Whirlpool ADG 2900 INSTALLATION manual

FOR PREFINISHED & INTEGRATED (SINGLE & DOUBLE) MODELS

(NOTE: FOR INTEGRATED PANEL PREPARATION INSTRUCTIONS REFER TO SUPPLIED SHEET)

ELECTRICAL INFORMATION

POWER SUPPL

Y CORD

A) Care should be taken when the appliance is installed or

removed, to reduce the likelihood of damage to the power

supply cord.

B) If the power supply cord is damaged, it must be replaced by

the Manufacturer, Service Agent or a similarly qualified

person, in order to avoid a hazard.

EAR

THING INSTRUCTIONS

A) This appliance must be earthed. In the event of malfunction

or breakdown, earthing will reduce the risk of electric shock

by providing a path of least resistance for electric current.

Improper connection of the equipment-earthing conductor

can result in a risk of electric shock. Check with a qualified

electrician or service representative if you are in doubt as to

whether the appliance is properly earthed.

B) This appliance is equipped with a power supply cord having

an equipment-earthing conductor and an earthing plug. The

power supply plug must be plugged into an appropriate

outlet that is installed and earthed in accordance with all

local Codes and Regulations.

Do not modify the power supply plug provided with the

appliance - if it will not fit the outlet, have a proper outlet

installed by a qualified electrician. Do not use an extension

cord, adaptor plug or multiple outlet box.

BEFORE YOU START - DOUBLE & SINGLE MODELS

PARTS SUPPLIED

DOUBLE MODELS (INTEGRATED & PREFINISHED)

SINGLE MODELS (INTEGRATED & PREFINISHED)

T

OOLS NEEDED

Wooden Chopping Board Drill & No.2 Phillips Bit

Tape Measure No.2 Phillips Screwdriver

Spirit Level Flat Screwdriver

Safety Glasses Adjustable Wrench or M5 Socket

Utility Knife Ø50mm Hole Saw

Pencil Side Cutting Pliers

Sandpaper

(page 2 of 8)

INSTALLATION PREPARATION

ELECTRICAL PREP

ARATION

A) The switched power outlet for the appliance should be

installed in a cabinet or on a wall adjacent to the under bench

space in which the appliance is to be installed. Note: The

power outlet must be accessible after installation.

B) The power outlet should be positioned between 150mm and

450mm from the cavity.

PLUMBING & DRAINAGE PREP

ARATION

A) A readily accessible valve must be installed in the water

supply pipe.

B) If the supply pressure exceeds 1000kPa, then a pressure

limiting valve must be used.

C) Review Plumbing Options on pages 3-4. Choose a method that

best suits your needs.

CA

VITY PREPARATION

A) If installing multiple products side by side a minimum 2.5mm

clearance must be maintained around the 's.

B) On corner installations, ensure that there is a gap between

the adjacent cabinetry (e.g.door knobs) and the sides of the

open . A 12.7mm minimum gap is recommended.

C) Where the is installed under a bench top, it is

required that bare wood surrounding the is

sealed with an oil based paint or polyurethane to prevent

possible steam damage. The air in the cavity can get very hot

and humid (saturated at 65

o

C)

D) Ensure the cavity sides are plumb (vertical) as this will assist

with levelling the .

E) Ensure the cavity provides sufficient material to secure the

using the mounting tabs (refer to step 1, page 5).

If there is nothing to screw to, add something. See page 3 or

4 for screw locations.

F) The services hole MUST be immediately adjacent to the rear

lower corner of the cabinetry. If not, the hoses will prevent

the being pushed back into the cavity all the

way. The hole can be located on either side depending on the

location of the services.

R

R

R

R

R

R

R

R

INSTALLATION INSTRUCTIONS

NOTE TO THE INSTALLER

1. Read these instructions completely and carefully.

2. Installation of this requires basic mechanical and electrical skills.

3. Be sure to leave these Instructions with the Customer.

4. At the completion of the installation, the Installer must perform Final Check List as per Section 11

of these Installation Instructions.

5. Remove all packaging materials supplied with the .

NOTE T

O THE CONSUMER

Keep these Installation Instructions with your User Guide for future reference. must be securely

anchored before it is operated.

R

R

R

R

These instructions must be followed precisely to ensure correct venting and operation of the

. In

the event of a fault related to the incorrect installation, the installer will be liable for any repairs.

Before installing the , remove the house fuse or open the circuit breaker. Ensure all water connections are turned OFF. It is the responsibility of the plumber and electrician to ensure that each installation complies with all Codes and Regulations.

The MUST be installed to allow for future removal from the enclosure if service is required. The

installer is responsible for the installation. Improper installation is not covered under the Warranty.

If the is to be relocated from one installation to another it must be kept upright to avoid damage

from water spillage.

R

R

R

R

R

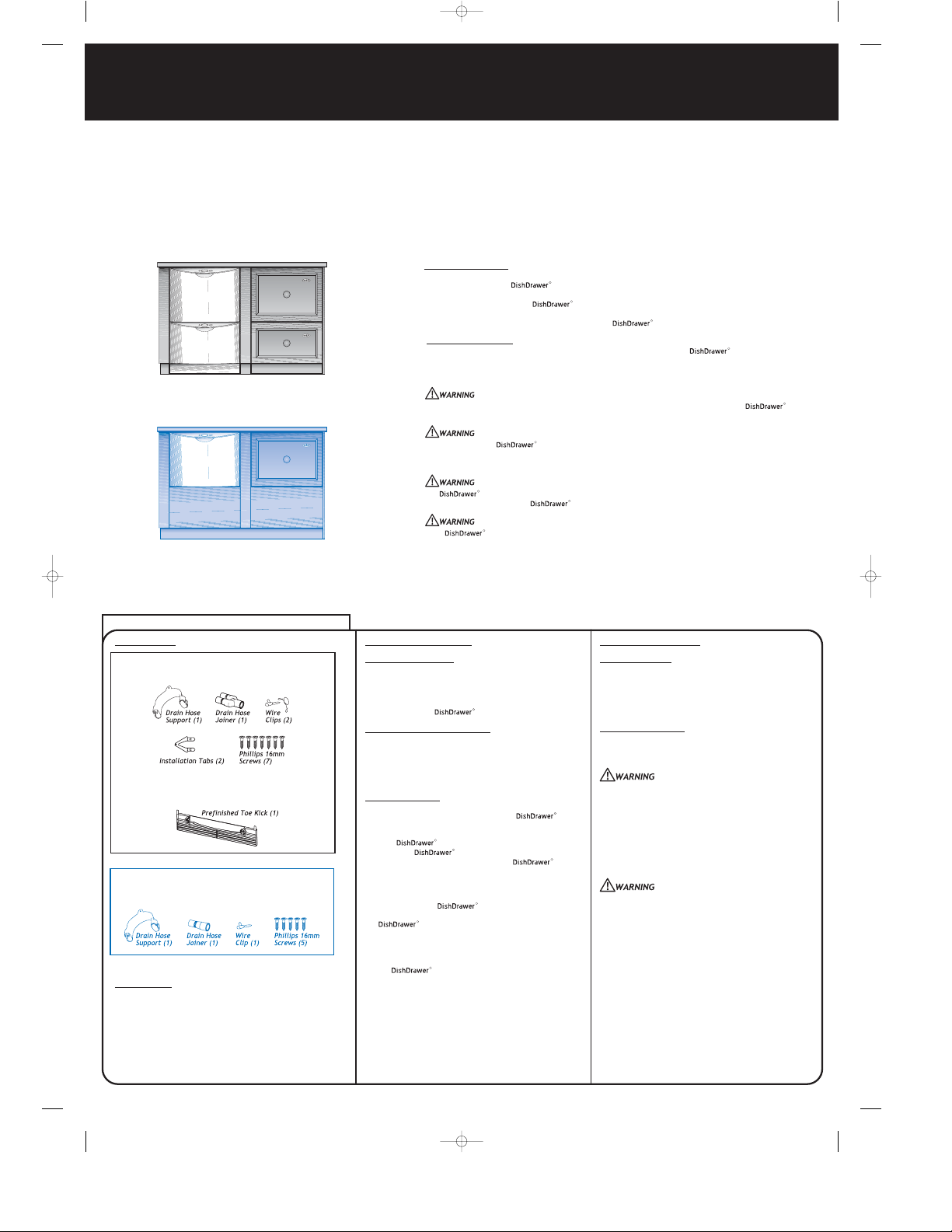

DOUBLE MODELS

MODELS Prefinished Integrated

MODELS Prefinished Integrated

SINGLE MODELS

1Gb00079 28-11-2002 18:50 Pagina 1

RRR

PLUMBING OPTIONS

Option 1 and Standpipe Ø38mm with Air Gap.

Option 2 with Waste Disposal.

Standpipe Ø38mm with Air Gap.

PLEASE NOTE: It is NOT recommended to connect the

to any part of the Waste Disposal System.

Option 3 using Sink Trap with Drain Hose Joiner.

NOTE: Prefinished Model is shown. There is no variation in plumbing

between Prefinished products and Integrated products. Option 1

and 2 are the preferred options. Options 1 & 2 or use of a Dual

Inlet

Airgap satisfy Kosher requirements.

DOUBLE MODEL

SERVICE'S SPECIFICATION

*For an Integrated the product depth is specified with an

18mm Integrated Door Panel thickness.

Water Connection

Recommended COLD (Maximum 60°C).

3/4 " BSP (GB20) to suit flat washer.

Water Softener Models

Refer to your User Guide on how to set up your water

softener.

Water Pressure

Drain Connection

Drain Hose Joiner to suit

Ø19mm ± 2mm waste tee.

Electrical Connection

230-240 VAC power outlet

9Amps Minimum.

Toe Kick Depth

Prefinished

50-65mm; Integrated 67mm less the Toe Kick Panel

thickness (Minimum Panel thickness using the supplied screws is 9mm).

# Door Front Height

Prefinished

717.5mm; Integrated 717.5mm minimum.

Length of Services

Drain hose - 2250mm

Inlet hose - 1750mm

Power supply cord - 1965mm

NOTE: Services approximately exit product

189mm from left; 550mm from front; 793mm from top.

R

R

(page 3 of 8)

THE CAVITY

NOTE: All depth measurements are taken from the front

face of the adjacent cabinetry.

Ensure the edges of the services hole are smooth or

covered.

+

Min thickness of cavity

sides is

16mm

90°

Ø50mm

services hol e

can be either

side, immediatel y

adjacent to

corner

+

+

600mm

580mm

throughout cavity

820mm-880mm

+

97mm

505mm

+

+

640.5mm

14mm

From front

of cabinetry

These marks indicate mounting tab

+

*

R

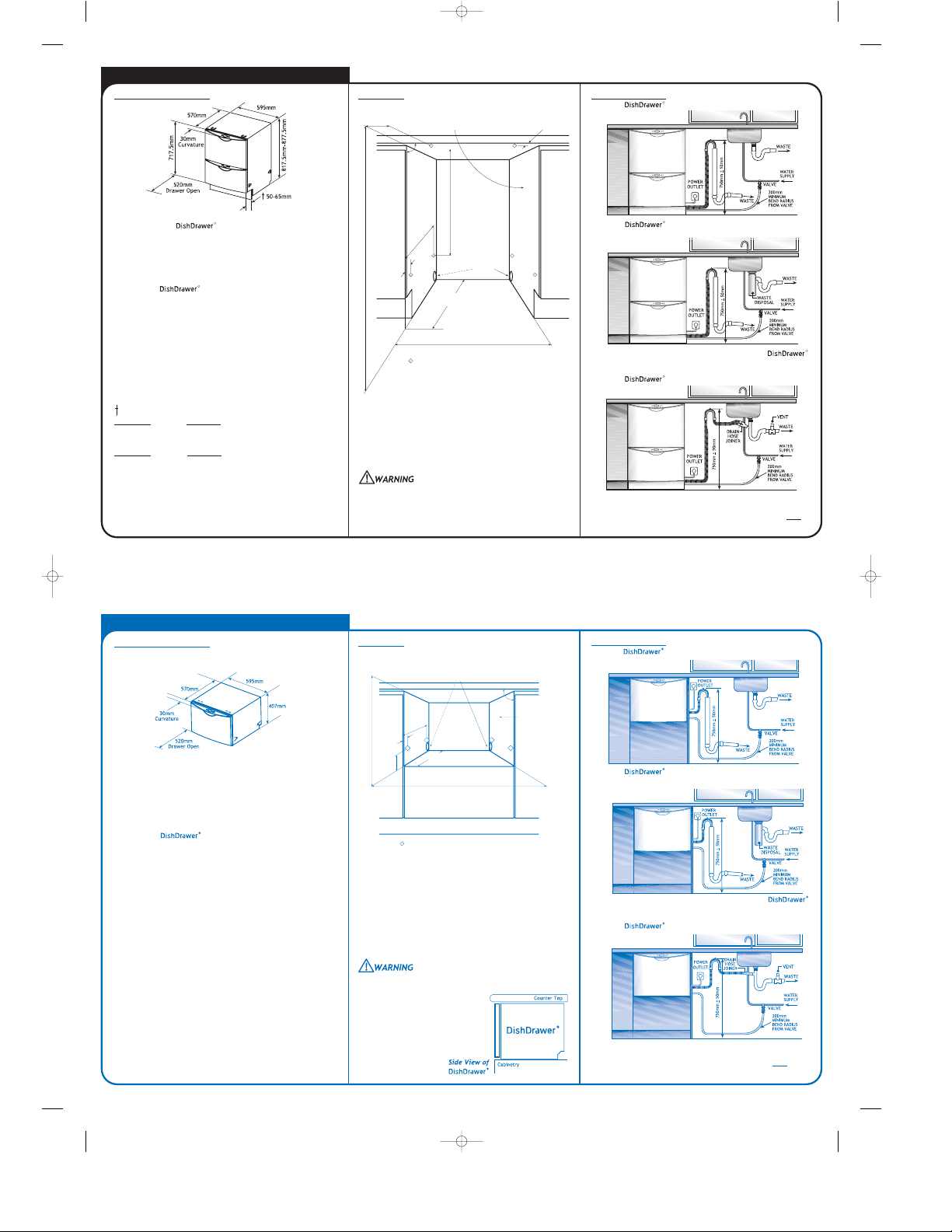

PLUMBING OPTIONS

Option 1 and Standpipe Ø38mm with Air Gap.

Option 2 with Waste Disposal.

Standpipe Ø38mm with Air Gap.

PLEASE NOTE: It is NOT recommended to connect the

to any part of the Waste Disposal System.

Option 3 using Sink Trap with Drain Hose Joiner.

NOTE: Prefinished Model is shown. There is no variation in plumbing

between Prefinished products and Integrated products. Option 1 and

2 are the preferred options. Options 1 & 2 or use of a Dual

Inlet

Airgap satisfy Kosher requirements.

SINGLE MODEL

SERVICE'S SPECIFICATION

*For an Integrated the product depth is specified with an 18mm

Integrated Door Panel thickness.

Water Connection

Recommended COLD (Maximum 60°C).

3/4 " BSP (GB20) to suit flat washer.

Water Softener Models

Refer to your User Guide on how to set up your water

softener.

Water Pressure

Drain Connection

Drain Hose Joiner to suit

Ø19mm ± 2mm waste tee.

Electrical Connection

230-240 VAC power outlet

4.5Amps Minimum.

Weight

Full 42kg Prefinished

Empty 28kg Prefinished

Length of Services

Drain hose - 2250mm

Inlet hose - 1750mm

Power supply cord - 1965mm

NOTE: Services approximately exit product

189mm from left; 550mm from front;

393mm from top.

(page 4 of 8)

THE CA

VITY

NOTE: All depth measurements are taken from the front

face of the adjacent cabinetry.

NOTE: To align drawer front to adjacent cabinetry, the

product to counter top clearance can be increased

from 3mm.

Ensure the edges of the services hole are smooth or covered.

Cabinetry must

not extend beyond

cavity base

*

505mm

+

Min thickness

of cavity

sides is 16mm

90°

Ø50mm services hole can be either side,

immediately adjacent to corner

+

600mm

580mm

throughout cavity

410mm

67mm

97mm

+

+

These marks indicate mounting tab

screw locations (refer to step 1 page 5)

+

#

Maximum Minimum

Water Softener Models 1000kPa (145 p.s.i.) 100kPa (14.5 p.s.i.)

Other Models 1000kPa (145 p.s.i.) 30kPa (4.3 p.s.i.)

Maximum Minimum

Water Softener Models 1000kPa (145 p.s.i.) 100kPa (14.5 p.s.i.)

Other Models 1000kPa (145 p.s.i.) 30kPa (4.3 p.s.i.)

1Gb00079 28-11-2002 18:50 Pagina 2

Loading...

Loading...