Whirl

AUTOMATIC ICE MAKER

Use and Care Guide

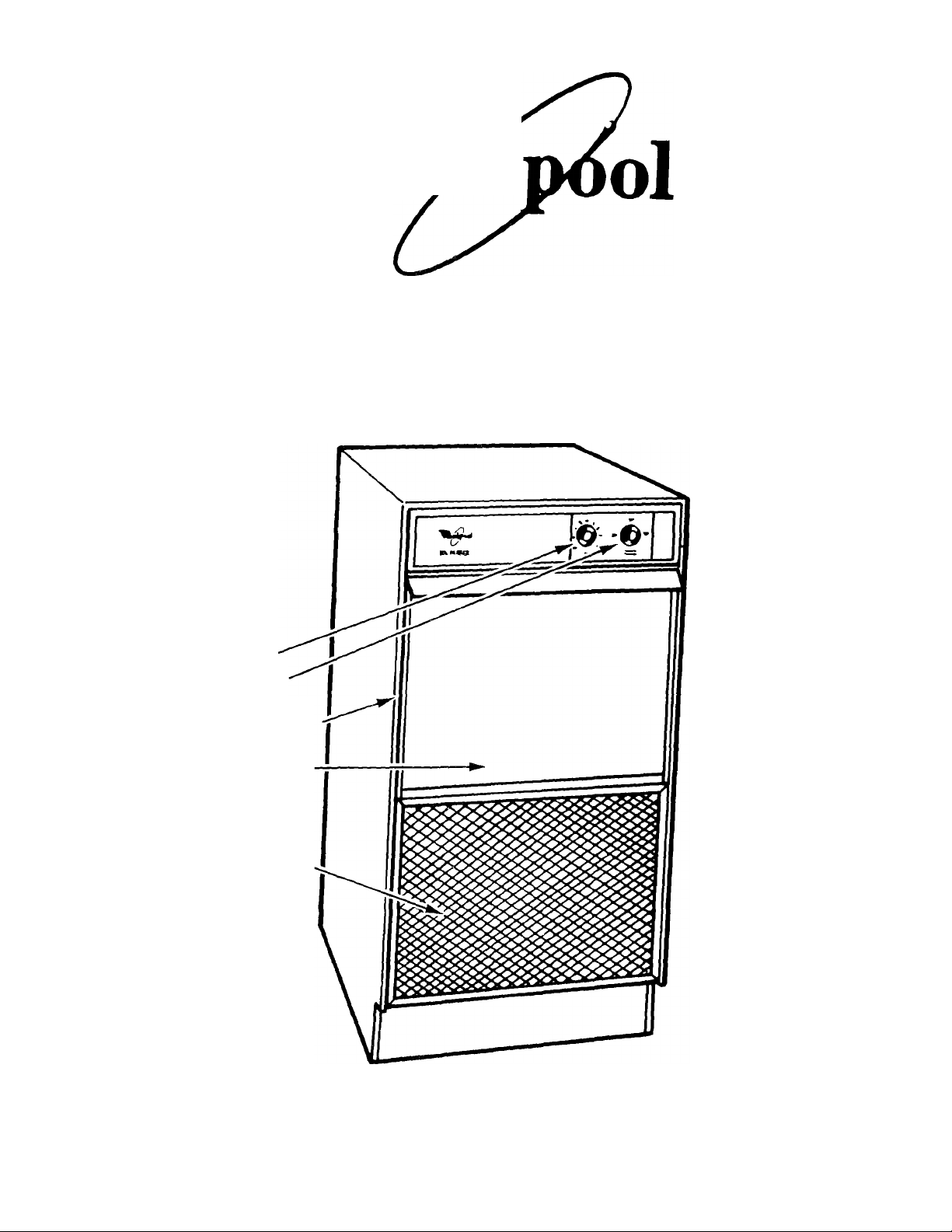

Ice Thickness Control

Cycle or Service Switch

Model and Serial Number Plate

(inside, not shown)

Bin

Grille

Part No. 756637 Rev, B

BEFORE OPERATING THE ICE MAKER

It is your responsibility to make sure that the ice

maker:

" has been installed where it is protected from

the elements.

• is located so that the front is not blocked to

restrict incoming or discharge air flow.

• is properly leveled.

• is located in a well ventilated area with tem

peratures above 55°F (13°C) and below 110°F

(43°C). Best results are obtained at temperatures

between 70°F (21°C) and 90°F (32°C).

ICE MAKER OPERATION

How it makes ice:

is properly connected to a water supply and

drain.

is properly connected to electricity. A 11 5 Volt,

60 Hz.. 15 amp fused electrical supply is required.

NOTE: Time delay fuse or circuit breaker is

recommended.

is properly electrically grounded.

is not operated by anyone unable to use it

properly.

is used only for the job it was designed to perform,

is properly maintained.

4. Fresh water enters the machine for the next ice

making cycle.

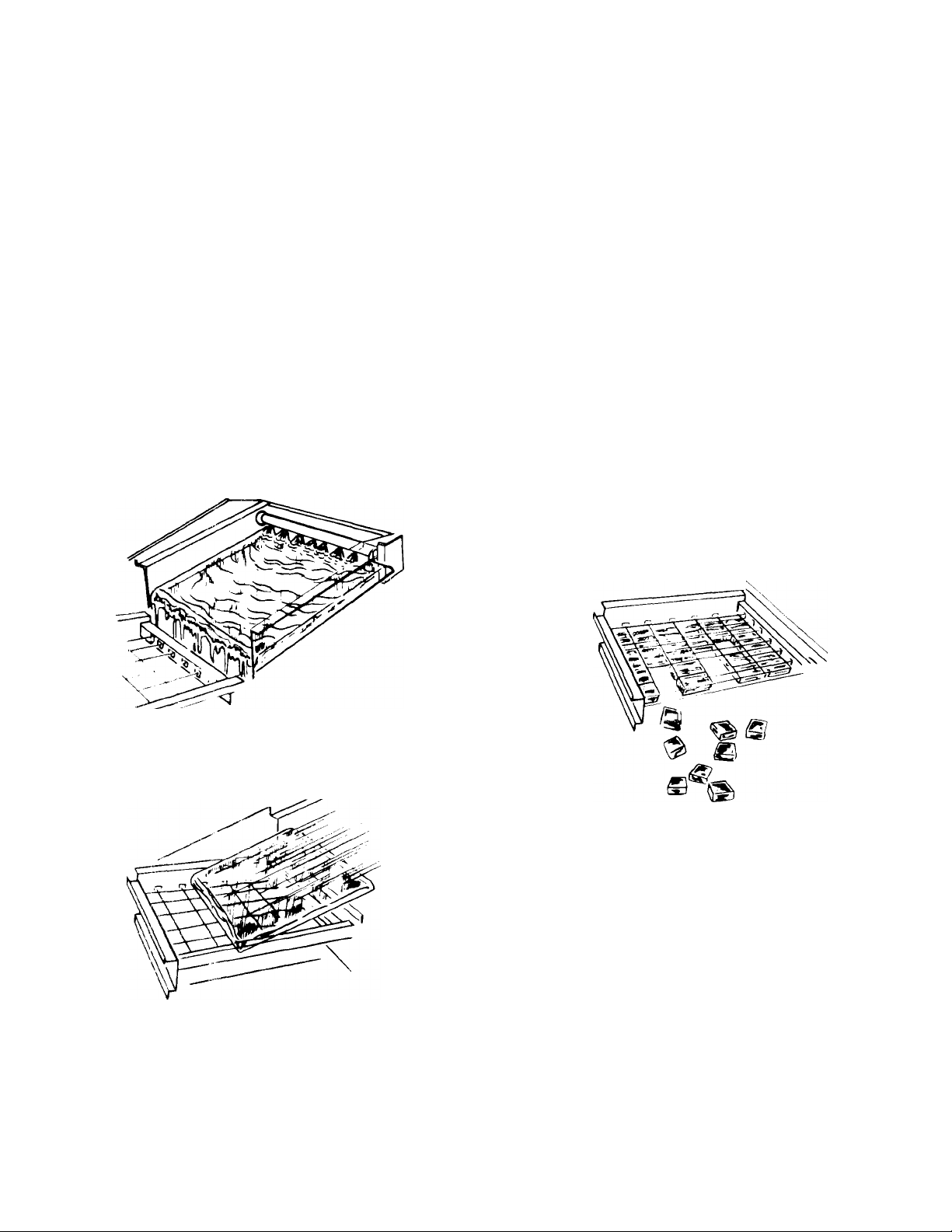

1. vVater is constantly circulated over a freezing

plate. As the water freezes into ice the minerals in

the v\,ater are rejected. This produces a clear sheet

of ice with a low mineral content.

2 When the desired thickness is reached, the ice

siieet is released and slides on to a cutter grid. The

grid divides the sheet into individual cubes.

3 The water containing the rejected minerals is

drained after each freezing cycle.

5. Cubes fall into the storage bin. When the bin is

full the ice maker shuts off automatically and re

starts when more ice is needed.

To Operate the Ice Maker;

1 Select ice thickness (Figure 1). The ice maker

has been pre set to produce ice approximately O"

thick, while operating in a room ambient of

70T (21°C).

Operation in different ambient temperatures may

require readjusting the control toward "THICK”

or "THIN."

Best operation will be obtained with ice 1/2” to

5/8” thick.

If operating in a warm room ambient (above 90°F

[32°C] ) DO NOT set control to maximum thick

ness or the unit may malfunction.

GENERAL CARE AND CLEANING

2. To start the normal ice making cycle, turn service

or cycle switch to "ON.”

3. To stop ice maker operation, turn service or

cycle switch to "OFF."

4. The "CLEAN” setting is used whenever solutions

are circulated through the ice maker for cleaning.

Only the water pump operates at this setting.

Periodically inspect and clean the ice maker to

keep it operating at peak efficiency and to prevent

premature failure of system components.

Both the ice making system and the air cooled

condenser need to be cleaned regularly.

Cleaning exterior surfaces:

Wasli the exterior enamel surfaces and gaskets

with warm water and mild soap or detergent. Rinse

and dry. Regular use of a good household appliance

cleaner and wax will help protect the finish.

Note; Do not use harsh or abrasive cleaners on

enamel surfaces as they may scratch the finish.

Craning the condenser:

/\ dirty or clogged condenser;

• prevents proper air flow.

• reduces ice making capacity.

• causes higher than recommended operating

temperatures which may lead to component

failure.

To Clean ;

GRILLED

PANEL

1. Disconnect electrical power supply to the

machine or place the service switch in the "OFF”

position. The condenser fan should not operate

while removing dirt from the condenser.

2. Remove the two screws from the bottom of the

grilled front panel.

CAUTION: Switch must be in "OFF” position to

keep condenser fan from rotating. Do not touch

condenser fins. They are sharp. Refrigerant tubing

gets very hot during normal operation. Be careful.

3. Pull forward and down to remove the panel.

FIGURE 3

4. Remove dirt and lint from the condenser fins

with a soft brush and then use a vacuum cleaner to

remove the dirt from the unit compartment

(Figure 3).

Caution: Condenser fins are sharp and can bend

easily. Use care when brushing the condenser to

keep from bending the fins. Condenser tubing gets

hot enough during normal operation to burn your

hand. Use care and do not touch the tubing.

5. Replace the grilled front panel and screws.

Loading...

Loading...