Whirlpool CGM2751TQ0, CGM2751TQ1, CGM2761TQ0, CGM2761TQ1, CEM2750TQ0 Installation Guide

...

- A gaz ou

Table of Contents/Table des matibres ........................................ 2

8577208

www.whirlpool.com

TABLEOF CONTENTS

TABLEDESMATii RES

DRYER SAFETY ............................................................................ 2

iNSTALLATiON REQUIREMENTS .............................................. 4

Tools and Parts .......................................................................... 4

Location Requirements .............................................................. 4

Electrical Requirements ............................................................ 6

Gas Supply Requirements ........................................................ 7

Venting Requirements .............................................................. 8

INSTALLATION INSTRUCTIONS = GAS DRYER .................. 10

install Coin Slide and Coin Box ................................................ 10

Make Gas Connection .............................................................. 10

Connect Vent ............................................................................ 10

Complete installation .............................................................. 10

INSTALLATION INSTRUCTIONS = ELECTRIC DRYER ........ 11

InstaU Coin Slide and Coin Box ................................................ 11

Make Electrical Connection ...................................................... 11

Connect Vent ............................................................................ 15

Complete InstaUation .............................................................. 15

CHANGING TO A 30= OR 60=MINUTE TIMING CAM ........... 16

Sl_CURITl_ DE LA SI_CHEUSE .............................................. 19

EXIGENCES D'INSTALLATION ................................................ 21

OutiUage et pi_ces .................................................................... 21

Exigences d'emptacement ...................................................... 21

Specifications @ecMques ....................................................... 23

Specifications de i'aiimentation en gaz .................................. 24

Exigences concernant I'Gvacuation ......................................... 25

INSTRUCTIONS D'INSTALLATION = SI_CHEUSE A GAZ ....27

hstaUation d'une glissiere et d'une caisse _ monnaie .......... 27

Raccordement a Ia canaUsation de gaz .................................. 28

Raccordement du conduit d%vacuation ................................ 28

Achever rinstaUation ............................................................... 29

INSTRUCTIONS D'INSTALLATION = SI_CHEUSE

i_LECTRIQUE ............................................................................ 29

Installation d'une glissiere et d'une caisse a monnaie .......... 29

Raccordement electrique ........................................................ 29

Conduit d'evacuation .............................................................. 34

Achever rinstaUation ................................................................ 34

INSTALLATION D'UNE CAME DE MINUTAGE POUR

30 OU 60 MINUTES ................................................................. 34

DRYERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

it is recommended that the owner post, in a prominent location, instructions for the customer's use in the event the customer smells

gas. This information should be obtained from your gas supplier.

Post the following warning in a prominent location.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

I FOR YOUR SAFETY

WARN(NG: For your safety, the information in this manua( must be followed to m(n(mize 1

the risk of fire or e×p(os(on, or to prevent property damage, persona( injury, or death. 1

- Do not store or use gasoline or other flammab(e vapors and Hqu(ds in the vicinity of this

or any other app(iance.

- WHAT TO DO IF YOU SMELL GAS:

®Do not try to Hght any appl(ance.

®Do not touch any e)ectr(ca( switch; do not use any phone in your bui(ding.

®C(ear the room, bui(ding, or area of aH occupants.

®Immediate(y call your gas supplier from a neighbor's phone. Follow the gas suppHer's

instructions.

®ff you cannot reach your gas supp(ier, call the fire department.

- hstaHation and service must be performed by a qualified installer, service agency, or

the gas supplier.

In the State of Massachusetts, the following installation instructions apply:

m InstalIations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

m If using a ball vaIve, it shaiI be a T-handle type.

m A flexible gas connector, when used, must not exceed 3 feet.

iMPORTANT SAFETY iNSTRUCTiONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

m

Read all instructions before using the dryer.

m

Do not place items exposed to cooking oiIs in your dryer.

Items contaminated with cooking oils may contribute to

a chemicai reaction that could cause a load to catch fire.

m Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, dry-

cleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

m Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

m Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

m Do not reach into the dryer if the drum is moving.

m Do not instal! or store the dryer where it will be exposed

to the weather.

m Do not tamper with controls.

Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair instruc-

tions that you understand and have the skills to carry out.

m Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

m Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

m Clean lint screen before or after each load.

m Keep area around the exhaust opening and adjacent sur-

rounding areas free from the accumulation of lint,dust,

and dirt.

_, The interior of the dryer and exhaust vent should be

cleaned periodica!ly by qualified service personnel.

_, See installation instructions for grounding requirements.

SAVE THESE iNSTRUCTiONS

iMPORTANT: The gas instaiiation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223=1/NFPA 54 or the Canadian Naturat Gas and Propane Installation Code, CSA B149=1=

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Eiectrica( Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22,1,

iNSTALLATiONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools needed

_, 8" orlO" Pipewrench

8' or 10" adiustable wrench

_, Flat-blade screwdriver

Phillips screwdriver

_, Adiustable wrench that opens to 1" (2.5 cm) or hex-head

socket wrench

_, Level

_, 5/16"socket wrench

_, Utility knife

Vent clamps

_, Pipe-ioint compound resistant to LP gas

_, Caulk gun and caulk (for installing new exhaust vent)

_, Pliers

_, Putty knife

Parts supplied

Remove parts bag from dryer drum. Check that all parts were

included.

_, Wedge cone

Foot boot (4)

Dryer foot (4)

_, 5/16"-18x 21/2" bolt

_, 3 pin timing cam

_, 6 pin timing cam

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

mfinstalling a gas dryer:

mMPORTANT: Observe all governing codes and ordinances.

[] Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

[] Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

"Recessed Area and Closet Installation Instructions" below for

minimum spacing requirements.

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather.

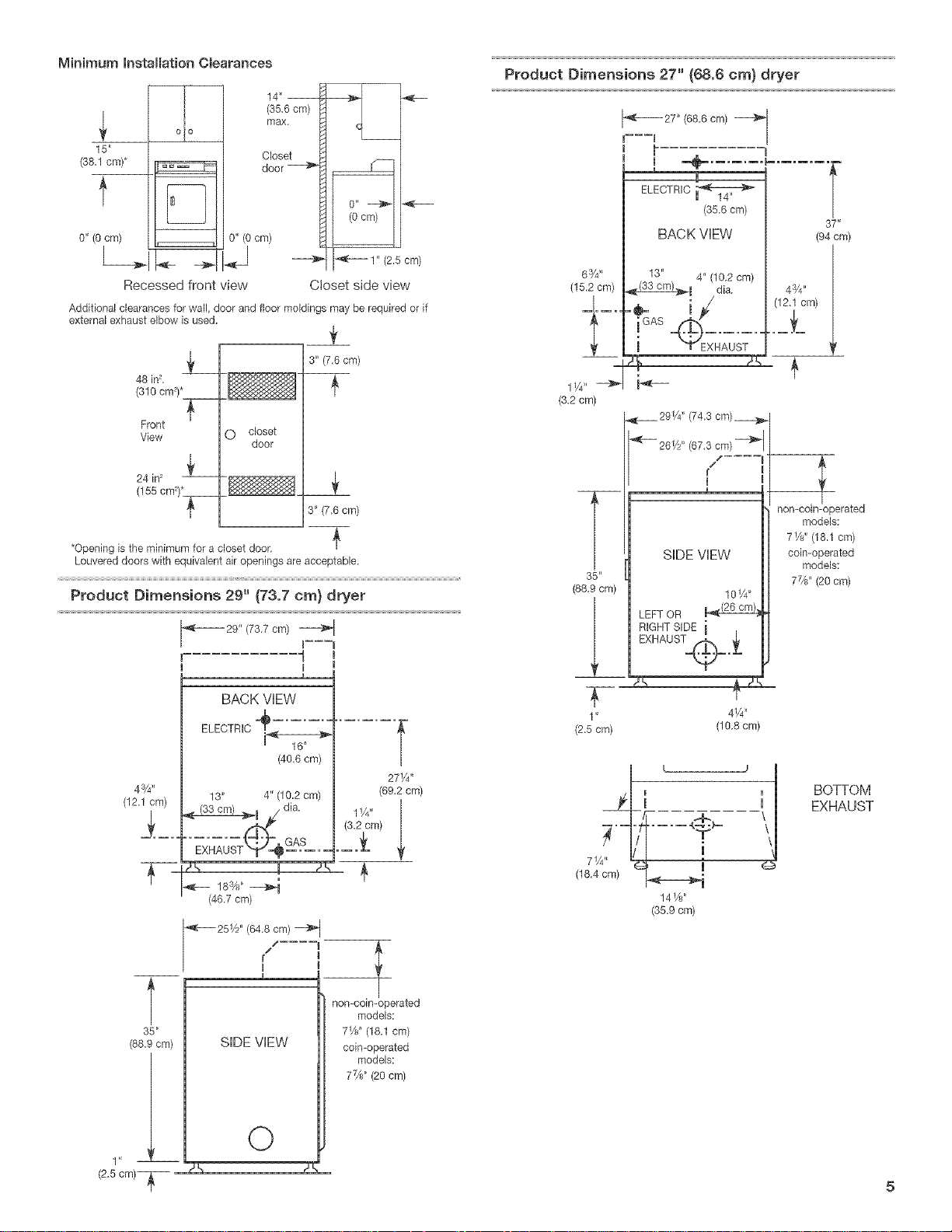

Recessed Area and Ctoset Installation Instructions

This dryer may be installed in a recessed area or cioseL For

recessed area and closet installations, minimum clearances can

be found on the serial tag on the dryer.

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease of

installation, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air opening

in the top and bottom is required. Louvered doors with equivalent

air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

MinimumlnstaB_ationClearances

14" --

(85,6 cm)

oIO

15"

(3&1 cm)*

max,

Closet

door

f

Product Dimensions 27" (68,6 cm) dryer

_4

_:-_ 27" (68.6 cm)

mmmj

O" (0 cm)

I ÷-.J

Additional clearances for wall, door and floor moldings may be required or if

external exhaust elbow is used.

*Opening is the minimum for a closet door,

Louvered doors with equivalent air openings are acceptable.

,-- 0" (0 cm)

Recessed front view

Front

View

24 in2

(155 cm_)*

O closet

5 cm)

Ctoset side view

3" (7.6 cm)

door

3" (7.6 cm)

€

Product Dimensions 29" (73.7 cm} dryer

_b-_ 29" (73.7 cm)

1

I

BACK VEW

63/4 '_

(15.2 cm) _B dis, 4:W'

-I--" i / (12.1 era)

(32 cm)

13" 4" (10,2 cm)

' _A8

._____ 29 V4"(74,3 cm)_____

26_//' (67.3 cm) ----_l

t

F

SIDE VEW

35 _

(88.9 cm)

LEFt OR

RIGHT SIDE i

10W

EXHAUST ,i

37 _

(94 cm)

non-coin-operated

models:

7 V_"(1& 1 cm)

coin-operated

models:

7%" (20 cm)

BACK VEW

ELECTRIC # .......

43/4'_

12 1 cm 13" 4" (102 cm)

' ' _m dl&

EXHAUST _-q_ .....

18 sX'#* ---a_ i

(46,7 cm)

'_---- 25_/2' (64.8 cm)

t

35"

(88.9 cm)

t _

(2.5 cm)_- -

SHDEVEW

O

m 16"

(40.6 cm)

[/

I

27 V4"

(69,2 cm)

11/4``

(3.2 cm)

non-coin-operated

models:

7W (18.1 cm)

coin-operated

models:

7%" (20 cm)

1"

(2.5 cm)

71/4'_

(18.4 cm)

41/4,,

(10,8 cm)

L

BOTTOM

i EXHAUST

\

\

14%'*

(35,9cm)

!!!!iL;i_i:i:_!i:!i_ii,i:t;i!di_:i_i:i!!_i:Fdiii_i:!_fi:i_ii!tiiii_ii:4i_...(_i!iiiil!i)iiT_i!'_!'_

Recommended Ground Method

The dryer, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSl/NEPA 70, latest edition,

or Canadian ElectricaI Code, CSA C22.1, and a!l local codes and

ordinances.

GROUNDING INSTRUCTIONS

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong,

Do not use an adapter,

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock,

IMPORTANT: The dryer must be electrically grounded in

accordance with local codes and ordinances or, in the absence of

local codes, with the National Electrical Code, ANSI/NEPA 70,

latest edition, or Canadian Electrical Code, CSA C22.1.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA Intemationa!

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

[] A 120-volt, 60-Hz, AC-only, 15- or 20-amp, fused electrical

circuit is required. A time-delay fuse or circuit breaker is also

recommended. It is recommended that a separate circuit

serving only this dryer be provided.

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of a malfunction or

breakdown, grounding wiii reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

> :

IMPORTANT: The dryer must be electrically grounded in

accordance with local codes and ordinances or, in the absence

of local codes, with the National Electrical Code, ANSI/NEPA 70,

latest edition, or Canadian Electrical Code, CSA C22.1.

The National Electric Code requires a 4-wire supply connection

for homes built after 1996, dryer circuits involved in remodeling

after 1996, and all mobile home installations.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

[] In U.S.: A four-wire or three-wire, single-phase, 120/240-volt,

60-Hz, AC-only electrical supply (or four-wire or three-wire,

120/208-volt, if specified on the modeI/serial rating plate) is

required on a separate, 30-amp circuit, fused on both sides of

the line. A time-delay fuse or circuit breaker is recommended.

[] In Canada: A four-wire only, single phase 115/230-volt, 60-Hz

electrical supply is required on a separate, 30-amp circuit,

fused on both sides of the line. A time-delay fuse or circuit

breaker is recommended.

RecommendedGroundMethod

[] InU.S.:Itisyourresponsibilitytocontactaqualifiedelectrical

installertoensurethattheelectricalinstallationisadequate

andinconformancewiththeNationalElectricaICode,

ANSI/NFPA70,latestedition,andalllocalcodesand

ordinances.

[] InCanada:Itisyourresponsibilitytoinstallthedryerin

accordancewithCanadianElectrica!Code,CSAC22.1

installationcodesandallnationalorlocalcodes.

Canadianmodelsareequippedwithafour-wire,30-amprated

flexible-typepowercord.Thepowercordmustbeplugged

intoamating30-ampreceptacle.

GROUNDING INSTRUCTIONS

_' For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of a malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer uses a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

_' For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Expmosion Hazard

Use a new CSA International approved gas suppmy mineo

_nstaH a shut-off vamve,

Securely tighten aH gas connections.

ff connected to LP, have a quaBified person make sure

gas pressure does not exceed 14" (36 cm) water

column,

Examp{es of a qualified person incmude:

micensed heating personnel,

authorized gas company personnem, and

authorized service personnel

Failure to do so can resumt in death, expmosion, or fire.

IMPORTANT: Observe all governing codes and ordinances.

This insta!lation must conform with all local codes and

ordinances. In the absence of local codes, installation must

conform with American Nationa! Standard, National Fuel Gas

Code ANSI Z223.1/NFPA 54 or CAN/CSA B149.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

The design of this dryer has been certified by CSA International

for use at altitudes up to 10,000 feet (3048 m) above sea leveI at

the B.T.U. rating indicated on the model/serial plate. Burner input

adjustments are not required when the dryer is operated up to

this elevation.

When installed above 10,000 feet (3048 m), a four percent (4%)

reduction of the burner B.T.U. rating shown on the mode!/serial

plate is required for each 1,000 foot (305 m) increase in elevation.

For assistance when converting to other gas types and/or

installing above 10,000 feet (3048 m) elevation, contact your local

service company.

Type of Gas

This dryer is equipped for use with natural gas. It is design-

certified by CSA International for LP (propane and butane) gases

with appropriate conversion. No attempt shal! be made to convert

the dryer from the gas specified on the serial/rating plate for use

with a different gas without consuIting the serving gas supplier.

Conversion must be done by a qualified service technician. Gas

conversion kit part numbers are listed on the gas valve burner

base.

GasSupplyLine

Recommendedmethod

@Provideagassupplylineof1/2"rigid(IPS)pipetothedryer

location.PipeiointcompoundsthatresisttheactionofLPgas

mustbeused.DonotuseTEFLON_ttape.WithLPgas,

pipingortubingsizecanbe1/2"minimum.Usually,LPgas

suppliersdeterminethesizeandmaterialsusedinthesystem.

Alternatemethod

@Thegassupplymayalsobeconnectedusing%"approved

copperoraluminumtubing.Ifthetotallengthofthesupply

lineismorethan20feet(6.1m),largertubingwillberequired.

Ifusingnaturalgas,donotusecoppertubing.Pipeioint

compoundsthatresisttheactionofLPgasmustbeused.

F[exiMemetalapplianceconnector:

@Itisrecommendedthatanewflexiblestainlesssteelgasline,

design-certifiedbyCSAInternational,beusedforconnecting

thedryertothegassupplyline.(Thegaspipewhichextends

throughthelowerrearofthedryerisprovidedwith%"mate

pipethread.)

@Donotkinkordamagetheflexiblestainlesssteelgasline

whenmovingthedryer.

Rigidpipeconnection:

Therigidpipeconnectionrequiresacombinationofpipefittings

toobtainanin-lineconnectiontothedryer.

[] Installed in a confined area:

Ifthe dryer is installed in a confined area such as a bathroom

or closet, provision must be made for enough air for

combustion and ventilation. Check governing codes and

ordinances or refer to the "Recessed Area and Closet

Installation Instructions" in the "Location Requirements"

section.

Gas Supply Pressure Testing

A 1/8"NPT minimum plugged tapping, accessible for gauge

testing, must be installed immediately upstream of the gas supply

connection to the dryer.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of the system at test

pressures in excess of 1/,psig.

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent,

Do not use a metal foil vent,

Failure to follow these instructions can result in death

or fire.

@Mustincludeashutoffvalve:

Thesupplylinemustbeequippedwithamanualshutoffvalve

installedwithin6ft.(1.8m)ofdryerinaccordancewith

NationalFuelGasCode,ANSiZ223.1.inCanada,an

individualmanualshutoffvalvemustbeinstalledin

accordancewiththeB149installationcodesCAN/CGA

B149.1andCAN/CGAB149.2.Thisvalveshouldbelocatedin

thesameroomasthedryer,itshouldbeinalocationthat

allowseaseofopeningandclosing.Donotblockaccessto

shutoffvalve.Thevalveisforturningonorshuttingoffgasto

thedryer.

B

A ..............

A. Gas supp!y line

B. Shutoff valve "open" position

C. To dryer

1-@TEFLON is a registered trademark of E.L Du Pont De Nemours and Company,

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

[] The dryer vent must not be connected into any gas vent,

chimney, wahl, ceiling, or a concealed space of a building.

[] Do not use an exhaust hood with a magnetic latch.

[] Do not instal[ flexible metal vent in enclosed wails, ceilings or

floors.

[] 4" (10.2 cm) heavy metal vent and cIamps must be used.

[] Use clamps to seal al[ joints. Vent must not be connected or

secured with screws or other fastening devices which extend

into the interior of the vent. Do not use duct tape.

iMPORTANT: Observe all governing codes and ordinances.

Use a heavy metal vent. Do not use plastic or metal foiI vent.

Rigid metal vent is recommended to prevent crushing and

kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible meta! vent

to avoid sagging and kinking that may result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home or business.

Exhaust hood must be at least 12" (30.5 cm) from the ground or

any object that may be in the path of the exhaust (such as

flowers, rocks or bushes).

Ifusinganexistingventsystem,cleanlintfromtheentirelength

ofthesystemandmakesureexhausthoodisnotpluggedwith

lint.ReplaceanyplasticormetalfoiIventwithrigidmetalor

flexiblemetalvent.

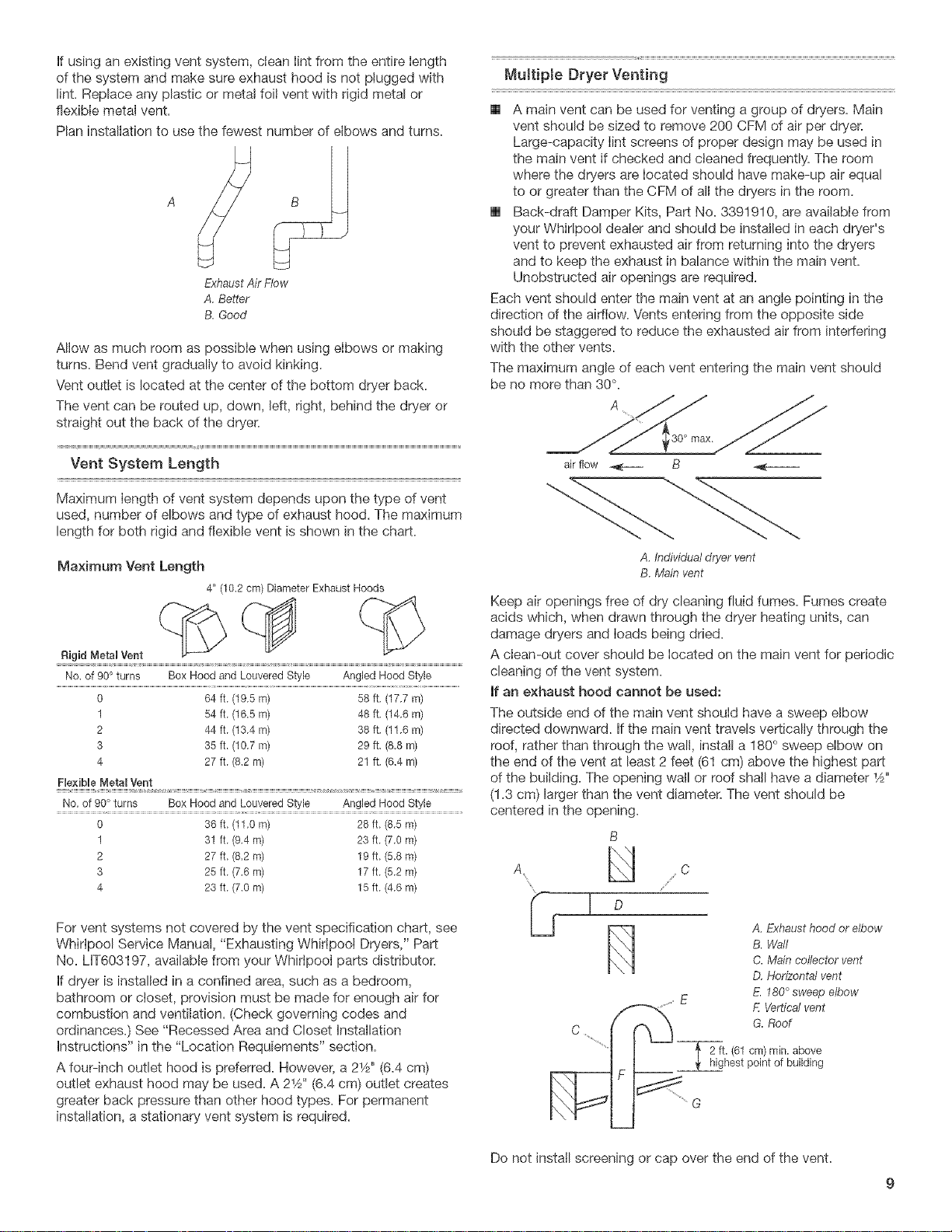

Planinstallationtousethefewestnumberofelbowsandturns.

ExhaustAir Flow

A.Better

B.Good

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

Vent outlet is located at the center of the bottom dryer back.

The vent can be routed up, down, left, right, behind the dryer or

straight out the back of the dryer.

Multipte Dryer Venting

[] A main vent can be used for venting a group of dryers. Main

vent should be sized to remove 200 CFM of air per dryer.

Large-capacity lint screens of proper design may be used in

the main vent if checked and cleaned frequently. The room

where the dryers are located should have make-up air equal

to or greater than the CFM of all the dryers in the room.

[] Back-draft Damper Kits, Part No. 3391910, are available from

your Whirlpool dealer and should be installed in each dryer's

vent to prevent exhausted air from returning into the dryers

and to keep the exhaust in balance within the main vent.

Unobstructed air openings are required.

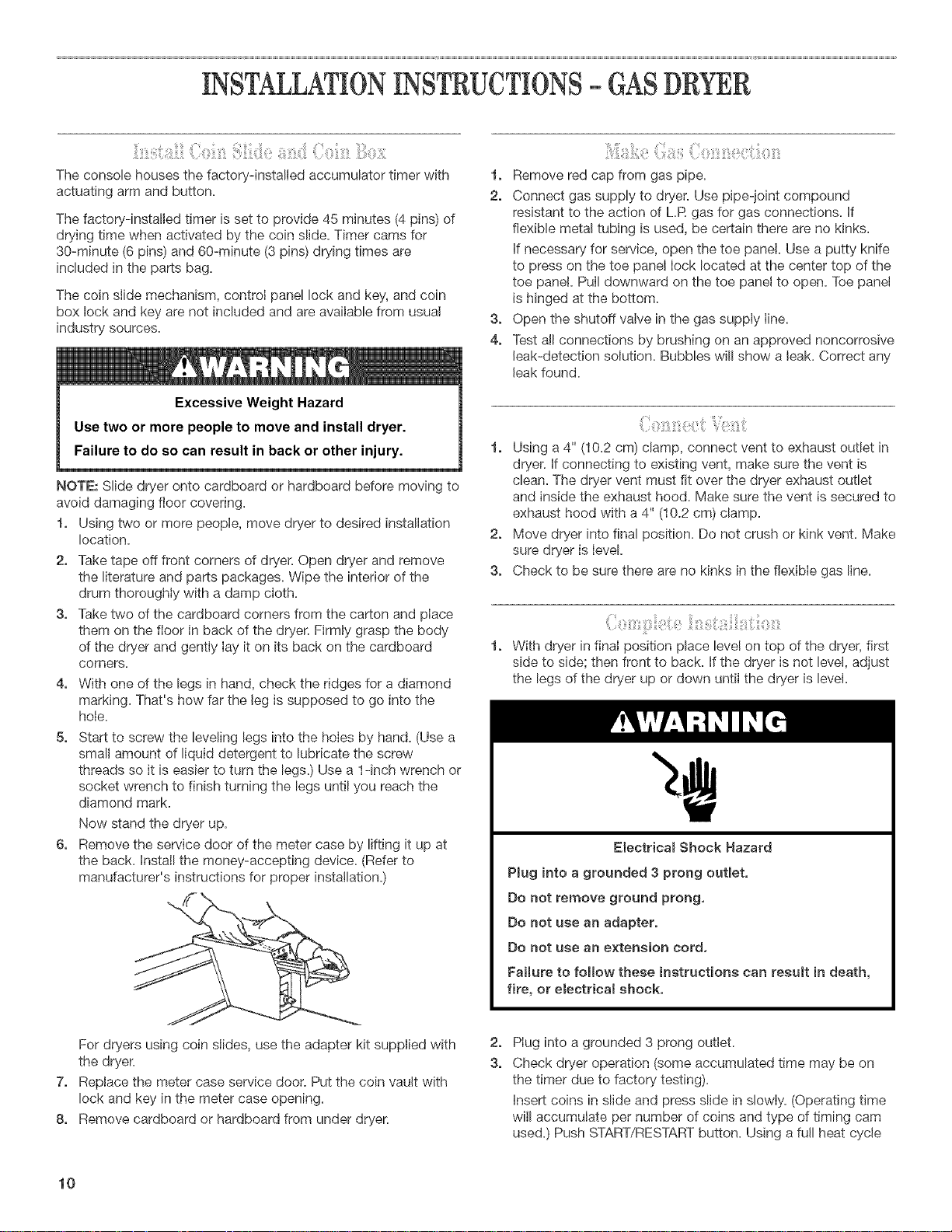

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should

be no more than 30°.

A _

Vent System Length

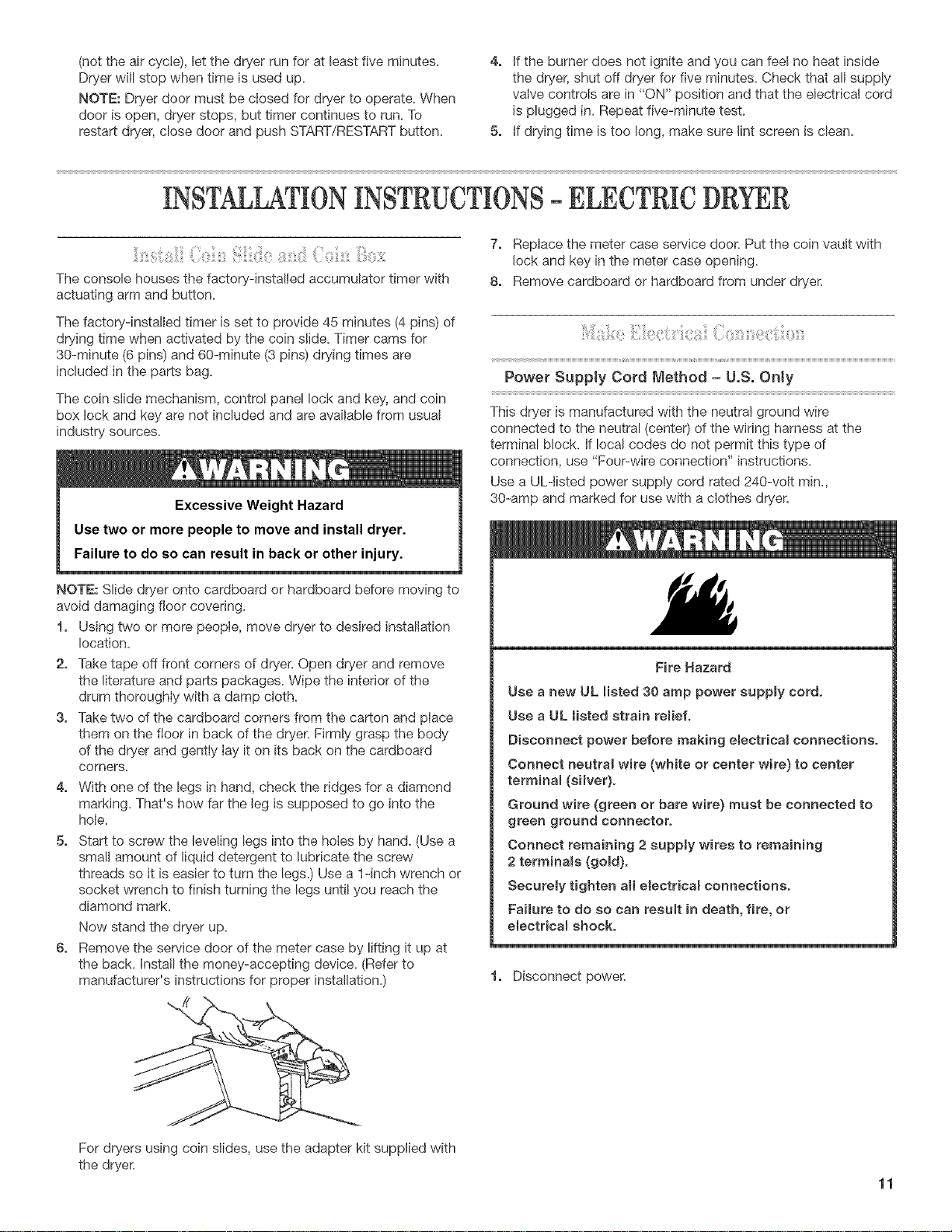

Maximum length of vent system depends upon the type of vent

used, number of elbows and type of exhaust hood. The maximum

length for both rigid and flexible vent is shown in the chart.

Maximum Vent Length

4" (10.2 crn) Diameter Exhaust Hoods

Rigid Metal Vent

No. of 90 ° turns Box Hood and Louvered Style Angled Hood Style

O

1

2

3

4

FlexibleMetalVent

No. of 90° turns Box Hood and Louvered Style Angled Hood Style

0 36 fL (11,0 rn) 28 fL (8,5 rn)

1 31 fL (9,4 rn) 23 ft, (7_0 rn)

2 27 fL (8.2 rn) 19 ft_ (5_8rn)

3 25 fL (7.6 rn) 17 ft, (52 rn)

4 23 fL (7.0 rn) 15 ft_ (4_6rn)

64 fL (19,5 rn) 58 ft. (17,7 rn)

54 fL (16.5 rn) 48 ft, (14,6 rn)

44 fL (13,4 rn) 38 ft. (11,8 rn)

35 fL (10,7 rn) 29 ft. (8,8 rn)

27 fL (8.2 rn) 21 ft, (6.4 rn)

air flow _ B _,_--

A.Individualdryervent

B. Mainvent

Keep air openings free of dr},,cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and Ioads being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

If an exhaust hood cannot be used:

The outside end of the main vent should have a sweep elbow

directed downward. If the main vent travels vertically through the

roof, rather than through the wall, install a 180 ° sweep eIbow on

the end of the vent at least 2 feet (61 cm) above the highest part

of the building. The opening wail or roof shall have a diameter _A"

(1.3 cm) larger than the vent diameter. The vent should be

centered in the opening.

B

A C

,2

For vent systems not covered by the vent specification chart, see

Whirlpool Service Manual, "Exhausting Whirlpool Dryers," Part

No. UT603197, available from your Whirlpool parts distributor.

If dryer is installed in a confined area, such as a bedroom,

bathroom or cioset, provision must be made for enough air for

combustion and ventilation. (Check governing codes and

ordinances.) See "Recessed Area and Closet Installation

Instructions" in the "Location Requiements" section.

A four-inch outlet hood is preferred. However, a 2_A"(6.4 cm)

outlet exhaust hood may be used. A 2_A'' (6.4 cm) outlet creates

greater back pressure than other hood types. For permanent

installation, a stationary vent system is required.

A.Exhausthoodorelbow

_q B.WallC.Maincollectorvent

D. Horizontalvent

E

E. 180°sweepelbow

E Verticalvent

......( rh

.........t I _ _'t. (61 Crn)rnin. above

__j__ G_hest point of building

Do not install screening or cap over the end of the vent.

INSTALLATIONINSTRUCTIONS- GASDRYER

iii_ii:i!!ii_ii:iii_iiiiiiiii,_iii_i_iiii_!i_i!!i!!iiiii_i,ii!ii_i!':¸i_i:ii:i_iifd'_il:i_i:!d!!i_il!!i,_i:iii_i_:

The console houses the factory-installed accumulator timer with 1°

actuating arm and button. 2.

The factory-installed timer is set to provide 45 minutes (4 pins) of

drying time when activated by the coin slide. Timer cams for

30-minute (6 pins) and 60-minute (3 pins) drying times are

included in the parts bag.

The coin slide mechanism, control panel lock and key, and coin

box lock and key are not included and are available from usual

industry sources.

NOTE: Slide dryer onto cardboard or hardboard before moving to

avoid damaging floor covering.

1. Using two or more people, move dryer to desired installation

location.

2. Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe the interior of the

drum thoroughly with a damp cloth.

3. Take two of the cardboard corners from the carton and place

them on the floor in back of the dryer. Firmly grasp the body

of the dryer and gently Iay it on its back on the cardboard

corners.

4. With one of the legs in hand, check the ridges for a diamond

marking. That's how far the leg is supposed to go into the

hole.

5. Start to screw the leveling legs into the holes by hand. (Use a

small amount of liquid detergent to lubricate the screw

threads so it is easier to turn the legs.) Use a 1-inch wrench or

socket wrench to finish turning the legs until you reach the

diamond mark.

Now stand the dryer up.

6. Remove the service door of the meter case by lifting it up at

the back. Install the money-accepting device. (Refer to

manufacturer's instructions for proper installation.)

i!iiif!i i!i,:_ii_'iiiiii!!iiii_(iio i_i!i_i_i_i!i__i!_cii:i_ii_!:_

Remove red cap from gas pipe.

Connect gas supply to dryer. Use pipe-joint compound

resistant to the action of LR gas for gas connections. If

flexible metal tubing is used, be certain there are no kinks.

If necessary for service, open the toe panel. Use a putty knife

to press on the toe panel Iock located at the center top of the

toe panel. PulI downward on the toe panel to open. Toe panel

is hinged at the bottom.

3_

Open the shutoff valve in the gas supply line.

4,

Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leak found.

1. Using a 4" (10.2 cm) clamp, connect vent to exhaust outlet in

dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured to

exhaust hood with a 4" (10.2 cm) clamp.

2. Move dryer into final position. Do not crush or kink vent. Make

sure dryer is level.

3. Check to be sure there are no kinks in the flexible gas line.

With dryer in final position place leve! on top of the dryer, first

side to side; then front to back. Ifthe dryer is not level, adjust

the legs of the dryer up or down until the dryer is level.

Electrica_ Shock Hazard

P_ug into a grounded 3 prong out_et,

Do not remove ground prong,

Do not use an adapter.

Do not use an extension cord,

Failure to follow these instructions can result in death,

fire, or electrical shock,

For dryers using coin slides, use the adapter kit supplied with

the dryer.

7. Replace the meter case service door. Put the coin vault with

lock and key in the meter case opening.

8. Remove cardboard or hardboard from under dryer.

10

2,

Plug into a grounded 3 prong outlet.

3.

Check dryer operation (some accumulated time may be on

the timer due to factory testing).

Insert coins in slide and press slide in slowly. (Operating time

will accumulate per number of coins and type of timing cam

used.) Push START/RESTART button. Using a full heat cycle

(not the air cycle), let the dryer run for at least five minutes.

Dryer will stop when time is used up.

NOTE: Dryer door must be closed for dryer to operate. When

door is open, dryer stops, but timer continues to run. To

restart dryer, close door and push START/RESTART button.

INSTALLATIONINSTRUCTIONS- ELECTRICDRYER

The console houses the factory-installed accumulator timer with

actuating arm and button.

The factory-installed timer is set to provide 45 minutes (4 pins) of

drying time when activated by the coin s!ide. Timer cams for

30-minute (6 pins) and 60-minute (3 pins) drying times are

included in the parts bag.

The coin slide mechanism, control panel lock and key, and coin

box lock and key are not included and are available from usual

industry sources.

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

4. Ifthe burner does not ignite and you can feel no heat inside

the dryer, shut off dryer for five minutes. Check that all supply

valve controls are in "ON" position and that the electrical cord

is plugged in. Repeat five-minute test.

5. If drying time is too long, make sure lint screen is clean.

7, Replace the meter case service door. Put the coin vault with

lock and key in the meter case opening.

8. Remove cardboard or hardboard from under dryer.

Power Supply Cord Method = U.S. Onty

This dryer is manufactured with the neutral ground wire

connected to the neutral (center) of the wiring harness at the

terminal block. If local codes do not permit this type of

connection, use "Four-wire connection" instructions.

Use a UL-tisted power supply cord rated 240-volt min.,

30-amp and marked for use with a clothes dryer.

NOTE: Slide dryer onto cardboard or hardboard before moving to

avoid damaging floor covering.

1. Using two or more people, move dryer to desired installation

location.

2. Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe the interior of the

drum thoroughly with a damp cloth.

3. Take two of the cardboard corners from the carton and place

them on the floor in back of the dryer. Firmly grasp the body

of the dryer and gently lay it on its back on the cardboard

corners.

4. With one of the legs in hand, check the ridges for a diamond

marking. That's how far the leg is supposed to go into the

hole.

5. Start to screw the leveling legs into the holes by hand. (Use a

small amount of liquid detergent to lubricate the screw

threads so it is easier to turn the legs.) Use a 1-inch wrench or

socket wrench to finish turning the legs until you reach the

diamond mark.

Now stand the dryer up.

6. Remove the service door of the meter case by lifting it up at

the back. Install the money-accepting device. (Refer to

manufacturer's instructions for proper installation.)

Fire Hazard

Use a new UL listed 30 amp power suppmy cord,

Use a UL listed strain remief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminam (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminams (gold).

Securely tighten aH electricam connections,

Failure to do so can result in death, fire, or

electricam shock.

1. Disconnect power.

For dryers using coin slides, use the adapter kit supplied with

the dryer.

11

Loading...

Loading...