Part No.8535840

Installation Instructions

IMPORTANT:

Read and save these

instructions.

Installer: Leave Installation Instructions with

homeowner.

Homeowner: Keep Installation Instructions for

future reference.For best performance,

install dryer according to Installation

Instructions. Failure to complete

installation as instructed could void

warranty.

Save Installation Instructions for local

inspector’s use.

Have questions about your dryer?

Call your dealer or local authorized service company.

When you call, you will need the dryer model number and serial

number.Both numbers are on the model/serial rating plate located in

the door well behind the dryer door and on front of opening.

Record the numbers here for handy reference:

Model No.

Serial No.

Electric Dryer

2

Before you begin...

Tools needed for installation

Parts supplied for installation

• level

• gloves

• adjustable wrench that opens to

1" or 1" hex-head socket wrench

• flat-blade screwdriver

• #2 Phillips screwdriver

• safety glasses

• tin snipes (new vent installation)

• caulking gun and compound

• wire strippers (direct wire

installation)

4 leveling legs

Remove parts

package from dryer

drum. Check that all

parts were included.

Explosion Hazard

Keep flammable materials and

vapors, such as gasoline, away

from dryer.

Place dryer at least 18 inches

above the floor for a garage

installation.

Failure to do so can result in

death, explosion, or fire.

WARNING

Your safety and the safety of

others are very important.

We have provided many impor tant

safety messages in this manual

and on your appliance.Always read

and obey all safety messages.

This is the safety alert

symbol.

This symbol alerts you to

potential hazards that can kill or

hurt you and others.

All safety messages will follow the

safety alert symbol and either the

word “DANGER” or “WARNING”.

These words mean:

You can be killed or seriously

injured if you don’t follow

instructions.

You can be killed or seriously

injured if you don’t immediatel

y

follow instructions.

DANGER

WARNING

For proper drying

performance:

The location must provide:

• Protection from weather and

water: Do not store or use dr yer

where it will be exposed to water and

weather.

• Room temperature above 45°F: If

room temperature is below 45°F,

automatic cycles may not shut off.

• Level floor: Maximum slope under

entire dryer should not be more than

1 inch. If slope is greater than 1 inch,

install Extended Dryer Feet Kit, Part

No.279810. Clothes may not tumble

properly and automatic sensor cycles

may not operate correctly if dryer is

not level.

• Sturdy floor to suppor t dr yer weight

of 175 pounds.

It is your responsibility to:

• Observe all governing codes and

ordinances.

• Check code requirements: Some

codes limit or do not permit

installation of clothes dryers in

garages, closets, mobile homes or

sleeping quarters. Contact your local

building inspector.

• Comply with the installation

specifications and dimensions.

• Consider spacing requirements for

companion appliances.

• Properly install dryer.

• Check that you have everything

necessary for proper installation.

• Contact a qualified installer to insure

that the electrical installation meets

all national and local codes and

ordinances.

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructions are not followed.

Check that you have everything

necessary for correct installation.

Proper installation is your

responsibility.

3

Parts needed for installation

Check local codes and see electrical

and venting requirements, Panels A

and B, before purchasing parts.

Determine if you will need to purchase

a power supply cord kit or power

supply cable.

Electrical

If using a power supply cord:

Dryer power supply cord must be:

• U.L.-listed

• 120/240-volt minimum

• 30-ampere

• Type SRD or SRDT

• At least 4 feet long

The wires that connect to the dryer

must end in ring terminals or spade

terminals with upturned ends.

The receptacle must be located within

3 feet of the top, back center of the

control console.

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to do so can result in death or

fire.

WARNING

Venting system

Four-inch heavy metal exhaust vent

and clamps must be used. Dura Safe™

vent products are recommended.

Dura Safe vent products can be

purchased from your dealer or by

calling Whirlpool Parts & Accessories

1-800-442-9991, Mon-Fri: 8am to 9pm

(CST), Sat: 9am to 4:30pm (CST).

Visit our internet site at

http://www.whirlpoolappliances.com/

accessories

See Page 11 for more information.

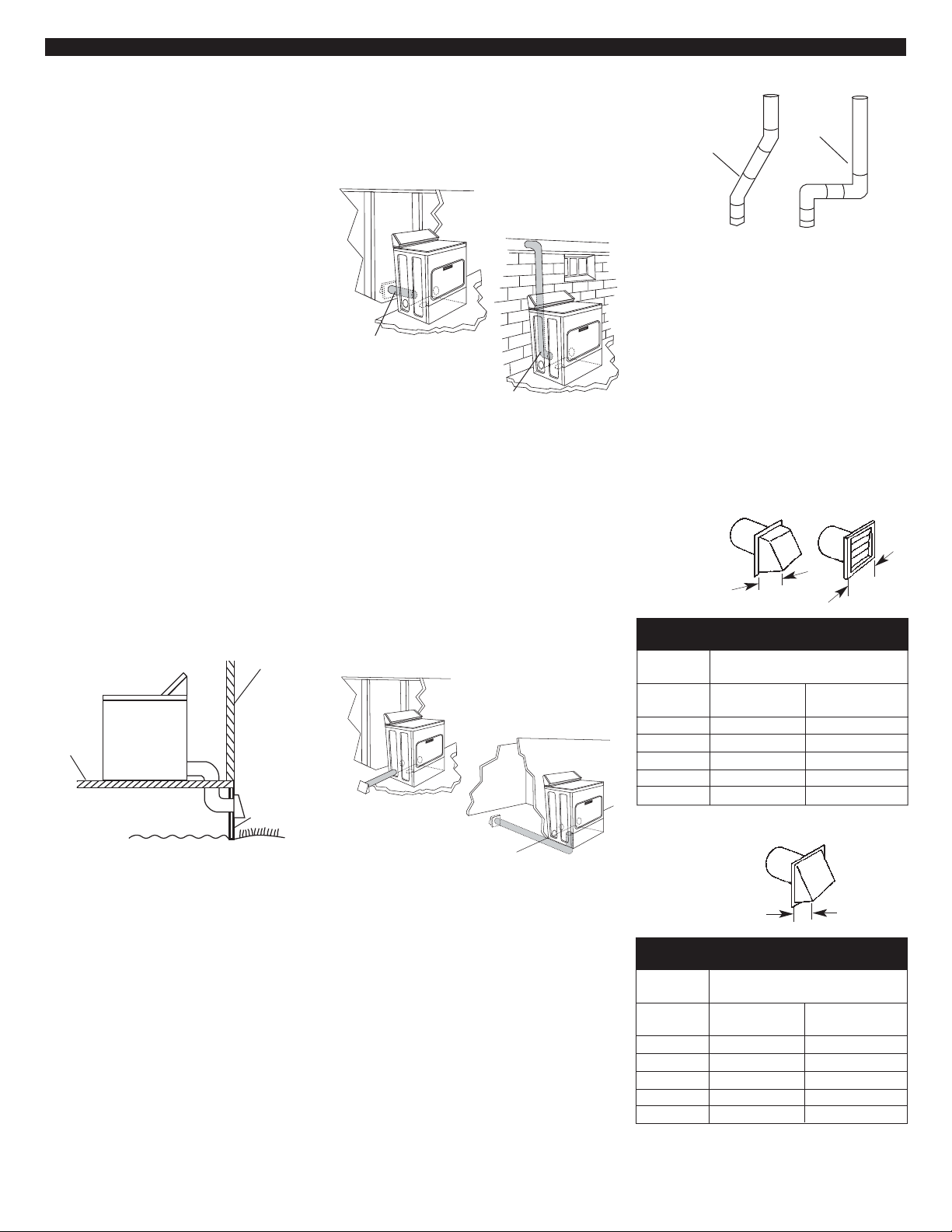

Exhaust hood

Do Not use exhaust hoods with

magnetic latches.

4"

4"

2-1/2"

Preferred Acceptable

Mobile home installations

require:

• Mobile Home Installation Kit, Part

Number 346764*

• Metal exhaust system hardware*

Floors sloped greater than

1 inch:

Require Extended Dryer Feet Kit, Part

No.279810*.

*Available for purchase from your

dealer.

If your outlet

looks like this:

Choose this

power supply cord:

4-wire

receptacle

(14-30R)

4-wire power supply cord

with ring or spade terminals

and U.L.-listed strain relief

3-wire power supply cord

with ring or spade terminals

and U.L.-listed strain relief

3-wire

receptacle

(10-30R)

If connecting by direct wire:

Power supply cable must match power

supply (4-wire or 3-wire) and be:

• flexible armored or non-metallic

sheathed copper cable (with ground

wire). All current-carrying wires must

be insulated. See Panels D and E.

• 10-GAUGE SOLID COPPER WIRE.

(Do not use aluminum.)

• at least 4 feet long.

4

0"*

0"*

15"

* Wall, door and floor molding may require

additional spacing.

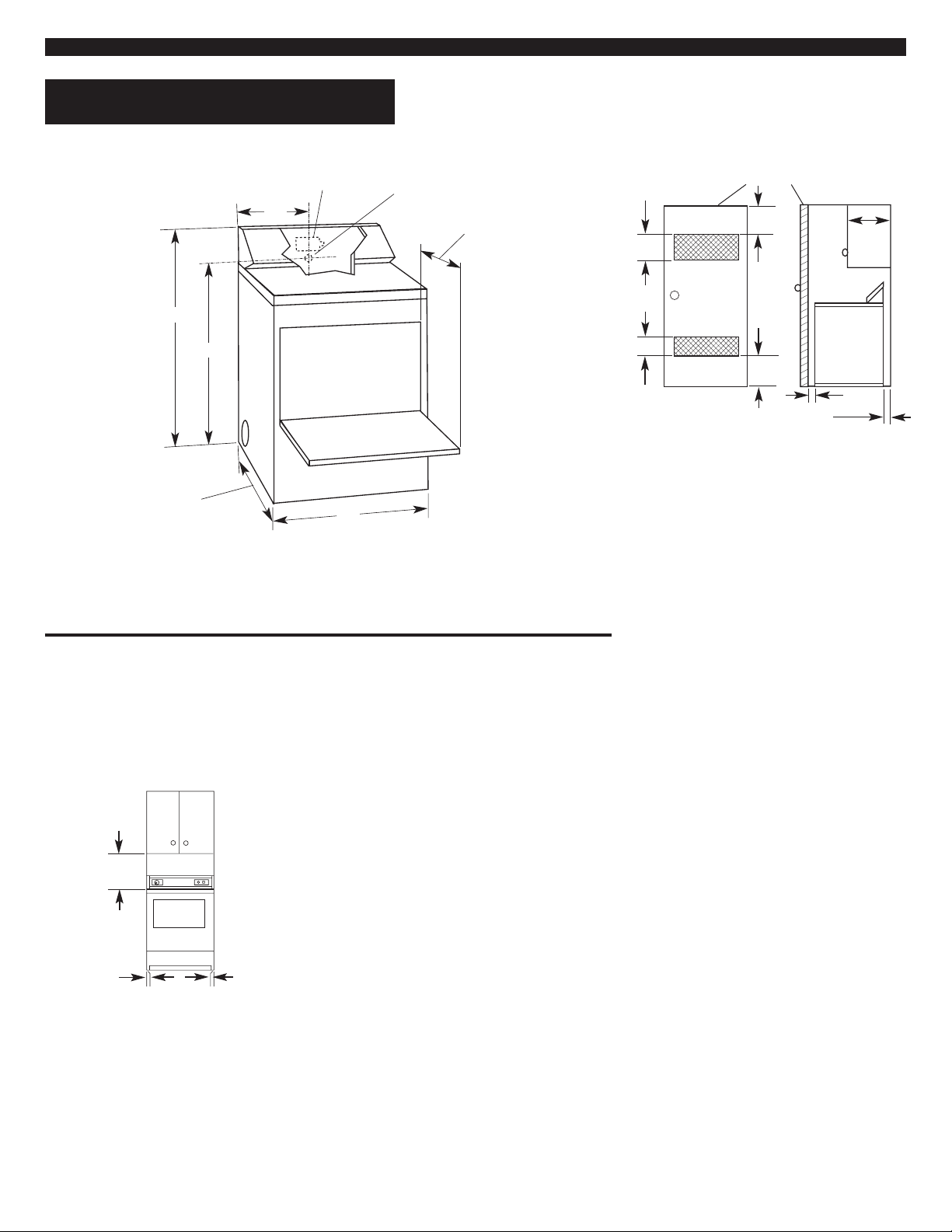

Recessed area installation

Closet/confined area installation

3"

3"

24 sq.in.**

Front view

1"

closet door

** Minimum top and bottom air openings for

closet door.

*** External exhaust elbow requires

recommended spacing.

Side view

14"

max.

spacing

5" is recommended ***

0" is minimum

• A clothes dryer produces

combustible lint and must be

exhausted outdoors.

• If codes permit, dryer may be

installed in a recessed area or closet

using dimensions shown.

If a closet door is installed: The

minimum unobstructed air openings

are required. Louvered doors with

equivalent air openings are

acceptable.

Installation clearances.

Use recommended clearance for

easier installation.

Recommended/minimum

Back – 5"/0"

Sides – 1"/0"

Top –18"/15"

Front – 1"/1"

Dryer dimensions

14"

power supply

cord/cable

strain relief

terminal block

cover

The dryer door

extends 14" from the

front of the dryer

when fully opened.

29-1/4" (models with flush

mounted door handle)

30-1/4" (models with extended

mounted door handle)

43-1/8"

11"

38-1/4"

27"

Dimensions shown with feet extended 1"

from bottom of dryer.

*Most installations will require at least 5"

clearance behind the dryer for the dryer vent.

• Dimensions are in inches and are the

minimum allowable.

• Additional spacing should be

considered for ease of installation

and servicing. Companion appliance

spacing should also be considered.

Installation clearances.

Use recommended clearance for

easier installation.

Recommended/minimum

Back – 5"/0"

Sides – 1"/0"

Top –18"/15"

Front view

48 sq.in.**

WARNING — To reduce the risk of fire

this appliance MUST BE EXHAUSTED

OUTDOORS

5

Electrical

requirements

Electrical Shock Hazard

Plug into a grounded 3-prong

outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these

instructions can result in death,

fire, or electrical shock.

WARNING

If codes permit and a separate

ground wire is used, it is

recommended that a qualified

electrician determine that the

ground path is adequate.

Important: Observe all governing

codes and ordinances.

A four-wire or three-wire, single phase,

120/240-volt, 60-Hz, AC-only, electrical

supply (or four-wire or three-wire,

120/208-volt if specified on

model/serial rating plate) is required

on a separate 30-ampere circuit, fused

on both sides of the line. A time-delay

fuse or circuit breaker is

recommended.

Recommended ground

method

It is the personal responsibility and

obligation of the customer to contact a

qualified electrician to assure that the

electrical installation is adequate and

is in conformance with the National

Electrical Code, ANSI/NFPA 70 —

latest edition* and all local codes and

ordinances.

Copies of the standards listed may be obtained

from:

* National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

Exhaust requirements

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions

can result in death or fire.

WARNING

• Do Not use non-metal flexible vent,

or exhaust hoods with magnetic

latches.

• Do Not exhaust dryer into any gas

vent, chimney, furnace, cold air vent,

wall, ceiling, concealed space of a

building, attic or crawl space, or any

other vent used for venting.

• Do Not install flexible vent in

enclosed walls, ceilings or floors.

Important: Observe all governing

codes and ordinances.

Exhaust your dryer to the outside.

Moisture and lint indoors may cause:

• Lint to gather around the dryer where

it can be fuel for a fire.

• Moisture damage to woodwork,

furniture, paint, wallpaper, carpet, etc.

• Housecleaning problems and health

problems.

Dura Safe™ venting products are

recommended and are available

from your dealer.

Four-inch diameter vent must be

used.

Use a heavy metal vent. Do Not use

plastic or metal foil vent.

Rigid metal vent is recommended to

prevent crushing and kinking.

Flexible metal vent must be fully

extended and supported when the

dryer is in its final position. Remove

excess flexible vent to avoid sagging

and kinking that may result in reduced

air flow.

An exhaust hood should cap the

exhaust vent to prevent rodents and

insects from entering the home.

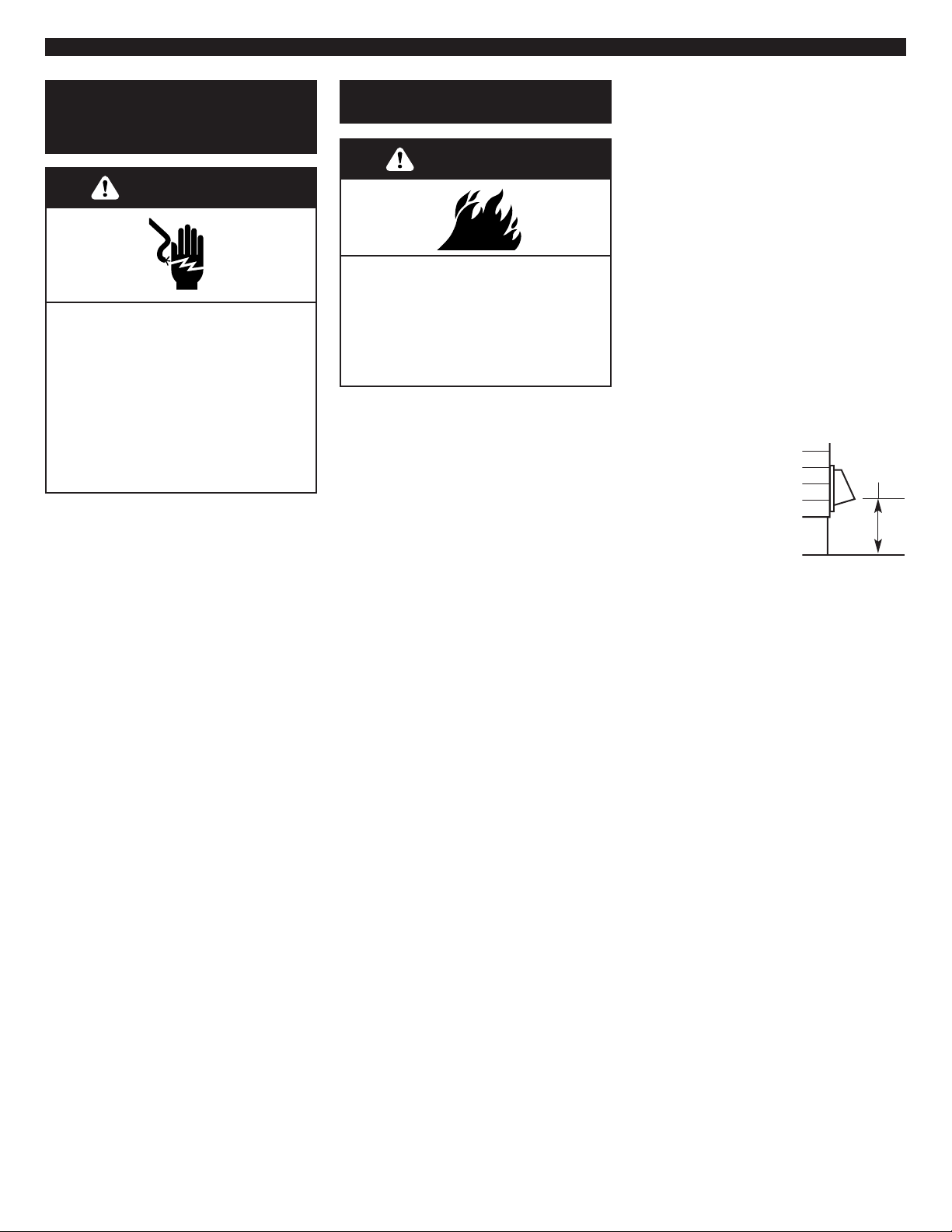

Exhaust outlet hood

must be at least 12

inches from the ground

or any object that may

be in the path of the

exhaust (such as

flowers, rocks or

bushes, etc.).

If using an existing exhaust system,

clean lint from entire length of

system and make sure exhaust

hood is not plugged with lint.

Replace any plastic or metal foil vent

with rigid metal or flexible metal vent.

Use clamps to seal all joints. Do Not

use duct tape, screws or other

fastening devices that extend into the

interior of the vent to secure vent.

Service check: Back pressure in any

exhaust system used must not exceed

0.6 inches in water column measured

with an incline manometer at the point

that exhaust vent connects to dryer.

12"

minimum

6

Mobile home installation

requirements

If codes permit, this dryer is suitable

for mobile home installations.The

installation of the dryer must conform

to the

U.S. Manufactured Home Construction

and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal

Standard for Mobile Homes

Construction and Safety, Title 24, HUD

Part 280) latest edition.

outside

wall

floor

skirting

enclosed

area

The dryer must be fastened to the

floor.

Order Mobile Home Installation Kit,

Part No.346764, from your dealer. Kit

includes the necessary fastening

hardware and detailed installation

instructions. Metal exhaust system is

also available through your dealer.

Special provisions must be made for

the introduction of outside air into the

dryer when installed in a mobile home.

The area of any opening for the

introduction of outside air (such as a

nearby window) should be at least

twice as large as the dryer exhaust

opening.

The dryer must be exhausted

outside.

The exhaust vent must be securely

fastened to a non-combustible por tion

of the mobile home structure and must

not terminate beneath the mobile

home.

better

exhaust air

flow

acceptable

2-1/2"

Acceptable —

4"

4"

Preferred —

Maximum length of 4" diameter

metal vent

When you have a 4' hood

Number of

90° elbows

0

1

2

3

4

Rigid

64 feet

54 feet

44 feet

35 feet

27 feet

Flexible

(fully extended

36 feet

31 feet

27 feet

25 feet

23 feet

Maximum length of 4" diameter

metal vent

When you have a 2-1/2' hood

Number of

90° elbows

0

1

2

3

4

Rigid

58 feet

48 feet

38 feet

29 feet

21 feet

Flexible

(fully extended)

28 feet

23 feet

19 feet

17 feet

15 feet

Typical installations exhaust from the rear

of the dryer.

This dryer may be converted to exhaust

out the right or left side or through the bottom.

Typical installations

for left or right side

exhausting.

straight back

offset

Typical installations

for bottom exhausting.

Plan the exhaust vent

installation

Route the vent

The exhaust outlet is located at the

center of the rear of the dryer.

The exhaust vent can be routed up,

down, left, right or straight out the

back of the dryer.See “Recessed

area/closet installation” section, Page

4, for space requirements.

To convert the dryer, the following kits

are available from your dealer.

Exhaust Kit No.279818 (white)

Exhaust Kit No.279819 (almond)

Exhaust Kit No.279925 (biscuit)

Exhaust Kit No.279969 (silver)

Determine vent length

Select the route that will provide the

straightest and most direct path

outdoors. Plan the installation to use

the fewest number of elbows and

turns. Avoid making 90° turns.

When using elbows or making

turns, allow as much room as

possible.Bend vent gradually to avoid

kinking.

7

The maximum length of the exhaust

system depends upon:

• the type of vent (rigid or flexible

metal).

• the number of elbows used.

• side or bottom exhaust.Side or

bottom exhaust adds a 90° turn

inside the dryer.To determine

maximum exhaust length, add one

90° tur n to the chart.

1. See the exhaust vent length chart

that matches your type hood for the

maximum vent lengths you can use.

Do not use vent runs longer

than specified in exhaust vent

length charts.

Exhaust systems longer than

specified will:

— Accumulate lint creating a

potential fire hazard.

— Shorten the life of the dryer.

— Reduce performance, resulting in

longer drying times and

increased energy usage.

2. Determine the number of elbows

you will need.

3. In the column listing the type of

metal vent you are using (rigid or

flexible), find the maximum length of

metal vent on the same line as the

number of elbows.

4. Determine the number of 4-inch

diameter vent clamps required.

The maximum length using a 2" x

6" rectangular vent with 2 elbows

and a 2-1/2" exhaust hood is 8 feet.

For exhaust systems not covered

by exhaust vent length charts (such

as multiple unit hookups, plenums,

and power-assist fans), see Service

Manual, Part No.603197. (To

purchase the Service Manual, see

your Use and Care Guide for a tollfree telephone number.)

Installation steps

If installing washer and dryer, install

dryer first.

SLIDE DRYER ONTO CARDBOARD

OR HARDBOARD BEFORE MOVING

ACROSS TO PREVENT FLOOR

DAMAGE.

A. Install vent system

Put on safety glasses and gloves.

Install exhaust hood.

Use caulking

compound to seal

exterior wall opening

around exhaust hood.

Connect exhaust vent

to hood. (Exhaust vent MUST fit inside

hood.) Secure vent to hood with 4-inch

clamp.

Run exhaust vent to dryer location.

Use the straightest path possible.

Avoid 90° turns. Use clamps to seal all

joints.Tin snips may be needed to cut

vent to required length.

Remove tape from

dryer cabinet.

Open dryer door

and remove tape

from dryer drum.

(Not all dryer

drums are taped.)

Remove drying

rack, if included.Turn dryer drum

counterclockwise to make sure all tape

was removed.Wipe dr um with damp

cloth to remove any dust.

B. Prepare the dryer

diamond

marking

Excessive Weight Hazard

Use two or more people to move and

install dryer.

Failure to do so could result in back

or other injury.

WARNING

Take two cardboard corners from dryer

carton and place them on floor in back

of dryer.Fir mly grasp body of dryer

and gently lay it on its back on the

cardboard corners.

Start to screw legs into holes by hand.

Use an adjustable wrench or 1” hexhead socket wrench to finish turning

legs until you reach the ridge with the

diamond marking.

Stand dryer up on cardboard or

hardboard.

8

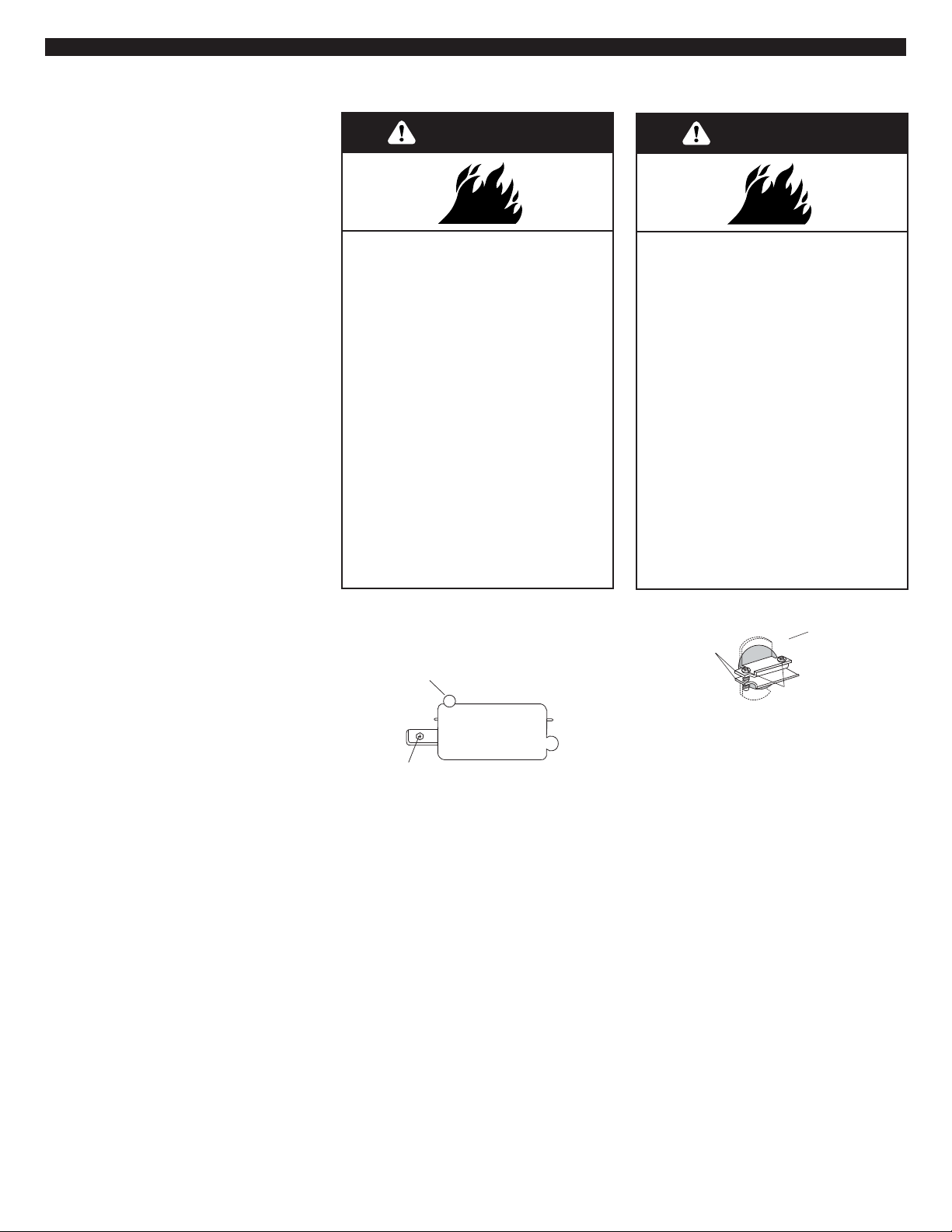

1. Disconnect the power supply.

2. Remove hold-down screw and

terminal block cover.

Power supply cord

terminal

block

cover

hold-down screw

external ground

conductor screw

Fire Hazard

Use a new UL approved 30

ampere power supply cord.

Use a UL approved strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or

center wire) to center terminal

(silver).

Ground wire (green or bare wire)

must be connected to green

ground connector.

Connect remaining 2 supply wires

to remaining 2 terminals (gold).

Securely tighten all electrical

connections.

Failure to do so can result in

death, fire, or electrical shock.

WARNING

3. Assemble 3/4" U.L.-listed strain

relief (U.L.marking on strain relief) into

the hole below terminal block opening.

Tighten strain relief screws just

enough to hold the two clamp sections

together.Install power supply

cord/cable through the strain relief.

Complete installation following

instructions for your type of

connection:

• Four-wire (recommended method)

• Three-wire (if four-wire is not

available)

Direct wire

rear

panel

strain relief

screws

strain relief

clamp sections

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL approved strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or

center wire) to center terminal

(silver).

Ground wire (green or bare wire)

must be connected to green

ground connector.

Connect remaining 2 supply

wires to remaining 2 terminals

(gold).

Securely tighten all electrical

connections.

Failure to do so can result in

death, fire, or electrical shock.

WARNING

C. Electrical connection

GROUNDING INSTRUCTIONS:This

appliance must be grounded. In the

event of malfunction or breakdown,

grounding will reduce the risk of

electric shock by providing a path of

least resistance for electric current.

If using a power supply cord, the plug

must be plugged into an appropriate

outlet that is properly installed and

grounded in accordance with all local

codes and ordinances.

If using a direct wire connection, this

appliance must be connected to a

grounded metal, permanent wiring

system; or an equipment-ground

conductor must be run with the circuit

conductors and connected to the

equipment-ground terminal or lead on

the appliance.

WARNING - Improper connection of

the equipment-grounding conductor

can result in a risk of electric shock.

Check with a qualified electrician or

serviceman if you are in doubt as to

whether the appliance is properly

grounded. Do not modify the power

supply cord plug. If it will not fit the

outlet, have a proper outlet installed by

a qualified electrician.

9

Four-wire connection...

Four-wire power supply cord at least four feet

long must have four, No.-10 copper wires and

match a four-wire receptacle of NEMA Type

14-30R.The fourth wire (ground conductor)

must be identified with a green cover and the

neutral conductor by a white cover.

NEUTRAL

NEUTRAL (white)

3/4" U.L.-listed

strain relief

ground prong

ground wire

(green)

ring terminals

spade

terminals with

upturned ends

4. Remove center terminal block

screw.

6. Connect ground wire (green)

of power supply cord to

external ground conductor

screw. Tighten screw.

external ground

connection

7. Connect neutral wire

(white or center) of

power supply cord

under center screw of

the terminal block.

Tighten screw.

8. Connect the other wires

to outer terminal block

screws.Tighten screws.

9.Tighten strain

relief screws.

10. Insert tab of ter minal block cover into

slot of the dryer rear panel. Secure

cover with hold-down screw.

5. Remove appliance ground wire (green

with yellow stripes) from external ground

connector screw. Fasten under center,

silver-colored terminal block screw.

POWER SUPPLY CORD

14-30R Four-wire receptacle (required for mobile homes)

4. Remove center terminal block

screw.

7. Place the hooked end of the

neutral wire (white or center)

of power supply cable under

the center screw of terminal

block (hook facing right).

Squeeze hook end together.

Tighten screw.

8. Place the hooked ends of the

other power supply cable wires

under the outer terminal block

screws (hook facing right).

Squeeze hooked ends

together.Tighten screws.

6. Connect the ground wire

(bare) of the power supply

cable to the external

ground conductor screw.

Tighten screw.

10. Insert tab of ter minal block cover into

slot of dryer rear panel. Secure cover

with hold-down screw.

9.Tighten strain relief screws.

5. Remove appliance ground wire

(green with yellow stripes) from

external ground connector screw.

Fasten under center, silver-colored

terminal block screw.

DIRECT WIRE

Preparing the wire:

3/4" U.L.listed strain

relief

to

disconnect

box

NEUTRAL wire

(white or center)

10-gauge, 3-wire

with ground wire

(Romex)

5"

3-1/2"

1" of wires

stripped of

insulation

bare ground

wire

Direct wire cable must have

four feet of extra length so

dryer can be moved if needed.

Strip 5 inches of outer covering

from end of cable.Leave bare

ground wire at 5 inches. Cut

1-1/2 inches from 3 remaining

wires. Str ip insulation back

1 inch.

Shape

ends of

wires

into a

hook.

10

Three-wire power supply cord at least four

feet long must have three, No.-10 copper

wires and match a three-wire receptacle of

NEMA Type 10-30R.

4. Loosen or remove center terminal

block screw.

6. Connect the other wires

to outer terminal block

screws.Tighten screws.

7.Tighten strain relief screws.

8. Insert tab of ter minal block cover into

slot of dryer rear panel. Secure cover

with hold-down screw.

5. Connect the neutral wire (white

or center) of power supply cord to

the center, silver-colored terminal

screw of the terminal block.Tighten

screw.

POWER SUPPLY CORD

Three-wire connection...

NEUTRAL

NEUTRAL

(white or center)

3/4" U.L.-listed

strain relief

This blade connected

to this conductor.

ring

terminals

spade

terminals with

upturned ends

Where local codes permit

connecting cabinet-ground conductor to neutral wire:

10-30R Three-wire receptacle

Where local codes permit

connecting cabinet-ground conductor to neutral wire:

4. Loosen or remove center terminal

block screw.

7.Tighten strain relief screws.

8. Insert tab of ter minal block cover

into slot of dryer rear panel.

Secure cover with hold-down

screw.

6. Place the hooked ends of the

other power supply cable wires

under the outer terminal block

screws (hook facing right).

Squeeze hooked ends together.

Tighten screws.

5. Place the hooked end of the neutral

wire (white or center) of power

supply cable under the center screw

of the terminal block (hook facing

right). Squeeze hooked end

together.Tighten screw.

DIRECT WIRE

Preparing the wire:

Direct wire cable must have

four feet of extra length so

dryer can be moved if

needed.

Strip 3-1/2 inches of outer

covering from end of cable.

Strip insulation back 1 inch. If

using 3-wire cable with

ground wire, cut bare wire

even with outer covering.

Shape

ends of

wires into

a hook.

10-gauge, 3-wire or,

10-gauge, 3-wire with

ground wire (Romex)

3/4" U.L.-listed

strain relief

Three-wire with ground wire:

Bare wire cut short. Wire is

not used. Dryer is grounded

through direct wire cable.

to disconnect

box

NEUTRAL wire

(white or center)

1" of wires

stripped of

insulation

3-1/2"

11

F. Check operation

4" clamp

4" clamp

Using a 4-inch clamp, connect exhaust

vent to exhaust outlet in dryer. If

connecting to existing exhaust vent,

make sure the vent is clean.

The dryer exhaust vent must fit over

the dryer exhaust outlet and inside the

exhaust hood.

Make sure exhaust vent is secured to

exhaust hood with a 4-inch clamp.

Move dryer into final position. Do not

crush or kink exhaust vent.Make sure

dryer is level.

Check that you:

✔ did not skip any steps.

✔ installed all parts.

✔ proper ly installed dr yer legs.

✔ leveled dryer.

✔ have secured all exhaust vent joints

with 4" clamps.

✔ have all the tools you started with.

Plug power supply cord into grounded

outlet or connect direct wire to power

supply. Turn power supply on.

Read the Use and Care Guide to fully

understand your new dryer. Select a

full heat cycle (not the air cycle) and

start dr yer. After five minutes, open

dryer door.You should feel heat inside

dryer.

If dryer does not operate properly,

check the following:

✔ electr ical supply is connected.

✔ house fuse is intact and tight; or

circuit breaker has not tripped.

✔ dr yer door is closed.

✔ controls are set in a running or “On”

position.

✔ star t button has been pushed fir mly.

If dryer makes an unusual noise,

check that dryer is level.

D. Level and exhaust

dryer

Dryer must be level to reduce noise

and assure proper performance.

Slide dryer onto cardboard or

hardboard before moving across

floor to prevent floor damage.

Move dryer close to its permanent

location. Leave enough room to

connect exhaust vent.Remove

cardboard or hardboard from under

dryer

Check levelness of dr yer by placing a

level on top of dryer, first side to side,

then front to back. If dryer is not level,

adjust dryer legs up or down.

If legs are not long enough to level

dryer, order Extended Dryer Feet Kit,

Part No.279810 (sold two legs per

kit), from your dealer.

6. Connect the other

wires to outer terminal

block screws.Tighten

screws.

7.Tighten strain

relief screws.

8. Insert tab of ter minal

block cover into slot of

dryer rear panel.

Secure cover with holddown screw.

5. Remove the appliance ground wire (green

with yellow stripes) from the external ground

connector screw. Connect appliance ground

wire and the neutral wire (white or center) of

the power supply cord/cable under the

center, silver-colored terminal block screw.

Tighten screw.

9. Connect a separate copper ground wire

from the external ground connector screw

to an adequate ground.

4. Remove center terminal

block screw.

DIRECT WIRE

OR POWER SUPPLY CORD

Where local codes Do Not permit

connecting cabinet-ground conductor to neutral wire:

Three-wire power supply cord must be

four feet long and have three, No.-10

copper wires and match a three-wire

receptacle of NEMA Type 10-30R.

Direct wire power supply cable must be

prepared as shown in “Preparing the wire”

of the three-wire connection direct-wire

steps above.

If codes permit and a separate ground

wire is used, it is recommended that a

qualified electrician determine that the

ground path is adequate.

Printed in U.S.A.

Part No.8535840

© 2002 Whirlpool Corporation

Benton Harbor, Michigan 49022, U.S.A.

Moving dryer to a new location?

Check with a licensed electrician to

confirm that supply voltage at new

home matches voltage specified on

the model/serial rating plate.

Shut off electrical supply

to dryer. Unplug power

supply cord and tape it

securely to dryer.(Or

disconnect power supply

cable from dryer.)

Tape lint collector lid to

cabinet.

Tape top to cabinet.

Tape door to

front panel.

Turn leveling legs

all the way in.

Slide dryer onto cardboard or

hardboard before moving it across

the floor to prevent damaging floor

covering.

For more information, or to

have your venting

professionally installed, call

the Consumer Assistance

Center.Check your Use and

Care Guide for a toll-free

number to call or call the

dealer from whom you

purchased this appliance.The

dealer is listed in the Yellow

Pages of your phone

directory under “Appliances

— Household — Major —

Service and Repair.”

SURE CONNECTTMVent Kit

CRUSH

RESISTANT

Dura Safe

TM

Kits Make Installation Easy

◆ Provides 4 1/2"

clearance between

dryer and wall

◆ Snap-Lock fittings

◆ Total kit length 8 feet

◆ Additional vent can

be snapped between

sections for

longer runs

Kit Contains:

2- 4' vent sections with attached close elbows

1- Wall plate for close clearance installations

2- 4" clamps

Part #4396028

Sections separate,

fittings can face

same or opposite

Extra long

band-clamp

for dryer

connection

Swivel collar

Beveled edges

allow corner

installations

Telescoping

sections

Swivel collar

wall connection

◆ Provides 2 1/2" clearance

between dryer and wall

◆ Great for closet installations

◆ 0"-18", 18"-29" or 29"-50"

periscopes include one male

snap-lock fitting, one extra

long draw-band collar and

one clamp

2

1

/2

"

2 1/2"

Periscopes For Offset

Outlets, Tight Installations

◆ Use when vent outlets

overlap or are offset

◆ Excess length can

be trimmed to fit

18"-29" and 29"-50" Periscope

0"-18" Periscope

0"-18" : Part #4396037

18"-29" : Part #4396011

29"-50" : Part #4396014

Part #4396037

18"-29" : Part #4396011 29"-50" : Part #4396014

Dura Safe and Sure Connect are Trademarks of Whirlpool, U.S.A.

.

Parte No.8535840

Instrucciones de instalación

IMPORTANTE:

Lea y conserve estas

instrucciones

Instalador: Deje las instrucciones de

instalación con el propietario.

Propietario: Guarde las instrucciones de

instalación para referencia futura.

Para un mejor funcionamiento, instale la

secadora de acuerdo con las instrucciones

de instalación. No completar la instalación

de acuerdo con las instrucciones podría

anular la garantía.

Conserve las instrucciones de instalación para

uso del inspector de instalaciones

eléctricas local.

¿Tiene preguntas sobre su secadora?

Llame a su distribuidor o a la compañía de servicios autorizada de su

localidad.

Cuando llame, necesitará el número del modelo y el número de serie

de la secadora. Ambos números están en la placa de modelo/serie,

la cual se encuentra en la cavidad de la puerta detrás de la puerta

de la secadora y al frente de la abertura.

Anote todos los números aquí para tenerlos a mano

cuando los necesite.

Modelo No.

Serie No.

Secadora

eléctrica

2

Antes de empezar...

Herramientas que se

necesitan para la

instalación

Piezas suministradas

para la instalación

• Nivel

• Guantes

• destornillador Phillips #2

• Llave ajustable que se abra 2,5 cm

(1 pulg.) (en la ilustración) o llave

tubular hexagonal de 2,5 cm

(1 pulg.)

• Desarmador de punta plana

• Gafas protectoras

• Tijeras de hojalatero (para

instalaciones con nueva salida

de aire)

• Pistola y compuesto de masillar

(instalación de nueva ventilación)

• Pelador de alambres

(instalaciones de alambre directo)

4 patas

niveladoras

Saque el paquete de

piezas del tambor de

la secadora.Verifique

que se hayan incluido

todas las piezas.

Peligro de explosión

Mantenga los materiales y

vapores inflamables, como la

gasolina, alejados de la secadora.

Para instalar la secadora en un

garaje, coloque la secadora al

menos a 45,7 cm (18 pulg.) sobre

el piso.

No seguir estas instrucciones

puede ocasionar la muerte, una

explosión o un incendio.

AD VERTENCIA

Su seguridad y la seguridad de los

demás son muy importantes.

Hemos incluido muchos mensajes

importantes de seguridad en este

manual y en su electrodoméstico. Lea y

obedezca siempre todos los mensajes

de seguridad

Este es el símbolo de alerta de

seguridad.

Este símbolo le alerta sobre los

peligros potenciales que podrían

causarle la muerte o herir le a usted o a

otras personas.

Todos los mensajes de seguridad

seguirán al símbolo de alerta de

seguridad y a la palabra “PELIGRO” o

“ADVERTENCIA”. Estas palabras

significan:

Podría morir o sufrir graves lesiones

si no sigue las instrucciones.

Todos los mensajes de seguridad le

indicarán cuál es el peligro potencial, le

indicarán cómo reducir las posibilidades

de lesionarse y le dirán qué podría

ocurrir si no se siguen las instrucciones.

Podría morir o sufrir graves lesiones

si no sigue inmediatamente

las

instrucciones.

PELIGRO

ADVER TENCIA

Para el debido funcionamiento

de la secadora:

El lugar debe proporcionar:

• Protección contra la intemperie y el

agua: no guarde ni utilice la secadora

en un lugar donde estaría expuesta al

agua y a la intemperie.

• Temperatura ambiental superior a

los 7°C (45°F): Si la temperatura es

inferior a los 7°C (45°F), los ciclos

automáticos podrían no detenerse.

• Nivel del piso: La inclinación máxima

debajo de toda la secadora no debe

ser mayor de 2,5 cm (1 pulgada).Si la

inclinación es mayor de 2,5 cm

(1 pulgada) instale el Conjunto de

Extensión de Patas para Secadora,

Parte No.279810. Si la secadora no

está nivelada, la ropa podría no girar

debidamente y los ciclos de detección

automática podrían no funcionar

correctamente.

• Piso resistente para resistir el peso

de la secadora de 79,4 kg (175 libras).

Es su responsabilidad:

• Observar todos los códigos y

reglamentos aplicables.

• Verificar los requisitos del código:

Algunos códigos limitan o no permiten

la instalación de las secadoras de

ropa en garajes, closets (armarios),

casas móviles o rodantes o en

dormitorios. Póngase en contacto con

el inspector de edificaciones de su

localidad.

• Cumplir con las especificaciones y

dimensiones de instalación.

• Tomar en cuenta los requisitos de

espacio para artefactos que se

instalen al lado de la secadora.

• Instalar debidametne la secadora.

• Compruebe que tiene todo lo

necesario para una instalación

correcta. La instalación correcta es

su responsabilidad.

• Ponerse en contacto con un

instalador calificado para asegurarse

de que las instalaciones eléctricas y

de gas cumplan con todos los

códigos y reglamentos nacionales y

locales.

3

Piezas para adquirir:

Peligro de incendio

Utilice un conducto metálico

pesado.

No utilice conducto plástico.

No utilice un conducto de lámina

metálica.

No seguir estas instrucciones

puede ocasionar la muerte o un

incendio.

AD VERTENCIA

Sistema de salida de aire

Se debe utilizar un conducto de salida

de aire metálico y pesado de 102 mm

(4 pulgadas) y abrazaderas.Se

recomiendan productos de salida de

aire Dura Safe™.

Puede adquirir productos de salida de

aire Dura Safe de su distribuidor o

llamando a Whirlpool Parts &

Accesories al número 1-800-442-9991,

de lunes a viernes, de 8 a.m. a 9 p.m.

(Hora Central estándar), sábado de

9 a.m. a 4:30 p.m.(HCE). Visite

nuestro sitio en Internet en la dirección

http//www.whirlpoolappliances.com

/accessories.

Para más información vea la página 11.

Campana exterior de salida

de aire

No utilice campanas exteriores de

salida de aire con cierres

magnéticos.

Las instalaciones en casas

móviles o rodantes requieren:

• Conjunto de instalación en casas

rodantes, Parte Número 346764*

• Artículos de ferretería para el

sistema de escape de metal*

Suelos con inclinaciones mayores

de 2,5 cm (1 pulg.):

Requieren Conjunto de extensión de

patas para secadoras, Par te No.

279810*.

*Disponible de compra de su distribuidor.

10,2 cm

(4 pulg.)

10,2 cm

(4 pulg.)

6,4 cm

(2-1/2 pulg.)

Preferible Aceptable

Consulte los códigos locales y vea los

requisitos eléctricos y de ventilación,

Paneles A y B, antes de comprar

pieza alguna. Determine si necesitará

comprar un juego de cordón de

suministro de energía o un cable de

suministro de energía.

Eléctrico:

Si usa un cordón de suministro de

energía:

El cordón de suministro de energía de

la secadora debe ser:

• Aprobado por U.L.

• 120/240 voltios mínimo

• 30 amperios

• Tipo SRD o SRDT

• Por lo menos de 4 pies de largo

Los alambres que conectan a la

secadora deben terminar en

terminales en anillo o en horquilla con

los extremos hacia arriba.

El contacto debe estar situado a no

más de 3 pies del centro posterior y

superior de la consola de control.

Si su contacto

tiene esta

apariencia:

Escoja este cordón

de suministro de energia

contacto para

4 alambres

(14-30R)

cordón de suministro de energía

de 4 alambres con terminales en

anillo o en horquilla y

dispositivo de protector de

cables aprobado por U.L.

cordón de suministro de energía

de 3 alambres con terminales en

anillo o en horquilla y

dispositivo de protector de

cables aprobado por U.L.

contacto para

3 alambres

(10-30R)

Si la conexión es por alambre

directo:

El cable de suministro de energía

debe corresponder al suministro (4 ó 3

alambres) y ser:

• Cable de cobre con armadura

flexible o blindaje no metálico (con

alambre de conexión a tierra). Todos

los alambres conductores de

corriente deben estar aislados.Vea

los Paneles D y E.

• ALAMBRE SÓLIDO DE COBRE DE

CALIBRE 10 (No use aluminio).)

• por lo menos de 4 pies de largo.

4

7,6 cm

(3 pulg.)

7,6 cm

(3 pulg.)

310 cm

2

(48 pulg.2)***

155 cm

2

(24 pulg.2)***

Vista de frente

2,5 cm

(1 pulg.)

Puerta del closet (armario)

Vista de

frente

0 cm

(0 pulg.)**

0 cm

(0 pulg.)**

38,1 cm

(15 pulg.)

** Puede necesitarse más espacio para molduras

de paredes, suelos o puertas.

*** Aberturas mínimas para el aire en la parte

superior e inferior de la puerta del closet.

**** Se requiere el espacio recomendado para un

codo de salida de aire externo.

** Puede necesitarse más espacio para molduras

de paredes, suelos o puertas.

Vista lateral

Instalación en área empotrada

ADVERTENCIA – Para reducir el

riesgo de incendio este artefacto

DEBE VENTILARSE HACIA EL

EXTERIOR.

Instalación en

armario/área confinada

35,6 cm

(14 pulg.)

máx.

el espaciamiento

12,7 cm

(5 pulg.) es

recomendado****

• Una secadora de ropa produce

pelusa combustible y debe ventilarse

hacia el exterior.

• Las dimensiones están en

centímetros y pulgadas y son las

mínimas permisibles.

Si se instala una puerta para el

closet: se requieren aberturas

mínimas no obstruidas para asegurar

que haya flujo adecuado de aire.Son

acceptables las puertas de persiana

con aberturas para el aire

equivalentes.

Espacios de la instalación.

Utilice los espacios recomendados

para facilitar la instalación.

Recomendados/mínimos

Parte posterior –

12,7 cm/0 cm (5 pulg./0 pulg.)

Costados –

2,5 cm/0 cm (1 pulg./0 pulg.)

Parte superior –

45 cm/38,1 cm (18 pulg./15 pulg.)

Parte delantera –

2,5 cm/2,5 cm (1 pulg./1 pulg.)

Dimensiones de la secadora

35.6 cm

(14 pulg.)

La puerta de la secadora se

extiende 35,6 cm (14 pulgadas)

desde el fente de la secadora

cuando se abre totalmente.

27,9 cm

(11 pulg.)

Dimensiones mostradas con pies extendidos 25,4 mm

(1 pulgada) desde la parte inferior de la secadora.

*La mayoría de las instalaciones requerirán al menos un

espacio de 12,7 cm (5 pulg.) detrás de la secadora para el

conducto de salida de aire de la secadora.

• Se debe considerar espacio

adicional para facilitar la instalación y

el servicio (reparaciones y

mantenimiento).También se deben

considerar los requisitos de espacio

para artefactos que se instalen al

lado de la secadora.

Espacios de la instalación.

Utilice los espacios recomendados

para facilitar la instalación.

Recomendados/mínimos

Parte posterior –

12,7 cm/0 cm (5 pulg./0 pulg.)

Costados –

2,5 cm/0 cm (1 pulg./0 pulg.)

Parte superior –

45 cm/38,1 cm (18 pulg./15 pulg.)

protector de cables del cordón/cable

de suministro eléctrico

cubierta del

bloque terminal

74,3 cm (29-1/4 pulg.)

(modelos con manija de la puerta

con montaje embutido)

76,8 cm (30-1/4 pulg.)*

(modelos con manija extendida

de puerta)

109,5 cm

(43-1/8

pulg.)

97,2 cm

(38-1/4

pulg.)

68,6 cm (27 pulg.)

5

Requisitos eléctricos

Peligro de choque eléctrica

Enchufe la secadora en un

tomacorriente puesto a tierra con

3 terminales.

No quite el terminal de conexión a

tierra.

No use un adaptador.

No use un cordón de extensión.

No seguir estas instrucciones

puede ocasionar la muerte, un

incendio o un choque eléctrico.

AD VERTENCIA

Si los códigos lo permiten y se

utiliza un alambre de puesta a tierra

separado, se recomienda que un

electricista calificado determine si

la trayectoria de la puesta a tierra

es adecuada.

Importante: Observe todos los

códigos y reglamentos aplicables.

Se requiere un suministro eléctrico de

cuatro alambres o tres alambres,

monofásico, 120/240 voltios, 60 Hz,

CA solamente (o de cuatro alambres o

tres alambres, 120/208 voltios si lo

especifica la placa de modelo/serie

nominal) en un circuito independiente

de 30 amperios, con fusibles en

ambos lados de la línea. Se

recomienda usar un fusible retardador

o un cortacircuitos.

Método recomendado de

puesta a tierra

Es la responsabilidad personal y

obligación del cliente tomar contacto

con un electricista calificado para

asegurar que la instalación eléctrica

es adecuada y que cumple con el

Código Eléctrico Nacional, ANSI/NFPA

70 – última edición * y con todos los

códigos y reglamentos locales.

Se pueden obtener copias de las normas

mencionadas anteriormente de:

* National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

Suministro de gas

Peligro de incendio

Utilice un conducto metálico

pesado.

No utilice conducto plástico.

No utilice un conducto de lámina

metálica.

No seguir estas instrucciones

puede ocasionar la muerte o un

incendio.

AD VERTENCIA

• No utilice un conducto flexible no

metálico ni campanas exteriores de

salida de aire con cierres

magnéticos.

• No coloque la salida de aire de la

secadora en ningún conducto de

gas, chimenea, horno, conducto,

conducto de aire frío, pared, cielo

raso, espacio cerrado de un edificio,

un ático o sótano de pequeña altura

ni en ningún conducto de

ventilación.

• No instale un conducto flexible en

paredes, cielos rasos o pisos

encerrados.

Importante: Observe todos los

códigos y reglamentos aplicables.

Realice la salida de aire de la

secadora a exteriores. La humedad

y las pelusas a interiores pueden

hacer que:

• Las pelusas se acumulen alrededor

de la secadora donde se pueden

convertir en combustible para un

incendio.

• La humedad dañe maderas,

muebles, pintura, papel de

empapelar, alfombras, etc.

• Surjan problemas de limpieza y

problemas de salud.

Se recomiendan productos de

salida de aire Dura Safe™ los

cuales puede adquirir de su

distribuidor.

Se debe utilizar un conducto de

diámetro de 10,2 cm (4 pulg.).

Utilice conducto metálico pesado.

No utilice conductos plásticos o de

lámina metálica.

Se recomienda utilizar un conducto

metálico rígido para evitar

aplastamientos o enroscamientos.

El conducto metálico flexible debe

estar totalmente extendido y apoyado

cuando la secadora esté en su

posición definitiva. Elimine el conducto

flexible sobrante para evitar que

cuelgue o se retuerza, lo que puede

reducir el flujo del aire.

Una campana

exterior de salida de

aire debe tapar el

coducto de salida de

aire para evitar que los

roedores y los insectos

se introduzcan en la

casa.

La campana exterior de salida de

aire debe estar al menos a 30,5 cm

(12 pulg.) del suelo o cualquier objeto

que pueda interponerse en la vía de

salida de aire (como flores, rocas o

arbustos, etc.).

Si utiliza un sistema de salida de

aire existente, limpie las pelusas a

lo largo de todo el sistema de

salida de aire y asegúrese de que la

campana exterior de salida de aire

no esté taponada con pelusas.

Reemplace cualquier conducto de

ventilación de plástico o papel

metálico con un conducto rígido o

flexible de metal.

Utilice abrazaderas para conductos

para sellar todas las juntas. No utilice

para asegurar el conducto cinta

adhesiva para conductos, tornillos ni

otros dispositivos de sujeción que se

extiendan hacia el interior del

conducto.

Revisión de servicio: La presión

posterior en cualquier sistema de

salida de aire utilizado no debe ser

mayor de 1,5 cm (0,6 pulg.) de

columna de agua medida con un

manómetro inclinado en el punto

donde el coducto de salida de aire se

conecta con la secadora.

30,5 cm

(12 pulg.)

mínimo.

6

Requisitos de instalación en una

casa móvil o rodante

Si los códigos lo permiten, esta

secadora puede instalarse en una

casa móvil o rodante. La instalación

de la secadora debe cumplir con los

requisitos del U.S.Manufactured

Home Construction and Safety

Standard (Norma de construcción y

seguridad de casas manufacturadas),

Título 24 CFR, Parte 3280

(anteriormente Federal Standard for

Mobile Homes Construction and

Safety, Título 24, HUD Parte 280)

última edición.

Pared

exterior

Piso

Zocalillo

Área

encerrada

La secadora debe fijarse al piso.

Pida a su distribuidor el Conjunto para

instalación en casa móvil o rodante,

Parte No.346764. El conjunto incluye

los elementos de fijación necesarios e

instrucciones de instalación

detalladas.También puede solicitar a

su distribuidor los elementos metálicos

del sistema de salida de aire.

Se deben hacer disposiciones

especiales para la introducción del

aire del exterior en la secadora

cuando se instala en una casa móvil o

rodante. El área de cualquier abertura

para la introducción de aire del

exterior (como una ventana cercana)

debe tener al menos el doble del

tamaño de la abertura de salida de

aire de la secadora.

La secadora tiene que tener salida de

aire al exterior.

El conducto de salida de aire debe

fijarse con seguridad a una parte no

combustible de la estructura de la

casa móvil o rodante y no debe

terminar debajo de la casa móvil o

rodante.

mejor

flujo de aire de

salida

bien

Seleccione la ruta que proporcione

la vía más recta y directa hacia el

exterior. Planifique la instalación de

forma que utilice el menor número de

codos y ángulos. Evite hacer ángulos

de 90°.

Deje el máximo espacio posible

cuando utilice codos o forme

ángulos. Doble el conducto

gradualmente para no retorcerlo.

6,4 cm

(2-1/2 pulg.)

Aceptable —

10,2 cm

(4 pulg.)

10,2 cm

(4 pulg.)

Preferido —

Longitud máxima del conducto metálico

de 10,2 cm (4 pulg.) de diámetro

Cuando usted tiene una campana de sa

lida de

aire de 10,2 cm (4 pulg.)

Número

de

codos de 90°

0

1

2

3

4

Rigido

19,5 m (64 pies)

16,5 m (54 pies)

13,4 m (44 pies)

10,7 m (35 pies)

8,2 m (27 pies)

Flexible

(completamente

extendido)

11,0 m (36 pies)

9,4 m (31 pies)

8,2 m (27 pies)

7,6 m (25 pies)

7,0 m (23 pies)

Longitud máxima del conducto metálico

de 10,2 cm (4 pulg.) de diámetro

Cuando usted tiene una campana de sa

lida de

aire de 6,4 cm (2-1/2 pulg.)

Número

de

codos de 90°

0

1

2

3

4

Rigido

17,7 m (58 pies)

14,6 m (48 pies)

11,6 m (38 pies)

8,8 m (29 pies)

6,4 m (21 pies)

Flexible

(completamente

extendido)

8,5 m (28 pies)

7,0 m (23 pies)

5,8 m (19 pies)

5,2 m (17 pies)

4,6 m (15 pies)

En las instalaciones usuales la salida de aire

se realiza por la parte posterior de la secadora.

La secadora puede adaptarse para tener salida

de aire por el costado derecho o izquierdo o a

través de la parte inferior.

Instalaciones usuales

para salida de aire

por el costado

izquierdo o derecho.

Recto

Acodado

Instalaciones usuales

para salida de aire

por la parte inferior.

Planifique la instalación del conducto de salida de aire

Dirija el conducto

El orificio de salida de aire se

encuentra al centro de la parte

posterior de la secadora.

El conducto de salida de aire puede

dirigirse hacia arriba, hacia abajo,

hacia la izquierda, hacia la derecha o

recto fuera de la parte posterior de la

secadora. Para requisitos de espacio,

vea la sección de “Instalación en área

empotrada/closet (armario)” en la

página 4.

Para adaptar la secadora su

distribuidor tiene disponibles los

siguientes conjuntos:

Conjunto de salida de aire

No.279818 (blanco)

Conjunto de salida de aire

No.279819 (almendra)

Conjunto de salida de aire

No.279925 (biscuit)

Conjunto de salida de aire

No.279969 (plateado)

Determine la longitud del

conducto

7

La longitud máxima del sistema de

salida de aire depende de:

• el tipo de conducto utilizado (rígido o

flexible)

• el número de codos utilizados

• si la salida de aire es por el costado o

por la parte inferior.La salida de aire

por el costado o por la parte inferior

agrega un ángulo de 90° dentro de la

secadora. Para determinar la máxima

longitud de la salida de aire, agregue

un ángulo de 90° en la tabla.

1.Vea la tabla de longitudes de

conductos de salida de aire que

corresponda a su tipo de campana

para determinar las longitudes

máximas de conductos que puede

utilizar.

No utilice conductos más largos

que los especificados en las tablas

de longitudes de conductos de

salida de aire.

Los sistemas de salida de aire más

largos de lo especificado:

- Acumulan pelusas creando peligro

potencial de incendio.

- Reducen la vida útil de la secadora.

- Reducen el funcionamiento, lo que

produce tiempos de secado más

prolongados y aumenta el consumo

de energía.

2. Determine el número de codos que

necesitará.

3. En la columna en la que se indica el

tipo de conducto de metal que está

utilizando (rígido o flexible), busque la

longitud máxima de conducto de

metal en la misma línea del número

de codos.

4. Determine el número requerido de

abrazaderas para conductos de

diámetro de 10,2 cm (4 pulg.).

La longitud máxima utilizando un

conducto rectangular de 5,1 cm x

15,2 cm (2 pulg. x 6 pulg.) con 2

codos y una campana exterior de

salida de aire de 6,4 cm (2-1/2 pulg.)

es 2,4 m

(8 pies).

Para los sistemas de salida de aire

no incluidos en las tablas de

longitudes (tales como sistemas de

conexiones para unidades múltiples,

plenos o ventiladores con aporte de

energía exterior), consulte el Manual

de Servicio, Parte No.603197. (Para

comprar el Manual de Servicio, busque

el número para llamar gratis en su

Manual de uso y cuidado).

Etapas de la

instalación

Si está instalando una lavadora y

una secadora, instale la secadora

primero.

DESLICE LA SECADORA SOBRE UN

PEDAZO DE CARTÓN O MADERA

DURA ANTES DE MOVERLA PARA

NO DAÑAR EL PISO.

A. Instale el sistema de

ventilación (nueva

instalación)

Póngase gafas

protectoras y guantes.

Instale la campana

exterior de salida de

aire. Use masilla de

calafatear para sellar

la abertura de la pared exterior

alrededor de la campana de salida de

aire.

Conecte el conducto de salidad de

aire a la campana. (El conducto de

salida de aire DEBE calzar dentro de

la campana). Asegure el conducto a la

campana con una abrazadera de

10,2 cm (4 pulg.)

Dirija el conducto de salida de aire

hasta donde está la secadora. Utilice

la vía más recta posible.Evite formar

ángulos de 90º. Utilice abrazaderas

para sellar todas las juntas. Podría

necesitar tijeras de hojalatero para

cortar el conducto a la longitud

requerida.

Quite la cinta

adhesiva del

gabinete de la

secadora. Abra la

puerta de la

secadora y quite la

cinta adhesiva del

tambor de la

secadora. (No todos los tambores de

secadora tienen cinta adhesiva).

Saque la rejilla de secado si está

incluida. Gire el tambor de la secadora

en sentido contrario al de las

manecillas del reloj para asegurarse

de que quitó todas las cintas. Limpie

el tambor con un paño húmedo para

eliminar el polvo.

B.Prepare de la secadora

marca de

rombo

Peligro de peso excesivo

Se necesitan dos o más personas

para mover e instalar la secadora.

No seguir esta instrucción puede

ocasionar una lesión en la espalda

u otra lesión.

AD VERTENCIA

Tome dos ángulos de cartón de la

caja de la secadora y colóquelos en el

piso detrás de la secadora. Sujete con

firmeza la secadora y apoye con

cuidado su parte posterior sobre los

ángulos de cartón.

Comience a atornillar las patas en los

orificios manualmente. Utilice una llave

ajustable o una llave tubular de

2,5 cm (1 pulgada) para terminar de

darles vueltas a las patas hasta llegar

a la estría con la marca de rombo.

Coloque la secadora en posición

vertical sobre un pedazo de cartón o

madera dura.

8

1. Desconecte el suministro de

energía.

2. Retire el tor nillo de retención y la

cubierta del bloque terminal.

Cordón de suministro

de energía

cubierta del

bloque

terminal

tornillo de retención

tornillo externo

del conductor de

puesta a tierra

Peligro de Incendio

Utilice un cordón de suministro

eléctrico nuevo de 30 amperios

aprobado por U.L.

Use un protector de cables con

aprobación U.L.

Desconecte el suministro eléctrico

antes de hacer las conexiones

eléctricas.

Conecte el alambre neutro (el

blanco o el del centro) con el

terminal del centro (plateado).

El alambre de tierra (el verde o el

desnudo) se debe conectar con el

conector verde de tierra.

Conecte los 2 alambres de

suministro restantes con los 2

terminales restantes (los dorados).

Apriete firmemente todas las

conexiones eléctricas.

No seguir estas instrucciones

puede causar la muerte, incendio

o choque eléctrico.

AD VERTENCIA

3. Ensamble un dispositivo de

protector de cable de 3/4” aprobado

por U.L.(aparece la marca U.L. en el

dispositivo) en el agujero debajo de la

abertura del bloque terminal. Apriete

los tornillos del dispositivo de protector

de cables sólo lo suficiente para

sostener juntas las dos secciones de

apriete. Instale el cordón/cable de

suministro de energía a través del

dispositivo de protector de cables.

Complete la instalación siguiendo

las instrucciones para su tipo de

conexión:

• Cuatro alambres (método

recomendado)

• Tres alambres (si no se dispone

de cuatro alambres)

Alambre directo

panel

posterior

tronillo externo del

conductor de cables

secciones de apriete

del dispositivo de

protector de cables

Peligro de Incendio

Utilice alambres de cobre sólido

de calibre 10.

Use un protector de cables con

aprobación U.L.

Desconecte el suministro

eléctrico antes de hacer las

conexiones eléctricas.

Conecte el alambre neutro (el

blanco o el del centro) con el

terminal del centro (plateado).

El alambre de tierra (el verde o el

desnudo) se debe conectar con el

conector verde de tierra.

Conecte los 2 alambres de

suministro restantes con los 2

terminales restantes (los

dorados).

Apriete firmemente todas las

conexiones eléctricas.

No seguir estas instrucciones

puede causar la muerte, incendio

o choque eléctrico.

AD VERTENCIA

C.Conexión eléctrica

Esta secadora está fabricada con el

conductor de puesta a tierra del

gabinete conectado al alambre

NEUTRO (central) del mazo de

alambres en el bloque terminal. Si los

códigos locales NO permiten este tipo

de conexión, use las instrucciones

para “Conexión de 4 alambres”.

INSTRUCCIONES PARA LA

CONEXIÓN A TIERRA:Este ar tefacto

debe ser conectado a tierra. En el

caso de funcionamiento defectuoso o

avería, la conexión a tierra reducirá el

riesgo de choque eléctrico al

proporcionar una vía de menor

resistencia para la corriente eléctrica.

Si se usa un cordón de suministro

eléctrico, el enchufe debe conectarse

en un contacto apropiado, que esté

debidamente instalado y conectado a

tierra de acuerdo con todos los

códigos y ordenanzas locales.

Si se usa una conexión directa de

alambre, este artefacto debe ser

conectado a un sistema de cableado

permanente de metal puesto a tierra,

o un conductor para la conexión a

tierra del equipo debe ser pasado con

los conductores del circuito y

conectado al terminal o cable de

puesta a tierra del equipo en el

artefacto.

ADVERTENCIA – La conexión

indebida del conductor para la

conexión a tierra del equipo puede

ocasionar un riesgo de choque

eléctrico.Verifique con un electricista o

personal de servicio técnico calificado

para asegurarse de que la conexión a

tierra del artefacto sea apropiada. No

modifique el enchufe del cordón de

suministro de energía. Si no encaja en

el contacto, contrate un electricista

calificado para que instale un contacto

apropiado.

9

Conexión de cuatro alambres...

El cordón de suministro de energía de cuatro

alambres de por lo menos 4 pies de largo debe

tener 4 alambres de cobre No.10 y poder

encajarse en un contacto para cuatro alambres

NEMA tipo 14-30R. El cuarto alambre (conductor

de conexión a tierra) debe identificarse con una

cubierta verde y el conductor neutro con una

cubierta blanca.

NEUTRO

NEUTRO (blanco)

protector de cables

de 3/4”, aprobado

por U.L.

terminal de

conexión a tierra

alambra de conexión

a tierra (verde)

terminales en anillo

terminales en

horquilla con extremos

hacia arriba

4. Retire el tornillo central del bloque

terminal.

6. Conecte el alambre de

conexión a tierra (verde) del

cordón de suministro de

energía al tornillo del

conector externo de puesta

a tierra. Apriete el tor nillo.

conexión a

tierra externa

7. Conecte el alambre

neutro (blanco o

central) del cordón de

suministro de energía

debajo del tornillo

central del bloque

terminal. Apriete el

tornillo.

8. Conecte los otros

alambres a los tornillos

externos del bloque

terminal. Apriete los

tornillos.

9. Apriete los tornillos del

dispositivo de protector

de cables.

10. Inserte la lengüeta de la cubier ta del bloque

terminal en la ranura del panel posterior de la

secadora. Asegure la cubier ta con el tor nillo de

retención.

5. Retire el alambre de conexión a tierra del

artefacto (verde con franjas amarillas) del

tornillo externo del conector de puesta a

tierra. Fíjelo debajo del tor nillo central

color plateado del bloque terminal.

CORDÓN DE SUMINISTRO

DE ENERGÍA

Contacto 14-30R de cuatro alambres (requerido para casas rodantes)

4. Retire el tornillo central del

bloque terminal.

7. Coloque el extremo en

gancho del alambre neutro

(blanco o central) del cable

de suministro de energía

debajo del tornillo central

del bloque terminal (con el

gancho a la derecha).

Apriete entre sí los

extremos del gancho.

Apriete el tornillo.

8. Coloque los extremos en

gancho de los otros alambres

del cable de suministro de

energía debajo de los

tornillos externos del bloque

terminal (con el gancho a la

derecha). Apr iete entre sí los

extremos de los ganchos.

Apriete los tornillos.

6. Conecte el alambre de

conexión a tierra (cable

desnudo) del cordón de

suministro de energía al

tornillo del conector externo

de puesta a tierra.

Apriete el tornillo.

10. Inserte la lengüeta de la cubier ta del

bloque terminal en la ranura del panel

posterior de la secadora. Asegure la

cubierta con el tornillo de retención.

9. Apriete los tornillos del dispositivo

de protector de cables.

5. Retire el alambre de conexión a tierra del

artefacto (verde con franjas amarillas) del

tornillo externo del conector de puesta a

tierra. Fíjelo debajo del tor nillo central color

plateado del bloque terminal.

ALAMBRE DIRECTO

Preparación del alambre:

protector de

cables de 3/4",

aprobado por

U.L.

a la caja de

desconexión

alambre NEUTRO

(blanco o del centro)

de calibre 10, con

3 alambres y con

alambre de

conexión a tierra

(Romex)

5"

3-1/2"

1" del alambre

pelado de su

aislamiento

alambre de

conexión a

tierra pelado

El cable directo debe tener 4

pies de longitud extra para

poder mover la secadora si se

necesita.

Pele 5 pulgadas de la cubierta

externa del extremo del cable.

Deje desnudo el alambre de

conexión a tierra en 5”.Cor te

1-1/2” de los restantes 3

alambres. Pele el aislamiento

1” hacia atrás.

Dé forma

de gancho

a los

extremos

de los

alambres.

10

El cordón de suministro de energía de tres

alambres de por lo menos 4 pies de largo

debe tener 3 alambres de cobre No.10 y

poder encajarse en un contacto para tres

alambres NEMA tipo 10-30R.

4. Afloje o retire el tornillo

central del bloque terminal.

6. Conecte los otros alambres

a los tornillos externos del

bloque terminal. Apr iete

los tornillos.

7. Apriete los tornillos del disp

ositivo de protector de cables.

8. Inserte la lengüeta de la cubier ta del bloque

terminal en la ranura del panel posterior de la

secadora. Asegure la cubier ta con el tor nillo

de retención.

5. Conecte el alambre neutro (blanco

o central) del cordón de suministro

de energía al tornillo central, de

color plateado, del bloque terminal.

Apriete el tornillo.

CORDÓN DE SUMINISTRO

DE ENERGÍA

Conexión de tres alambres...

NEUTRO

NEUTRO

(blanco o del centro)

protector de cables

de 3/4" aprobado

por U.L.

Esta hoja conectada

a este conductor

terminales

en anillo

terminales en

horquilla con

extremos hacia

arriba

Cuando los códigos locales lo permiten

conexión del conductor de puesta a tierra del gabinete al

alambre neutro:

Contacto 10-30R de tres alambres

Cuando los códigos locales lo permiten

conexión del conductor de puesta a tierra del gabinete al

alambre neutro:

4. Afloje o retire el tornillo

central del bloque terminal.

7. Apriete los tornillos del disp

ositivo de protector de cables.

8. Inserte la lengüeta de la cubier ta del bloque

terminal en la ranura del panel posterior de la

secadora. Asegure la cubier ta con el tor nillo

de retención.

6. Coloque los extremos en gancho

de los otros alambres del cable

de suministro de energía debajo

de los tornillos externos del

bloque terminal (con el gancho a

la derecha). Apr iete entre sí los

extremos de los ganchos.Apriete

los tornillos.

5. Coloque el extremo en gancho del

alambre neutro (blanco o central) del

cable de suministro de energía debajo del

tornillo central del bloque terminal (con el

gancho a la derecha). Apr iete entre sí los

extremos del gancho.Apr iete el tor nillo.

ALAMBRE DIRECTO

Preparación del alambre:

El cable directo debe tener

4 pies de longitud extra para

poder mover la secadora si se

necesita.

Pele 3-1/2 pulgadas de la

cubierta externa del extremo del

cable.Pele el aislamiento

1pulga hacia atrás. Si está

usando un cable de 3 alambres

con alambre de conexión a

tierra, corte el alambre desnudo

al ras con la cubierta exterior.

Dé forma

de gancho

a los

extremos

de los

alambres.

de calibre 10 con 3

alambres, o de calibre

10, con 3 alambres y

alambre de conexión a

tierra (Romex)

protector de cables

de 3/4", aprobado

por U.L.

De 3 alambres con alambre de conexión a

tierra: alambre pelado cor tado más pequeño.

No se usa el alambre. La secadora está

conectada a tierra a través del cable directo.

a la caja de

desconexión

alambre NEUTRO

(blanco o del centro)

1" de los

alambres

pelados de su

aislamiento

3-1/2"

11

Abrazadera

de 10.2 cm

(4 pulg.)

Abrazadera

de 10.2 cm

(4 pulg.)

Utilizando una abrazadera de 10,2 cm

(4 pulg.), conecte el conducto de

salida de aire en el orificio de salida

de aire de la secadora. Si está

haciendo la conexión en un conducto

de salida de aire existente, asegúrese

de que el conducto esté limpio.

El conducto de salida de aire de la

secadora debe calzar sobre el orificio

de salida de aire de la secadora y

dentro de la campana exterior de

salida de aire.

Asegúrese de que el conducto de

salida de aire esté fijado a la campana

exterior de salida de aire con una

abrazadera de 10,2 cm (4 pulg.).

D.Level and exhaust

dryer

La secadora debe estar nivelada

para reducir el ruido y asegurar su

debido funcionamiento.

Deslice la secadora sobre un

pedazo de cartón o madera dura

antes de moverla por el piso para

no dañar el piso.

Mueva la secadora cerca de su lugar

permanente. Deje suficiente espacio

para conectar el conducto de salida

de aire. Quite el pedazo de cartón o

madera dura que está debajo de la

secadora.

Verifique si la secadora está nivelada,

colocando un nivel sobre la secadora,

primero de lado a lado, luego de

adelante para atrás.Si la secadora no

está nivelada, ajuste las patas de la

secadora hacia arriba o hacia abajo

hasta que esté nivelada.

6. Conecte el alambre neutro

(blanco o central) del cordón de

suministro de energía al tornillo

central, de color plateado, del

bloque terminal. Apr iete el

tornillo.

7. Apriete los tornillos del disp

ositivo de protector de cables.

8. Inserte la lengüeta de la cubier ta

del bloque terminal en la ranura

del panel posterior de la secadora.

Asegure la cubierta con el tornillo

de retención.

5. Retire el alambre de conexión a tierra del

artefacto (verde con franjas amarillas) del

tornillo externo del conector de puesta a tierra.

Conecte el alambre de puesta a tierra (blanco

o central) del cordón/cable de suministro de

energía debajo del tornillo central, de color

plateado del bloque terminal. Apr iete el tor nillo.

9. Conecte un alambre de cobre de conexión a

tierra separado del tornillo del conector externo de puesta

a tierra a un punto adecuado de conexión a tierra.

4. Afloje o retire el tornillo

central del bloque terminal.

ALAMBRE DIRECTO O

CORDÓN DE SUMINISTRO

DE ENERGÍA

Cuando los códigos locales No lo permiten

conexión del conductor de puesta a tierra del gabinete al

alambre neutro:

El cordón de suministro de energía de tres

alambres debe tener 4 pies de largo y tener

3 alambres de cobre No.10 y poder

encajarse en un contacto para tres

alambres NEMA tipo 10-30R.

El cable directo de suministro de energía

debe ser preparado como se muestra en

“Preparación del alambre” de los pasos de

la conexión directa de tres alambres.

Si los códigos locales lo permiten y se

usa un alambre de conexión a tierra

separada, se recomienda que un

electricista calificado determine que la

vía de conexión a tierra sea adecuada.

F. Verifique el

funcionamiento

Asegúrese si:

✔ no omitió algún paso de la

instalación.

✔ instaló todas las piezas.

✔ instaló debidamente las patas de la

secadora.

✔ la secadora está nivelada.

✔ haya asegurado todas las juntas

del ducto de escape con

abrazaderas de 4”.

✔ tiene todas las herramientas con

las que comenzó.

Enchufe el cordón de suministro de

energía en un contacto conectado a

tierra o conecte el alambre directo a