Page 1

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

BASIC OPERATION OF COMMERCIAL STACKED

WASHER/DRYER

n

For additional information, see

www.WhirlpoolCommercialLaundry.com

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage

or weaken the electronic control assembly. The new control

assembly may appear to work well after repair is finished,

but failure may occur at a later date due to ESD stress.

n

Use an anti-static wrist strap. Connect wrist strap to green

ground connection point or unpainted metal in the appliance.

-ORTouch your finger repeatedly to a green ground connection point

or unpainted metal in the appliance.

n

Before removing the part from its package, touch the anti-

static bag to a green ground connection point or unpainted

metal in the appliance.

n

Avoid touching electronic parts or terminal contacts; handle

electronic control assembly by edges only.

n

When repackaging failed electronic control assembly in anti-

static bag, observe above instructions.

GENERAL USER INFORMATION

Scrolling ‘out of order’ message, followed by a failure

or diagnostic code, showing in display

This condition indicates the washer/dryer is inoperative. Diagnostic

codes being displayed on the upper portion of the display pertain

to the dryer section, and diagnostic codes displayed on the lower

portion of the display apply to the washer section. Diagnostic codes

displayed on both the upper and lower portions of the display

pertain to the control system of both the washer and dryer.

Cold Start (initial use):

‘0 Minutes’ showing in display

This condition indicates the cycle is complete and the washer/dryer

cannot be operated. Coins dropped or debit inputs during this

condition will be stored in escrow but cannot be used until normal

operation is restored by opening and closing the door. If a door

switch has failed, causing ‘0 MINUTES’ to remain in the display

after the door is opened and closed, it must be replaced before

normal operation can be restored.

Warm Start (after power failure):

A few seconds after power is restored, if a cycle was in progress

at the time of the power failure, ‘RESELECT CYCLE’ will flash

in the display, indicating the need for a key press to restart

the washer or dryer.

Washer is programmed at the factory as follows:

n

11 minute wash period

n

3 rinses (extra rinse not enabled)

n

$2.00 wash price

Dryer is programmed at the factory as follows:

n

5 minutes per quarter

n

$1.50 dry price

Washer Door Lock

Prior to beginning a cycle, there is a door lock routine of lock/

unlock/relock, then cycle begins. The door will remain locked

until the end of a cycle or approximately 2 minutes after a

power interruption.

Pricing

After the door is opened and then closed following the completion

of a cycle, the display indicates the cycle price (unless set for free

operation, where the display will flash ‘SELECT CYCLE’). As coins

are dropped or debit inputs arrive, the display will change to lead

the user through the initiation of a cycle.

There are four (4) types of dryer pricing:

Fixed ‘Vend’ Pricing

A dryer set up for ‘Fixed Cycle’ operation can only accept

additional time accumulated by increments equal to the length

of a complete dry cycle. A maximum of 99 minutes may be

purchased; no additional credit is given for coins dropped

with 99 minutes in the display.

Accumulator Pricing

If the price is set to one coin 1, then accumulator pricing is in effect.

Cycle time can be purchased one coin at a time up to the maximum

time of 99 minutes.

Fixed Cycle With Top Off Pricing

A dryer set to offer ‘Top Off’ capability will allow time to be added

to an existing dry cycle in increments equal to the number of

minutes of dry time per quarter (coin 1), up to 99 minutes, regardless

of the cost required to start the dryer. No credit is given for coins

or debit inputs entered when the control is displaying 99 minutes.

With Card Payment System: In Enhanced Debit Mode, the top off

price can be set independently (see VALUE OF COIN 2), and the top

off time is calculated according to the following equation:

full cycle price

top off time =

top off price

x full cycle length

Penny increment offset is not applied to top off purchases.

Free Cycles

This is established by setting the cycle price to zero. When this

happens, ‘SELECT CYCLE’ will appear rather than a cycle price.

Any cycle started as a free cycle will automatically terminate

when the door is opened.

PART NO. W10920938A PAGE 1

Page 2

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

Debit Card Ready

This washer/dryer is debit card ready. It will accept a variety of

debit card systems, but does NOT come with a debit card reader.

Refer to the debit card reader manufacturer for proper washer/dryer

set-up. In models converted to a Generation 1 debit card system,

debit pulses represent the equivalent of one coin (coin 1).

CONTROL SET-UP PROCEDURES

IMPORTANT: Read all instructions before operating.

n

Coin Payment Models: Insert service switch key and turn

counter-clockwise.

n

With Card Payment System: Once a Generation 2 debit card

reader is installed (according to the reader manufacturer’s

instructions), the set-up modes can be changed by inserting a

set-up card (supplied by the reader manufacturer) into the card

slot. Inserting the service switch key and turning will only access

the service mode.

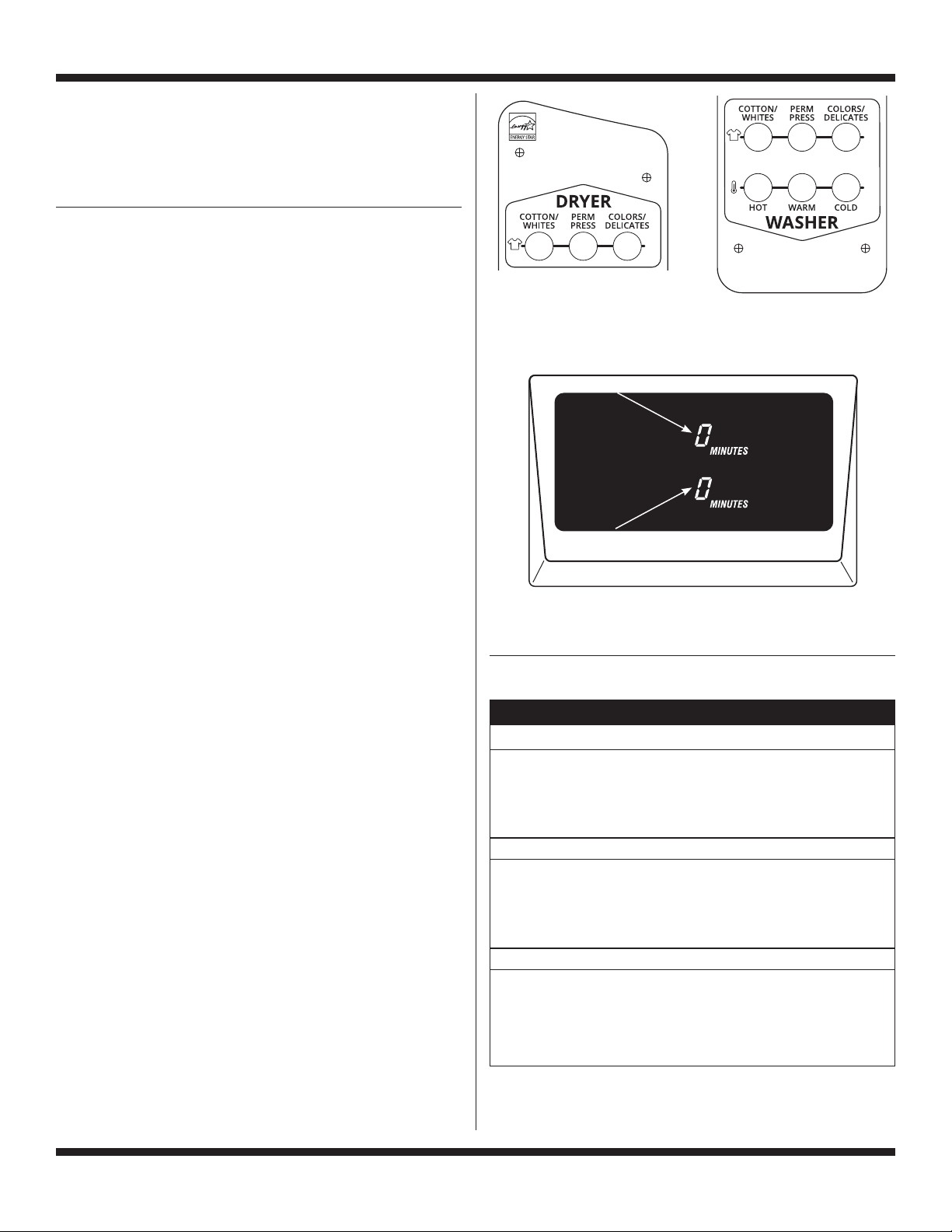

The washer/dryer is now in the set-up mode. The bottom

temperature setting buttons and the lower portion of the display are

used to set up the digital control for the washer. The upper three

fabric setting buttons and the upper portion of the display are used

to set up the controls for the dryer.

The display can contain four numbers and/or letters and a decimal

point on both the top and bottom display portions. These are used

to indicate the set-up codes and related code values available for

use in programming the washer/dryer.

Start Operating Set-Up

Washer/dryers are preset at the factory and do not require any

programming. However, if you want to change the settings, follow

the ‘Set-Up Codes’ guide.

The first code shown in each segment is the factory default setting.

The set-up code is indicated by the one or two left-hand characters.

The set-up code value is indicated by the two or three right-hand

characters.

Dryer control

setting buttons

Dryer display

Washer display

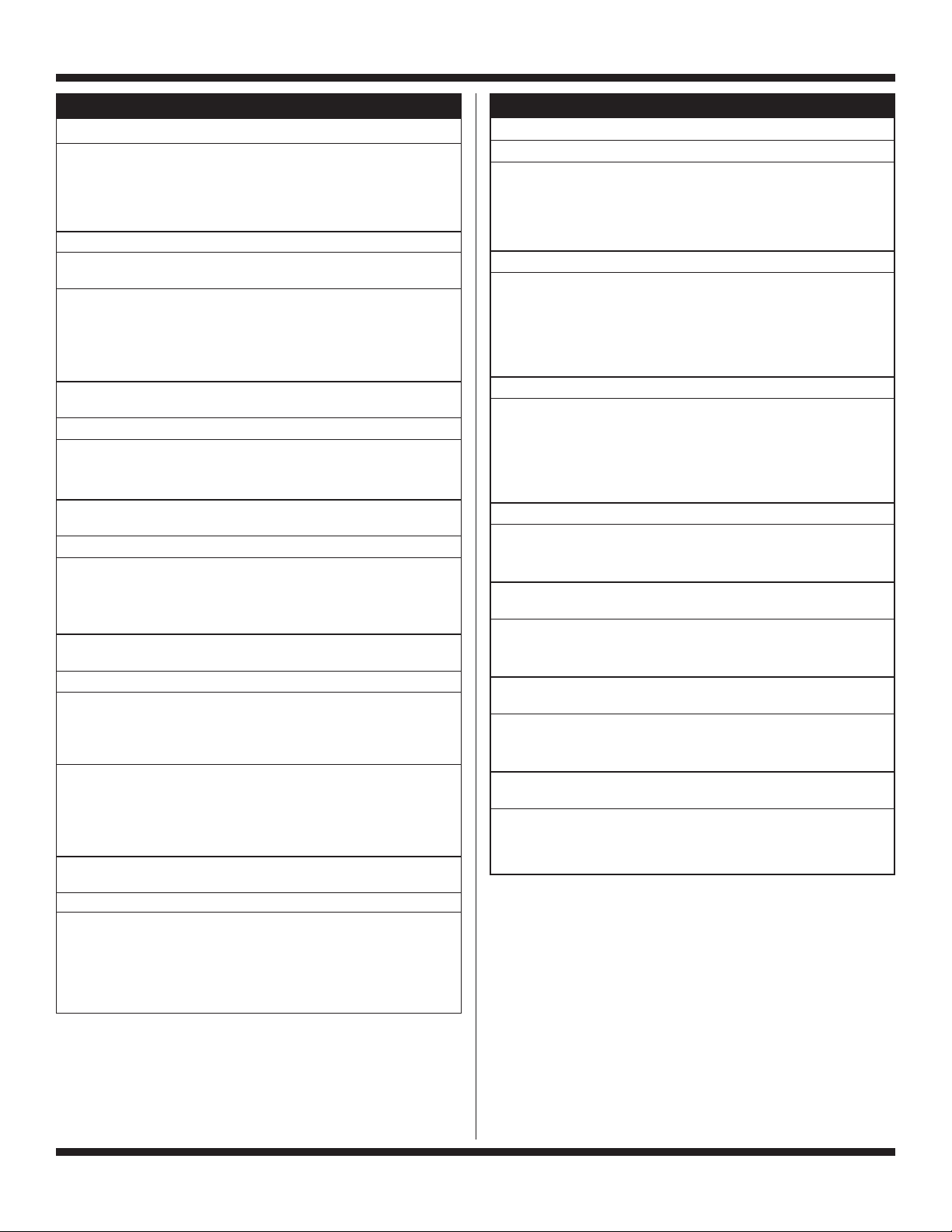

SET-UP CODES

Washer control

setting buttons

Display

CODE EXPLANATION

6 06 REGULAR CYCLE PRICE (DRYER)

6 06

Represents the number of quarters (coin 1) needed to start the dryer;

6 quarters = $1.50.

Press the lower middle (WARM) button once to advance to next code.

g

6 08 REGULAR CYCLE PRICE (WASHER)

6 08

middle left (COTTON/WHITES) button, decrease by

(HOT) button. Factory default of 8 quarters = $2.00.

Press the lower middle (WARM) button once to advance to next code.

g

7 05 REGULAR DRY TIME (DRYER)

7 05 Represents the number of minutes per quarter (coin 1).

Factory default of 5 minutes per coin. Example: 6 quarters

x 5 minutes = 30 minutes. By pressing the upper left (COTTON/

WHITES) button, value adjusts from 1–99 minutes.

Press the lower middle (WARM) button once to advance to next code.

g

may adjust from 0–200 (See VALUE OF COIN 1). Advance from 0–200 by

pressing the upper left (COTTON/WHITES) button. Factory default of

Represents the number of quarters (coin 1) needed to start the washer;

may adjust from 0–200 (See VALUE OF COIN 1). Increase by pressing the

pressing the lower left

PAGE 2

Page 3

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

CODE EXPLANATION CODE EXPLANATION

7 11 WASH LENGTH (WASHER)

7 11 This is the number of minutes for WASH. Washer comes from

the factory preset with 11 minutes; may adjust from 9–17 minutes.

Increase by pressing the middle left (COTTON/WHITES) button,

decrease by pressing the lower left (HOT) button.

Press the lower middle (WARM) button once to advance to next code.

g

8 00 TYPE OF DRYER PRICING (DRYER)

8 00 Fixed Cycle with Top Off. For detailed description, see General

Dryer User Information.

8 FC With Card Payment System: Fixed Cycle. For detailed

description, see General Dryer User Information.

Use the upper right (COLORS/DELICATES) button to change

this selection.

Press the lower middle (WARM) button once to advance to next code.

g

8 00 ADDITIONAL RINSE OPTION (WASHER)

This option is either NOT SELECTED ‘00’ or SELECTED ‘Ar.’

8 00

8 Ar

Press the lower right (COLD) button to change this selection.

Press the lower middle (WARM) button once to advance to next code.

g

9 00 CYCLE COUNTER OPTION

This option is either NOT SELECTED ‘00’ or SELECTED ‘0C.’

9 00 Not Selected ‘00.’

9 0C Selected ‘0C’ and not able to be deselected.

Press the lower right (COLD) button three consecutive times

to select ‘0C.’ Once selected ‘0C’ it cannot be deselected.

Press the lower middle (WARM) button once to advance to next code.

g

1.00 MONEY COUNTER OPTION

This option is either NOT SELECTED ‘00’ or SELECTED ‘0C.’

1.00 Not Selected ‘00.’

1.0C Selected ‘0C.’

Press the lower right (COLD) button three consecutive times

to select ‘0C’ and three consecutive times to deselect (Not Selected

‘00’). Counter resets by going from ‘OFF’ to ‘ON.’

1.C0 Selected ‘C0’ and not able to be deselected.

To select ‘C0’ and not able to be deselected, first select ‘0C,’

then within two seconds press the lower right (COLD) button

twice, the lower left (HOT) button once, and exit the set-up mode.

Press the lower middle (WARM) button once to advance to next code.

g

2.00 SPECIAL PRICING OPTION

This option is either NOT SELECTED ‘00’ or SELECTED ‘SP.’

2.00 Not Selected ‘00,’ and next available code will be A.00.

2.SP Selected ‘SP.’ Press the lower right (COLD) button once

to change this selection.

If SPECIAL PRICING OPTION is selected, there is access to codes ‘3.XX’

through ‘9.XX.’

Press the lower middle (WARM) button once to advance to next code.

g

Not Selected ‘00.’

Selected ‘Ar.’

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED:

3.06 SPECIAL CYCLE PRICE (DRYER)

3.06 Represents the number of quarters (coin 1) to start the dryer;

may adjust from 0–200 (See VALUE OF COIN 1). Advance

from 0–200 by pressing the upper left (COTTON/WHITES) button.

Factory default of 6 quarters = $1.50.

Press the lower middle (WARM) button once to advance to next code.

g

3.08 SPECIAL CYCLE PRICE (WASHER)

3.08 Represents the number of quarters (coin 1) to start the washer;

may adjust from 0–200 (See VALUE OF COIN 1). Increase by

pressing the middle left (COTTON/WHITES) button, decrease

by pressing the lower left (HOT) button. Factory default of

8 quarters = $2.00.

Press the lower middle (WARM) button once to advance to next code.

g

4.05 SPECIAL DRY TIME (DRYER)

4.05 Represents the number of minutes per quarter (coin 1).

Factory default of 5 minutes per coin. Example: 6 quarters

x 5 minutes = 30 minutes. By pressing the upper left

(COTTON/WHITES) button, the value can be adjusted

from 1–99 minutes.

Press the lower middle (WARM) button once to advance to next code.

g

5.00 TIME-OF-DAY CLOCK, MINUTES

5.00 This is the TIME-OF-DAY CLOCK, minute setting; select 0–59

minutes by pressing the lower left (HOT) button.

Press the lower middle (WARM) button once to advance to next code.

g

6.00 TIME-OF-DAY CLOCK, HOURS

NOTE: Uses military time or 24 hr. clock.

6.00 This is the TIME-OF-DAY CLOCK, hour setting; select 0–23 hours

by pressing the lower left (HOT) button.

Press the lower middle (WARM) button once to advance to next code.

g

7.00 SPECIAL PRICE START HOUR

NOTE: Uses military time or 24 hr. clock.

7.00 This is the START HOUR; 0–23 hours. Select START HOUR

by pressing the lower left (HOT) button.

Press the lower middle (WARM) button once to advance to next code.

g

8.00 SPECIAL PRICE STOP HOUR

NOTE: Uses military time or 24 hr. clock.

8.00 This is the STOP HOUR; 0–23 hours. Select STOP HOUR

by pressing the lower left (HOT) button.

Press the lower middle (WARM) button once to advance to next code.

g

PAGE 3

Page 4

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

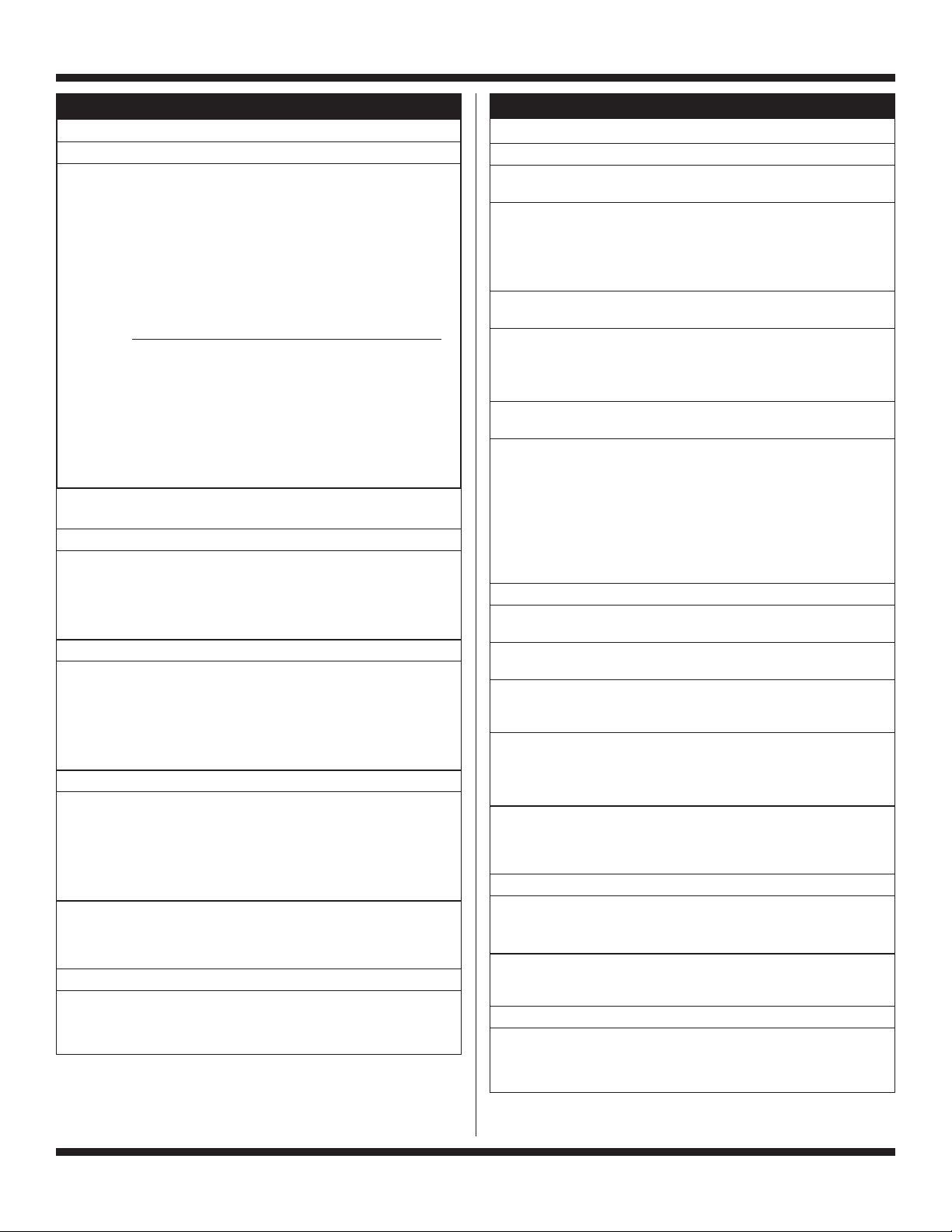

CODE EXPLANATION

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED (cont.):

9.10 SPECIAL PRICE DAY

9.10 This represents the day of the week and whether special pricing

is selected for that day. A number followed by ‘0’ indicates no

selection that particular day (9.10). A number followed by an ‘S’

indicates selected for that day (9.1S). To change the value of ‘0’

and ‘S,’ use the lower right (COLD) button.

Days of the week (1–7) are selected by pressing the lower left

(HOT) button.

When exiting set-up code ‘9.’, the display must show current day

of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

Press the lower middle (WARM) button once to advance to next code.

g

A.00 VAULT VIEWING OPTION

This option is either NOT SELECTED ‘00’ or SELECTED ‘SC.’

A.00 Not Selected ‘00.’

A.SC Selected ‘SC.’ Press the lower right (COLD) button once

for this selection. When selected, the money and/or cycle counts

will be viewable (if counter option[s] is selected) when the coin

box is removed.

Press the lower middle (WARM) button once to advance to next code.

g

b.05 VALUE OF COIN 1

b.05 This represents the value of coin 1 in number of nickels:

05 = $0.25.

Increase between 1 and 200 nickels by pressing the middle left

(COTTON/WHITES) button, decrease by pressing the lower left

(HOT) button.

Press the lower middle (WARM) button once to advance to next code.

g

C.20 VALUE OF COIN 2/VALUE OF DRYER TOP OFF

C.20 This represents the value of coin 2 in number of nickels:

20 = $1.00.

Increase between 1 and 200 nickels by pressing the middle left

(COTTON/WHITES) button, decrease by pressing the lower left

(HOT) button.

Press the lower middle (WARM) button once to advance to next code.

g

E.00 ADD COINS OPTION

This option is either NOT SELECTED ‘00’ or SELECTED ‘AC.’ This

option causes the customer display to show the number of coins

(coin 1) to enter, rather than the dollars-and-cents amount.

E.00 Not Selected ‘00.’

E.AC Selected ‘AC.’ Press the lower right (COLD) button

three consecutive times to change this selection.

Press the lower middle (WARM) button once to advance to next code.

g

CODE EXPLANATION

F.00 ENHANCED PRICING OPTION

F.00 Not Selected ‘00.’

F.CP Cycle-Based pricing enabled. This option allows configuration

of different prices for cold, warm, and hot water wash cycles.

F.SU Super Cycle pricing enabled. This option allows customers

to upgrade cycles by depositing extra money. Set-up codes

‘H.’ and ‘h.’ will be displayed only when this option is enabled.

Press the lower right (COLD) button for this selection.

Press the lower middle (WARM) button once to advance to next code.

g

H.01 SUPER CYCLE UPGRADE PRICE

(Skipped unless Super Cycle pricing is enabled.)

H.01 This represents the number of coin 1 required to upgrade a

base cycle to a super cycle. Advance from 0–33 by pressing

the lower left (HOT) button.

Press the lower middle (WARM) button once to advance to next code.

g

h.01 SUPER CYCLE TYPE

(Skipped unless Super Cycle pricing is enabled.)

h.01 This represents the Super Cycle upgrade option. Press the

lower left (HOT) button to step through upgrade options 1

through 3 as follows:

01 – enhanced wash, extra 3 minutes of wash tumble

02 – extra rinse for all cycles.

03 – both 01 and 02.

Press the lower middle (WARM) button once to advance to next code.

g

J.Cd PAYMENT MODE (COIN/DEBIT OPTION)

J.Cd Both coin and debit selected. Press the lower right (COLD) button

three consecutive times to change this selection.

_

J.C

Coins selected, debit disabled. Press the lower right (COLD) button

three consecutive times to change this selection.

J._d With Card Payment System: Debit Card selected, coins

disabled. Press the lower right (COLD) button three consecutive

times to change this selection.

J.Ed Enhanced Debit is self-selected when a Generation 2 card reader

is installed in the washer/dryer. The Ed option cannot be manually

selected or deselected.

Press the lower middle (WARM) button once to advance to next code.

g

L.00 PRICE SUPPRESSION OPTION

This option causes the customer display to show ‘ADD’ or

‘AVAILABLE’ rather than the amount of money to add (used

mainly in debit installations).

L.00 Not Selected ‘00.’

L.PS Selected ‘PS.’ Press the lower right (COLD) button once

to change this selection.

Press the lower middle (WARM) button once to advance to next code.

g

n.CE CLEAR ESCROW OPTION

When selected, money held in escrow for 30 minutes without

further escrow or cycle activity will be cleared.

n.00 Not Selected ‘00.’

n.CE Selected ‘CE.’ Press the lower right (COLD) button once

to change this selection.

Press the lower middle (WARM) button once to advance to next code.

g

in addition to the programmed wash time.

PAGE 4

Page 5

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

CODE EXPLANATION

U.00 PENNY INCREMENT OFFSET (DRYER)

U.00 This represents the penny increment price offset used in

Generation 2 (Enhanced Debit) models. Choose from 0–4

pennies by pressing the upper left (COTTON/WHITES) button.

Press the lower middle (WARM) button once to advance to next code.

g

U.00 PENNY INCREMENT OFFSET (WASHER)

U.00 This represents the penny increment price offset used in

Generation 2 (Enhanced Debit) models. Choose from 0–4

pennies by pressing the lower left (HOT) button.

Press the lower middle (WARM) button once to advance to next code.

g

A1.00 PREWASH LENGTH (WASHER)

A1.00 This is the number of minutes of PREWASH. Choose 00 to disable

the prewash or select between 2 and 7 minutes by pressing the

lower left (HOT) button.

Press the lower middle (WARM) button once to advance to next code.

g

If cycle counter (9 0C) is selected, the following is true:

1 00 Cycles in HUNDREDS. 1 02 = 200

2 00 Cycles in ONES. 2 25 = 225

TOTAL CYCLES = 225

This is “VIEW ONLY” and cannot be cleared.

Press the lower middle (WARM) button once

to advance to next code.

If money counter (1.0C or 1.C0) is selected, the following is true:

3 00 Dollars in HUNDREDS. 3 01 = $100.00

4 00 Dollars in ONES. 4 68 = $168.00

5 00 Number of CENTS. 5 75 = $100.75

TOTAL = $168.75

END OF SET-UP PROCEDURES

EXIT FROM SET-UP MODE

n

Turn service switch key clockwise and remove

or remove manual set-up card.

DIAGNOSTIC GUIDE

Before servicing, check the following:

n

Make sure there is power at the wall outlet.

n

Verify that both hot and cold water faucets are open and water

supply hoses are unobstructed.

n

Check all connections before replacing components. Look for

broken or loose wires, failed terminals, or wires not pressed

into or onto connections far enough.

n

A potential cause of a control not functioning is corrosion on

connections. Observe connections and check for continuity

with an ohmmeter.

n

Connectors: Look at top of connector. Check for broken or loose

wires. Check for wires not pressed into connector far enough

to engage metal barbs.

n

Resistance checks must be made with power cord unplugged

from outlet, and with component connectors disconnected.

DIAGNOSTIC MODE

To enter the ‘Diagnostic Mode,’ first enter ‘Start Operating Set-Up.’

Then press and hold the lower right (COLD) button for 1 second

while in set-up code six, anytime a diagnostic code is present, or while

dAS displays if operating with a Generation 2 card reader.

On entry to diagnostic mode, the entire display will flash, a cycle

in process is canceled, money in escrow is cleared, and diagnostic

codes are cleared. If a diagnostic code persists on the portion of

the washer/dryer not being tested, it can be acknowledged with the

lower middle (WARM) button prior to starting a diagnostic cycle.

This would be used when, for example, the dryer is out of service

and a diagnostic cycle is to be run on the washer.

There are six possible ways to initiate cycle activity from diagnostic

mode as follows:

1. Washer Cleanout Cycle – With the entire display flashing,

this cycle is started by pressing the center right (COLORS/

DELICATES) button.

Use the Washer Cleanout Cycle once a month to keep the inside

of your washer fresh and clean. This cycle uses a higher water

level. Use with liquid chlorine bleach to thoroughly clean the

inside of your washer. This cycle should not be interrupted.

IMPORTANT: Do not place garments or other items in the

washer during the Washer Cleanout Cycle. Use this cycle

with an empty wash drum.

2. Washer Cycle Credit – With the entire display flashing, a cycle

may be credited by pressing the lower left (HOT) button (CC will

display). When the service mode is exited, ‘SELECT CYCLE’ will

be displayed unless the end-of-cycle door opening is required.

3. Washer Manual Overview Test Cycle – With the entire display

flashing, this cycle is started by pressing the center left (COTTON/

WHITES) button. This cycle provides more typical full length fills,

tumbles, and drains, and allows for a more thorough analysis of

the washer operation, including pressure sensor behavior.

4. Washer Quick Spin Cycle – With the entire display flashing, this

cycle is started by pressing the center middle (PERM PRESS)

button. This cycle provides a method to quickly drain and spin

(remove water from the washer), if desired.

5. Washer Quick Overview Test Cycle – With the entire display

flashing, this cycle is started by pressing the lower middle

(WARM) button. This cycle provides a quick verification that

the cold and hot water valves, dispenser, and pump motor are

working. It also includes door lock, drain, and spin operations.

6. Dryer Field Diagnostic Cycle – With the entire display flashing,

this cycle is started by pressing the upper middle (PERM PRESS)

button. Additional time can be added by pressing the upper left

(COTTON/WHITES) button. This cycle can be used to credit lost

customer dryer time.

Pressing the lower right (COLD) button will exit diagnostic mode

and cancel a diagnostic cycle in process.

PAGE 5

Page 6

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

FAILURE DISPLAYS

Active dryer diagnostic codes are shown on the upper portion of

the display and active washer diagnostic codes are shown on the

bottom portion of the display.

DRYER DIAGNOSTIC CODES

If the set-up mode is entered and one of the following errors

has previously occurred, the appropriate diagnostic code will

be in the display on the upper portion of the screen.

DRYER

DISPLAY EXPLANATION

d 5

d 9

d 13

d 16

F 01

F 22

F 23

F 70

F 71

COIN 1 ERROR

Blocked coin 1 or coin drop UI control circuit failure

(coin recognition and customer display disabled while

blockage persists).

LOW VOLTAGE DETECTION ERROR

Voltage detected below 90 VAC for 8 seconds.

COIN 2 ERROR

Blocked coin 2 or coin drop UI control circuit failure

(coin recognition and customer display disabled

while blockage persists).

GENERATION 2 DEBIT CARD

READER ERROR

Not receiving communications from installed debit

card reader in Enhanced (Generation 2) Debit mode.

DRYER MOTOR CONTROL

CIRCUIT ERROR

Dryer motor control circuit error (cycles and price

display disabled until diagnostic code is manually

cleared). The control doesn’t know if the motor relay

is bad (stuck on), the motor relay drive circuit is bad

(shorted), causing the motor relay to stay on, or the

motor relay feedback circuit is bad.

EXHAUST THERMISTOR OPEN ERROR

Exhaust thermistor open, temperature drops

below 18°F (>50 kΩ) for 1 minute in Run mode,

or immediately in Factory Diagnostic Mode.

EXHAUST THERMISTOR

SHORTED ERROR

Exhaust thermistor shorted, temperature above 250°F

(<500 Ω) for 1 minute in Run mode, or immediately

in Factory Diagnostic Mode.

COMMUNICATION FAILURE

FROM DRYER CCU TO UIC

UIC is not receiving communications from CCU

(cycles and price display disabled while error persists

or is manually cleared).

COMMUNICATION FAILURE

FROM UIC TO DRYER CCU

CCU is not receiving communications from UIC

(cycles and price display disabled while error persists

or is manually cleared).

DRYER

DISPLAY EXPLANATION

F 73

F 74

UIC MICROPROCESSOR ERROR

UIC Microprocessor is not able to read or verify

EEPROM (cycles and price display disabled until

diagnostic code is manually cleared).

UIC EEPROM ERROR

UIC EEPROM memory is a CRC failure (cycles and price

display disabled until diagnostic code is manually cleared).

WASHER DIAGNOSTIC CODES

If the set-up mode is entered and one of the following errors

has previously occurred, the appropriate diagnostic code will

be in the display on the lower portion of the screen.

WASHER

DISPLAY EXPLANATION AND RECOMMENDED PROCEDURE

F 01

F 04

F 11

WASHER CCU ERROR

Communication error within the Central Control Unit

(CCU); the pump drive in CCU fails to activate; one of

the main relays in the CCU fails to activate.

Possible Causes

– A power surge/drop.

– Reversed polarity or mis-wire, along with open

ground switches.

Surge/drop procedure

1. Clear error code.

2. Unplug washer or disconnect power.

3. Wait 2 minutes before reconnecting power.

4. Verify CCU by running a short diagnostic test.

Mis-wire or reversed polarity procedure

1. Clear error code.

2. Check outlet for correct polarity. To check within

washer for polarity at the RFI, white to cabinet

ground must be 0 volts.

3. Check the white wire on the RFI filter to ensure correct

polarity. White wire needs to be toward front of washer.

If the RFI filter is not easily accessible, the polarity test

can be made on the washer CCU. Disconnect power.

Check for resistance or continuity at IF2 from terminal

#1 to ground or any bare metal on the washer cabinet.

Reading should be infinite or show as an open circuit.

4. Check that the ground switches of the toe panel

and rear panel are correctly closed.

5. Verify CCU by running a short diagnostic test.

If these procedures do not correct the failure, replace

the CCU control.

ACCELEROMETER FAILURE

The accelerometer component failed. The X, Y, and Z

limits are outside of the normal range.

Possible Causes

– CCU dislodged from mounting.

– Accelerometer failure on CCU.

MCU ERROR

Motor Control Unit (MCU) has a failure.

Possible Causes

– A repeating under or overvoltage condition. If the

failure occurs during a high-speed spin, the door

remains locked for 2 minutes.

– A broken drive belt.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Using Ohm meter, check wire harness connections

for continuity between drive motor and the MCU.

4. Check the motor and do a continuity test (page 15).

5. The MCU is good if the motor operates in diagnostic mode.

If the motor fails to turn on, replace the MCU.

PAGE 6

Page 7

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

WASHER

DISPLAY EXPLANATION AND RECOMMENDED PROCEDURE

F 20

F 21

NO WATER DETECTED ENTERING WASHER

The water fill level is not detected by the pressure

sensor. NOTE: The message “no H20” will appear

before the F20 error is displayed, and the washer may

try three times before the failure code is activated.

Possible Causes

– No water to washer; faucet(s) turned off.

– Defective hot and/or cold valve(s).

– Plugged or kinked inlet hoses or valves.

– Pressure sensor or pressure sensor hose

damaged, kinked, or disconnected.

– Electrical connection from CCU (PS8) to pressure

sensor damaged.

– Drain hose forced down into standpipe > 6" (152 mm).

– Blocked inlet from dispenser to tub.

Procedure

1. Clear error code by opening and closing the main

door or by power cycling the control by removing

power and then reestablishing power to the control.

2. Unplug washer or disconnect power.

3. Check incoming water pressure at faucet.

4. Check inlet hoses for possible leaks.

5. Make sure pressure sensor hose is in good condition

and properly connected to tub and pressure sensor.

6. Verify that water is not running out of the drain hose

(siphoning) as it is filling.

7. Perform continuity test on wire harness connections

from CCU to inlet valves (VCH7 and VSF2), and to

pressure sensor (PS8).

8. Check inlet valves by running a diagnostic test.

9. Check that the pump is not running while the

washer is filling.

10. Verify pressure sensor operation by accessing

Help Mode while running a paid cycle (see Help

Mode Symbols and Elements, page 14).

LONG DRAIN

The drain time exceeds 8 minutes without reaching

empty level in pressure sensor.

NOTE:

n

Suds can cause delays in draining, indicated by an

alternating display of “SudS” and a countdown timer.

Washer drains for 4 minutes, pauses 5 minutes, then

tries again for 4 additional minutes of draining. F21

will display if washer does not drain. (Normal drain

takes less than 2 minutes).

Possible Causes

– Damaged or blocked pump/pump filter.

– Washer fills during drain.

– Excess suds causing cavitating pump.

– Drain hose blocked, kinked, or exceeds

recommended height.

– Poor connection between CCU (DP2) and drain pump.

Procedure

1. Clear error code.

2. Unplug washer or disconnect power.

3. Make sure the drain hose is not sealed into the standpipe.

4. Ensure the drain height is not more than 8 ft (2.4 m)

above the base of the washer.

5. Check the drain hose and make sure it is not

plugged or kinked.

6. Check the drain pump/pump filter for foreign objects

or worn impeller.

7. Check the electrical connection between the pump

and the CCU (DP2).

8. Check the pump using a diagnostic mode.

9. Check pressure sensor operation in Help Mode and

the condition of the pressure sensor hose.

If all the above are OK and pump is powered but does

not pump water or water flow is poor, replace the pump.

WASHER

DISPLAY EXPLANATION AND RECOMMENDED PROCEDURE

F 22

F 24

DOOR LOCK ERROR

Washer will make several attempts to lock the door,

then customer will be asked to open door, clear

obstructions, shut door, and reselect cycle. Washer

will attempt to lock the door again. This procedure

can repeat two times before customer loses vend

and washer resets. If entire procedure happens twice

without a successful door lock, F22 will appear.

Possible Causes

– Misaligned or broken door latch.

– Electrical connections from CCU (DLS2, DL3)

to door lock are damaged.

– Misaligned, broken, or overtightened door hook.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Ensure that the latch is secured to the front panel.

4. Check for misaligned, broken, cracked, or loose

door hook.

5. Check the electrical connections between CCU

(DLS2, DL3) and latch.

If the latch fails to lock after checking all of the above,

replace the latch.

TEMPERATURE SENSOR ERROR

Water temperature sensor value is out of range

(23°F to 217°F [–5°C to 103°C])

NOTE: To find correct Ohm reading, refer to the

Water Temperature Sensor section, page 15.

Possible Causes

– Water temperature sensor damaged.

– Electrical connections from CCU (SET2)

to temperature sensor damaged.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Perform Ohm test on Water Temperature Sensor and

harness connection. This reading can be taken from

the cable attached to CCU terminal SET2.

If the water temperature sensor is out of range,

replace it.

PAGE 7

Page 8

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

WASHER

DISPLAY EXPLANATION AND RECOMMENDED PROCEDURE

F 25

F 26

TACHOMETER ERROR

If the MCU is unable to properly detect motor speed,

the washer shuts down. If a failure occurs during highspeed spin, the door remains locked for 2 minutes.

Possible Causes

– Damaged or poor contact in electrical connection

from MCU to drive motor.

– Inverted wires on RFI or ground switch(es) open.

Procedure for damaged MCU connection

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Check for broken belt.

4. Verify that the shipping system, including shipping

bolts and spacers, is removed, and that the power

cord is not tangled in any components inside rear

of washer.

5. Verify electrical connection between MCU and drive

motor connector.

6. Reassemble any disassembled parts.

7. Reconnect to power.

8. Check operation of drive motor in diagnostic mode;

if drum tumbles, the MCU and motor are OK.

Procedure for inverted wires on RFI

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Look for reversed polarity at RFI filter.

4. Make sure that the ground switches of the toe panel

or rear panel are closed and working correctly.

5. Check operation of drive motor in diagnostic mode;

if drum tumbles, the motor is OK.

If, after these procedures, the drum fails to tumble,

replace the MCU. If motor operation is not restored,

replace the motor.

DOOR SWITCH ERROR

The door switch circuit is open for 5 seconds while the

door is locked.

Possible Causes

– Electrical connections from CCU (DLS2) to door

switch in latch are damaged.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Verify the electrical connection between CCU and

door switch by using the Help Mode (see appropriate

symbols, page 14) or continuity test at CCU (DLS2)

connection.

If the door switch circuit fails to open or close, replace

the door latch.

WASHER

DISPLAY EXPLANATION AND RECOMMENDED PROCEDURE

F 27

F 28

OVERFLOW CONDITIONS

The overflow contact on the pressure sensor is closed

for more than 60 seconds. If the washer displays F27,

the washer is probably full of water, and the water supply

has been shut off. If not, water will be pouring out

of the washer from the dispenser and door.

Possible Causes

– Inlet valve(s) unable to close.

– Pressure sensor hose is kinked.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. If water continues to flow into washer, inlet valve

needs to be replaced.

4. Check if pressure sensor hose is kinked or damaged.

5. Verify functionality of inlet valves and pressure

sensor by running a diagnostic cycle.

COMMUNICATION FAILURE BETWEEN

CCU AND MCU

The communication between the Central Control Unit

(CCU) and the Motor Control Unit (MCU) has failed.

Possible Causes

– Reversed polarity or mis-wire along with open

ground switch(es).

– Communication cable from CCU (MI3) to MCU

is damaged.

Procedure for reversed polarity or mis-wire

1. Clear error code.

2. Unplug washer or disconnect power.

3. Check outlet for correct polarity.

4. Check the white wire on the RFI filter to ensure

correct polarity. White wire needs to be toward front

of washer. If the RFI filter is not easily accessible,

the polarity test can be made on the washer CCU.

Disconnect power. Check for resistance or continuity

at IF2 from terminal #1 to ground or any bare metal

on the washer cabinet. Reading should be infinite

or show as an open circuit.

5. Check that the ground switches of the toe panel

and rear panel are correctly closed. Refer to

Grounding System Wiring Diagram.

Procedure for communication cable

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Perform continuity test on wire harness connections

from CCU (MI3) to MCU (be careful not to spread the

Rast connector ends).

4. Verify the drive motor operation in diagnostic mode.

If drum fails to tumble, replace the MCU.

PAGE 8

Page 9

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

WASHER

DISPLAY EXPLANATION AND RECOMMENDED PROCEDURE

F 29

F 31

DOOR UNLOCK ERROR

The door is unable to unlock after six tries.

Possible Causes

– Misaligned or broken door latch.

– Electrical connections from CCU (DLS2, DL3)

to door lock are damaged.

– Misaligned, broken, or overtightened door hook.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Manually unlock the door (page 15).

4. Ensure that the latch is secured to the front panel.

5. Check for misaligned, broken, cracked, or loose

door hook.

6. Check the electrical connections between CCU

(DLS2, DL3) and latch (see page 15).

If the latch fails to unlock after checking all of the

above, replace the latch.

OVERHEATING OF MOTOR

The heat sink exceeds 212°F (100°C). If this condition

is met, the CCU resets the MCU, then waits for the

motor to cool down before restarting the motor.

This procedure can repeat up to four times before

F31 is displayed.

Possible Causes

– Improper installation of washer.

– Poor electrical connection from CCU (MS2) to MCU.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Verify the washer is not located near a source

of heat and has proper ventilation.

4. Check the electrical connections between CCU

(MS2) and MCU.

5. Verify the drive motor operation in diagnostic mode.

If, after the above tests, the motor overheats, replace

the motor.

WASHER

DISPLAY EXPLANATION AND RECOMMENDED PROCEDURE

F 33

F 34

F 70

PUMP DISCONNECTED

The electrical connection between the pump and the

CCU is lost.

Possible Causes

– Poor connection between CCU (DP2) and drain

pump.

– Pump thermal overload caused by the pump

running for an extended period of time.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Check electrical connection between pump and

CCU (DP2) (see page 15).

4. Check the pump using a diagnostic mode.

If the pump still does not run, replace the pump.

LOAD DETECTED IN WASHER

DURING WASHER CLEANOUT CYCLE

The washer detects a load inside the washer tub

at the beginning of the Washer Cleanout Cycle.

Possible Causes

– Load inside the washer during the Washer

Cleanout Cycle.

– Friction between the drum and bellows material.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Remove clothes from washer drum.

4. Check for misaligned or damaged bellows rubbing

the drum.

If bellows adjustment does not correct the friction issue,

the spin basket will need to be replaced.

COMMUNICATION FAILURE

BETWEEN CCU AND UIC

Communication between Central Control Unit (CCU)

and User Interface Control (UIC) has failed.

Possible Causes

– Electrical connection between CCU and UIC

is damaged.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Verify that the communication cable is connected

in the lower connector of the UIC.

4. Verify continuity in the cable between the CCU

and the UIC.

If, after these procedures, the continuity test fails,

replace the communication cable. If F70 is still

present, replace the CCU.

PAGE 9

Page 10

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

WASHER

DISPLAY EXPLANATION AND RECOMMENDED PROCEDURE

F 73

F 74

d 5

d 9

UIC FAILURE

Communication error within the User Interface Control.

Possible Causes

– A power surge/drop.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Wait 2 minutes before reconnecting power.

4. Verify UIC by attempting to start a cycle or run

diagnostic mode.

If these procedures do not correct the failure,

replace the UI control.

COIN 1 ERROR

The Coin 1 sensor is detected as blocked

for 8 seconds.

Possible Causes

– Coin vault full of money.

– Blocked or dirty sensor.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Check for broken coin sensor switch on coin drop.

4. Check the wire harness connections between User

Interface (AA4) and the coin sensor switch to ensure

wires do not block the coin switch beam.

5. Shorting the connections 2 and 3 at AA4 on

UIC or installing jumper (Whirlpool part number

W10785124) on UIC AA4 connection will simulate

a good coin sensor.

If the above procedures do not solve the problem,

replace the UIC.

LOW VOLTAGE DETECTION ERROR

Incoming voltage detected below 90vac for 8 seconds.

Possible Causes

– Voltage drop due to multiple washers

on same circuit.

– Worn outlet.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Check the wire harness connection between the RFI

filter and the transformer.

If the above procedures do not solve the problem,

replace the UIC.

WASHER

DISPLAY EXPLANATION AND RECOMMENDED PROCEDURE

d 13

d 16

Critical errors are indicated as part of the ‘out of order’ message.

NOTE: Errors d5, d13, and d16 will not stop the ongoing cycle,

although they will not allow another cycle to begin until the error

is addressed.

COIN 2 ERROR

The Coin 2 sensor is detected as blocked

for 8 seconds.

Possible Causes

– Coin vault full of money.

– Blocked or dirty sensor.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Check for blocked coin sensor switch on coin drop.

4. Check the wire harness connections between User

Interface (AA4) and the coin sensor switch to ensure

wires do not block the coin switch beam.

5. Shorting the connections 2 and 3 at AA4 on

UIC or installing jumper (Whirlpool part number

W10785124) on UIC AA4 connection will simulate

a good coin sensor.

d13 only occurs with coin 2 installed. If the above

procedures do not solve the problem, replace the UIC.

GENERATION 2 DEBIT CARD

READER ERROR

No communication from installed debit card reader

in Generation 2 debit mode for 5 minutes.

Possible Causes

– Card reader Gen 2 not installed, when washer

is in Ed mode.

– Poor contact or communication cable not

connected between UIC (AA3) and the card reader.

– Card reader failure.

Procedure

1. Clear error code.

2. Unplug the washer or disconnect power.

3. Check the wire harness connections between User

Interface (AA3) and the debit card reader Gen 2. Do

continuity test on cable.

4. Make sure you are using a Gen 2 card reader.

5. Reconnect power and wait for 5 minutes.

If the above procedures do not solve the problem,

replace the card reader.

PAGE 10

Page 11

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

WASHER QUICK OVERVIEW TEST

n

This cycle consists of 9 steps. In each step, the washer will

perform a Control Action as described in the table below. Once

the action is completed, the washer will move to the next step.

n

Each step can be differentiated from the others by looking at the

display indication. Steps can be advanced if the test requires it.

n

To move to the next step before a control action is complete,

press any key pad except the lower right (COLD) button.

n

To exit the Quick Overview Test at any time, press the lower

right (COLD) button.

Step INDICATION

DISPLAY

Control

Action to be Checked

1 COLORS Door locks, drum

turns 1/2 revolution,

then door unlocks

and relocks.

2 PREWASH Accelerometer tests

Note: “Prewash” flashes are performed.

on the display and is

very easy to miss.

3 CCU Fill by both cold water n Cold water inlet valves

EEPROM Version inlet valves (1 gal. [4 L])

(EC xx) into BLEACH

PERM PRESS compartment.

4 CCU Fill by hot water inlet

Software Version valve to Wash Level

(SC xx) into MAIN WASH

COTTONS compartment.

5 MCU

Software Version

(Sn xx)

COLORS

6 MCU

Hardware Version

Drum executes

tumbling at

wash speed

(30 sec).

(Hn xx)

PERM PRESS

7 UIC Drain pump is ON.

EEPROM Version

(EU xx)

COTTONS

8 UIC Drum rotates

Software Version counter-clockwise

(SU xx) and ramps up.

COLORS Performs unbalance

procedure before and

after spinning. If not

interrupted, the drum

will slow and stop;

after reaching 0 rpm,

the door unlocks and

Step 9 will be skipped.

9 PERM PRESS This Step is only

apparent if Step 8 is

MANUALLY ADVANCED

prior to the drum

reaching 0 rpm

(washer pumps out

if needed). Door

unlocks (washer

returns to flashing

mode).

The drain pump may be running in any of the last three steps,

depending on the water level in the washer and position of the

pressure sensor.

** In the event of an MCU-CCU communications error, the UI

display will go blank for up to 5 minutes and then display an

F28 error message.

** The washer will drain until pressure sensor reaches lowest level

for 10 seconds, then moves to next step.

Actuators

n

Door lock system

n

Child safety routine

n

Motor control (MCU)*

n

Accelerometer

n

#2 and #3

n

Pressure sensor:

n

Suds Level

n

Hot water inlet

n

valve #1

n

Pressure sensor:

n

Wash Level

n Motor

n Motor control (MCU)*

n

Drain pump

n

Pressure sensor**

n

Motor

n

Motor control (MCU)*

n

Drain pump on

n

Door unlock

WASHER MANUAL OVERVIEW TEST

Before replacing any system components, perform this

Manual Overview Test.

n

This cycle consists of 8 steps. In each step, the washer will

perform a Control Action as described in the table below. Once

the action is completed, the washer will move to the next step.

Check Exit Condition column.

n

Each step can be differentiated from the others by looking at the

display indication.

n

To move to the next step before a control action is complete,

press any key pad except the lower right (COLD) button.

n

When Step 8 is complete, the test runs again starting at Step 1.

n

To exit the Manual Overview Test at any time, press the lower

right (COLD) button.

Step DISPLAY Condition

Exit

Control

Action Checked

1 COLORS On Door locks, drum

completion turns 1/2 revolution, n Child safety routine

only then door unlocks

and relocks.

2 PREWASH On Accelerometer tests

completion are performed.

only

3 PERM On Filling with both

PRESS key press cold inlet valves.

or if overfill

level is

detected

4 COTTONS On key Drum executes

press or reversing movement n Motor Control (MCU)*

completion at wash speed

(10 min.).

5 COLORS On key Drain pump is on

press or (4 min.).

completion

6 PERM On Drain pump is on

PRESS completion (reach Suds Level

only plus 10 sec.).

7 COTTONS On key Drum rotates counter-

press or clockwise and ramps n Motor Control (MCU)*

completion up to maximum speed.

8 COLORS On key press Stop motor to 0 rpm.

only after Door unlocks.

rpm = 0 and

door is

unlocked

The drain pump may be running in any of the last three steps,

depending on the water level in the washer and position of the

pressure sensor.

** In the event of an MCU-CCU communications error, the UI

display will go blank for up to 5 minutes and then display an

F28 error message.

To be

n

Door lock system

n

Accelerometer

n

Both Cold Inlet

n

Valves #2 and #3

n

Overfill level

n

Motor

n

Drain Pump

n

Drain Pump

n

Motor

n

Motor

n

Motor Control (MCU)*

n

Door lock system

PAGE 11

Page 12

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

DIAGNOSTIC TEST QUICK GUIDE

The following table summarizes button function among the diagnostic sub-modes.

Diagnostic Mode Button Function Table

Function in

Function in Function in Diag.

Function in Diag.

Function in Diag. Cycle

Diag. Code Display Flashing Cycle Running Sub-Mode Cycle Running Sub-Mode Running Sub-Mode

Button Display Sub-Mode Sub-Mode (Washer Running) (Dryer Running) (Dryer & Washer Running)

LOWER LEFT Ignore Toggle Customer Go to help mode Toggle Customer Go to help mode

(HOT) BUTTON Wash Cycle Credit Wash Cycle Credit

LOWER MIDDLE Acknowledge Diag. Start Washer Quick Ignore Start Washer Quick Ignore

(WARM) BUTTON Code (Keep Code) Overview Test Cycle Overview Test Cycle

Go to Set-up Mode

LOWER RIGHT Clear Diag. Code Exit Diag. Display Cancel Diag. Cycle Cancel Diag. Cycle Cancel Diag. Cycles

(COLD) BUTTON Exit Diag. Code Flashing Sub-Mode Go to Set-up Mode Go to Set-up Mode Go to Set-up Mode

Display Sub-Mode Go to Set-up Mode

Go to Display

Flashing Sub-Mode

CENTER LEFT (COTTON/ Ignore Start Washer Manual Ignore Start Washer Manual Ignore

WHITES) BUTTON Overview Test Cycle Overview Test Cycle

CENTER MIDDLE Ignore Start Washer Quick Ignore Start Washer Quick Ignore

(PERM PRESS) BUTTON Spin Cycle Spin Cycle

CENTER RIGHT (COLORS/ Ignore Start Washer Ignore Start Washer Ignore

DELICATES) BUTTON Cleanout Cycle Cleanout Cycle

UPPER LEFT (COTTON/ Ignore Ignore Ignore Increment dryer test Increment dryer test

WHITES) BUTTON time by one minute time by one minute

Rolls from 99 back Rolls from 99 back

to 2 minutes to 2 minutes

UPPER MIDDLE Acknowledge Diag. Start Dryer Field Start Dryer Field Ignore Ignore

(PERM PRESS) BUTTON Code (Keep Code) Diag. Cycle Diag. Cycle

Go to Set-up Mode

UPPER RIGHT (COLORS/ Ignore Ignore Ignore Ignore Ignore

DELICATES) BUTTON

HELP MODE

Help mode is entered by pressing the lower left (HOT) button

while in special pricing option 2.XX (or while dAS displays if

operating with Generation 2 card reader). In help mode, the

software revision is displayed. The help mode is advanced

by pressing the lower middle (WARM) button. See Help Mode

Submenu on page 13 for the order in which items are displayed.

Press the lower left (HOT) button at any time to exit help mode.

Help Codes

Help

Code

Description

00 No Help Code

OF Oversuds detected during cycle, and washer was not able to resolve

an unbalance condition detected during the final spin related to the

oversuds detection (via pressure sensor) earlier in the cycle

32 More than six unbalance retries during the final spin – spin (and cycle)

has been aborted

33 Oversuds detected during wash cycle, and washer was not able to

resolve the condition – cycle has been aborted. Washer unable to

sense that water has been fully drained within required time, sensing

as an oversuds condition

71 Generation 2 debit card cycle polling message out of sequence

74 Generation 2 debit card remaining balance message out of sequence

75 Generation 2 debit card new card balance message out of sequence

88 Invalid messaging state found in data acquisition communications

comm_suprv ( ) routine

99 Mismatch of cycle settings between CCU and UI. Wash cycle may not

run as defined by card reader setup

PAGE 12

Page 13

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

123456

Help Mode Submenu

n

This sub-menu consists of many steps.

n

To change to the next step, press the lower middle (WARM) button.

n

To exit Help Mode and return to set-up mode or dAS mode, press the lower left (HOT) button.

Submode Display Portion Description Note

1h.XX lower

2h.XX lower

The XX value has a meaning according to the Help Code Table. This value is stored

in EEPROM, and is added to as a new error is reported. The oldest drops out of history.*

3h.XX lower Help code 3

1.X## upper Dryer CCU Error History code 1

1.X## lower Washer CCU Error History code 1

2.X## upper Dryer CCU Error History code 2

2.X## lower Washer CCU Error History code 2

3.X## upper Dryer CCU Error History code 3

3.X## lower The X is f or d and ## is the code num as defined in the Ranked Washer CCU Error History code 3

4.X## upper

Stacked Washer/Dryer Diagnostic Codes Table.**

Dryer CCU Error History code 4

4.X## lower Washer CCU Error History code 4

5.X## lower Washer UIC Error History code 1

6.X## lower Washer UIC Error History code 2

7.X## lower Washer UIC Error History code 3

8.X## lower Washer UIC Error History code 4

Sr.ON lower Suds routine selection. Default setting for the washer is to have the suds routine on; • Pressing the center right

standard time is added to the cycle and communicates to the end user via the UI display (COLORS/DELICATES) button

if suds is detected during the first two drain/spins and the final spin. If turned off, “Sr.--,” will toggle the “Sr” setting

gain the ability to reduce suds routine time with the next programming option. from “ON” to “--.”

SL.05 lower Suds routine time selection; can only change the setting if “Sr.--” is selected. Default • Pressing the center left (COTTON/

setting for the washer is “05” minutes of suds/kill foam routine during the first two WHITES) button will toggle the

drain/spins. Allowable programming range is 0–5 minutes. “SL” setting. For proper suds

handling, it is recommended to

keep the setting at “05” minutes.

rE.10 lower Maximum final spin rebalance attempts. Default setting for the washer is “10” • Pressing the center left (COTTON/

rebalance attempts before the cycle is cancelled. For out-of-balance load, allowable WHITES) button will toggle the

programming range is 4–10 attempts. “rE” setting.

SC.XX upper Where XX is the number of the dryer CCU software version

SC.XX lower Where XX is the number of the washer CCU software version

EC.XX lower Where XX is the number of the washer EEPROM CCU version

SU.XX lower Where XX is the software version of the UIC

EU.XX lower Where XX is the EEPROM version of the UIC

SPIN XXX lower Where XXX is the speed in rpm (SPIN element of display is used for this)

P XXX lower Where XXX is the relative amount of power being requested of the motor

U XXX lower Where XXX is the relative amount of unbalance in the system.

NOTE: 255 indicates that the unbalance has not been calculated; 254 indicates

that the unbalance could not be calculated. Any other value is the current unbalance

of the MCU.

* To erase the three help codes, press the lower right (COLD) button.

** The Errors displayed in this section are the history errors that have occurred

in the washer/dryer (not necessarily an error that is in progress).

Button Continuity Test

Check Between

Button Contacts

A 3 and 6

B 3 and 5

C 3 and 4

D 2 and 6

E 2 and 5

F 2 and 4

G 1 and 6

H 1 and 5

I 1 and 4

Help code 1

Help code 2

ABC

DEF

GH I

PAGE 13

Page 14

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

HELP MODE SYMBOLS AND ELEMENTS

Along with the steps of the help mode, symbols and elements are mapped, at all times, to reflect the state of various inputs and outputs.

Dryer (Upper)

Display Symbol Description

Dryer motor sensed on

OR Dryer heater relay on

& Dryer motor relay on

Dryer door sensed closed

°

Low voltage sensed

*

Washer (Lower)

Display Symbol Description

WASH Water sensed above wash level

RE Washer redistributing due

to out-of-balance condition

DOOR LOCKED Washer door sensed locked

COLD Cold water output on

HOT Hot water output on

OR Door unlock output on

AVAILABLE Washer drain pump output on

°

Washer door sensed closed

Help Mode Button Function Table

Button Name

on Interface Button Function Help Code Not Displayed Help Code Displayed

LOWER LEFT Slew Exits help mode and returns to set-up mode – Exits help mode and returns to set-up mode –

(HOT) BUTTON either dAS display or Manual Set-up Mode (2.) either dAS display or Manual Set-up Mode (2.)

LOWER RIGHT Mode Select Inactive – no result Clears all three help codes

(COLD) BUTTON

LOWER MIDDLE Mode Advance Advances to next help mode screen Advances through each help code or from last

(WARM) BUTTON to the extended fill option

Dryer Drive Motor Resistance

Generic

Result While

Result While

Dryer Temperature and Thermistor Values

Resistance Contact Points

Winding (Ω) of Measurement

Lt. blue wire in back at pin 4

MAIN 2.4–3.6 Ω and bare copper wire on pin 5

of black drive motor switch.

Lt. blue wire in back at pin 4

START 2.4–3.8 Ω and bare copper wire on pin 3

of black drive motor switch.

Dryer Exhaust Temperatures

Fabric Setting Heat Turns Off* Heat Turns On

Cotton/ 155° ± 5°F

Whites (68° ± 3°C)

Perm 155° ± 5°F

Press (68° ± 3°C)

Colors/ 140° ± 5°F

Delicates (60° ± 3°C)

*The measured overshoot using the glass bulb thermometer in the exhaust outlet

can be 30°F (17°C) higher.

heat turn off

temperature

10–15°F

(6–8°C)

Below the

Dryer Gas Valve Resistance

Terminals Resistance

1 to 2 1365 Ω ± 25

1 to 3 1560 Ω ± 25

4 to 5 1220 Ω ± 50

IMPORTANT: Make sure all harness wires are looped back

through the strain relief after checking or replacing coils.

Thermistor

resistance value

at heater shutoff

Fabric (digital or analog

Setting Temperature meter) kΩ

Cotton/ 155° ± 5°F

Whites (68° ± 3°C)

Perm 155° ± 5°F

Press (68° ± 3°C)

Colors/ 140° ± 5°F

Delicates (60° ± 3°C)

2.1 1.7

2.1 1.7

2.8 2.3

Dryer Thermistor Resistance

Thermistor Resistance

Temp. Res. Temp. Res.

°F (°C) kΩ °F (°C) kΩ

50°F (10°C) 19.9 80°F (27°C) 9.2

60°F (16°C) 15.3 90°F (32°C) 7.4

70°F (21°C) 11.9 100°F (38°C) 5.7

PAGE 14

Page 15

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

H

C

1

1

1

1

1

1

Be sure to perform the Diagnostic Tests before replacing the

system components.

Washer Pump Motor Continuity Test

Pins

1 to 2 Normal = approx. 12.3 Ω

Abnormal = Infinity

Results

Washer Motor Continuity Test

1. Unplug washer or disconnect power.

2. Disconnect the wire harness from the motor and measure the

resistance of the motor. Use the following table:

Pins

Results

1 to 2 Normal = approx. 6.45 Ω

2 to 3 Abnormal = Infinity

1 to 3

Transformer Connector

Primary 30–35 ohms

Blue to blue 1 ohm

White to white 2 ohms

Yellow to blue 0.5 ohms

Red to red 11 ohms

Water Temperature Sensor

1. Unplug washer or disconnect power.

2. Disconnect the wire harness from the water temperature sensor

and measure the resistance of the sensor. Use the following table.

An abnormal condition is an open circuit. This reading can be

taken from the cable attached to the CCU terminal SET2.

Temperature

32°F (0°C) 35.9 kΩ

86°F (30°C) 9.7 kΩ

104°F (40°C) 6.6 kΩ

122°F (50°C) 4.6 kΩ

140°F (60°C) 3.2 kΩ

158°F (71°C) 2.3 kΩ

203°F (96°C) 1 kΩ

Results

Water Valve Locations

Hot Inlet

Valve #1

Cold Inlet

Valve #2

Cold Inlet

Valve #3

Washer CCU Wire Harness Connector Table

Unplug washer/dryer or disconnect power before taking ohm

measurements.

(Ω) Ohm Abnormal Pin Wire

Terminal Component Value Value Connectors* Coding

RP2 Wax Motor 1.2 kΩ Infinity** 1, 2

at 25°C

DLS2 Door Locked Switch Continuity: 1, 2

Locked/Unlocked door locked.

No Continuity:

door unlocked.

DL3 Door Lock Coil 165 Ω Infinity**

Locked or Unlocked

1, 2 door lock

2, 3 door unlock

SET2 Temperature Varies with Infinity** 1, 2

Sensor temperature

changes.

See above.

DP2 Drain Pump 13 Ω Infinity** 1, 2

DCS3 Door Switch Continuity 1, 2

at door close.

No continuity

at door open.

VSF2 Hot Inlet Valve #1 812 Ω Infinity** 1, 3 (hot

valve #1)

VCH7 Cold Inlet Valve #3 812 Ω, Infinity** 1, 3 (cold

Cold Inlet Valve #2 either coil

IF2 RFI 30 Ω

(or more than

10% lower

or higher) valve #2)

Infinity**

(or more than

valve #3)

5, 7 (cold

1, 2

10% lower

or higher)

Infinity**

PS8 Pressure Sensor

4, 7, and 8

**The number 1 pin has been marked on the bottom part of the connector.

**An infinity measurement occurs when the multimeter does not detect an ohm reading.

Manually Unlocking the Door Lock System

1. Unplug washer or disconnect power.

2. Remove the toe kick panel.

3. Reach up along the inside of the front and locate the bottom

of the latch assembly.

4. At the bottom of the latch assembly is a tear-drop shaped tab.

5. Gently pull the tab down about 1/4" (6 mm) or until a click is heard.

PAGE 15

ELECTRONIC ASSEMBLIES –

REMOVAL OR REPLACEMENT

IMPORTANT: Electrostatic (static electricity) discharge may cause

damage to electronic control assemblies. See page 1 for details.

NOTE: Be sure to perform the Diagnostic Tests before replacing the

control board.

Page 16

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

WASHER

CENTRAL CONTROL UNIT

(CCU)

PK

PK

IF2

1

2

RFI

FILTER

(120

VOLT)

4 7 8121357 13

1

2

1

1

2

3

3

2

1

DP2

MI3

MS2

1

2

3

2

1

PUMP

MOTOR

MOTOR CONTROL UNIT (MCU)

DRUM MOTOR

(OPTIONAL)

COIN SENSOR2

CARD

READER

BACK-UP

BATTERY

COIN

SENSOR1

AVAIL2

AVAIL1

ENABLE1

ENABLE2

POWER

GROUND

ATLAS

J901

J900

AA2

(GEN 1)

USER INTERFACE CONTROL (UIC)

WA3

WB3

EE1

AA4

AA5

AA3

123 123 123412341234

123456

1

2

3

AA1

AA8

WC3

3

21

GG6

DOOR LOCK

HOT

VALVE

#1

COLD

VALVE

#2

COLD

VALVE

#3

TUB

THERMOSTAT

VCH7

VSF2

DCS3

DL3

DLS2

RP2

SET2

PS8

BU

UIC TRANSFORMER

120/22.5/-4.5/-26-/

26 VOLT

BK W

12 3

PRESSURE

TRANSDUCER

VAULT

SWITCH

SERVICE

SWITCH

BK BK

OR

Y

OR

MEMBRANE

SWITCH

GY

HEATER

RELAY 1

GND

NEUTRAL

DOOR

L1

MOTOR

NO

COM

DRYER CCU

EXHAUST TEMP

EXHAUST TEMP RTN

EXHAUST

THERMISTOR

R/WR/W

TSG

TS

BK

120

VOLTS

BK - LINE L1

R - LINE L2

240 VOLTS

120 VOLTS

W - NEUTRAL N

DOOR

SWITCH

W

LBU

WF1

D1

D

G/Y

P14-3

P14-6

P8-2

P8-3

P8-4

W

THERMAL FUSE

BELT

SWITCH

LBU

LBU

T

P9-1

P9-2

BK

THERMAL

CUT-OFF

HI-LIMIT

THERMOSTAT

HEATER

A1

R

R/W

BK

R

MAIN

START

MOTOR

TC01 TC03 HL1

HL3

NC

H1 H2

BU/W

1

2

5

3

6

R

C1

G/Y

4M

P2-1

P2-2

P2-3

VDD

DATA

VSS

TERMINAL CONSTRUCTION

SPLICE

IN LINE CONNECTION

TF1 TF2

121231212

2

WIRING DIAGRAM – ELECTRIC MODELS

PAGE 16

Page 17

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

WASHER

CENTRAL CONTROL UNIT

(CCU)

IF2

1

2

112 135713

1

2

1

1

2

3

3

2

1

DP2

MI3

MS2

PUMP

MOTOR

1

2

3

2

1

MOTOR CONTROL UNIT (MCU)

DRUM MOTOR

PK

PK

VCH7

VSF2

DCS3

DL3

DLS2

RP2

SET2

PS8

RFI

FILTER

(120

VOLT)

BK W

UIC TRANSFORMER

120/22.5/-4.5/-26-/

26 VOLT

DOOR LOCK

COLD

VALVE

#2

#3

HOT

VALVE

#1

TUB

THERMOSTAT

12 3

1

2

3

AA1

PRESSURE

TRANSDUCER

VAULT

SWITCH

SERVICE

SWITCH

BK BK

OR

Y

OR

(OPTIONAL)

COIN SENSOR2

CARD

READER

BACK-UP

BATTERY

COIN

SENSOR1

AVAIL2

AVAIL1

ENABLE1

ENABLE2

POWER

GROUND

ATLAS

J901

J900

WA3

WB3

EE1

AA4

AA5

AA3

123123 123412341234

123456

AA2

(GEN 1)

USER INTERFACE CONTROL (UIC)

AA8

WC3

3

21

GG6

BU

MEMBRANE

SWITCH

DRYER CCU

P2-1

P2-2

P2-3

VDD

DATA

VSS

HEATER

RELAY 1

GND

NEUTRAL

DOOR

L1

MOTOR

NO

COM

P8-2

P8-3

P8-4

P9-1

P9-2

BK

A1

EXHAUST TEMP

EXHAUST TEMP RTN

EXHAUST

THERMISTOR

R/WR/W

TSG

TS

P14-3

P14-6

P14-4

P14-5

OR

R

MAIN

START

MOTOR

BELT

SWITCH

R

LBU

LBU

NC

BU/W

BU/W

BU/W

1M

2M

5M

3M

6M

G/Y

4M

B3

THERMAL

CUT-OFF

HI-LIMIT

THERMOSTAT

HL1

HL3

GY

LBU

R

IGNITOR

VALVE NO. 1

VALVE NO. 2

FLAME SENSOR

W

G/Y

HOLD

ASSIST

MAIN

IGR

IG

1V

1

2

4

5

3

3V

FS1FS2

50 - 500 Ω

VALVE

MOV

BU/W

W

W

DOOR

SWITCH

F1

TERMINAL CONSTRUCTION

SPLICE

IN LINE CONNECTION

W - NEUTRAL N

120 VOLTS

BK - LINE L1

GROUND

G/Y

W

BK

A1

COLD

VALVE

D1

D

THERMAL

FUSE

TF1

TF2

TC01 TC03

HL1

478 21321212

2

WIRING DIAGRAM – GAS MODELS

PAGE 17

Page 18

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE/TEST

NOTE: Possible Cause/Tests must be performed in the sequence shown for each problem.

BLANK DISPLAY Possible Causes

– UIC not powered or no power to the washer/dryer.

– Wrong communication between CCU and UIC.

Procedure for UIC not powered

1. Check that the washer/dryer is plugged into a working outlet.

2. Unplug washer/dryer or disconnect power.

3. Check continuity from the power cord to the line filter.

4. Check continuity from the line filter to the transformer.

5. Perform Ohm meter test on the transformer (page 15).

Procedure for wrong communication

1. Unplug the washer/dryer or disconnect power.

2. Wait for 2 minutes.

3. Reconnect power.

If the display fails to turn on, replace the UIC.

TOUCH-PADS DO NOT RESPOND Possible Causes

WHEN PRESSED – Keypad ribbon disconnected, damaged, or contaminated, or installed with ribbon flap in wrong position.

– Door switch disconnected, loose, or damaged.

Procedure if matrix key board is disconnected

In this error, the keypad does not respond in any mode (normal operation, set-up, etc.).

1. Unplug washer/dryer or disconnect power.

2. Check that the keypad ribbon is connected to the UIC.

3. Clean the matrix keypad ribbon of soap or other residues.

4. Check the ribbon connector on the control board to see if there is corrosion on the contacts.

Verify the function of the keypad: perform keypad matrix test in service manual. If keypad fails to operate, replace it.

Procedure if door switch is disconnected

In this error, the keypad works normally in set-up mode, but will not start a user paid cycle.

1. Verify door switch operation by performing test for F26 error code (page 8), even if the F26 code is not displayed.

If the above procedures fail to solve the problem, replace the UIC.

WON’T DISPENSE 1. Verify that water is coming into the dispenser.

2. Verify that the washer/dryer is level.

3. Remove the insert and verify that the dispenser drawer is not clogged with detergent.

WASHER/DRYER VIBRATES 1. Verify that the washer/dryer is level.

2. Verify that the shipping system, including shipping bolts and spacers, is removed, and that the power cord

is not tangled in any components inside the rear of the washer/dryer.

3. Verify that the leveling legs are locked into place and firmly in contact with the floor.

4. Check for unbalanced load, especially when washing very small loads.

5. Verify that dampeners are all connected in place and not damaged.

6. Correct any twists in the door bellows.

7. Ensure proper drive belt placement on motor pulley.

8. Ensure that the washer/dryer is not installed on a wooden riser with a platform less than 3/4" (19 mm) thick.

DRUM WON’T ROTATE 1. Check for broken drive belt.

2. Check for drive motor failure error codes (F11, F25, F28).

• Check the electrical connection and verify the function of the cable between the MCU and drive motor.

3. Make sure that the door locks properly.

INCORRECT WATER TEMPERATURE 1. Make sure that the inlet hoses are connected properly.

2. Check the water temperature sensor for an abnormal condition (page 15). Make sure the hoses from the inlet

valves to the dispenser are connected properly.

3. Verify hot and cold water operation in Quick Overview Test in diagnostic mode.

4. Check for blocked filter screen in inlet valves.

PAGE 18

Page 19

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

NOTES

PAGE 19

Page 20

FOR SERVICE TECHNICIAN ONLY - DO NOT REMOVE OR DESTROY

NOTES

PAGE 20

02/18

Loading...

Loading...