Whirlpool ACH 6601, ACH, 7601, ACH 9601 NSTRUCTIONS AND ADVICE FOR INSTALLING, USING AND SERVICING OF COOKERS

Page 1

Page 2

INSTRUCTIONS AND ADVICE FOR INSTALLING,

תירבעשומיש תוארוה

תירבע

USING AND SERVICING OF COOKERS

cm60x60 - cm70x60 and cm 90x60

םירונתה תקוזחתו שומיש ,הנקתהל עדימו תוארוה

מ"ס 90x60 -ו מ"ס 70x60 - מ"ס 60x60

ACH 6601

ACH 7601

ACH 9601

ENGLISH Instructions for use Page 3-30

31-57

םידומע

שומיש תוארוה

תירבע

Page 3

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS 4-7

DESCRIPTION OF THE APPLIANCE 8-10

USER’S INSTRUCTIONS 11-17

TROUBLESHOOTING 18

TECHNICAL FEATURES 19-21

INSTRUCTIONS FOR THE INSTALLER 22-28

AFTER-SALES SERVICE 29

3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

This manual and the appliance itself provide important safety advices, to be read and observed

at all times.

All safety advices give specic details of the potential risk present and indicate how to reduce

risk of injury, damage and electric shock resulting from improper use of the appliance. Carefully

observe the following instructions:

• The appliance must be disconnected from the power supply before carrying out any installation

work.

• The power cable must be long enough for connecting the appliance, once tted in its housing, to

the power supply socket.

• For installation to comply with current safety regulations, an all-pole disconnect switch with

minimum contact gap of 3 mm must be utilized.

• Do not use multiple plug adapters or extension leads.

• Do not pull the power supply cable in order to unplug the appliance.

• The electrical components must not be accessible to the user after installation.

• During and after use, do not touch the heating elements or interior surfaces of the appliance - risk

of burns. Do not allow the appliance to come into contact with cloths or other ammable materials

until all the components have cooled suciently.

• At the end of cooking, exercise caution when opening the appliance door, letting the hot air or

steam exit gradually before accessing the oven. When the appliance door is shut, hot air is vented

from the aperture above the control panel. Do not obstruct the vent apertures.

• Use oven gloves to remove pans and accessories, taking care not to touch the heating elements.

• Do not place ammable materials in or near the appliance: a re may break out if the appliance is

inadvertently switched on.

• Do not heat or cook sealed jars or containers in the appliance. The pressure that builds up inside

might cause the jar to explode, damaging the appliance.

• Do not use containers made of synthetic materials.

• Overheated oils and fats catch re easily. Always remain vigilant when cooking foods rich in fat and

oil.

• Never leave the appliance unattended during food drying.

• If alcoholic beverages are used when cooking foods (e.g. rum, cognac, wine), remember that alcohol

evaporates at high temperatures. As a result, there is a risk that vapours released by the alcohol may

catch re upon coming into contact with the electrical heating element.

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

You have purchased one of our products

for which we thank you. We are condent

that this new appliance, modern, functional

and practical, made with top quality

materials, will meet all your demands. This

new appliance is easy to use but before

installing and using it, it is important to

read this handbook through carefully. It

provides information for a safe installation,

use and maintenance. Keep this handbook

in a safe place for future reference.

The manufacturer reserves the right to

make all the modications to its products

that it deems necessary or useful, also

in your interests, without prejudicing

its essential functional and safety

characteristics. The manufacturer cannot

be held responsible for any inaccuracies

due to printing or transcription errors that

may be found in this handbook.

N.B.: the pictures shown in the gures in

this handbook are purely indicative.

• The installation, adjustments,

conversions and maintenance operations

listed in section «INSTRUCTIONS FOR

THE INSTALLER» must only be carried

out by qualied personnel .

• The installation of all-gas and combi

appliances must comply with the

standards in force.

• The appliance must only be used for

its original purpose, that is, cooking for

domestic use. Any other use is considered

improper and, as such, dangerous.

• The manufacturer cannot be held

responsible for any damage to persons

or property resulting from an incorrect

installation, maintenance or use of the

appliance.

• Once the packaging has been removed

from the outer surfaces and the various

inner parts, thoroughly check that the

appliance is in perfect condition. If

you have any doubts do not use the

appliance and call in a qualied person.

• The packaging materials used

(cardboard, plastic bags, polystyrene

foam, nails, etc.) must not be left with in

easy reach of children because they are

a potential hazard source. All packaging

materials used are environmentallyfriendly and recyclable.

• The electrical safety of this appliance

is only guaranteed if it is correctly

connected to a suitable earth system,

as prescribed by the electrical safety

standards. The manufacturer disclaims all

responsibility if these instructions are not

followed. Should you have any doubts,

seek the assistance of a qualied person.

• Before connecting the appliance ensure

that the rating plate data corresponds to

that of the gas and electricity supply (see

section «TECHNICAL FEATURES»).

The use of any electrical appliance

requires certain fundamental rules to

be observed:

• Do not touch the appliance with wet or

damp hands or feet.

• Do not use the appliance when barefoot.

• Do not pull the power cable to unplug

the appliance from the mains socket.

• Do not leave the appliance exposed to

the atmosphere (rain, sun, etc.).

WARNING: The appliance and its

accessible parts become hot during use.

Care should be taken to avoid touching

heating element. Children less than 8

years of age shall be kept away unless

continuously supervised.

The oven door glass and the accessible

5

Page 6

IMPORTANT SAFETY INSTRUCTIONS

parts will become hot when in use. To

avoid burns and scalds young children

should be kept away.

Young children should be supervised

to ensure that they not play with the

appliance.

This appliance can be used by children

aged from 8 years and above and persons

with reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they have been given

supervision or instruction concerning

use of the appliance in a safe way and

understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not

be made by children without supervision.

WARNING: ln order to prevent accidental

tipping of the appliance, for example by a

child climbing over the open oven door,

or too high weights are leant on the open

oven door, two chains must be screwed

on the back on the cooker and xed to the

wall with hooks. Ensure the chains are taut.

Please refer to instructions for installation.

Unattended cooking on a hob with fat or

oil can be dangerous and may result in re.

• Never try to extinguish a re with

water, but switch of the appliance and

then cover ame e.g. with a lid or a re

blanket .

• Danger of re: Do not store items on the

cooking surfaces.

• Do not use harsh abrasive cleaners or

sharp metal scrapers to clean the oven

glass door since they can scratch the

surface, which may result in shattering of

the glass. Never use sponges or abrasive

products, and solvents to remove stains

or adhesives on the painted or stainless

steel surfaces.

• The appliance is not intended to be

operated by means of an external timer

or separate remote-control system.

• Ensure that the appliance is switched o

before replacing the lamp to avoid the

possibility of electric shock.

• Do not use a steam cleaner to clean a

hob, oven or range.

• The appliance is to be placed directly on

the oor and shall not be mounted on

a base.

• Keep the appliance clean. Food residues

can be a re hazard.

• When the oven is not in use, do not use

it to store foodstus or containers: if it

is accidentally turned on, it can cause

damage and accidents.

• If an electrical socket near the appliance is

used, ensure that the cables of any other

electrical appliances do not come into

contact with the oven and are at a sucient

distance from the hot parts of the oven.

• After using the appliance ensure that

all the controls are in the o or closed

position, and check that the “0” on the

knob corresponds with the symbol “•“

printed on the front panel.

• Before carrying out any kind of

cleaning, adjustment, conversion or

maintenance operation, disconnect

the appliance from the electricity

supplies.

• In case of problems and/or malfunction,

turn o the appliance and disconnect

it from the mains electricity supplies,

Do not attempt to tamper with it. Any

repairs, or adjustments must be carried

out exclusively by qualied personnel.

For this reason, we recommend that you

to contact your nearest Service Centre

specifying the model of your appliance

6

Page 7

IMPORTANT SAFETY INSTRUCTIONS

and the type of problem.

The appliance was designed and made in

accordance with the European standards

listed below:

=> EN 30-1-1, EN 30-2-1 and EN 437

plus subsequent amendments

(gas)

=> EN 60 335-1 and EN 60 335-2-6 (electrical)

plus relative amendments

The appliance complies with the prescriptions

of the European Directives as below:

=> 2006/95 EC concerning electrical safety

(BT).

=> 2004/108 EC concerning electromagnetic

compatibility (EMC).

=> 2009/142/ EC concerning gas safety.

Oven accessories that could come into

contact with foodstus are made with

materials that comply with the provisions

of the 89/109 EC directive dated 21/12/88.

This product complies with EU Directive

2002/96/EC.

The crossed-out dustbin symbol reported on

the appliance indicates that the appliance

must be disposed of separately from other

domestic refuse at the end of its useful life.

It must therefore be delivered to a waste

recycling centre specically for electric and

electronic equipment or returned to the

retailer at the moment of purchase of a new

equivalent appliance.

The user is responsible for delivering the

appliance to the appropriate collection

centre at the end of its useful life, Failure to

do so may result in a ne, as provided for by

laws governing waste disposal.

Dierential collection of waste products

for eventual recycling, treatment and

environmentally friendly disposal helps

reduce possible negative eects on the

environment and health, and also enables

the materials making up the product to be

recycled.

For more detailed information on the

available refuse collection systems, refer

to the local Municipal Solid Waste disposal

centre or the shop where the product was

purchased.

Producers and importers are responsible

for fullling their obligations as regards

recycling, treatment and environmentally

friendly disposal by directly or indirectly

participating in the collection system.

7

Page 8

DESCRIPTION OF THE APPLIANCE

PRESENTATION

The cookers are tted with a hob to gas,

and a electric oven;. the latter can be either

conventional or forced type (with fan).

The burners are equipped with safety

thermocouples (Tc) (g. 6).

Each knob on the front panel has a diagram

printed above it showing to which burner it

refers. The combination of the dierent sized

burners oers the possibility of various types of

cooking.

If the cooker has electronic clock with end-ofcooking which makes it possible to use the oven

without supervision, to guarantee the customer

a good and safe use of the appliance it has a

safety thermostat that starts working should

the main thermostat malfunction. In such an

event, the electricity is interrupted temporarily:

do not attempt to repair it yourself but turn

the appliance o and contact your nearest

Assistance Centre.

There are grooves in the oven walls, called

steps (g. 1) on which we can place the

accessories listed below (g. 2). The type and

the quantity of accessories vary according

to the model:

• oven shelf (A)

• drip tray or drip pan (B)

• cake or pizza tray (C)

1

8

2

Page 9

DESCRIPTION OF THE APPLIANCE

DESCRIPTION OF THE CONTROLS

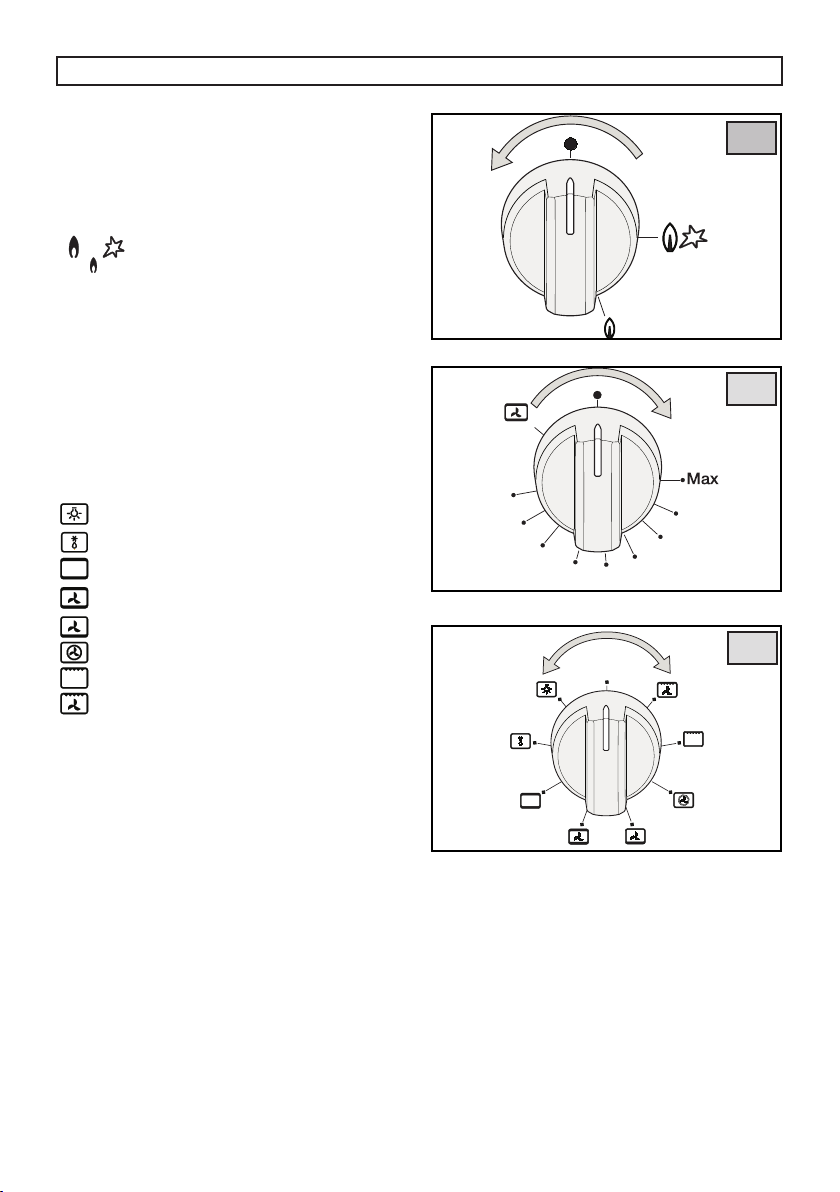

HOB GAS BURNER KNOB (A)

By rotating the knob in an anticlockwise

direction, the following symbols appear:

0

= Closed position

= “Full on” position

= “Reduced rate” position

THERMOSTAT KNOB FOR THE FAN OVEN (B)

By turning the oven knob clockwise we will nd

the dierent oven temperature values (from

50°C to Maxi).

FAN OVEN FUNCTION SELECTOR KNOB (8)

(C)

By turning the knob to the right or to the left

we will nd the following symbols:

0

= Oven o

= Oven light on, which stays on for all

functions

= Fan on

= Top and bottom heating elements on

= Top and bottom heating elements and fan

on

= Bottom heating element and fan on

= Rear heating element and fan on

= Grill

= Grill heating element and fan on

A

b

C

YELLOW WARNING LIGHT

When lit it indicates that either the electric

oven or electric grill is working. While the oven

is being used the light will switch o when the

set temperature is reached. During baking it

is normal for the yellow light to switch on and

o several times as the oven temperature is

controlled.

RED WARNING LIGHT

When lit it indicates that one or more of the

hob electric plates is on if the hob is mixed or

electric, or one of the oven electric components.

9

Page 10

DESCRIPTION OF THE APPLIANCE

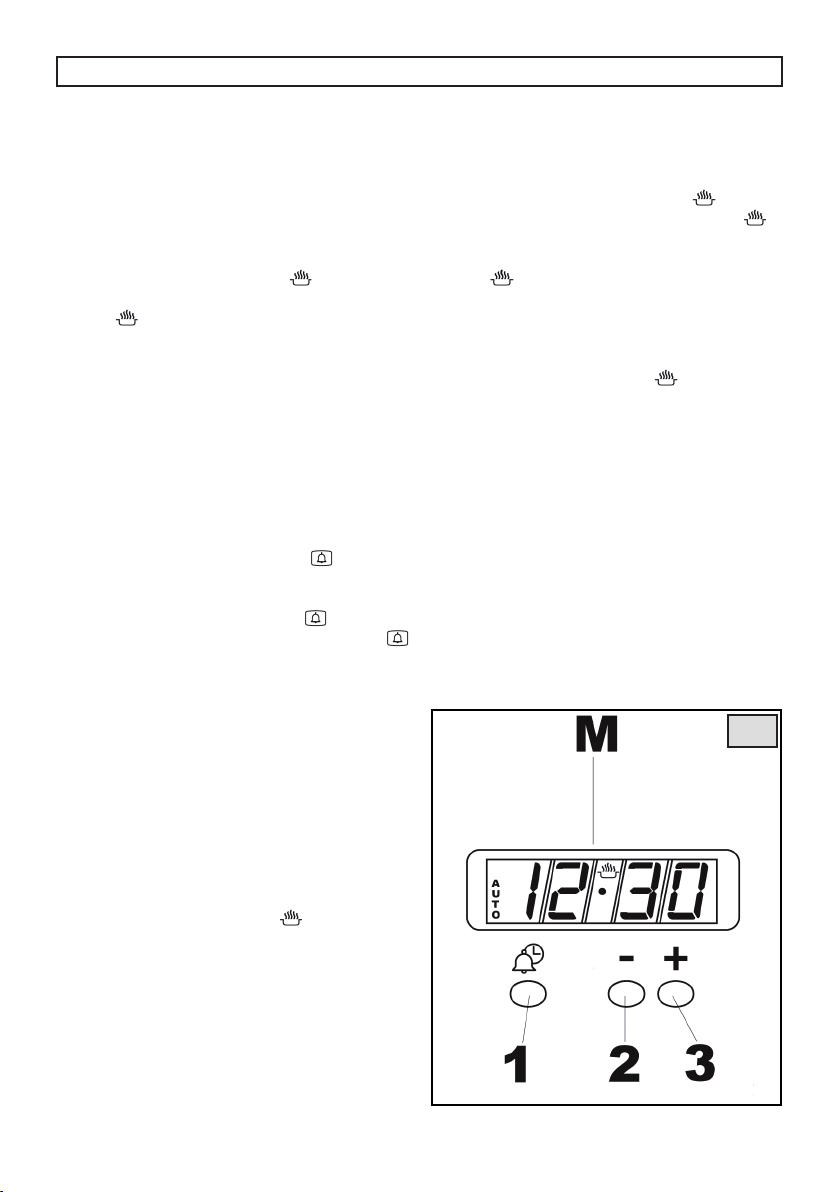

ELECTRONIC PROGRAMMER «TOUCH» (E)

Setting the time.

After connecting to mains or after a power

cut, symbol “A” and “0,00” will both ash

simultaneously on the display.

Keep pressed for some seconds simultaneously

+ and - buttons or just MODE button, till when

symbol “A” turn o and symbol

Time can be set just when the dot beneath the

symbol

Time cannot be adjusted during cooking

program run.

If time is selected while a automatic cooking

program is running, this is deleted.

Program selection

Keep pressed for some seconds MODE

button and pressing it in turns, the following

programs are selected:

1. Minute Minder

The time turns o, the symbol

and with + and - buttons is possible to select

the time alarm. At the end of the set time, the

buzzer will start and the symbol

turn o the buzzer and turn o the symbol

keep pressed for some seconds MODE button.

The minute minder program runs

independently of other cooking programs.

2. Semiautomatic Program with Duration

Select with + and - buttons the duration. The

time of the day turns o, symbol “A” and “dur”

ash. At the end of the set time, the buzzer will

start and the symbol “A” ashes. To turn o the

buzzer press MODE button.

Now the oven is o. Keep pressed for some

seconds simultaneously + and - buttons or just

MODE button and the symbol

ashes.

or End Time

turn on.

turns on

ashes. To

is illuminated.

3. Fully automatic program with Duration

and End time

Select with + and - buttons the duration and

the end time. The time of the day turns o,

symbol “A” and “End” ash. Symbol turns o

and the symbol “A” turns on. The symbol

illuminated again when the cooking starts. At

the end of the set time, the buzzer will start, the

symbol

To turn o the buzzer press MODE button.

Now the oven is o. To set the programmer

on manual operation keep pressed for some

seconds simultaneously + and - buttons or just

MODE button and the symbol

Changing/Clearing programs

Each program can be cleared keeping pressed

for some seconds simultaneously + and buttons. Symbol “A” turns o.

Each program can be changed keeping

pressed for some seconds MODE button and

then pressing it in turns to the function to be

changed. The adjustment can be done with +

and - buttons.

Is it possible to check whenever the progress

of program keeping pressed for some seconds

MODE button and then pressing in turns to the

function to be checked.

turns o and the symbol “A” ashes.

is illuminated.

is

E

10

Page 11

USER’S INSTRUCTIONS

HOB: GENERAL NOTES ON SAFETY

• When using the burners or the plates, do not

leave the appliance unsupervised. Ensure

that children do not play with the appliance.

In particular, make sure that pan handles

are positioned correctly and supervise the

cooking of foods which use oils and fats, as

these are highly inammable.

• Do not use aerosols or sprays near the

appliance when it is in use.

• Even after use, the burners or the plates

remain hot for a long period; to avoid

burning, do not place hands or other objects

on them.

• After using the appliance, ensure that all the

controls are in the closed or o position.

When a gas cooker is being used it

produces heat and humidity in the room

where it is installed. For this reason the

room must be well ventilated, keeping

the natural ventilation openings free and

switching on the mechanical aeration

system (paragraph «VENTILATION and

LOCATION AND AERATION).

used for a long time additional aeration

may be necessary, for instance, opening

a window, or a more eective aeration by

increasing the power of the mechanical

system if there is one.

If the cooker is

LIGHTING THE BURNERS

Lighting of burners equipped with safety

thermocouples (g. 6, ref. TC)

When the burners are equipped with

safety thermocouples you have to turn

counterclockwise to the “Full on“ position, the

knob corresponding to the burner you wish

to use, then press the knob and repeat the

operations described previously. Once lit, keep

the knob pressed for about 10 seconds.

4

Optimum use of the burners

To get the maximum yield with the minimum

consumption of gas it is handy to keep the

following points in mind:

• Once the burner has been lit, adjust the

ame according to your needs.

• Use an appropriately sized pan for each

burner (see the table below and g. 4).

• When the content of the pan start to boil, turn

the knob down to “Reduced rate position”

(small ame).

Burners Ø pan cm

Ultra-Rapid 22÷24

Rapid 20÷22

Semi-rapid 16÷18

Auxiliary 12÷14

OVEN: GENERAL SAFETY INSTRUCTIONS

• Do not leave the oven unsupervised during

use. Ensure that children do not play with the

appliance.

• Always grip the centre of the oven door when

opening. Do not practice excessive pressures

on the door when it is open.

• Do not worry if condensation forms on the

door and on the internal walls of the oven

during cooking. This does not compromise

its eciency.

• When opening the oven door, be very careful

of scalding vapours.

• The appliance becomes very hot during use.

Do not touch the heating elements inside

the oven. Wear oven gloves when placing or

removing pans from the oven.

• When inserting or removing food from

the oven, check that excess juices do not

overow onto the oven base (oils and fats are

highly inammable when overheated).

• Use containers that will resist the

temperatures indicated on the thermostat

knob.

• For good results during cooking, we strongly

recommend not to cover the base of the

oven or the grill with aluminium foil or other

materials.

11

Page 12

USER’S INSTRUCTIONS

• When grilling always put a little water in the

grill pan. The water prevents the grease from

burning and from giving o bad smells and

smoke. Add more water during grilling to

compensate for evaporation.

• After using the appliance ensure that all the

controls are in the o position.

• WARNING!!! During and after use, the oven

door glass and the accessible parts can be

very hot, therefore keep children away from

the appliance.

IMPORTANT!!

Always keep the oven door closed during

baking or grilling.

WHAT TO DO THE FIRST TIME YOU USE THE

OVEN

If the appliance has a programming

accessory, place it on the manual position,

and, before cooking for the rst time, ensure

the oven is empty and its door closed, heat the

oven at maximum temperature for 2 hours. This

will allow the protective coating on the interior

of the oven to be burnt o and dissipate the

associated smells. During this time do not stay

in the same room and keep it aerated.

After the hour or so has elapsed leave the oven

to cool down and then clean its interior with

hot water and a mild detergent. Also wash the

accessories (shelves, trays, drip pan, spit..) prior

to use.

Prior to any cleaning, disconnect the

appliance from the electricity mains.

HOW TO USE THE MULTIFUNCTION

OVEN

DEFROSTING AT ROOM

TEMPERATURE

Turn the selector knob to the symbol and place

the food you want to defrost inside the oven.

The length of time required depends on the

quantity and type of food.

Selecting this function will only activate the

fan. Mild air circulation around frozen food will

slowly defrost it. It is particularly suitable for

fruit and cakes.

TRADITIONAL COOKING

Turn the selector knob to the symbol and

adjust the thermostat knob to suit the desired

temperature.

If pre-heating is recommended wait till the

thermostat yellow led turns o before placing

foods inside the oven. This option turns on

both bottom and top heating units, evenly

distributing heat on your foods.

This type of cooking is ideal for all kind of foods

(meats, sh, bread, pizzas, cakes..).

COMBINED TRADITIONAL + FAN

COOKING

Turn the selector knob to the symbol and

adjust the thermostat knob to suit the desired

temperature.

If pre-heating is recommended wait till the

thermostat yellow led turns o before placing

foods inside the oven. This option turns on

both bottom and top heating units, and heat is

distributed by fan ventilation.

This combination is suitable for rapid cooking

and allows for the use of more plates positioned

on the dierent levels of the oven (g. 5).

12

Page 13

USER’S INSTRUCTIONS

DEFROSTING + WARM UP BY HOT AIR

Turn the selector knob to the symbol and set

the temperature on the thermostat knob,

now place the food inside the oven. Selecting

this function will activate the bottom heating

unit and its heat is distributed by the fan.

This function is particularly recommended to

defrost and warm up ready-made meals.

FAN + REAR HEATING COMBINED

COOKING

Turn the selector knob to the symbol and

set the thermostat knob to the desired

temperature, then place your food the oven. If

oven needs pre-heating wait till the thermostat

yellow led turns o before placing foods inside

it. This function activates the rear heating unit

and the fan distributes the heat produced. This

combination allows for a fast and even cooking

of several dierent foods placed on the diverse

levels of the oven (g. 5).

CONVETIONAL GRILL COOKING

Turn the selector knob to the symbol and set the

thermostat knob to the desired temperature.

Selecting this function the top central heating

element turns on and heat is distributed

directly on food surface.

Apart from grilling, this function is ideal to add

a golden roast to your recipes or to toast bread

slices.

The grill function automatically activates

the eventual spit. When you use the grill, do

not forget to place the drip pan beneath it to

collect any sauce dripping, as suggested in the

“USEFUL COOKING TIPS “ section.

FAN GRILL COOKING

Turn the selector knob to the symbol and set the

thermostat knob to the desired temperature.

Selecting this function the top central heating

element turns on and heat is distributed by the

fan. This procedure mitigates the direct heat on

food surface and uses milder temperatures. It

is therefore recommended for an even golden

and crispy nish touch, ideal for whole sh and

poultry.

When you use the grill, do not forget to

place the drip pan beneath it to collect any

sauce dripping, as suggested in the “USEFUL

COOKING TIPS “ section.

13

5

Page 14

USER’S INSTRUCTIONS

USEFUL COOKING TIPS

Cakes and bread:

• Heat the oven for at least 15 minutes before

you start cooking bread or cakes.

• Do not open the door during baking

because the cold air would stop the yeast

from rising.

• When the cake is cooked turn the oven o

and leave it in for about 10 minutes.

• Do not use the enamelled oven tray or drip

pan, supplied with the oven, to cook cakes

in.

• How do you know when the cake is

cooked? About 5 minutes before the end of

cooking time, put a cake tester or skewer in

the highest part of the cake. If it comes out

clean the cake is cooked.

• And if the cake sinks? The next time use less

liquids or lower the temperature 10°C.

• If the cake is too dry: Make some tiny holes

with a toothpick and pour some drops of

fruit juice or spirits on it. The next time,

increase the temperature 10°C and set a

shorter cooking time.

• If the cake is too dark on top: the next time

put the cake on a lower shelf, cook it at a

lower temperature and longer.

• If the top of the cake is burnt: cut o

the burnt layer and cover with sugar or

decorate it with cream, jam, confectioner’s

cream, etc..

• If the cake is too dark underneath: the next

time place it on a higher shelf and cook it at

a lower temperature.

• If the cake or bread is cooked nicely outside

but is still uncooked inside: the next time

use less liquids, cook at a lower temperature

and longer.

• If the cake will not come out of the tin: slide

a knife around the edges, place a damp

cloth over the cake and turn the tin upside

down. The next time grease the tin well and

sprinkle it with our or bread crumbs.

• If the biscuits will not come away from the

baking tray: put the tray back in the oven for

a while and lift the biscuits up before they

cool. The next time use a sheet of baking

parchment to prevent this happening

again.

Meat:

• If, when cooking meat, the time needed is

more than 40 minutes, turn the oven o 10

minutes before the end of cooking time to

exploit the residual heat (energy saving).

• Your roast will be juicier if cooked in a closed

pan; it will be crispier if cooked without a

lid.

• Normally white meat, poultry and sh need

medium temperatures (less than 200°C).

• To cook “rare” red meats, high temperatures

(over 200°C) and short cooking times are

needed.

• For a tasty roast, lard and spice the meat.

• If your roast is tough: the next time leave

the meat to ripen longer.

• If your roast is too dark on top or

underneath: the next time put it on a higher

or lower shelf, lower the temperature and

cook longer.

• Your roast is underdone? Cut it in slices,

arrange the slices on a baking tray with the

gravy and nish cooking it.

Grilling:

• Sparingly grease and avour the food

before grilling it.

• Always use the grill pan to catch the juices

that drip from the meat during grilling.

• Always put a little water in the drip pan. The

water prevents the grease from burning

and from giving o bad smells and smoke.

Add more water during cooking because it

evaporates.

• Turn the food half way through cooking.

• If you are grilling fatty poultry (goose)

pierce the skin so the fat can drip away.

The aluminium can be easily corroded if

it comes into contact with organic acids

present in the foods or added during

baking (vinegar, lemon juice). Therefore

it is advised not to put directly the foods

on aluminium or enamelled trays, but

ALWAYS use the proper oven paper.

14

Page 15

USER’S INSTRUCTIONS

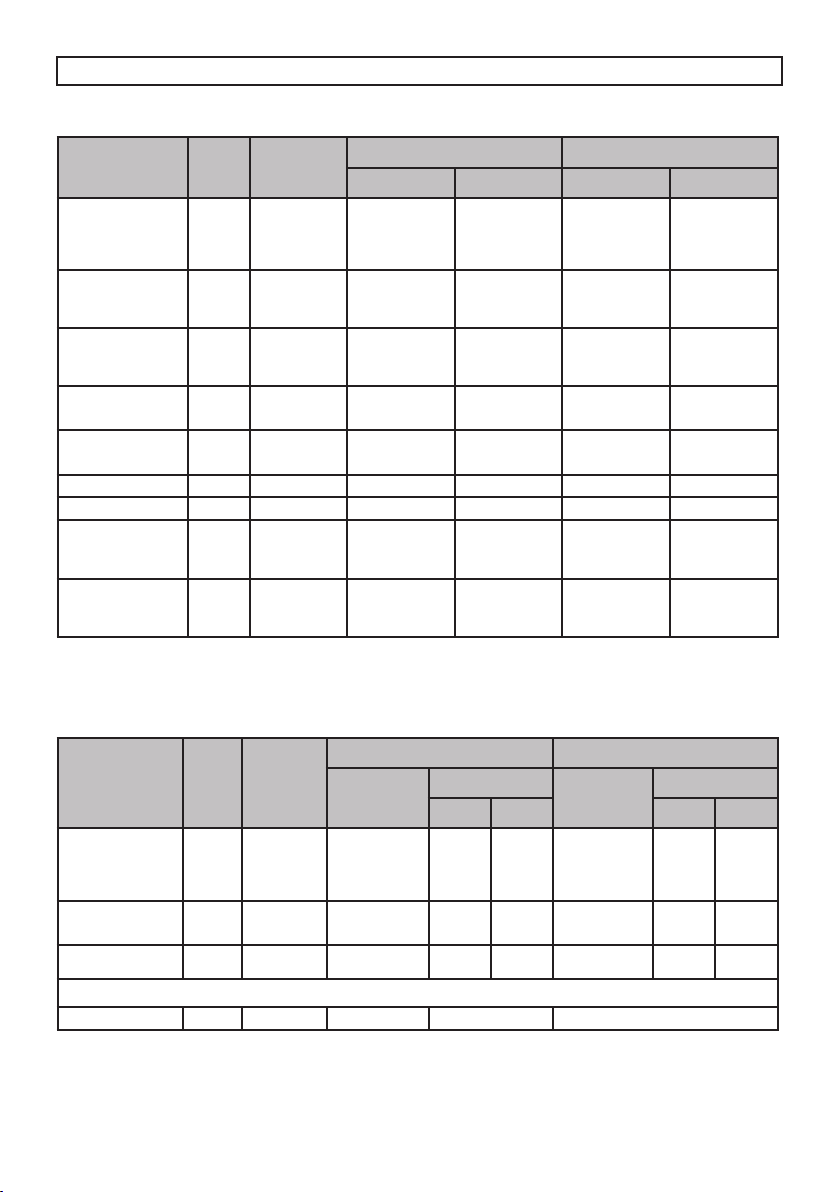

COOKING/BAKING TABLE

Cooking by natural convenction Cooking by forced convenction

Temperatures

in °C

200-225

200-225

200-225

200-225

200-Max

200-Max

200-Max

200-225

200-225

200-225

200

175

210-225

210-225

225-Max 25-30 225-Max 20-25

225-Max 20-25 220 20

190

200

200

190

200

200

Cooking time

in minutes

100-120

40-50

100-120

100-120

50-60

60-70

50-60

80-90

100-120

90-110

30-35

20-25

60-75

60-75

15

20

40-45

52

65

45

Temperatures

in °C

190

190

190

190

200-Max

200-Max

200-Max

190

190

190

170-190

160-170

225-Max

225-Max

170-190

190-200

190-200

170-190

190-200

190-200

(with fan)

Cooking time

in minutes

100-120

100-120

100-120

90-110

80-100

GRILLING TABLE

Cooking by natural convenction

Cooking time

Temperatures

in °C

225-Max

200-225

225

225-Max

225-Max

225-Max 2-3 2-3 200 2-3 2-3

SPIT (*)

in minutes

1st side

12-15

5

20

=

=

2nd

side

12-15

Cooking by forced convenction

Temperatures

in °C

5

20

=

=

200

200

200

=

=

(with fan)

Cooking time

1st side

15

10

in minutes

=

=

7

40-50

50

60

50

70-80

25-30

15-20

30-40

30-40

15

20

40-45

45

65

45

2nd

side

10

=

=

10

7

kg

1

1

1

1

1

1

1

1

1

1

1

1

2,5

2,5

0,8

0,8

0,8

1

Position of

the oven

shelf from

the bottom

2

1

2

1

2

2

2

2

2

2

2

2

1

1

2

2

2

2

2

2

2

2

Position of

the oven

shelf from

the bottom

3

3

2

3

3

3

Foods

MEAT

Roast veal

Roast beef

Roast pork

Roast lamb

GAME

Roast hare

Roast pheasant

Roast partridge

POULTRY

Roast chicken

Roast turkey

Roast duck

FISH

Roast sh

Casseroled sh

BAKED PASTA

Lasagne

Cannelloni

PIZZA 1

BREAD 1

PASTRIES

Biscuits in general

Shortcrust pastry

Victoria sponge 0,8

CAKES

Angel cake

Fruit cake

Chocolate cake

The values given in the tables (temperatures and cooking times) are approximate and may vary according to each person’s

cooking habits. This table gives cooking times on only one shelf. If you are cooking with a fan oven and you are using more

than one shelf (placing the shelves on the 1st and 3rd or 2rd and 4rd position) cooking time will be about 5 to 10 minutes

longer.

Foods

MEAT

Chop

Beefsteaks

Half chicken (each

half 0.5 kg)

FISH

Trout

Sole

BREAD

Toast

CHICKEN 1.3 2 225-Max 80-90 =

The values given in the tables (temperatures and cooking times) are approximate and may vary according to each person’s

cooking habits. In particular, temperatures and times for grilling meat will greatly depend on the thickness of the meat and

on personal tastes.

Weight

Weight

kg

0,50

0,15

0,42

0.20

15

Page 16

USER’S INSTRUCTIONS

CLEANING AND MAINTENANCE

• Prior to any maintenance work or

cleaning, disconnect the appliance from

the electricity mains.

• Do not use a steam cleaner to clean this

appliance.

• Do not wash the parts if they are still hot.

• Do not use metal pads, abrasive powders

or corrosive spray products for cleaning

• Do not leave vinegar, coee, milk, salty

water or the juice of lemon or tomato

on enamelled surfaces for any length of

time.

• Switch o the oven before removing the

fan guard for cleaning. Replace the guard

after cleaning

HOT PLATE

The enamelled steel pan supports, enamelled

burner caps and burner heads need to be

cleaned after each time they are used with

warm soapy water, rinsed and then dried well

to keep them in good condition.

WARNINGS:

• After cleaning, check that the heads burners

and the relative burner caps, are correctly

positioned in their housings (g. 6).

• Take care not to disturb the ignition spark

plugs or ame failure devices.

• If you nd a tap is dicult to open or close

do not force it but call for technical assistance

urgently.

• After use, to keep them in good condition,

the hot plates should be treated with specic

products, easily found in the shops, to keep

the surfaces clean and shining. This will also

prevent rust from forming.

• If any liquid spills over it must always be

removed with a sponge.

STRUCTURE

All the cooker parts (in enamelled or painted

metal, steel, or glass) should be cleaned

frequently with warm soapy water and then

rinsed and dried with a soft cloth.

DO NOT use rough or abrasive materials or

sharp metal scrapers to clean the oven glass

doors as they could scratch and cause the glass

to break

NEVER use sponges or abrasive products, and

aromatic or aliphatic solvents to remove stains

or adhesives on the painted or stainless steel

surfaces.

OVEN CAVITY

Do not spray or wash the thermostat

bulb with acid based products (check the

product label before use).

The manufacturer cannot be held liable for

any damage caused by incorrect cleaning.

The oven cavity should be cleaned after each

use to remove cooking residuals and or grease

or sugar which, if burnt on when the oven is

used again, will form deposits or unremovable

stains as well as unpleasant smells.

To maintain the shine of the enamelled parts,

clean them with warm soapy water, rinse

and dry them thoroughly. ALWAYS wash the

accessories used.

OVEN SIDEWALL GRIDS (g. 7)

To allow for a better cleaning of the side grids,

you can extract them this way:

1. Push with a nger on the last of the slots to

release the grid from its hold.

2. Lift it towards the top and extract the grid.

To put them back into place, reverse the order of

this operation.

6

16

7

Page 17

USER’S INSTRUCTIONS

OVEN DOOR REMOVAL

The oven door can be removed to give easier

access to the oven when cleaning.

To remove, proceed as follows:

• Open the oven door and insert rivet or nail

(R) in the hole (F) of the hinge (g. E).

• Partially close the door, forcing it upwards at

the same time to free stop tooth and hinge

sector.

• Once the hinge is free, pull the door forwards

tilting it slightly upwards to free sector.

• To reassemble proceed in the reverse order,

paying attention to the correct position of

sectors.

REPLACING THE OVEN LAMP (g. 9)

Ensure the appliance is switched o before

replacing the lamp to avoid the possibility

of electric shock..

IIn the event one or both oven lamps need

replacing, the new lamps must comply with the

following requisites: 15 W - 230 V~ - 50 Hz - E

14 - and must be resistant to high temperature

(300°C).

Draw out the side guide rails as described

above.Then, remove the glass protection

cap (V) from the bulb socket, lifting it with a

screwdriver (C) placed between the cap and

the oven wall and replace the lamp. Fit the

accessories back in reverse order.

E

9

The lamp used in the appliance is specically

designed for electrical appliances and is not

suitable for household room illumination

(Commission Regulation (EC) No 244/2009).

OVEN SEAL

The oven seal guarantees the correct

functioning of the oven. We recommend you:

• clean it, avoiding abrasive tools or products.

• check its state now and then.

If the oven door seal has become hard or

is damaged, contact our Service Centre

and avoid using the oven until it has been

repaired.

17

Page 18

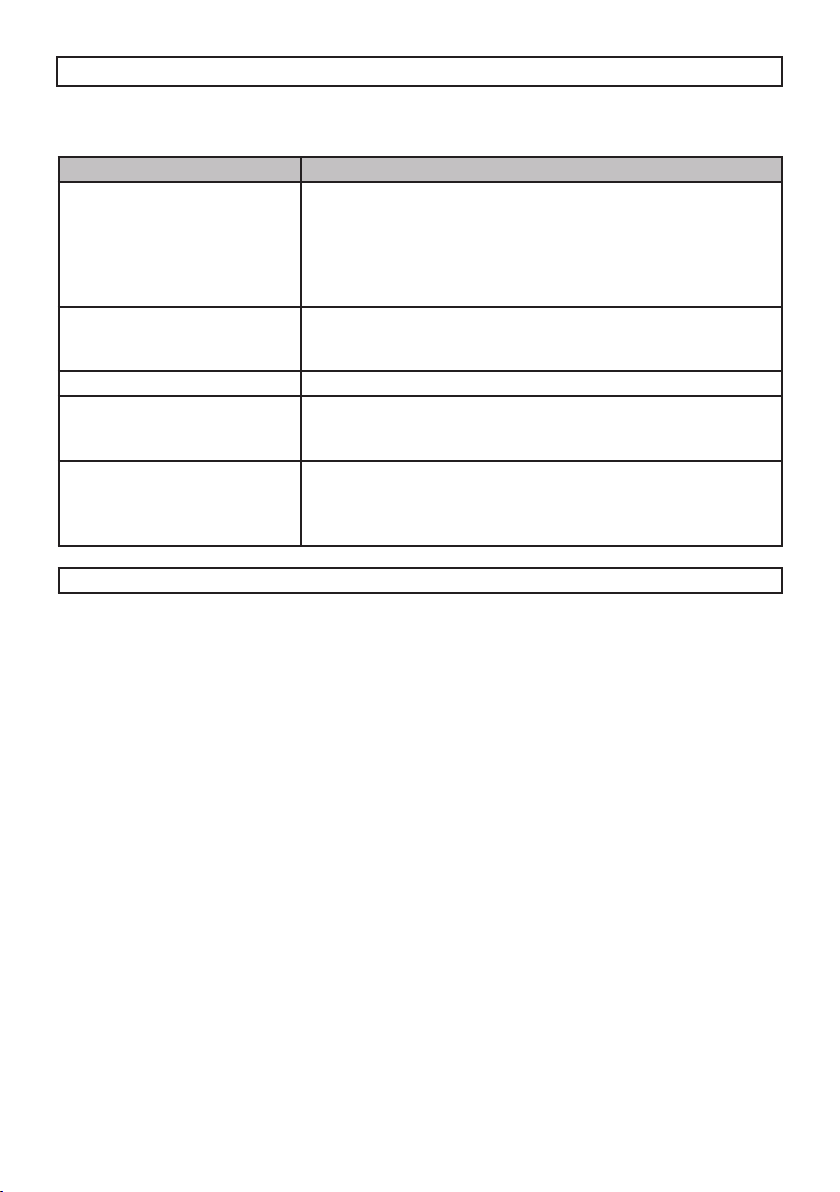

TROUBLESHOOTING

Some of the problems occur because of simple maintenance oversights or operation mistakes and

can easily be resolved without having to call for technical assistance.

PROBLEM REMEDY

The appliance is not working • Make sure the gas cock is open

The electric oven is not working

The thermostat is not working • Call our Service Centre

The electric thermostat warn-

ing light does not switch on

during use

The oven light does not switch on• Make sure the lamp is rmly screwed in place

Warning: Servicing should be carried out only by authorised personnel.

• Check the plug is in

• Check that the knobs are set correctly for cooking and then

repeat the operations given in the handbook

• Check the electrical system safety switches (RCD). If there is

failure in the system call an electrician in.

• Check that the programmer accessory, if there is one, is on the

manual position and then repeat the operations described in

the manual

• Turn the thermostat round to a hotter temperature

• Turn the selector round to a dierent function

• Buy a lamp for high temperatures at one of our Service Centre

and t it following the instructions given in the paragraph

«REPLACING THE OVEN LAMP».

18

Page 19

TECHNICAL FEATURES MODEL ACH 6601 (cm 60x60)

BURNER TECHNICAL DATA TABLE

Burners

N. Denomination mbar g/h L/h 1/100 mm Min Max “X”mm 1/100 mm

6 Ultra-Rapid

3 Semi-rapide

4 Auxiliary

Operating

Pressure Gas

LPG - Butane

LPG - Propane

Natural

LPG - Butane

LPG - Propane

Natural

LPG - Butane

LPG - Propane

Natural

28-30

37

20

28-30

37

20

28-30

37

20

Rate

236

232

131

129

73

71

309

171

95

Diameter

Injectors

95

95

125-K

68

68

98-Z

51

51

75-X

Heat Input

1350

1350

1350

600

600

600

400

400

400

3250

3250

3250

1800

1800

1800

1000

1000

1000

Air

regulation

sleve

opening

= 62

= 34

= 28

By-pass

BURNER DISPOSITION

OUTSIDE COOKER DIMENSIONS (g.10)

Type

height h mmwidth Lmmdepth P

cooker

60 x 60 850 600 600

ELECTRIC COMPONENTS

Description Nominal data

Lower heating element of the oven

Top heating element of the oven-grill

Rear heating element

Oven lamp

Rear fan

Cable type and section

1400 W a 240 V

800 + 1800 W

2000 W

15 W - E 14 – T 300

25..29 W

H05 RR-F 3x1.5

mm

10

19

Page 20

TECHNICAL FEATURES MODEL ACH 7601 (cm 70x60)

BURNER TECHNICAL DATA TABLE

Burners

N. Denomination mbar g/h L/h 1/100 mm Min Max “X”mm 1/100 mm

5 Ultra-Rapid

3 Rapide

3 Semi-rapide

4 Auxiliary

Operating

Pressure Gas

LPG - Butane

LPG - Propane

Natural

LPG - Butane

LPG - Propane

Natural

LPG - Butane

LPG - Propane

Natural

LPG - Butane

LPG - Propane

Natural

28-30

37

20

28-30

37

20

28-30

37

20

28-30

37

20

Rate

236

232

218

214

131

129

73

71

309

276

171

95

Diameter

Injectors

95

95

125-K

88

88

117-Y

68

68

98-Z

51

51

75-X

Heat Input

1350

1350

1350

800

800

800

600

600

600

400

400

400

3250

3250

3250

3000

3000

2900

1800

1800

1800

1000

1000

1000

Air

regulation

sleve

opening

= 62

= 44

= 34

= 28

By-pass

BURNER DISPOSITION

OUTSIDE COOKER DIMENSIONS (g.10)

Type

height h mmwidth Lmmdepth P

cooker

70 x 60 850 700 600

ELECTRIC COMPONENTS

Description Nominal data

Lower heating element of the oven

Top heating element of the oven-grill

Rear heating element

Oven lamp

Rear fan

Cable type and section

1400 W a 240 V

800 + 1800 W

2000 W

15 W - E 14 – T 300

25..29 W

H05 RR-F 3x1.5

mm

10

20

Page 21

TECHNICAL FEATURES MODEL ACH 9601 (cm 90x60)

BURNER DISPOSITION

Burners

N. Denomination mbar g/h 1/100 mm Min Max 1/100 mm

2 Rapid LPG 30 218 88 800 3000 44

3 Semi-rapide LPG 30 131 68 600 1800 34

4 Auxiliary LPG 30 73 51 400 1000 28

6 Ultra-rapide LPG 30 276 98 1600 3800 65

Operating

Pressure Gas

Rate

ELECTRIC COMPONENTS

Description Nominal data

Lower heating element

Top heating element

Rear heating element

Oven lamp

Fan motor

Cooling fan motor

Cable type and section

Diameter

Injectors

Heat Input By-pass

1700 W a 240 V

1400 + 2200 W

2000 W

15 W - E 14 – T 300

25..29 W

12 W

H05 RR-F 3x1.5 mm

2

21

Page 22

INSTRUCTIONS FOR THE INSTALLER

TECHNICAL INFORMATION

• The installation, adjustments, conversions

and maintenance operations listed in this

part must only be carried out by qualied

personnel. The manufacturer cannot be

held responsible for any damage to persons

or property resulting from an incorrect

installation of the appliance.

• The safety and automatic adjustment devices

of the appliances may, during its life, only

be modied by the manufacturer or duly

authorised supplier.

• In accordance with the gas standard, the allgas and combi appliances are “class 1” (free

standing) or “class 2 subclass 1” (recessed)

and, as such, must comply with the clearances

specied in g. 11 consequently any side

walls must be no higher than the work top.

The appliance is to be placed directly on the

oor and should not be mounted on a base.

• The walls adjacent to and surrounding the

appliances must be able to withstand an

over temperature of 70 K.

• The installation of all-gas and combi

appliances must comply with the standards

in force.

• This appliance is not connected to a

ue for discharge of the combustion

products; therefore, it must be connected

in compliance with the above mentioned

installation rules. Particular attention must

be paid to the instructions given below for

ventilation and aeration.

INSTALLATION

UNPACKING YOUR COOKER

• Once the wrapping has been removed from

the outer surfaces and the various inner

parts, thoroughly check that the appliance is

in perfect condition.

If you have any doubts do not use the

appliance and call in a qualied person.

• Some parts mounted on the appliance are

protected by a plastic lm. This protection

must be removed before using the appliance.

We recommend slitting the plastic lm along

the edges with a sharp knife or pin.

• Do not move the appliance by the handle.

The packaging materials used (cardboard,

bags, polystyrene foam, nails etc.) must

not be left anywhere within easy reach

of children as they are a potential hazard

source.

22

11

Page 23

INSTRUCTIONS FOR THE INSTALLER

VENTILATION

The appliance should not be installed in a room

of volume less than 20 m³.

The quantity of air necessary is that required

for a regular combustion of the gas and for the

ventilation of the room. The natural ow of air

must be direct through permanent openings

in the walls of the room that open directly to

the outside with a minimum cross section

of 100 cm

positioned so they cannot be obstructed.

Indirect ventilation is also allowed by taking air

from adjacent rooms to the one to be ventilated,

strictly complying with the prescriptions of the

standards in force.

2

(g. 12). These openings must be

AIR INLET MIN. SECT. 100 cm

12

2

13

LOCATION AND AERATION

Gas cookers must always discharge the

products of combustion and the moisture

through hoods connected to flues or directly

to the outside (fig. 13). If it is impossible to use

a hood, a fan installed on the window or wall,

facing the outside, is allowed and should be

switched on each time the appliance is used

(g. 14) provided the rules and regulations in

force relating to ventilation.

POSITIONING THE COOKER

The appliances are tted with the following

parts to enable them to be correctly positioned:

• Adjustable feet (g. 15), to be tted to the

appliance, which allow the height of the

cooker to be aligned with other kitchen

furniture This can be done by means of

the terminal part of the leg themselves.

• The socket or the switch must be accessible

once the appliance is installed.

AIR INLET MIN. SECT. 100 cm

AIR INLET MIN. SECT. 100 cm

2

14

2

15

23

Page 24

INSTRUCTIONS FOR THE INSTALLER

GAS CONNECTION

Before connecting the appliance check that

the data on the rating plate axed to the

cooker, correspond to those of the gas mains.

A label on the back of this handbook and at

the back of the cooker gives the appliance

adjustment conditions, that is, the type of

gas and operating pressure.

Once the cooker is installed, check there

are no leaks using a soapy solution (never

a ame).

The appliance’s gas inlet tting is a threaded

1/2” male cylindrical type, in compliance

with the ISO 228-1 standards. If gas is

distributed through ducts the appliance

must be connected to the gas mains with:

• a rigid steel pipe, in accordance with

standards, whose joints must be made using

threaded ttings in accordance with the

UNI-ISO 7/1 standard. The use of hemp with

suitable adhesives or Teon tape as a sealant

is allowed.

• copper pipe, in accordance with the standard,

whose joints must be made using sealed

ttings in accordance with the standard.

• a flexible stainless steel, seamless pipe

in accordance with the standard, with a

maximum 2 metre extension and seals in

accordance with the standard.

• a flexible rubber hose in accordance with

the standard, with an 8 mm diameter for

LPG and 13 mm for natural gas or town

gas, maximum 1500 mm in length, firmly

secured to the hose fitting with a safety

clamp as per the standard.

If the gas is supplied directly from a gas

cylinder, the appliance, fed by a pressure

regulator in accordance with the standard,

must be connected:

• with a copper pipe in accordance with

the standard, whose joints must be made

using sealed ttings in accordance with the

standard.

• with a exible stainless steel, seamless

pipe in accordance with the standard,

with a maximum 2 metre extension and

seals in accordance with the standard. We

recommend applying the special adapter to

the exible pipe, easily found on the market,

to facilitate connection to the pressure

regulator’s hose tting on the cylinder.

• with a flexible rubber hose in accordance

with the standard, with an 8 mm diameter,

minimum 400 mm in length, maximum

1500 mm in length, firmly secured to the

hose fitting with a safety clamp as per the

standard.

Isolating tap

Hose

assembly

Connection

point

Hose

assembly

24

Connection

point

HOT SURFACE

16

Page 25

INSTRUCTIONS FOR THE INSTALLER

ATTENTION:

• If the appliance is going to be recessed

(class 2 subclass 1), connect it to the gas

supply source using only exible stainless

steel, seamless pipes in accordance with

the standard.

• If the appliance is going to be installed

free-standing (class 1) and if you use

the exible rubber hose, it is necessary

to follow the instructions and the g. 16

given below:

• On its route, the hose must not touch any

parts where the over temperature is than

95°C.

• The hose must not be subject to any kind

of torsional stress or tractive force, there

must be no pinched parts or really sharp

bends.

• It must not touch anything that can cut,

that has sharp corners, etc.

• The whole length of the hose must be

easy to inspect in order to keep a check on

its condition.

• It must be replaced within the date

printed on it.

25

Page 26

INSTRUCTIONS FOR THE INSTALLER

ELECTRICAL CONNECTION

The electrical connection must be carried

out in accordance with the current

standards and laws in force.

Before connecting check that:

• The system and electrical sockets amperage

is adequate for the appliance maximum

power (see data label axed on the back of

the cooker).

• The socket or system has an eective earth

connection in accordance with current

standards and prescriptions of the law. All

responsibility is disclaimed if this is not

complied with.

• The plug and socket or the multipolar switch

must be accessible after installation of the

appliance.

• If the appliance has no power cable,

connect one with a suitable cross section

to the terminal board (see paragraph

«CONNECTING THE POWER CABLE).

When connecting to the mains with a socket:

• Fit to the power cable (if without) a

standardized plug, suitable for the load

which is indicated on the data label. Connect

the wires making sure they correspond as

shown below, and remember that the earth

wire must be longer than the phase wires:

letter L (phase) = brown wire

letter N (neutral) = blue wire

symbol

• The power cable must be laid so that no parts

of it ever reach a temperature of 75 °C.

• For connecting do not use, adapters or

shunts as they could cause false contacts

resulting in hazardous overheating.

(earth) = green/yellow wire

When connecting directly to the mains:

• Install a multipolar switch that can withstand

the appliance load, with a minimum opening

between the contacts of 3 mm.

• Remember that the earth wire must not be

cut out by the switch.

CONNECTING THE POWER CABLE

The all-electric cookers and some combi

versions leave the factory ready for singlephase power, butt they can, with due

modications, be powered by three phase

systems by following these instructions:

• Remove the rear panel from the cooker.

• Move the connecting plates in the

terminal board according to the type

of connection you want, following the

diagram in g. 16 A for ACH 6601- ACH

7601 models and 16 B for ACH 9601 model

You will also nd this diagram axed to the

back of the cooker.

• Connect the power cable, whose cross

section must be suitable (TECHNICAL

FEATURES paragraph), keeping the earth

wire longer than the phase wires.

• Secure the cable in the clamp and t the rear

panel in place.

16A

26

16b

Page 27

INSTRUCTIONS FOR THE INSTALLER

ADJUSTMENTS

• Always disconnect the appliance from

the electricity supply before making any

adjustment.

• All seal must be replaced by the

technician following any adjustment or

regulation.

• The adjustment of the reduce rate

(simmer) must be undertaken only with

burners functioning on natural gas

while in the case of burners functioning

on L.P.G, the screw must be locked down

fully (in clockwise direction).

• “Primary air adjustment” on hob gas

burners is unnecessary.

TAPS

All gas taps are male cone type with only one

way of passage. Adjustment of the “Reduced

rate” position as follows:

• Turn the burner on and place the knob on

the “Reduced rate” position (small ame).

• Remove the knob (A) of the tap which is attached

by simply applying pressure to the rod.

• When the taps is equipped with ame failure

device, the adjustment screw (V) is over (g.

17) or on the side of the stem (g.18).

• Check that the ame does not go out when

the knob is sharply switched from the “Full

on” to “Reduced rate” positions.

CONVERSIONS

REPLACING THE INJECTORS

Our burners can be adapted to dierent types

of gas by simply installing the injectors suitable

for the gas you want to use. To help the installer,

the table (TECHNICAL FEATURES paragraph)

gives the burner nominal heat input, injector

diameter and operating pressure of the

dierent gas types.

Comply with the following instructions:

Injector replacement - Hob burners.

To change the injectors on the hob, remove the

burner cup and head and with a 7 mm Ø socket

spanner replace them (g.19).

After having replaced the injectors, it

will be necessary to proceed with burner

adjustment as explained in the previous

paragraphs. The technician must replace

any seals after the adjustments have been

made.

MAINTENANCE

Prior to any maintenance work or changing

parts, disconnect the appliance from the

gas and electricity power sources.

17

18

CHANGING THE FLEXIBLE GAS HOSE

In order to guarantee that the gas hose is always

in excellent condition we strongly recommend

changing it on the date you will nd printed on

it.

19

27

Page 28

INSTRUCTIONS FOR THE INSTALLER

REPLACING THE TAPS (g. 20)

To change a tap proceed as follows:

• Remove pan supports, burner heads and

knobs.

• Unscrew the burners securing screws.

• Remove the lateral sides, lid and hob.

• Unscrew the check nuts of rails (D) and/or of

any thermocouples and remove tap (R) by

unscrewing the screws (V).

• Partly remove the burners small supply pipes

and change the relative part.

• Replace the seal (G) each time you change a

tap so as to guarantee a perfect t between

body and rail.

• Reassemble all the parts following the same

procedure but in the reverse order.

REPLACING THE ELECTRICAL COMPONENTS

• The rear protection will have to be removed

in order to change the electrical heating

elements, lamp holder, terminal board and

power cable.

• If you have to change the power cable,

always keep the earth wire longer than

the phase wires and, in addition, follow all

the instructions given in the “ELECTRICAL

CONNECTION” .

• To change the oven lamp see the instructions

given in the «REPLACING THE OVEN LAMP».

• To change lamp holder (P), remove the side

panels and then use a screwdriver to push

the two locking tabs (M) (g. 21) and remove

the lamp holder from the inside of the oven.

• To replace the ignition generator, remove the

left side panel of the appliance.

• To change the thermostat, commutators or

hob heating elements, the work top has to

be removed.

20

21

28

Page 29

AFTER-SALES SERVICE

Before calling the After-Sales Service:

1. See if you can solve the problem yourself

with the help of the suggestions given in

the “Troubleshooting guide”.

2. Switch the appliance o and back on again

it to see if the fault persists.

If after the above checks the fault still

occurs, get in touch with the nearest AfterSales Service.

Any repair or adjustments must be done by

a qualied personnel.

Always specify:

• A brief description of the fault;

• The type and exact model of the cooker;

• Your full address;

• Your telephone number.

If any repairs are required, please contact an

authorized After-Sales Service (to guarantee

that original spare parts will be used and repairs

carried out correctly).

29

Page 30

SPACE FOR DATA LABEL

TECNO 461308157_000

30

Page 31

םיניינע ןכות

תובושח תוחיטב תוארוה32-34

רישכמה רואית35-37

שמתשמל ךירדמ38-44

תויעב ןורתפ45

ינכט טרפמ46-48

ןיקתמל תוארוה49-55

הריכמה רחאל תוריש56

31

Page 32

32

תובושח תוחיטב תוארוה

.תע לכב רומשל שי וילעו אורקל שי ותוא בושח יתוחיטב עדימ םיללוכ ומצע רישכמהו הז ךירדמ

קזנ ,העיצפל ןוכיסה תא תיחפהל דציכ ןייצמו תומייקה תויורשפאה תונכסה תא טרפמ יתוחיטבה עדימה לכ

:תואבה תוארוהה לע דיפקהל שי .רישכמב ןוכנ אל שומישמ האצותכ תולמשחתהו

.הנקתה תדובע לכ עוציב ינפל למשחהמ רישכמה תא קתנל שי

,ולש תבשותה ךותב ןקתוה אוהש רחאל ,רישכמה רוביחל קיפסמ ךורא למשח לבכב שמתשהל שי

.למשחה עקש לא

יבטוק בר קותינ קספמב שמתשהל שי ,תומייקה תוחיטבה תונקתב דומעת הנקתההש תנמ לע

.מ"מ 3 לש ירעזמ עגמ חוורמ םע

.םיכיראמ םילבכב וא םימאתמב שמתשהל ןיא

.עקשהמ רישכמה תא קתנל ידכ למשחה לבכ תא ךושמל ןיא

.הנקתהה רחאל שמתשמל םישיגנ ויהי אל םיילמשחה םיביכרהש דיפקהל שי

תנכס - רישכמה לש םיימינפה םיחטשמב וא םומיחה יפוגב תעגהל ןיא ,שומישה רחאלו ךלהמב

ולש םיקלחה לכש דע תעגל רישכמב תעגל םירחא םיקילד םירמוח וא תוילטמל רשפאל ןיא .תויווכ

.תקפסמ הדימב וררקתה

רוטיקה וא םחה ריוואל חינהלו ,רישכמה תלד תחיתפב תוריהז הנשמב טוקנל שי לושיבה םויסב

ךרד אצוי םח ריווא הרוגס רישכמה תלד רשאכ .רונתה ךות לא םיידי םיטישומש ינפל הגרדהב תאצל

.רורוואה חתפ תא םוסחל ןיא .הרקבה חול לעמש רורוואה חתפ

.םימחה םיקלחב תעגל אל רהזיהלו םילכו תוינבת איצוהל ידכ רונתל תופפכב שמתשהל שי

ץורפל היושע ,תועטב קלדיי רישכמה םא :רישכמה תברקב וא ךותב םיקילד םירמוח חינהל ןיא

םורגל יושע םכותב רבטצמש ץחלה .רישכמה ךותב םימוטא לוביק ילכ וא תונצנצ לשבל וא םמחל ןיא

.רישכמב עוגפלו ץצופתהל םהל

.םייטתניס םירמוחמ םייושעה לוביק ילכב שמתשהל ןיא

הנשמ לע דיפקהל שי .תוריהמב רועבל םיליחתמ הדימה לע רתי םיממחתמש םינמושו םינמש

.ןמשבו ןמושב רישע ןוזמ םילשבמשכ תוריהז

.ןוזמ שוביי ןמזב החגשה אלל רישכמה תא ריאשהל ןיא םלועל

םכילע )ןייו קאינוק ,םור ןוגכ( ןוזמ לושיב תעב םיילוהוכלא תואקשמב םישמתשמ םתאו הדימב

םיררחתשמש םידאהש הנכס תמייק ,ךכמ האצותכ .תוהובג תורוטרפמטב ףדנתמ לוהוכלא יכ רוכזל

.ילמשחה םומיחה ףוג םע עגמב וקלדי לוהוכלאהמ

.הפירש

Page 33

33

תובושח תוחיטב תוארוה

תרמשנ הז רישכמ לש למשחה תוחיטב

תכרעמל יוארכ רבוחמ אוה םא קר

ינקתב םושרש יפכ ,המיאתמ הקראה

תאזב רוטפ ןרציה .למשחה תוחיטב

אל הלא תוארוהו הדימב תוירחאמ

ונפ ,קפס םכל שי םא .הכלהכ תומשוימ

.ךמסומ עוצקמ שיאמ הרזע תלבקל

םינותנהש ואדו ,רישכמה רוביח ינפל

םימאות גורידה תיחול ינותנב םימושרה

םכלש למשחהו זגה תקפסא לש הלאל

.)"ינכט טרפמ" ףיעסב ונייע(

בייחמ אוהש ילמשח רישכמב שומיש לכ

:דוסי יללכ רפסמ יפ לע לועפל

םיילגר וא םיידי םע רישכמב תעגל ןיא

.תוחל וא תובוטר

.םיפחי רישכמב שמתשהל ןיא

תנמ לע למשחה לבכ תא ךושמל ןיא

.למשחה עקשמ רישכמה תא קתנל

יקזנל ףושח רישכמה תא ריאשהל ןיא

.)'וכו שמש ,םשג( הביבסה

םייושע םישיגנה ויקלח לכו רישכמה :הרהזא

טוקנל שי .שומישה ךלהמב דואמ םמחתהל

ףוגב תעגלמ ענמיהל תנמ לע תוריהזב

8 ליגל תחתמ םידלי קיחרהל שי .םומיחה

.תע לכב םהילע םיחיגשמ םא אלא רישכמהמ

םישיגנה היקלח לע רונתה לש תיכוכזה תלד

שי .שומישה ךלהמב דואמ םמחתהל היושע

.תויווכ עונמל תנמ לע םיריעצ םידלי קיחרהל

תנמ לע תע לכב םיריעצ םידלי לע חיגשהל שי

.רישכמה םע םיקחשמ םניא םהש אדוול

,תויזיפ תולוכי ילעב םישנא ןכו הלעמו 8 ינב םידלי

וא/ו ןויסינ אלל וא תודורי השיח וא ,תוילטנמ

םדא םא רישכמב שמתשהל םיאשר תונמוימ

םדא םא וא םהילע חיגשמ םתוחיטב לע יארחאה

רישכמב החטבב שמתשהל דציכ םתוא החנמ הז

.וב תונומטה תונכסה תא ןיבהלו

ןיא .רישכמה םע קחשל םידליל רשפאל ןיא

ןויקינה תולועפ תא עצבל םידליל רשפאל

.החגשה אלל הקוזחתהו

לופיל רישכמהמ עונמל תנמ לע :הרהזא

רונתה תלד לע ספטמ דלי םא לשמל ,תועטב

םידבכ םילקשמ םיניעשמ םא וא ,החותפה

גירבהל שי ,החותפה רונתה תלד לע ידמ

ריקל ןתוא עבקלו רונתה בגב תוארשרש יתש

.תוחותמ תוארשרשה יכ אדוול שי .םיוו תרזעב

.הנקתהה תוארוהב ונייע ,םיפסונ םיטרפל

דחא תא םתשכרש לע םכל םידומ ונא

,ינרדומ רישכמש םיחוטב ונא .ונירצוממ

שומיש ךות רצויש ,הז ישומישו ילנויצקנופ

לכב דומעי ,רתויב םייתוכיאה םירמוחב

רישכמב שמתשהל לק .םכלש תושירדה

וליחתתו ותוא וניקתתש ינפל ךא ,שדחה

תא בטיה וארקתש בושח וב שמתשהל

יתוחיטב עדימ ללוכ אוה .הזה ךירדמה

ךירדמה תא ורמש .הקוזחתו שומיש ,הנקתהל

.ידיתע שומיש לכל חוטב םוקמב הזה

לכ תא עצבל תוכזה תא ומצעל רמוש ןרציה

,וירצומב םיבייחתמה וא םישרדנה םייונישה

ילבמ ,תישיאה םכתבוטלו ויניע תואר יפל

ינייפאמ תאו תוינויחה תולועפה תא ןכסל

תאזב רוטפ ןרציה .םירצומה לש תוחיטבה

תויושעש תויועט וא קויד רסוח לכ לע תוירחאמ

.ותדלקה וא ותספדהמ האצותכ ךירדמב עיפוהל

הז ךירדמבש םירויאב תוגצומה תונומתה :.ב.נ

.דבלב השחמהל ןה

תא עצבל יאשר ךמסומ עוצקמ שיא קר

יונישה ,ןוויכה ,הנקתהה תולועפ לכ

תוארוה" קלחב תוטרופמש הקוזחתהו

."ןיקתמל

זג לע םילעופה םירישכמ תנקתה תעב

דומעל שי םיבלושמ םירישכמ וא דבלב

.םילחה םינקתה לכב

הרטמל קרו ךא רישכמב שמתשהל שי

,רמולכ ,דעונ אוה המשלש תירוקמה

בשחנ רחא שומיש לכ .יתיב לושיב

.ןכוסמ ,ךכשו ,יואר אל שומישכ

לכ רובע תוירחאמ תאזב רוטפ ןרציה

האצותכ םרגייש שוכרל וא םדאל קזנ

ןוכנ אל שומיש וא הקוזחת ,הנקתהמ

.רישכמב

הזיראה ירמוח לכ תאצוה רחאל

םיקלחהו םיינוציחה םיחטשמהמ

הדיפקב וקדב ,םינושה םיימינפה

םא .ןיוצמ בצמב אצמנ רישכמהש

רישכמב ושמתשת לא ,קפס םכל שי

.ךמסומ עוצקמ שיאל ורשקתהו

הזיראה ירמוח תא ריאשהל ןיא

תויקש ,ןוטרקה תספוק( שומישבש

)ב"צויכו םירמסמ ,רקלק ,קיטסלפה

םהש ןוויכמ םידלי לש םדי גשיהב

לכ .םרובע הנכסל ירשפא רוקמ םיווהמ

הביבסל םייתודידי םה הזיראה ירמוח

.רוזחמל םינתינו

Page 34

34

תובושח תוחיטב תוארוה

שיא קר .םכמצעב רישכמב לפטלו תוסנל

תלועפ לכ עצבל יאשר ךמסומ עוצקמ

םכל םיצילממ ונא ,ךכ לשב .ןוויכ וא ןוקית

בורקה תורישה זכרמ םע רשק רוציל

גוסו רישכמה םגד ןויצ ךות ,םכתיבל

.היעבה

םייפוריאה םינקתל םאתהב רצויו ןנכות רישכמה

:םיאבה

EN -ו EN 30-1-1, EN 30-2-1 >=

תוולנה תופסותה לכו )זג( 437

EN 60 335-2-6 -ו EN 60 335-1 >=

תוולנה תופסותה לכו )למשח(

תויפוריאה תויחנהב םושרל םאות רישכמה

:תואבה

למשחב תוחיטב רבדב EC 2006/95 >=

.)BT(

תומיאת רבדב 2004/108 EC >=

.)EMC( תיטנגמורטקלא

.זגב תוחיטב רבדב 2009/142 EC >=

ןוזמ ירמוחב תעגל םייושע רשא רונתה יקלח

היחנה לש תונקתל םימאותש םירמוחמ םייושע

.21/12/88 ךיראתמ 89/109 EC

. 2002/96/ EC תיפוריא היחנה םע םאות הז רצומ

ןייצמ ךירדמב עיפומש קוחמה הפשאה חפ למס

הפשאהמ דרפנב רישכמה תא ךילשהל שי יכ

ריבעהל שי .ולש םייחה תלחות םויסב תיתיבה

דעוימה תלוספ רוזחמל זכרמ לא רישכמה תא

תעב קוושמל וריזחהל וא ינורטקלאו ילמשח דויצל

.המוד ילמשח רישכמ תשיכר

רישכמה תרבעה לע תאזב יארחא שמתשמה

.ולש םייחה תלחות םויסב םיאתמ ףוסיא זכרמל

יפכ תוסנק רורגל לולע וז היחנה רחא יולימ יא

.תלוספ תכלשה לע םילחה םיקוחב עבקנש

הב לופיטה ,הרוזחמ ךרוצל הפשאה תדרפה

םצמצל עייסמ הביבסל יתודידי ןפואב התכלשהו

הביבסה לע תוירשפאה תוילילשה תוכלשהה תא

םירמוחה תא רזחמל רשפאמו תואירבה לעו

.רצומה יושע םהמש

ףוסיא תוכרעמ רבדב םיפסונ םיטרפ תלבקל

תלוספ תכלשהל זכרמה לא ונפ ,תומייקה הפשאה

רצומה הבש תונחל וא םכירוגמ רוזאב הקצומ

.שכרנ

תושירדב הדימע לע םיארחא םינאוביהו םינרציה

יתודידי ןפואב הכלשהו לופיט ,רוזחמל תועגונה

ףיקע וא רישי קלח תחיקל ידי-לע הביבבסל

.תלוספ ףוסיא תוכרעמב

אלל ןמש וא ןמוש תועצמאב םייריכב לושיב

הלולעה תנכוסמ הלועפ הווהמ החגשה

.הפירשב םייתסהל

הפירשה תא תובכל תוסנל ןיא םלועל

תא תובכל ןיפוליחל אלא ,םימ תרזעב

תרזעב הבהלה תא תוסכלו רישכמה

.םימוד םיצפח וא שא יוביכ תכימש ,הסכמ

יבג לע םיטירפ ןסחאל ןיא :הפירש תנכס

לושיבה יחטשמ

וא םיקזח יוקינ ירמוחב שמתשהל ןיא

לע דוריגל םישמשמה םידח תכתמ יצפח

םהו רחאמ תיכוכזה תלד תא תוקנל תנמ

םורגלו תיכוכזה חטשמ תא טורשל םילולע

םיגופסב שמתשהל ןיא םלועל .רבשיהל ול

םינמוש יריסמ ןכו ,םיקחוש םירצומ וא

םינמוש וא םימתכ תדרוה ךרוצל םהינימל

יחטשמ וא םיעובצה םיחטשמהמ וקבדנש

.דלח-לא תדלפ

רצע ןועש תרזעב רישכמב שמתשהל ןיא

קוחרמ הטילשל תדרפנ תכרעמ וא ינוציח

םתאש ינפל יובכ רישכמהש ואדו

עונמל ידכ ,הרונה תא םיפילחמ

.תולמשחתה לש תורשפא

תא תוקנל תנמ לע רוטיקב שמתשהל ןיא

.רונתה וא םייריכה

הפצרה לע תורישי רישכמה תא חינהל שי

.סיסב יבג לע וביכרהל ןיאו

ןוזמ תויראש .יקנ רישכמה לע ורמש

.הפירשל םורגל תולוכי

שמתשהל ןיא ,שומישב וניא רונתה רשאכ

ילכ וא ןוזמ ירמוח ןסחאל תנמ לע וב

לולע אוה ,תועטב קלדיי אוה םא :לוביק

.הנואתלו קזנל םורגל

למשח עקשב םישמתשמ םתא םא

םילבכהש ואדו ,רישכמה תברקב אצמנש

םיעגונ םניא םיילמשחה םיביכרה ראש וא

םימחה םיקלחהמ קיפסמ םיקוחרו רונתב

.רונתה לש

לכש ואדו ,רישכמב שומישה םויסב

)off( יובכ בצמב תואצמנ תורקבה

ספדומש "" למסל םאות "0" רותפכהשו

.ימדקה חולה לע

,ןוויכ ,ןויקינ תלועפ לכ עוציב ינפל

רישכמה תא וקתנ ,הקוזחת וא יוניש

.למשחהמ

ובכ ,הלקת וא/ו היעב תררועתמו הדימב

ןיא .למשחהמ ותוא וקתנו רישכמה תא

Page 35

35

רישכמה רואית

רויא( םיבלש םיארקנה םיצירח םנשי רונתה תונפדב

ןלהל םימושרה םירזיבאה תא חינהל ןתינ םהילע )1

םאתהב םינתשמ םירזיבאה תויומכו יגוס .)2 רויא(

:םגדל

)A( רונתה ףדמ

)B( םילזונ תריגא תינבת וא שגמ

)C( הציפ וא תוגוע תייפאל שגמ

הגצה

לוכי רונתה ;ילמשח רונתו םייריכ םיללוכ םירונתה

תובהל .ררוואמ םע רונת וא ,ליגר רונת תויהל

)thermocouples( ימרת דמצ תוללוכ םייריכה

.)6 רויא ,Tc( יתוחיטב

םישרת שי ימדקה חולב םירותפכהמ דחא לכ לעמ

ןיב בולישה .ךייש אוה הבהל וזיאל הארמה ספדומ

תונונגסב לשבל םכל רשפאמ םינוש םילדגב תובהל

.םינוש

םויסל הנומ םע ינורטקלא ןועש ללוכ רונתה םא

דומעל ילבמ רונתב שמתשהל ןתינש ךכ ,לושיבה

דמ םג ללוכ אוה ,לכואה לע חיגשהלו ןמזה לכ ודיל

רונתב שומישה תוחיטב לע רמושש יתוחיטב םוח

.לקלקתמ ישארה םוחה דמו הדימב לועפל ליחתמו

ןיא :רצק ןמזל קספנ למשחה םרז ,הזכ הרקמב

תא תובכל אלא ,םכמצעב תאז ןקתלו תוסנל

בורקה תורישה דקומ םע רשק רוצילו רישכמה

.םכתיבל

2

1

Page 36

36

רישכמה רואית

�

A

b

C

םירקבה רואית

)A( זג םייריכ רעבמ רותפכ

אבה למסה ,ןועשה ןוויכ דגנ רותפכה בוביס ידי-לע

:עיפומ

0יובכ =

ההובג הבהל לע קלוד =

הכומנ הבהל לע קלוד =

)B( רונתה ררוואמל םוח דמ רותפכ

וגצוי ,ןועשה ןוויכ םע רונתה רותפכ בוביס ידי-לע

דעו 50°C -מ לחה( תונושה רונתה תורוטרפמט

.)תיברמה הרוטרפמטל

)C( )8( רונתה ררוואמ תולועפ תריחב רותפכ

םילמסה לאמשל וא ןימיל רותפכה בוביס ידי-לע

:ועיפוי םיאבה

0יובכ רונתה =

לכל ךכ תראשנו תקלוד רונתה תרואת =

תולועפה

לעופ ררוואמה =

םילעופ ,ןותחתהו ןוילעה ,םומיחה יפוג =

ררוואמהו ,ןותחתהו ןוילעה ,םומיחה יפוג =

םילעופ

םילעופ ררוואמהו ןותחתה םומיחה ףוג =

םילעופ ררוואמהו ירוחאה םומיחה ףוג =

לירג =

םילעופ ררוואמהו לירגה =

לירגה וא רונתהש תנייצמ וז הרונ ,תקלוד איה רשאכ

הבוהצ הערתה תרונ

הרונה ,רונתב שומישה ןמזב .םילעופ ילמשחה

.הרדגוהש הרוטרפמטל עיגי רונתה רשאכ הבכת

תובכיהלו קלדיהל היושע הרונה ,היפא ךלהמב

.רונתה תרוטרפמט תרקבמ קלחכ ,םעפל םעפמ

המודא הערתה תרונ

רתוי וא דחאש תנייצמ וז הרונ ,תקלוד איה רשאכ

בצמ לע אצמנ רותפכה םא םילעופ םומיחה יפוגמ

למשחה יביכרמ דחאש וא ,ילמשח וא בלושמ

.םילעופ

Page 37

37

רישכמה רואית

תרזעב תינכתה לש םויסה ןמזו ךשמ תא ורחב

"End"ו "A" למסהו הבכי ןועשה .- -ו + םינצחלה

למסה .קלדיי "A" למסהו הבכיי למסה .ובהבהי

ןמזה םויסב .לחי לושיבה רשאכ בוש קלדיי

הבכיי למסה ,לעפת תילוקה הערתהה ,רדגוהש

וצחל תילוקה הערתהה יוביכל .בהבהי "A" למסהוו

הלועפל תינכתה תא ןווכל ידכ .יובכ רונתה ,תעכ

לע תוינש המכ ךשמב הכורא הציחל וצחל ,תינדי

MODE ןצחלה לע קר וא דחיב - -ו + םינצחלה

הציחל תרזעב תוינכתהמ תחא לכ תוקנל ןתינ

.דחיב - -ו + םינצחלה לע תוינש המכ ךשמב הכורא

הציחל ידי לע תוינכתהמ תחא לכ ףילחהל ןתינ

זאו MODE ןצחלה לע תוינש המכ ךשמב הכורא

ןווכל ןתינ .הלועפה יונישל וילע תורצק תוציחל

ידי לע תוינכתהמ תחא לכ תומדקתה תא קודבל ןתינ

MODE ןצחלה לע תוינש המכ ךשמב הכורא הציחל

.הלועפה תקידבל וילע תורצק תוציחל זאו

.MODE ןצחלה לע

.קלדיי

תוינכת יוקינ/תפלחה

.הבכיי "A" למסה

.- -ו + םינצחלה תרזעב

למסהו

3 .םויס ןמזו ךשמ םע תיטמוטוא תינכת

תקספה רחאל וא ,למשחל רישכמה רוביח רחאל

.הגוצתב "0,00" םע דחי בהבהי "A" למסה ,למשח

םינצחלה לע תוינש המכ ךשמב הכורא הציחל וצחל

למסהש דע MODE ןצחלה לע קר וא דחיב - -ו +

למסל תחתמש הדוקנה דוע לכ העשה תא ןווכל ןתינ

לושיב תינכתש ןמזב העשה תא ןווכל ןתינ אל

תיטמוטוא לושיב תינכתש ןמזב העש םתרחב םא

ןצחלה לע תוינש המכ ךשמב הכורא הציחל וצחל

ןיב רבעמל תורצק תוציחל וילע וצחל זאו MODE

םינצחלה תרזעבו קלדנ

ןמזה םויסב .הארתהה ןמז תא רוחבל ןתינ - -ו +

למסהו לעפת תילוקה הערתהה ,רדגוהש

וצחל

יאמצעו דרפנ ןפואב תלעופ תילוקה תרוכזתה תינכת

למסהו תילוקה הערתהה יוביכל .בהבהי

המכ ךשמב MODE ןצחלה לע הכורא הציחל

)E( ינורטקלא תונכת ישקמ

.העשה ןוויכ

.עיפוי

למסהו םלעי "A"

.תבהבהמ

.קחמית איה ,תלעופ

תינכת תריחב

:תואבה תוינכתה

1 .תילוק תרוכזת

למסה ,הבכנ ןועשה

.לושיבה תוינכת ראשמ

.תלעופ

.תוינש

E

ןמז וא ךשמ םע תיטמוטוא יצח תינכת 2 .

.- -ו + םינצחלה תרזעב תינכתה ךשמ תא ורחב

םויסב .ובהבהי "dur"ו "A" למסהו הבכי ןועשה

"A" למסהו לעפת תילוקה הערתהה ,רדגוהש ןמזה

ןצחלה לע וצחל תילוקה הערתהה יוביכל .בהבהי

המכ ךשמב הכורא הציחל וצחל .יובכ רונתה ,תעכ

ןצחלה לע קר וא דחיב - -ו + םינצחלה לע תוינש

.קלדיי

למסהו MODE

םויס

.MODE

Page 38

38

שמתשמל ךירדמ

בושח ,זגה תכירצ תא תיבטימ הרוצב לצנל ידכ

םייריכב יבטימ שומיש

:תואבה תודוקנה תא רוכזל

תא ונווכ ,רעבמה תא םתקלדהש רחאל

.םכלש םיכרצל םאתהב הבהלה תמצוע

תחא לכל םיאתמ לדוגב ריסב ושמתשה

.)4 רויאבו ןלהלש הלבטב ונייע( תובהלהמ

ובבוס ,חותרל הליחתמ ריסה תלוכת רשאכ

שא( "הכומנ הבהל" בצמל רותפכה תא

.)הנטק

םייריכמ"סב ריס רטוק

ההובג תוריהמ22-24

ריהמ20-22

תוריהמ-יצח16-18

רזע12-14

תויללכ תוחיטב תוארוה :רונת

ךלהמב החגשה אלל רונתה תא ריאשהל ןיא

םע םיקחשמ םניא םידליש ואדו .שומישה

.רישכמה

תעב רונתה תלד זכרמב זוחאל ודיפקה

תלדה לע ידמ בר ץחל ליעפהל ןיא .התחיתפ

.החותפ איה רשאכ

לע םיבעתמ םימ םא שושחל םיכירצ םכניא

ךלהמב רונתה לש תוימינפה תונפדהו תלדה

.ותלועפ ביטב עגופ וניא הז רבד .לושיבה

רונתה תלד תחיתפ תעב תוריהז הנשמב וטקנ

.םידאמ ורהזיהו

ךלהמב דואמ םמחתהל יושע רישכמה

ךותבש םומיחה יפוגב תעגל ןיא .שומישה

םתא רשאכ תופפכב ושמתשה .רונתה

.רונתהמ תוינבת םיאיצומ וא םיסינכמ

,רונתהמ ןוזמ םיאיצומ וא םיסינכמ םתא רשאכ

םישלוג םניא ורגינש םילזונו םיצימש וקדב

םירמוח םה םינמושו םינמש( רונתה סיסב לע

.)םיממחתמ םה רשאכ דואמ םיקילד

תורוטרפמטב םידימעה לוביק ילכב ושמתשה

.םוחה דמ רותפכ ןייצמש

ונא ,לושיבה ךלהמב תויבטימ תואצות תלבקל

וא רונתה סיסב תא תוסכל אל םוחב םיצילממ

.םירחא םירמוחב וא םוינימולא ריינב לירגה

תוחיטבל עגונב תויללכ תורעה :םייריכ

ריאשהל ןיא םייריכב םישמתשמ םתא רשאכ

םניא םידליש ואדו .החגשה אלל רישכמה תא

ךכל דחוימב בל ומיש .רישכמה םע םיקחשמ

תוחנומ תותבחמהו םיריסה לש תוידיהש

ליכמה ןוזמ לושיב לע וחיגשהו ןוכנ םוקמב

םיקילד םירמוח םה ולא ןכש ,םינמושו םינמש

.דואמ

תברקב םיססרמ וא םיסיסרתב שמתשהל ןיא

.שומישב אוה רשאכ רישכמה

תוטלפה וא תובהלה ,שומישה םותב םג

עונמל ידכ ;בר ןמז ךשמב תומח תוראשנ

ןהילע חינהל וא םיידיב ןהב תעגל ןיא ,היווכ

.םיצפח

םירקבה לכש ואדו ,רישכמב שומישה םותב

.יובכ בצמב וא םירוגס

םירציימ םה ,זג םע םייריכב םישמתשמ רשאכ

,ךכ לשב .םינקתומ םה ובש רדחב תוחלו םוח

ךות ,רדחה תא בטיה ררוואלו דיפקהל םכילע

תקלדהו םיחותפ רורוואה יחתפ לע הרימש

םוקימו רורווא« לע םיקלחב ונייע( םידאה טלוק

ךשמב רונתב םישמתשמ םא.)»םידאה טלוקו

,רוזאה תא רתוי ררוואל וכרטצתש ןכתי בר ןמז

קזח רורווא וא ,ןולח תחיתפ ידי-לע לשמל

,םידאה טלוק לש המצועה תלדגה ידי-לע רתוי

.ןקתומ אוהו הדימב

םייריכה תקלדה

יתוחיטב ימרת דמצ םיללוכה םייריכ תקלדה

)TC ,6 רויא(

םכילע ,יתוחיטב ימרת דמצ םיללוכ םירעבמה רשאכ

קילדהל םכנוצרבש רעבמה לש רותפכה תא בבוסל

ןכמ רחאלו "ההובג הבהל" םוקימל ןועשה ןוויכ דגנ

הראותש הלועפה תא בוש עצבלו רותפכה לע ץוחלל

לע ץוחלל וכישמה ,רעבמה תקלדה רחאל .ליעל

.תוינש 10 -כ ךשמב רותפכה

4

Page 39

39

שמתשמל ךירדמ

רונתה תולועפב שמתשהל דציכ

רדחה תרוטרפמטב הרשפה

ןוזמה תא וסינכהו למסה לא רותפכה תא ובבוס

שורדש ןמזה ךשמ .רונתה ךותל רישפהל םכנוצרבש

.ןוזמה גוסו תומכל םאתהב הנתשמ הרשפהל

תמירז .ררוואמה תא קר הליעפמ וז תורשפא תריחב

.טאל ותוא רישפת אופקה ןוזמל ביבסמ הנידע ריווא

.תוגועו תוריפל דחוימב המיאתמ וז הלועפ

ליגר לושיב