Page 1

INSTALLATIONINSTRUCTIONS

COMMERCIALDRYER- Gas or Electric

INSTRUCTIONSPOUR NSTALLATION D'UNE

SECHEUSECOMMERCIALE- A gaz ou (_lectrique

Table of Contents/Table des mati_res ........................................ 2

W10184582A

SP - W10184583A

www.whirlpoolcommerciallaundry.com

Page 2

TABLEOF CONTENTS

TABLEDESMATIERES

DRYER SAFETY ............................................................................ 2

INSTALLATION REQUIREMENTS .............................................. 5

Tools and Parts .......................................................................... 5

Location Requirements .............................................................. 5

Electrical Requirements - Gas Dryer ........................................ 7

Electrical Requirements - Electric Dryer (U.S.A. Only) ............ 8

Electrical Requirements - Electric Dryer (Canada Only) .......... 9

Gas Supply Requirements .................................................... 10

Venting Requirements ............................................................ 11

INSTALLATION INSTRUCTIONS - COIN SLIDE

AND COIN BOX ...................................................................... 12

INSTALLATION INSTRUCTIONS - GAS DRYER .................. 13

Make Gas Connection .............................................................. 13

Connect Vent ............................................................................ 13

Complete Installation .............................................................. 13

INSTALLATION INSTRUCTIONS- ELECTRIC DRYER ........ 14

Make Electrical Connection ...................................................... 14

Connect Vent ............................................................................ 18

Complete Installation .............................................................. 18

CHANGING TO A 30- OR 60-MINUTE TIMING CAM .......... 19

REVERSING THE DOOR SWING .......................................... 19

MAINTENANCE INSTRUCT{ONS .......................................... 20

WARRANTY .............................................................................. 21

SECURITI_ DE LA SECHEUSE .............................................. 22

EXIGENCES D'INSTALLATION ................................................ 25

Outillage et pi_ces .................................................................... 25

Exigences d'emplacement ...................................................... 26

Specifications electriques - s6cheuse _ gaz ........................... 27

Specifications electriques - Pour le Canada seutement .........28

Specifications de I'alimentation en gaz .................................. 29

Exigences concernant I'evacuation .......................................... 30

INSTALLATION D'UNE GLISS_I_RE

ET D'UNE CAISSE ._ MONNAIE .............................................. 32

INSTRUCTIONS D'INSTALLATION - SI_CHEUSE A GAZ ....32

Raccordement h la canalisation de gaz .................................. 32

Raccordement du conduit d'evacuation ................................ 32

Achever I'instaltation ................................................................ 33

INSTRUCTIONS D'INSTALLATION - SECHEUSE

I_LECTRIQUE ............................................................................ 33

Raccordement du conduit d'evacuation ................................ 33

Achever l'instatlation ................................................................ 34

INSTALLATION D'UNE CAME DE MINUTAGE DE 30 OU 60

MINUTES ...................................................................................... 34

INVERSION DU SENS D'OUVERTURE DE LA PORTE ............35

INSTRUCTIONS D'ENTRETIEN .................................................. 35

GARANTIE .................................................................................... 36

DRYERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Page 3

WARNING - ".iskofFire"

- Clothes dryer installation must be performed by a qualified installer.

- Install the clothes dryer according to the manufacturer's instructions and local codes.

- Do not install a clothes dryer with flexible plastic venting materials, if flexible metal

(foil type) duct is installed, it must be of a specific type identified by the appliance

manufacturer as suitable for use with clothes dryers. Flexible venting materials are

known to collapse, be easily crushed, and trap lint. These conditions will obstruct

clothes dryer airflow and increase the risk of fire.

- To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO iF YOU SMELL GAS:

®Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

= Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

= if you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1.

3

Page 4

In the State of Massachusetts, the following installation instructions apply:

[] Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] If using a ball valve, it shall be a T-handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

IMPORTANT SAFETY INSTRUCTIONS

WARNING." To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

[] Read all instructions before using the dryer.

[] Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

[] Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, dry-

cleaning solvents, or other flammable or explosive

substances as they give off vapors that could ignite or

explode.

[] Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

[] Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

[] Do not reach into the dryer if the drum is moving.

[] Do not install or store the dryer where it will be exposed

to the weather.

[] Do not tamper with controls.

[] Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

[] Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

[] Clean lint screen before or after each load.

[] Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

[] The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

[] See installation instructions for grounding requirements.

SAVE THESE INSTRUCTIONS

[] It is recommended that the owner post, in a prominent location, instructions for the customer's use in the event the customer smells

gas. This information should be obtained from your gas supplier.

[] Post the following warning in a prominent location.

I FOR YOUR SAFETYDo not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. I

Page 5

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools needed

m 8" (20 cm) or 10" (25 cm) Pipe wrench

m 8" (20 cm) or 10" (25 cm) adjustable wrench

m Flat-blade screwdriver

m Phillips screwdriver

m Adjustable wrench that opens to 1" (25 mm) or 1" (25 mm)

hex-head socket wrench

m Level

m 5_6"socket wrench

m Utility knife

m Vent clamps

m Pipe-joint compound resistant to LP gas

m Caulk gun and caulk (for installing new exhaust vent)

m Pliers

m Putty knife

Parts supplied

Remove parts bag from dryer drum. Check that att parts were

included.

m Wedge Cone

m Foot boot (4)

m Dryer foot (4)

m 5_6-18 x 21/2`' bolt

m 3 pin timing cam

m 6 pin timing cam

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

if installing a gas dryer:

iMPORTANT: Observe all governing codes and ordinances.

[] Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

[] Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

"Recessed Area and Closet Installation Instructions" below

for minimum spacing requirements.

NOTE: The dryer must not be installed in an area where it will

be exposed to water and/or weather.

This dryer may be installed in a recessed area or closet.

For recessed area and closet installations, minimum clearances

can be found on the warning label on the rear of the dryer.

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes

and ordinances.

If closet door is installed, the minimum unobstructed air opening

in the top and bottom is required. Louvered doors with equivalent

air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

5

Page 6

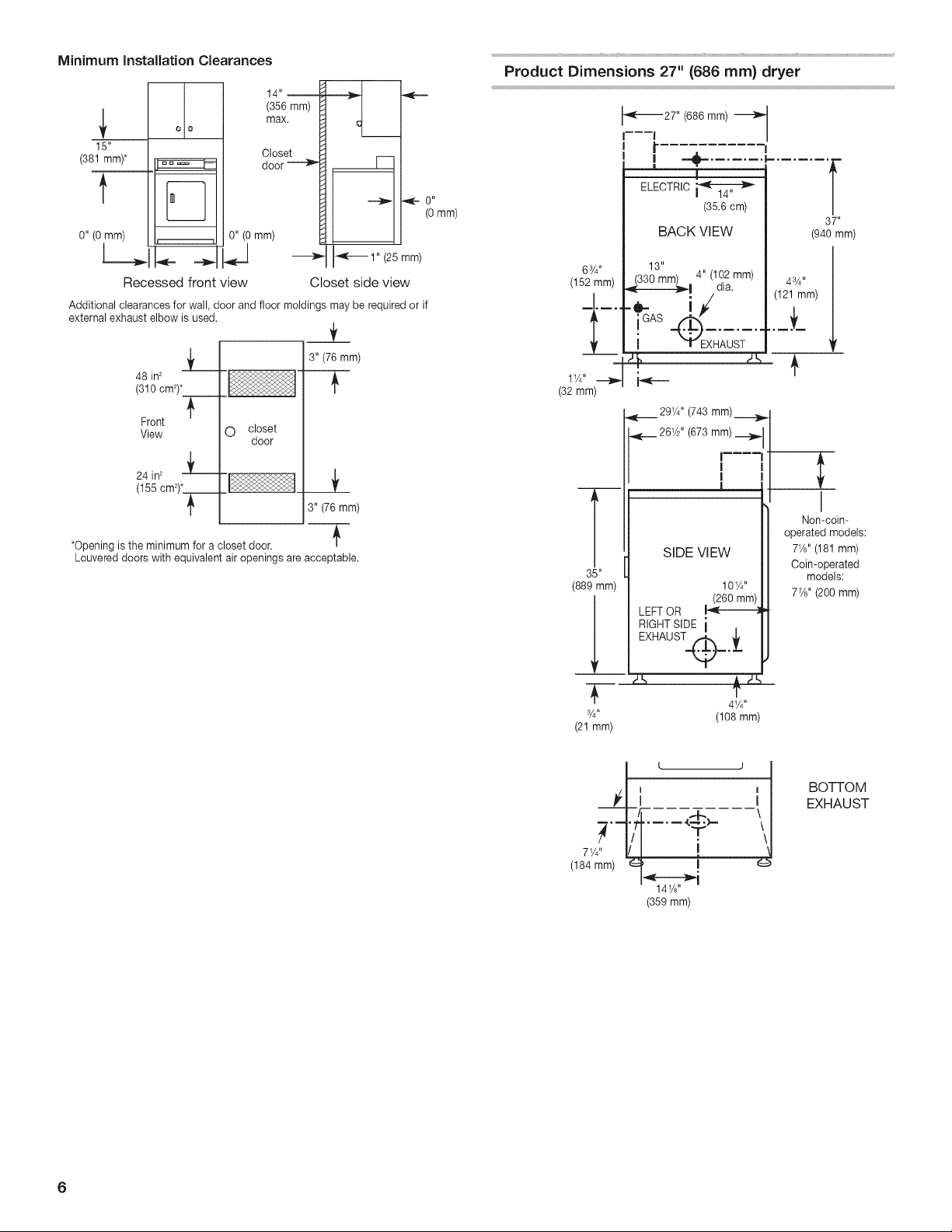

Minimum Installation Clearances

Product Dimensions 27" (686 ram} dryer

_ mm__--_

oto

15"

(381 mm)*

f

0" (0 mm)

Additional clearances for wall, door and floor moldings may be required or if

external exhaust elbow is used.

Inl I

r_

Recessed front view

max._ _

Closet {q

door 1__:[--

O"(0mm) _

-_ _4[----- 1" (25 mm)

Closet side view

_t_

3" (76 mm)

48 in_

(310 cm2)*

Front

View

*Opening is the minimum for a closet door.

Louvered doors with equivalent air openings are acceptable.

O closet

door

3" (76 mm)

0"

(0 mm)

63/4 ''

(152 mm)

£

11/4" ____

(32mm)

35"

(889 mm)

"_L_-----27 '' (686 mm)

.........r

_L_CT_,C_ /

(35.6 cm) |

BACK VIEW (940mm)

13" 4" (102 mm) 43/4,,

_ /dia. (121 mm)

" As

i _.IT;;.....k

i-4_--

291/4'' (743 mm)

261/2'' (673 mm)

I ....

I

I

I

operated models:

SIDE VIEW

LEFT OR

RIGHT SIDE i

101/4''

(260 mm)

71/8'' (181 mm)

Coin-operated

77/8'' (200 mm)

37"

/

I

Non-coin-

models:

T

3/4"

(21mm)

41/4''

(108 mm)

I

71/4" I/I !

(184 mm) _ I ¢=_

(359 mm)

BOTTOM

EXHAUST

Page 7

Recommended Ground Method

The dryer, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSl/NFPA 70, latest edition,

or Canadian Electrical Code, CSA C22.1, and all local codes

and ordinances.

GROUNDING INSTRUCTIONS

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

iMPORTANT: The dryer must be electrically grounded in

accordance with local codes and ordinances or, inthe absence of

local codes, with the National Electrical Code, ANSl/NFPA 70,

latest edition, or Canadian Electrical Code, CSA C22.1.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

[] A 120 volt, 60 Hz, AC only, 15- or 20-amp, fused electrical

circuit is required. A time-delay fuse or circuit breaker is also

recommended. It is recommended that a separate circuit

serving only this dryer be provided.

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

7

Page 8

if using a power supply cord:

it is your responsibility

[] To contact a qualified electrical installer.

[] To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSl/NFPA

70-latest edition and all local codes and ordinances.

The National Electrical Code requires a 4-wire power supply

connection for homes built after 1996, dryer circuits involved

in remodeling after 1996, and all mobile home installations.

A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch Park,

Quincy, MA 02269.

[] To supply the required 3 or 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply (or 3 or 4 wire, 120/208 volt

electrical supply, if specified on the serial/rating plate) on a

separate 30-amp circuit, fused on both sides of the line. A

time-delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit. Do not have a fuse in the

neutral or grounding circuit.

[] Do not use an extension cord.

[] If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Electrical Connection

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

[] A UL listed 30-amp power supply cord, rated 120/240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

[] A UL listed strain relief.

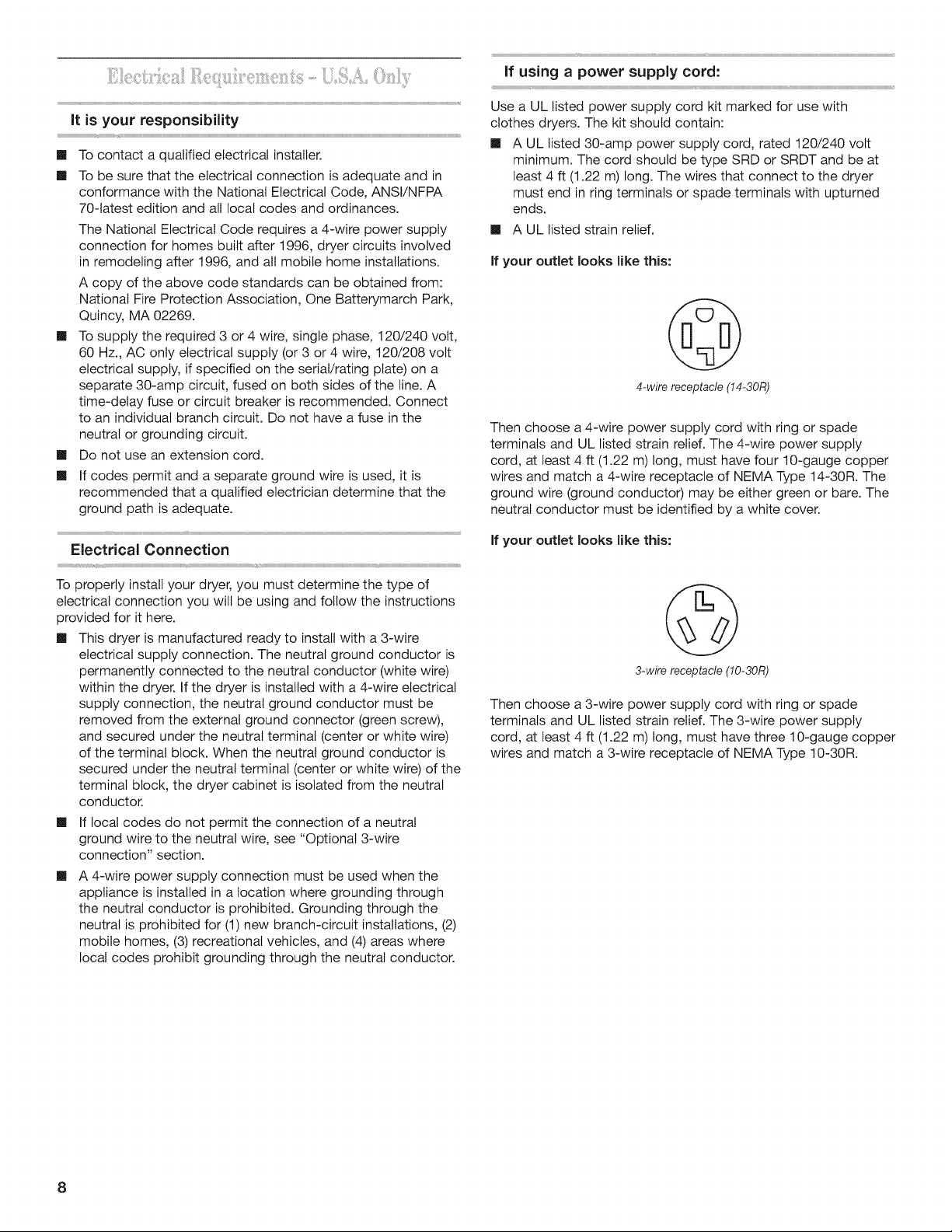

If your ouUet looks like this:

4-wirereceptacle(14-30R)

Then choose a 4-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 4-wire power supply

cord, at least 4 ft (1.22 m) long, must have four 10-gauge copper

wires and match a 4-wire receptacle of NEMA Type 14-30R. The

ground wire (ground conductor) may be either green or bare. The

neutral conductor must be identified by a white cover.

If your ouUet looks like this:

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

[] This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground conductor is

permanently connected to the neutral conductor (white wire)

within the dryer. If the dryer is installed with a 4-wire electrical

supply connection, the neutral ground conductor must be

removed from the external ground connector (green screw),

and secured under the neutral terminal (center or white wire)

of the terminal block. When the neutral ground conductor is

secured under the neutral terminal (center or white wire) of the

terminal block, the dryer cabinet is isolated from the neutral

conductor.

[] If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see "Optional 3-wire

connection" section.

[] A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral is prohibited for (1) new branch-circuit installations, (2)

mobile homes, (3) recreational vehicles, and (4) areas where

local codes prohibit grounding through the neutral conductor.

3-wire receptacle (10-30R)

Then choose a 3-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 3-wire power supply

cord, at least 4 ft (1.22 m) long, must have three 10-gauge copper

wires and match a 3-wire receptacle of NEMA Type 10-30R.

Page 9

Ifconnectingbydirectwire:

Powersupplycablemustmatchpowersupply(4-wireor3-wire)

andbe:

[] Flexiblearmoredcableornonmetallicsheathedcoppercable

(withgroundwire),protectedwithflexiblemetallicconduit.All

current-carryingwiresmustbeinsulated.

[] 10-gaugesolidcopperwire(donotusealuminum).

[] Atleast5ft(1.52m)long.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer uses a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

[] For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

[] Tosupplytherequired4wire,singlephase,120/240volt,

60Hz.,AConlyelectricalsupplyonaseparate30-amp

circuit,fusedonbothsidesoftheline.Atime-delayfuseor

circuitbreakerisrecommended.Connecttoanindividual

branchcircuit.

[] ThisdryerisequippedwithaCSAInternationalCertified

PowerCordintendedtobepluggedintoastandard14-30R

waltreceptacle.Thecordis5ft(1.52m)inlength.Besure

wattreceptacleiswithinreachofdryer'sfinallocation.

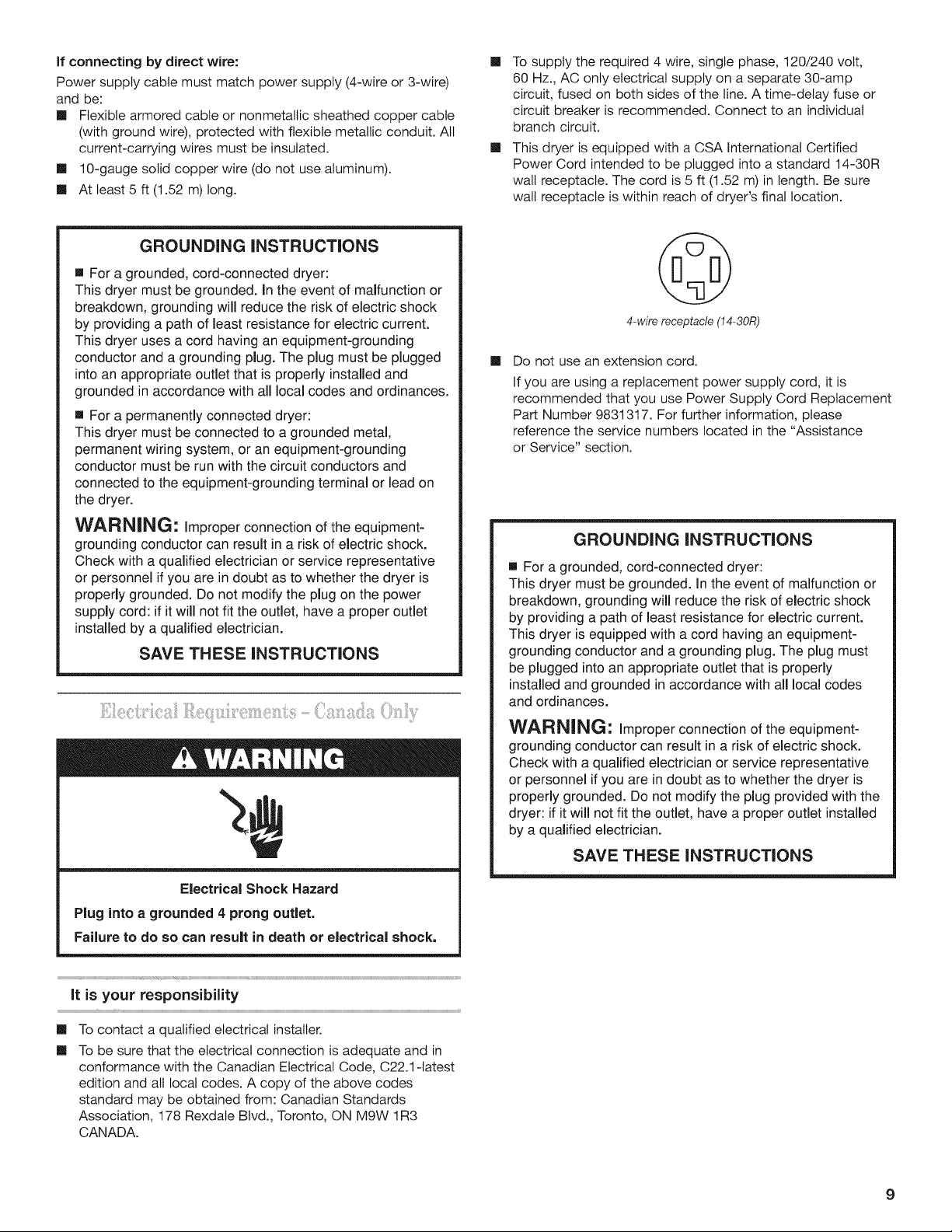

4-wirereceptacle(14-30R)

[]

Do not use an extension cord.

If you are using a replacement power supply cord, it is

recommended that you use Power Supply Cord Replacement

Part Number 9831317. For further information, please

reference the service numbers located in the "Assistance

or Service" section.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Electrical Shock Hazard

Plug into a grounded 4 prong outlet.

Failure to do so can result in death or electrical shock.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

It is your responsibility

[]

To contact a qualified electrical installer.

[]

To be sure that the electrical connection is adequate and in

conformance with the Canadian Electrical Code, C22.1-1atest

edition and all local codes. A copy of the above codes

standard may be obtained from: Canadian Standards

Association, 178 Rexdate Blvd., Toronto, ON M9W 1R3

CANADA.

9

Page 10

_iiiiiiii_i!:_!!iil;iiii_i:!ii?ili:i::iiiii?¸!i:!_%i?_!:ii:ii::'_!i!:_:_iiii_:_i_i_!!%:i:!!ii_

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (330 rnnrn)water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

IMPORTANT: Observe all governing codes and ordinances.

This installation must conform with all local codes and

ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1/NFPA 54 or CAN/CSA B149.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

The design of this dryer has been certified by CSA International

for use at altitudes up to 10,000 feet (3048 m) above sea level at

the B.T.U. rating indicated on the model/serial plate. Burner input

adjustments are not required when the dryer is operated up to

this elevation.

When installed above 10,000 feet (3048 m), a four percent (4%)

reduction of the burner B.T.U. rating shown on the model/serial

plate is required for each 1,000 foot (305 m) increase in elevation.

For assistance when converting to other gas types and/or

installing above 10,000 feet (3048 m) elevation, contact your

local service company.

Type of Gas

Gas Supply Line

Recommended method

[] Provide a gas supply line of 1/2"rigid (IPS) pipe to the dryer

location. Pipe joint compounds that resist the action of LP gas

must be used. Do not use TEFLON_'ttape. With LP gas,

piping or tubing size can be 1/2"minimum. Usually, LP gas

suppliers determine the size and materials used in the system.

Alternate method

[] The gas supply may also be connected using %" approved

copper or aluminum tubing. If the total length of the supply

line is more than 20 ft. (6.1 m), larger tubing will be required.

If using natural gas, do not use copper tubing. Pipe joint

compounds that resist the action of LP gas must be used.

Flexible metal appliance connector:

[] It is recommended that a new flexible stainless steel gas line,

design-certified by CSA International, be used for connecting

the dryer to the gas supply line. (The gas pipe which extends

through the lower rear of the dryer is provided with %" mate

pipe thread.)

[] Do not kink or damage the flexible stainless steel gas line

when moving the dryer.

Rigid pipe connection:

The rigid pipe connection requires a combination of pipe fittings

to obtain an in-line connection to the dryer.

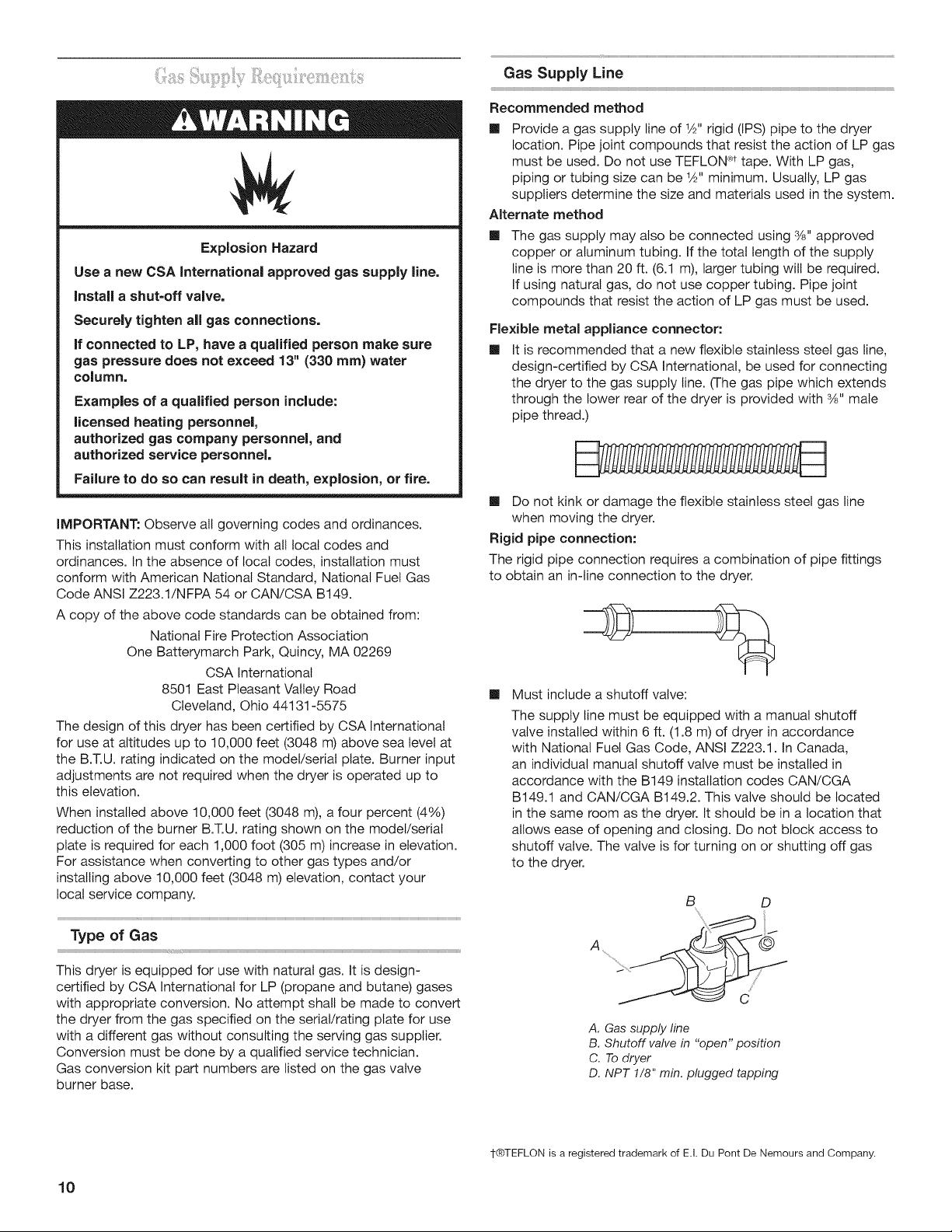

[] Must include a shutoff valve:

The supply line must be equipped with a manual shutoff

valve installed within 6 ft. (1.8 m) of dryer in accordance

with National Fuel Gas Code, ANSI Z223.1. In Canada,

an individual manual shutoff valve must be installed in

accordance with the B149 installation codes CAN/CGA

B149.1 and CAN/CGA B149.2. This valve should be located

in the same room as the dryer. It should be in a location that

allows ease of opening and closing. Do not block access to

shutoff valve. The valve is for turning on or shutting off gas

to the dryer.

B D

_'_'_",_,_,_, ii

This dryer is equipped for use with natural gas. It is design-

certified by CSA International for LP (propane and butane) gases

with appropriate conversion. No attempt shall be made to convert

the dryer from the gas specified on the serial/rating plate for use

with a different gas without consulting the serving gas supplier.

Conversion must be done by a qualified service technician.

Gas conversion kit part numbers are listed on the gas valve

burner base.

10

A. Gas supply line

B. Shutoff valve in "open" position

C. To dryer

D. NPT 1/8" min. plugged tapping

1-®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

Page 11

[] Installed in a confined area:

Ifthe dryer is installed in a confined area such as a bathroom

or closet, provision must be made for enough air for

combustion and ventilation. Check governing codes and

ordinances or refer to the "Recessed Area and Closet

Installation Instructions" in the "Location Requirements"

section.

Gas Supply Pressure Testing

A 1A"NPT minimum plugged tapping, accessible for gauge

testing, must be installed immediately upstream of the installed

shut-off valve to the dryer.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of the system at test

pressures in excess of 1Z2"psig.

Exhaust hood must be at least 12" (305 mm) from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks, or bushes).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

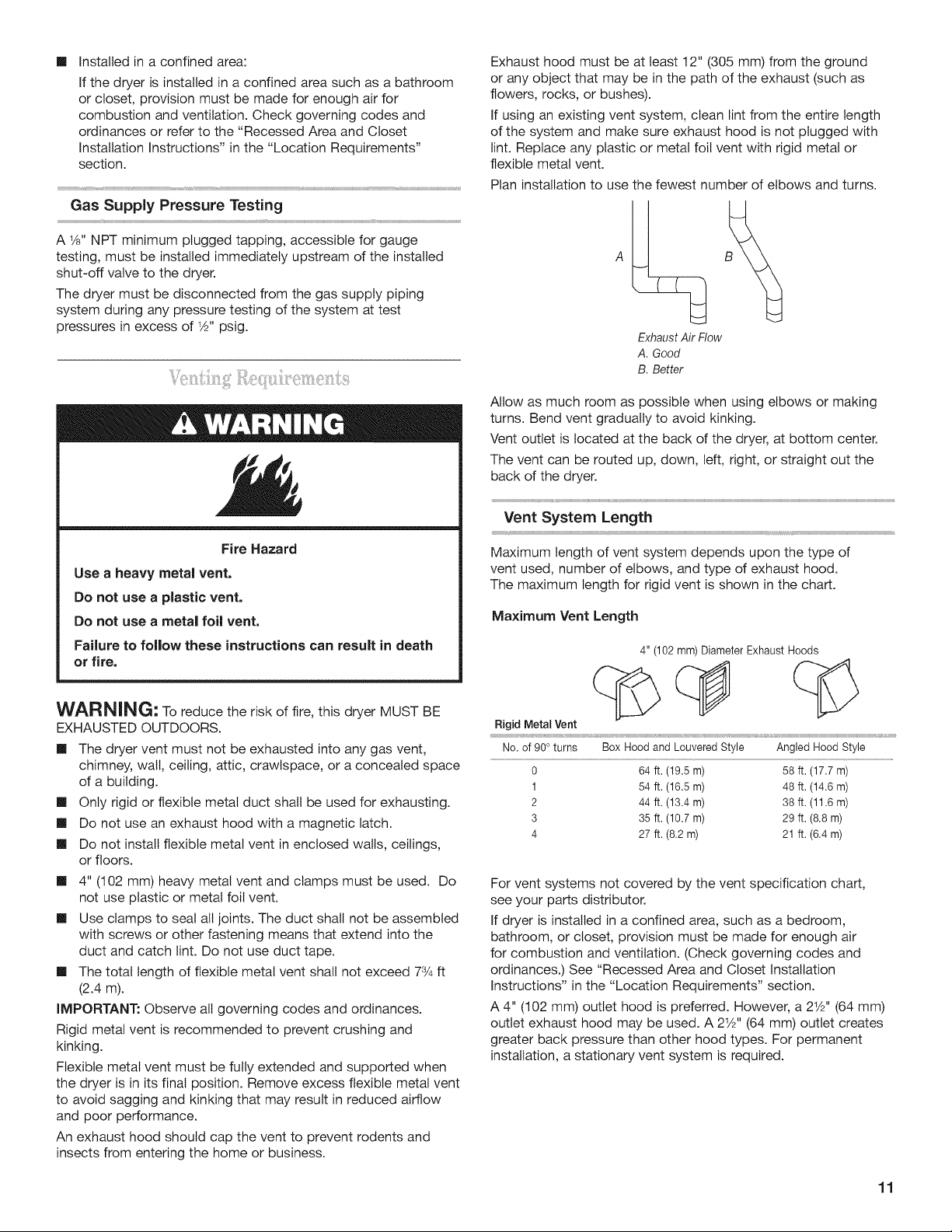

Plan installation to use the fewest number of elbows and turns.

ExhaustAir Flow

A. Good

B.Better

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

Vent outlet is located at the back of the dryer, at bottom center.

The vent can be routed up, down, left, right, or straight out the

back of the dryer.

Fire Hazard

Use a heavy metal vent,

Do not use a plastic vent.

Do not use a metal foil vent,

Failure to follow these instructions can result in death

or fire.

WARNING; To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

[] The dryer vent must not be exhausted into any gas vent,

chimney, walt, ceiling, attic, crawtspace, or a concealed space

of a building.

[] Only rigid or flexible metal duct shall be used for exhausting.

[] Do not use an exhaust hood with a magnetic latch.

[] Do not install flexible metal vent in enclosed walls, ceilings,

or floors.

[] 4" (102 mm) heavy metal vent and clamps must be used. Do

not use plastic or metal foil vent.

[] Use clamps to seat all joints. The duct shall not be assembled

with screws or other fastening means that extend into the

duct and catch lint. Do not use duct tape.

[] The total length of flexible metal vent shall not exceed 7s/4ft

(2.4 m).

iMPORTANT: Observe all governing codes and ordinances.

Rigid metal vent is recommended to prevent crushing and

kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that may result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home or business.

Vent System Length

Maximum length of vent system depends upon the type of

vent used, number of elbows, and type of exhaust hood.

The maximum length for rigid vent is shown in the chart.

Maximum Vent Length

4" (102 mm) Diameter Exhaust Hoods

Rigid Metal Vent

No. of 90° turns Box Hood and Louvered Style Angled Hood Style

0 64 ft. (19.5 m) 58 ft. (17.7 m)

1 54 ft. (16.5 m) 48 ft. (14.6 m)

2 44 ft. (13.4 m) 38 ft. (11.6 m)

3 35 ft. (10.7 m) 29 ft. (8.8 m)

4 27 ft. (8.2 m) 21 ft. (6.4 m)

For vent systems not covered by the vent specification chart,

see your parts distributor.

If dryer is installed in a confined area, such as a bedroom,

bathroom, or closet, provision must be made for enough air

for combustion and ventilation. (Check governing codes and

ordinances.) See "Recessed Area and Closet Installation

Instructions" in the "Location Requirements" section.

A 4" (102 mm) outlet hood is preferred. However, a 21/2`' (64 mm)

outlet exhaust hood may be used. A 21/2`' (64 mm) outlet creates

greater back pressure than other hood types. For permanent

installation, a stationary vent system is required.

11

Page 12

[] A main vent can be used for venting a group of dryers. The

main vent should be sized to remove 200 CFM of air per

dryer. Large-capacity lint screens of proper design may be

used in the main vent if checked and cleaned frequently. The

room where the dryers are located should have make-up air

equal to or greater than the CFM of all the dryers in the room.

[] Back-draft Damper Kit, Part No. 3391910, is available from

your dealer and should be installed in the vent of each dryer

to prevent exhausted air from returning into the dryers and

to keep the exhaust in balance within the main vent.

Unobstructed air openings are required.

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should

be no more than 30°.

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and loads being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

If an exhaust hood cannot be used:

The outside end of the main vent should have a sweep elbow

directed downward. If the main vent travels vertically through the

roof, rather than through the walt, install a 180° sweep elbow on

the end of the vent at least 2 ft. (610 mm) above the highest part

of the building. The opening in the walt or roof shall have a

diameter 1Z2"(13 mm) larger than the vent diameter. The vent

should be centered in the opening.

B

U C

air flow _ B -_---

A.Individualdryervent

B. Mainvent

INSTALLATIONINSTRUCTIONS- COINSLIDEANDCOINBOX

The console houses the factory-installed accumulator timer with

actuating arm and button.

The factory-installed timer is set to provide 45 minutes (4 pins)

of drying time when activated by the coin slide. Timer cams for

30-minute (6 pins) and 60-minute (3 pins) drying times are

included in the parts bag.

The coin slide mechanism, control panel lock and key, and coin

box lock and key are not included and are available from usual

industry sources.

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

NOTE: Slide dryer onto cardboard or hardboard before moving to

avoid damaging floor covering.

1. Using two or more people, move dryer to desired installation

location.

2. Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe the interior of the

drum thoroughly with a damp cloth.

12

0w ...............E

E"180f°sn:e;edbow F _ G highestpoint

_._o_al vent

__ /- J_::::::::_ of building

Do not install screening or cap over the end of the vent.

3=

Take two of the cardboard corners from the carton and place

them on the floor in back of the dryer. Firmly grasp the body

of the dryer and gently lay it on its back on the cardboard

corners.

4=

With one of the legs in hand, check the ridges for a diamond

marking. That's how far the leg is supposed to go into the

hole.

5=

Start to screw the leveling legs into the holes by hand. (Use a

small amount of liquid detergent to lubricate the screw

threads so it is easier to turn the legs.) Use a 1" (25 mm)

wrench or socket wrench to finish turning the legs until you

reach the diamond mark.

Now stand the dryer up.

6=

Remove the service

door of the meter case

by lifting it up at the

back. Install the money-

accepting device. (Refer

to manufacturer's

instructions for proper

installation.)

For dryers using coin

slides, use the adapter kit supplied with the dryer.

7=

Replace the meter case service door. Put the coin vault with

lock and key in the meter case opening.

8.

Remove cardboard or hardboard from under dryer. Adjust the

legs of the dryer up or down until the dryer is level.

Page 13

INSTALLATIONINSTRUCTIONS- GASDRYER

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Remove red cap from gas pipe.

2. Connect gas supply to dryer. Use pipe-joint compound

resistant to the action of LR gas for gas connections. If

flexible metal tubing is used, be certain there are no kinks.

If necessary for service, open the toe panel by removing the

21A'' hex-head screws from the bottom of the panel. Then lift

up on the panel while pulling the bottom of the panel away

from the dryer.

3. Open the shutoff valve in the gas supply line.

4. Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leak found.

1=

With dryer in final position, place level on top of the dryer, first

side to side; then front to back. If the dryer is not level, adjust

the legs of the dryer up or down until the dryer is level.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 4" (102 mm) clamp.

2. Using two or more people, move dryer to desired installation

location. Do not crush or kink vent. Make sure dryer is level.

3. Check to be sure there are no kinks in the flexible gas line.

2. Plug into a grounded 3 prong outlet.

3. Check dryer operation:

Insert coins. Operating time will accumulate per number of

coins. Push START/RESTART button. Using a full heat cycle

(not the air cycle), let the dryer run for at least five minutes.

Dryer will stop when time is used up.

NOTE: Dryer door must be closed for dryer to operate. When

door is open, dryer stops, but timer continues to run. To

restart dryer, close door and push START/RESTART button.

4. Ifthe burner does not ignite and you can feel no heat inside

the dryer, shut off dryer for five minutes. Check that all supply

valve controls are in "ON" position and that the electrical cord

is plugged in. Repeat five-minute test.

5. Ifdrying time is too long, make sure lint screen is clean.

13

Page 14

INSTALLATIONINSTRUCTIONS-ELECTRICDRYER

Power Supply Cord Method = U.S. Only

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold),

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

1. Disconnect power.

2. Remove hold-down screw and the terminal block cover.

A. External ground conductor screw

B. Tab

C. Terminalblock cover

D. Hold-down screw

3=

Assemble ,_A"(19 mm) UL-listed strain relief (UL marking on

strain relief) into the hole below the terminal block opening.

Tighten strain relief screws just enough to hold the two clamp

sections together. Install power supply cord through the

strain relief.

A. Strain relief clamp sections

B. Dryer cabinet

C. Strain relief screws

This dryer is manufactured with the neutral ground wire

connected to the neutral (center) of the wiring harness at the

terminal block. If local codes do not permit this type of

connection, use "Four-wire connection" instructions.

Use a UL-listed power supply cord rated 240 volt min.,

30-amp and marked for use with a clothes dryer.

4=

Complete installation following instructions for your type of

electrical connection:

* Four-wire (recommended method)

Three-wire (if four-wire is not available)

14

Page 15

Power Supply Cord,

Four-wire electrical connection:

B C D

i'

G

/

A. Spadeterminalswithupturnedends E

B.Neutral

C.s/4"(19mm) UL-Iistedstrainrelief

D.Neutral(white)

E. Ringterminals

F. Groundwire

G.Groundprong

Four-wire power supply cord must have four,

No. 10 copper wires and match a four-wire

receptacle of NEMA Type 14-30R. The

fourth wire (ground conductor) must be

identified by a green cover and the neutral

conductor by a white cover.

5. Remove the center terminal block screw.

6. Remove the appliance neutral ground wire

from the external ground conductor screw.

Fasten under center, silver-colored

terminal block screw.

7. Connect the ground wire of the power

supply cord to the external ground

conductor screw. Tighten screw.

8. Connect the neutral wire (white or center)

of the power supply cord under the center

screw of the terminal block. Tighten

screw.

9. Connect the other wires to outer terminal

block screws. Tighten screws.

10. Tighten strain relief screws.

11. Insert tab of the terminal block cover into

slot of the dryer rear panel. Secure cover

with hold-down screw.

A g

A. External ground conductor screw

B. Appliance neutral ground wire

C. Center terminal block screw

D. Outer terminal block screws

E. Strain relief screw

F. Neutral (center wire)

G. Ground wire

15

Page 16

Power Supply Cord,

Three=wire electrical connection:

_m A ....................

Thisbladeconnectedto B

.....thisconductor. ...................................

E D C

A. Spade terminals with upturned ends

B.Ring terminals

C.Neutral (white or center)

D.s/4"(19 mm) UL-Iisted strain relief

E. Neutral

Three-wire power supply cord must

have three, No. 10 copper wires and

match a three-wire receptacle of NEMA

Type 10-30R.

Use this method where local codes permit connecting

neutral ground wire to neutral wire: A ................................ _Z_

5. Loosen or remove the center terminal 1_1_.__ O__1

block screw. F .....................

Connect the neutral wire (white or center)

of the power supply cord to the center,

silver-colored terminal screw of the

terminal block. Tighten screw.

E ..........

7. Connect the other wires to outer terminal _ .........

8. Tighten strain relief screws.

block screws. Tighten screws. _ C

9. Insert tab of the terminal block cover into D ............

slot of the dryer rear panel. Secure cover

with hold-down screw.

A. External ground conductor screw

B. Center terminal block screw

C. Outer terminal block screws

D. Strain relief screw

E. Neutral (center wire)

F.Appliance neutral ground wire

Use this method where local codes do not permit

connecting neutral ground wire to neutral wire:

5. Remove the center terminal block screw.

A ..........!1 C

6. Remove the appliance neutral ground wire

from the external ground conductor

uw h

screw. Connect the appliance neutral

ground wire and the neutral wire (white or

center) of the power supply cord under

the center, silver-colored terminal block

screw. Tighten screw.

G

7. Connect the other wires to outer terminal

block screws. Tighten screws.

8. Tighten strain relief screws.

E

9. Insert tab of the terminal block cover into

slot of the dryer rear panel. Secure cover

F ...................

with hold-down screw.

10. After reattaching the terminal cover,

connect a separate copper ground wire

from the external ground conductor screw

to an adequate ground.

If codes permit and a separate ground wire is

used, it is recommended that a qualified

electrician determine that the ground path is

adequate.

A. Separate copper ground wire

B. External ground conductor screw

C. Appliance neutral ground wire

D. Center terminal block screw

E. Outer terminal block screws

F. Strain relief screw

G. Neutral (center wire)

B

16

Page 17

Direct Wire Method = U.S. Only

Fire Hazard

Use 10 gauge copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

1. Disconnect power.

2. Remove hold-down screw and terminal block cover.

A. External ground conductor screw

B. Tab

C. Terminalblock cover

D. Hold-down screw

3=

Install 3A" conduit connector into the hole below the terminal

block opening. Connect flexible metallic conduit and tighten

connector screw. Install direct wire cable through the flexible

metallic conduit.

L

A. Conduit connector

B. Dryer cabinet

C. Connector screw

J

......._ g

Direct wire cable must match power supply (4-wire or 3-wire)

and be:

[] Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), protected with flexible metallic conduit. All

current-carrying wires must be insulated.

[] 10-gauge solid copper wire (do not use aluminum).

[] At least 5 ft. (1.52 m) long.

Direct Wire,

Four-wire electrical connection:

to I °_r_e_jof / -_ _

_ 5" (127mm) _

Shape ends ground wireat5" (127 mm). Cut11/2"

ofwiresinto (38 mm) from3 remaining wires. Strip

ahook. insulationback1"(25 cm).

A. s/4"(19 mm) conduitconnector

fromendof cable.Leavegreenor bare

Strip 5" (127 mm) ofoutercovering

B.Neutral(whiteorcenter)

C.Groundwire(greenor bare)

D. lO-gauge,3wirewith groundwirein

flexiblemetallicconduit

5. Remove the center terminal block screw.

6. Remove the appliance neutral ground

wire from the external ground conductor

screw. Fasten under center, silver-

colored terminal block screw.

7. Connect the ground wire (green or bare)

of the direct wire cable to the external

ground conductor screw. Tighten screw.

8. Place the hooked end of the neutral wire

(white or center) of the direct wire cable

under the center screw of the terminal

block (hook facing right). Squeeze hook

end together. Tighten screw.

9. Place the hooked ends of the other

direct wire cable wires under the outer

terminal block screws (hook facing right).

Squeeze hooked ends together. Tighten

screws.

10. Insert tab of the terminal block cover into

slot of the dryer rear panel. Secure cover

with hold-down screw.

4=

Complete installation following instructions for your type of

electrical connection:

• Four-wire (recommended method)

Three-wire (if four-wire is not available)

F

E¸

A. External ground conductor screw

B.Appliance neutral ground wire

C.Center terminal block screw

D.Outer terminal block screws

E.Neutral (center wire)

F.Green or bare ground wire

D

17

Page 18

DirectWire,

Three-wire electrical connection:

Three wire with ground wire: green or bare

wire cut short. Wire is not used. Dryer is

grounded through neutral conductor.

A 1" (25 mm)

ofwires

to strippedof

disconnect insulation

box _

Use this method where local codes permit

connecting neutral ground wire to

neutral wire:

5. Loosen or remove the center terminal

block screw.

6. Place the hooked end of the neutral wire

(white or center) of the direct wire cable

under the center screw of the terminal

block (hook facing right). Squeeze

hooked end together. Tighten screw.

7. Place the hooked ends of the other

direct wire cable wires under the outer

terminal block screws (hook facing right).

Squeeze hooked ends together. Tighten

screws.

8. Insert tab of the terminal block cover into

slot of the dryer rear panel. Secure cover

with hold-down screw.

C

A. External ground conductor screw

B. Center terminal block screw

C. Outer terminal block screws

D. Neutral (center wire)

E.Appliance neutral ground wire

C

(89 mm)

Strip 31/2'' (89 mm) of outer

Shapeends

of wiresinto

a hook.

A. s/4"(19 mm) conduit connector

B. Neutral (white or center)

C. lO-gauge, 3 wire with ground wire in

flexible metallic conduit

covering from end of cable.

Strip insulation back 1" (25 mm).

If using 3 wire cable with ground

wire, cut green or bare wire even

with outer covering.

Use this method where local codes do

not permit connecting neutral ground

wire to neutral wire:

5. Remove the center terminal block screw.

6. Remove the appliance neutral ground wire

from the external ground conductor screw.

Connect the appliance neutral ground wire

and the neutral wire (white or center) of the

direct wire cable under the center, silver-

colored terminal block screw. Tighten

screw.

7. Connect the other wires to outer terminal

block screws. Tighten screws.

8. Insert tab of the terminal block cover into

slot of the dryer rear panel. Secure cover

with hold-down screw.

9. After reattaching the terminal cover,

connect a separate copper ground wire

from the external ground connector screw

to an adequate ground.

If codes permit and a separate ground wire is

used, it is recommended that a qualified

electrician determine that the ground path is

adequate.

A......... C

A. Separate copper ground wire

B. External ground conductor screw

C. Appliance neutral ground wire

D. Center terminal block screw

E. Outer terminal block screws

F. Neutral (center wire)

1. Using a 4" (102 mm) clamp, connect vent to exhaust outlet in

dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured to

exhaust hood with a 4" (102 mm) clamp.

2. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is bevel.

1=

With dryer in final position place level on top of the dryer, first

side to side; then front to back. If the dryer is not level, adjust

the legs of the dryer up or down until the dryer is bevel.

18

2. Plug in dryer or reconnect power.

3. Check dryer operation (some accumulated time may be on

the timer due to factory testing).

Insert coins in slide and press slide in slowly. (Operating time

will accumulate per number of coins and type of timing cam

used.) Push START/RESTART button. Using a full heat cycle

(not the air cycle), let the dryer run for at least five minutes.

Dryer will stop when time is used up.

NOTE: Dryer door must be closed for dryer to operate. When

door is open, dryer stops, but timer continues to run. To

restart dryer, close door and push START/RESTART button.

4. Ifdrying time is too long, make sure lint screen is clean.

5. Now start the dryer and allow it to complete a full heat cycle

(not air cycle) to make sure it is working properly.

Page 19

CHANGINGTOA30-OR60-MINUTETIMINGCAM

Electrical Shock Hazard

Disconnect power before making cam changes.

Failure to follow these instructions can result in death

or electrical shock.

You can install the 30-minute or 60-minute timing cam (shipped

with dryer) as follows:

1. Unplug dryer or disconnect power.

2. Unlock meter case.

3. Turn the timing cam by hand until the V-shaped notch lines up

below the ratchet tooth.

.............. _ D

A.Ratchettooth _.\

B.Timir_gcam

c D ivelug k%\\\

D. V-shapednotch _X_

,<j

4. Insert a narrow, flat-blade screwdriver under the timing cam

near the clock shaft. Gently lift cam straight up and off shaft

making sure that the V-shaped notch clears the ratchet tooth.

5. Place new cam (hub side down) over clock shaft. Line up flat

side of shaft with flat side of cam hole. Check that drive lug is

in place.

6. Turn cam until V-shaped notch lines up with ratchet tooth.

7. Press cam down in place on motor shaft. Make sure that

V-shaped notch clears the ratchet tooth.

8. Close and lock the meter case.

REVERSINGTHEDOORSWING(OPTIONAL)

You can change your door swing from a right-side opening to a

left-side opening, if desired.

D

c

1. Place towel (A)on top of dryer to protect surface.

2. Open dryer door. Remove bottom screws from cabinet side of

hinges (B). Loosen (do not remove) top screws from cabinet

side of hinges.

3. Lift door until top screws in cabinet are in large part of hinge

slot. Putt door forward off screws. Set door (handle side up)

on top of dryer. Remove top hinge screws from cabinet.

4. Remove screws attaching hinges to door.

5. Remove screws from all sides of door (5 screws). Holding

door over towel on dryer, grasp sides of outer door and gently

lift to separate it from inner door (do not pry apart). Do not pull

on door seal or plastic door catch.

6=

Be certain to keep cardboard

spacer centered between doors.

Reattach outer door panel to

inner door panel so handle

is on the side where hinges

were just removed.

7=

Attach door hinges to dryer door so that the larger hole is

at the bottom of the hinge and the hinge pin is toward the

door front.

8. Remove the 4 screws that attach 2 plugs (C) on the handle

side. Attach plugs to opposite side using the same 4 screws.

9. Insert screws into bottom holes on left

side of cabinet. Tighten screws halfway.

Position door so large end of door hinge

slot is over screws. Slide door up so

screws are in bottom of slots. Tighten

screws. Insert and tighten top screws in

hinges.

10. Close door and check that door strike aligns with door

catch (D).

19

Page 20

MAINTENANCEINSTRUCTIONS

Maintenance instructions:

[] Clean lint screen after each cycle.

[] Removing accumulated lint:

• From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

• From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

[] Keep area around dryer clear and free from combustible

materials, gasoline, and other flammable vapors and liquids.

[] Keep dryer area clear and free from items that would obstruct

the flow of combustion and ventilation air.

If dryer does not operate, check the following:

[] Electric supply is connected.

[] Circuit breaker is not tripped or house fuse is not blown.

[] Door is closed.

[] Controls are set in a running or "ON" position.

[] START/RESTART button has been pushed firmly.

[] For gas dryers, check that gas supply shutoff valves are set

in open position.

If you need assistance:

The Commercial Laundry Support Center will answer any

questions about operating or maintaining your dryer not covered

in the Installation Instructions.

Just dial 1-800 NO BELTS (1-800-662-3587) -- the call is

toll free.

When you call, you will need the dryer model number and serial

number. Both numbers can be found on the serial-rating plate

located in the dryer door well.

20

Page 21

WHIRLPOOLCOMMERCIALLAUNDRYWARRANTY:

CAM2752,CEM2750,CGM2751,CAM2762,CEM2760,CGM2761,CSP2760,

CSP2761,CEW91OO,CGW91OO,CHW9900

LiMiTED WARRANTY

For the first three years from the date of purchase, when this commercial appliance is installed, maintained, and operated according to the

instructions attached to or furnished with the product, Whirlpool Corporation (thereafter "Whirlpool") will pay for factory specified parts or

original equipment manufacturer parts to correct defects in materials or workmanship that existed when this major appliance was purchased.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THiS LIMITED WARRANTY SHALL BE PRODUCT REPAIRAS PROVIDED HEREIN. Proof of

original purchase date is required to obtain service under this warranty.

iTEMS WHIRLPOOL WiLL NOT PAY FOR

This limited warranty does not cover:

1.

Costs including transportation, shipping, or custom duties for covered parts.

2.

Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance,

to replace or repair fuses, or to correct external wiring or plumbing.

3.

Replacement parts or repair labor if this commercial appliance is used for other than normal, commercial use or when it is used

in a manner that is inconsistent to published user or operator instructions and/or installation instructions.

4.

Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood,

acts of God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products

not approved by Whirlpool.

5=

Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6.

Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7.

The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed

in accordance with published installation instructions.

8=

Damage resulting from exposure to chemicals.

9.

Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

DiSCLAiMER OF iMPLiED WARRANTIES

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO THREE YEARS OR THE SHORTEST PERIOD ALLOWED BY LAW. Some states and provinces do

not allow limitations on the duration of implied warranties of merchantability or fitness, so this limitation may not apply to you. This warranty

gives you specific legal rights, and you also may have other rights that vary from state to state or province to province.

LiMiTATiON OF REMEDIES; EXCLUSION OF iNCiDENTAL AND CONSEQUENTIAL DAMAGES

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THiS LiMiTED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN.

WHIRLPOOL SHALL NOT BE LIABLE FOR iNCiDENTAL OR CONSEQUENTIAL DAMAGES. Some states and provinces do not allow

the exclusion or limitation of incidental or consequential damages, so these limitations and exclusions may not apply to you. This

warranty gives you specific legal rights, and you also may have other rights that vary from state to state or province to province.

if you need service, please contact your authorized Whirlpool Commercial Laundry distributor. To locate your authorized Whirlpool

Commercial Laundry distributor, or for web inquiries, visit www.WhirlpoolCommercialLaundry.com.

For written correspondence:

Whirlpool Commercial Laundry Service Department

Benton Harbor, MI 49022-2632 USA

2000 N M 63

5/08

21

Page 22

P P P

SECURITEDELASECHEUSE

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de s_curite importants dans ce manuel et sur votre appareil m_nager. Assurez-vous de

toujours lire tous les messages de s_curite et de vous y conformer.

Ce symbole d'alerte de s_curit_ vous signale les dangers potentiels de d_c_s et de blessures graves h vous

et h d'autres.

Voici le symbole d'alerte de s_curit&

Tous les messages de securite suivront le symbole d'alerte de s_curite et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient •

Risque possible de d_cbs ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_cbs ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s_curite vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

AVERTISSEMENT - "Risque d'incendie"

m

L'installation de la s_cheuse a linge doit 6tre effectu_e par un installateur qualifi_.

m

Installer la s_cheuse conforrn_rnent aux instructions du fabricant et aux codes Iocaux,

m

Ne pas installer de s_cheuse _ linge avec des mat_riaux d'_vacuation en plastique

souple. Si un conduit m_tallique souple (de type papier d'alurninium) est installS,

celui-ci doit _tre d'un type sp_cifique identifi_ par le fabricant de I'appareU et

convenir h une utilisation avec les s_cheuses _ linge. Les mat_riaux d'_vacuation

souples sont connus pour s'affaisser, 6tre facilement _cras_s et bloquer la charpie.

Ces situations obstrueront le d_bit d'air de la s_cheuse h linge et augmenteront le

risque d'incendie,

Pour r_duire le risque de blessure grave ou de d_c_s, suivre routes

les instructions d'installation.

Conserver ces instructions.

22

Page 23

AVERTISSEIViENT • Pour votre securite, les renseignements dans ce manuel doivent

_tre observes pour reduire au minimum les risques d'incendie ou d'explosion ou pour

eviter des dommages au produit, des blessures ou un deces.

- Ne pas entreposer ou utiiiser de I'essence ou d'autres vapeurs ou liquides

inflammables a proximite de cet appareil ou de tout autre appareil electromenager.

-QUE FAIRE DANS LE CAS D'UNE ODEUR DE GAZ :

®Ne pas tenter d'allumer un appareil.

• Ne pas toucher a un commutateur electrique; ne pas utiliser le telephone se trouvant

sur les lieux.

• _:vacuer tous les gens de la piece, de I'edifice ou du quartier.

• Appeler immediatement le fournisseur de gaz d'un telephone voisin. Suivre ses

instructions.

• ,_ defaut de joindre votre fournisseur de gaz, appeler les pompiers.

- L'installation et I'entretien doivent _tre effectues par un installateur qualifie, une

agence de service ou le fournisseur de gaz.

AVERTISSEMENT : L'odorat ne permet pas toujours la d_tection d'une fuite de gaz.

Les distributeurs de gaz recommandent remploi d'un d6tecteur de gaz (homologation UL ou CSA).

Pour d'autre information, contacter le fournisseur de gaz local.

En cas de detection d'une fuite de gaz, ex6cuter les instructions "Que faire dans le cas d'une odeur de gaz".

iMPORTANT : L'installation du gaz dolt se conformer aux codes Iocaux, ou en I'absence de codes Iocaux, au code canadien

d'installation B149.1 du gaz naturel ou du propane.

La secheuse dolt 6tre 61ectriquement reliee & la terre conformement aux codes Iocaux ou en I'absence de codes Iocaux, au Code

canadien de I'electricit6, CSA C22.1.

Dans rEtat du Massachusetts, les instructions d'installation suivantes sont applicables

m=Les travaux d'installation et reparation doivent 6tre ex6cut6s par un plombier ou tuyauteur qualifie ou licencie, ou par le

personnel qualifi6 d'une entreprise licenci6e par I'Etat du Massachusetts.

m=Si une vanne & boisseau spherique est utilisee, elle dolt comporter une manette "T".

m=Si un conduit de raccordement flexible est utilis6, sa Iongueur ne doit pas depasser 3 pi.

23

Page 24

IMPORTANTES INSTRUCTIONS DE SI_CURITI_

AMERTISSEMENT • Pour r6duire le risque d'incendie, de choc 61ectrique ou de blessure Iors de I'utilisation de

la s6cheuse, il convient d'observer certaines pr6cautions el6mentaires dont les suivantes :

• Lire toutes les instructions avant d'utiliser la s6cheuse.

• Ne pas placer des articles expos6s aux huiles de cuisson

dans votre secheuse. Les articles contamin6s par des

huiles de cuisson peuvent contribuer & une r6action

chimique qui pourrait causer a la charge de s'enflammer.

• Ne pas faire s6cher dans la machine des articles qui ont

d6j& et6 nettoy6s, lav6s, imbib6s, ou tach6s d'essence,

de solvants pour nettoyage a sec, d'autres substances

inflammables, ou de substances explosives puisqu'elles

d6gagent des vapeurs qui peuvent provoquer un

incendie ou une explosion.

• Ne pas permettre & des enfants de jouer sur ou

I'int6rieur de la s6cheuse. Une surveillance 6troite est

n6cessaire Iorsque la s6cheuse est utilis6e pros d'eux.

• Avant d'enlever la s6cheuse du service ou la jeter, enlever

la porte du compartiment de s6chage.

• Ne pas mettre la main dans la s6cheuse si le tambour est

en mouvement.

• Ne pas installer ni entreposer la s6cheuse oQelle sera

expos6e aux intemp6ries.

• Ne pas jouer avec les commandes.

CONSERVEZ CES INSTRUCTIONS

• Ne pas reparer ni remplacer une piece de lasecheuse ou

essayer d'en faire I'entretien &moins d'une recommandation

specifique dans le guide d'utlilisation et d'entretien, ou

publi6e dans les instructions de r6paration par I'utilisateur

que vous comprenez et pouvez executer avec competence.

• Ne pas utiliser un produit assouplissant de tissu ou des

produits pour eliminer la statique & moins qu'ils ne soient

recommandes par le fabricant du produit assouplissant de

tissu ou du produit.

• Ne pas utiliser la chaleur pour faire secher des articles

fabriqu6s avec du caoutchouc mousse ou des mat6riaux

semblables.

• Nettoyer le filtre & charpie avant et apr_s chaque charge.

• Ne pas laisser la charpie, la poussi_re, ou la salet6

s'accumuler autour du syst_me d'6vacuation ou autour de

I'appareil.

• Un nettoyage periodique de I'int6rieur de la s6cheuse et du

conduit d'6vacuation dolt _tre effectu6 par une personne

qualifi6e.

• Voir les instructions d'installation pour les exigences de

liaison de I'appareil &la terre.

I On recommande que le proprietaire place les instructions _ I'usage du client & un endroit bien visible, pour le cas oQ le client

percevrait une odeur de gaz. Ces renseignements doivent 6tre obtenus aupr_s de votre foumisseur de gaz.

m Placer I'avertissement qui suit _ un endroit bien visible.

POUR VOTRE SECURIT¢:

Ne pas entreposer ni utiliser de I'essence ou d'autres produits liquides ou gazeux inflammables & proximite de cet appareil ou de

tout autre appareil electrom6nager.

24

Page 25

EXIGENCESD'INSTALLATION

0 t:iiiiiii iiiii ilill iiiiii'i !!i;

Rassembter les outils et pi_ces necessaires avant de commencer

I'instatlation. Life et respecter les instructions d'instattation

fournies avec chacun des outits de cette liste.

Outillage n_cessaRe

m Cte & tube de 8" (20 cm) [] Couteau utititaire

ou 10" (25 cm) [] Bride de fixation

[] Cle &molette de 8" [] Compose d'etancheite des

(20 cm) ou 10" (25 cm) raccords filetes - r6sistant

[] Toumevis h lame plate au propane

[] Toumevis Phillips [] Pistolet & calfeutrage et

[] Cle & molette avec compose de catfeutrage

ouverture jusqu'& (pour l'instatlation d'un

1" (25 mm) ou cte nouveau circuit

h douille hexagonate d'evacuation)

[] Niveau [] Pince

[] Cle h douitle de 5/16" [] Couteau h mastic

Pi_ces fournies

Retirer le sac de pi_ces du tambour de la secheuse. V_rifier

la presence de toutes les pi_ces.

[] Coin [] Came de minutage h

[] Patin (4) 3 broches

[] Pied de la secheuse (4) [] Came de minutage h

[] Boulon de ,%6-18x 21/2`' 6 broches

[]

Veilter h ce que les bords inferieurs de la caisse ainsi que

I'arri_re et les c6tes inf6rieurs de la secheuse soient exempts

d'obstructions, afin de permettre le passage adequat de I'air

de combustion. Voir ta section "Instructions d'instattation darts

un encastrement ou un placard" pour I'espace de

degagement minimal.

NOTE : La secheuse ne dolt pas _tre instaltee en un endroit

oO etle serait exposee h de I'eau ou aux intemperies.

instructions pour I'instailation dans un

encastrement ou un placard

Cette secheuse peut _tre installee dans un placard ou un

encastrement. Pour I'instatlation dans un placard ou un

encastrement, on dolt respecter les distances de separation

minimales mentionnees sur la plaque signatetique de lasecheuse.

Les distances de separation sont exprimees en pouces; il s'agit

des distances minimales. It est utile de prevoir des distances de

separation superieures pour faciliter I'installation et les travaux

d'entretien, ou si ceci est exige par les codes et r_glements

Iocaux.

Si la porte du placard est installee, on dolt respecter la taitle

minimale des ouvertures d'entr_e d'air au sommet et en bas. On

peut utiliser une porte h jalousies offrant une surface de passage

d'air equivalente.

Le circuit d'evacuation de la secheuse dolt _tre retie & I'exterieur.

Aucun autre appareil utitisant un combustible ne dolt _tre instatte

dans le m_me placard.

Risque d'explosion

Garder [es mati_res et les vapeurs inflammables, teile

que I'essence, loin de la s_cheuse.

Ne pas installer darts un garage.

Le non-respect de ces instructions peut causer

un d_ces, une explosion ou un incendie.

Pour i'instailation d'une s_cheuse & gaz :

IMPORTANT : Respecter les dispositions de tous les codes

et r_glements en vigueur.

[] Determiner les exigences des codes : Certains codes limitent

ou prohibent I'instatlation d'une secheuse dans un garage, un

placard, ou une chambre h coucher. Consulter I'inspecteur

local des b&timents.

25

Page 26

Distances de s_paration minimales

Dimensions du produit = S_cheuse de 27" (686 ram)

_I:------'27" (886 mm)

15"

(381 mm)*

o" (o ram) .__.

max. _

Porte du _ F--

placard 1

0" (0 mm)

._ ==='==_1[_L_--'-1 '' (25 mm)

Encastrement, vue avant Placard, vue laterate

On doit pr@oir un espacementadditionnel pour tenircompte @entuellement

des mouluresdu mur,de la porte et du plancher,ou si lecircuit d'@acuation

comporte un coude. _-

48 in_

(310 cm2)*

Vue

avant

O Porte du

placard

!

3" (76 mm)

_{

3" (76 mm)

* Taille minimale de I'ouverture pour la porte du placard. On peut utiliser une

porte _ jalousies offrant une surface de passage d'air 6quivalente.

0 II

(0 mm)

(152 mm)

CANALISATIONDEGAZ _

11/4" _

(32 mm)

(889 mm)

CABLE

ELECTRIQUE I (35!4cm)

63/4 ''

(330 mm) 4" (102 mm)

I_="- DECHANGE

,___j 291/411(743 mm).j_._

VUE LATC:RALE --

BOUCHE DE

DECHARGE, COTE

GAUCHE OU COTE

35"

DROIT

1

i I

!

VUE ARRIERE

13"

dia. 43/4"

i/ •

261/2'' (673 mm) J}_-I

I

I

I

(260 mm)

101/4"

37"

(940 mm)

(121 mm)

I

ModUles sans

m6canisme de

commande _ pi_ces

71/8"(181 mm)

ModUles avec

m6canisme de

commande _ pi_ces

77/?' (200 mm)

?

3/4"

(21ram)

71/4" /L!"

(184 mm) _=_ 141/?' I d=_

[(359 ram) i

41/4''

(108 mm)

I

_= \\

FtVACUATION

PAR LE BAS

26

Page 27

Methode recommand_e de liaison _ la terre

Apr_s I'installation, la secheuse dolt _tre etectriquement reliee & la

terre conformement aux prescriptions des codes et r_glements

Iocaux; en I'absence de code local, respecter les prescriptions du

code national en vigueur : National Electrical Code, ANSl/NFPA

70 (edition la plus recente), ou Code canadien de I'electricite,

CSA C22.1, ainsi que cetles des codes et r_glements Iocaux.

Risque de choc _lectrique

Brancher sur une prise & 3 alv_oles reli_e b la terre.

Ne pas enlever la broche de liaison & la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un c_ble de rallonge.

Le non-respect de ces instructions peut causer

un d_ces, un incendie ou un choc _lectrique.

IMPORTANT : La secheuse dolt _tre electriquement reliee & la

terre conformement aux prescriptions des codes et r_gtements

Iocaux; en I'absence de code local, respecter les prescriptions du

code national en vigueur : National Electrical Code, ANSl/NFPA

70 (6dition la plus r6cente), ou Code canadien de I'etectricit6,

CSA C22.1.

Si un conducteur distinct de liaison & la terre est utitise (Iorsque le

code en vigueur le permet), on recommande qu'un etectricien

quatifie verifie la qualite de la liaison _ la terre.

On peut obtenir un exemptaire du code national en vigueur

I'adresse suivante :

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

[] Uappareil dolt _tre atimente par un circuit electrique de 120 V

(CA seulement), 60 Hz, protege par un fusible de 15 ou 20 A.

On recommande I'emploi d'un fusible temporise ou d'un

disjoncteur. It est egalement recommande d'utiliser un circuit

separ_ pour la secheuse.

INSTRUCTIONS DE LIAISON ,_ LA TERRE

I Pour une s6cheuse reli_e & la terre et connect_e par un

cordon :

Cette s_cheuse doit @re reli_e &la terre. En cas de mauvais

fonctionnement ou de panne, la liaison & la terre r_duira le

risque de choc _lectrique en offrant au courant _lectrique un

acheminement d'_vacuation de moindre r_sistance. Cette

s_cheuse est aliment_e par un cordon _lectrique

comportant un conducteur reli_ & laterre et une fiche de

branchement munie d'une broche de liaison & la terre. La

fiche dolt @re branchee sur une prise appropri_e qui est

bien install_e et reli_e & la terre conform_ment &tousles

codes et r_glements Iocaux.

AVERTISSEMENT " Le raccordement incorrect de

cet apparel au conducteur de liaison & la terre peut susciter

un risque de choc _lectrique. En cas de doute quant & la

qualit_ de liaison & la terre de la s_cheuse, consulter un

_lectricien ou un technicien ou un personnel qualifi& Ne pas

modifier la fiche de branchement fournie avec la s_cheuse;

si la fiche ne correspond pas & la configuration de la prise

de courant, demander & un _lectricien qualifi_ d'installer une

prise de courant appropri_e.

CONSERVEZ CES INSTRUCTIONS

27

Page 28