Page 1

DOUBLE

PLEASE NOTE: Y

clearer instruction.

our model of DishDrawer may differ from the model shown in the diagrams. Diagrams have been simpliÞ ed to enable

INTEGRATED PANEL PREPARATION

FOLLOW THESE INSTRUCTIONS BEFORE REFERRING TO PRODUCT INSTALLATION INSTRUCTION SHEET P/N 526609.

P/N 526610A

DOUBLE MODELS ONLY

(page 1 of 4)

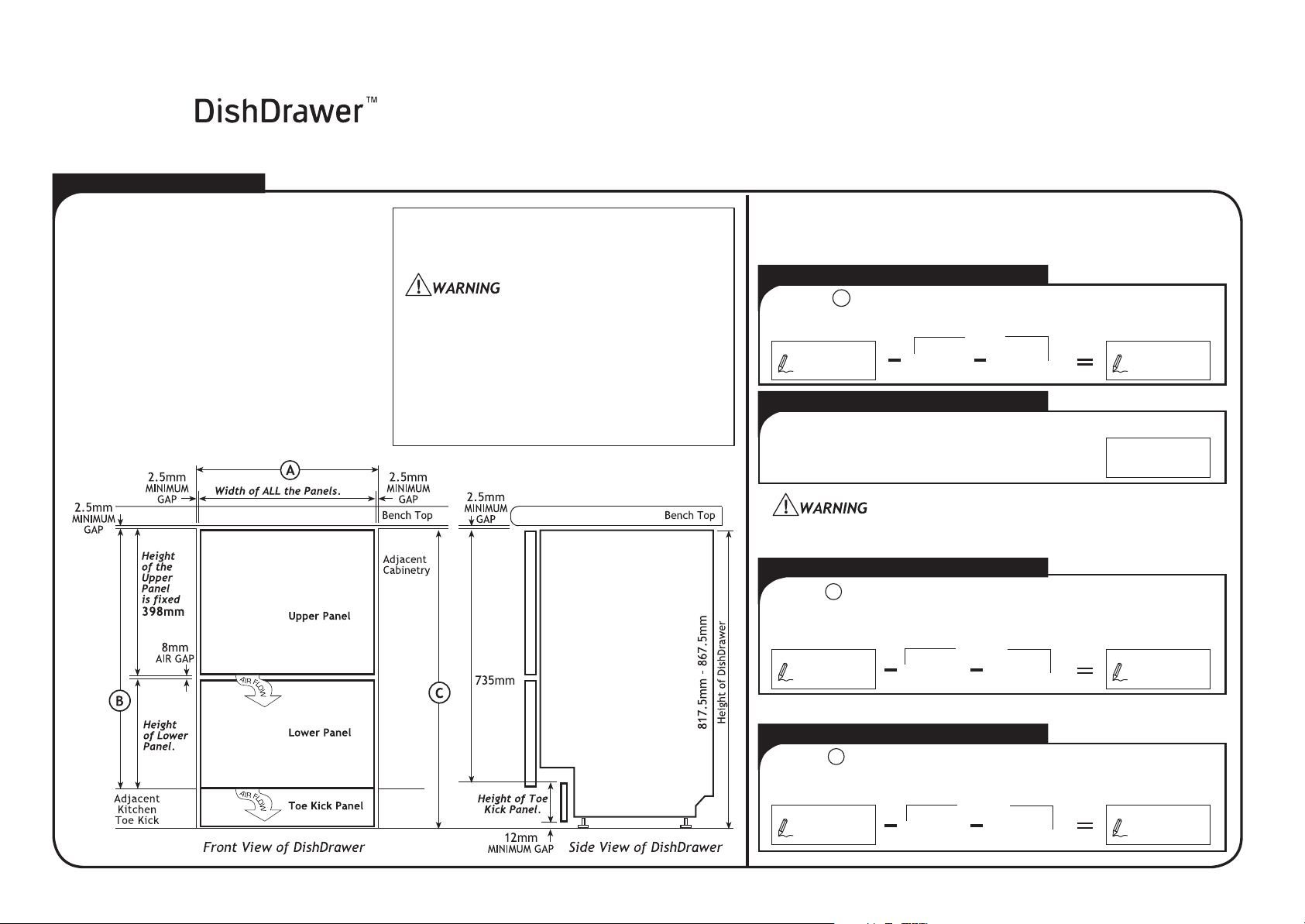

BEFORE

The Doors and T

DishDrawer can match your kitchen cabinetry.

The diagram below, with the addition of your

own measurements will help you calculate the

width of all the Panels, the height of the

Lower P

Panel.

is FIXED at 398mm.

TOE KICK PANEL

The T

Panel thickness.

Toe Kick

the Integrated Toe Kick Panel.

YOU START

oe Kick Panels of the

anel and the height of the Toe Kick

NOTE: The height of the Upper Panel

DEPTH

oe Kick Panel Depth is 67mm less the

NOTE: The Black PreÞ nished

supplied is an alternative to making

INTEGRATED PANEL MATERIAL

Upper & Lower Panel Thickness 16mm minimum.

Above 18mm Product depth will be affected.

Toe Kick Panel Thickness 9-19mm

Drawer Front material must be suitable for damp

conditions or adequately sealed to withstand

moisture. Additional protection can be provided

by using a “Moisture Resistant Board”.

Ensure the Product is not plugged in.

The installation of the Panels requires an

electrical connection and must be performed by

a suitably qualiÞ ed person.

The size of each Panel can be calculated below.

Write the required measurement in the Þ rst box and

then subtract the following dimensions in each equation.

WIDTH OF ALL PANELS

Measure the width of the cavity, and

A

put the dimension here.

5mm

2.5mm 2.5mm

MIN. GAP MIN. GAP

Width of

(Minimum

ALL Panels

HEIGHT OF UPPER PANEL

Height of Upper Panel

The height of the Upper Panel is Þ xed.

The air vent between the Upper and Lower Panels must not be

covered. An air gap of 8mm MUST be provided.

398mm

HEIGHT OF LOWER PANEL

Measure from the top of the adjacent cabinet

door to the top of the adjacent kitchen Toe

Kick, and put the dimension here.

B

406mm

398mm 8mm

AIR GAP

Height of

Lower Panel

(Minimum

595mm)

308mm)

HEIGHT OF TOE KICK PANEL

Measure the height from the adjacent cabinet

door fronts to the fl oor, and put the dimension

here.

C

747mm

735mm 12mm

MIN. GAP

Height of

Toe Kick Panel

(Minimum 70.5mm)

Page 2

P/N 526610A (page 2 of 4)

DOUBLE MODELS ONLY

Safety Glasses, Tape Measure, Pencil, Needle-Nose Pliers,

Drill & Phillips Bit or Phillips Screwdriver,

25mm Spade Bit or 25mm Hole Saw,

Small Hand or Jig Saw.

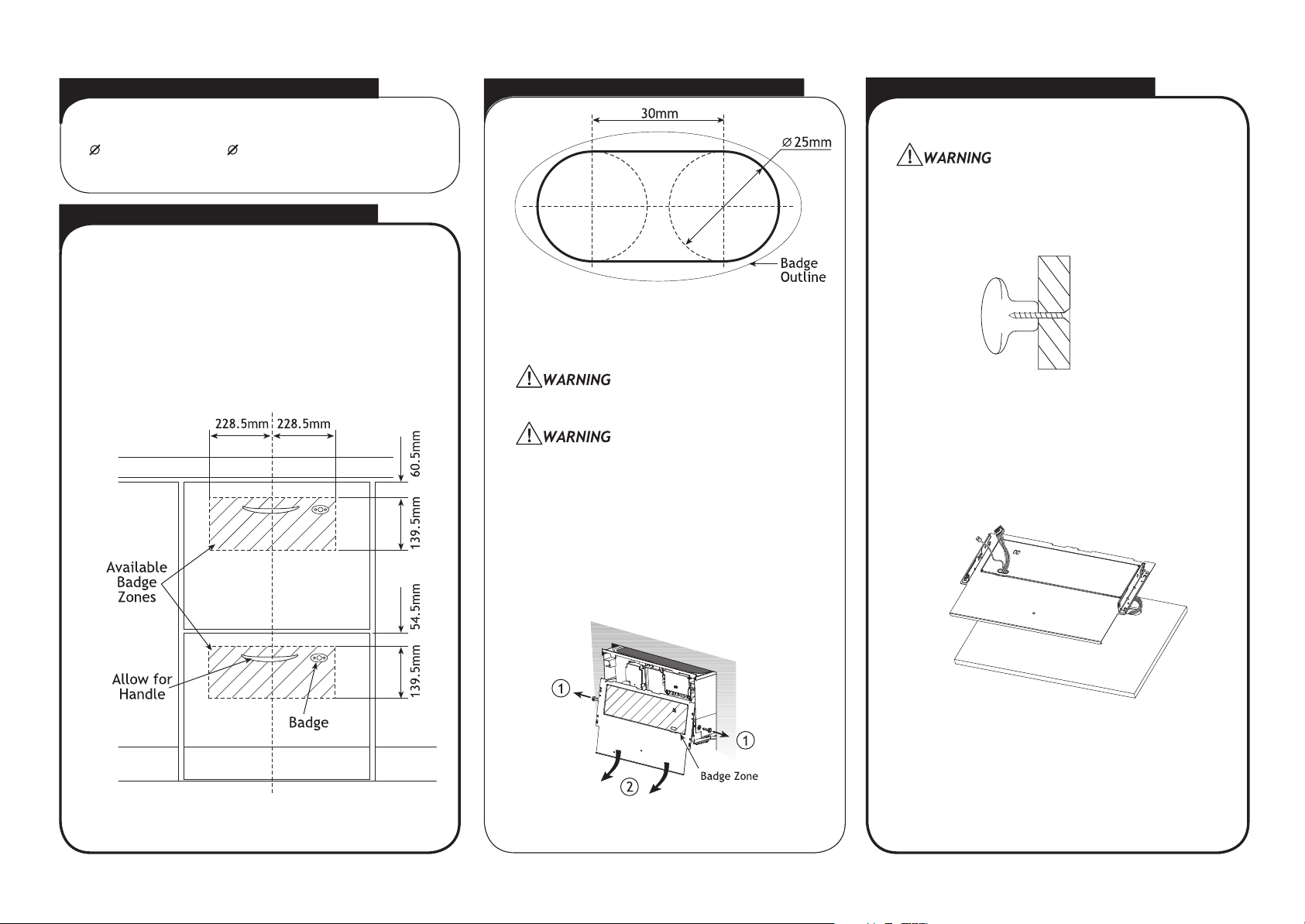

1 BADGE & HANDLE POSITION

On both Panels, select the Badge position to suit the

cabinetry design, within the available badge zones.

If required the Badge may be centred on the edge of

the badge zone.

The handle position will also need to be taken into

account.

2 BADGE CUT OUT & BRACKET REMOVAL TOOLS NEEDED

(Badge cut out shown actual size)

Cut the badge slot in each Panel by drilling

two 25mm diameter holes and cutting out the

remaining material between the holes.

Accuracy is essential when cutting the Badge

slot to ensure a neat Þ t to hold the Badge.

Ensure the Product is not plugged in.

To remove the Mounting Brackets withdraw the

pins from the drawer sides, using a pair of

needle-nose pliers.

3 FITTING THE HANDLE & BADGE

Fit the customer supplied handle.

When mounting the handle, ensure

fastenings do not protrude beyond the

back surface of the Panel.

Fit a Badge to each Panel by feeding the wires

through to the back and pressing the Badge

into the cut out.

If needed adhere the Badge to the Panel with

an adhesive.

Gently slide the Mounting Bracket off in a

downwards and outwards motion. Disconnect

the Mounting Bracket and Badge earthing wires,

along with the Badge harness. Remove the

Badge from the Mounting Bracket.

NOTE: The rectangular recess in the Mounting

Bracket can also be used to deÞ ne the badge

zone.

Page 3

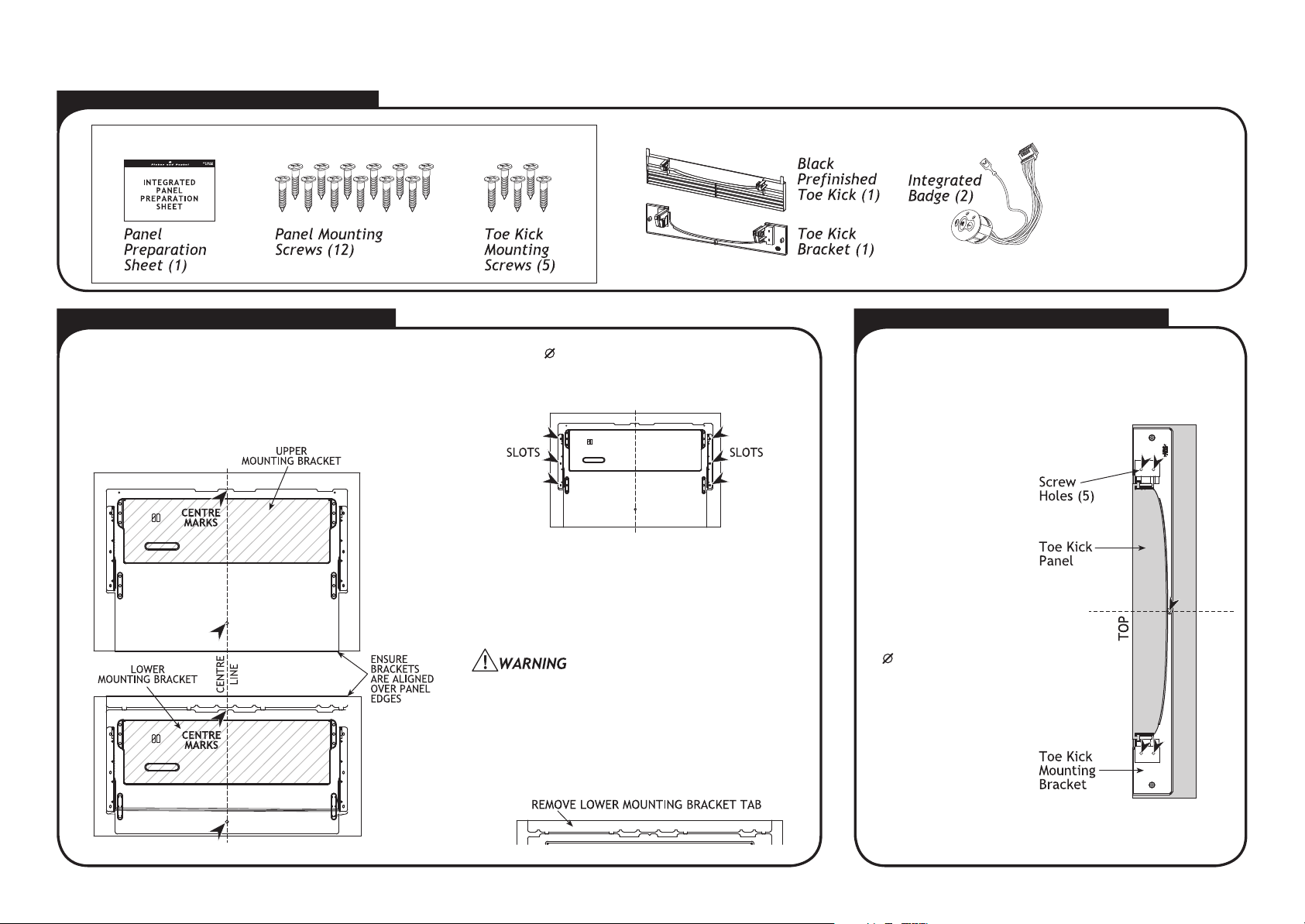

PARTS LIST FOR DOUBLE MODELS

P/N 526610A (page 3 of 4)

DOUBLE MODELS ONLY

INTEGRATED PARTS KIT P/N 526675

4 SECURING THE MOUNTING BRACKETS

Each Mounting Bracket is directly screwed to the

back of each Integrated Panel. On a soft surface

centralise and align the Upper Mounting Bracket on

the Upper Panel and the Lower Mounting Bracket on

the Lower Panel.

Using the 6 4mm x 16mm screws supplied, secure

the Mounting Bracket to each Panel at the 6 points

shown in the diagram.

NOTE: The Mounting Brackets need to be securely

Þ xed to each Panel. Where possible use the 6 outer

slots shown above. If these slots can not be used,

select alternative slots, as close as possible to the

outer slots. Ensure the screws are evenly spaced

about the Panel.

For some materials pilot holes may need to be

drilled Þ rst before screwing the Mounting Bracket

onto the Panel. Ensure the drill does not damage

the face of the Panel.

IMPORTANT

Break off the tab at the top of the Lower

Mounting Bracket, after Panel has been

secured.

P/N 526681

P/N 526682

5 SECURING THE TOE KICK PANEL

Chrome supplied

P/N 526618

OTHER COLOURS

AVAILABLE

Black Kit P/N 526683

Satin Chrome Kit P/N 526684

Brass Kit P/N 526685

NOTE: If using the supplied Black PreÞ nished Toe

Kick, proceed to Step 6 Earthing the Mounting

Brackets and Connecting the Badge Wires.

Place Toe Kick

Panel face down

on a soft surface

and mark a vertical

centre line.

Centralise the

plastic Mounting

Bracket on top of

the Toe Kick Panel.

Align the top of the

Bracket with the

top of the Panel.

Using the 5

4mm x 16mm

screws provided Þ x

the Mounting

Bracket to the Toe

Kick Panel.

Page 4

P/N 526610A (page 4 of 4)

DOUBLE MODELS ONLY

6 EARTHING THE MOUNTING BRACKETS & CONNECTING THE BADGE WIRES 7 FITTING THE PANELS TO THE PRODUCT

Ensure the Product is not plugged in.

The Badge Isolator Board is an electrostatic

sensitive device. Ensure you are adequately

earthed when connecting or disconnecting the

Badge by wearing an earthing strap or by

earthing yourself to the DishDrawer.

Partially open the drawer. Fit the assembled Panels

by sliding in an inwards and upwards motion. The

rubber seal between the Drawer and Panels must

be kept in place.

Plug the green

Badge earthing

wire onto a

Mounting Bracket

tab. Plug the

earthing wire from

the Product onto

the other Mounting

Bracket tab.

Secure the Panels by inserting the

pins on either side of the Drawer.

Ensure that the rib on the pin is

vertical.

Check the Þ t of the Panels, making sure the air

ß ow gap is 8mm between the Upper and Lower

Panels.

NOTE: Do not Þ t the Toe Kick Panel

(or supplied Black PreÞ nished Toe Kick)

to the DishDrawer until the Product is in the

cavity.

Connect the Badge

plug to the top of the

Badge Isolator Box.

INTEGRATED PANEL PREPARATION IS COMPLETE.

The Product is now ready to install. Refer to

Product Installation Instruction Sheet P/N 526609.

Page 5

INTEGRATED PANEL PREPARATION SINGLE

PLEASE NOTE: Your model of DishDrawer may differ from the model shown in the diagrams. Diagrams have been simpliÞ ed to enable

clearer instruction. FOLLOW THESE INSTRUCTIONS BEFORE REFERRING TO PRODUCT INSTALLATION INSTRUCTION SHEET P/N 526609.

BEFORE YOU START

P/N 526610A (page 1 of 4)

SINGLE MODELS ONLY

The Door of the DishDrawer

can match your kitchen

cabinetry. The diagram

below, with the addition of

your own measurements will

help you calculate the width

and height of the Panel.

Ensure the Product is not

plugged in.

The installation of the Panel

requires an electrical

connection and must be

performed by a suitably

qualif ed person.

Use the following diagram if installing the DishDrawer at ß oor

level.

The size of each Panel can be calculated below.

Write the required measurement in the Þ rst box and

then subtract the following dimensions in each equation.

WIDTH OF THE PANEL

Measure the width of the cavity, and

A

put the dimension here.

5mm

2.5mm 2.5mm

MIN. GAP MIN. GAP

The air vent below the Panel must not be covered.

An air gap of 9mm MUST be provided.

Width of the Panel

(Minimum 595mm)

HEIGHT OF THE PANEL

Measure the height of adjacent

cabinet door fronts in kitchen, and put

the dimension here.

INTEGRATED PANEL MATERIAL

Upper & Lower Panel Thickness 16mm minimum.

Above 18mm Product depth will be affected.

B

(Minimum 398mm)

9mm

AIR GAP

Height of

the Panel

Drawer Front material must be suitable for damp conditions or

adequately sealed to withstand moisture. Additional protection

can be provided by using a “Moisture Resistant Board”.

Page 6

P/N 526610A (page 2 of 4)

SINGLE MODELS ONLY

Safety Glasses, Tape Measure, Pencil,

Needle-Nose Pliers, Drill & Phillips Bit or

Phillips Screwdriver,

or 25mm Hole Saw, Small Hand or Jig Saw.

25mm Spade Bit

1 BADGE & HANDLE POSITION

On the Panel, select the Badge position to suit the

cabinetry design, within the available badge zone.

If required the Badge may be centred on the edge of

the badge zone.

The handle position will also need to be taken into

account.

2 BADGE CUT OUT & BRACKET REMOVAL TOOLS NEEDED

(Badge cut out shown actual size)

Cut the badge slot in the Panel by drilling

two 25mm diameter holes and cutting out the

remaining material between the holes.

Accuracy is essential when cutting the Badge

slot to ensure a neat Þ t to hold the Badge.

Ensure the Product is not plugged in.

To remove the Mounting Bracket withdraw the

pins from the drawer sides, using a pair of

needle-nose pliers.

3 FITTING THE HANDLE & BADGE

Fit the customer supplied handle.

When mounting the handle, ensure fastenings

do not protrude beyond the back surface of the

Panel.

Fit the Badge to the Panel by feeding the wires

through to the back and pressing the Badge into

the cut out.

If needed adhere the Badge to the Panel with an

adhesive.

Gently slide the Mounting Bracket off in a

downwards and outwards motion. Disconnect

the Mounting Bracket and Badge earthing wires,

along with the Badge harness. Remove the

Badge from the Mounting Bracket.

NOTE: The rectangular recess in the Mounting

Bracket can also be used to deÞ ne the badge

zone.

Page 7

P/N 526610A (page 3 of 4)

SINGLE MODELS ONLY

PARTS LIST FOR SINGLE MODELS

INTEGRATED PARTS KIT P/N 526675P/N 526675

4 SECURING THE MOUNTING BRACKET

The Mounting Bracket is directly screwed to the

back of the Integrated Panel. On a soft surface

centralise and align the Mounting Bracket on the

Panel.

Chrome supplied

P/N 526618

OTHER COLOURS AVAILABLE

Black Kit P/N 526683

Satin Chrome Kit P/N 526684

Brass Kit P/N 526685

Using the 6

4mm x 16mm screws supplied, secure

the Mounting Bracket to the Panel at the 6 points

shown in the diagram.

5 EARTHING THE MOUNTING BRACKET

Ensure the Product is not plugged in.

NOTE: The Mounting Bracket needs to be securely

Þ xed to the Panel. Where possible use the 6 outer

slots shown above. If these slots can not be used,

select alternative slots, as close as possible to the

outer slots. Ensure the screws are evenly spaced

about the Panel.

For some materials pilot holes may need to be

drilled Þ rst before screwing the Mounting Bracket

onto the Panel. Ensure the drill does not damage

the face of the Panel.

Plug the green

Badge earthing

wire onto a

Mounting Bracket

tab. Plug the

earthing wire from

the Product onto

the other Mounting

Bracket tab.

Page 8

6 CONNECTING THE BADGE WIRES 7 FITTING THE PANEL TO THE PRODUCT

Ensure the Product is not plugged in.

The Badge Isolator Board is an electrostatic

sensitive device. Ensure you are adequately

earthed when connecting or disconnecting the

Badge by wearing a earthing strap or by

earthing yourself to the DishDrawer.

P/N 526610A (page 4 of 4)

SINGLE MODELS ONLY

Connect the Badge

plug to the top of the

Badge Isolator Box.

Partially open the drawer. Fit the assembled

Panel by sliding in an inwards and upwards

motion. The rubber seal between the Drawer

and Panel must be kept in place.

Secure the Panel by inserting the

pins on either side of the Drawer.

Ensure that the rib on the pin is

vertical.

Check the Þ t of the Panel, making sure the

air ß ow gap is 9mm between the Panel and

cabinetry.

INTEGRATED PANEL PREPARATION IS COMPLETE.

The Product is now ready to install. Refer to

Product Installation Instruction Sheet P/N 526609.

Loading...

Loading...