Whirlpool CAWC529PQ1 Parts Diagram

TECH SHEET - DO NOT DISCARD PAGE 1

WARNING

Electric Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere.

ESD may damage or weaken the

electronic control assembly. The new

control assembly may appear to work well

after repair is finished, but failure may

occur at a later date due to ESD stress.

■

Use an anti-static wrist strap. Connect

wrist strap to green ground connection

point or unpainted metal in the

appliance

-ORTouch your finger repeatedly to a green

ground connection point or unpainted

metal in the appliance.

■

Before removing the part from its

package, touch the anti-static bag to a

green ground connection point or

unpainted metal in the appliance.

■

Avoid touching electronic parts or

terminal contacts; handle electronic

control assembly by edges only.

■

When repackaging failed electronic

control assembly in anti-static bag,

observe above instructions.

DIAGNOSTIC GUIDE

Before servicing, check the following:

■

Make sure there is power at the wall outlet.

■

Has a household fuse blown or circuit

breaker tripped? Time delay fuse?

■

Are both hot and cold water faucets open

and water supply hoses unobstructed?

■

All tests/checks should be made with a VOM

or DVM having a sensitivity of 20,000 ohms

per volt DC or greater.

■

Check all connections before replacing

components. Look for broken or loose

wires, failed terminals, or wires not pressed

into connections far enough.

■

The most common cause for control failure

is corrosion on connectors. Therefore,

disconnecting and reconnecting wires will

be necessary throughout test procedures.

■

Connectors: Look at top of connector.

Check for broken or loose wires. Check for

wires not pressed into connector far enough

to engage metal barbs.

■

Resistance checks must be made with

power cord unplugged from outlet, and with

wiring harness or connectors disconnected.

06/04 FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 326038065

PAGE 2 TECH SHEET - DO NOT DISCARD

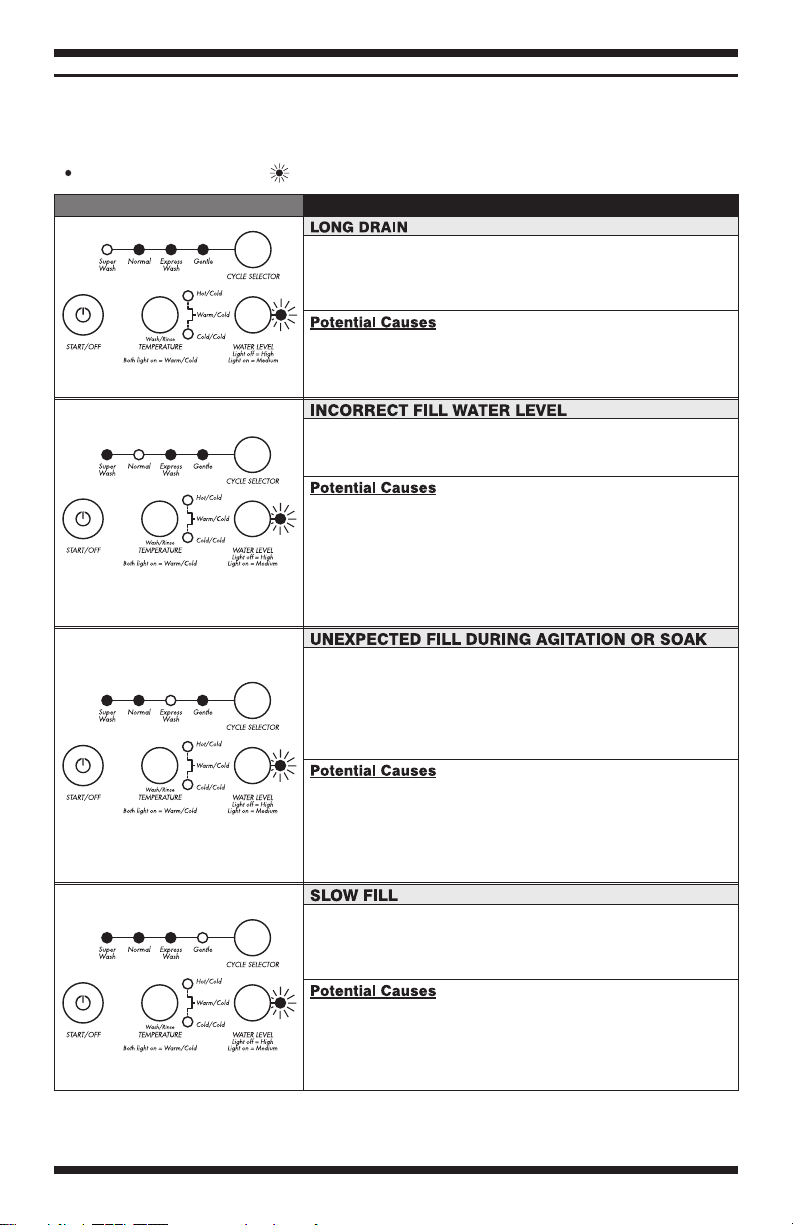

DISPLAY FAULT/ERROR CODES AND POTENTIAL CAUSES

To indicate the following Fault/Error codes, the control panel displays different patterns in LEDs.

Example: During a Slow Fill error, the Gentle and TEMPERATURE LEDs are off, the WATER

LEVEL LED blinks, all other LEDs are on.

= LED on continuously = LED flashes on and off

LEDS ACTIVATED EXPLANATION/RECOMMENDED PROCEDURE

If the drain time exceeds 6 minutes, the wash cycle will

stop. Push the START/OFF button to reset the operation

mode, a Drain task is executed and the previously selected

cycle resumes.

■

Drain pump failure.

■

Drain hose: check for proper connection, kinks or clogs.

■

Pressure switch contact failure.

Wash cycle stops. Press START/OFF button to enter

Standby mode. Execute a Diagnostic Test to drain the

water.

■

Incorrect electrical connection to pressure switch.

■

Pressure switch contact failure.

■

Pressure switch is defective.

■

Pressure switch hose is damaged or loose.

■

Air dome is clogged.

■

Drain hose: check for proper height, kinks or clogs.

The pressure switch contact selected has opened during

agitation task. The wash cycle stops and a Drain task is

executed. Once the Drain is complete, the cycle stops.

Push the START/OFF button to reset the operation mode, a

Fill task is executed and the previously selected cycle

resumes.

■

Water or clothes were removed from basket after Fill task

was complete.

■

Pressure switch hose is damaged or loose.

■

Drain hose is improperly connected.

■

Water leaking from washer tub.

If the Fill task exceeds 20 minutes, the wash cycle stops.

Push the START/OFF button to reset the operation mode, a

Fill task is executed according to previous Temperature

selection and the previously selected cycle resumes.

■

Water inlet valve is clogged or damaged.

■

Water pressure is too low.

■

Water hose is closed/clogged.

■

Water supply faucet(s) turned off.

NOTE: When an error occurs, it is displayed on the interface board (LEDs). If a new cycle starts,

the electronic control saves the error for technician’s reference. If no errors are found when

running the same wash cycle or a new selection, the electronic control cancels the stored error.

PART NO. 326038065 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 3

■

DIAGNOSTIC TEST

The control must be in the off state before

pressing the touchpad sequence to start the

test.

Starting the Test Mode

■

Push the START/OFF button to turn washer

off.

■

Unplug washer or disconnect power.

■

Plug in washer or reconnect power. All

LEDs should blink twice.

■

Within 10 seconds, simultaneously press

TEMPERATURE and WATER LEVEL

buttons. The WATER LEVEL LED will stay

on and all other LEDs should be off. If any

other LEDs are on, the starting procedure

has failed. Repeat the starting procedure.

Stopping the Test Mode

To exit the Components Test routine at any

time, press the START/OFF button or unplug

washer. When the START/OFF button is

pressed during Test Mode, the electronic

control switches to Standby Mode.

Test Program Control

In order to advance to the next step of the test

procedure, press the CYCLE SELECTOR

button.

Last Error Occurred

To display the last error that occurred,

simultaneously press the WATER LEVEL and

CYCLE SELECTOR buttons.

LED Test

Press the TEMPERATURE button. All LEDs

should be on.

Component Tests

Pressure Switch (Medium Level)

and Cold Water Valve Test

■

Press the CYCLE SELECTOR button.

■

The Super Wash LED comes on.

■

The cold water valve is activated.

■

The pressure switch opens for a

Medium level fill task.

■

When the fill is complete, the Super

Wash LED flashes.

Pressure Switch (High Level)

and Hot Water Valve Test

■

Press the CYCLE SELECTOR button.

■

The Normal LED comes on.

■

The hot water valve is activated.

■

The pressure switch opens for a High

When the fill is complete, the Normal

LED flashes.

Motor Test

NOTE: To bypass this test and continue to the

next component test, press the CYCLE

SELECTOR button twice.

■

Press the CYCLE SELECTOR button.

■

The Express Wash LED comes on.

■

The motor begins a 15-minute agitation

task.

■

When the agitation is complete, the

Express Wash LED flashes.

Drain Pump and Brake Actuator

(on traction) Test

■

Press the CYCLE SELECTOR button.

■

The Gentle LED comes on.

■

The brake actuator and pump are

activated.

■

After 20 seconds, the pressure switch

opens and the motor begins a

10-minute spin cycle.

■

When the spin cycle is complete, the

Gentle LED flashes.

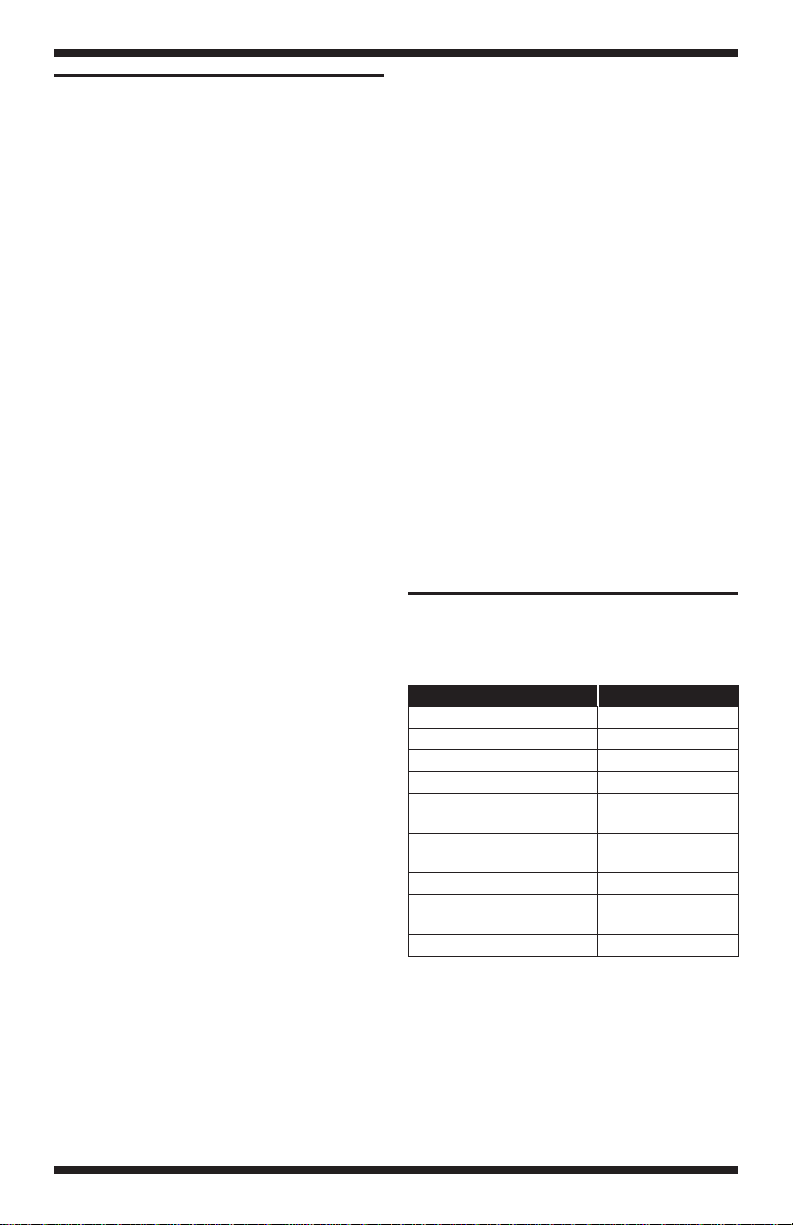

COMPONENT CONTINUITY TEST

Disconnect the wire harness and measure

resistance using the following table:

COMPONENT RESISTANCE

Wire Harness continuity

Power Cord continuity

Hot Water Valve

Cold Water Valve

Motor black/white and

red terminals

Motor black/white and

yellow terminals

Drain Pump

Brake Actuator –

on traction

Brake Actuator – at rest

890–1090 Ω

890–1090 Ω

5.32–6.12 Ω

5.32–6.12 Ω

24–28 Ω

710–869 Ω

403–493 Ω

level fill task.

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 326038065

PAGE 4 TECH SHEET - DO NOT DISCARD

CONTROL BOARD REMOVAL OR

REPLACEMENT

IMPORTANT:Electrostatic(static electricity)

discharge may cause damage to electronic

control assemblies. See page 1 for details.

NOTE: Be sure to perform the Diagnostic

Tests before replacing the control board.

To remove Electronic Control Board (PCB)

and Interface Board:

1. Unplug washer or disconnect power.

2. Remove the Top.

3. Remove the PCB’s protective covering.

4. Pull out the connectors from the PCB

terminals.

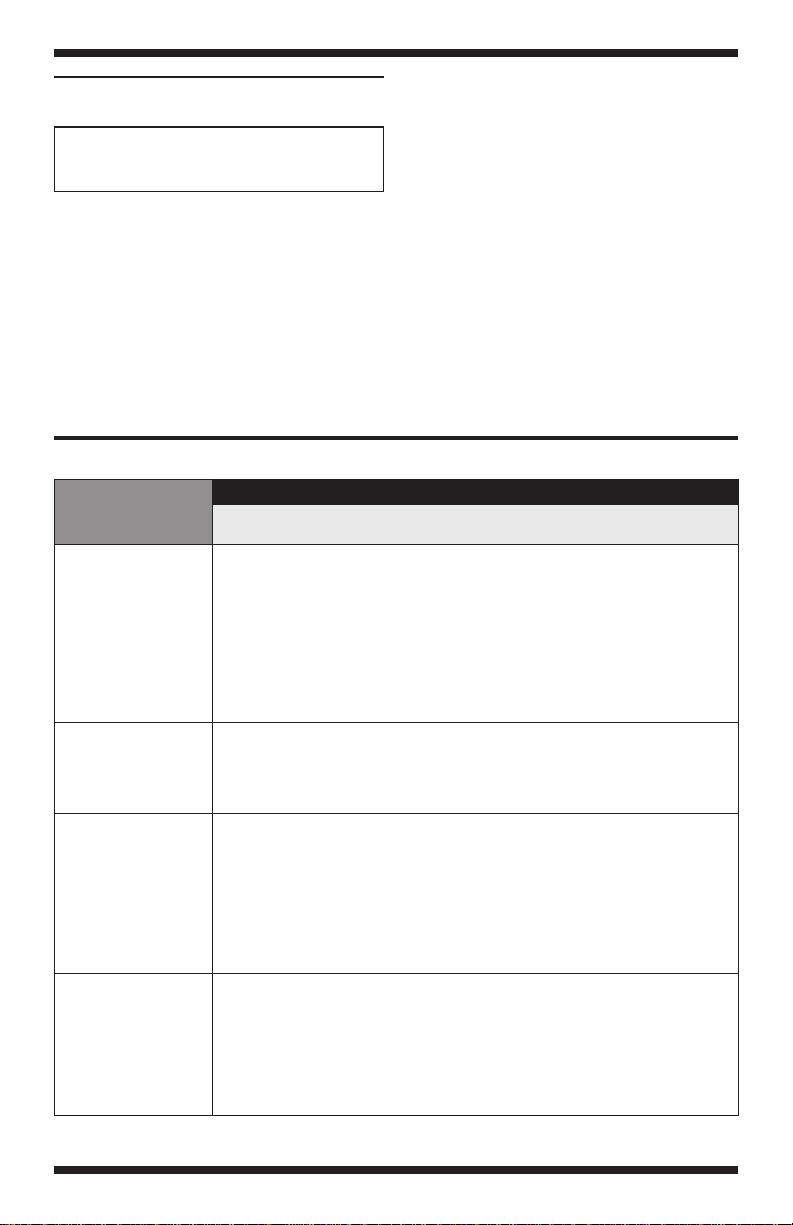

TROUBLESHOOTING GUIDE

PROBLEM

WON’T POWER UP

LEDS DON’T LIGHT

WON’T START CYCLE

WON’T FILL

NOTE: Possible Cause/Tests MUST be performed in the sequence shown

for each problem.

1. Press START/OFF button.

2. Open and close the lid.

3. Unplug washer or disconnect power.

4. Check water connections to the unit and within the unit. Check for plugged

screen in water source.

5. Check that unit is plugged into a working outlet and for blown fuses.

6. Check installation.

7. Check continuity of lid switch.

8. Check wiring harness connections.

9. Check the PCB by running the Diagnostic Test.

2. Check that unit is plugged into a working outlet and for blown fuses.

3. Unplug washer or disconnect power.

4. Check continuity of line cord and coil.

5. Check harness connections to Electronic Control board (PCB).

6. Check the PCB by running the Diagnostic Test.

1. Unplug washer or disconnect power.

2. Check continuity of lid switch.

3. Check that water pump is clear of foreign objects and not plugged or

damaged.

4. Check the brake lining for foreign objects or wear.

5. Check inlet valve for abnormal condition. See “Won’t Fill.”

6. Check motor for abnormal condition. See “Motor doesn’t run.”

7. Check wire harness connections.

8. Check the PCB by running the Diagnostic Test.

1. Unplug washer or disconnect power.

2. Check installation. Verify hot and cold water faucets are open.

3. Check inlet valves.

4. Check water connection to the unit and within the unit. Check for plugged

screen in water source.

5. Check continuity of lid switch.

6. Replace the water inlet valve.

7. Check the PCB by running the Diagnostic Test.

5. Remove the six screws fastening the PCB

and the Interface Board.

6. Remove each board from the support.

To reassemble PCB and Interface Board:

1. Place the PCB and Interface Board into the

support.

2. Use the six screws to fasten the boards

together.

3.

Attach the connectors to the PCB terminals.

4. Secure the PCB’s protective covering in

place.

5. Secure the Top in place.

6. Plug in washer or reconnect power.

POSSIBLE CAUSE/TEST

PART NO. 326038065 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 5

TROUBLESHOOTING GUIDE

PROBLEM

MOTOR DOESN’T

RUN

WON’T AGITATE

WON’T DRAIN

WON’T SPIN

WATER DRAINS

BEFORE END OF

CYCLE

WATER LEVEL

OVERFLOWS

NOTE: Possible Cause/Tests MUST be performed in the sequence

shown for each problem.

1. Unplug washer or disconnect power.

2. Check Installation.

3. Check continuity of motor.

4. Check continuity of lid switch.

5. Discharge and connect capacitor to an ohmmeter in Rx100 scale

(“0” to “infinite”).

6. Check continuity of coil.

7. Check continuity of motor.

8. Check wiring harness connections.

9. Check the PCB by running the Diagnostic Test.

1. Unplug washer or disconnect power.

2. Check continuity of lid switch.

3. Check continuity of pressure switch.

4. Check continuity of motor.

5. Check drain hose.

6. Check brake actuator.

7. Check mechanism assembly.

8. Check wire harness connections.

9. Check the PCB by running the Diagnostic Test.

1. Check hose installation.

2. Unplug washer or disconnect power.

3. Check continuity of lid switch.

4. Check wire harness connections.

5. Check continuity of pressure switch.

6. Check that drain hose and drain pump filter are clear of foreign objects.

7. Check continuity of drain pump.

8. Check the PCB by running the Diagnostic Test.

1. Make sure right amount of detergent was used.

2. Unplug washer or disconnect power.

3. Check continuity of lid switch.

4. Tighten the wedge.

5. Check continuity of brake actuator.

6. Check continuity of wiring harness.

7. Check continuity of pressure switch.

8. Check that water pump is clear of foreign objects and not plugged or

damaged.

9. Check motor for abnormal condition. See “Motor doesn’t run.”

10. Check mechanism assembly.

11. Check the PCB by running the Diagnostic Test.

1. Check hose installation. Minimum height 33" (85 cm) from washer to base.

2. Unplug washer or disconnect power.

3. Check the PCB by running the Diagnostic Test.

1. Clothes were placed in basket after fill. Place clothes before filling.

2. Check hose installation.

3. Unplug washer or disconnect power.

4. Check pressure switch continuity.

5. Check seal installation.

6. Check that air dome is clear of foreign objects and not plugged.

7. Check inlet water valve installation.

8. Verify the unit is level.

9. Check pump drain system.

10. Check operating pressure switch.

11. Check the PCB by running the Diagnostic Test.

POSSIBLE CAUSE/TEST

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 326038065

Loading...

Loading...