Whirlpool 9757668 Instruction Sheet

TECH SHEET - DO NOT DISCARD PAGE 1

WARNING

Electric Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

Caution: Label all wires

prior to disconnection when

servicing controls. Wiring

errors can cause improper

and dangerous operation.

Verify proper operation after

servicing.

PART NO. 9757668

NOTE: This sheet contains important Technical Service Data

FOR SERVICE TECHNICIAN ONLY

DO NOT REMOVE OR DESTROY

NOTE: Drawing shows door is opened,

unlocked, and burners off.

L1

GND

BK

BK

DOOR

SWITCH

OVEN

TEMP

SENSOR

COM

N.O.

Y

Y

V

t°

V

OVEN CONTROL

P4-3

Y

P3-3

Y

P3-4

V

P3-6

V

P3-7

TRANSFORMER

OVEN LIGHT RELAY

K-4

LATCH RELAY

K-3

COOLING

FAN RELAY

K-8

P4-1

P4-4

P4-5

P4-7

W

CONTROL TOD

BK/W

LATCH DRIVE

BR

GY

96.1°±3°C

(205°±6°F)

M

WW

OVEN LIGHT 1

OVEN LIGHT 2

OVEN TOD

120°+10°-0°C

()

248°+18°-0°F

COOLING

FAN M OTO R

M

N

W

W

W

W

DOOR LATCH

SWITCH

N.O.

BU

P3-1

P3-2

BROIL RELAY

K-2

BK

GND

BK

SURFACE BURNER

IGNITION SWITCHES

BK

BK

BK

P2-2

BAKE RELAY

G

BK

K-1

BK

P2-1

P2-4

COM

BU

BU

R

GY

COOLING FANTOD

70°±3°C

(158°±6°F)

W

BU

OR

R

BROIL SOLENOID

S

BAKE SOLENOID

S

OR

OR

J1

DSI

10 9 2 1436

SURFACE IGNITORS

587

BAKE

GND

BROIL

05/04 FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 9757668

PAGE 2 TECH SHEET - DO NOT DISCARD

Pressing the TEMP pad “up” arrow (▲)

DIAGNOSTICS

Unplug range or disconnect power before

performing the following checks:

The most common cause for control

■

failure is corrosion on connectors.

Therefore, disconnecting and

reconnecting wires will be necessary

throughout test procedures.

Check all connections before replacing

■

components, looking for broken or

loose wires, failed terminals, or wires

not pressed into connectors far enough.

All tests/checks should be made with a

■

VOM or DVM having a sensitivity of

20,000 ohms per volt DC or greater.

Resistance checks must be made with

■

power cord unplugged from outlet, and

with wiring harness or connectors

disconnected.

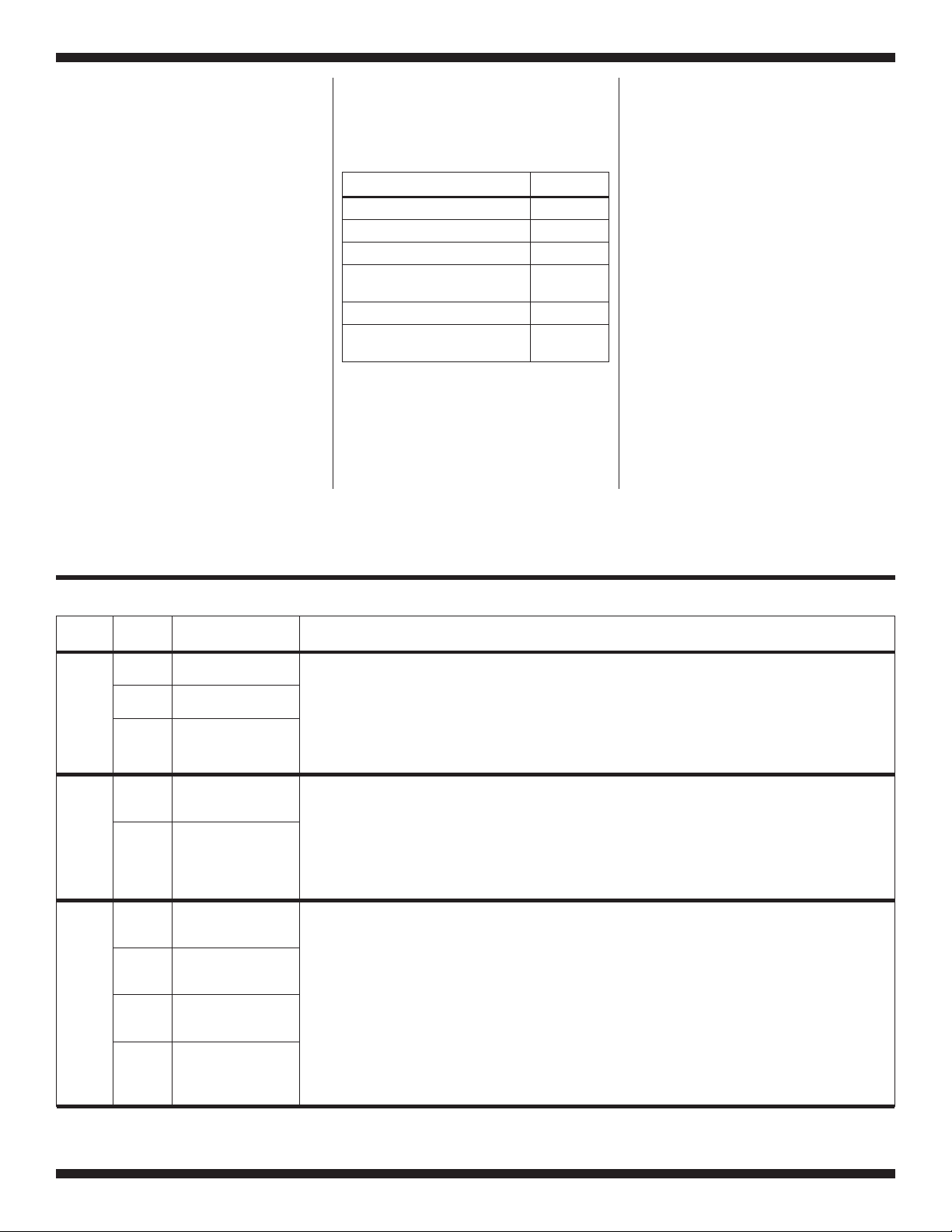

Hidden EOC Functions

User activates all hidden EOC functions by

pressing and holding the appropriate key

for 5 seconds. Below is a list of hidden

functions or features:

HIDDEN FUNCTIONS KEY

Temperature calibration offset Bake

°F to °C Broil

Recall last failure code Off/Cancel

Disable/enable cycle end audible

signal

Cook Time

Disable/enable reminder signal Timer Set

Disable/enable valid data entry

signals

Stop Time

Temperature Adjustment

Press and hold BAKE pad for five (5)

■

seconds. Current offset, if any, is shown

in 3-digit display. CAL is shown in

4-digit display (3 digits on right).

■

adjusts the temperature in 5.6°C (10°F)

increments in the following sequence:

Celsius: 0°, 5.6°, 11.1°, 16.7°, -16.7°,

-11.1°, -5.6°, 0°; (Fahrenheit: 0°, 10°, 20°,

30°, -30°, -20°, -10°, 0°) and so on.

Press START/ENTER pad to activate the

■

desired temperature adjustment. If the

START/ENTER pad is not pressed

within 5 minutes, adjustment is ignored.

BAKE temperature adjustment cannot

■

result in operating temperatures higher

than 274°C (525°F) or lower than 77°C

(170°F), as measured at oven cavity

center.

Once the BAKE temperature has been

■

adjusted, BROIL temperatures are

automatically offset to the same degree.

CLEAN temperature is also offset

■

automatically when BAKE temperature

is adjusted. If BAKE temperature has

been raised, CLEAN temperature is

offset +3°C (+5°F). If BAKE

temperature has been lowered, CLEAN

temperature is offset -3°C (-5°F).

FAILURE/ERROR DISPLAY CODES

4-DIGIT

DISPLAY

F3

F1

F2

3-DIGIT

DISPLAY

E0

E1

E2

E0

E1

E0

E1

E2

E3

LIKELY FAILURE

CONDITION

EEPROM

communications error

EEPROM checksum

failure

UL A/D error(s)

Shorted key

Keytail unplugged

Oven sensor opened

Oven sensor shorted

BAKE/BROIL range

over temperature

CLEAN range over

temperature

1. Verify failure if not displayed, using CANCEL/OFF key. Press key for 5 seconds until last error code

is displayed.

2. Unplug range or disconnect power longer than 30 seconds.

3. Plug in range or reconnect power and observe for longer than 1 minute.

4. If failure remains, go to step 5.

5. Unplug range or disconnect power.

6. Replace control.

1. Verify failure if not displayed, using CANCEL/OFF key. Press for 5 seconds.

2. Unplug range or disconnect power.

3. If applicable, ensure membrane tail is seated in connector on back of control.

4. Plug in range or reconnect power and observe for longer than 1 minute.

5. If failure remains, go to step 6.

6. Unplug range or disconnect power.

7. Replace control.

1. Unplug range or disconnect power.

2. Disconnect sensor from harness.

3. Measure sensor value (between connector pins) between 1000

(900° F), (room temperature approx. = 1080

possible short. If measurements do not correlate to real temperature, or if short is found, replace sensor.

4. Trace the wires and connectors to the sensor from control, and back to control. If wire or connection

is damaged, replace the harness.

5. Reconnect the sensor to the harness.

6. Plug in range or reconnect power.

7. Press BAKE and START/ENTER. Observe for longer than 1 minute. If failure remains, go to step 8.

8. Unplug range or disconnect power.

9. Replace control.

SUGGESTED CORRECTIVE ACTION PROCEDURE

Ω

Ω

). Also measure from sensor connector to sensor casing for

@0°C(32° F) and 2697Ω@ 482° C

Continued...

PART NO. 9757668 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 3

4-DIGIT

DISPLAY

F5

3-DIGIT

DISPLAY

E0

E1

E2

LIKELY FAILURE

CONDITION

Door and switches

do not agree

Door latch not

operating

Latch error during

CLEAN

SUGGESTED CORRECTIVE ACTION PROCEDURE

1. Press CANCEL/OFF key. Program and start the CLEAN mode. Ensure door is closed and latched.

2. Unplug range or disconnect power.

3. Check integrity of wires and connectors from control to door switch, and control to door latch switch.

4. If no damage to wires or connectors:

-Check continuity of the door switch circuit from oven control. If continuity is not present, replace door switch

(If door switch is integral to the door latch motor assembly, replace entire door latch motor assembly).

-Check continuity of door latch switch circuit. If continuity is not present, replace door latch motor assembly.

5. Plug in range or reconnect power.

6. Press CANCEL/OFF key. Program and start the CLEAN mode, and observe for 1 minute to ensure

that operation is normal.

1. Verify error code by pressing and holding CANCEL/OFF key for 5 seconds. Momentarily (less than 5 sec.)

press CANCEL/OFF key again to remove error code display.

2. If the door is not latched (locked), ensure that it is completely closed. Press CLEAN then START/ENTER.

Verify that the latch motor is operating.

3. Unplug range or disconnect power.

4. If motor did operate, check integrity of latch mechanism from cam/eccentric, through actuating rod, to latch

pawl and door slot. Ensure that pawl aligns with the door slot. Correct any mechanical malfunction. Go to

step 6.

5. If motor did not operate, check continuity of the latch motor and of electrical connections between oven

control and door latch motor assembly.

-Ifcontinuity is not present, replace door latch motor assembly.

-Ifcontinuity is present, replace control.

6. Plug in range or reconnect power.

7. Put range into CLEAN mode to verify proper operation.

1. Unplug range or disconnect power.

2. Check wires and connectors from control to door switch, then from door switch to control.

3. If no damage to wires or connectors, replace door switch (If door switch is integral to the door latch motor

assembly, replace entire door latch motor assembly).

4. Plug in range or reconnect power.

5. Press CANCEL/OFF key. Program and start the CLEAN mode, and observe for 1 minute to ensure that

operation is normal.

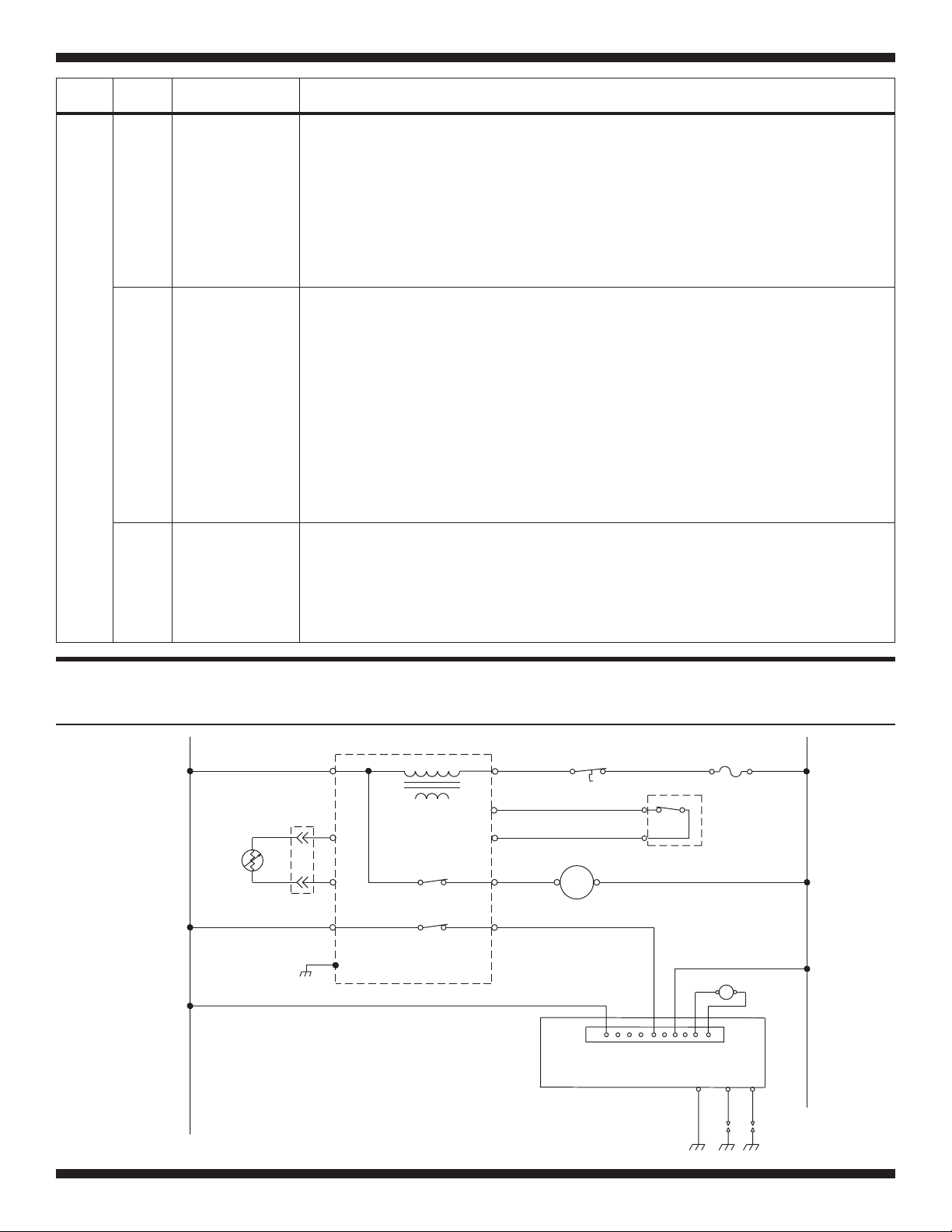

STRIP CIRCUITS

CLEAN

L1

BK

BK

BK

The following individual circuits are for use in diagnosis, and are shown in the ON position.

Do not continue with the diagnosis of the appliance if a fuse is blown, a circuit breaker is tripped,

or if there is less than a 120 volt (115 volt Canada) power supply at the wall outlet.

BK

OVEN

TEMP

SENSOR

BR

W

BU

BU

LATCH DRIVE

R

DSI

CONTROL TOD

96.1° ±3°C

(205°±6°F)

M

J1

10 9 2 143658

SWITCH

N.O.

COM

W

7

OVEN CONTROL

P4-3

V

V

P3-6

t°

V

V

P3-7

P2-2

G

GND

TRANSFORMER

LATCH RELAY

K-3

BAKE RELAY

K-1

P4-1

P3-1

P3-2

P4-5

P2-4

OVEN TOD

120°+10°-0°C

()

248°+18°-0°F

BAKE SOLENOID

OR

S

R

BAKE

GND

BROIL

N

WW

W

W

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 9757668

Loading...

Loading...