS

COMPONENT ACCESS

COMPONENT ACCESSCOMPONENT ACCESS

COMPONENT LOCATION.....................................................................13

ACCESSING COMPONENTS IN THE DOOR ....................................... 14

ACCESSING COMPONENTS INSIDE THE TUB ..................................17

ACCESSING COMPONENTS OF THE PUMP ASSEMBLY .................20

SERVICING THE DOOR HINGE....................................................................23

Section Four

TROUBLESHOOTING AND DIAGNOSISTROUBLESHOOTING AND DIAGNOSIS

TROUBLESHOOTING AND DIAGNOSIS

TROUBLESHOOTING AND DIAGNOSISTROUBLESHOOTING AND DIAGNOSIS

TROUBLESHOOTING CHART.............................................................. 25

COMMON CYCLE TIME CHART...........................................................26

HOW TO USE COMMON CYCLE TME ................................................. 28

COMMON CYCLE TIME CHART NOTES ............................................. 31

DIAGNOSTIC CYCLE TIME CHART.....................................................35

RAPID ADVANCE FEATURE & DIAGNOSTIC CYCLES...................... 36

Section Five

TECH TIPSTECH TIPS

TECH TIPS

TECH TIPSTECH TIPS

WIRING DIAGRAM ................................................................................ 37

MODEL SPECIFIC SERVICE PARTS TABLE .......................................38

USER INTERFACE SWITCH MATRIX...................................................38

STRIP CIRCUITS ................................................................................... 39

ELECTRONIC CONTROL CONNECTOR PINS ....................................40

..............................................................................................

...............................................

..............................................................................................

................................................................................

........................................

................................................................................

......................................................

...........................

......................................................

1313

13

1313

2525

25

2525

3737

37

3737

III

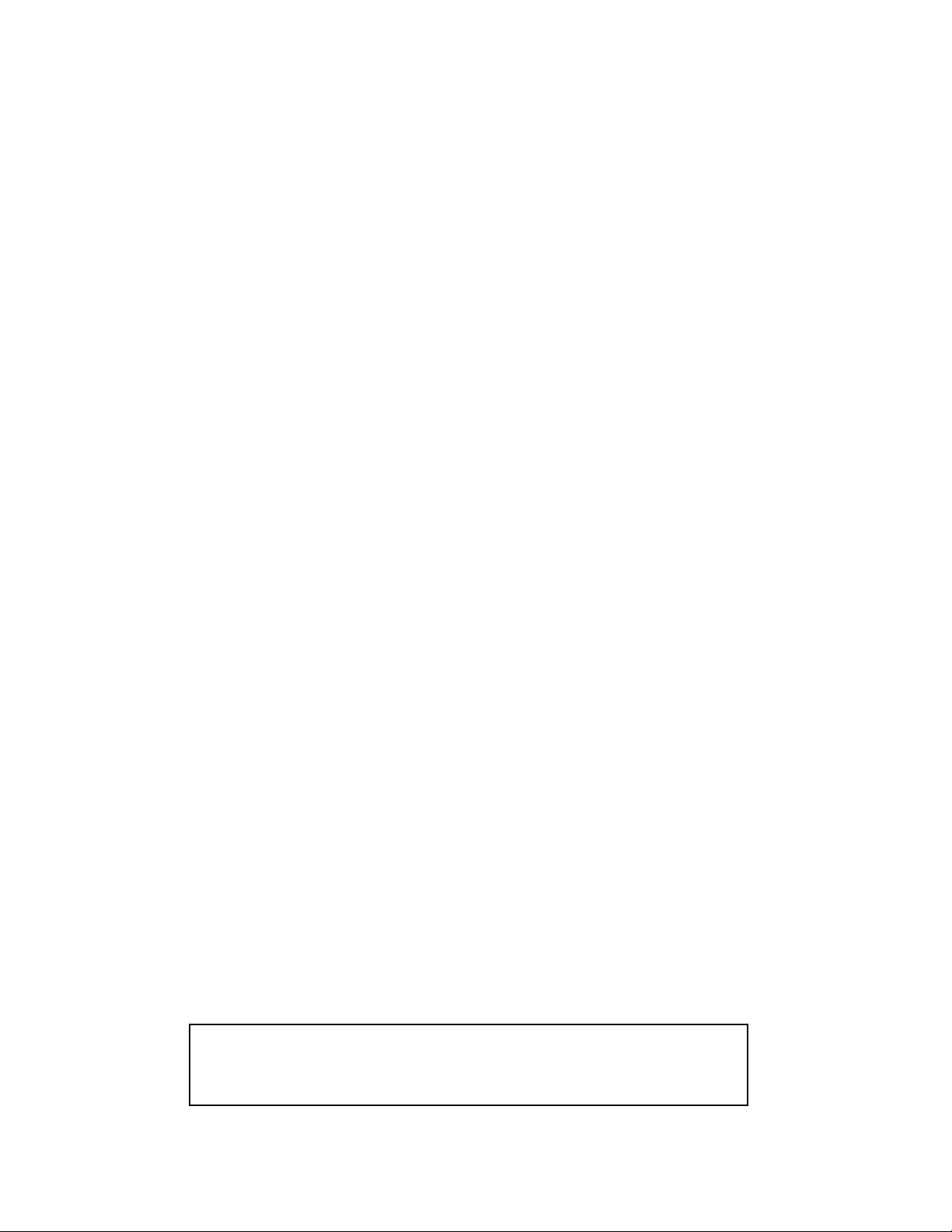

MODEL/SERIAL NUMBER PLATE

SERIAL NUMBER DESIGNATOR

SERIAL NUMBER

MANUFACTURING SITE

F = Findlay , OH

YEAR OF MANUFACTURE

L = 2001

WEEK OF MANUFACTURE

PRODUCT SEQUENCE NUMBER

F L 36 50001

MODEL NUMBER DESIGNATOR

MODEL NUMBER

Product Group

G = Gold Series Dishwasher

Product Identification

U = Undercounter

Series Code

800 = Baseline and Contract Models

900 = Midline and Retail Derivatives

1000 = Voyager Platform

G 1500

U

Model/Serial

Number Plate

(Left side of

frame behind

door)

XT K

B

0

Feature Code

PW = Premium Wash System

SW = Standard Wash System

XT = Extra Tall Tub

Year of Introduction

K = 2001

Color Code

B = Black Monochromatic

Q = White Monochromatic

T = Bisquit Monochromatic w/frameless panel

S = Black Console w/Stainless Steel panel

ENGINEERING CHANGE

0 = Basic Release; 1 = First Revision; 2 = Second Revision

SAFETY

! WARNING

ELECTRICAL SHOCK HAZARD

Disconnect power before servicing the dishwasher.

Replace all panels before operating the dishwasher.

Failure to do so can result in death or electrical shock.

PB

SECTION ONE

INSTALLATION CONSIDERATIONS

GENERAL CONSIDERATIONS

For complete installation procedures see the “Installation Instructions” in the

literature packet provided with the dishwasher .

A video presentation, Key Features and Installation Considerations, part number

4317280V, is available. This video covers the entire installation process.

Each location will present a different set of challenges that can be anticipated and solved before installation begins.

• Check the planned location of the dishwasher.

• Easy access to hot water, drain line and electricity.

• Convenient access for loading. The dishwasher door should open and close freely .

• The opening under the counter should be square and the cabinet fronts should be perpendicular to the floor.

• Make sure the cabinet opening is free of intrusions such as braces or utility lines.

• Do not install the dishwasher on carpeted floors.

• An outside wall behind the dishwasher should be insulated to prevent the water line, inlet valve

and drain line from rupturing.

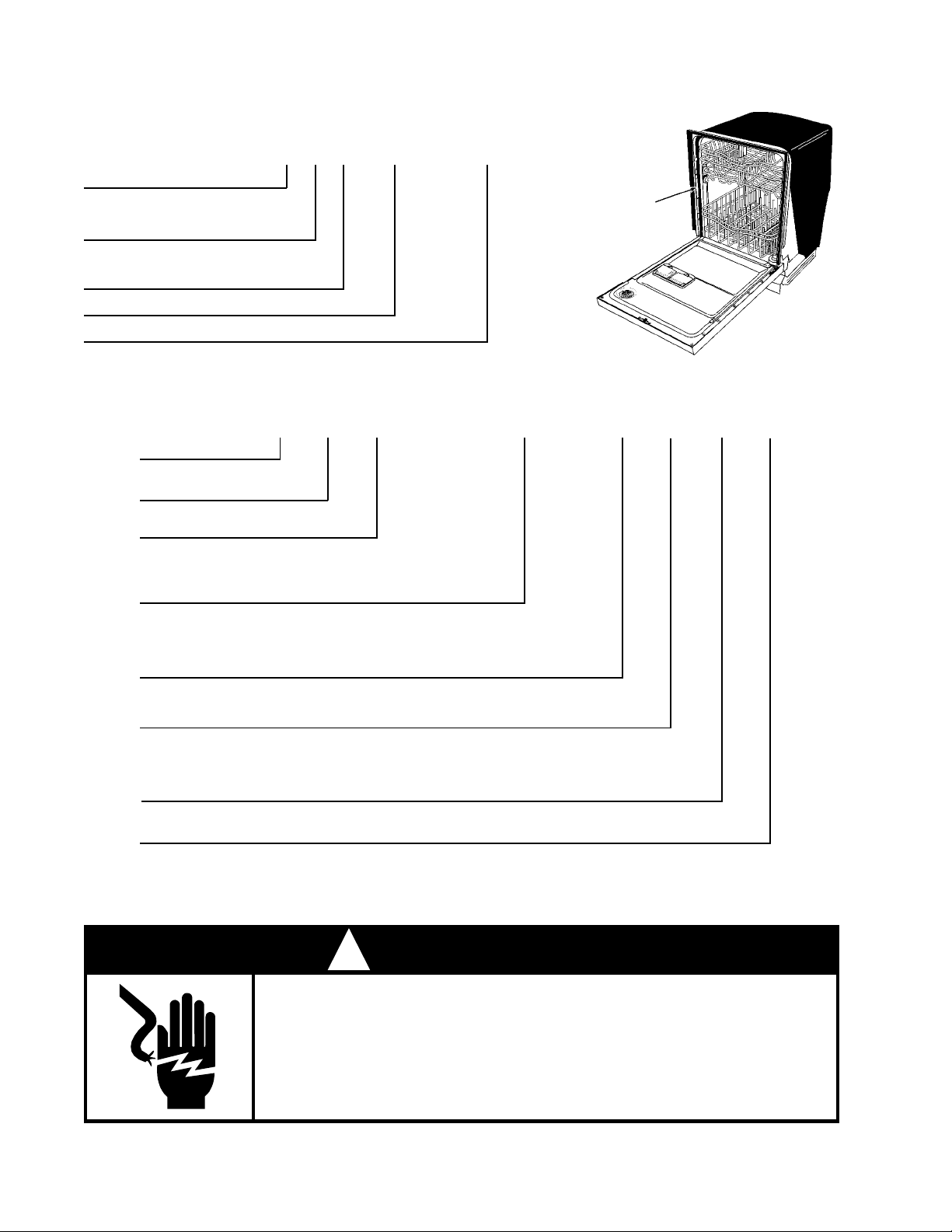

The application of a horizontal pump and filter

technology allows for the tub to be designed three

inches deeper than current models. This deeper

tub and longer door design will impact the installation process because there is less working

space available underneath the unit and correct

routing and placement of the drain hose, water

supply and electrical wiring is critical.

The tub must be level. Reduced water consumption of this dishwasher requires that it be installed

level and plumb for proper water recirculation back

into the sump area during operation.

Do not remove the drain

hose from the left side of

the tub. This loop in the

drain hose provides proper back pressure for the

soil sensor. If the loop is

removed, the dishwasher

will not initiate Automatic

Purge Filtration.

Drain Hose

Loop

Main Wash Motor

View of Sump Assembly from Underneath

Showing Horizontal Wash Pump Motor

and Drain Pump Motor

Drain Pump

Motor

1

SPECIFICATIONS

ELECTRICAL SUPPLY: (Under Load) 60Hz, 120V AC

SUPPLY WATER FLOW RATE: (To Fill 2 Quarts (1.9 L) in 27 secs.) - 120psi Max., 20psi Min.

SUPPLY WATER TEMPERATURE: 120° F to 160° F (49° C to 71° C)

WA TER CHARGE: 1.8 Gal. (6.8 L) / First Fill

1.7 Gal. (6.5 L) / All Other Fills

LOWER SPRAY ARM ROTATION: 25 TO 40 RPM

UPPER SPRAY ARM ROTATION: 25 TO 35 RPM

APF DRAIN: .1 Gal. (.38 L)

HEATING ELEMENT HEATING RATE: 1°+ F Rise per Minute

2

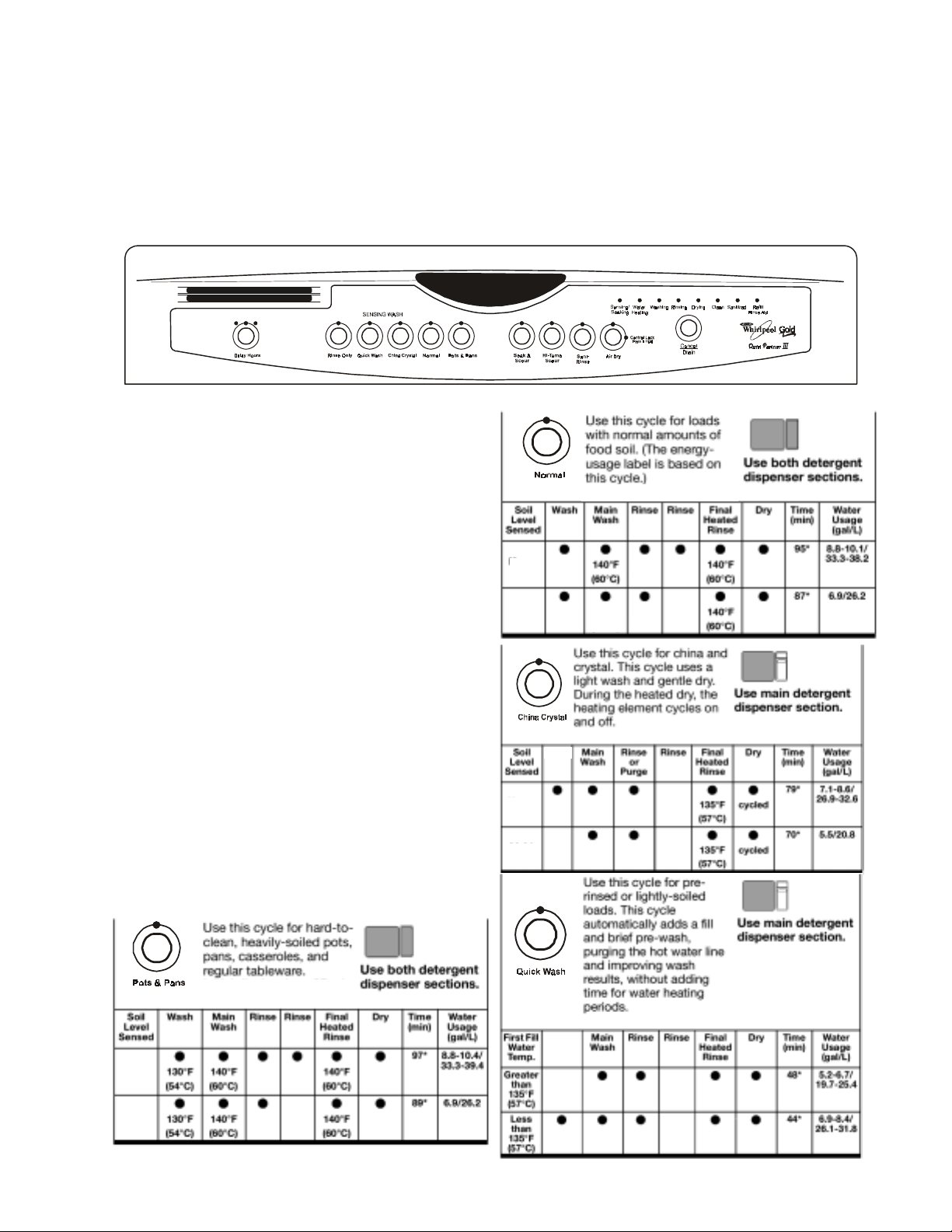

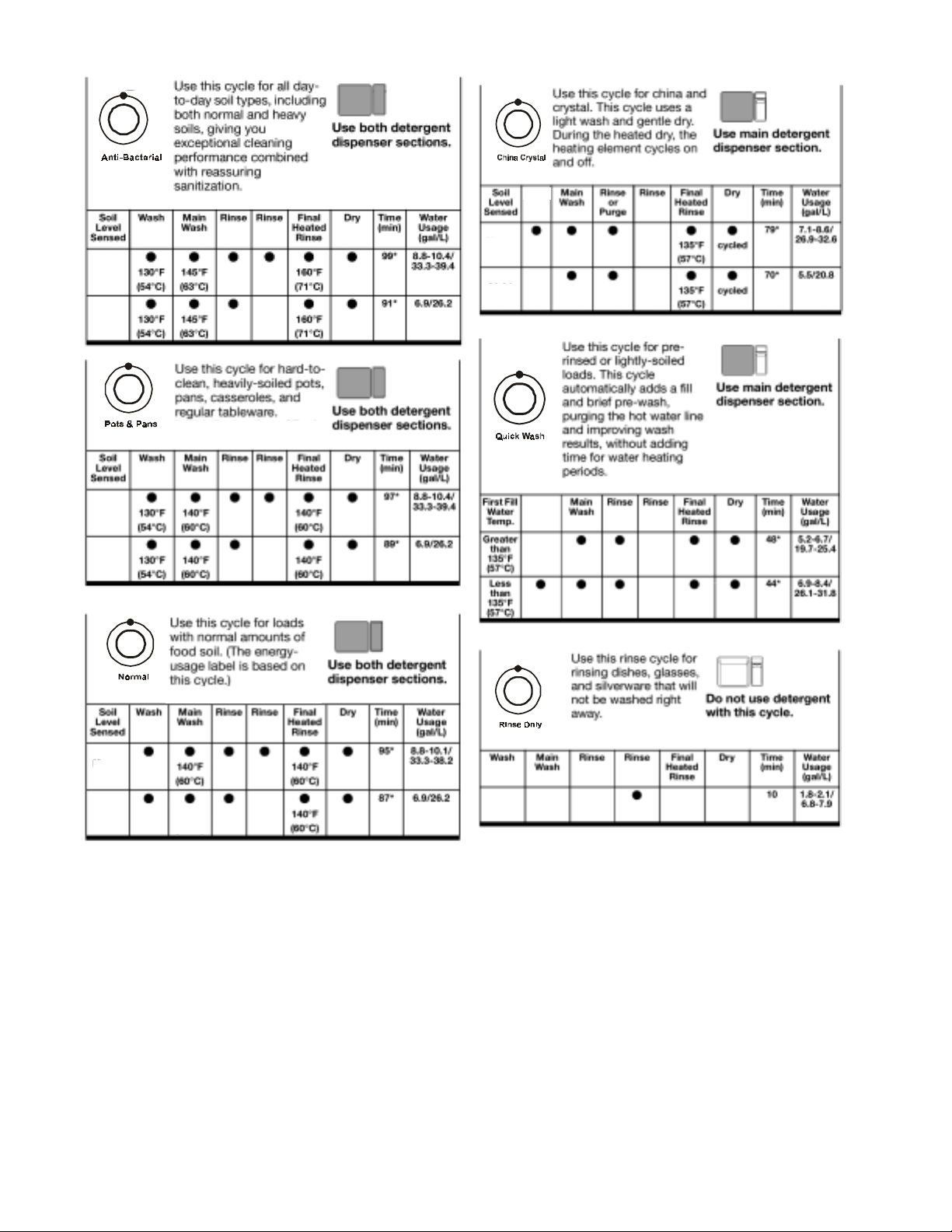

MODEL: GU1200XTK

SECTION TWO

THEORY OF OPERATION

CONTROL PANEL

248

CYCLES

CYCLE SELECTION CHART

Select the wash cycle and options desired. Upon

selecting the cycle key , the cycle will begin immediately . Cycles may be changed at any time, during the first fill. Options can be selected or

changed at any time.

NOTE: The last options used will be recalled from

memory automatically upon selecting a cycle, (if

the option is valid with the cycle selected).

A “ ” shows what steps are in each cycle.

•

T emperatures indicate where extra heat is added.

Water usage is shown in U.S. gallons/liters.

Cycle time includes dry time. An asterisk (*) by

the cycle time indicates the cycle time might be

longer depending on the temperature of the water

entering the dishwasher. The cooler the water,

the longer the cycle time. If the water is already

hot enough, the cycle time will be as shown.

High

Low 130 F

High

Low

Rinse

(54 C)

º

º

Purge

Pots & Pans

High

Low

Rinse

3

NOTE: The Soil Sensor monitors water pressure at the output of the drain pump. Cycle time

and/or water usage can vary from the numbers

above as the sensor adjusts the cycle for the best

wash performance. Water pressure varies depending on the soil concentration in the accumulator.

One or all of the following may be used to achieve

the desired washing performance of a selected

wash cycle.

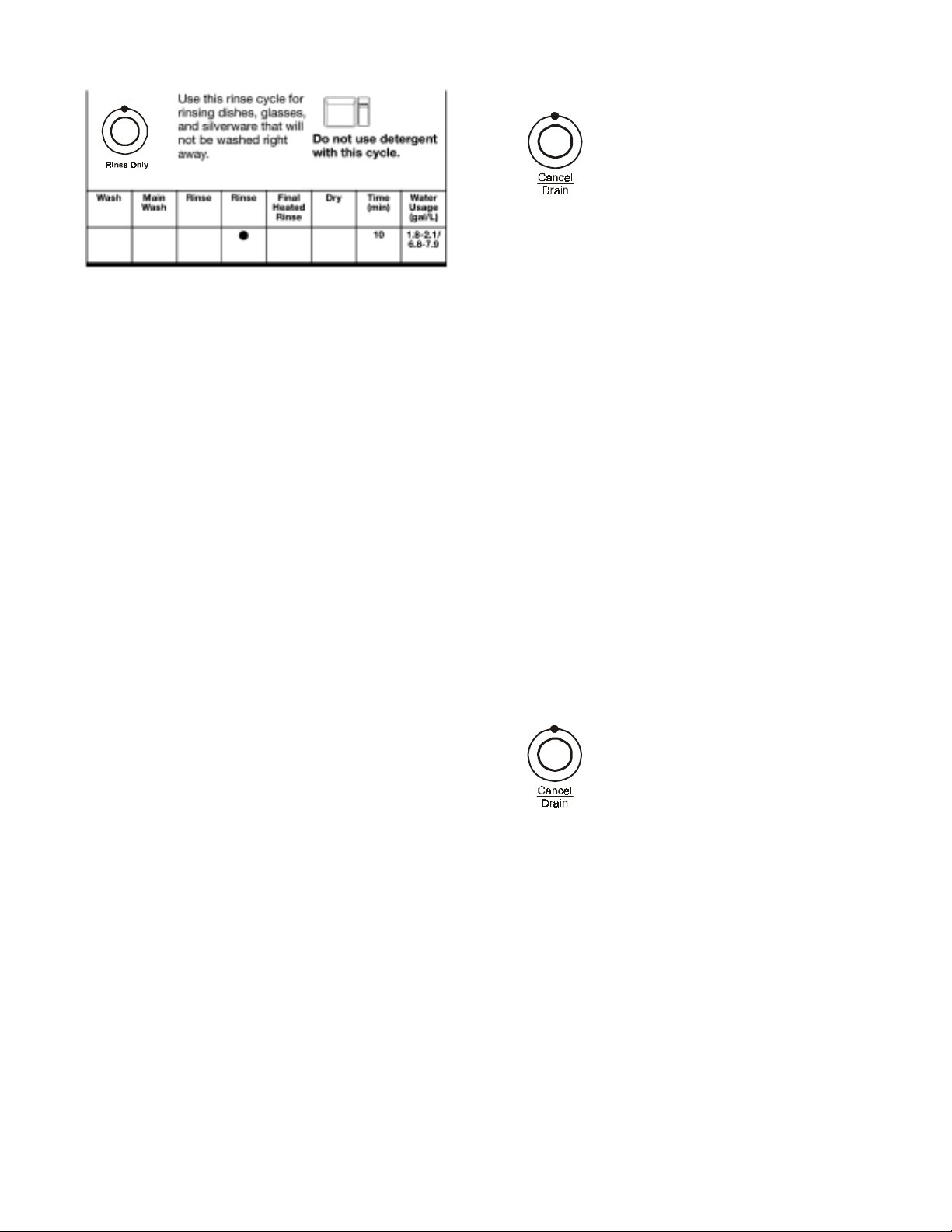

Canceling a Cycle

Anytime during a cycle, press

The dishwasher starts a two minute drain (if

needed.) Let the dishwasher drain completely.

The light turns off after two minutes.

To Stop the Drain

Press CANCEL/DRAIN a second time to stop the

drain immediately. Always drain the dishwasher

before starting a new cycle.

To Clear the Indicators

Press CANCEL/DRAIN before starting the dishwasher to clear all options and cycles.

Changing a Cycle or Setting

Automatic Purge Filtration

The Automatic Purge Filtration (APF) feature may

also be invoked if the soil sensor detects excessive soils. This can occur during selected wash

or rinse cycles. APF mode provides one or more

purges of excess soils trapped in the soil accumulator at specified intervals in the cycle.

The APF operates for a total of 10 seconds while

the wash motor is operating in a wash or rinse

mode. The accumulator screen will be cleaned

from jets on the underside of the lower spray arm.

During the first five seconds, the drain motor turns

on and the fill valve is activated. This purges the

soiled water from the accumulator and begins to

add fresh water. For the remaining five seconds,

the drain pump is turned off, but the fill valve remains activated to bring wash water up to proper

level.

During the first minute of a cycle:

1. Press a new cycle and/or options.

2. Check the detergent dispensers. They

must be filled properly for the new cycle.

After the first minute of a cycle:

1. Press:

CANCEL/DRAIN glows. The dishwasher starts

a two minute drain (if needed.) Let the dishwasher

drain completely.

2. Check the detergent dispensers. They

must be filled properly for the new cycle.

3. Close the door.

4. Press a new cycle and/or options.

5. Press Start.

4

ADDING ITEMS DURING A CYCLE

Items can be added any time before the main wash starts. Open the door and check the detergent

dispenser. If the cover is still closed, add items.

To Add Items:

1. Lift up the door latch to stop the cycle. Wait for the spraying action to stop before opening the

door.

2. Open the door. If the detergent dispenser cover is still closed, add the item(s).

3. Close the door firmly until it latches. The dishwasher resumes the cycle after a five (5) second

pause.

OPTION SELECTION

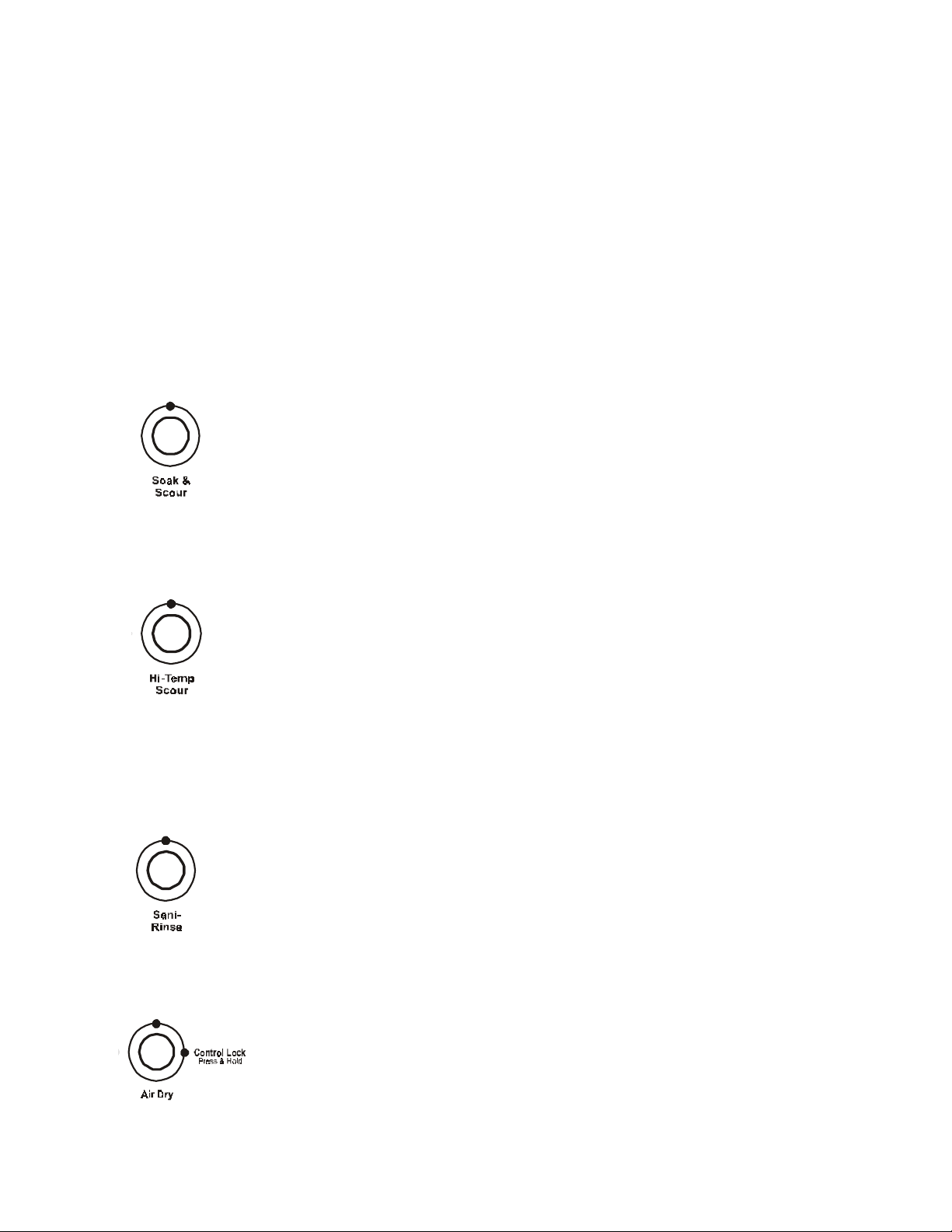

Soak & Scour

Select this option to run a 4 hour pre-soak before the selected cycle. The pre-soak

consists of a standard fill, an initial 8 minute wash, then 13 wash pulses, each 90

seconds long with a 16 minute pause between pulses. This keeps the dishes wet

and soaking. At the conclusion of the pre-soak, the dishwasher drains and the

selected cycle begins.

NOTE: The Soak & Scour option is allowed with the Pots & Pans cycle only.

Hi-Temp Scour

Select this option to increase the target water temperature during the wash portion of

the cycle. Hi-Temp Scour raises this target water temperature to 145° F (63° C) in the

Main Wash for all cycles. In the Pots & Pans cycle, Hi-Temp Scour also raises the

target water temperature to 135° F (57° C) in the pre-wash. Heating the

water helps improve washing results. Hi-Temp Scour is useful when loads contain

baked-on food.

This option adds heat, water and wash time by adding at least one additional rinse mode to the cycle.

NOTE: Hi-Temp Scour is an option with Pots & Pans and Normal.

Sani-Rinse

Select this option to raise the water temperature in the final rinse to approximately

160° F (70° C) for 10 minutes. Sani-Rinse adds heat and time to the cycle. In the

Normal cycle, this high temperature rinse sanitizes the dishes and glassware in accordance with the NSF International requirements (#95/480/05/2480).

NOTE: Sani-Rinse is an option with the Pots & Pans and Normal cycles.

Air Dry

Select this energy-saving option to dry without heat. Air drying is useful when loads

contain plastic dinnerware that may be sensitive to high temperatures. The dishes

take longer to dry and spotting can occur. For best drying, use a liquid rinse aid.

Some items, such as plastics, may need towel drying.

NOTE: Rinse Only does not have a dry period. Air Dry is an option with all other cycles.

5

Control lock

Use the Control Lock to prevent the dishwasher from accidentally being turned on. Use

the ControlLock, also, to prevent accidental cycle or option changes during a cycle.

When the Lock LED is lit, all buttons are disabled.

NOTES:

• The dishwasher door can be opened while the controls are locked.

• The lock can be turned on while the dishwasher is running.

To Turn on the Control Lock:

Press and hold Air Dry for four (4) seconds. The LOCK LED will glow.

To Turn off the Lock:

Press and hold Air Dry for 4 seconds. The LED turns off.

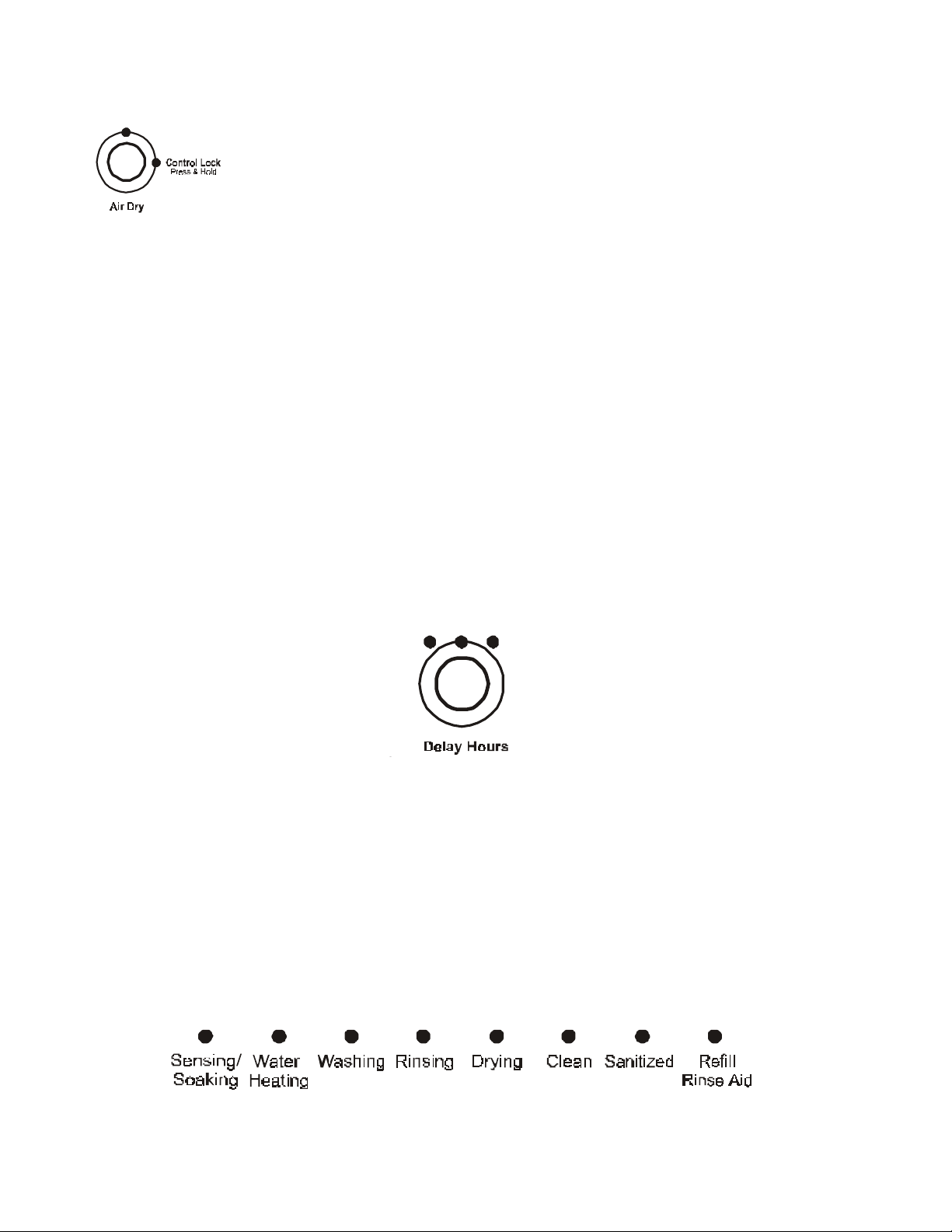

Delay Hours

Select this option to run the dishwasher at a later time or during off-peak hours.

To Delay the Start:

1. Close the door.

2. Press Delay Hours 1 time for a 2-hour delay, 2 times or a 4-hour delay or 3 times for an 8hour delay .

3. Select a wash cycle and options.

The number glows above Delay Hours. The dishwasher starts the cycle in the selected number of

hours.

NOTE: T o cancel the delay and begin cycle immediately , press Delay Hours until all delay hours LEDs

are off.

248

Cycle Status Indicators

The progress of the dishwashing cycle can be followed with the Cycle Status Indicators.

6

Sensing/Soaking

The dishwasher senses the soil level on the dishes. Soil level determines the length of some cycles,

the amount of heat added to the wash and the number of rinses needed in the cycle for the load. It also

senses the temperature of the water during thermal hold water heating periods. SENSING/SOAKING

glows during the soil sensing and thermal hold portions of the cycle. Wash action continues while

sensing occurs. SENSING/SOAKING also glows during “soaking” events and the 4-hour pre-soak

cycle invoked by the Soak & Scour Option.

Sanitized

If the Sani Rinse option is selected, SANITIZED glows when the Sani Rinse cycle is finished. If the

dishwasher did not properly sanitize the dishes, the light flashes at the end of the cycle. This can

happen if the cycle is interrupted or the dishwasher failed to reach sani temperatures. The light goes

off when any key is selected or the door is opened and reclosed.

Clean

CLEAN glows when a cycle is finished. The light turns off when the door is opened and reclosed or any

key is pressed.

CONTROL PANEL

MODEL: GU1500XTK

CYCLES

OPTIONS

CYCLE SELECTION CHART

Select the wash cycle and options desired. Upon selecting the cycle key , the cycle will begin immediately . Cycles may be changed at any time, during the first fill. Options can be selected or changed at

any time.

NOTE: The last options used will be recalled from memory automatically upon selecting a cycle, (if

the option is valid with the cycle selected).

A “ ” shows what steps are in each cycle.

•

Temperatures indicate where extra heat is added.

Water usage is shown in U.S. gallons/liters.

Cycle time includes dry time. An asterisk (*) by the cycle time indicates the cycle time might be longer

depending on the temperature of the water entering the dishwasher. The cooler the water, the longer

the cycle time. If the water is already hot enough, the cycle time will be as shown.

7

High

Rinse

High

Low

High

Low

Low

Purge

Rinse

High

Low 130 F

(54 C)

º

º

8

FUNCTION DESCRIPTION

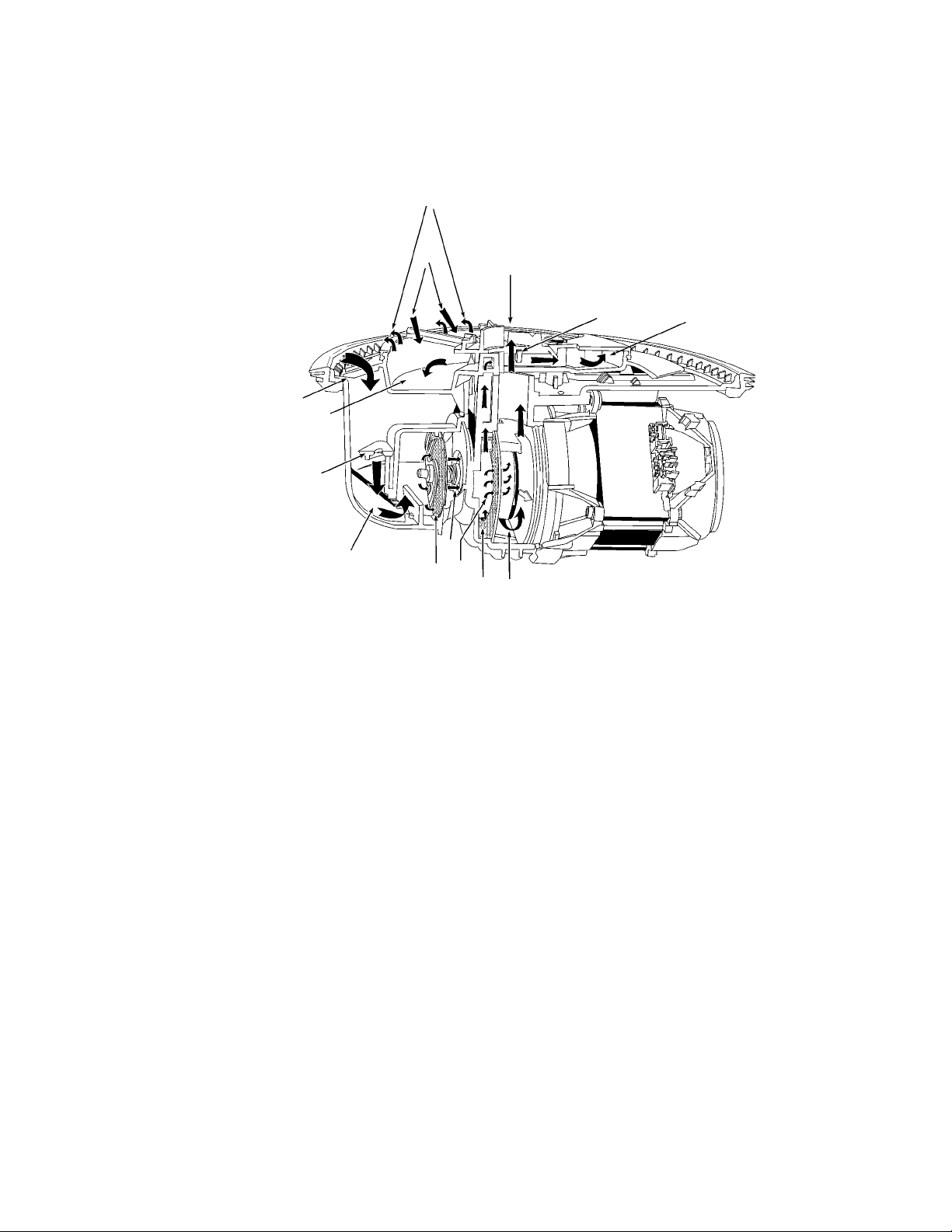

The washing action of the Point Voyager Dishwasher performs more work and maintains higher performance with reduced energy consumption. This is accomplished with the following: 1) A redesigned

wash system using separate wash and drain pumps. 2) A soil sensor and thermistor which monitor

washing conditions. 3) An electronic control board which adjusts cycle functions to optimize washing

performance.

8

10

2a

7

2b

2c

4

6b

3

Wash/Rinse Function

1. The main wash water passes from the

spray arm nozzles, over the dish load and

into the sump assembly, where a number

of operations occur.

2. Water and soils pass through the course

protection grate at the top of the sump assembly (2a) and then passes through the

foreign object protector (2b) into the main

wash pump inlet chamber (2c).

3. The water then passes through the chopper assembly where food particles are reduced in size so they can pass through

the water delivery system. (3)

4. Water is drawn through the impeller and

into the pump chamber. (4)

5. Here, 20 percent of the water is diverted

towards the soil accumulator. Food soils

in this water stream are captured by the

separation screen. (5)

6. Downstream restrictions limit the water

flow into the accumulator to 10 percent.

11

6a

5

11

7

(6a) The remaining water is allowed to

rejoin the main wash flow by passing

through the separation screen. (6b)

7. This heavily soiled water is distributed

throughout the accumulator. (7) Soils will

remain trapped in the accumulator until a

drain or Automatic Purge Filtration event

takes place.

8. Since the water in the accumulator is under some minimal pressure, it rejoins the

main wash water by flowing through the

accumulator screen into the tub. (8)

9. For this to occur properly it is critical that

the dishwasher be installed perfectly level.

10. Jets located on the underside of the lower

spray arm continuously wash down the accumulator screen to allow more soils to

concentrate. (10)

11. The remaining 80 percent of the wash

water will flow from the impeller through

the volute and up through the spray arms.

(11)

9

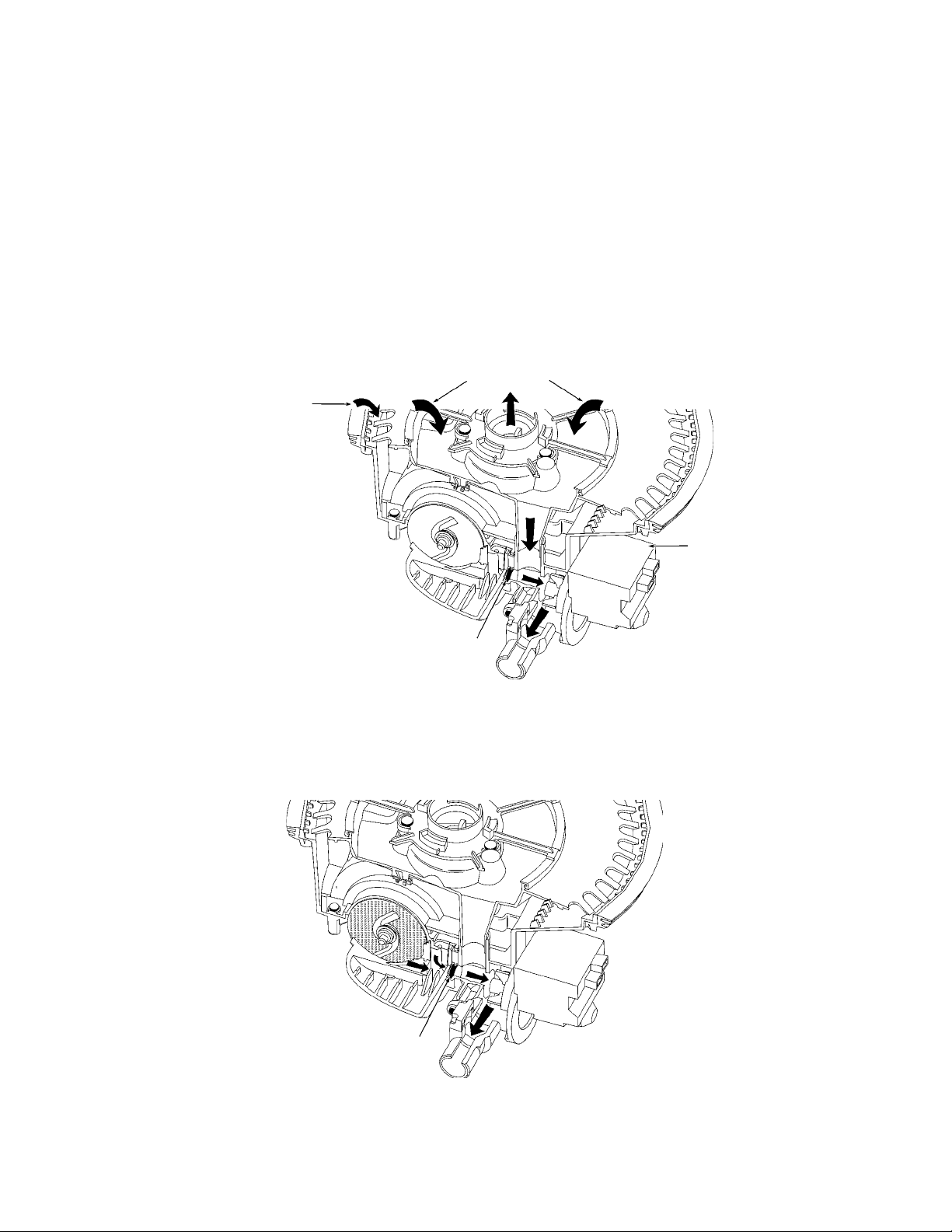

Drain Function

1. During the Drain function, a separate drain pump motor is started while the main wash pump

motor continues to operate for 1 minute. (1) This accomplishes three goals.

2. First, the jets on the underside of the lower spray arm continue to flush soils from the accumulator screen while the water is drained from the unit. (2)

3. Second, negative pressure in the main wash pump inlet chamber keeps the check valve closed,

allowing the drain pump to remove soiled water from the accumulator. (3)

4. Third, the spray arms will rinse down the interior of the wash tub while the water is drained,

leaving the inside free of soils. (4)

2

4

3

2

1

5. The main wash pump then stops creating positive pressure in the pump’s inlet chamber. This

opens the check valve allowing the remaining water to be drained away. (5)

5

10

Loading...

Loading...