Page 1

R-102

JOB AID

Part No. 8178551

2003 69˝ HIGH

COUNTER-DEPTH

SIDE-BY-SIDE

REFRIGERATOR

CONSUMER CARE TECHNICAL

EDUCATION GROUP PRESENTS

Model GC1SHAXM

Page 2

FORWARD

This Whirlpool Job Aid, “2003 69˝ High Counter-Depth Side-By-Side Refrigerator” (Part No.

8178551), provides the technician with information on the installation, operation, and service

of the 2003 69

model being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the re

frigerator.

The Wiring Diagram and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

˝ High Counter-Depth Side-By-Side Refrigerator. For specific information on the

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide information that will enable the service technician to properly

diagnose malfunctions and repair the 2003 69˝ High Counter-Depth Side-By-Side Refrigerator.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the refrigerator to its proper operational status.

-

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2006, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

Page 3

TABLE OF CONTENTS

Page

GENERAL .............................................................................................................................. 1-1

Refrigerator Safety ............................................................................................................. 1-1

Model & Serial Number Designations ................................................................................ 1-2

Model & Serial Number Label And Tech Sheet Locations ..................................................

1-3

INSTALLATION INFORMATION

Cutout Dimensions ............................................................................................................. 2-1

Door Removal .................................................................................................................... 2-2

Water Hookup ....................................................................................................................

THEORY OF OPERATION

Overview ............................................................................................................................ 3-1

User Interface .................................................................................................................... 3-2

Electronic Control Board .................................................................................................... 3-4

Thermistors ........................................................................................................................ 3-4

Defrost Operation ............................................................................................................... 3-5

Fan Operation And Delay ...................................................................................................

In-Door Ice ......................................................................................................................... 3-7

COMPONENT ACCESS

Component Locations ........................................................................................................ 4-1

Removing A Refrigerator Or Freezer Light Bulb ................................................................

Removing The Defrost Bimetal ..........................................................................................

Removing The Refrigerator Thermistor Housing ...............................................................

Removing The Water & Ice Dispenser Board Interface .....................................................

Removing The Evaporator Tray .........................................................................................

Removing The Control Board .............................................................................................

Removing The Water Valves ..............................................................................................

Removing The Condenser Fan Motor ..............................................................................

Removing The Compressor Terminal Box,

The Relay & Overload And Run Capacitor ....................................................................4-11

..................................................................................................... 3-1

........................................................................................................ 4-1

............................................................................................ 2-1

2-6

3-6

4-2

4-3

4-4

4-5

4-7

4-8

4-9

4-10

- iii -

Page 4

COMPONENT TESTING ........................................................................................................ 5-1

Component Testing Chart ..................................................................................................

DIAGNOSTICS & TROUBLESHOOTING ............................................................................. 6-1

User Interface Failure Feedback ........................................................................................ 6-3

Troubleshooting Chart ........................................................................................................

Electronic Control Board Pin Locations ............................................................................. 6-8

User Interface Board Pin Locations ................................................................................... 6-9

Thermistor Resistance/Temperature Chart ........................................................................

5-1

6-5

6-9

WIRING DIAGRAM & STRIP CIRCUITS

Wiring Diagram .................................................................................................................. 7-1

Strip Circuits ....................................................................................................................... 7-2

TECH TIPS ............................................................................................................................. 8-1

Removing The Original Gasket ..........................................................................................

............................................................................... 7-1

8-1

- iv -

Page 5

WARNING

DANGER

GENERAL

REFRIGERATOR SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your

appliance. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

1-1

Page 6

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER G C 1 S H A X M Q 0 0

PRODUCT GROUP

G = Whirlpool Gold

PRODUCT IDENTIFICATION

C = Counter Depth (24

CAPACITY / CUBIC FOOT SIZE

1 = 11 or 21

MODEL SERIES / SHELVES

S = Shelf Variation

MODEL FEATURES / PANS

H = Crisper Variation

MODEL FEATURE CODE

A = IDI W/Grille Filter

DOOR SWING

X = SXS

YEAR OF INTRODUCTION

M = 2003

COLOR CODE

Q = White

B = Black

S = Stainless

ENERGY/POWER DESIGNATOR (NUMERIC)

0 = Original, 1 = 1st Change, 2 = 2nd Change, etc.

ENGINEERING CHANGE (NUMERIC)

0 = Basic Release

1 = First Revision

2 = Second Revision

˝ Deep)

SERIAL NUMBER

SERIAL NUMBER SA R 48 10001

MANUFACTURING RESPONSIBILITY

SA = Fort Smith, AR

YEAR OF PRODUCTION

R = 2004

WEEK OF PRODUCTION

48th Week

PRODUCT SEQUENCE NUMBER

1-2

Page 7

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model/Serial Number label and Tech Sheet locations are shown below.

Model & Serial Number Label Location

(On Lower Right Side Of Refrigerator Liner)

Tech Sheet Location

(Behind Grille)

1-3

Page 8

— NOTES —

1-4

Page 9

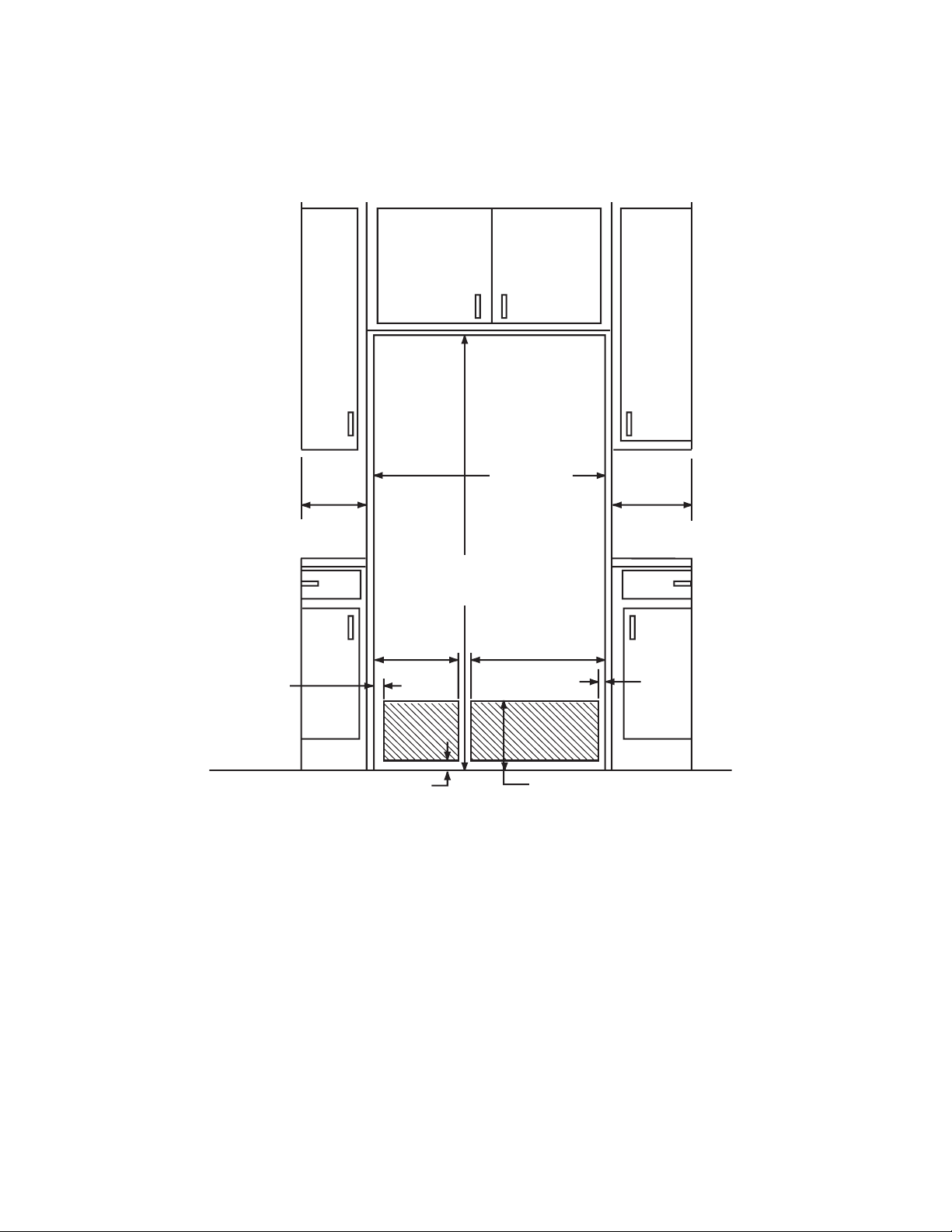

INSTALLATION INFORMATION

21/2"

(6.4 cm

)

2"

(5.1 cm

)

2"

(5.1 cm

)

91/4"

(23.5 cm

)

12

1

/

2

"

(32 cm

)

69"

(175.0 cm

)

36

"

(91.5 cm)

13

1

/

4

"

(34 cm)

16

1

/

2

"

(42 cm)

20

1

/4"

(51.5 cm)

CUTOUT DIMENSIONS

2-1

Page 10

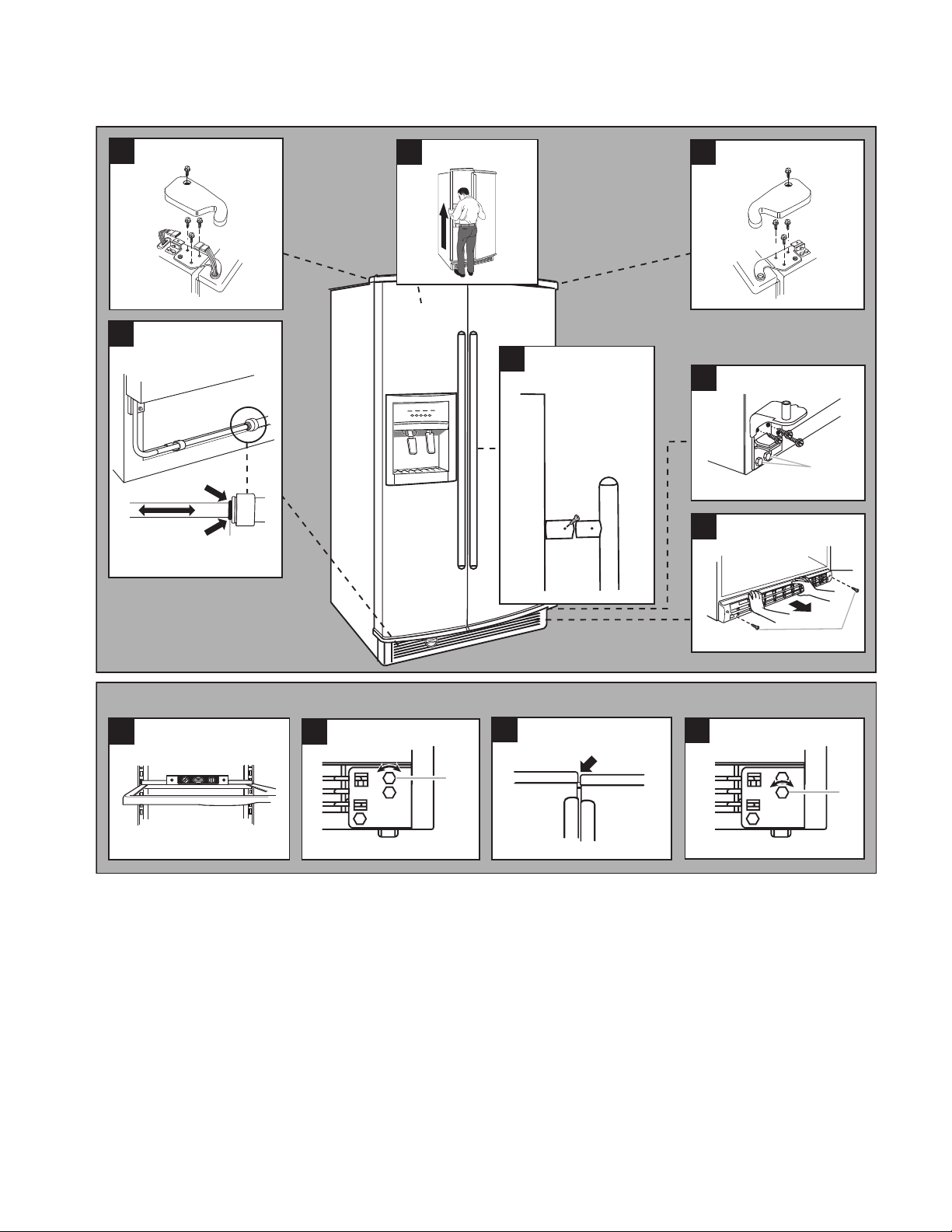

DOOR REMOVAL

WARNING

1. Do not remove screw 1

2. Wiring plug

1

2

TOOLS REQUIRED

1/2ʺ & 5/16ʺ Hex-Head Socket Wrenches

Flat-Blade Screwdriver

#1 & #2 Phillips Screwdrivers

BEFORE YOU BEGIN

Turn the refrigerator control OFF. Unplug the

refrigerator or disconnect power. Remove the

food and any adjustable door or utility bins

from the doors.

HANDLE REMOVAL (OPTIONAL)

1. Using a Phillips screwdriver, remove the

screws located on the inside of each door

handle. Pull the door handle straight out

from the door (see Illustration 1). Save the

screws for reattaching the handles.

2. To make the cabinet flush, use a flat-blade

screwdriver, and remove the screws at

taching the door handle posts to the re

frigerator cabinet. Reverse the procedure

to replace the handles.

3. Close both doors and keep them closed

until you are ready to lift them off the cabinet.

4. If you have a dispenser (ice or water),

disconnect the water dispenser tubing,

located behind the base grille on the freezer

door side (see Illustration 3). To do this,

press the red outer ring against the face

of the fitting, and pull the dispenser tubing

free. NOTE: On some models, you will

have to remove the tubing from a hose

clip.

5. Remove the top left hinge screw and cover

as shown (see Illustration 4).

6. Disconnect the wiring plug as shown.

-

-

DOOR REMOVAL

Electrical Shock Hazard

Disconnect power before removing

doors.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Open both doors and remove the two

screws from the base grille. Pull the base

grille forward and remove it (see Illustra

tion 2).

7. Remove the remaining left hinge screws

and hinge (see Illustration 4).

8. Carefully lift the freezer door straight up

and off the bottom hinge (see Illustration

5). The water dispenser tubing will remain

attached to the freezer door, and will pull

through the bottom left hinge. Make sure

that you protect the dispenser tubing from

damage when you set the door on the

floor.

9. Remove the top right hinge cover and

screws (see Illustration 6).

10. Lift the refrigerator door straight up and

off the bottom hinge.

11. Disassemble the hinges as shown (see Il

lustration 7). Do not remove the screws.

-

-

2-2

Page 11

2

Base Grille

10

Door Alignment

8

Level

9

Rear Leveling

1. Rear roller leveling screw

11

Front Leveling

1. Front roller leveling screw

Door Closing and Alignment

6

Top Right Hinge

Bottom Hinge

7

1. Do Not Remove Screws

1. Screws

Handle Removal

(Optional)

1

4

3

Water Dispenser

Tubing Connection

1. Red Outer Ring

1

5

Door Removal

1

1

Top Left Hinge

1

1

2-3

Page 12

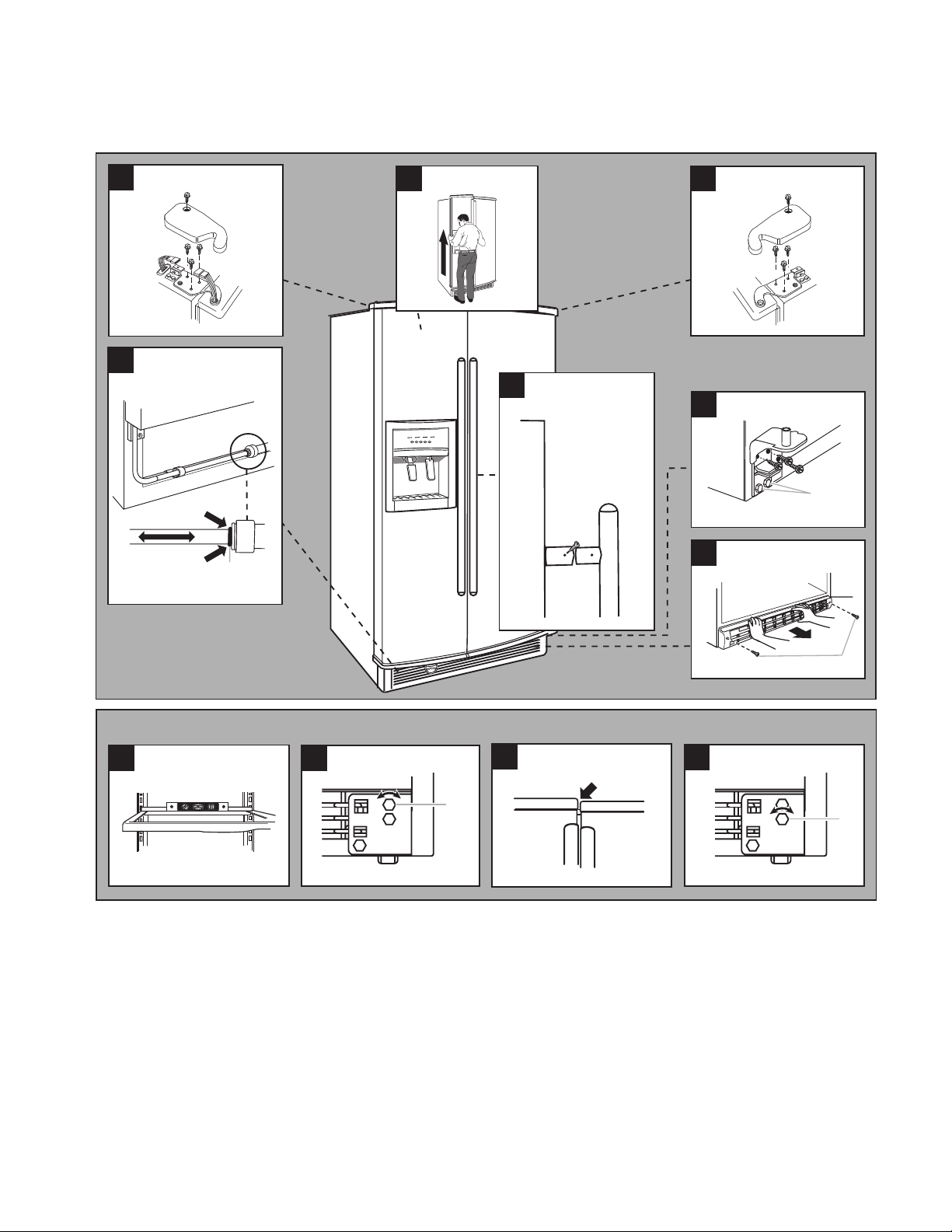

DOOR AND HINGE REPLACEMENT

1. Do not remove screw 1

2. Wiring plug

1

2

DOOR CLOSING AND ALIGNMENT

1. If removed, replace both bottom hinges

and tighten the screws.

2. Carefully feed the dispenser tubing through

the bottom left hinge before replacing the

freezer door on the hinge.

NOTE: Provide additional support for the doors

while the top hinges are being replaced. Do not

depend on the door magnets to hold the doors

in place while you are working.

3. Reconnect the water dispenser tubing

by pushing the tubing into the fitting until

it stops, and the black mark touches the

face of the fitting (see Illustration 3). On

some models, replace the tubing in the

hose clip.

4. Align and replace the top left hinge (see

Illustration 4) and tighten the screws.

5. Reconnect the wiring plug.

6. Replace the left hinge cover and screws.

7. Carefully lift the refrigerator door and set

it on the bottom right hinge.

8. Align and replace the top right hinge (see

Illustration 6).

9. Replace the hinge cover and screws.

10. Plug in refrigerator or reconnect power.

Door Closing

1. Move the refrigerator into its final position.

2. Place a level inside the refrigerator at the

back of the top shelf (see Illustration 8).

3. Locate the leveling screws behind the base

grille of the refrigerator on either side.

4. Use a hex-head socket wrench and adjust

the rear roller leveling screws until the

refrigerator is level. Turn the rear roller

leveling screw to the right to raise that

side of the refrigerator, or to the left to

lower it (see Illustration 9). Make sure the

refrigerator is level before proceeding.

Door Alignment

If the doors are uneven after leveling the

refrigerator (see Illustration 10), perform the

following steps.

1. Use a hex-head socket wrench and adjust

the front roller leveling screws until the

doors are even. Turn the front roller leveling

screw to the right to raise that side of the

refrigerator, or to the left to lower it (see

Illustration 11).

NOTE: Open and close both the refrigerator

and freezer doors after each adjustment to

check the door alignment.

2. Open the doors and replace the base

grille. Align the grille with the bottom of the

cabinet and reattach with the screws.

NOTE: Be sure to refasten the Tech Sheet

behind the base grille.

2-4

Page 13

2

Base Grille

10

Door Alignment

8

Level

9

Rear Leveling

1. Rear roller leveling screw

11

Front Leveling

1. Front roller leveling screw

Door Closing and Alignment

6

Top Right Hinge

Bottom Hinge

7

1. Do Not Remove Screws

1. Screws

Handle Removal

(Optional)

1

4

3

Water Dispenser

Tubing Connection

1. Red Outer Ring

1

5

Door Removal

1

1

Top Left Hinge

1

1

2-5

Page 14

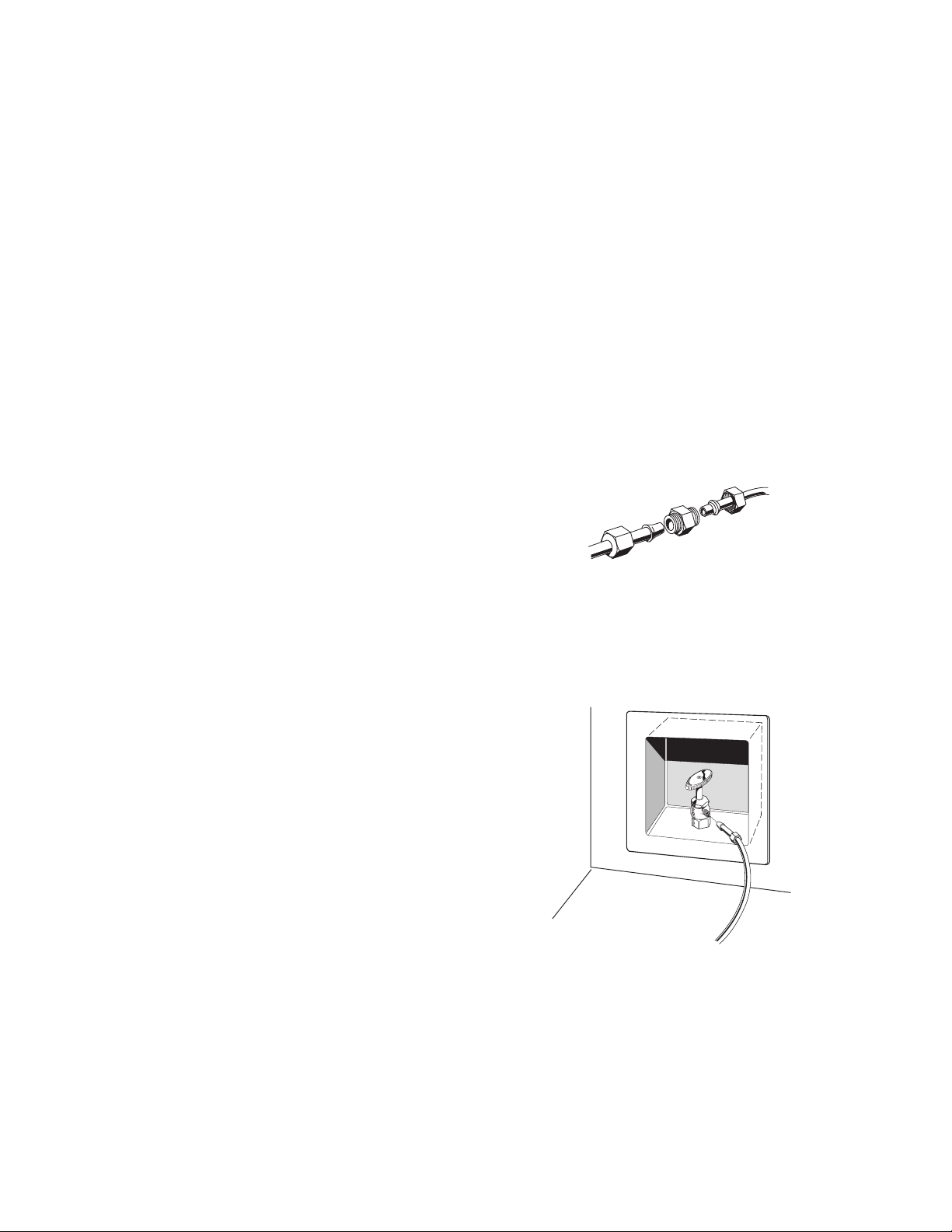

WATER HOOKUP

READ ALL DIRECTIONS COMPLETELY

BEFORE YOU BEGIN.

IMPORTANT:

In order to prevent possible leakage resulting

in property damage, be sure:

1. If you are operating the refrigerator before

installing the water connection, turn the

ice maker to the OFF position to prevent

operation without water.

2. Use copper tubing.

3. Install tubing only in areas where temperatures will remain above freezing.

4. All installations must be in accordance with

local plumbing code requirements.

5. See the “Installation Guide” for further

information.

COLD WATER SUPPLY

The ice maker water valve contains a flow washer which is used as a water pressure regulator.

The ice maker needs to be connected to a cold

water line with water pressure between 30-120

psi. If you have questions about your water

pressure, call a licensed, qualified plumber.

If your refrigerator has a water filter car-

•

tridge, it may further reduce the water

pressure when used in conjunction with

a reverse osmosis system. Remove the

water filter cartridge.

CONNECTING TO THE

REFRIGERATOR

1. Unplug refrigerator or disconnect power.

2. Remove the shipping tape from the gray,

coiled water tubing on the rear of the re

frigerator.

Style 1

1. Thread the provided nut onto the coupling

on the end of the copper tubing.

Style 2

1. Thread the provided nut onto the water

valve, as shown. First tighten the nut by

hand, then tighten it with a wrench two

more turns. Do not overtighten.

-

REVERSE OSMOSIS WATER

SUPPLY

IMPORTANT: The pressure of the water sup-

ply coming out of a reverse osmosis system

going to the water inlet valve of the refrigerator

needs to be between 30-120 psi. If a reverse

osmosis water filtration system is connected

to your cold water supply, the water pressure

to the reverse osmosis system needs to be a

minimum of 40 - 60 psi. If the water system to

the reverse osmosis water system is less than

40 - 60 psi:

Check to see whether the sediment filter

•

in the reverse osmosis system is blocked.

Replace the filter if necessary.

•

Allow the storage tank on the reverse

osmosis system to refill after heavy us

age.

FINAL CHECKS

1. Turn water supply valve ON and check for

leaks. Tighten any connections or nuts that

leak (including connections at the valve).

2. Plug in refrigerator or reconnect power.

-

NOTE: It may take up to 24 hours for the

ice maker to begin producing ice.

2-6

Page 15

THEORY OF OPERATION

OVERVIEW

The design of the 69ʺ tall counter-depth sideby-side refrigerator is similar to freestanding

side-by-side refrigerators. There are, however,

some very unique and important differences.

This section will review the operation of this

product and explain those unique differences.

The control system consists of an electronic

user interface, located on the ice and water

dispenser, an electronic control board, located

at the left rear of the unit compartment, and

thermistors, located in the refrigerator and

freezer compartments. These controls com

municate with each other, and manage virtually

all of the functions of this refrigerator, with the

exception of the in-door ice making feature.

-

3-1

Page 16

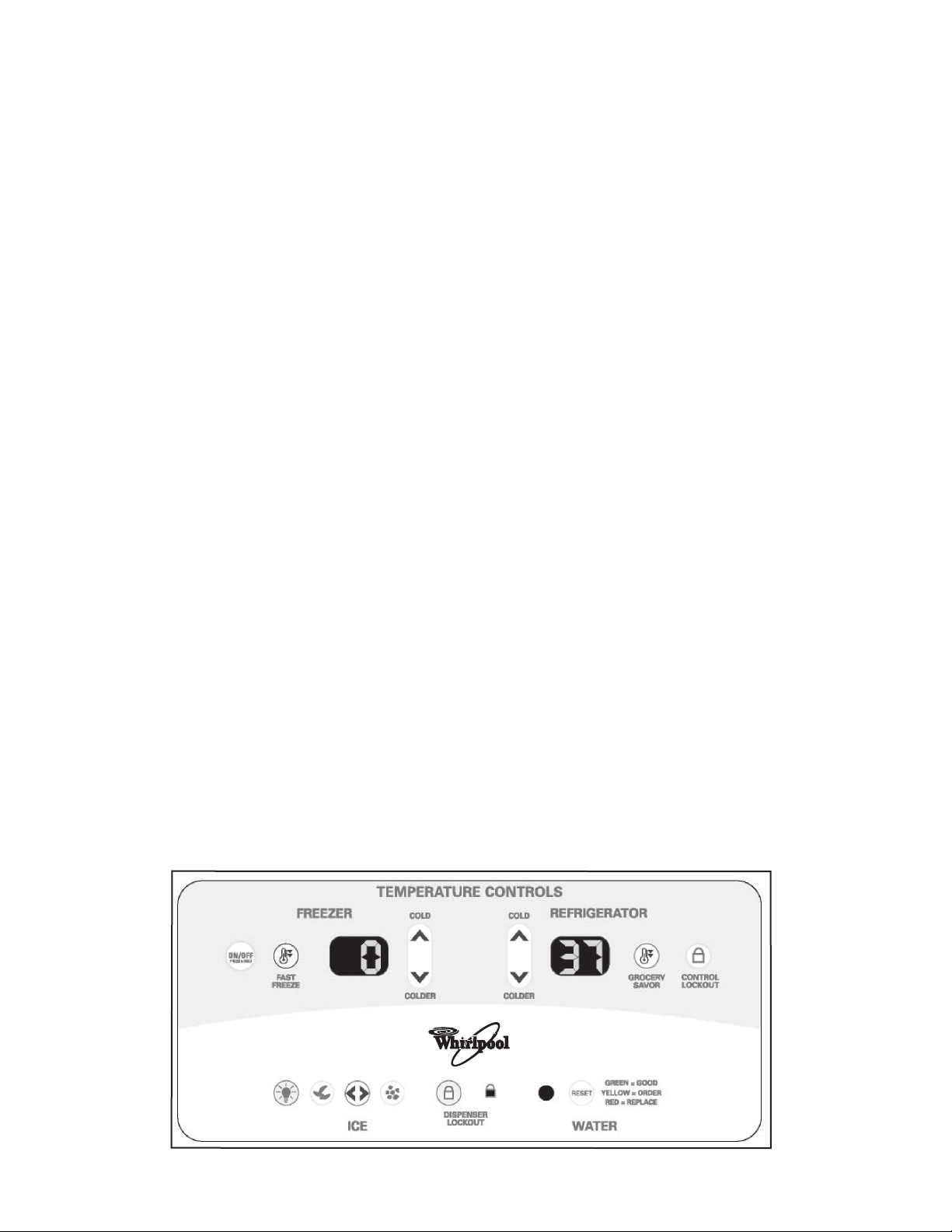

USER INTERFACE

The user interface allows the customer to

adjust the temperatures, choose what kind of

ice to be dispensed, and monitor the remain

ing water filter capacity. There are also lockout

modes for the temperature controls and the ice

and water dispenser. The temperatures are

only displayed in Fahrenheit.

Each function is described below.

ON/OFF—Press the keypad for 2 seconds to

turn the unit on and off.

When the unit is turned “off”:

• Only the central decimal point shows in

both temperature displays.

• All functions are disabled.

• All lamps and lights are off.

When the unit is turned “on”:

• All functions are restored at power-up.

• Temperature settings before powerdown are remembered.

• Fast Freeze and/or Grocery Savor

mode will be discontinued after powerup, if selected prior to power-down.

• The compressor will wait 7 minutes to

start.

• The condenser fan will wait 1 minute to

start after the compressor starts.

NOTE: At the first power-up, the control will

start in the following DEFAULT operating

-

mode:

• Unit is in the “On” state.

• Freezer temperature is set at 0ºF; Re

frigerator temperature set at 37ºF.

• Self Diagnostic Mode enabled for 10

minutes.

• Ice in Cube mode.

• Dispenser light “off”.

• Time to defrost will be set at 30 hours of

compressor run time, or 50 hours actual

time.

FREEZER (Temperature Settings)—Adjust

ment ranges from –5

COLD or COLDER keypad is pressed, the set

temperature will raise or lower 1

shows only the set temperature.

REFRIGERATOR (Temperature Settings)—

Adjustment ranges from 33

time the COLD or COLDER keypad is pressed,

the set temperature will raise or lower 1

display shows only the set temperature.

FAST FREEZE—Pressing this keypad places

the freezer section into continuous cool-down

mode for 24 hours. The control will then return

to the last freezer set temperature. While in

this mode, the FAST FREEZE keypad is illumi

nated. Pressing the keypad a second time will

terminate the FAST FREEZE mode. The refrig

erator section temperature is not affected.

°F to +5°F. Each time the

°F. The display

°F to 41°F. Each

-

-

°F. The

-

-

3-2

Page 17

GROCERY SAVOR—Pressing this keypad

places the refrigerator section into continuous

cool-down mode for 6 hours. The temperature

is regulated down to 33°F. After the 6 hour period, the control returns to the last refrigerator

set temperature. Pressing the keypad a second

time will terminate the GROCERY SAVOR

mode. While in this mode, the GROCERY

SAVOR keypad is illuminated.

CONTROL LOCKOUT—Pressing this keypad

for 2 seconds disables all user interface control

keypads relating to temperature regulation.

While in this mode, the CONTROL LOCKOUT

keypad is illuminated. If any other keypad is

pressed, the LOCKOUT keypad indicator will

blink twice. Pressing the CONTROL LOCKOUT

keypad again for 2 seconds, will enable all

temperature control functions.

DISPENSER LIGHT—Pressing this keypad

will turn the dispenser light on. Pressing the

keypad again will turn off the light. When in the

“off” mode, the light will illuminate when either

dispenser paddle is pressed.

ICE MODE—This keypad toggles between

cubed and crushed ice. In the cubed mode,

the CUBED ICE indicator will illuminate. In the

crushed mode, the CRUSHED ICE indicator

will illuminate.

DISPENSER LOCKOUT—Pressing this key

pad for 2 seconds disables the ice and water

dispenser functions, and the related user inter

face control keypads. While in this mode the

DISPENSER LOCKOUT keypad is illuminated.

If any other dispenser keypad or dispenser

paddle is pressed, the LOCKOUT keypad indi

cator will blink twice. Pressing the DISPENSER

LOCKOUT keypad again for 2 seconds will

enable all of the dispenser functions.

WATER FILTER INDICATOR—The water filter

indicator function is the same as on other Whirl

pool refrigerators with filtered water systems.

Pressing the RESET keypad for 2 seconds

will reset the indicator back to green, and the

counter will start over. The filter indicator can

only be reset when the filter indicator light is

“red,” no matter when the filter is changed.

Maximum filter capacity is 400 gallons, or for

a time period not to exceed 6 months.

-

-

-

-

3-3

Page 18

ELECTRONIC CONTROL BOARD

The main electronic control board is located

at the right rear of the unit compartment (fac

ing from the rear). The main electronic board

communicates with the user interface. It also

receives and reacts to feedback from other

THERMISTORS

Temperature is regulated with the use of two

thermistors that provide feedback to the main

control board. One thermistor is located on the

back wall of the refrigerator section, and the

other is located on the left wall of the freezer

section.

NOTE: Thermistors are very reliable and seldom fail.

sources, such as water valves, thermistors,

defrost bimetal, refrigerator and freezer light

switches, and the air damper. The electronic

control board directly controls, or supplies power

to, virtually all functions of the refrigerator.

The refrigerator thermistor controls:

• Motorized air baffle (damper)

• Evaporator fan (only when the air baffle

is open)

The freezer thermistor controls:

• Compressor

• Condenser fan

• Evaporator fan (only when the air baffle

is closed)

3-4

Page 19

DEFROST OPERATION

Defrost is controlled by the main control board,

and incorporates the use of the “pulsed” de

frost. However, this defrost system is uniquely

different than other Whirlpool electronic refrig

erators.

• Defrost is initiated by a different set of

criteria (listed below).

• The bimetal/thermofuse combination

switches off the defrost heater, and

provides additional defrost circuit pro

tection.

• The defrost bimetal is placed on the

neutral side of the defrost heater, and

the thermofuse protects the “line” side

of the circuit.

• The electronic control does not “timeout” and terminate the defrost cycle.

Defrost is terminated only by the open

ing of the bimetal switch contacts, or the

opening of the thermofuse in case the

bimetal fails.

• The bimetal opens at 45

and closes at 19°F ±5° (–7°C ±3°).

• The thermofuse will open at 162

(72°C).

The defrost cycle is initiated:

• When power is connected (after the

initial power-up) to the refrigerator and

the bimetal is closed (unit is cold).

• With no door openings.

- When 30 hours of compressor run

time, or 50 hours actual time, has

passed since the last defrost cycle.

°F ±5° (7°C ±3°)

°F

• If a door was opened.

-

-

The following occurs when the defrost cycle

is initiated:

-

-

When defrost bimetal thermostat opens:

- After 8 hours of cumulative compres

sor run time.

• The compressor runs continuously for

at least 8 hours.

• Cooling function switches OFF (compressor and both fans are OFF).

• The air-baffle/damper switches to the

CLOSED position.

• The heater starts to heat the evaporator

with the following timing:

- 5 minutes ON, 1 minute OFF.

- 3 minutes ON, 1 minute OFF repeat-

edly.

- Bimetal thermostat opens at 45°F ±5°

(7°C ±3°).

• The defrost heater is switched OFF.

• The compressor is activated after

7 minutes of drip time.

• The condenser fan is activated 1 minute

after the compressor.

• The evaporator fan is activated after

10 minutes from bimetal opening, or

3 minutes after the compressor starts.

• The air baffle is opened 3 minutes after

the compressor is activated, or a total

time of 10 minutes from the bimetal

opening.

-

3-5

Page 20

FAN OPERATION AND DELAY

Both the condenser and evaporator fan motors operate on DC voltage. The control board

supplies 115 volts AC to each motor, where it

is converted to DC.

EVAPORATOR FAN

• Fan Start Delay—Fan is energized

3 minutes after the compressor starts.

• Fan Stop Delay—Fan is switched OFF

1 minute after the compressor stops.

• IMPORTANT: Evaporator fan shuts off

when either the refrigerator or freezer

door is opened.

CONDENSER FAN

• Fan start delay—Fan is energized

1 minute after the compressor starts.

• Fan stops when the compressor shuts

off.

POWER FAILURE / TEMPERATURE RISE

This product has no audible alarm. However, it

will alert the customer of a long power outage,

or temperature rise, if the temperature rises

above 17.6

following will happen:

• The “alert” will only be indicated on the

• The freezer temperature display blinks

• The actual compartment temperature

• All settings and memory are saved and

°F (–8°C). Should this occur, the

freezer temperature display.

continually, and will show the actual

freezer compartment temperature from

the time the power is restored. If there

are consecutive outages, the display

will show the highest temperature for

the entire period.

will display until the freezer COLD or

COLDER keypad is pressed. The “alert”

is terminated, and the display will revert

back to the set temperature.

are continued after power has been restored, i.e. FAST FREEZE, GROCERY

SAVOR, and ice preference.

DEFAULT SETTINGS

If communication between the user interface

and the control board is lost for more than

3 minutes, the user interface assumes the

board is working correctly. The control board

stores the current temperature settings, but

will go into a “default mode,” and maintain

preset temperatures. Once communication is

restored, the stored settings are again used.

If communication is broken between the user

interface and the control board during an “ON”

cycle:

Electronic Control

• Default temperatures that will be maintained are:

- Refrigerator section: 41

- Freezer section: 0

User Interface

• Freezer display flashes “CF” and Set

Temp alternately (Communication

Fault).

• Refrigerator display flashes the Set

Temperature.

• The user interface keypads will be dis

abled

• The ice maker will be disabled.

• The water filter status indicator light

will blink, and the reset keypad will be

disabled.

• The refrigerator and freezer interior

lights will be off, except for the indicators

above.

Default Operation If Thermistors Fail:

• Refrigerator thermistor fails:

- Damper and evaporator fan will be

cycled “on” 15 minutes and “off”

30 minutes.

• Freezer thermistor fails:

- Compressor and evaporator fan will

run continuously.

°F (5°C).

°F (–18°C).

-

3-6

Page 21

IN-DOOR ICE

IMPORTANT:

The In-Door Ice (IDI) feature and function on

this product is the same as on all other IDI

refrigerators.

Although physically interchangeable with other

IDI electronic controls, these control boards

are unique to this product and will not function

in other IDI product, nor will other IDI controls

function in this product.

If replacement controls are needed, order by

model number.

The IDI control board and the ice maker are

powered directly from the control board. This

allows the main control board to monitor the ice

maker water fill, and the closing of the freezer

light switch when the door is opened. When

the freezer door is opened, the ice maker is

temporarily disabled.

The IDI diagnostic routine is also identical, and

the checkout procedure is the same. For more

information on diagnostics, or IDI design and

function, refer to Job Aid #4322658A.

3-7

Page 22

— NOTES —

3-8

Page 23

COMPONENT ACCESS

WARNING

This section instructs you on how to service components inside the 2003 69˝ High Counter-Depth

Side-By-Side Refrigerator. The components and their locations are shown below.

of the components called out below are not serviced in this section.

COMPONENT LOCATIONS

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

NOTE: Some

Ice Maker

Freezer Light

Freezer Thermistor

Defrost Bimetal (Behind Evaporator Cover)

User Interface

Evaporator Tray (Behind Grille)

Compressor Terminal Box

Overload & Relay

Water Valves

Condenser Fan Motor

Refrigerator Light

Air Door

Refrigerator Thermistor

Water Reservoir Tubing

Control Board Assembly

4-1

Page 24

REMOVING A REFRIGERATOR OR FREEZER LIGHT BULB

1. Unplug refrigerator or disconnect power.

2. To remove the freezer light bulb:

a) Unhook the four tabs from the light cover

(located behind the in-door ice maker)

and remove the cover.

Freezer Light Cover

b) Pull the light bulb out of the socket.

Freezer Light Bulb

3. To remove the refrigerator light bulb:

a) Remove the screw from the lens.

b) Lower the back of the lens and unhook

the three tabs from the liner slots.

Refrigerator Light Lens Light Bulb

Lens Screw

c) Pull the light bulb so that the terminals

are free of the socket and remove the

bulb.

4-2

Page 25

REMOVING THE DEFROST BIMETAL

WARNING

7. Lift the top evaporator cover and unhook

the two tabs from the slots in the cover,

then pull the cover up around the drawer

slides, and out of the unit.

Top Evaporator Cover

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Remove the food and shelves from the

freezer compartment.

3. Pull forward on center of the top air guide.

Unsnap the four liner catches from the

guide supports, and remove the guide.

Liner Catch

(1 of 4)

Pull

Out

Air Guide

2 Tabs

In Slots

Screw (1 of 4)

2 Shelf

Supports

Screw (1 of 4)

Bottom

Evaporator

Cover

8. Cut the indicated wire tie from around the

defrost bimetal wires and tubing.

9. Disconnect the two heater connectors and

the evaporator fan motor connector from

the defrost bimetal.

10. Unsnap the defrost bimetal from the evaporator tubing and disconnect the ground

wire and 5-wire connector from the liner.

4. Remove the screw from each of the two

indicated shelf supports and remove

the supports (see the top right column

photo).

5. Remove the four screws from the top

evaporator cover.

6. Remove the four screws from the bottom

evaporator cover and remove the cover.

Evaporator Fan

Motor Connector

Heater Connectors

5-Wire

Connector

Wire Tie

Defrost Bimetal

4-3

Page 26

REMOVING THE REFRIGERATOR THERMISTOR HOUSING

WARNING

4. Unclip the refrigerator thermistor and wire

from the housing.

5. Place the thermistor in ice water (refer to

page 6-9 for the correct readings).

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

Refrigerator Thermistor

1. Unplug refrigerator or disconnect power.

2. Remove the food and shelf that is in front

of the refrigerator thermistor.

3. Remove the screw from the refrigerator

thermistor housing and turn the housing

over.

Unclip

Refrigerator Thermistor Housing Screw

4-4

Page 27

REMOVING THE WATER & ICE

WARNING

DISPENSER BOARD INTERFACE

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

Push

Down

Pull

Out

2. Lift the overflow tray from the water and

ice dispenser.

Overflow Tray

3. Push down on the bottom of the front cover

housing of the water and ice dispenser,

then pull the housing out at the bottom,

and unhook it at the top (see the top photo

in the right column).

4. Disconnect the two edge connectors from

the board interface and remove the hous

ing assembly.

Board Interface Edge Connectors

Continued on the next page.

-

4-5

Page 28

5. Remove the three screws from the interface

board cover and remove the cover.

Board Interface Cover Screws

IMPORTANT: Due to static electricity, always

handle circuit boards by the edges to avoid

damage to the circuitry.

6. Remove the two screws from the interface

board and remove the board from the

housing.

Interface Board Screws

Interface Board

4-6

Page 29

REMOVING THE EVAPORATOR TRAY

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

NOTE: The evaporator tray is not customer

removable.

1. Unplug refrigerator or disconnect power.

2. Remove the two screws from the bottom

grille and remove the grille.

3. Remove the two 9/32

screws from the filter bracket, and push

the bracket assembly to the right as far as

it will go.

Filter Bracket Screws

4. Pull the evaporator tray out from below

the unit and remove it.

ʺ (7 mm) hex-head

Bottom Grille Screws

Evaporator

Tray

4-7

Page 30

REMOVING THE CONTROL BOARD

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Remove the six screws from the unit compartment cover and remove the cover.

4. Using a small screwdriver, start at the top

of the cover, and pry the tabs on the hous

ing from the loops on the cover. When all

the loops are free, remove the cover.

Top Of Housing Cover Open

-

Unit Compartment Cover Screws (3 of 6)

3. Remove the two screws from the control

board housing cover and pull the assembly

out of the unit.

Control Board Housing

Cover Screws

5. Remove the four screws from the control

board.

6. Disconnect the wire connectors from the

control board and remove it from the hous

ing.

Wire Connectors

4 Control Board Screws

-

4-8

Page 31

REMOVING THE WATER VALVES

WARNING

3. Disconnect the two water outlet lines from

the water valves.

4. Disconnect the four electrical connectors

from the valve terminals. NOTE: One

valve has 3/16

has 1/4

reversed.

ʺ terminals so that they cannot be

ʺ terminals and the other

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Remove the six screws from the unit compartment cover and remove the cover.

Unit Compartment Cover Screws (3 of 6)

5. Remove the two 9/32ʺ hex-head screws

from the valve bracket.

6. Disconnect the two water inlet lines from

the water valves and remove the valve

assembly from the unit.

Bracket

Screws

Brn & Blk Connectors

Blu & Wht Connectors

Water Outlet Lines

4-9

Water Inlet Lines

Page 32

REMOVING THE CONDENSER FAN MOTOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Remove the six screws from the unit compartment cover and remove the cover.

4. Remove the three Torx (#15) screws from

the condenser fan motor and remove the

motor from the bracket.

Fan Motor Torx

Screws (2 of 3)

Unit Compartment Cover Screws (3 of 6)

3. Using a 9/16ʺ socket, remove the hex-nut

and fan blade from the condenser fan mo

tor.

Fan Blade

9/16ʺ Socket

5. Disconnect the wire connector from the

fan motor.

-

Fan Motor Connector

4-10

Page 33

REMOVING THE COMPRESSOR TERMINAL BOX,

WARNING

THE RELAY & OVERLOAD AND RUN CAPACITOR

4. To remove the compressor terminal

box:

a) Use a screwdriver and pry the top of the

terminal box away from the compres

sor.

-

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Remove the six screws from the unit compartment cover and remove the cover.

Unit Compartment Cover Screws (3 of 6)

Pry Top Of Terminal Box

Away From Compressor

b) Use a screwdriver and unsnap the

locking tab at the lower front of the

compressor, then pull the box away

from the compressor so that you can

access the relay and overload.

3. Place a screwdriver blade into the indicated slot of the compressor terminal box

cover, and pry the cover off the box.

Pry Cover Off

Terminal Box

Pry Lower Front Of

Terminal Box Away

From The Compressor

Continued on the next page.

4-11

Page 34

5. To remove the relay and overload:

6. To remove the run capacitor:

a) Remove the terminal box from the

compressor (see step 4 for the proce

dure).

b) Pry the relay off the top two pins of the

compressor.

c) Pry the overload off the bottom pin of

the compressor.

Relay

Overload

a) Remove the terminal box from the

-

compressor (see step 4 for the proce

-

dure).

b) Use a 1/2

˝ socket and remove the run

capacitor nut from the bracket.

1/2ʺ Socket

Run Capacitor

d) Disconnect the white (1), blue (2), and

black (3) wires from the relay terminals.

NOTE: The terminal numbers are embossed on the connector.

e) Disconnect the black wire from the

overload terminal.

Overload

Relay

Black (3)

White (1)

Blue (2)

Black

c) Disconnect the white (1) and black (3)

wires from the relay terminals (see the

photo at the bottom left).

d) Loosen the screw from the left strain

relief and remove the wire and run

capacitor.

Run Capacitor

Wire

4-12

Strain Relief

Page 35

COMPONENT TESTING

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

The chart below lists all major electrical components and the procedure for checking them. All

continuity/resistance checks should be done with harness connectors unplugged.

COMPONENT TESTING CHART

COMPONENT

Compressor:

Run Windings

Start Windings

Start Relay 120 VAC Continuity

Overload Protector 120 VAC Continuity

Run Capacitor

Electric Air Baffle

(Motor)

Thermistors:

RC Side

FC Side

VOLTAGE AT

COMPONENT

120 VAC

120 VAC Momentary resistance

120 VAC

Low voltage;

cannot measure

RESISTANCE / WATTS

Compressor pins:

1 to 5 Ω

3 to 11

Approx. 8450

2700 Ω at 77ºF (25ºC)

8750

Ω

Ω, 1.5 Watts

Ω at 32ºF (0ºC)

TEST LOCATIONS

See Tech-Sheet

Performance Data Chart.

Terminals “S” and “R”

Between terminals.

Check at capacitor;

reverse test leads and

check again.

Check resistance at

Control Board terminals

16/4 & 12/7. During normal operation, 120V is

present at Baffle termi

nals 1 & 2.

RC thermistor at Control

Board pins 4/1 & 4/3.

FC thermistor at Control

Board pins 4/2 & 4/4.

-

Continued on the next page.

5-1

Page 36

COMPONENT TEST LOCATIONS

VOLTAGE AT

COMPONENT

RESISTANCE / WATTS

Electronic Control Board Will have 120V at

User Interface Board

Defrost Bimetal

Defrost Heater

Evaporator Fan Motor

Condenser Fan Motor

Ice Dispenser Motor

120 VAC

120 VAC

120 VAC

120 VAC

120 VAC

120 VAC

120 VAC

Opens @ 45ºF±5º (7ºC±3º)

Closes @ 19ºF±5º (–7ºC±3º)

Opens @ 162ºF (72ºC)Thermofuse

27 to 21 Ω

N/A120 VAC

N/A

550 to 650 Watts

3 Watts

5 Watts

N/A

Control Board terminals

3 & 2.

Will have 120V at User

Interface pins 5/3 & 5/1.

Check for continuity.

Check resistance at

Control Board terminals

16/1 & 12/1 or at heater.

Cannot read resistance/

120 VAC converted to

DC voltage in the motor.

Cannot read resistance/

120 VAC converted to

DC voltage in the motor.

Will have 115 VDC at

Dispenser Motor terminals 1 & 5. DC polarity

determines the rotation

of the motor:

Terminal 1 5

Crushed: – +

Cube: + –

5-2

Page 37

DIAGNOSTICS & TROUBLESHOOTING

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

Diagnostics on this product are different than

on other Whirlpool SxS refrigerators. Several

error codes are available, however there is no

“diagnostic mode” that can be “entered” on the

electronic control to allow operation of each

function separately.

Virtually all functional component testing must

be performed similarly to a non-electronic

product by verifying whether the component

is “good,” or whether there is voltage present

at the component. To know how these components function in this product, refer to the

“Theory of Operation” section and the contents

of this section.

IMPORTANT INFORMATION

Electronic Control Board

• Virtually all components and functions are

electrically connected to and controlled by

the Electronic Control Board both on the

“line” and “neutral” side. The exception is the

ice dispenser motor and the dispenser light.

These components are directly connected

to and controlled by the User Interface.

• The majority of components and functions

controlled by the Electronic Control Board

are switched on the “neutral” side of the

circuit. This means the “line” side of the

circuit to the component(s) always has

voltage potential.

User Interface Control Board

• The User Interface Control Board is also

energized by “line” and “neutral” circuits

through the Electronic Control Board.

Communication between the two boards

is through the “TX” and “RX” circuits (refer

to the Wiring Diagram and Strip Circuit).

• Turning OFF the refrigerator turns off all of

the interior and indicator lights except two

dots (“.”) in the temperature displays.

6-1

Page 38

SUGGESTIONS ON DIAGNOSIS

IMPORTANT:

1. Check harness connectors for good contact.

2. Before replacing any component verify,

whenever possible, that the component

has proper continuity or resistance values.

There must be proper power to operate the

component.

Display Shows Error Codes

• If error codes “C”, “d” or “CF” show in the

display, refer to the “User Interface Failure

Feedback” and “Component Testing” charts

and check out the appropriate component(s).

Display Is Normal

• Disconnect power for 10 seconds and reconnect power. If error code is displayed

after 3 minutes, refer to the “User Interface

Failure Feedback” and “Component Testing” charts, and check out the appropriate

component(s).

• If no error codes display and a malfunction

is occurring, check or troubleshoot the fol

lowing appropriate areas. Also refer to the

“Component Testing” and “Troubleshooting”

charts.

- Electrical system

- Restricted or lack of proper airflow

- Defrost system

- Unusual noises

- Cooling system

Display Is Blank

• Refer to “User Interface Failure Feedback”

and “Troubleshooting” charts.

-

6-2

Page 39

USER INTERFACE FAILURE FEEDBACK

WARNING

The User Interface can display several failure codes. The display will only show the code(s) for

10 minutes, then revert back to the set temperature(s). To access these codes again, disconnect

power to the refrigerator for 10 seconds and then power it up again. It may take 3 minutes for the

error code(s) to display. The following table summarizes these codes.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

FAILURE

No lights inside the refrigerator.

No display indicators

except “.” dots in both

temperature displays.

No indicators illuminate

on user interface.

Unit may or may not be

cooling.

Code “d” blinking on the

refrigerator display.

POSSIBLE CAUSE TEST PROCEDURE—ACTION

The refrigerator is OFF.

No power to the user interface

from the control board.

Air door stuck or open circuit.

Press the ON/OFF keypad for two seconds to

turn the unit ON.

Unplug refrigerator or disconnect power.

Check circuits/connectors from control board

to user interface.

Attempt to turn ON unit by pressing the ON/

OFF keypad.

If unit is cooling, control board is in default

mode.

If unit is not cooling, unit may be OFF with no

way to turn it ON.

Refer to the “Troubleshooting Chart.”

Perform resistance checks (refer to “Component Testing” section).

Verify the proper wire connections to the air door

motor and control board. Refer to “Component

Testing,” page 5-1, and “Strip Circuits,” page

7-3.

Replace the air door.

Code “C” blinking on the

refrigerator display.

Code “C” blinking on the

freezer display.

Refrigerator thermistor failure.

Freezer thermistor failure.

6-3

Perform resistance checks (refer to “Component Testing” section).

Verify the proper connections to the main

board and the resistance value of the thermistor.

Replace the main board.

Perform resistance checks (refer to “Component Testing” section).

Verify the proper connections to the main board

and the resistance value of the thermistor.

Replace the main board.

Continued on the next page.

Page 40

FAILURE POSSIBLE CAUSE TEST PROCEDURE—ACTION

Code “CF” blinking on the

freezer display.

18ºF (–8ºC) or higher

temperature reading is

blinking on the freezer

display.

Communication failure between

main board and user interface.

Over-temperature condition due

to power failure.

Verify the proper connections & circuits for RX

and TX.

Replace the user interface and if the problem

persists, replace the main board.

Verify proper main plug connection.

Press the freezer temperature keypad to reset.

6-4

Page 41

TROUBLESHOOTING CHART

WARNING

The following table shows the various types of appliance faults:

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

PROBLEM POSSIBLE CAUSE

No indicators or functions

on user interface.

Indicators for set temperatures display correctly,

but dispenser light is dim

when turned on, and ice

will not dispense.

No water when dispenser

lever is pressed.

No ice dispensed when

dispenser lever is

pressed .

No power supply.

Open neutral circuit to user

interface.

Microswitch or water valve failure. Verify proper wire connections to microswitch

Microswitch or ice motor failure. Verify proper wire connections to microswitch

TEST PROCEDURE—ACTION

Verify circuits RX and TX. Verify proper wire

connections from main board pins 12/11 &

12/12, to user interface pins 3/1 & 3/2.

Refer to wiring diagram.

Replace the user interface.

Check for proper wiring and connections of

neutral circuit from control board (pin 12/10)

to user interface (pin 5/1).

at main board pins 6/3 & 16/9. Verify water

valve connections at main board pins 6/2 and

6/5.

Refer to “Component Testing” section & “Strip

Circuits.”

Replace the control board.

at user interface board pins 3/3 & 5/3. Verify

ice motor connections at user interface board

pins 5/4 and 5/5.

Refer to “Component Testing” section & “Strip

Circuits.”

Replace the user interface.

Refrigerator compartment

light does not switch on

when door is opened.

Freezer compartment

light does not switch on

when door is opened.

Burned out lamp.

Loose wiring connections.

Door switch failure.

Burned out lamp.

Loose wiring connections.

Door switch failure.

6-5

Verify if the lamp is good.

Verify proper operation of refrigerator com-

partment door switch and connections.

Verify if the lamp is good.

Verify proper operation of freezer compart

ment door switch and connections.

Continued on the next page.

-

Page 42

PROBLEM POSSIBLE CAUSE

TEST PROCEDURE—ACTION

Ice maker not producing

any ice.

Evaporator fan motor

does not run.

Condenser fan motor

does not run.

Loose connections.

Ice maker failure.

IR receiver relay failure.

IR receiver and emitter optics

failure.

Fan motor stuck.

Control board may have initiated

fan delay.

Refrigerator or freezer light

switches not closing fan circuit.

Loose connection.

Control board.

Fan motor stuck.

Control board may have initiated

fan delay.

No voltage to fan motor.

Loose connection.

Control board.

Verify proper wire connections. Refer to the

wiring diagram.

Refer to the ice maker “Diagnostic & Troubleshooting” section in In-Door Ice Job Aid

#4322658A.

Replace the IDI electronic boards.

NOTE: In-Door Ice infrared electronic boards

used in this product are unique to this product. Other IDI boards fit, but will not allow the

icemaker to function.

Verify that motor spins freely.

Verify that the control board is not in fan de

lay.

Motor rectifies 120 volts AC to DC for operation.

Verify both light switches function properly.

Verify proper circuit and wire connections

back to the control board.

Replace the control board.

Verify that motor spins freely.

Verify that the control board is not in fan delay.

Motor rectifies 120 volts AC to DC for operation.

Verify proper wire circuit and connections

back to the control board.

Replace the control board.

-

Compressor will not run. Check the compressor for the following:

Refrigerator turned OFF.

Control board may have initiated

delay.

Overload or relay failure.

Loose/open electrical connections.

Compressor is stuck.

Control board.

• Unplug refrigerator or disconnect power.

• Verify that control board is not in compressor start delay mode. (Refer to “Theory of

Operation” Section).

• Verify proper wire connections.

• Voltage to main control board is missing,

replace the main control board.

• Verify that overload and relay are good. If

not, replace.

• Verify compressor windings are good, (refer to the Tech Sheet), and that the com

pressor is not stuck. Replace compressor,

if necessary.

-

6-6

Page 43

PROBLEM POSSIBLE CAUSE

TEST PROCEDURE—ACTION

Will not defrost.

Refrigerator too cold or

too warm.

Defrost heater.

Defrost bimetal / thermofuse.

Control board.

Air door may be stuck or frozen

open.

User interface may be malfunctioning.

Defrost can be initiated by disconnecting and

reconnecting power. Main control board will

attempt to initiate defrost upon restart:

• If bimetal is closed, defrost cycle will start.

Relay on main control board will click one

time.

• If bimetal or defrost circuit is open, defrost

cycle will not start, and the cooling cycle

will begin. Relay on main control board will

click twice (once to initiate defrost and the

second time to switch back to cooling).

Unplug refrigerator or disconnect power.

Refer to “Component Testing” on page 5-2.

Check for continuity through heater, bimetal,

and thermofuse.

Check for loose electrical connections.

If all checks out, replace the main control

board.

Check air door operation.

Unplug refrigerator or disconnect power.

Check resistance of refrigerator thermistor.

Replace user interface.

6-7

Page 44

ELECTRONIC CONTROL BOARD PIN LOCATIONS

3 2 1

BL BK BR

6 5 4

3 2 1

4 3

2 1

8 7 6

16 15 14 13 12 11

5 4 3

10 9

2 1

6 5 4 3

12 11 10 9 8 7

2 1

FC RC

3 PIN CONNECTOR (Control Board)

Pin 1 Line

Pin 2 Compressor Command (

Line)

Pin 3 Neutral

6 PIN CONNECTOR (Control Board)

Pin 1 Ice Maker Ice Valve Return (Line)

Pin 2 Water Valve Feedback (

Pin 3 Condenser Fan Line (

Pin 4 Ice Maker Ice Valve Neutral (

Pin 5 Water Valve Neutral (

Pin 6 Condenser Fan Load (

Line)

Line)

Neutral)

Neutral)

Neutral)

16 PIN CONNECTOR (Control Board)

Pin 1 Freezer Line

Pin 2 Door

Pin 3 Receiver IDI

Pin 4 Air Door

Pin 5 Lamps

Pin 6 Freezer Lamp Feedback (

Pin 7 Refrigerator Lamp Feedback (

Pin 8 Ice Maker Ice Valve Return (

Pin 9 Water Valve Feedback (

Pin 10 N.C.

Pin 11 Emitter IDI Neutral (

Line

Line

Line

Line

Line)

Line)

Line)

Line)

Neutral)

Pin 12 Freezer Lamp Load (

Pin 13 Refrigerator Lamp Load (

Pin 14 Defrost Heater (

Pin 15 Ice Maker Load (

Pin 16 Receiver IDI Load (

Neutral)

Neutral)

Neutral)

Neutral)

Neutral)

12 PIN CONNECTOR (Control Board)

Pin 1 Bimetal Feedback (Neutral)

Pin 2 N.C.

Pin 3 Freezer Lamp Feedback x Re-

ceiver IDI (

Line)

Pin 4 N.C.

Pin 5 Air Door Feedback (

Pin 6 Emitter IDI Line (

Pin 7 Air Door Load (

Pin 8 Evaporator Fan Load (

Pin 9 N.C. (

Pin 10 Door Neutral (

Pin 11 Door RX (

Pin 12 Door TX (

Neutral)

Neutral)

Signal)

Signal)

Line)

Line)

Neutral)

Neutral)

4 PIN CONNECTOR (Control Board)

Pin 1 Refrig. Therm. Common (Signal)

Pin 2 Freezer Therm. Common (

Pin 3 Refrig. Therm. (

Pin 4 Freezer Therm. (

Signal)

Signal)

NOTE: Refrigerator thermistor

wires are marked with red tape.

Signal)

6-8

Page 45

USER INTERFACE BOARD PIN LOCATIONS

5

4

3

2

1

1

2

3

5 PIN CONNECTOR (User Interface)

Pin 1 Neutral

Pin 2 Dispenser Lamp Load (

Pin 3 Line

Pin 4 DC Ice Motor

Pin 5 DC Ice Motor

Neutral)

3 PIN CONNECTOR (User Interface)

Pin 1 Door TX (Signal)

Pin 2 Door RX (

Pin 3 DC Ice Motor Power Supply (Line)

Signal

THERMISTOR RESISTANCE / TEMPERATURE CHART

Temperature Temperature Resistance

F °C (Ohm)

°

77.0 25 2700

50.0 10 5348

45.0 7 6033

40.0 4 6989

35.0 2 7916

* 32.0 0 8750

30.2 –1 9216

25.0 –4 10483

20.0 –7 12269

15.0 –9 14019

10.0 –12 16497

5.0 –15 19474

0 –18 22417

–5.0 –21 27402

–10.0 –23 31717

–15.0 –26 37922

–20.0 –29 44130

–25.0 –32 53111

–30.0 –34 62155

* To accurately check a thermistor, place it in ice water for 60 seconds, then measure its resistance.

6-9

Page 46

— NOTES —

6-10

Page 47

WIRING DIAGRAM & STRIP CIRCUITS

Cond.

Fan

Compr.

Plug

Disp.

Va

lve

Wa

ter

Disp. Sw.

I/M

Va

lve

Ice Chute

Door Heater

Dispenser

Heater

Input

Communication

Input / Output

Communication

Door

Heater

Door

Heater

Switch*

Ice Maker

IDI Emitter

IDI Receiver

FZR Thermistor

RFG Thermistor

Dispenser

Light

DC Ice Dispenser

Motor

RX

TX

GND

CONTROL BOARD

N L L L L

L

LL L

L

L

L

L

L

N N N N

N

N

N

N

N

N

N

1

4

2

3

1

2

8

6

3

2

3

1

4

4

5

12 3

3 / 3

5 /

5

5 / 4

5 /

3

5 /

1

3 /

2

3 / 1

5 /

2

3 1 2

Ice

Disp.

Evap.

Fan

Defrost

Bimetal

Defrost

Heater

Thermofuse

Air Door

FZR Light

Switch

BR

BL

BRBRBR

BR

BL

S BLBK

YL

BL

OR

BL

BL

BL

BK

BL

V

V

WH

BR

BK

GN / YL

BR

BL

BR

BR

BR

BL

BL

BR

BK

BK

WH

WH

WH

OR

GR

V

S BL

YL

BK

OR

BK

PK

BL

BL

GR

WH

OR

OR

RFG Light

Switch

User Interface

DC Power

Supply

16 / 5

16 / 3

6 / 3

6 / 6

16 / 9

16 / 15

16 / 11

6 / 2

6 / 5

6 / 4

6 / 1

16 / 8

16 / 7

16 / 13

16 / 12

16 / 6

16 / 14

12 / 1

12 / 6

12 / 3

16 / 1

16 / 4

12 / 10

12 / 11

4 / 1

4 / 3

4 / 2

4 / 4

12 / 12

16 / 2

12 / 8

12 / 7

12 / 5

* Early Production

WIRING DIAGRAM

7-1

Page 48

COMPRESSOR

L1 N

Control Board

Control Board

Bimetal

1 3

16 / 1

BR

BR

S BL

BL

OR

OR

WH

16 / 14

12 / 1

Defrost Heater

Defrost

Thermofuse

Bimetal Feedback

To

Control Board

N

Overload

C

BR BK

BL

S

M

Compressor

Run

Capacitor

PTC Relay

RUN

START

L1

Control Board

1 2

L1 N

Control Board

(Fan Delay)

Control Board

1 3

6 / 3 B

L B

LBR BR 6 / 6

Condenser

Fan Motor

L1 N

Control Board

(Fan Delay)

Control Board

1

3

16 / 1BR

BR

BK BL

12 / 8

Evaporator

Fan Motor

CONDENSER FAN MOTOR

STRIP CIRCUITS

DEFROST

EVAPORATOR FAN / DELAY

7-2

Page 49

DAMPER (AIR DOOR MOTOR)

L1

N

Control Board

Control Board

1

3

2

1

3

16 / 4BR

BR

V

BL

OR

12 / 7

12 / 5

Air Door Motor

(Door Open)

Air Door Feedback

To

Control Board

L1

N

Control Board

Refrigerator Light

Control Board

1

3

16 / 5

16 / 13

16 / 7

Refrigerator

Light Sw.

Feedback To Control Board

BR

BR

PK BL BL

PK

L1

N

Control Board

Freezer Light

Control Board

1

3

16 / 5

16 / 12

16 / 6

Freezer

Light Sw.

Feedback To IDI Receiver Board

BR

BR

GR BL

BL

GR

L1

N

Control Board

User Interface

Dispenser Light

Control Board

1

5 / 2 5 / 1

3

16 /

2

12 / 10

BR

BR GR BL

BL

REFRIGERATOR LIGHT

FREEZER LIGHT

DISPENSER LIGHT

7-3

Page 50

WATER DISPENSER

L1

N

Control Board

Control Board Control Board

1

3

6 / 3

BR

BR WH BL

BL

V

6 / 2

16 / 9

6 / 5

Dispenser

Valve

Wa

ter

Dispenser Sw

.

L1

N

Control Board

Control Board

1 3

16 / 2

12 / 10

Ice Chute

Door Heater

BR

BR BL

BL

L1

N

DC

Powe

r

Supply

Control Board

Control Board

User Interface

Ice

Dispenser Sw

.

1

3 / 3

1 5

5 4

16 /

2

BR BR

S BL

Y B

K

BL

BL

5 / 1

3

12 / 10

DC Dispenser

Ice Motor

L1

N

Control Board

Control Board

Heater Switch

3

1

16 / 2

BR

BR BR BL

BL

12 / 10

Freezer Door Heater

Dispenser

Housing Heater

ICE DISPENSER

NOTE: The ice dispenser motor rotates CW to

dispense crushed ice, and reverses rotation CCW

to dispense cubes. Reversing the DC voltage to

the motor changes its rotation.

ICE CHUTE DOOR HEATER

FREEZER DOOR & DISPENSER HOUSING HEATERS

7-4

Page 51

Control Board

Refrigerator Thermistor

Freezer Thermistor

4 / 1

4 / 3

4 / 2

4 / 4

BK

WH

WH

BK

L1

N

User Interface

Control Board

1

3

5 / 3

5 / 1

3 / 2

3 / 1

16 / 2

12 / 10

12 / 11

12 / 12

Line

Neutral

RX Signal

TX Signal

BR

BR

BL

WH

OR

BL

IDI ICE MAKER

L1

N

Ice Maker

Control Board

Control Board

IDI Receiver

Board

Freezer

Light Sw.

IDI Emitter

Board

I/M Fill Valve

3

1

6

3 3

3

12

2

1

8

4

4

2

4

12 / 3

16 / 3

16 / 5

16 / 6

16 / 15

6 / 4

6 / 1

16 / 8

16 / 11

12 / 6

BR

BK S BL

BL

BL

BR

BK

BL

BR YL

V

BR

OR

BR GR

THERMISTORS

POWER & COMMUNICATIONS CIRCUITS BETWEEN BOARDS

7-5

Page 52

— NOTES —

7-6

Page 53

TECH TIPS

REMOVING THE ORIGINAL GASKET

NOTE: Replacing the gasket requires trimming

away only the soft part of the original foamedin-place (FIP) gasket. Once the soft part of the

FIP gasket is removed, a channel is exposed

to install the service gasket.

To remove the original door gasket:

1. Cut the soft corner section of the FIP gasket.

3. Clean the remaining soft gasket burr from

all sides of the door.

Soft Burr

Channel

4. Clean the FIP gasket corner from the flash

and burr that was created when the gasket

was manufactured. The service gasket may

now be installed.

2. Trim the soft part of the gasket with a

knife around all four sides to expose the

channel where the service gasket will be

mounted.

Upper Soft Part

Of Foamed Gasket

Clean Away All Flash

And Burr

8-1

Page 54

INSTALLING THE SERVICE

GASKET

1. Insert the service gasket into the rigid foamed gasket channel.

2. Seat the service gasket securely into the

rigid foamed gasket channel with a mal

let.

Seat Gasket Into Rigid

Foamed Gasket Channel

-

Channel In

FIP Gasket

Insert Gasket Into Rigid

Foamed Gasket Channel

8-2

Page 55

PRODUCT SPECIFICATIONS

AND

WARRANTY INFORMATION SOURCES

IN THE UNITED STATES:

FOR PRODUCT SPECIFICATIONS AND WARANTY INFORMATION CALL:

FOR WHIRLPOOL PRODUCTS: 1-800-253-1301

FOR KITCHENAID PRODUCTS: 1-800-422-1230

FOR ROPER PRODUCTS: 1-800-447-6737

FOR TECHNICAL ASSISTANCE WHILE AT THE CUSTOMER’S HOME CALL:

THE TECHNICAL ASSISTANCE LINE: 1-800-253-2870

HAVE YOUR STORE NUMBER READY TO IDENTIFY YOU AS AN

AUTHORIZED SERVICER

FOR LITERATURE ORDERS:

PHONE: 1-800-851-4605

FOR TECHNICAL INFORMATION AND SERVICE POINTERS:

www.servicematters.com

IN CANADA:

FOR PRODUCT SPECIFICATIONS AND WARRANTY INFORMATION CALL:

1-800-461-5681

FOR TECHNICAL ASSISTANCE WHILE AT THE CUSTOMER’S HOME CALL:

THE TECHNICAL ASSISTANCE LINE: 1-800-488-4791

HAVE YOUR STORE NUMBER READY TO IDENTIFY YOU AS AN

AUTHORIZED SERVICER

Page 56

Loading...

Loading...