IMPORTANT:

Part No, 8316558 Rev, A

Read and save

these instructions

IMPORTANT

Installer:Leave InstallationInstructions

withthe owner.

Owner: Keep InstallationInstructionsfor

futurereference.

Save InstallationInstructionsforlocal

electricalinspector'suse.

www.whirlpool.oom

COMMERCIAL

DRYER

ELECTRIC

120-volt, 60 Hz

120/240-volt, 60 Hz

COMMERCIAL

LAUNDRY

PRODUCTS

]B 'ore you start...

Your safety and the safety of others are very important.

We have provided many important

safety messages in this manual and

on your appliance. Always read and

obey all safety messages.

This is the safety alert symbol.

This symbol alerts youto

potential hazards that can kill

or hurt you and others.

All safety messages will follow the

safety alert symbol and either the word

"DANGER" or WVARNING". These

words mean:

WARNING:Foryoursafetythe

informationinthis manualmustbe

followedto minimizetheriskoffire or

explosionortopreventproperty

damage,pemonalinjuryordeath.

You can be killed or seriously

injured if you don't immediately

follow instructions.

You can be killed or seriously

injured If you don't follow

instructions.

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructions are not followed.

• Donottoncbanyelectrical

switch;donotusaanyphonein

yourbuilding.

• Cleartheroom,buildingorareaof

all occupants.

• Immediatelycallyourgassupplier

-- Donotstoreorusegasoline,

orotherflammablevaporsandliquids

inthevicinityofthis oranyother

appliance.

--WHAT TODOIFYOUSMELLGAS:

• Donottrytolight anyappliance.

froma neighbor'sphone.Follow

thegassuppliersinstructions.

• ifyoucannotreachyourgas

supplier,callthe firedepnrbnent.

-- Installationandservicemustbe

donebya qualifiedinstaller,

serviceagencyorthegassupplier.

It is your

responsibility to:

Ol_rve all governing cedes and

ordinances.

Check code r_:lulmments: Some codes

Explosion Hazard

Keep flammable materials and

vapors, such as gasoline, away

from dryer.

Place dryer at least 18 inches

(45.8 cm) above the floor for a

garage installation.

Failure to do so can result in death,

explosion, or fire.

aGnS

Postgdswarning in o prominent

locollon.

itisrecommended that the operator

post, ina prominent location,

instructionsfor the customer's use in the

event the customer smeltsgas. This

informationshould be obtained from

your local gas supplier.

limit or do not permit installation of clothes

dryers in garages, closets, mobile homes or

sleeping quarters. Contact your local

building inspector,

Comply with the installation specifications

and dimensions.

Consider spacing requirements for

companion appliances.

Make sure you have everything necessary

for proper installation,

Properly install dryer.

Contact a qualified installer to insure that

the electrical and gas installcfllons meet all

national and local codes and ordinances.

Exhaust to _Jh:kx_s: Dryer must be

exhausted outdoors to prevent exposure to

harmful substances in the gas fuels.

Note: The dryer must not be installed In an

area where it will be exposed to water

and/or weather,

IMPORTANTSAFETYINSlRUCE)NS

WARNING_ Tomclu_ '1_ dskofI_,

et_hi¢ shock, _ inlu_ to I_rsom wi_m

mir1_lyour c_llcmce, foEow bl:_¢

precautions,including the following:

1. Read all instructionsbefore usingthe

appliance.

2. DO not dry articlesthat have been

previously cleaned in,washed in,

soaked in, or spotted with gasoline,

dry-cleaning solvents, or other

flammable or explosive substances, as

they give off vapaurs that could ignite

Or exp--.

3. DO not allow childrento play on orin

the appliance. Close supervisionof

children isnecessary when the

appliance is used near children.

4. Before the appliance isremoved from

service or discarded, remove the dear

to the drying compartment,

5. Do not reach into the appliance ifthe

drum ismoving.

6. Do not installorstore this appliance

where itwill be exposed to the

weather,

7. Do not tamper with cOnITOIS,

8. Do not repair or replace any part of

the appliance or affempt any

servicing unless specifically

recommended inthe user-

maintenance instTuctionsor in

pu_ user-repair Instructions that

you understand and have the skillsto

carry out,

9. Do not use fabric softeners or products

to eliminate static unless

recommended by the manufacturer

of the fabric softener or product.

10. Do not use heat to dry articles

containing foam rubber or similarly

textured rubber-like materials,

11. Clean Ilntscreen before or after each

load.

12. Keep area around the exhaust

opening and adjacent su#ounding

areasflee from the accumulation of

lint,dust, and dirt.

13.The interiorof the appliance and

exhaust duct should be cleaned

periodically by qualified service

personnel

14.Do not place items exposed to

cooking oils inyour dryer. Items

contaminated with cooking oilsmay

contribute to a chemical reaction the

could cause a load to catch fire,

SAVETHESEINSTRUCTIONS

Post this warning in a prominent

location.

FORYOURSAFETY

DOnot storeor use gasoline or

other flammable vapors and liquids

In the vicinity of thisor any other

appliances.

Page 2

The console houses the accumulator

timer with actuating arm and button,

The timer is set to provide 45 minutes

(4 pins) of drying time when activated

by the coin slide. Timer cams for

30- minute (6 pins) and 60-minute

(3 pins) drying times are included in

the parts bag,

The coin-slide mechanism, control

panel lock and key, and coin-box leck

and key are not included and are

available from usual industry sources.

To change to a

30- or 60-minute

timingcam

(for mechanical timer

models only)

Electrical Shock Hazard

Disconnect power before

making cam changes.

Failure to do so can result in

death or electrical shock.

Each coin-operated dryer is

equipped with a 45-minute timer

cam that provides 45 minutes of

drying time when activated by the

coin slide.

You can install the 30-minute or

60-minute timing cam (shipped with

drye0 as follows:

I. Unlock meter case. Reach into

control panel area,

2. Turn the timing cam by hand until

the "V" -shaped notch lines up

below the ratchet tooth,

ralchet looth smlng cam

Une u lug

clear

ratchet hub

tooth, down

ddve

4. Place new cam (hub side down)

over clock shaft. Line up fiat side of

shaft with flat side of cam hole,

Check that drive lug is in place.

5. Turn cam until "V" -shaped notch

lines up with ratchet tooth,

6. Press cam down in place on motor

shaft, Make sure that "V _ -shaped

notch clears the ratchet tooth.

7. Close and lock the meter case,

Exhaust

requirements

Fire Hazard

Use a heavy metal vent.

0o not use a plastic vent.

Do not use a metal foil vent.

Failure to do so can result In

death or fire.

Do not use non-metal flexible vent,

metal vent that is smaller than four

inches in diameter or exhaust hoods with

magnetic latches.

The dryer must be exhausted outdoors.

Do not exhaust dryer into a gas vent,

chimney, wall, ceiling, or concealed

space of a building.

Do not install flexible vent in enclosed

walls, ceilings or floors,

If using an existing exhaust system, cleon

lint from entire length of exhaust system.

Make sure exhaust hood is not plugged

with lint.

The exhaust system should be inspected

and cleaned yearly,

Replace any plastic or metal foil exhaust

vent with rigid metal or flexible metal

vent.

Use4"110.2cm) ventclamps to

secureventsystem.

exhaust airl_w

Metalflexibleventmust be fully

extended and supportedwhen the

dryerisinitsfinalposition.DO NOT

KINKOR CRUSH THEVENT,The metal

flexibleventmustbe complelely

open to allow adequate exhaust air

to flow.

Allow as much room as possible

when using elbows or making turns.

Bend vent gradually to avoid kinking.

Remove excess flexible vent to avoid

sagging and kinking that may result in

reduced air flow,

Exhaustouflet islocatedatthe

centerofthe bottom dryerback.

The exhaustventcan be routedup,

down, left,fight,behindthe dryeror

straightoutthe back ofthedryer.

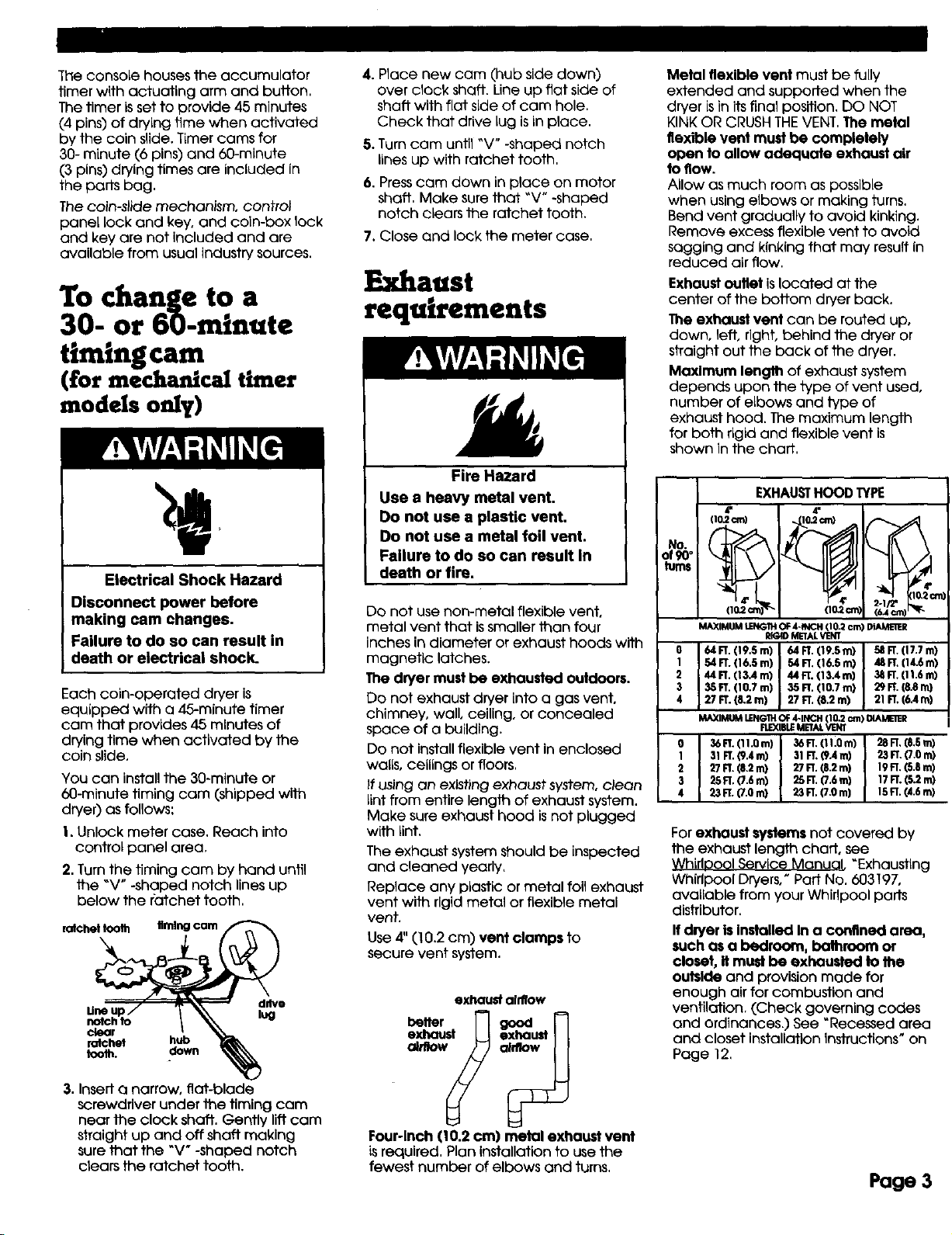

Maxlmum lengthofexhaustsystem

depends upon thetype ofventused,

number ofelbows and typeof

exhausthood.The maximum length

forboth rigidand flexibleventis

shown inthe chart,

EXHAUSTHOOD TYPE

(lO.2cm)

MAXIMUMLENGTHOF4-R4C1"1(I 0,2cm) _R

O 64 FT. (19.S m) 64 FT. (19.S m) 58 FT.(17.7 m)

1 54 FT. (16.S m) 54 FT,(|6.S m) 48 FT.(14.6 m)

2 44 FT.(r3.4 m) 44 FT. (13.4 m) 38 FT.(11.6 m)

3 35 FT. (10.7 m) 35 FT.(10.7 m) 29 FT.(8.8 m)

4 27 FT. (8.2 rn) 27 FT. (8.2 m) 21 FT.(6.4 m)

MAXIMUMLEFU_IHOf 4-INCH 110.2c:m)1_4AME11ER

31 FT.(9.4 n0 31FT, (9.4 m) 23 FT.(7.0 m)

27 FT.(8.2 m) 27 FT.(S.2 m) 19R. (S.S m)

25R, (7.6 m) _5 FT.(7.6 m) 17 FT.(5.2 m)

36 FT.(11.0 m) 36 FT.(11.Qm) 28 FT,[S,5 m)

23 FT.(7.0 m) 23 FT.(7.0 m] 15FT.(4.6 m)

RIGIDMETALVENT

FLEXIBLEMETALVENT

Forexhaust systems notcoveredby

theexhaustlengthchart,see

WhirlooolServiceManual °Exhausflng

WhirlpoolDryers/PartNo.603197,

avaliablefrom yourWhirlpoolparts

distributor,

If dryer is Installed In a confined area,

such as a bedroom, bothroom or

closet, It must be exhausted to the

outside and provision made for

enough air for combustion and

ventilation, (Check governing codes

and ordinances.) See "Recessed area

and closet installation instructions" on

Page 12,

3. Insert a narrow, fiat-blade

screwdriver under the timing cam

near the clock shaft. Gently lift cam

straight up and off shatt making

sure that the _V + -shaped notch

ctears the ratchet tooth.

Four-lnch 110.2 cm) metal exhaust vent

L_required, Plan Installation to use the

fewest number of elbows and turns.

Page 3

An exhaust hood should cap the

exhaust vent to prevent exhausted air

from returning Into the dryer. The

outlet of the hood must be at least

12 inches (30.5 cm) from the ground

or anything else that may be in the

path of the exhaust.

Four-lnch outlet hood is preferred.

However, a 2-1/2-inch (6.4 cm) outlet

exhaust hood may be used. A

2-1/2-inch (6.4 cm) outlet creates

greater back pressure than other

hood types. For permanent

installation, a stationary exhaust

system is required,

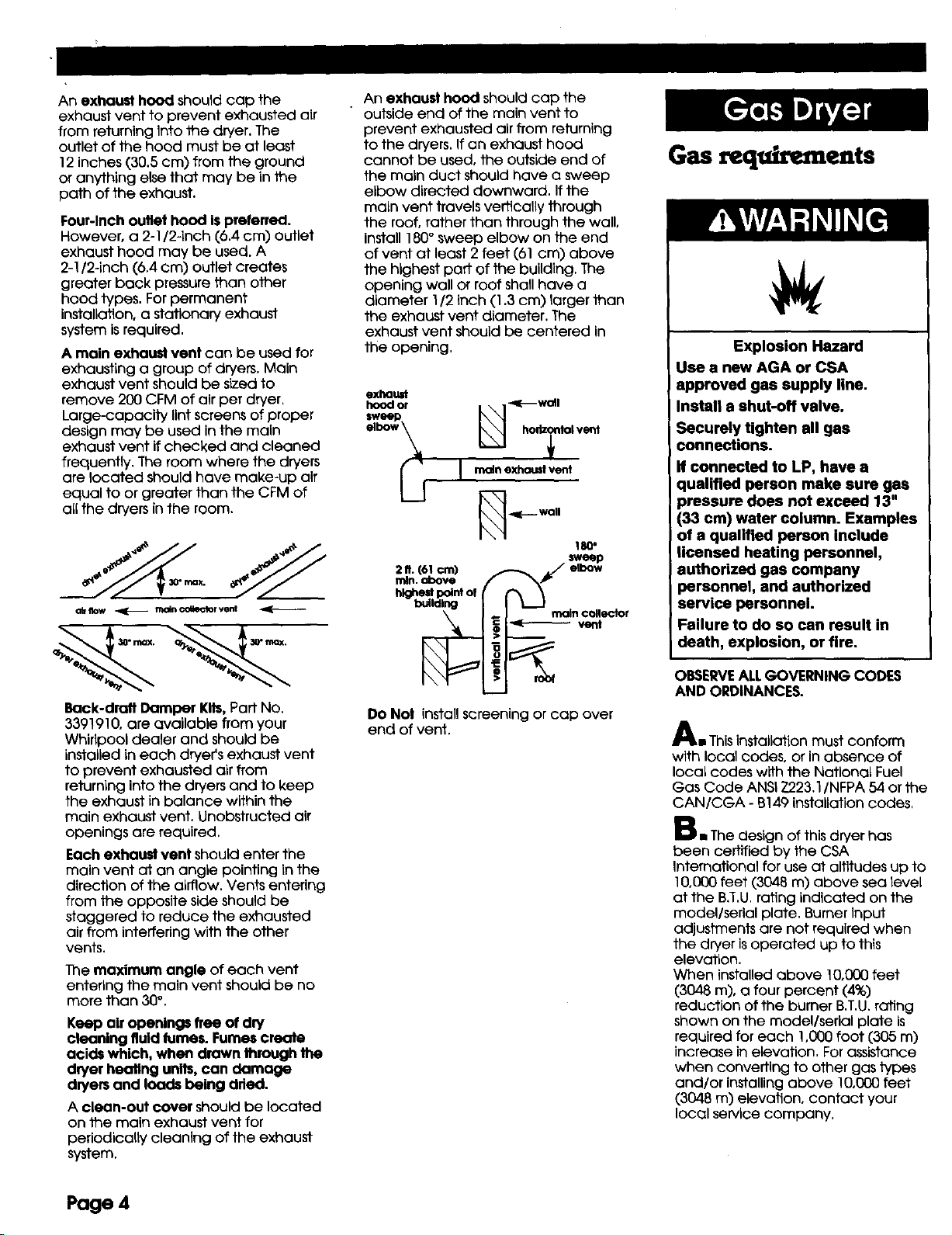

A main exhaust vent can be used for

exhausting a group of dryers. Main

exhaust vent should be sized to

remove 200 CFM of air per dryer.

Large-capacity lint screens of proper

design may be used in the main

exhaust vent if checked and cleaned

frequently. The room where the dryers

are located should have make-up air

equal to or greater than the CFM of

all the dryers in the room.

al_fl_v _ m_n_venl

" rex,

Back-droft Damper Kits,PartNo.

3391910,areavailablefromyour

Whirlpooldealerand shouldbe

installedineach dryer'sexhaustvent

topreventexhaustedairfrom

returningintothedryersand tokeep

theexhaustinbalance wifhinthe

main exhaustvent.Unobstructedair

openingsarerequired,

Each exhaust vent shouldenterthe

main vent atan angle pointinginthe

directionoftheairflow.Ventsentering

fromthe oppositesideshouldbe

staggeredtoreduce the exhausted

airfrominterferingwiththeother

vents.

The maximum angle of each vent

enteringthe main vent should be no

more than 30°.

Keep air openings free of dry

cleaning fluid fumes. Fumes create

acids which, when drawn through the

dryer heating units, can damoge

dryers and loads being tided.

A clean-out cover should be located

on the main exhaust vent for

perlodicaltycleaning of the exhaust

system.

An exhaust hood should cap the

outside end of the main vent to

prevent exhausted air from returning

to the dryers. If an exhaust hood

cannot be used, the outside end of

the main duct should have a sweep

elbow directed downward. If the

main vent travels vertically through

the roof, rather than through the wall,

install 180° sweep elbow on the end

of vent at least 2 feet (61 cm) above

the highest part of the building. The

opening wall or roof shall have a

diameter 1/2 inch (1.3 cm) larger than

the exhaust vent diameter. The

exhaust vent should be centered in

the opening,

exhaust

elbow_ hol_ntol vent

___ 1 moln exhoustvent

_ _E--wall

211.161cm) j_/ elbow

building maincollector

vent

Do Net installscreeningorcap over

end ofvent,

Gas requirements

Explosion Hazard

Use a new AGA or CSA

approved gas supply line.

Install a shut-off valve.

Securely tighten all gas

connections.

If connected to LP, have a

qualified person make sure gas

pressure does not exceed 13"

(33 era) water column. Examples

of a qualified person include

licensed heating personnel,

authorized gas company

personnel, and authorized

service personnel.

Failure to do so can result in

death, explosion, or fire.

OBSERVEALLGOVERNING CODES

AND ORDINANCES.

Ae This installation must conform

with local codes, or in absence of

local codes with the National Fuel

Gas Code ANSI Z223.1/NFPA 54 or the

CAN/CGA - B149 installation codes,

Be The design of this dryer has

been certified by the CSA

International for use at altitudes up to

10,000 feet (3048 m) above sea level

at the B.T,U. rating indicated on the

model/serial plate. Burner input

adjustments are not required when

the dryer is operated up to this

elevation.

When installed above 10,000 feet

(3048 m), a four percent (4%)

reduction of the burner B.T.U. rating

shown on the model/serial plate is

required for each 1,000 foot (305 m)

increase in elevation, For assistance

when converting to other gas types

and/or installing above 10,000 feet

(3048 m) elevation, contact your

localservicecompany,

Page 4

Ca Check that dryer is equipped

with the correct burner for the

particular type of gas used. Burner

information can be found on the

serial/rating plate In the door well of

the appliance. If this information does

not agree with the type of gas

available, see your dealer,

D mThis dryer is equipped for use

with NATURAL GAS. It is certified by

CSA International for manufactured,

mixed and L.P, (propane and

butane) gases with appropriate

conversion. No attempt shall be

made to convert the appliance from

the gas specified on the serial/rating

plate for use with a different gas

without consulting the serving gas

supplier. Conversion must be done by

a qualified service technician. Gas

conversion kit port numbers are listed

on the gas valve burner base.

E mProvide a rigid gas supply line of

1/2-inch IPSpipe to the dryer

location. If the total length of the

supply line is more than 20 feet

(6.1 m), larger pLpe will be needed.

For L.P. gas usage, 3/8-Inch,

approved copper tubing may be

used, Pipe-joint compounds suitable

for use with L.P. gas should be use

FnThe supply line shall be equipped

with a shutoff valve installed within 6

ft. (1.8 m) of dryer in accordance with

the National Fuel Gas Code, ANSI

Z223,1 -- latest edition*. In Canada,

an individual manual shutoff valve

must be installed in accordance with

the B 149 installation codes CAN/CGA

B149.1 and CAN/CGA B149.2", This

valve should be located in the same

room as the dryer and should be in a

location that aUows ease of opening

and closing. Do Not block access to

the shutoff valve.

G i If the dryer is Installed in a

confined area such as a bathroom or

closet, provision must be made for

enough air for combustion and

ventilation. (Check governing codes

and ordinances, or refer to the

section of this instruction covering

recessed and closet installations.)

H m If local codes and ordinances

permit, it is recommended that new

flexible metal tubing, design-certified

by the AGA or CSA, be used for

connecting the dryer to the gas

supply line, (The gas feed pipe which

extends through the lower rear of the

dryer isprovided with 3/8-inch metal

pipe thread,)

el Lfrigid __

pipe is used

asa I I

combination of pipe fittings must

be used to obtain an in-line

connection to the dryer.

J n Make sure that lower edges of

the cabinet, plus the back and

bottom sides of the dryer are free of

obstructions to permit adequate

clearance of air openings for

combustion air, See "Recessed area

and closet installation instructions,"

page 12, for minimum spacing

requirements,

Ki For ease of installation,

operation and servicing (If ever

needed) adequate space should be

provided around the dryer,

Li A 1/8-inch NPT plugged tapping,

accessible for gauge testing, must be

installed immediately upstream of the

gas supply connection to the dryer,

The dryer must be disconnected from

the gas supply piping system during

any pressure testing of the system at

test pressures in excess of 1/2 psig.

The dryer must be isolated from the gas

supply piping system by closing the

equipment shut-off valve during any

pressure testing of the gas supply piping

system at test pressures equal to or less

than 1/2 psi (3,45 kPa)

EJectrlcal

requirements

Electrical Shock Hazard

Plug into agrounded3-prongoutlet.

Do not remove ground prong.

Do not useanadapter.

Do not use anextensioncord.

Failuretofollowthese instructlons

can result In death,tim, or electrlcal

shock.

A 120-volt, 60-Hz, AC-only, 15-or

20-ampere fused electrical supply is

required. A time-delay fuse or circuit

breaker is recommended,

It isrecommended that a separate

circuit serving only this appliance be

provided,

Ifcodes permit and a separate ground

wire isused, itisrecommended that a

qualified electrician determine that the

ground path Is adequate.

Recommended

ground method

The dryer, when installed, must be

electrically grounded in accordance

with local codes, or in the absence of

local codes, with the National

Electrical Code, ANSI/NFPA 70**, or

the Canadian Electrical Code, CSA

C22.1".

GROUNDING INSTRUCTIONS: This

appliance must be grounded. In the

event of malfunction or breakdown,

grounding will reduce the riskof

electric shock by providing a path of

least resistance for electric current.

The power supply cord plug must be

plugged into an appropriate outlet

that isproperly installed and

grounded in accordance with all

local codes and ordinances,

WARNING - Improper connection of

the equipment-grounding conductor

can result in a risk of electric shock.

Check with a qualified electrician or

serviceman if you are in doubt as to

whether the appliance isproperly

grounded. Do not modify the plug

provided with the appliance - if it will

not fit the outlet, have a proper outlet

installed by a qualified electrician.

3-prong ground-type

outlet

3-pron_ _

grouna _:_

.°°

power /

supply cord ground

Copies of the standards listed above may

be obtaLned from:

* CSA international

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

** National Fire Protection Association

One Batteryrnarch Park

Quinoey, Massachusetts 02269

prong

Important: Observe all gaveming

codes and ordinances. Page 5

Now Start...

With dryer in laundry area.

Excessive Weight Hazard

Usetwoor morepeople to moveend

installdryer.

Failureto do se can resultin beckor

otherinjury.

3-prong,

ground-type

gas supply line

mRemove the service door of the

meter case, Lift

the service door

up at the back

and remove,

install money-

accepting

device, (Refer to

manufaturer's

instructions for proper installation.)

For dryers using coin slides, use

adapter kit supplied with dryer.

Replace the meter case service door.

Put the coin vault with lock and key

the meter case opening,

• Move dryer close to final

position. Remove cardboard or

hardboard from under dryer.

• Remove red cap from gas pipe.

Carefully move dryer into final

position. Place level on top of the

dryer, first side to side; then front to

back, If the dryer is not level, adjust

the legs of the dryer up or down until

the dryer is level.

1. TO exhaust dryer, see Exhaust

requirements, Pages 3-4. Connect

exhaust vent system to dryer exhaust

outlet and exhaust hood using 4"

(10.2 cm) clamps, Use caulking to

seal exterior wall opening around

exhaust hood.

2. Carefully move dryer into

final position. Place level on top of

the dryer, first side to side; then front

to back. If the dryer is not level, adjust

the legs of the dryer up or down until

the dryer is level.

3 • Plug power supply cord Into

grounded outlet.

4 • Check dryer operation (some

accumulated time may be on the

timer due to factory testing).

Insert coins in slide and press slide in

slowly. (Operating time win

accumulate per number of coins and

1ype of timing cam used.) Push

START/RESTARTbutton. Using a full

heat cycle (not the air cycle), let the

dryer run for at least five minutes.

Dryer will stop when time is used up.

gas shutoff valve

l a Take tape off front corners of

dryer. Open dryer and remove the

literature and parts packages. Wipe

the interior of the drum thoroughly

with a damp cloth.

mTake two of the cardboard

corners from the carton and place

them on the floor in back of the dryer.

Firmlygrasp the body of the dryer

and genfiy lay it on its back on the

cardboard corners.

wWith one of the legs in hand,

check the ridges for a diamond

marking. That's how far the leg is

supposed to go into the hole.

i Start to screw the leveling legs

into the holes by hand. (Use a small

amount of liquid detergent to

lubricate the screw threads so it is

easier to turn the legs.) Use a 1-inch

wrench or socket wrench to finish

turning the legs until you reach the

diamond mark.

Now stand the dryer up,

Slide dryer onto cardboard or

hardboard before moving across floor

to avoid damaging floorcovering,

• Connect gas supply to dryer.

Use pipe-joint compound resistant to

the action of L.P, gas for gas

connections, if flexible metal tubing is

used, be certain there are no kinks,

If necessary for service, open the toe

panel, use a putty knife to press on

the toe panel lock located at the

center top of the toe panel Pull

downward on the toe panel to open.

Toe panel Is hinged at the bottom.

9m Open the shutoff valve in the

gas supply line.

lOre Usea non-corrosive leak

detection fluid to check for leaks.

Bubbles around connections will

indicate a leak, NEVER lEST FOR GAS

LEAKSWITH A FLAME. If a leak

appears, shut off gas valve controls

and adjust connections. Then check

connections again. Close toe panel

All connections must be wrench-

tightened.

Note: Dryer door must be closed for

dryer to operate. When door is open,

dryer stops, but fimer continues to run.

To restart dryer, close door and bush

START/RESTARTbutton.

5 • fffhe burner does notignite

and you can feel no heat inside 1he

dryer, shut off dryer for five minutes.

Check that all supply valve controls

are in "ON" position and that the

elecfrical cord is plugged in. Repeat

five-minute test,

6• If drying time is too long,

make sure lint screen is clean.

Page 6

Now Start...

Electrical

requirements

ifcodes permit and o separate

ground wire isused, It Is

recommended that a qualified

electdclan determine that the ground

path isadequate.

important: Observe all governing

codes and ordinances.

A four-wlreorthree-wire(Canada:

four-wireonly),sLngle-phase,120/240-

volt,60-Hz,AC-onlyelectrlcalsupply

(orfour-wlreorthree-wLre,120/208-

volt,ifspecifiedon themodel/serial

ratingplate)isrequiredon a

separate,30-ampere circuit,fusedon

bothsidesofthe line.A time-delay

fuseorcircuitbreakeris

recommended.

Recommended

ground method

In U.S.:

It isthe persenal responsibility and

obligation of the customer to contact

a qualified electrician to assure that

the electrical Installation isadequate

and in conformance with the

National Electrical Code, ANSI/NFPA

70", and all local codes and

ordinances.

In Canada.:

it isthe personal responsibility and

obligation of the customer to

install the dryer in accordance

with CAN I-B149 installation

codes** and all national or local

codes.

Canadian models are equipped

with a four-wire, 30-amp rated

flexible-type power cord. The

power cord must be plugged into

a mating 30-amp receptacle.

(NEMA type 14-30R).

Copies of the standards listed above may

be obtained from:

* National Fire Protection Association

One Balterymarch Park

Quincy, Massachusetts 02269

**CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

Excessive Weight Hazard

Usetwo or more peopleto moveand

install dryer,

Failureto do socanresult inback or

other injury.

With dryer in laundry area...

exhausr_'_

vent

l mTake tape off front corners of

dryer. Open dryer and remove the

literature and parts packages. Wipe

the interior of the drum thoroughly

with a damp cloth.

mTake two of the cardboard

corners from the carton and place

them on the floor in back of the dryer.

Firmly grasp the body of the dryer

and gently lay ff on its back on the

cardboard corners,

3_ With one of the legs in hand,

check the ridges for a diamond

marking. That's how far the leg is

supposed to go into the hole.

4m Start to screw the leveling legs

into the holes by hand, (Use a small

amount of liquid detergent to

lubricate the screw threads so it is

easier to turn the legs.) Usea 1-inch

wrench or socket wrench to finish

turning the legs unfil you reach the

diamond mark.

Now standthe dryerup.

Slide dryer onto cardboard or

hardboard before moving across floor

to avoid damaglng floor covedng.

box

5m Remove the service door of the

meter case, Uft

the service door

up at the back

and remove.

Install money-

accepting

device. (Refer to

manufaturer's

Instructions for proper Installation,)

For dryers using coin slides, use

adapter kit supplied with dryer.

Replace the meter case service door.

Putthe coin vault with lock and key

the meter case opening.

6m Move dryer close to final

position. Remove cardboard or

hardboard from under dryer.

Page 7

7 = U.S. installations:

Make electrical connection.

Thisdryer ismanufactured with the

cabinet-ground conductor

connected to the NEUTRAL(center) of

the wiring harness at the terminal

block. If local codes do NOTpermit

this type of connection, use "Four-

wire connection" Instructions.

For a grounded, cord-connected

appliance

GROUNDING INSTRUCTIONS:

Thisappliance must be grounded. In

the event of malfunction or

breakdown, grounding will reduce

the riskof electric shock by providing

a path of least resistance for electric

current,

If using a power suppiy cord, the plug

must be plugged into an appropriate

outlet that is properly installed and

grounded in accordance with all

local codes and ordinances.

WARNING - Improper connection of

the equipment-grounding conductor

can result in a risk of electric shock.

Check with a qualified electrician or

serviceman if you are in doubt as to

whether the appliance is properly

grounded. Do not modify the plug

provided with the appliance - if it will

not fit the outlet, have a proper outlet

installed by a qualified electrician,

Fora permanently connected

appliance --

GROUNDING INSTRUCTIONS:

This appliance must be connected to

a grounded metal permanent wiring

system; or an equipment-grounding

conductor must be run with the

circuit conductors and connected to

the equipment-grounding terminal or

lead on the appliance.

Canadian installations:

Fora grounded, cord-connected

appliance --

GROUNDING INSTRUCTIONS:

This appliance must be grounded. Ln

the event of malfunction or

breakdown, grounding will reduce

the risk of electric shock by providing

a path of least resistance for electric

current.

This appliance isequipped with a

cord having an equipment-grounding

conductor and a grounding plug. The

plug must be plugged Into an

appropriate outlet that Is properly

installed and grounded in

accordance with all local codes and

ordinances.

Page 8

WARNING - Improper connection of

the equipment-grounding conductor

can result in a riskof electric shock.

Check with a qualified electrician or

service representative or personnel if

you are in doubt as to whether the

appliance isproperly grounded. Do

not modify the plug provided with the

appliance - if ff will not fit the outlet,

have a proper outlet installed by a

qualified electrician.

Power supply cord

(o.s.o r)

Usea new UL-oppreved power supply

cord rated 240-volt mln., 30 amperes

and marked for use with a clothes

dryer.

-Fire Hazard

Use a new UL approved 30

ampere power supply cord.

Use a UL approved strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or

center wire) to center terminal

(silver).

Ground wire (green or bare wire)

must be connected to green

ground connector.

Connect remaining 2 supply

wires to remaining 2 terminals

(gold).

Securely tighten all electrical

connections.

i Failure to do so can result in

I death, fire, or electrical shock.

l)tmct wire (o.s.

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL approved strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or

center wire) to center terminal

(silver).

Ground wlre (green or bare wire)

must be connected to green

ground connector.

Connect remaining 2 supply

wires to remaining 2 terminals

(gold).

Securely tighten all electrical

connections.

Failure to do so can result Jn

death, fire, or electrical shock.

I. Disconnect the power supply.

external ground

_ductor scmw

tab _ .... _'_ bald-

Y "n°' I/®*"

_ scrow

2. Remove hold-down screw

and terminal block cover,

strain _-d_/er

relief .F*'_ \cabinet

clamp _:_ _N-

3. Assemble relief

3/4"U,L.-listed screws

strain relief (U.L marking on strain relief]

into the hole below terminal block

opening. Tighten strain relief screws just

enough to hold the two clamp

sections together. Install power supply

cord/cable through the strain relief.

Complete installationfollowing

instructions for your type of

connection:

• Four-wire (recommended method)

• Three-wire (iffour-wire is not

available)

Four-wire connection...

Four-wire power supply cord must have

four, No.-10 copper wires and match a

four-wire receptacle of NEMA Type

14-30R. The fourth wire (ground

conductor) must be identified with a

green cover and the neutral

conductor by a white cover,

Four-wire receptacle (required for mobile home.,

4. Remove center terminal block

screw.

5. Remove appliance ground wire --

(green with yellow stripes) from

external ground connector screw.

Fasten under center, silver-colored

terminal block screw.

6. Connect ground wire (green) of

power supply cord to external

ground conductor screw. Tighten

screw.

7. Connect neutral wire (white or

center) of power supply cord under /'"1

center screw of the terminal block.

Tighten screw.

8. Connect the other wLresto outer _

terminal block screws. Tighten screws. _-_

9. Tighten strain relief screws. J/

10. Insert tab of terminal block cover

into slot of the dryer rear panel. Secure

cover with hold-down screw.

Strip 5" (12.7 cm) of outer

covering from end of t

cable. Leave Dare ground

wire at 5 inches (12.7 cm).

Cut 1-1/2" (3.8 cm] from

8 remaining wires. 8triD

insulation back " inch

(2.5 cm),

ShaDe

ends

of

wires

into c

nook

4,Remove center terminal block screw.

5. Remove appliance ground wire

(green with yellow stripes) from

external ground connector screw, t-"__

Fasten under center, silver-coLored

terminal block screw.

6. Connect the ground wire (bare)

of the power supply cable to the

external ground conductor screw,

Tighten screw,

7. Place the hooked end of the

neutral wire (white or center) of

power supply cable under the center

screw of terminal block (hook facing

right). Squeeze hook end together.

Tighten screw.

8. Place the hooked ends of the

other power supply cable wires

under the outer terminal block screws

(hook facing right), Squeeze hooked

ends together. Tighten screws,

9. Tighten strain reliefscrews.

I O. Insert tab of terminal block cover

into slot of dryer rear panel. Secure

cover with hold-down screw,

Page 9

Three-wire connection...

Three-wire power supply cord must have

three, No.-10 copper wires and match a

three-wire receptacle of NEMA Type

] 0-30R,

Three-wire receptacle

Where local codes permit

connecting cabinet-ground conductor to neutral wire:

4. Loosen or remove center

terminal block screw.

5. Connect the neutral wire (white,

or center) of power supply cord to

the center, sUver-colored terminal

screw of the terminal block.

Tighten screw,

6. Connect the other wires to

outer terminal block screws,

Tighten screws.

7, Tighten strain relief screws, _ _"_

8. Insert tab of terminal block _ \\ \\ _r

cover into slot of dryer rear panel - _,_\ -

Secure cover with hold-down_

screw.

Shape

Where local codes permit

connecting cabinet-ground conductor to neutral wire:

4, Loosen or remove center

terminal block screw,

5. Place the hooked end of the

neutral wire (white or center) of

power supply cable under the center

screw of the terminal block (hook

facing right), Squeeze hooked end

together, Tighten screw.

6. Place the hooked ends of the

other power supply cable wires

under the outer terminal block

screws (hook facing right). Squeeze

hooked ends together. Tighten f---%

screws,

7. Tighten strain relief screws..__'-'* _

18niolnS_trtt_br_ef _reram:npaalnb'e_.CskecC[°Veer _.

cover with hold-down screw.

| I

Page I0

Three-wire connection...

Three-wire power supply cord must

have three, No.-lO copper wires and

match a three-wire receptacle of NEMA

Type 10-30R.

Direct wire power supply cable must be

prepared as shown in "Preparing the

wire* of the three-wire connection

direct-wire steps above,

Three-wire receptacle

Where local codes Do Notpermit

connecting cabinet-ground conductor to neutral wire:

9. After reattaching the terminal

cover, connect a separate copper

4. Remove center terminal block

screw,

•_. Remove the appliance harness

ground wire (green with yellow

stripes) from the external ground

connector screw, Connect

appliance harness ground wire and

the neutral wire (white or center) of

the power supply cord/cable under

the center, silver-colored terminal

block screw. Tighten screw,

6. Connect the other wires to out_

terminal block screws, Tighten

screws.

ground wire from the external

ground connector screw to an

adequate ground•

¢o-'h

n To exhaust dryer, see Exhaust

requirements, Pages 3-4, Connect

exhaust vent to dryer exhaust outlet

and exhaust hood using 4" (10.2 cm)

clamps. Use caulking to seal exterior

wall opening around exhaust hood,

1 Carefully move dryer into final

position, Place level on top of the

dryer, first side to side; then front to

back. If the dryer isnot level, adjust

the legs of the dryer up or down until

the dryer is level•

1 On in U,S. or Canada, plug

power supply cord Into grounded

outlet. Or, in the U.S. only, connect

direct wire to power supply.

Turn power supply on,

7. Tighten strain relief screws. _ _

8. Insed tab of terminal block cover

into slot of dryer rear panel. Secure

cover with hold-down screw,

1 • Check dryer operation (some

accumulated time may be on the

timer due to factory testing).

Insert coins in slide and press slide in

slowly, (Operating time will

accumulate per number of coins and

Jype of timing cam used,) Push

START/RESTARTbutton, Using a full

heat cycle (not the air cycle), let the

dryer run for at least five minutes.

Dryer will stop when time isused up,

Note: Dryer door must be closed for

dryer to operate, When door Is open,

dryer stops, but timer continues to run,

To restart dryer, close door and push

START/RESTARTbutton.

o

2 • if drying time istoo long,

make sure lint screen isclean.

13. Now start the dryer and allow

it to complete a full heat cycle (not

air cycle) to make sure it is working

properly.

Page 11

Recessed area and

closet installation

instructions

This dryer may be installed in a

recessed area or closet. For recessed

area and closet installations,

minimum clearances can be found

on the serial tag on the dryer.

The installation spacing is in inches

and is minimum allowable, Addllional

spacing should be considered for

ease of installation, servicing and

compliance with local codes and

ordinances.

If closet door is installed, the minimum

unobstructed air openings in top and

bottom Is required, Louvered doors

with equivalent air openings are

acceptable,

Companion appliance spacing

should be considered,

The dryer must be exhausted

outdoors.

No otherfuei-buming appliance may

be Installed in the same closet,

Minimum Installation Clearances

(3&6 ore) :

I_lax.

ClOset

doer ---_

O"(ocm)*

[0 ¢m)"

_-- I. [2,,_cm )

15"

(38.1 cm)'*

0" (0 cm]"

ol °

Recessed Closet

front view side view

Maintenance

instructions

• Clean lint screen offer each cycle.

• Keep dryer area clear and free from

combustible materials, gasoline and

other flammable vapors and liquids.

• Do not obstruct the flow of

combustion and ventilation air.

Moving the dryer

to a new location...

Slidedryer onto cardboard or

hardboard before moving across floor

to avoid damaging floor covering.

Gas dryer models:

• Disconnect electrical cord. Tape

securely to dryer.

• Shut off the gas supply valves in the

gas supply line.

• Disconnect gas pipe and fittings

from dryer and cap gas supply line.

Tape end of dryer gas pipe.

Elechic dryer models:

• Shut of electrical supply to dryer.

• Disconnect the power supply cord

or cable from the dryer terminal

block.

All models:

• Make sure leveling Legsare secure

in dryer base.

• Tape drum to front panel.

• Tape dryer door, lint screen and

end of gas pipe.

Before the appliance isremoved from

service or discorded, remove the

door to the dryer compartment.

If dryer does not

operate properly...

Check the following to be surethat:

I.Electric supply isconnected.

2. Circuff breakers are not tripped or

house fusesblown,

3. Door isclosed.

4, Controls are set in a running or

"ON" position,

5. Start button has been pushed

firmly.

6. For gas dryers, check that gas

supply shutoff valves are set in

open position.

If you need

assistance...

The Whirlpool Consumer Interaction

Center will answer any questions

about operating or maintaining your

dryer not covered in the Installation

Instructions. The Whirlpool Consumer

Interaction Center is open 24 hours

a day, 7 days a week. Just dial

1-800 NO BELTS(1-800-662-3587) --

the call is free.

When you call, you wi, need the dryer

model number and serial number.

Both numbers can be found on the

seflal-rating plate located on your

appliance,

3_ (7.6 cn_

0

I

Closet

front view

• Additional clearances fat wan, doo_ and floor

em_xh_elbo_w_beu_l u'r_l °r If exfoma'

** Openi .n_isminimum for clo6et door. Louvemd

door wli_ equivalent air opening is

acceptable.

Page 12

Product dimensions

__-_--t 29" (73.7 cm)-_

I"........... 7

I

i

ELECTRIC_ .......

4-3/4" 13" 4_(I 0.2 cm) (69.2 cm)

(12,1 cm) dla. 1-I/4" ]

29" (73.7 cm) dryer

(40,6 cm)

27-114"

3S"

(88.9 cm)

<--25- I12" (64.8 cm) -_

/ ....

/

f

I

I

non-coin-operated

models:

7-I/8" (18.1 cm)

coin-operated

models:

7-7/8" (20 cm)

I-I/4"--),-

(3.2 cm)

EXHA_',--W-4,--_.A--$........t

18-3/8" _,

146.7cm)

BACK VIEW

27" (68.6 cm) dryer

"q_-_-27" (68.6 cm)---_"

_mB I

(35.6 cm) |

13 I'

_33 cm_ 4" (10.2 cm)

__ i/ (,2.1cm>

_.-._; .... __

dlo. 4-314"

BACK VIEW

37"

(94 cm)

35"

(88.9 cm)

-r--

1"

12.5 era)

'r

I"

(2.5 cm)

-<--25-112" (64.8 cm) --_

4),/" m_b_

10-114"

LEFTOR

RIGHTSIDE ! .

ExHA0sT_

JN A _L,"

T

4-1/4"

(10.8 cm)

SIDEVIEW

SIDE VIEW

non-coin-

operated models:

7-118" (18.1 cm)

coin-operated

models:

7-7/8" (20 cm)

7-114"

(I 8,4 cm)

(35.9cm)

BOTTOM EXHAUST

PartNo.8316.558Rev.A

© 2000Whlripaol Corporation

Preparedby WhlrlpoolCorporation,Benton Harbor,Michigan49022

PrintedinU,S,A.

Loading...

Loading...