Whirlpool EL87TRRRQ Use And Care Manual

®

UPRIGHT FREEZER

Use & Care Guide

For questions about features, operation/performance,

parts or service, call: 1-800-253-1301.

In Canada, call for assistance 1-800-807-6777,

www.whirlpool.com or www.whirlpool.com/canada

or visit our website at...

CONGÉLATEUR

VERTICAL

Guide d’utilisation

et d’entretien

Au Canada, pour assistance, composez le 1-800-929-6631.

ou visitez notre site web à

www.whirlpool.com/canada

1-82515-001

Table of Contents/Table des matières .................. 2

TABLE OF CONTENTS

TABLE DES MATIÈRES

FREEZER SAFETY .........................................................................3

Proper Disposal of Your Old Freezer or Refrigerator ..................3

INSTALLATION INSTRUCTIONS..................................................4

Unpacking ....................................................................................4

Location Requirements................................................................4

Electrical Requirements ...............................................................4

Water Supply Requirements........................................................4

Water Supply Connection............................................................5

Freezer Door.................................................................................6

Adjust the Door ............................................................................8

FREEZER USE................................................................................8

Ensuring Proper Air Circulation....................................................8

Using the Control .........................................................................8

Key Eject Lock .............................................................................9

Ice Maker......................................................................................9

FREEZER FEATURES..................................................................10

Refrigerated Shelves..................................................................10

Door Bin......................................................................................10

Storage Basket...........................................................................10

Storage Gate ..............................................................................10

FREEZER CARE ...........................................................................11

Cleaning Your Frost-Free Freezer..............................................11

Base Grille ..................................................................................11

Defrosting and Cleaning Your Manual Defrost Freezer.............11

Changing the Light Bulb ............................................................12

Power Interruptions....................................................................12

Moving Care...............................................................................12

TROUBLESHOOTING ..................................................................13

ASSISTANCE OR SERVICE.........................................................14

FREEZER WARRANTY ................................................................15

SÉCURITÉ DU CONGÉLATEUR..................................................17

Mise au rebut appropriée de votre vieux

congélateur ou réfrigérateur.......................................................17

INSTRUCTIONS D'INSTALLATION.............................................18

Déballage....................................................................................18

Emplacement d’installation........................................................18

Spécifications électriques ..........................................................19

Spécifications de l’alimentation en eau .....................................19

Raccordement de la canalisation d'eau ....................................19

Portes du congélateur................................................................20

Ajustement de porte...................................................................23

UTILISATION DU CONGÉLATEUR.............................................23

Pour s’assurer d’une circulation d’air appropriée......................23

Utilisation de la commande........................................................23

Serrure à clé séparée .................................................................24

Machine à glaçons .....................................................................24

CARACTÉRISTIQUES DU CONGÉLATEUR...............................25

Clayettes de réfrigération ...........................................................25

Balconnet de porte.....................................................................25

Panier coulissant ........................................................................25

Barrière d’entreposage...............................................................25

ENTRETIEN DU CONGÉLATEUR ...............................................26

Nettoyage du congélateur sans givre ........................................26

Grille de la base..........................................................................26

Dégivrage et nettoyage du congélateur

à dégivrage manuel....................................................................26

Remplacement de l'ampoule d’éclairage ..................................27

Pannes de courant électrique ....................................................28

Déménagement..........................................................................28

DÉPANNAGE.................................................................................28

ASSISTANCE OU SERVICE.........................................................30

GARANTIE DU CONGÉLATEUR.................................................31

2

FREEZER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of fire, electric shock, or injury when using your freezer, follow these basic precautions:

WARNING:

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

■ Plug into a grounded 3 prong outlet.

■ Do not remove ground prong.

■ Do not use an adapter.

■ Do not use an extension cord.

■ Disconnect power before servicing.

■ Replace all panels before operating.

■ Use nonflammable cleaner.

SAVE THESE INSTRUCTIONS

Proper Disposal of

Your Old Freezer or Refrigerator

WARNING

Suffocation Hazard

Remove doors or lid from your old freezer or

refrigerator.

Failure to do so can result in death or brain damage.

IMPORTANT: Child entrapment and suffocation are not problems

of the past. Junked or abandoned freezers or refrigerators are still

dangerous... even if they will sit for “just a few days.” If you are

getting rid of your old refrigerator or freezer, please follow these

instructions to help prevent accidents.

■ Keep flammable materials and vapors, such as gasoline,

away from freezer.

■ Use two or more people to move and install freezer.

■ Keep key away from children.

■ Remove doors or lid from your old freezer or refrigerator.

■ Disconnect power before installing ice maker (on ice maker

kit ready models only).

Before You Throw Away Your Old Freezer or Refrigerator:

■ Take off the doors or lid.

■ Leave the shelves in place so that children may not easily

climb inside.

3

INSTALLATION INSTRUCTIONS

Unpacking

WARNING

Excessive Weight Hazard

Use two or more people to move and install freezer.

Failure to do so can result in back or other injury.

Remove Packaging Materials

■ Remove tape and glue residue from surfaces before turning

on the freezer. Rub a small amount of liquid dish soap over

the adhesive with your fingers. Wipe with warm water and

dry.

■ Do not use sharp instruments, rubbing alcohol, flammable

fluids, or abrasive cleaners to remove tape or glue. These

products can damage the surface of your freezer. For more

information, see “Freezer Safety.”

When Moving Your Freezer:

Your freezer is heavy. When moving the freezer for

cleaning or service, be sure to protect the floor. Always pull

the freezer straight out when moving it. Do not wiggle or

“walk” the freezer when trying to move it, as floor damage

could occur.

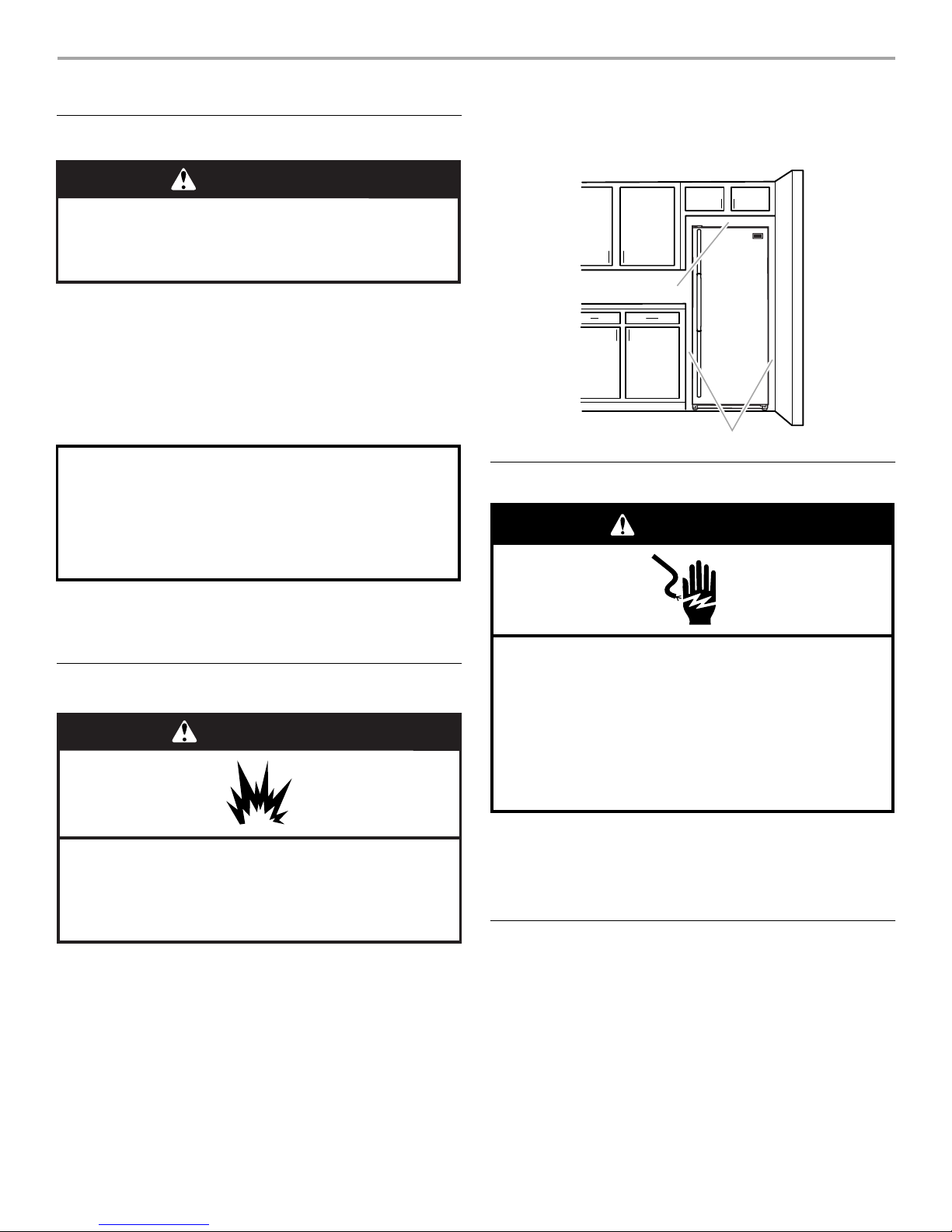

NOTE: This freezer may be installed side by side with another

refrigerator or freezer. Allow for a 3" (7.5 cm) clearance at the top

and sides and a ¹⁄₄" (0.64 cm) clearance between the appliances.

3" (7.5 cm)

3" (7.5 cm)

Electrical Requirements

WARNING

Clean Before Using

After you remove all of the packaging materials, clean the inside

of your freezer before using it. See the cleaning instructions in

“Freezer Care.”

Location Requirements

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from freezer.

Failure to do so can result in death, explosion, or fire.

IMPORTANT: Do not install the freezer near an oven, radiator, or

other heat source, nor in a location where the temperature will fall

below 40°F (5°C).

Check the strength of the floor before installing your freezer. It

should hold the weight of a freezer fully loaded with food.

Allow at least 3" (7.5 cm) of air space at the top and on both sides

of the freezer and 1" (2.5 cm) between the back of the freezer and

the wall. If the freezer is to be against a wall, leave extra space on

the hinge side so the door can open wider.

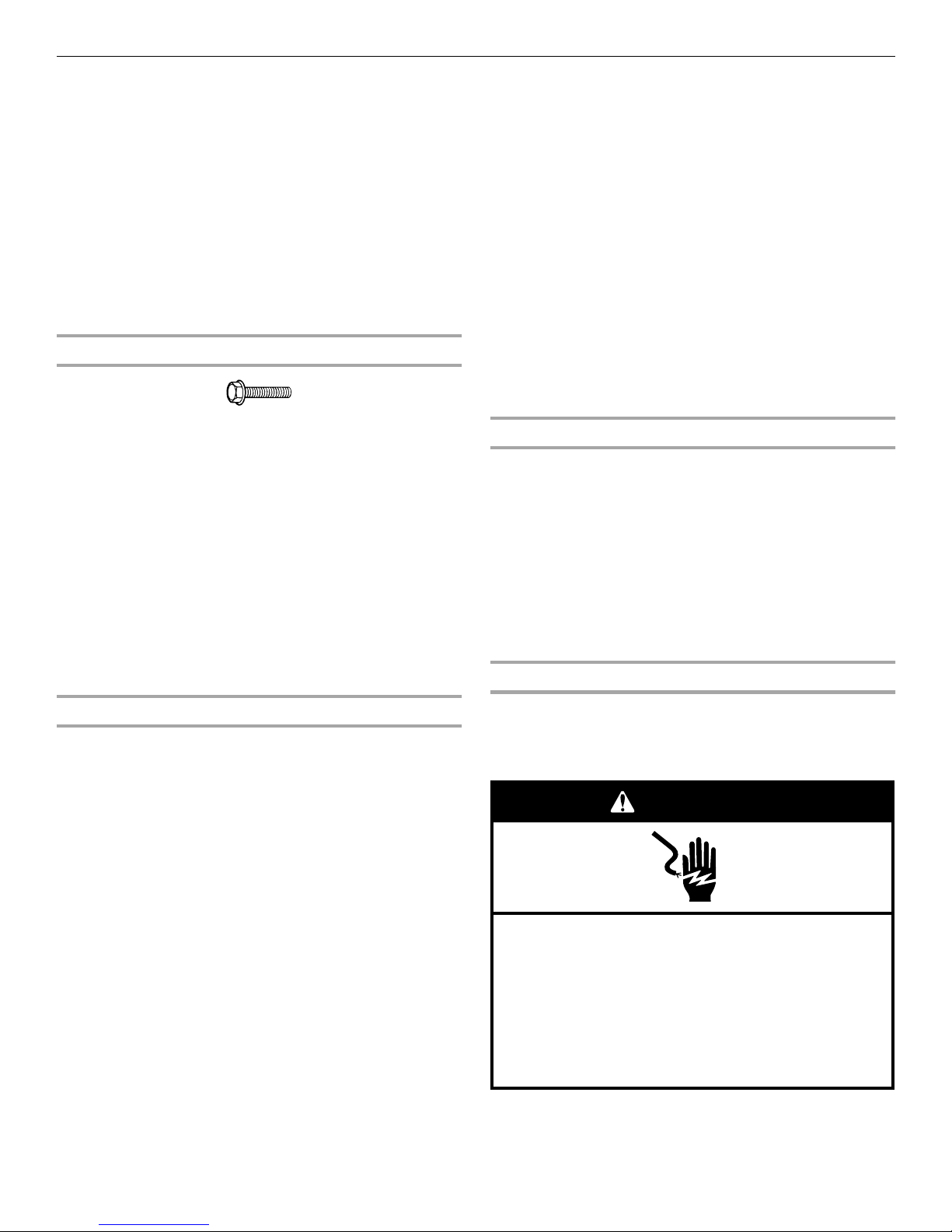

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Recommended grounding method

A 115 Volt, 60 Hz., AC only 15- or 20-amp fused, grounded

electrical supply is required. It is recommended that a separate

circuit serving only your freezer be provided. Use an outlet that

cannot be turned off by a switch or pull chain. Do not use an

extension cord.

Water Supply Requirements

Read all directions carefully before you begin.

IMPORTANT:

■ If you turn the freezer on before the water line is connected,

turn the ice maker OFF.

■ All installations must meet local plumbing code requirements.

■ Use plastic tubing and check for leaks. Install plastic tubing

only in areas where temperatures will remain above freezing.

TOOLS NEEDED: Flat-blade screwdriver, ⁷⁄₁₆" and ¹⁄₂" open-end

wrenches or two adjustable wrenches, ¹⁄₄" nut driver and drill bit,

hand drill or electric drill (properly grounded).

4

NOTE: Your freezer dealer has a kit available with a ¹⁄₄" (6.35 mm)

C

saddle-type shutoff valve, a union, and plastic tubing. Before

purchasing, make sure a saddle-type valve complies with your

local plumbing codes. Do not use a piercing-type or ³⁄₁₆"

(4.76 mm) saddle valve which reduces water flow and clogs more

easily.

Water Pressure

A cold water supply with water pressure of between 30 and

120 psi (207-827 kPa) is required to operate the water dispenser

and ice maker. If you have questions about your water pressure,

see “Troubleshooting” or call a licensed, qualified plumber.

Reverse Osmosis Water Supply

If a reverse osmosis water filtration system is connected to your

cold water supply, the water pressure to the system needs to be

a minimum of 40 to 60 psi (276 - 414 kPa).

If the water pressure to the reverse osmosis system is less than

40 to 60 psi (276 - 414 kPa), a booster pump can be inserted into

the small tubing that goes from the cold water line to the reverse

osmosis system.

If the water dispenser is still not dispensing water properly:

■ Check to see whether the sediment filter in the reverse

osmosis system is blocked. Replace the filter if necessary.

■ Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

■ If your refrigerator has a water filter cartridge, it may further

reduce the water pressure when used in conjunction with a

reverse osmosis system. Remove the water filter cartridge.

See “Water Filtration System.”

If you have questions about your water pressure, refer to

“Troubleshooting” or call a licensed, qualified plumber.

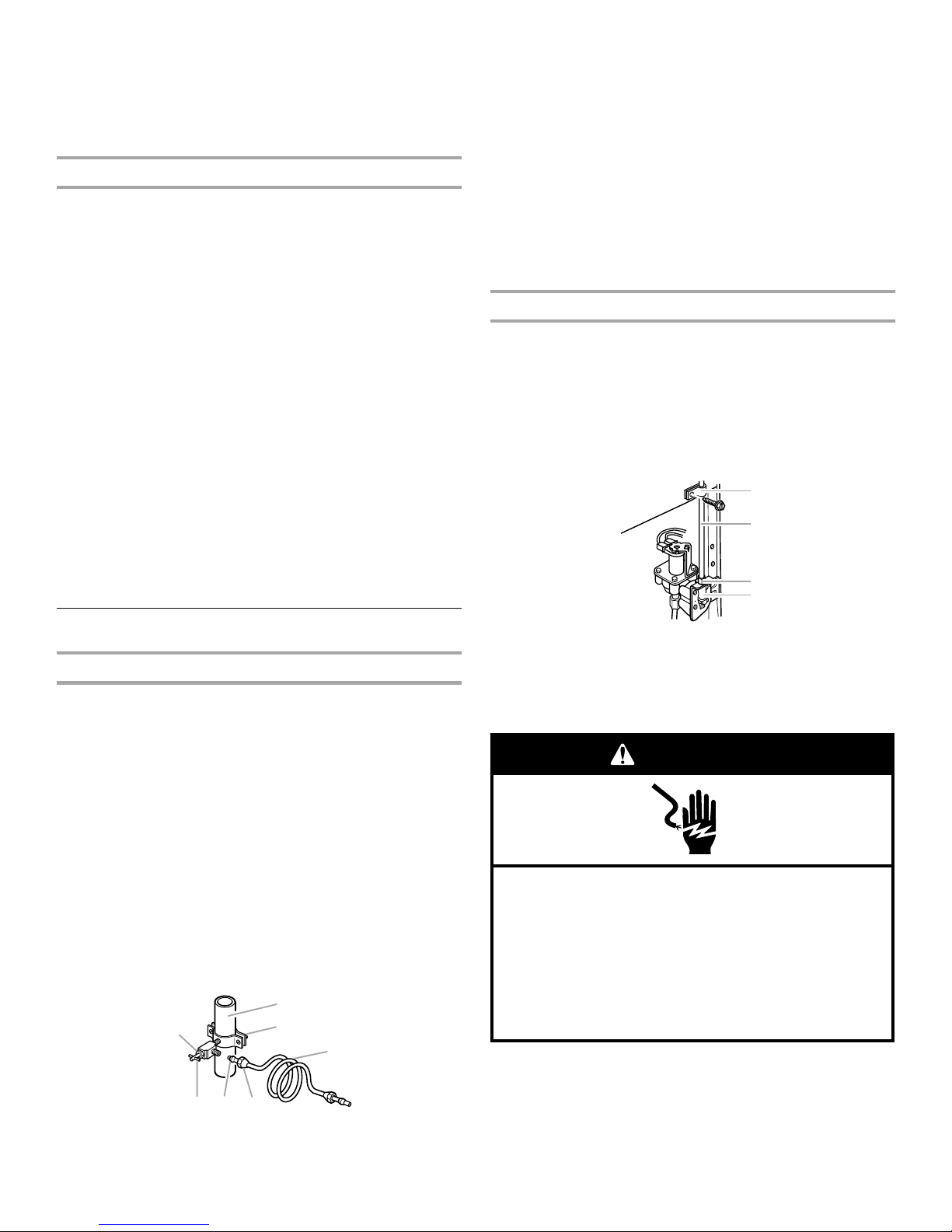

6. Fasten the shutoff valve to the cold water pipe with the pipe

clamp. Be sure the outlet end is solidly in the ¹⁄₄" (6.35 mm)

drilled hole in the water pipe and that the washer is under the

pipe clamp. Tighten the packing nut. Tighten the pipe clamp

screws carefully and evenly so washer makes a watertight

seal. Do not overtighten or you may crush the plastic tubing.

7. Slip the compression sleeve and compression nut on the

plastic tubing as shown. Insert the end of the tubing into the

outlet end squarely as far as it will go. Screw compression nut

onto outlet end with adjustable wrench. Do not overtighten.

8. Place the free end of the tubing in a container or sink, and

turn ON the main water supply. Flush the tubing until water is

clear. Turn OFF the shutoff valve on the water pipe. Coil the

plastic tubing.

Connect to Freezer

1. Attach the plastic tube to the valve inlet using a compression

nut and sleeve as shown. Tighten the compression nut. Do

not overtighten. Use the tube clamp on the back of the

freezer to secure the tubing to the freezer as shown. This will

help prevent damage to the tubing when the freezer is

pushed back against the wall.

2. Turn shutoff valve ON. Check for leaks. Tighten any

connections (including connections at the valve) or nuts that

leak.

A

B

D

Water Supply Connection

Connect to Water Line

1. Unplug freezer or disconnect power.

2. Turn OFF main water supply. Turn ON nearest faucet long

enough to clear line of water.

3. Locate a ½" to 1¹⁄₄" (12.7 mm to 3.18 cm) vertical cold water

pipe near the freezer.

IMPORTANT:

■ Make sure it is a cold water pipe.

■ Horizontal pipe will work, but drill on the top side of the

pipe, not the bottom. This will help keep water away from

the drill and normal sediment from collecting in the valve.

4. Determine the length of plastic tubing you need. Measure

from the connection on the lower left rear of freezer to the

water pipe. Add 7 ft (2.1 m) to allow for cleaning. Use ¹⁄₄"

(6.35 mm) O.D. (outside diameter) plastic tubing. Be sure

both ends of plastic tubing are cut square.

5. Using a grounded drill, drill a ¹⁄₄" (6.35 mm) hole in the cold

water pipe you have selected.

G

A

B

C

A. Tube clamp

B. Plastic tubing

C. Compression nut

D. Valve inlet

3. The ice maker is equipped with a built-in water strainer. If

your water conditions require a second water strainer, install

it in the ¹⁄₄" (6.35 mm) water line at either tube connection.

Obtain a water strainer from your nearest appliance dealer.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

4. Plug freezer into a grounded 3 prong outlet.

A. Cold Water Pipe

B. Pipe Clamp

C. Copper Tubing

D. Compression Nut

E. Compression Sleeve

F. Shutoff Valve

G. Packing Nut

DEF

5

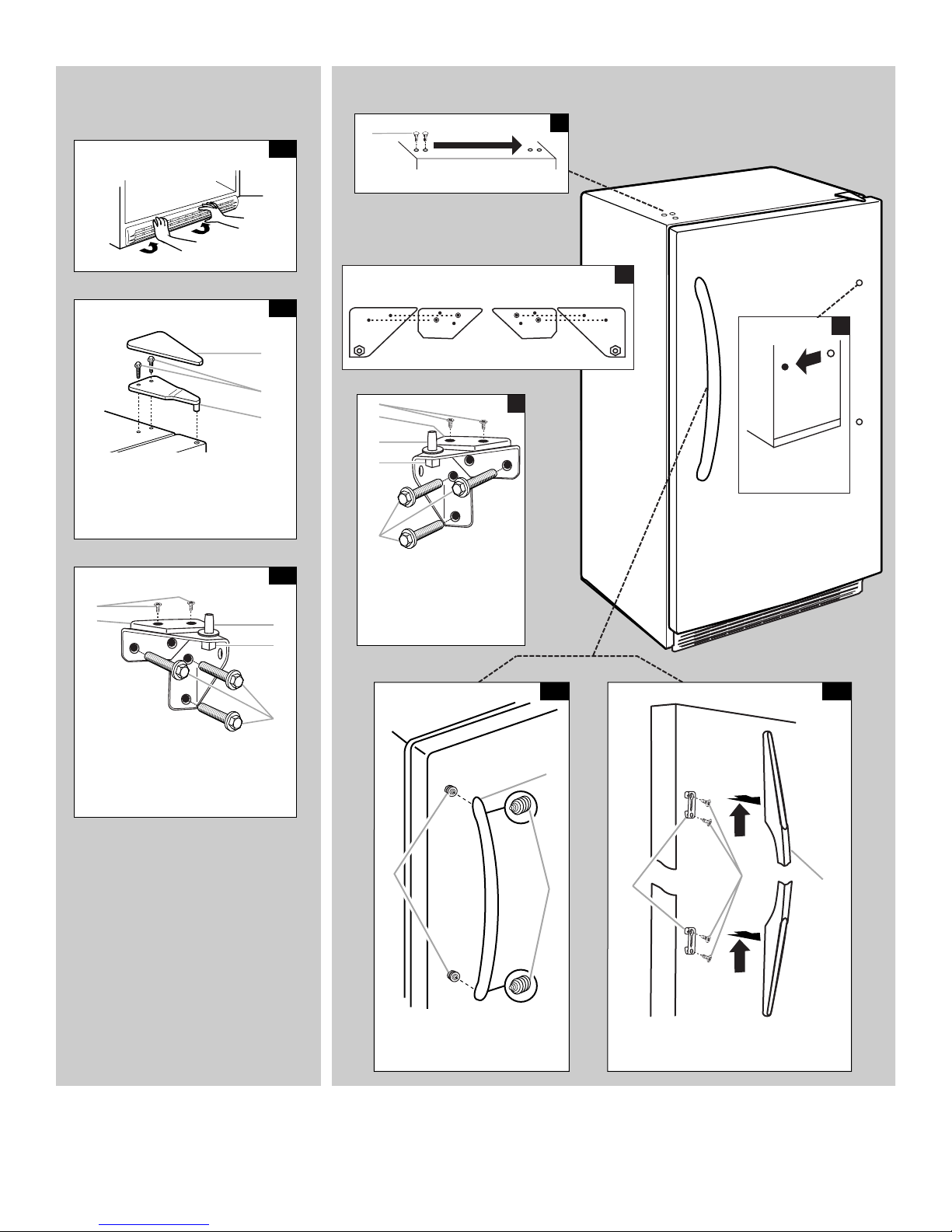

Freezer Door

TOOLS NEEDED: ⁵⁄₁₆" hex-head socket wrench, ⁵⁄₈" hex-head

socket wrench, ¹⁄₂" hex-head socket wrench, ³⁄₈" hex-head socket

wrench, #2 Phillips screwdriver, flat-blade screwdriver, ⁵⁄₁₆" openend wrench, flat 2" putty knife.

IMPORTANT:

■ All graphics referenced in the following instructions are

included later in this section after “Final Steps.” The graphics

shown are for a right-hand swing door (hinges factory

installed on the right).

■ If you only want to remove and replace the door, see the

“Remove Door and Hinges” and “Replace Door and Hinges.”

■ Before you begin, turn the control OFF, and remove food and

adjustable door or utility bins from door.

Remove Door and Hinges

" Hex-Head Hinge Screw

⁵⁄₁₆

1. Unplug freezer or disconnect power.

2. Open freezer door and remove base grille from the bottom

front of the freezer. See Base Grille Graphic 1A.

3. Close the freezer door and keep it closed until you are ready

to lift it free from the cabinet.

NOTE: Provide additional support for the door while the

hinges are being moved. Do not depend on the door magnets

to hold the door in place while you are working.

4. Remove the parts for the top hinge as shown in Top Hinge

Graphic 1B.

5. Lift the freezer door free from the lower hinge and cabinet and

set aside.

6. Remove 3 hex head hinge screws and bottom hinge

assembly. See Bottom Hinge Graphic 1C.

Style 1

1. Loosen set screws located on side of handle at each end.

See Graphic 1-1.

2. Remove handle from grommets.

3. Position the handle over grommets on the opposite side of

the freezer door.

4. Ensure grommets are fitted into handle holes.

5. Tighten the upper and lower set screws with hex key

provided. Do not overtighten set screw.

Style 2

1. Slide the handle up and off the clips. See Graphic 1-2.

2. Using a flat-blade screwdriver, remove the screws from the

clips and remove the clips from the door.

3. Position the clips on the opposite side of the freezer door and

reinstall the screws.

4. Position handle over the clips.

5. Apply even pressure and push down to lock in place.

Replace Door and Hinges

NOTE: Graphic may be reversed if door swing is reversed.

1. Replace the parts for the bottom hinge as shown and tighten

screws. See Bottom Hinge Graphic 1C. Replace the freezer

door.

NOTE: Provide additional support for the door while the

hinges are being moved. Do not depend on the door magnets

to hold the door in place while you are working.

2. Assemble the parts of the top hinge as shown in the Top

Hinge Graphic 1B. Do not tighten the screws completely.

3. Line up the door so that the bottom aligns evenly with the

cabinet. Tighten all screws.

Final Steps

Reverse Door (optional on some models)

IMPORTANT: If you want to reverse your door so that it opens in

the opposite direction, continue with “Reverse Door (optional)”

instructions. If you are not reversing the door, see “Replace Door

and Hinges.”

Cabinet

1. Remove the cabinet hinge hole plugs from the cabinet top

and move them to the opposite side hinge holes as shown in

Graphic 2.

2. Remove the door stop screws from the Bottom Hinge

bracket. See Bottom Hinge Graphic 1C

3. Remove the Hinge Pin Nut and Hinge Pin from the hinge

bracket.

4. Rotate the hinge bracket for installation on the opposite side

of the cabinet. See Graphic 3

5. Reinstall the Hinge Pin Nut and Hinge Pin to the hinge

bracket . Hinge Pin must point “up” when hinge bracket is

installed to the cabinet.

6. Invert the door stop so that the so that the countersunk holes

line up with the screw holes in the hinge assembly. See

Graphic 4

7. Reinstall the door stop screws. See Graphic 3.

8. Reinstall the hinge bracket to the cabinet with the 3 hex head

bolts.

Handle

Move the door handle from one side of the door to the other.

1. Check all holes to make sure that hole plugs and screws are

in place. Reinstall top hinge cover. See Top Hinge

Graphic 1B.

2. Replace the base grille. See Base Grille Graphic 1A.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

3. Plug into a grounded 3 prong outlet.

4. Reset the control. See “Using the Control.”

5. Return all removable door parts to door and food to freezer.

6

Door Removal &

Replacement

Base Grille

1A

Door Swing Reversal (optional)

A

A. Cabinet Hinge Hole Plugs

2

Top Hinge

A. Top Hinge Cover

3

/8" or

5

/8"

Hex-Head Hinge

B.

Screws (depending on model)

C. Top Hinge

Bottom Hinge

A

B

A. Door Stop Screws

B. Door Stop

C. Hinge Pin

D. Hinge Pin Nut

5

E.

/16"

Hex-Head Hinge Screws

Left Hand Hinge

Door Stop

Right Hand Hinge

Door Stop

4

1B

5

A

B

C

A

B

C

D

E

A. Door Stop Screws

1C

B. Door Stop

C. Hinge Pin

D. Hinge Pin Nut

5

E.

/16"

C

D

Hex-Head Hinge

Screws

Style 1 Style 2

E

3

Door Handle

Seal Screw

1-1

B

1-2

A

A. Grommet

B. Handle

C. Set Screws

C

A

B

C

A. Clips

B. Handle Screws

C. Handle

7

Adjust the Door

1. Locate the two front leveling legs taped among the packing

materials.

2. Screw these legs into the front holes on the bottom of the

freezer. The back of the freezer rests on two fixed supports.

3. Adjust the front legs just enough to lift the cabinet up off of

the floor.

NOTE: If your model is equipped with rollers, the front legs

should be lowered enough to lift the rollers off of the floor to

ensure the freezer does not roll forward when the door is

opened.

FREEZER USE

4. Place a leveling tool on top of the freezer first side to side,

then front to back. Turn leg counterclockwise to raise a

corner. Turn leg clockwise to lower a corner.

5. Repeat Step 4 until freezer is level.

6. After freezer is fully loaded with food, recheck with level as in

Step 4.

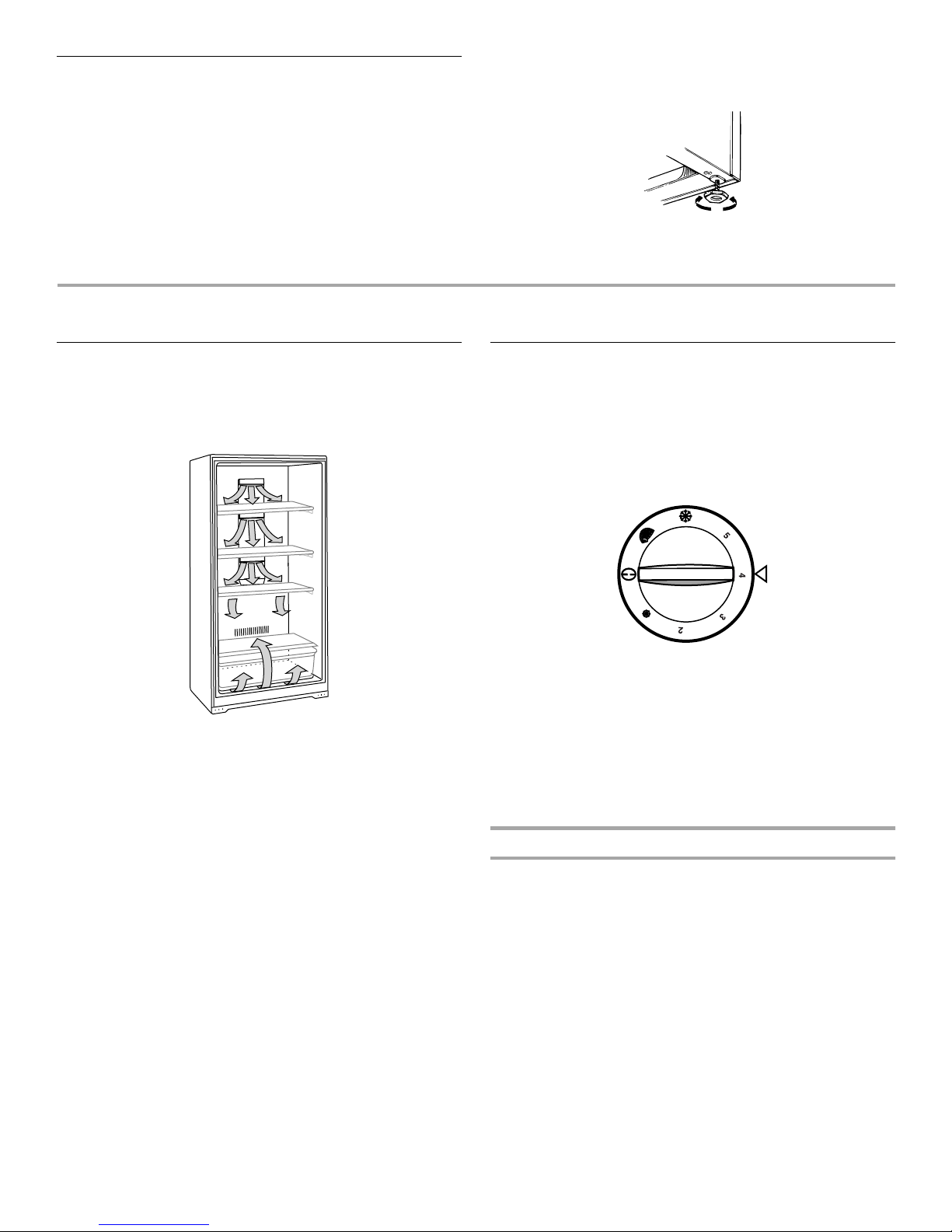

Ensuring Proper Air Circulation

In order to ensure proper temperature, you need to permit proper

airflow in the freezer. As shown in the illustration, cool air enters

through the freezer wall and moves down. The air then

recirculates through the vent near the bottom.

Do not block any of these vents with food packages. If the vents

are blocked, airflow will be prevented, and temperature and

moisture problems may occur.

IMPORTANT: To prevent odors and drying out of food, wrap or

cover foods tightly.

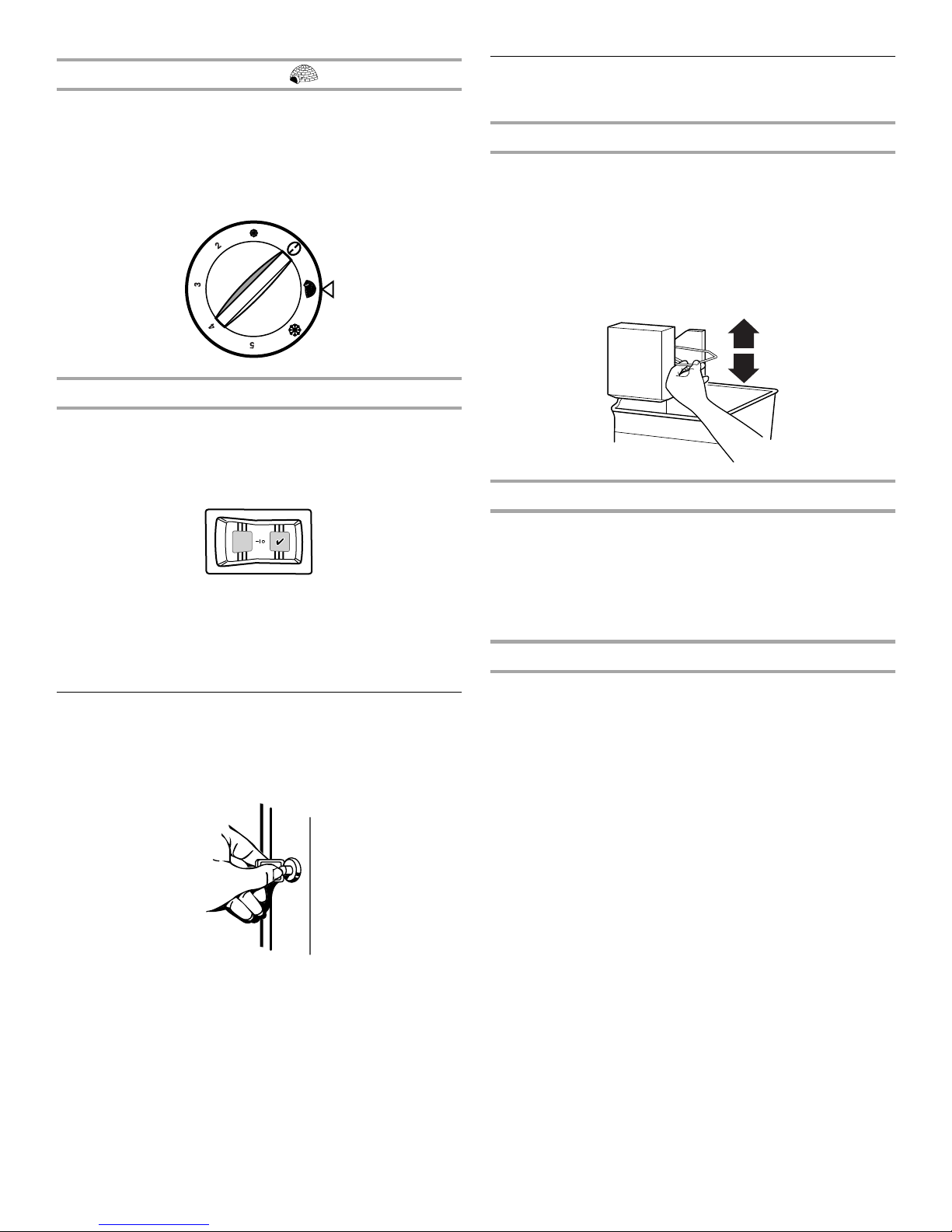

Using the Control

Turn the freezer temperature control to 4. This setting is designed

to maintain the temperature at or near 0°F (-17.8°C) under normal

operating conditions.

Allow the freezer to cool 6 to 8 hours before filling with frozen

food. Let the freezer cool overnight before adding large amounts

of unfrozen food. Never add more than 2 to 3 lbs (907 to 1,350 g)

of unfrozen food per cubic foot (28.32 L) of freezer space.

NOTE: When the freezer is first started, the compressor will run

constantly until the freezer is cooled. It may take up to 6 or

8 hours (or longer), depending on room temperature and the

number of times the freezer door is opened. After the freezer is

cooled, the compressor will turn on and off as needed to keep

the freezer at the proper temperature.

The outside of your freezer may feel warm. This is normal. The

freezer’s design and main function is to remove heat from

packages and air space inside the freezer. The heat is transferred

to the room air, making the outside of the freezer feel warm.

8

Adjusting Control

■ Turn control to a higher number for colder temperatures.

■ Turn control to a lower number for less cold temperatures.

NOTE: The small snowflake icon represents the number 1 or

the least cold setting. The large snowflake icon represents 6

or the coldest setting.

Fast Freeze (on some models)

This setting causes the freezer to run continuously, driving the

freezer temperature to the coldest possible temperature. To

activate, adjust the control knob to the igloo icon, which

represents the fast freeze setting. Use this feature just before

adding large amounts of unfrozen foods. For best food quality, do

not exceed 3 lbs (1,350 g) per cubic foot (28.32 L). Return to your

normal setting after 24 to 48 hours.

Temperature Alarm (on some models)

The temperature monitor alarm is located to the left of the

temperature control and sounds an audible alarm if the

temperature reaches 10°F (-12°C) or more above normal for the

selected setting.

The alarm is controlled by a three position switch.

Ice Maker

(on some models)

To Turn the Ice Maker On/Off

NOTE: Do not force the wire shutoff arm up or down.

■ To turn the ice maker on, simply lower the wire shutoff arm.

NOTE: Your ice maker has an automatic shutoff. As ice is

made, the ice cubes fill the ice storage bin and the ice cubes

will raise the wire shutoff arm to the OFF (arm up) position.

■ To manually turn the ice maker off, lift the wire shutoff arm to

the OFF (arm up) position and listen for the click to make sure

the ice maker will not continue to operate.

Ice Production Rate

| The proper setting for normal freezer use. The alarm

is on and the amber light will be illuminated.

0 Prevents the alarm from sounding when the freezer

is warm, such as during start-up or defrosting.

✔ Tests the alarm regardless of temperature.

Key Eject Lock

(on some models)

To lock or unlock the freezer, you must hold the key in the lock

while turning. The lock is spring loaded, so the key cannot be left

in the lock.

If the key is lost, contact your dealer for a replacement. Always

give the model and serial number of your freezer when requesting

a replacement key.

The ice maker should produce approximately 7 to 9 batches of

ice in a 24-hour period. If ice is not being made fast enough, turn

the Temperature Control toward a higher (colder) number in half

number steps. (For example, if the control is at 3, move it to

between 3 and 4.) Wait 24 hours and, if necessary, gradually turn

the Temperature Control to the highest setting, waiting 24 hours

between each increase.

Remember

■ Allow 24 hours to produce the first batch of ice. Discard the

first three batches of ice produced.

■ The quality of your ice will be only as good as the quality of

the water supplied to your ice maker. Avoid connecting the

ice maker to a softened water supply. Water softener

chemicals (such as salt) can damage parts of the ice maker

and lead to poor quality ice. If a softened water supply cannot

be avoided, make sure the water softener is operating

properly and is well maintained.

■ Do not store anything on top of the ice maker or in the ice

storage bin.

9

FREEZER FEATURES

This manual covers several different models. The freezer you

have purchased may have some or all of the items listed. The

locations of the features may not match those of your model.

Refrigerated Shelves

(on some models)

Your freezer is equipped with refrigerated interior shelves.

Packages in direct contact with the shelves will have the best

refrigeration. Fresh, unfrozen food packages should be stored

directly on the shelves and not on top of already frozen food

packages.

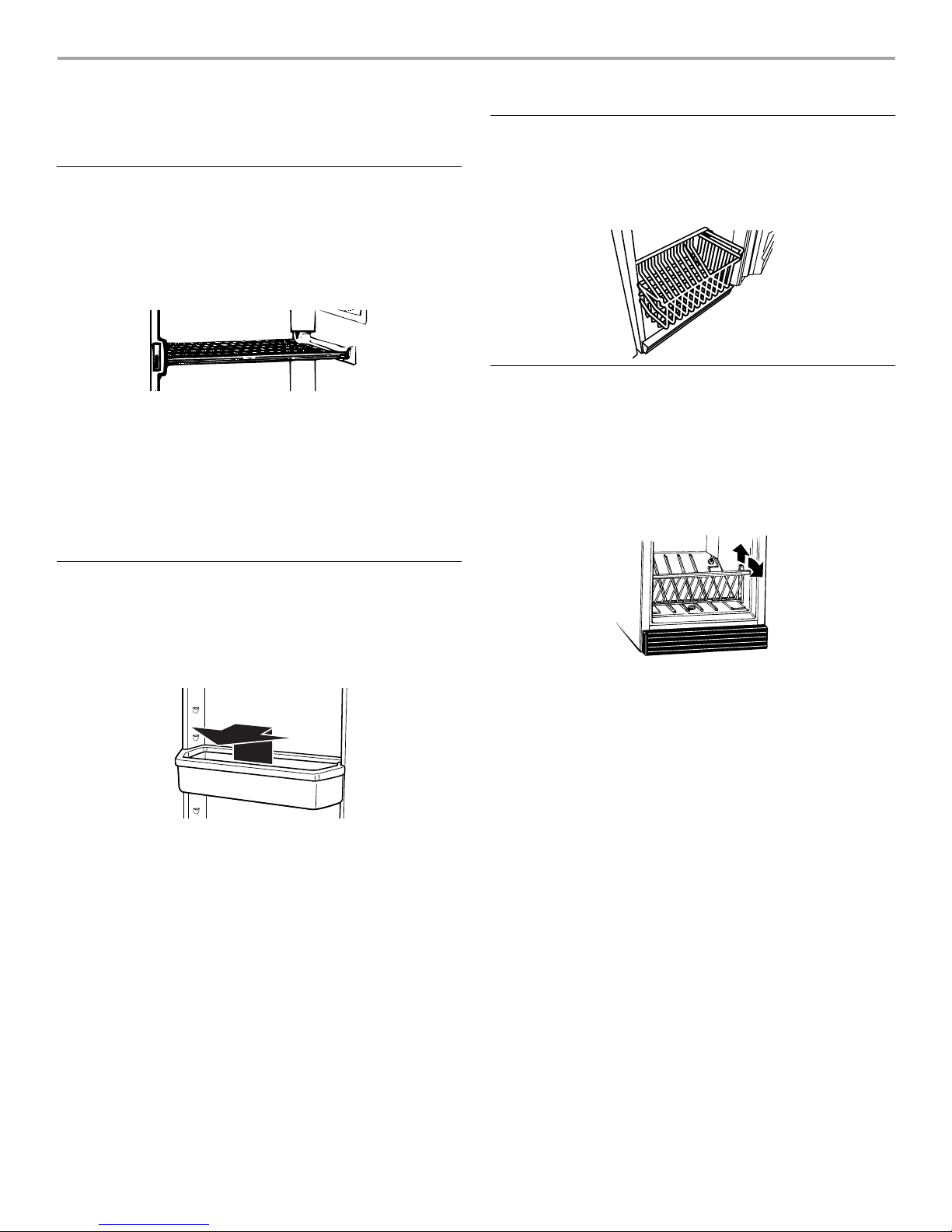

Storage Basket

(on some models)

The slide out basket provides separate storage space for items

that are difficult to store on freezer shelves. To remove the

basket, pull out and lift up.

When placing the food packages in your freezer, please

remember:

■ The cabinet shelves have the best freezing capability. The

door shelves and the bottom of the cabinet have a slightly

less cold temperature. Therefore, packages sensitive to

temperature (meat, poultry, etc.) should not be placed on the

door shelves or the freezer bottom.

■ Leave some space between the food packages so that cold

air can pass over and around them.

Door Bin

To remove and replace the bin:

1. Remove the bin by tipping the front of the bin forward and

sliding out.

2. Replace the bin by sliding it in above the desired support

tilting it back into place.

Storage Gate

(on some models)

To Lower and Raise the Storage Gate:

1. Lift the top of the gate up slightly, out of the supports. Pull the

gate forward and down.

2. Return the gate to the upright position. Lift the top of the gate

slightly to clear the supports. Lower the gate into the

supports.

10

Loading...

Loading...