Page 1

WHIRLPOOL CONSUMER SERVICES

October 2001

Model AWM6100

WHIRLPOOL AUSTRALASIA

CONSUMER SERVICES

SERVICE MANUAL

FRONT LOAD

WASHING MACHINE

Model AWM6100

Version 8570 610 53000

Copyright © 2001 Whirlpool (Australia) Pty. Limited

All rights strictly reserved. Reproduction or issue to third parties in any form whatsoever is

not permitted without written authority of Whirlpool (Australia) Pty. Limited

Whirlpool is a registered trademark of Whirlpool U.S.A.

This documentation is intended only for qualified technicians who possess the required qualifications and

are aware of the regulatory requirements applicable to servicing electrical appliances.

Whirlpool (Australia) Pty Limited Part No. SM3022

A. B. N. 28 003 578 023

Page 2

WHIRLPOOL CONSUMER SERVICES

BLANK PAGE

Model AWM6100

Page 2 of 22

Page 3

WHIRLPOOL CONSUMER SERVICES

CONTENTS

TECHNICAL DATA 4 - 5

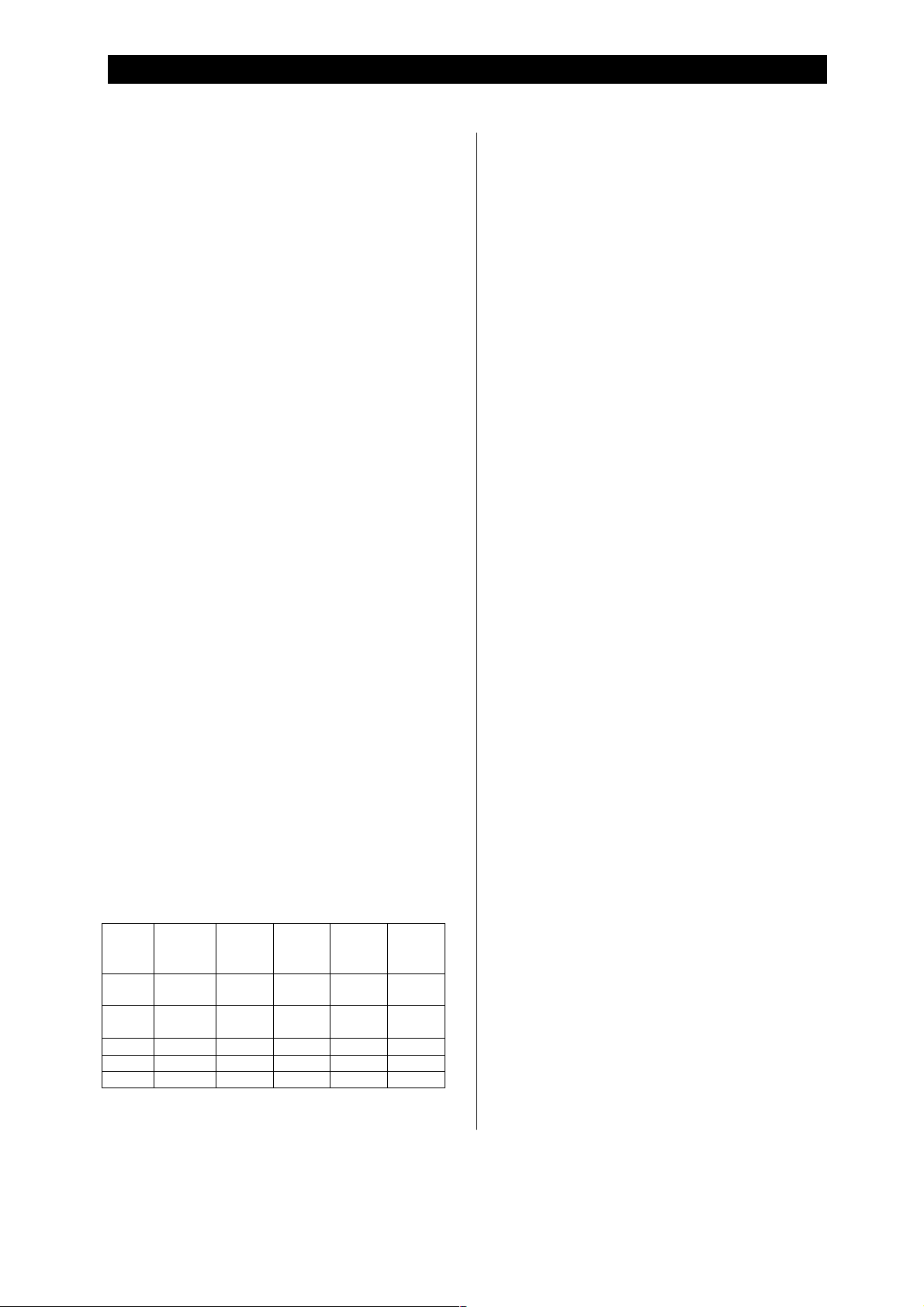

EXPLODED VIEW - CABINET 6

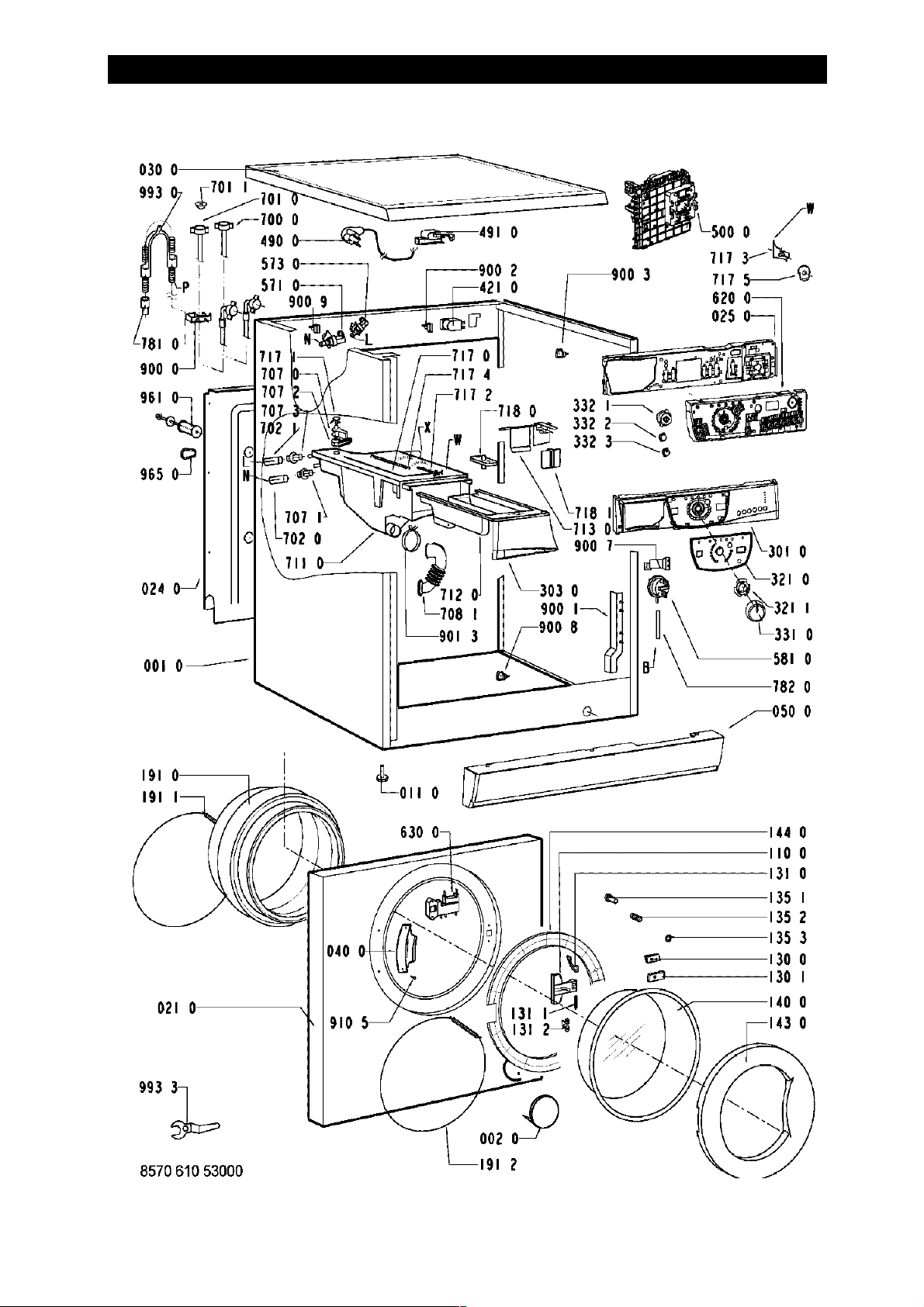

EXPLODED VIEW - DRUM 7

Model AWM6100

Page 3 of 22

Page

SPARE PARTS LIST 8 - 10

WIRING DIAGRAM 11

CIRCUIT DIAGRAM 12

PROGRAM DIAGRAM - Cotton 13

PROGRAM DIAGRAM - Synthetic 14

PROGRAM DIAGRAM - Delicate 15

PROGRAM DIAGRAM - Wool and Silk 16

PROGRAM DIAGRAM - Spinning Profiles 17

FAULT DIAGNOSIS 18

TEST SEQUENCE 19

FAILURE DURING NORMAL OPERATION 20

FAULT CODES 20

ADJUSTING DISTRIBUTION NOZZLE 21

TIMER CONNECTIONS 22

Page 4

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

TECHNICAL DATA

Door lock

Dimensions

Height 845 mm

Width 595 mm

Depth 620 mm

Weight

Nett 73 kg

Mains Connection

Voltage 230 - 240 V

Frequency 50 Hz

Power consumption 2.3 kW

Lock time (20 °C) 3 - 6 s

Unlock time 60 - 90 s

Voltage 230 - 240 V

Rated current:

Contact 4 - 5 16 (4) A

Heating element

Heating Tubular heating element with

NTC - sensor

Rated Voltage 230 - 240 V

Rated power 2050 W

Resistance 22 - 28 Ω

Page 4 of 22

Drum

Volume 53 l

Capacity of dry laundry

Cotton/coloured 6 kg

Cotton rapid 3 kg

Cotton short 6 kg

Easy care 2.5 kg

Easy care rapid 1.5 kg

Easy care short 2.5 kg

Delicate 1.5 kg

Wool 1 kg

Water Level (as sensed by the pressure

switch)

Level 1

Switching point 60± 5 mmWc

Reset point 35± 5 mmWc

Overflow 280 ± 20 mmWc

Water (level visible inside the drum)

Level 1

Switching point 25 - 39 mm

Overflow 267 - 306 mm

Nominal currents

Contacts

11 - 12 4 (4) A

11 - 14 16 (4) A

11 - 16 1 (1) A

Resistance NTC :

0°C 35.9 κΩ

30°C 9.8 κΩ

40°C 6.6 κΩ

50°C 4.6 κΩ

60°C 3.2 κΩ

70°C 2.3 κΩ

95°C 1.1 κΩ

Inlet valve - Cold/hot fill :

Water temp (max) 60 °C

Rated flow <100 kPa 4 l/min

Pressure range 50 - 1000 kPa

Nominal voltage 220 - 240 V

Frequency 50 Hz

Minimum starting voltage:

< 600 kPa 160 V

600 - 1000 kPa 170 V

Nominal current 35 mA

Nominal input 6 VA

Nominal (20 °C) 3.4 - 4.5 kΩ

Drain pump (synchronous)

Nominal Voltage 230 - 240 V

Nominal current 0,3 A

Nominal power 34 W

Frequency 50 Hz

Resistor (coil) 155 ± 7% Ω

Motor protection 170 °C

Capacity(H=1,25m) 14 ± 2 l/min

Page 5

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

TECHNICAL DATA (Cont.)

Program timer

Type SC1

Timer basic 4619 712 52201

Timer programmed 4619 744 80302

Nominal voltage 230 - .240 V

Frequency 50 Hz

Harness Connectors (See circuit

diagram)

OA4.1 - OA4.2 5. Option

OA4.3 - OA4.4 6. Option

OB4.1 - OB4.2 3. Option

OB4.3 - OB4.4 4. Option

OC4.1 - OC4.2 1. Option

OC4.3 - OC4.4 2. Option

SLT3.1 - SLT3.3 Temp.selector

SLS4.1 - SLS4.4 Spin speed selector

VCF3.1 - VCF3.3 Valve (cold water)

VHF3.1 - VHF3.3 Valve (hot water)

Pi5.1 = negative supply

Pi5.2 = data

Pi5.3 = clock

Pi5.4 = positive supply

Pi 5.5 = negative supply

PL3.1 - PL3.3 Pilot lamp

Connector

M7.1 - M7.7 Motor

DP2.1 - DP2.2 Pump

SET2.1 - SET2.2 NTC

DSS3.1 - DSS3.3 Door switch

PR2.1 - PR2.2 Pressostat

Speeds

Wash speed 54 rpm

Ramp speed 95 rpm

Spin speed 1200 rpm

Ambient Temperatures

Ambient temperature up to 70 °C

Storage temperature up to 85 °C

Output

Motor M7.6 - DSS 3.2 >40 V

in pump step AQ2.1 -DSS 3.2 240 V

NTC not measurable

Pump DP2.1 -DP2.2 240 V

Doorlock DSS3.1 -DSS 3.3 240 V

Pressostat E4 - E2 240 V

- empty PR2.1 - E2 240 V

- full PR2.2 - E2 240 V

Valve (Rast 2,5) V2.1 - V2.2 >170 V

Options not measurable

Display module Pi5.1 - Pi5. 5 V

Pi5.4 - Pi5.5 12 V

Motor

Type MCA52/64 - 148 t.f.

WHE 0

Belt ratio i = 1 : 15.9

Resistance contacts

6 - 7 68.7± 7% Ω

4 - 5 2.15± 7% Ω

2 - 3 1.89± 7% Ω

1 - 3 0.84± 7% Ω

Page 5 of 22

Single connector

HE2.1 - HE2.2 Heating element

PS2.1 - PS2.2 Pressostat

SM3.2 - SM3.3 Mains switch (3 fold

connector)

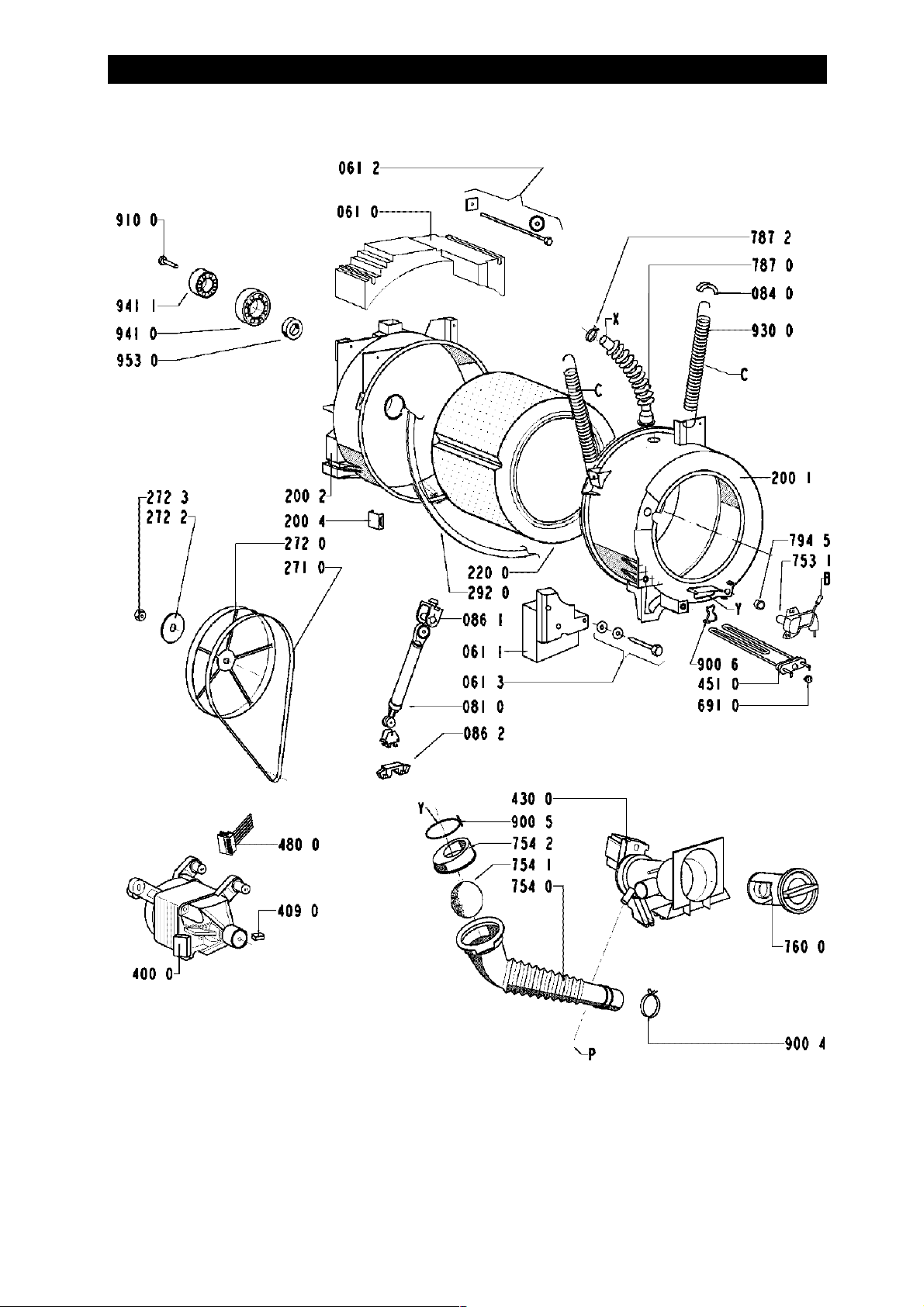

Program 32 positions

Step Cotton

/

Colour

Pre

wash

Main

wash

Rinse 22-28 22-28 22-28 22-28 22-28

Spin 29-31 29-31 29-31 29-31 29-31

Stop 32 32 32 32 32

02-06 03-06 04-06 - -

07-21 12-21 14-21 17-21 18-21

Easy

care

Delicate

Wool Silk

Page 6

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

EXPLODED VIEW - CABINET

Page 6 of 22

Page 7

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

EXPLODED VIEW - DRUM

Page 7 of 22

8570 610 53000

Page 8

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

PARTS LIST

Item Part No Description

001 0 4819 440 19716 Cabinet

002 0 4812 440 19343 Flap

011 0 4819 462 48472 Foot

021 0 4812 440 19818 Front

024 0 4812 440 18998 Panel, rear

025 0 4812 404 38551 Support control board VBL WH

030 0 4812 310 18586 Table top VBL WH

040 0 4812 417 18787 Hinge

050 0 4812 440 10406 Pedestal VBL, 53 l

061 0 4812 466 88458 Counter weight upper

061 1 4812 466 88459 Counter weight front

061 2 4819 310 39227 Mounting kit Weight top

061 3 4819 310 39228 Mounting kit Weight bottom

081 0 4812 529 18038 Shock absorber until 1200

084 0 4812 466 58001 Anti rattle, support spring

086 2 4812 401 18412 Stopper

110 0 4812 498 18139 Handle, door white

130 0 4812 417 28047 Plate Door lock

130 1 4812 417 28048 Plate, Doorlock, Lower

131 0 4812 417 28046 Lock Door

131 1 4812 417 28045 Pin Door Lock

131 2 4812 492 58022 Spring Door Lock

135 1 4812 498 18137 Knob Door safety

135 2 4812 491 48004 Spring

135 3 4812 290 68153 Holder, adjust. Door safety switch

140 0 4812 450 68219 Door glass

143 0 4812 440 19782 Glass door frame VBL WH

144 0 4812 440 19589 Frame, door glass DE-WT

191 0 4812 460 68527 Door bellow standard

191 0 4812 460 68532 Door bellow WH grease resistance

191 1 4812 492 18017 Strap

191 2 4819 530 58059 Ring

200 1 4812 418 18283 Tub 53l front

200 2 4812 418 18318 Tub rear

200 4 4812 290 88054 Clamp for tub WH

220 0 4812 418 18281 Drum 53l, 1000

271 0 4812 358 18056 V-ribbed belt WH 1250 J5

272 0 4812 528 58027 Pulley DIAM. 298

272 2 4812 532 18024 Washer

272 3 4812 505 18371 Nut M 12

292 0 4812 530 58101 Gasket Tub

301 0 4812 452 10744 Control panel

303 0 4812 498 78114 Handle

321 0 4812 452 10745 Insert panel

321 1 4812 532 98011 Fastener, Inlay

Page 8 of 22

Page 9

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

PARTS LIST (Cont.)

Item Part No Description

331 0 4812 414 58111 Knob, timer VBL complete

332 1 4812 513 18097 Push button, start VBL WH

332 2 4812 513 18098 Push button, spin speed VBL WH

332 3 4812 513 18099 Push button option VBL WH

400 0 4812 361 18301 Motor 800/1000 MCA 52

409 0 4812 362 48004 Brush, carbon motor CESET

421 0 4812 121 18142

430 0 4812 310 38525 Pump, drain with thermal protection

451 0 4812 259 28766 Heating element 240V, 53l

490 0 4812 310 18404 Kit cable, mains 5m 3x1,5

491 0 4812 321 28367 Strain relief

500 0 4812 282 18788 Timer SC1 (EI,PW,IR,RH)

571 0 4812 281 28382 Valve, magnet cold

573 0 4812 271 28449 Valve, magnet hot

581 0 4812 271 28441 Pressostat

620 0 4812 452 10374 Module Timer B S/DS

630 0 4812 280 58026 Door lock 3 TABS

691 0 4812 282 18702 Sensor NTC (SC1)

700 0 4812 530 28869 Hose, inlet hot

701 0 4819 530 28848 Hose, inlet

701 1 4819 466 69704 Gasket and filter

702 0 4819 530 29019 Hose internal

702 1 4819 530 28971 Hose, inlet internal

707 0 4812 526 48031 Nozzle Distribution

707 1 4812 526 48028 Nozzle

707 2 4812 526 48029 Nozzle

707 3 4812 526 48035 Nozzle hot

708 1 4812 530 48143 Bend

711 0 4812 418 88054 Detergent disp. 3C, 53l

712 0 4812 418 68198 Drawer 3 Compartment VBL

713 0 4812 418 88019 Flap Detergent Container

717 0 4812 418 78925 Bowden cable

717 1 4812 321 38013 Lever, Nozzle

717 2 4812 321 38012 Holder, adjustable

717 3 4812 278 88017 Slide

717 4 4812 492 38359 Spring, Nozzle

717 5 4812 282 18807 Cam for 3 Compartment drawer, SC1/VBL/WH

718 0 4812 526 48051 Siphon

718 1 4812 418 88018 Accessory

753 1 4819 418 68234 Chamber, air

754 0 4812 530 28826 Drain hose

754 1 4812 530 28832 Lock eco

754 2 4812 530 28829 Flange eco

760 0 4812 480 58105 Filter set pump

781 0 4819 530 28847 Drain hose

Interference filter 1,00 µF

Page 9 of 22

Page 10

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

PARTS LIST (Cont.)

Item Part No Description

782 0 4812 530 28827 Hose, pressostat

787 0 4812 530 28813 Steam hose

787 2 4819 401 18868 Clamp, hose 26,8 mm

794 5 4812 530 58095 Gasket, air trap

900 0 4812 255 18204 Holder, hose outlet

900 1 4812 290 88049 Bracket

900 2 4812 290 88077 Cable, clamp

900 3 4812 401 18446 Cable, clamp

900 4 4819 401 18872 Clamp, hose

900 5 4819 401 18529 Clamp, hose

900 6 4812 401 18444 Support, heating element

900 7 4812 256 98031 Holder, pressostat

900 8 4819 401 18823 Clamp

900 9 4819 404 78449 Support

901 3 4812 401 18414 Clamp, hose

910 0 4812 502 18383 Screw, Torx T40 M 8X 25

910 5 4812 502 18516 Screw 4,2 x 13

930 0 4819 492 38139 Spring, Suspension

941 0 4812 520 28004 Bearing, ball 6206

941 1 4812 520 28066 Bearing, ball 6204

953 0 4812 530 58099 Shaft seal 1200

961 0 4819 532 68829 Spacer

965 0 4812 466 68545 Cover BK/WH

993 0 4819 530 29028 Bow

993 3 4812 395 58004 Tool

Page 10 of 22

Page 11

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

WIRING DIAGRAM

00 Black

11 Brown

22 Red

33 Orange

44 yellow

55 Green

66 Blue

77 Violet

88 Grey

99 White

45 Yellow/Green

Page 11 of 22

Page 12

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

CIRCUIT DIAGRAM

Page 12 of 22

Page 13

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

PROGRAM DIAGRAM - Cotton

Page 13 of 22

Page 14

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

PROGRAM DIAGRAM - Synthetic

Page 14 of 22

Page 15

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

PROGRAM DIAGRAM - Delicate

Page 15 of 22

Page 16

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

PROGRAM DIAGRAM - Wool and Silk

Page 16 of 22

Page 17

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

PROGRAM DIAGRAM - Spinning Profiles

Page 17 of 22

Page 18

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

Page 18 of 22

FAULT DIAGNOSIS

1. The diagnostic tests must be performed on the machine without a wash load because the

out of balance detection system is disabled.

2. Set the cycle selector to "DRAIN"

3. Press :

a) "RINSE HOLD" button twice

b) "INTENSIVE RINSE" button twice

c) "START" button once,

4. The control panel will now display :

• 1000 speed LED on (Does not change for duration of the test sequence).

• "PREWASH" programme sequence LED on

• "WASH" programme sequence LED on

• "RINSE" programme sequence LED on

• "RINSE HOLD" programme sequence LED on

• "DRAIN/SPIN" programme sequence LED on - (This is Step 1 in the Table over)

5. Drain pump runs for approximately six seconds and the test sequence automatically

advances to Step 2.

6. By pressing the Prewash button once, the timer advances to step 3

Page 19

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

TEST SEQUENCE

Page 19 of 22

Pump Out

by pressing :

(See Note 1)

1 Start Pump out - - Stationary Rinse hold and

2 Advances

automatically

3 Prewash button Main

4 Easy iron button Main

5 Auto (or press

rinse hold button)

(Note 2)

6 Rinse hold button Fill via

Rinse hold button

7

Advances

8

automatically

(Note 3)

or Fill Via

:

Prewash Cold fill, no

wash

wash

Main

wash

fabric

softener

Pump out - 10s on,

Pump out - 6 min Spin Max

Temperature Time Drum

60 s (fill) Stationary Prewash button

heat

Warm fill, no

heat

Warm fill,

heat to 90°C

Cold fill, no

heat

Cold fill, no

heat

60 s (fill) Stationary Main wash fill

60 s (fill)

25 min

heat

55 s (fill) 80 s on,

60 s 80s on,

Rhythm

10 s on,

6 s off

2 s off

2s off

6s off

speed

Component(s)

Checked

Intensive rinse

buttons

and prewash fill

Heating circuit,

NTC, leakage

Easy ironing

button

Fabric softener fill

Pump

Pump, spin

LED *Step Advance to step

PWRRHD

*Programme Sequence LED's: P = Prewash W = W ash R = Rinse RH = Rinse Hold D = Drain

Note 1 Unless indicated by "Advances automatically", the test cycle can only be advanced by

pressing the appropriate button once within five minutes, otherwise the machine will

pump out and a false fault will be indicated.

Note 2. This part of the test sequence can be terminated after the fill by pressing the "Rinse

hold" button but the NTC will not be checked for accuracy.

Note 3. This part of the test sequence can be terminated at any time by changing the cycle on

the cycle selector then reselecting drain and press the start button. Once the machine

is empty of water, the start button may be pressed and held until the start button light

goes off to reset the timer ready for the next wash.

If a failure is detected during the test sequence the timer will :

1. Initiate the safety step routine :

A. Drain pump runs until pressure switch resets plus 30 seconds.

I. Main motor is turned off.

II. Water inlet valves are turned off.

III. Element is turned off

2. Stop the machine and illuminate the speed indicator LED's in a pattern to indicate the

fault code.

Page 20

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

Page 20 of 22

FAILURE DURING NORMAL OPERATION

If a failure is detected during normal operation, the machine will stop, the programme sequence

LED where the failure occurred will flash and the speed indicator LED's will illuminate in a

pattern to indicate the fault code.

FAULT CODES

Failure135679111416182021

Speed

LED's

Fault Detected Malfunction Perform the following:

1 Water not entering or not detected Check tap, cold inlet valve, pressure switch

3 Drain failure or not detecting

empty drum

5 NTC failure Check NTC

6 Tachometer failure (no motor

movement detected

7 Circuit board failure (motor triac) Replace timer

9 Drain failure Check drain pump, pressure switch, blocked

11 Electronic failure Replace timer

14 Electronic failure Replace timer

16 Control failure Replace timer

18 Control failure Replace timer

20 Control failure Replace timer

21 Control failure Replace timer

Check pressure switch, blocked drain, drain

pump

Check motor

drain

Page 21

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

Page 21 of 22

ADJUSTING DISTRIBUTION NOZZLE

1. Select any COTTON wash cycle with the prewash off and wait until water begins to enter

machine.

2. Turn the machine off at the power point.

3. Remove the machine lid.

4. Adjust the lever until the red pointer is over the index mark.

5. Replace the machine lid, turn on the power, open the detergent drawer slightly and make

sure that water is only entering the main wash (middle) compartment and that no water is

entering the fabric softener compartment.

Index

Mark

Adjustment

Lever

Page 22

WHIRLPOOL CONSUMER SERVICES

Model AWM6100

TIMER CONNECTIONS

Page 22 of 22

Loading...

Loading...