Whirlpool CGP2961EW1 Parts Diagram

!!

!

!!

COMMERICAL LAUNDRY

THIS SERVICE POINTER APPLIES TO THE FOLLOWING BRANDS:

!!

!

!!

REFRIGERATION PRODUCTS KITCHEN PRODUCTSLAUNDRY PRODUCTS

OEM BRANDS

L8178091-L8178091-

L8178091-

L8178091-L8178091March 2003March 2003

March 2003

March 2003March 2003

RR

emove & destroyemove & destroy

R

emove & destroy

RR

emove & destroyemove & destroy

pointer pointer

pointer

pointer pointer

dated dated

dated

dated dated

L8178091L8178091

L8178091

L8178091L8178091

September 2001September 2001

September 2001

September 2001September 2001

AA

A

AA

EMS 1000 Electronic-EMS 1000 Electronic-

EMS 1000 Electronic-

EMS 1000 Electronic-EMS 1000 Electronic-

Controlled DryersControlled Dryers

Controlled Dryers

Controlled DryersControlled Dryers

Only High-Temperature Setting Operates

Models CEP2960 &CGP2961

COMPLAINT:

There is no temperature change between the HIGH,

MEDIUM & LOW settings. Only the high-temperature

setting operates.

CAUSE:

The operating termostat bias heater has shorted internally,

or to ground, causing the triac on the control board to fail.

CORRECTION:

1. Test the operating thermostat bias heater as instructed below. Replace the operating thermostat with

#3387134, if the resistance reading is less than 6000

ohms.

2. Replace the control board with #3407149 if there is

no output voltage to the bias heater with the dryer set

on LOW.

DIAGNOSIS OF TRIAC-DRIVEN CIRCUITS

All triac-driven loads must be tested for an internal short, or a short to ground, prior to replacing the control board. The

dryer bias heater circuit is triac-driven. Triacs will fail if the load resistance is less than specified. Voltage to the load must

be tested with the load in the circuit. Removing the load from the circuit will cause the voltage to drop to 8 - 24 VAC,

depending on the temperature setting.

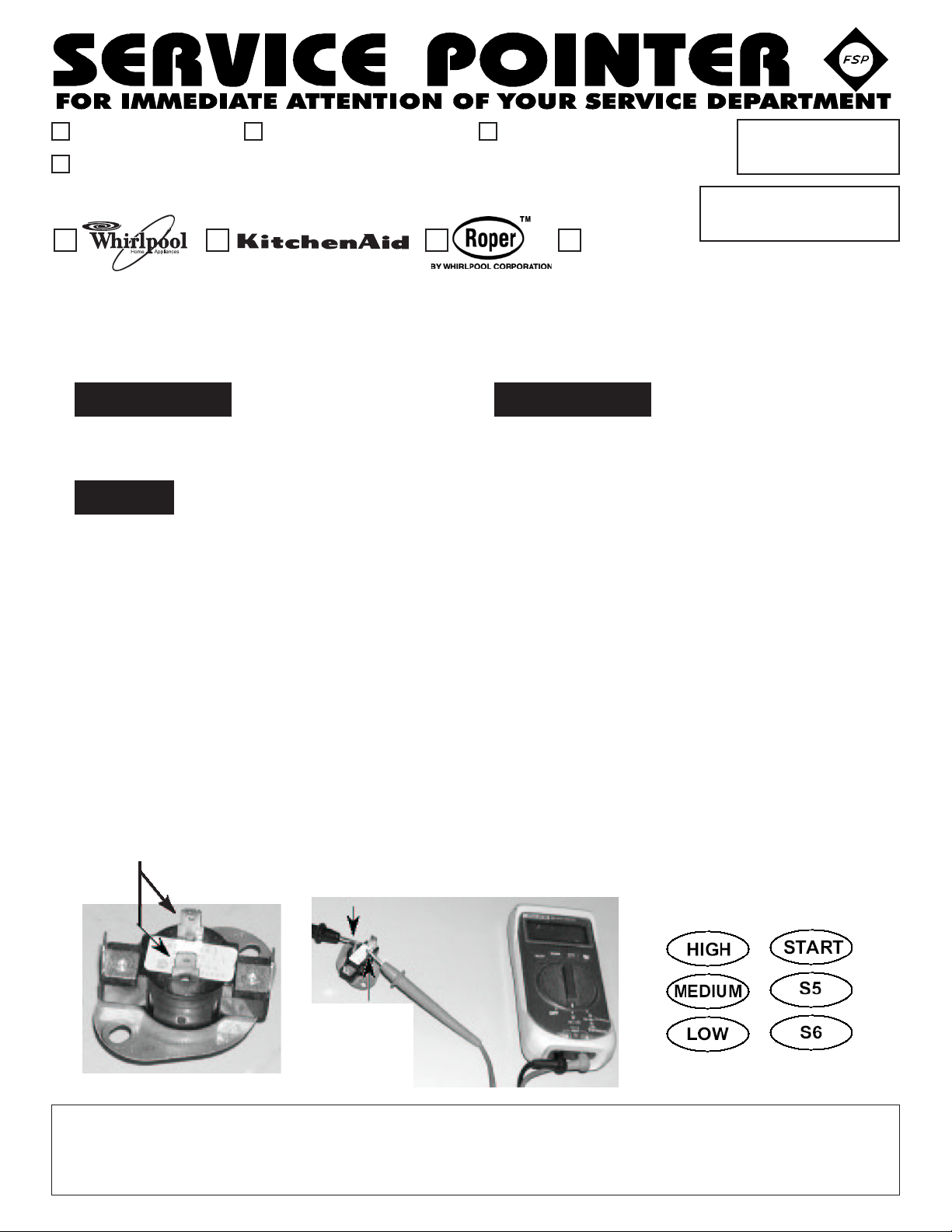

RESISTANCE TEST

1. Disconnect the power to the dryer by turning off the circuit breaker, or unplugging the unit from the electrical receptacle.

2. Remove the back cover of the dryer.

3. Remove the violet and black wires from the bias heater circuit on top of the operating thermostat.

4. Set the voltmeter to the 10K scale.

5. Read the resistance across the spade terminals.

BIAS HEATER TERMINALS

TOUCH METER

PROBES TO BIAS

HEATER TERMINALS

OPERATING THERMOSTAT

ALL SERVICE POINTERS ONLINE: http://www.whirlpoolcorp.com/servicematters/tech_ref/tech_ref_main.htm, SERVICE POINTERS

COMMERCIAL LAUNDRY ONLY: www.whirlpoolcorp.com/cltpsc, TECHNICAL INFORMATION, SERVICE POINTERS

To receive pointers by email or FAX, or to edit or delete a current email or Fax from our distribution, see

http://www.whirlpoolcorp.com/cltpsc/feedback/feedbacksubscribe_all.html, or FAX changes to 269-923-5342.

(continued)

VOLTAGE TEST

1. Set the voltmeter to read 120 VAC, and secure the meter test leads to the bias heater terminals.

2. Reconnect power to the dryer.

3. Open the access lid on the meter case and press the momentary contact switch “ON,” and then release. Press

START.

4. Press the MEDIUM button once, and check the voltage across the bias heater; it should read 40 - 80 VAC. Press the

MEDIUM button again to turn the circuit off.

5. Press the LOW button once, and check the voltage across the bias heater; it should read 120 VAC. Press the LOW

button again to turn the circuit off.

6. Replace the control board if there is no output voltage to the bias heater circuit on MEDIUM or LOW.

7. Press hidden button S6 (to the right of LOW) twice to exit the test routine.

VOLTAGE ACROSS THE BIAS HEATER CONTACTS: HIGH 0V, MEDIUM 40-80V, LOW 120V

Loading...

Loading...