INSTALLATION INSTRUCTIONS

ELECTRIC DRYER

INSTRUCCIONES DE INSTALACIÓN

SECADORA ELÉCTRICA

INSTRUCTIONS D'INSTALLATION

SECHE-LINGE ELECTRIQUE

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Índice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table des matières . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8528095 Rev A

8528095 Rév A

IMPORTANT: Save for local electrical inspector's use.

IMPORTANTE:

Guarde para tener a disposición del inspector de electricidad local.

IMPORTANT : Conserver ces instructions à l’usage de l’inspecteur des installations

électriques local.

2

TABLE OF CONTENTS

DRYER SAFETY

DRYER SAFETY............................................................................ 2

INSTALLATION REQUIREMENTS .............................................. 3

Tools and Parts .......................................................................... 3

Location Requirements.............................................................. 3

Electrical Requirements ............................................................ 4

Venting Requirements .............................................................. 5

INSTALLATION INSTRUCTIONS – ELECTRIC DRYER.......... 7

Install Ventwork ..........................................................................7

Prepare Dryer..............................................................................7

Electrical Connection..................................................................8

Level and Exhaust the Dryer ......................................................9

Check Operation ......................................................................10

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

follow instructions.

can be killed or seriously injured if you don't

You

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

instructions.

follow

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

WARNING:

including the following:

■ Read all instructions before using the dryer.

■ Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

■ Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, drycleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

■ Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

■ Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

■ Do not reach into the dryer if the drum is moving.

■ Do not install or store the dryer where it will be exposed

to the weather.

■ Do not tamper with controls.

■ Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair instructions that you understand and have the skills to carry out.

■ Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

■ Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

■ Clean lint screen before or after each load.

■ Keep area around the exhaust opening and adjacent sur-

rounding areas free from the accumulation of lint,dust,

and dirt.

■ The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

■ See installation instructions for grounding requirements.

SAVE THESE INSTRUCTIONS

3

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

■ Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

■ Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

“Recessed Area and Closet Installation Instructions” for

minimum spacing requirements.

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather. If room temperature is below

7º C (45º F), automatic cycles may not shut off.

■ Maximum slope under entire dryer should not be more than

2.5 cm (1") . If slope is greater than 2.5 cm (1") , install

Extended Dryer Feet Kit, Part No. 279810. Clothes may not

tumble properly and automatic sensor cycles may not operate

correctly if dryer is not level. Floor must be able to support

dryer weight of 79.4 kg (175 lbs).

INSTALLATION REQUIREMENTS

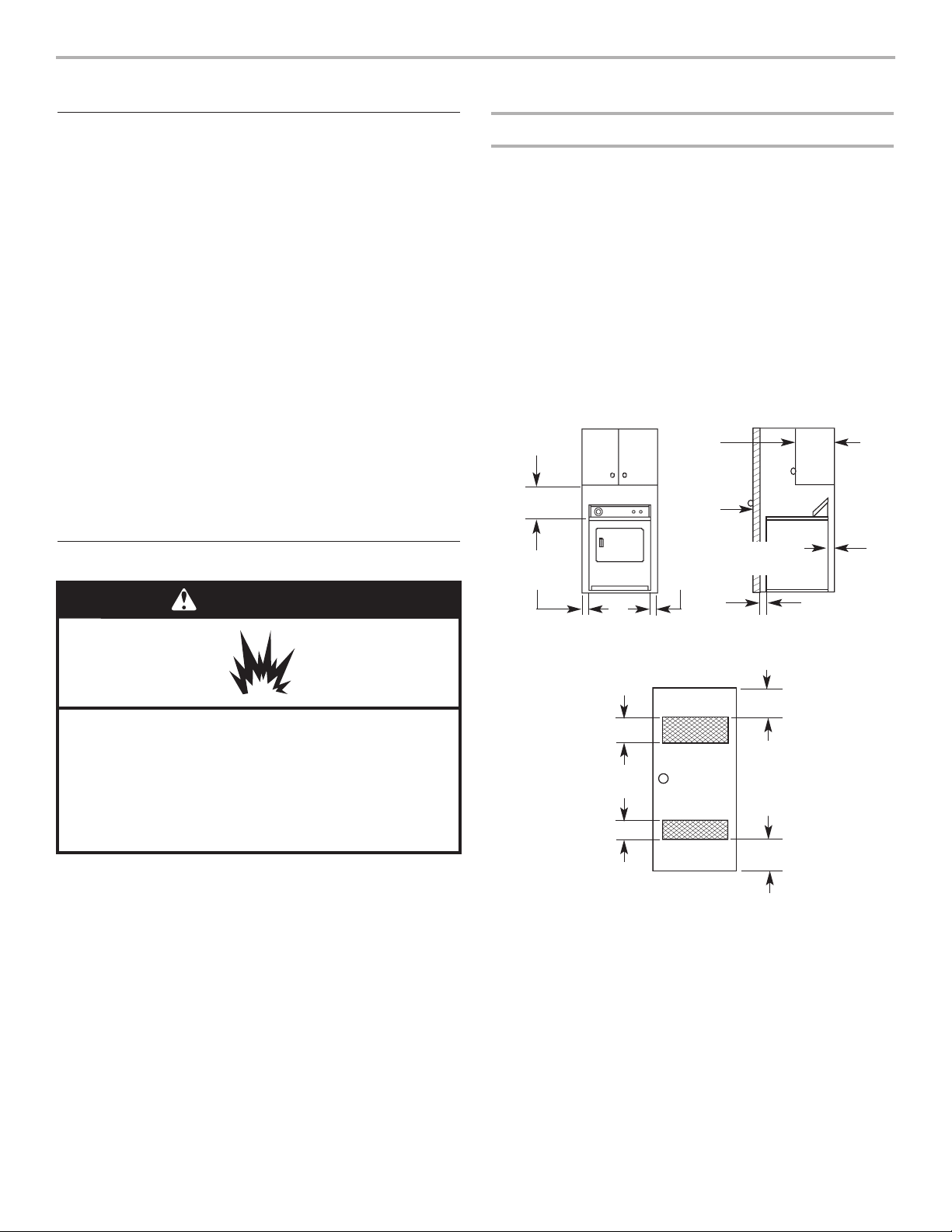

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet. For

recessed area and closet installations, minimum clearances can

be found on the serial tag on the dryer.

The installation spacing is in centimeters (inches) and is the

minimum allowable. Additional spacing should be considered for

ease of installation, servicing, and compliance with local codes

and ordinances.

If closet door is installed, the minimum unobstructed air opening

in the top and bottom is required. Louvered doors with equivalent

air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools needed

■ Flat-blade screwdriver

■ Phillips screwdriver

■ Adjustable wrench that opens to 2.5 cm (1")

■ Hex-head socket wrench

■ Level

■ 1/4" socket wrench or 1/4" nut driver

■ Utility knife

■ Vent clamps

■ Pipe-joint compound resistant to LP gas

■ Caulk gun and caulk (for installing new exhaust vent)

■ Tin snips

Parts supplied

Remove parts bag from dryer drum. Check that all parts were

included.

■ 4 leveling legs

Recessed front view Closet side view

Minimum Installation Clearances

Additional clearances for wall, door and floor moldings may be required or if

external exhaust elbow is used.

closet

door

Front

View

7.6 cm (3")

7.6 cm (3")

155 cm

2

(24"2)

310 cm

2

(48"2)

*Opening is the minimum for a closet door.

Louvered doors with equivalent air openings are acceptable.

2.5 cm (1")

Closet

door

35.6 cm

(14") max.

2.5 cm (1")

2.5 cm (1")

45.7 cm

(18")*

10.2 cm

(4")

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 46 cm (18 inches) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

4

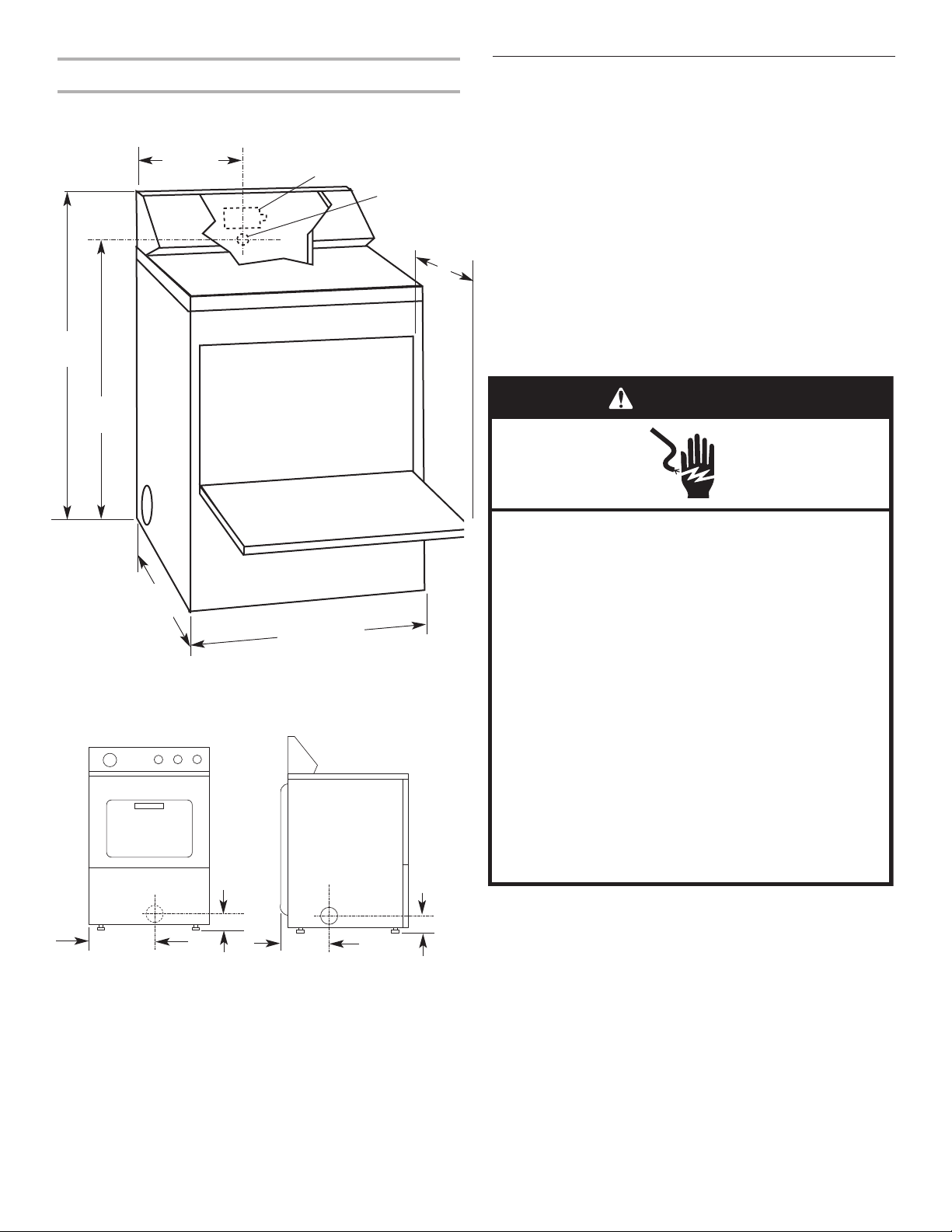

Product Dimensions

74.3 cm

(29-1/4")

terminal block cover

power supply

cord/cable

strain relief

109.5 cm

(43-1/8")

27.9 cm

(11")

Dimensions shown with feet extended 2.5 cm (1") from

bottom of dryer.

97.2 cm

(38-1/4")

68.6 cm (27")

35.6

cm

(14")

left or right

side exhaust

back

exhaust

10.8 cm

(4-1/4")

26 cm

(10-1/4")

35.9 cm

(14-1/8")

10.2 cm

(4")

Exhaust dimensions

The dryer door

extends 35.6 cm (14")

from the front of the

dryer when fully

opened.

Electrical Requirements

Important: Observe all governing codes and ordinances.

This dryer is supplied/fitted with an electricity supply cord and

European 16A plug. It should be connected to electricity supply

socket at the voltage shown on the rating plate. The minimum

supply fuse capacity should be 16A. The dryer must be

positioned so that the plug is accessible. If the fitted plug is not

used, the electrical connection must be carried out by a

competent electrician in accordance with local or national codes.

If the supply cord is damaged, it must be replaced with a

specially terminated cord by an authorized service agent or a

similarly competent person.

Do not use an adapter.

Do not use an extension cord.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond, path is adequate.

WARNING

Electrical Shock Hazard

Electrical earthing is required on this dryer.

Do not earth to a gas pipe.

Do not change the power supply cord plug. If it does

not fit the outlet, have a proper outlet installed by a

qualified electrician.

Do not have a fuse in the neutral or earthing circuit.

Do not use an extension cord with this dryer.

Check with a qualified electrician to be sure the dryer is

properly earthed.

Do not connect plug end of power supply cord into a

live receptacle before connecting power supply cord to

dryer terminal block.

Do not reuse old power supply cord.

Failure to follow these instructions could result in

death, fire, or serious injury.

5

Recommended Earthing Method

■ It is your responsibility to contact a qualified electrical installer

to ensure that the electrical installation is adequate and in

conformance with the National Electrical Code, ANSI/NFPA 70,

latest edition, and all local codes and ordinances.

Venting Requirements

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

■ The dryer vent must not be connected into any gas vent,

chimney, wall, ceiling, or a concealed space of a building, or

any other vent used for venting.

■ Do not use an exhaust hood with a magnetic latch.

■ Do not install flexible metal vent in enclosed walls, ceilings or

floors.

■ 10 cm (4") heavy metal vent and clamps must be used.

■ Use clamps to seal all joints. Vent must not be connected or

secured with screws or other fastening devices which extend

into the interior of the vent. Do not use duct tape.

IMPORTANT: Observe all governing codes and ordinances.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended to prevent crushing and

kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that may result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home or business.

Exhaust hood must be at least 30.5 cm (12") from the ground or

any object that may be in the path of the exhaust (such as

flowers, rocks or bushes).

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

EARTHING INSTRUCTIONS

■

For an earthed, cord-connected dryer:

This dryer must be earthed. In the event of a malfunction or

breakdown, earthing will reduce the risk of electric shock by

providing a path of least resistance for electric current. This

dryer uses a cord having an equipment-earthing conductor

and an earthing plug. The plug must be plugged into an

appropriate outlet that is properly installed and earthed in

accordance with all local codes and ordinances.

■

For a permanently connected dryer:

This dryer must be connected to a earthed metal, permanent

wiring system, or an equipment-earthing conductor must be

run with the circuit conductors and connected to the

equipment-earthing terminal or lead on the dryer.

WARNING: Improper connection of the equipment-

earthing conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the dryer is

properly earthed. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

6

Vent System Length

Maximum length of vent system depends upon the type of vent

used, number of elbows and type of exhaust hood. The maximum

length for both rigid and flexible vent is shown in the chart.

For vent systems not covered by the vent specification chart

(such as multiple unit hookups, plenums, and power-assist fans),

see Whirlpool Service Manual, “Exhausting Whirlpool Dryers,”

Part No. LIT603197, available from your Whirlpool parts

distributor.

If dryer is installed in a confined area, such as a bedroom,

bathroom or closet, provision must be made for enough air for

combustion and ventilation. (Check governing codes and

ordinances.) See “Recessed Area and Closet Installation

Instructions” in the “Location Requirements” section.

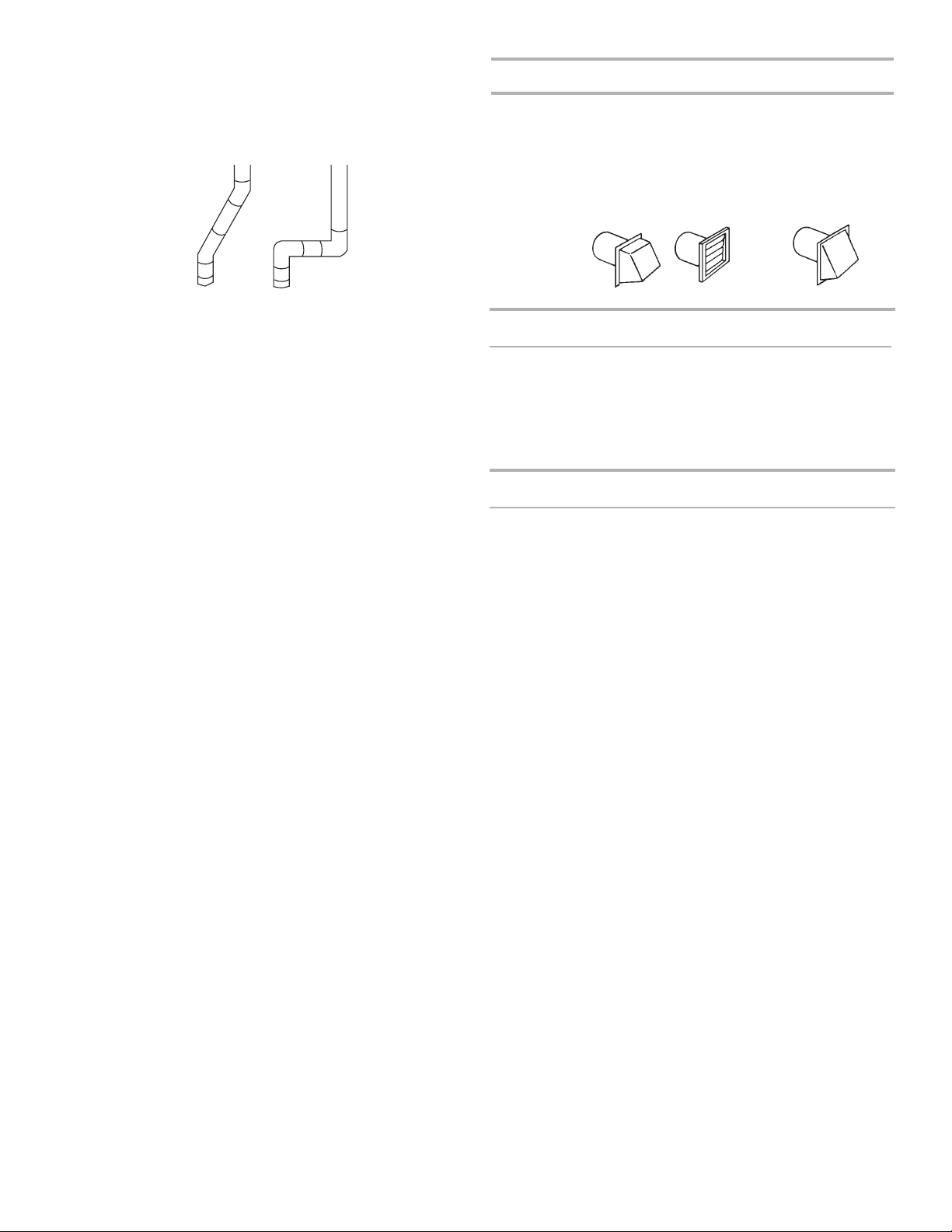

A four-inch outlet hood is preferred. However, a 6.4 cm (2¹⁄₂")

outlet exhaust hood may be used. A 6.4 cm (2¹⁄₂") outlet creates

greater back pressure than other hood types. For permanent

installation, a stationary vent system is required.

No. of 90° turns

No. of 90° turns

Flexible Metal Vent

10.2 cm (4") Diameter Exhaust Hoods

Maximum Vent Length

15.8 m (52 ft.)

13.4 m (44 ft.)

11.0 m (36 ft.)

8.2 m (27 ft.)

6.1 m (20 ft.)

9.4 m (31 ft.)

7.9 m (26 ft.)

6.7 m (22 ft.)

6.1 m (20 ft.)

5.5 m (18 ft.)

0

1

2

3

4

0

1

2

3

4

13.4 m (44 ft.)

11.0 m (36 ft.)

8.5 m (28 ft.)

6.4 m (21 ft.)

4.3 m (14 ft.)

7.0 m (23 ft.)

5.5 m (18 ft.)

4.3 m (14 ft.)

3.7 m (12 ft.)

3.0 m (10 ft.)

Box Hood and

Louvered Style

Angled Hood Style

Box Hood and

Louvered Style

Angled Hood Style

Rigid Metal Vent

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

Plan installation to use the fewest number of elbows and turns.

Avoid making 90º turns.

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

The vent can be routed up, down, left, right, behind the dryer or

straight out the back of the dryer.

Service check: Back pressure in any exhaust system used must

not exceed 15.2 mm (0.6") in water column, measured with an

incline manometer at the point that exhaust vent connects to

dryer.

The exhaust outlet is located at the center of the rear of the dryer.

The design of the flue system should ensure that any condensate

formed when operating the appliance is either retained and

subsequently evaporated or discharged. Following these

installation instructions should adequately meet this requirement.

A

B

Exhaust Air Flow

A. Better

B. Good

7

INSTALLATION INSTRUCTIONS – ELECTRIC DRYER

Install Ventwork

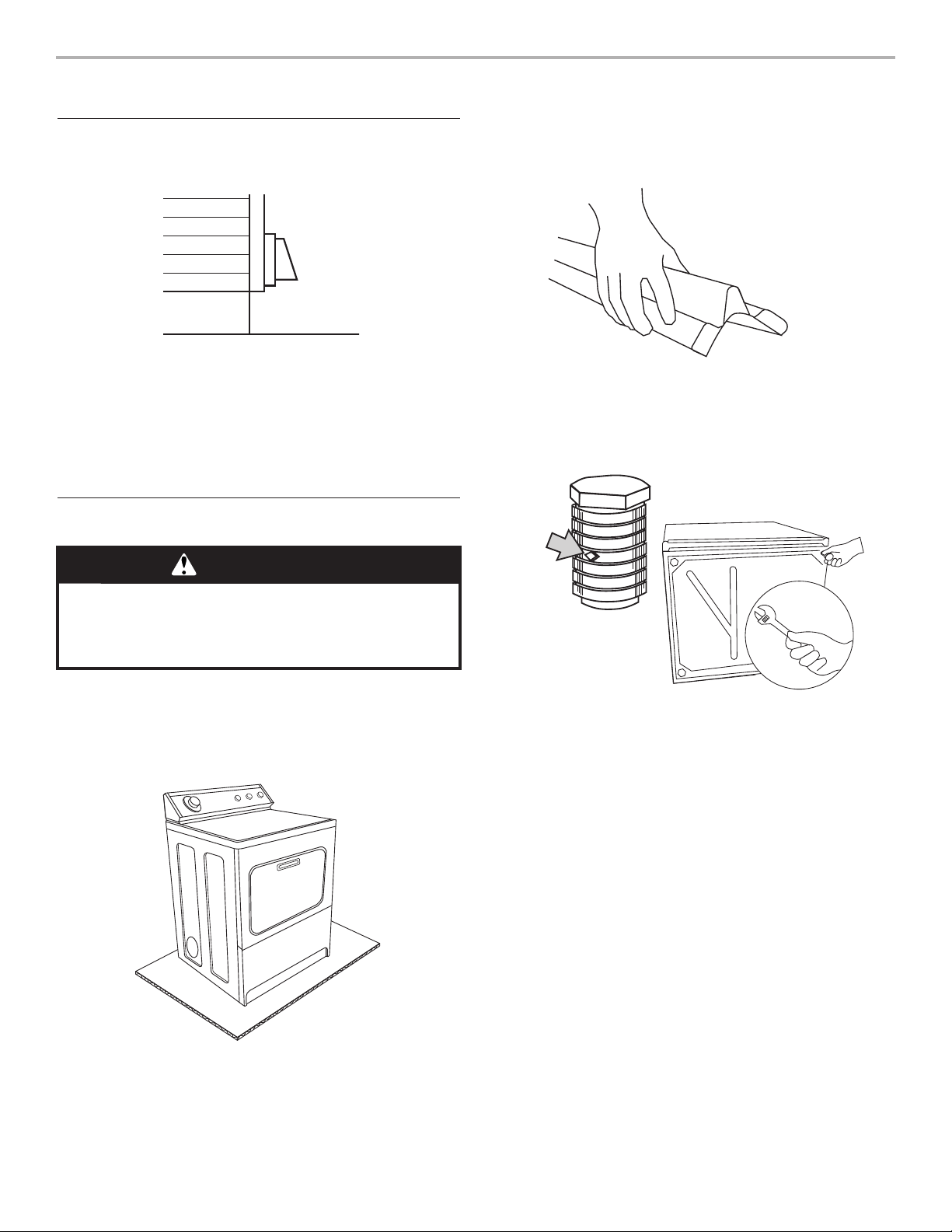

1. Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

2. Connect exhaust vent to hood. (Exhaust vent MUST fit inside

hood.) Secure vent to hood with a 100 mm (4") clamp.

3. Run exhaust vent to dryer location. Use the straightest path

possible. Avoid 90° turns. Use 100 mm (4") clamps to secure

vent peices. Tin snips may be needed to cut vent to required

length.

2. Take two cardboard corners from dryer carton and place

them on floor in back of dryer. Firmly grasp body of dryer

and gently lay it on its back on the cardboard corners.

3. Start to screw legs into holes by hand. Use an adjustable

wrench or 2.5 cm (1") hex-head socket wrench to finish

turning legs until you reach the ridge with the diamond

marking.

4. Stand dryer up on cardboard or hardboard.

diamond

marking

Prepare Dryer

1. Remove tape from dryer cabinet. Open dryer door and

remove tape from dryer drum. (Not all dryer drums are

taped.) Remove drying rack, if included. Turn dryer drum

counterclockwise to make sure all tape was removed. Wipe

drum with damp cloth to remove any dust.

WARNING

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

8

Electrical Connection

Plug supply cord into an earthed outlet. It should be connected to

an electricity supply socket at the voltage shown on the rating

plate. The minimum supply fuse capacity should be 16A. The

dryer must be positioned so that the plug is accessible. If the

fitted plug is not used, the electrical connection must be carried

out by a competent electrician in accordance with local or

national codes.

If the supply cord is damaged, it must be replaced with a

specially terminated cord by an authorized service agent or a

similarly competent person.

Do not use an adapter.

Do not use an extension cord.

Important: Observe all governing codes and ordinances.

If codes permit and an additional earth bond wire is used, it is

recommended that a competent electrician determine that the

earth bond path is adequate.

WARNING

Electrical Shock Hazard

Electrical earthing is required on this dryer.

Do not earth to a gas pipe.

Do not change the power supply cord plug. If it does

not fit the outlet, have a proper outlet installed by a

qualified electrician.

Do not have a fuse in the neutral or earthing circuit.

Do not use an extension cord with this dryer.

Check with a qualified electrician to be sure the dryer is

properly earthed.

Do not connect plug end of power supply cord into a

live receptacle before connecting power supply cord to

dryer terminal block.

Do not reuse old power supply cord.

Failure to follow these instructions could result in

death, fire, or serious injury.

9

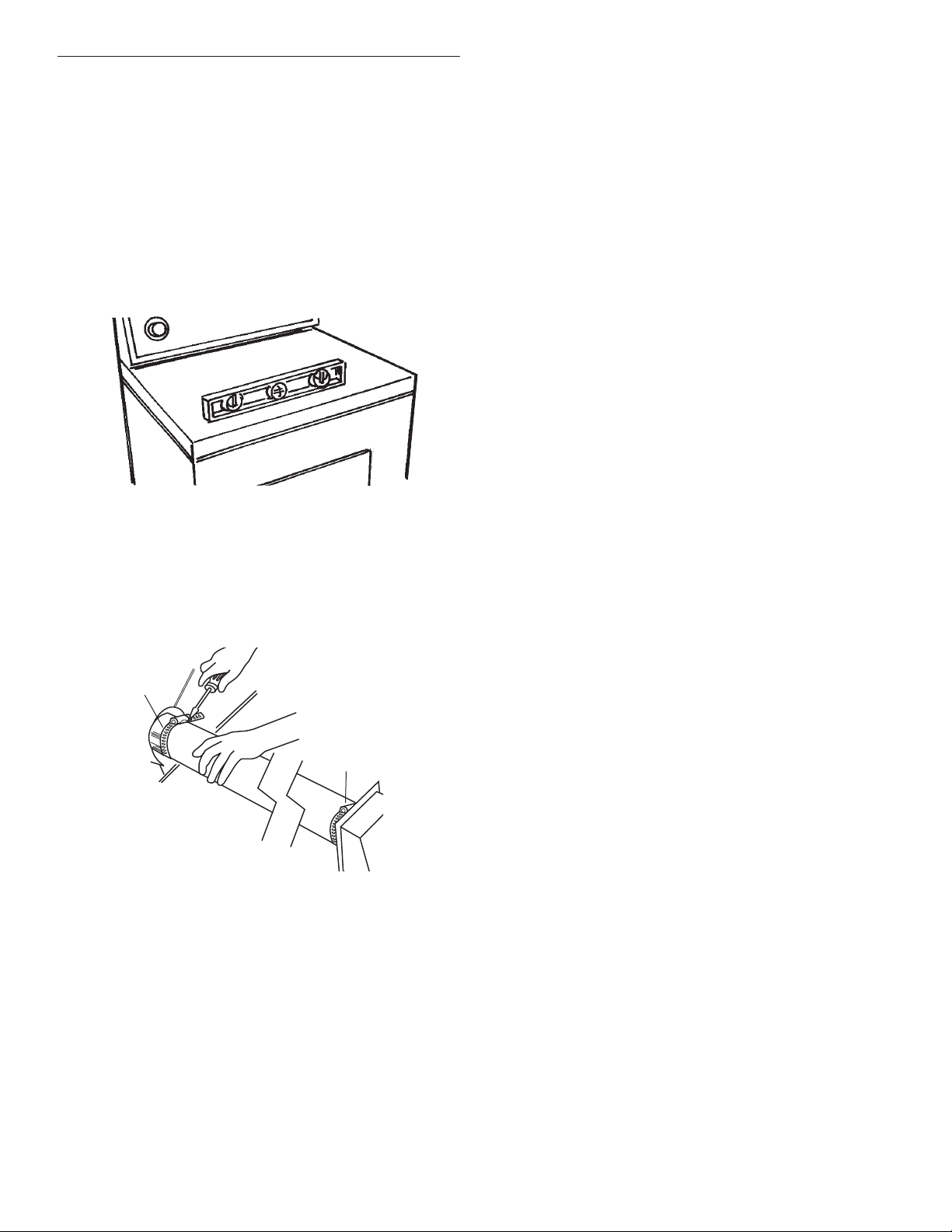

Dryer must be level to reduce noise and assure proper

performance.

Slide dryer onto cardboard or hardboard before moving across

floor to prevent floor damage.

1. Move dryer close to its permanent location. Leave enough

room to connect exhaust vent. Remove cardboard or

hardboard from under dryer.

2. Check levelness of dryer by placing a level on top of dryer,

first side to side, then front to back. If dryer is not level,

adjust dryer legs up or down.

3. If legs are not long enough to level dryer, order Extended

Dryer Feet Kit, Part No. 279810 (sold two legs per kit), from

your dealer.

4. Connect exhaust vent to exhaust outlet in dryer. The exhaust

vent must fit over the dryer exhaust outlet and inside the

exhaust hood vent.

Use 100 mm (4") vent clamps to seal all joints and to secure

exhaust vent to dryer exhaust outlet.

5. Move dryer into final position.

Level and Exhaust the Dryer

10.2 cm (4")

clamp

10.2 cm (4")

clamp

10

1. Check that you:

■ did not skip any steps.

■ installed all parts.

■ properly installed dryer legs.

■ leveled dryer.

■ have secured all exhaust vent joints with 100 mm (4")

clamps.

■ have all the tools you started with.

2. Plug power supply cord into earthed outlet or connect direct

wire to power supply. Turn power supply on.

3. Read the Use and Care Guide to fully understand your new

dryer. Select a full heat cycle (not the air cycle) and start

dryer. After five minutes, open dryer door. You should feel

heat inside dryer.

If dryer does not operate properly, check the following:

■ electrical supply is connected.

■ house fuse is intact and tight; or circuit breaker has not

tripped.

■ dryer door is closed.

■ controls are set in a running or “On” position.

■ start button has been pushed firmly.

If dryer makes an unusual noise, check that the dryer is level.

Check Operation

Te chnical Specification

Moving dryer to a new location?

Check with a licensed electrician to confirm that supply voltage

at new home matches voltage specified on the model/serial

rating plate.

Shut off

electrical supply

to dryer.

Disconnect

power supply

cable from dryer.

Tape top

to cabinet.

Ta pe

door to

front

panel.

Tur n

leveling

legs all the

way in.

Slide dryer onto cardboard or hardboard

before moving it across the floor to

prevent damaging floor covering.

(see rating plate in door opening for full model details)

220-240V ~ 50 Hz, 1ph

3100W, IPX4

Clothes capacity: 9.1 kg max.

ÍNDICE

SEGURIDAD DE LA SECADORA

SEGURIDAD DE LA SECADORA.............................................. 11

REQUISITOS DE INSTALACIÓN .............................................. 12

Piezas y herramientas.............................................................. 12

Requisitos de ubicación .......................................................... 12

Requisitos eléctricos................................................................ 13

Requisitos de ventilación ...................................................... 14

INSTRUCCIONES DE INSTALACIÓN – SECADORA

ELÉCTRICA ............................................................................ 16

Instalación de la ventilación ....................................................16

Preparación de la secadora......................................................16

Conexión eléctrica ....................................................................17

Nivelación y ventilación de la secadora ..................................18

Verifique el funcionamiento......................................................19

11

Su seguridad y la seguridad de los demás es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodoméstico. Lea y obedezca

siempre todos los mensajes de seguridad.

Este es el símbolo de advertencia de seguridad.

Este símbolo le llama la atención sobre peligros potenciales que pueden ocasionar la muerte o una lesión

a usted y a los demás.

Todos los mensajes de seguridad irán a continuación del símbolo de advertencia de seguridad y de la palabra

“PELIGRO” o “ADVERTENCIA”.

Estas palabras significan:

Si no sigue las instrucciones de inmediato, usted puede morir

PELIGRO

ADVERTENCIA

o sufrir una lesión grave.

Si no sigue las instrucciones, usted puede morir o sufrir una

lesión grave.

Todos los mensajes de seguridad le dirán el peligro potencial, le dirán cómo reducir las posibilidades de sufrir una lesión y lo

que puede suceder si no se siguen las instrucciones.

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

A fin de reducir el riesgo de incendio, descarga eléctrica o de daño a las personas que usen la secadora,

ADVERTENCIA:

deben seguirse las precauciones básicas, incluidas las siguientes:

■ Lea todas las instrucciones antes de usar la secadora..

■ No coloque los objetos expuestos a aceite para cocinar en

su secadora. Los objetos expuestos a aceites para cocinar

pueden contribuir a una reacción química que podría causar

que una carga se inflame.

■ No seque artículos que ya se hayan limpiado, lavado,

remojado o manchado con gasolina, disolventes de limpieza

en seco, u otras sustancias inflamables o explosivas ya que

despiden vapores que pueden encenderse o causar una

explosión.

■ No permita que jueguen los niños sobre o dentro de la

secadora. Es necesaria la cuidadosa vigilancia de los niños

toda vez que se use la secadora cerca de ellos.

■ Quite la puerta de la secadora al compartimiento de secado

antes de ponerla fuera de funcionamiento o de descartarla.

■ No introduzca las manos en la secadora cuando el tambor

está en movimiento

■ No instale o almacene esta secadora donde estará expuesta

a la intemperie.

■ No trate de forzar los controles.

■ No repare o reemplace ninguna pieza de la secadora ni trate

de repararla a menos que esto se recomiende

específicamente en este Manual de uso y cuidado o en

instrucciones de reparación publicadas para el usuario que

usted comprenda y sólo si cuenta con la experiencia

necesaria para llevar a cabo dicha reparación.

■ No utilice suavizantes de telas o productos para eliminar el

estático de prendas a menos que lo recomiende el

fabricante de suavizante de telas o del producto en uso.

■ No utilice calor para secar prendas que contengan espuma

de caucho o materiales de caucho con textura similar.

■ Limpie el filtro de pelusa antes y después de cada carga.

■ Mantenga el área alrededor de la abertura de ventilación y

entrada y las áreas adyacentes a esta abertura sin pelusa,

polvo o tierra.

■ La parte interior de la secadora y el ducto de escape se

deben limpiar periódicamente. Esta limpieza la debe llevar

a cabo un reparador calificado.

■ Vea la instrucciones de instalación para los requisitos de

conexión a tierra.

GUARDE ESTAS INSTRUCCIONES

Requisitos de ubicación

IMPORTANTE: Observe todos los códigos y reglamentos

aplicables.

■ Verifique los requisitos de los códigos. Algunos códigos

limitan, o no permiten, la instalación de la secadora en

garajes, clósets o en dormitorios. Póngase en contacto con el

inspector de construcciones de su localidad.

■ Asegúrese de que los bordes inferiores del armario, además

de la parte posterior y los lados de la secadora, estén libres

de obstrucciones, para permitir el espacio adecuado de

aberturas para la combustión de aire. Vea “Instrucciones para

la instalación empotrada o en clóset” para los requisitos

mínimos de espacio.

NOTA: No debe instalarse la secadora en un área en donde

pueda estar expuesta al agua y/o a la intemperie. Es posible que

los ciclos automáticos no se apaguen si la temperatura de la

habitación es inferior a 7º C (45º F).

REQUISITOS DE INSTALACIÓN

Instrucciones para la instalación empotrada o en

clóset

Esta secadora podrá instalarse en un área empotrada o en un

clóset. Para las instalaciones en áreas empotradas o clósets, se

pueden encontrar los espacios mínimos en la etiqueta de la serie

de la secadora.

El espacio de instalación es en centímetros (pulgadas) y es el

mínimo permitido. Debe considerarse espacio adicional para

facilitar la instalación, el servicio técnico y el cumplimiento de los

códigos y ordenanzas locales.

Si se ha instalado la puerta del clóset, se requieren aberturas

mínimas de ventilación sin obstrucciones en la parte superior e

inferior de la puerta. Se aceptan puertas tipo persianas con

aberturas de aire equivalentes.

La secadora deberá ventilarse al exterior.

No se puede instalar otro electrodoméstico que usa combustible

en el mismo clóset en que se encuentra la secadora.

Piezas y herramientas

Reúna las herramientas y piezas necesarias antes de comenzar la

instalación. Lea y siga las instrucciones provistas con cualquiera

de las herramientas enlistadas aquí.

Herramientas necesarias

■ Destornillador de hoja plana

■ Destornillador Phillips

■ Llave de tuercas ajustable que se abra a 2,5 cm (1")

■ Llave de tubo de cabeza hexagonal

■ Nivel

■ Llave de tubo de 1/4" o llave de tuercas de 1/4"

■ Cuchillo para uso general

■ Abrazaderas para ducto

■ Pegamento para tuberías resistente a gas L.P.

■ Pistola y masilla para calafateo (para instalar el nuevo ducto

de escape)

■ Tijeras para lata

Piezas suministradas

Retire la bolsa de piezas del tambor de la secadora. Verifique

que estén todas las piezas.

■ 4 patas niveladoras

Vista frontal del lugar empotrado Vista lateral del clóset

Espacios mínimos para la instalación

Se podrían necesitar espacios libres adicionales para las molduras de la pared,

de la puerta y del piso, o si se usa un codo externo de ventilación.

Puerta

del clóset

Vista

frontal

7,6 cm (3")

7,6 cm (3")

155 cm

2

(24"2)

310 cm

2

(48"2)

* La abertura es la mínima para la puerta del clóset.

Se aceptan puertas tipo persianas con aberturas de aire equivalentes.

2,5 cm (1")

Puerta del

clóset

35,6 cm

(14") máx.

2,5 cm (1")

2,5 cm (1")

45,7 cm

(18")*

10,2 cm

(4")

■ El declive máximo debajo de toda la secadora deberá ser de

menos de 1" (2,5 cm). Si el declive es mayor que 1" (2,5 cm),

instale el juego de extensión de patas de la secadora, Pieza

No. 279810. La ropa quizás no rote adecuadamente y los

ciclos del sensor automático posiblemente no funcionen

debidamente si la secadora no está nivelada. El piso deberá

ser lo suficientemente fuerte como para soportar el peso de la

secadora de 79,4 kg (175 lbs.).

12

ADVERTENCIA

Peligro de explosión

Mantenga los materiales y vapores inflamables, tales

como la gasolina, alejados de la secadora.

Coloque la secadora a un mínimo de 46 cm sobre el

piso para la instalación en un garaje.

No seguir esta instrucción puede ocasionar la muerte,

explosión o incendio.

13

Medidas del producto

74,3 cm

(29-1/4")

tapa del bloque de

terminal

protector de

cables del

cable/cordón

de suministro

de energía

109,5 cm

(43-1/8")

27,9 cm

(11")

Las medidas que se muestran son con las patas

extendidas a 2,5 cm (1") de la parte inferior de la secadora.

97,2 cm

(38-1/4")

68,6 cm (27")

35,6

cm

(14")

ventilación lateral a

la izquierda o a la

derecha

Ducto de escape

posterior

10,8 cm

(4-1/4")

26 cm

(10-1/4")

35,9 cm

(14-1/8")

10,2 cm

(4")

Dimensiones del ducto de escape

La puerta de la secadora se

extiende 35,6 cm (14") del

frente de la misma cuando

está completamente abierta.

Requisitos eléctricos

Importante: Observe todos los códigos y reglamentos aplicables.

Esta secadora está provista de un cable de suministro

eléctrico y un enchufe europeo de 16A. Deberá ser

conectada al receptáculo de suministro eléctrico con el

voltaje que se muestra en la placa de clasificación. La

capacidad mínima del fusible de suministro deberá ser de

16A. La secadora deberá colocarse de manera que el

enchufe esté accesible. Si no se usa el enchufe provisto, la

conexión eléctrica deberá llevarse a cabo por parte de un

electricista capacitado, según los códigos locales o

nacionales.

Si se ha dañado el cable de suministro, deberá reemplazarse con

un cable especialmente terminado, por parte de un agente de

servicio autorizado u otra persona similarmente calificada.

No use un adaptador.

No use un cable eléctrico de extensión.

Si los códigos lo permiten y se emplea una ligadura de conexión

a tierra adicional, es recomendable que un electricista calificado

determine si la trayectoria de conexión a tierra de la ligadura es

adecuada.

Peligro de choque eléctrico

Se requiere una conexión eléctrica a tierra para esta

secadora.

No conecte a tierra a un tubo de gas.

No cambie el enchufe del cable de suministro de

energía. Si no encaja en el contacto, consulte a un

electricista competente para instalar un contacto

adecuado.

No tenga un fusible en el circuito neutro o de conexión

a tierra.

No use un cable eléctrico de extensión con esta

secadora.

Verifique con un electricista calificado para asegurarse

de que la secadora esté conectada a tierra como es

debido.

No conecte el extremo del enchufe del cable de

suministro eléctrico en un contacto activado, antes de

conectar el cable de suministro eléctrico al bloque de

terminal de la secadora.

No vuelva a usar un cable de suministro eléctrico viejo.

No seguir estas instrucciones puede ocasionar la

muerte, incendio o lesiones graves.

ADVERTENCIA

14

INSTRUCCIONES PARA LA CONEXIÓN A TIERRA

■

Para la conexión de una secadora mediante cable

eléctrico conectado a tierra:

Esta secadora debe estar conectada a tierra. En el caso de

funcionamiento defectuoso o avería, la conexión a tierra

reducirá el riesgo de choque eléctrico al proporcionar una

vía de menor resistencia para la corriente eléctrica. Esta

secadora usa un cable que cuenta con un conductor para la

conexión a tierra del equipo y un enchufe de conexión a

tierra. El enchufe debe conectarse en un contacto apropiado,

que esté debidamente instalado y conectado a tierra de

acuerdo con todos los códigos y ordenanzas locales.

■

Para la conexión permanente de una secadora:

Esta secadora debe estar conectada a un sistema de

cableado de metal permanente, conectado a tierra, o se

debe tender un conducto para la conexión a tierra del equipo

con los conductores de circuito y conectado al terminal de

tierra del equipo o al conductor de suministro de la

secadora.

ADVERTENCIA: La conexión indebida del conductor

para la conexión a tierra del equipo puede ocasionar un

riesgo de choque eléctrico.

Si no está seguro de que la conexión a tierra de la secadora

es la adecuada, verifíquela con un electricista o

representante o personal de servicio competente. No

modifique el enchufe del cable de suministro de energía: si

no encaja en el contacto, consulte a un electricista

competente para instalar un contacto adecuado.

GUARDE ESTAS INSTRUCCIONES

Método recomendado de conexión a tierra

■ Usted es responsable de ponerse en contacto con un

instalador eléctrico calificado para asegurarse de que la

instalación eléctrica sea adecuada y de conformidad con el

National Electrical Code (Código Nacional Eléctrico),

ANSI/NFPA 70 - última edición y con todos los códigos y

ordenanzas locales.

Requisitos de ventilación

ADVERTENCIA: Para reducir el riesgo de incendio, esta

secadora DEBE VENTILARSE HACIA EL EXTERIOR.

■ El ducto de escape de la secadora no debe conectarse en

ningún ducto de escape de gas, chimenea, pared, techo o el

espacio oculto de un edificio ni ningún otro ducto que se use

para la ventilación.

■ No use capotas de ventilación con pestillos magnéticos.

■ No instale un ducto de escape de metal flexible en paredes,

techos o pisos encerrados.

■ Se debe usar un ducto de escape de metal pesado de 10 cm

(4") y abrazaderas.

■ Utilice abrazaderas para sellar todas las juntas. No debe

conectarse ni asegurarse el ducto de escape con tornillos ni

con ningún otro dispositivo que se extienda hacia el interior

de dicho ducto. No utilice cinta para ductos.

IMPORTANTE: Observe todos los códigos y reglamentos

aplicables.

Use un ducto de escape de metal pesado. No use ducto de

escape de plástico o de hoja de metal.

Se recomienda un ducto de escape de metal rígido para evitar

que se aplaste o se tuerza.

El ducto de escape de metal flexible debe extenderse y

sostenerse por completo cuando la secadora está en su

ubicación final. Quite el exceso del ducto de metal flexible para

evitar que se doble y se tuerza, lo cual podría dar lugar a una

reducción del flujo de aire y a un rendimiento insuficiente.

Una capota de ventilación debe tapar el ducto de escape para

evitar el ingreso de roedores e insectos a la casa o comercio.

La capota de ventilación debe estar por lo menos a 30,5 cm (12")

de distancia del piso o de cualquier objeto que pudiese estar en

el trayecto del ducto de escape (como flores, rocas o arbustos,

etc).

ADVERTENCIA

Peligro de Incendio

Use un ducto de escape de metal pesado.

No use un ducto de escape de plástico.

No use un ducto de escape de aluminio.

No seguir estas instrucciones puede ocasionar la

muerte o incendio.

15

Largo del sistema de ventilación

La longitud máxima del sistema de ventilación depende del tipo

de ducto que se use, el número de codos y el tipo de capota de

ventilación. La longitud máxima para el ducto de escape rígido y

flexible se muestra en el cuadro.

Para los sistemas de escape que no estén cubiertos en el cuadro

de especificación de la ventilación (tales como para conexión de

múltiples unidades, plénums y ventiladores de potencia), vea el

Manual de servicio de Whirlpool, “Ventilación de múltiples

secadoras”, Pieza N° LIT603197, disponible en el distribuidor de

partes Whirlpool.

Si la secadora está instalada en un área cerrada tal como un

dormitorio, baño o clóset, deberán tomarse las provisiones

necesarias para que haya aire suficiente para la combustión y la

ventilación. (Verifique los códigos y reglamentos aplicables.) Vea

“Instrucciones para la instalación empotrada o en clóset” en la

sección "Requisitos de ubicación”.

Se prefiere una capota de salida de cuatro pulgadas. Aún así,

podrá usarse una salida de escape de 6,4 cm (2¹⁄₂"). Una salida

de 6,4 cm (2¹⁄₂") ocasiona mayor contrapresión que los otros

tipos de capotas. Para una instalación permanente, se necesita

un sistema fijo de ventilación.

N° de vueltas de

90°

N° de vueltas

de 90°

Ducto de escape de metal flexible

1Capotas de ventilación de 10,2 cm (4") de diámetro

Longitud máxima del ducto de escape

15,8 m (52 pies)

13,4 m (44 pies)

11 , 0 m (36 pies)

8,2 m (27 pies)

6,1 m (20 pies)

9,4 m (31 pies)

7, 9 m (26 pies)

6,7 m (22 pies)

6,1 m (20 pies)

5,5 m (18 pies)

0

1

2

3

4

0

1

2

3

4

13,4 m (44 pies)

11 , 0 m (36 pies)

8,5 m (28 pies)

6,4 m (21 pies)

4,3 m (14 pies)

7, 0 m (23 pies)

5,5 m (18 pies)

4,3 m (14 pies)

3,7 m (12 pies)

3,0 m (10 pies)

Capota de

ventilación tipo

caja y tipo persiana

Capota de

ventilación angular

Capota de

ventilación tipo

caja y tipo persiana

Capota de

ventilación angular

Ducto de escape de metal rígido

Si se usa un sistema de ventilación existente, limpie la pelusa que

está en toda la longitud del sistema y asegúrese de que la capota

de ventilación no esté obstruida con pelusa. Reemplace cualquier

ducto de escape de plástico o de hoja de metal por uno de metal

rígido o de metal flexible.

Planifique la instalación a fin de usar el menor número posible de

codos y vueltas. Evite giros de 90º.

Cuando use codos o haga vueltas, deje todo el espacio que sea

posible. Doble el ducto gradualmente para evitar torceduras.

El ducto de escape puede ser dirigido hacia arriba, hacia abajo, a

la izquierda, derecha, detrás de la secadora o directamente hacia

atrás por la parte posterior de la misma.

Verificación de servicio: La presión posterior en cualquier sistema

de escape no deberá exceder los 15,2 mm (0,6") en la columna

de agua, medida con un manómetro inclinado en el punto en que

el ducto de escape se conecta con la secadora.

La salida de escape está ubicada en el centro de la parte

posterior de la secadora.

Al diseñar el sistema de tubería, deberá asegurarse de que la

condensación que se forme cuando el aparato esté en

funcionamiento, quedará retenida y se evaporará posteriormente

o se desechará. Al seguir estas instrucciones de instalación, este

requisito se cumplirá adecuadamente.

A

B

Flujo de aire de escape

A. Mejor

B. Bueno

16

INSTRUCCIONES DE INSTALACIÓN – SECADORA ELÉCTRICA

Instalación de la ventilación

1. Instale la capota de ventilación. Emplee una masilla de

calafateo para sellar la abertura de la pared externa

alrededor de la capota de ventilación.

2. Conecte el ducto de escape a la capota de ventilación. (El

ducto de escape DEBE encajar dentro de la capota.)

Asegure el ducto de escape a la capota de ventilación con

una abrazadera de 100 mm (4").

3. Extienda el ducto de escape a la ubicación de la secadora.

Use la trayectoria más recta posible. Evite giros de 90º.

Utilice abrazaderas de 100 mm (4") para asegurar las piezas

del ducto. Tal vez necesite tijeras para lata para cortar el

ducto en la longitud necesaria.

2. Tome dos esquinales de cartón de la caja de la secadora y

colóquelos sobre el piso, en la parte posterior de la secadora.

Sujete con firmeza el cuerpo de la secadora y colóquela sobre

su parte posterior, encima de los esquinales de cartón.

3. Comience a atornillar las patas con la mano. Use una llave

de tuercas ajustable o una llave de tubo de cabeza

hexagonal de 2,5 cm (1") para terminar de atornillar las patas

hasta alcanzar la marca en forma de diamante.

4. Ponga la secadora de pie sobre el cartón o madera dura.

dmarca en

forma de

diamante

Preparación de la secadora

1. Saque la cinta adhesiva del gabinete de la secadora. Abra la

puerta de la secadora y retire la cinta adhesiva del tambor

de la secadora. (No todos los tambores de la secadora están

pegados con cinta adhesiva.) Saque el estante de secado, si

está incluido. Gire hacia la izquierda el tambor de la

secadora, para asegurarse de que se haya quitado toda la

cinta adhesiva. Pásele un paño húmedo al tambor para

quitar el polvo.

ADVERTENCIA

Peligro de peso excesivo

Use dos o más personas para mover e instalar la

secadora.

No seguir esta instrucción puede ocasionar una lesión

en la espalda u otro tipo de lesiones.

17

Conexión eléctrica

Enchufe el cable de suministro en un contacto de conexión a

tierra. Deberá ser conectada a un receptáculo de suministro

eléctrico en el voltaje que se muestra en la placa de clasificación.

La capacidad mínima del fusible de suministro deberá ser de

16A. La secadora deberá colocarse de manera que el enchufe

esté accesible. Si no se usa el enchufe provisto, la conexión

eléctrica deberá llevarse a cabo por parte de un electricista

capacitado, según los códigos locales o nacionales.

Si se ha dañado el cable de suministro, deberá reemplazarse con

un cable especialmente terminado, por parte de un agente de

servicio autorizado u otra persona similarmente calificada.

No use un adaptador.

No use un cable eléctrico de extensión.

Importante: Observe todos los códigos y reglamentos aplicables.

Si los códigos lo permiten y se emplea una ligadura de conexión

a tierra adicional, es recomendable que un electricista

competente determine si la trayectoria de conexión a tierra de la

ligadura es adecuada.

Peligro de choque eléctrico

Se requiere una conexión eléctrica a tierra para esta

secadora.

No conecte a tierra a un tubo de gas.

No cambie el enchufe del cable de suministro de

energía. Si no encaja en el contacto, consulte a un

electricista competente para instalar un contacto

adecuado.

No tenga un fusible en el circuito neutro o de conexión

a tierra.

No use un cable eléctrico de extensión con esta

secadora.

Verifique con un electricista calificado para asegurarse

de que la secadora esté conectada a tierra como es

debido.

No conecte el extremo del enchufe del cable de

suministro eléctrico en un contacto activado, antes de

conectar el cable de suministro eléctrico al bloque de

terminal de la secadora.

No vuelva a usar un cable de suministro eléctrico viejo.

No seguir estas instrucciones puede ocasionar la

muerte, incendio o lesiones graves.

ADVERTENCIA

18

La secadora deberá estar nivelada para reducir el ruido y

asegurarse un rendimiento adecuado.

Deslice la secadora sobre cartón o madera dura antes de

desplazarla por el piso, para evitar que se dañe el mismo.

1. Trasládela cerca de su ubicación permanente. Deje suficiente

espacio para conectar la ventilación de escape. Quite el

cartón o madera que se encuentra debajo de la secadora.

2. Revise la nivelación de la secadora colocando un nivel en la

parte superior de la misma, primero de lado a lado y luego

del frente hacia atrás. Si la secadora no está nivelada, ajuste

las patas de la misma hacia arriba o hacia abajo.

3. Si las patas no son lo suficientemente largas como para

nivelar la secadora, pida un Juego de extensión de las patas

de la secadora, Pieza N° 279810 (se venden dos patas por

juego), en su distribuidor.

4. Conecte el ducto de escape a la salida de aire de la

secadora. El ducto de escape debe encajar sobre la salida

de aire de la secadora y dentro de la capota de ventilación.

Utilice abrazaderas para ducto de 100 mm (4") para sellar todas

las uniones y asegurar el ducto de escape a la salida de escape

de la secadora.

5. Mueva la secadora a su posición final.

Nivelación y ventilación de la secadora

abrazadera de 10,2

cm (4")

abrazadera de

10,2 cm (4")

19

1. Verifique que usted:

■ no se haya salteado ningún paso..

■ haya instalado todas las piezas.

■ haya instalado las patas niveladoras como es debido.

■ haya nivelado la secadora.

■ haya asegurado todas las uniones del ducto de escape con

abrazaderas de 100 mm (4").

■ tenga todas las herramientas con las que empezó.

2. Enchufe el cable de suministro de energía en el contacto de

conexión a tierra o conecte el alambre directo al suministro

de energía. Encienda el suministro de energía.

3. Lea el Manual de uso y cuidado para entender en su

totalidad cómo funciona la nueva secadora. Seleccione un

ciclo completo de calor (no un ciclo de aire) y ponga la

secadora en marcha. Después de cinco minutos, abra la

puerta de la secadora. Deberá sentir el calor en el interior de

la secadora.

Si la secadora no funciona adecuadamente, revise lo siguiente:

■ que el suministro eléctrico esté conectado.

■ que el fusible de la casa esté intacto y ajustado, o que no se

haya disparado el cortacircuitos.

■ que la puerta de la secadora esté cerrada.

■ que los controles estén fijados en una posición de

funcionamiento u "On" (encendido).

■ que se haya presionado con firmeza el botón de puesta en

marcha.

Si la secadora hace un ruido raro, revise si está nivelada.

Verifique el funcionamiento

Especificaciones técnicas

¿Va a mover la secadora a otro lugar?

Verifique con un electricista autorizado para confirmar que el

suministro de voltaje de la nueva casa coincida con el voltaje

especificado en la placa de clasificación de modelo/serie.

Cierre el

suministro

eléctrico a la

secadora.

Desconecte el

cable de

suministro de

energía de la

secadora.

Pegue la

parte

superior al

gabinete

con cinta

adhesiva.

Pegue la

puerta al

panel

frontal

con cinta

adhesiva

Gire las

patas

niveladoras

completam

ente hacia

adentro.

Deslice la secadora hacia un cartón o una

madera antes de desplazarla por el piso para

evitar que se dañe el revestimiento del mismo.

(vea la placa de clasificación en la abertura de la puerta para

obtener detalles completos acerca del modelo)

220-240V ~ 50 Hz, 1ph

3100W, IPX4

Capacidad de ropa: 9,1 kg. máx.

20

TABLE DES MATIERES

SECURITE DU SECHE-LINGE

SECURITE DU SECHE-LINGE.................................................. 20

EXIGENCES D'INSTALLATION ................................................ 21

Outillage et pièces .................................................................. 21

Exigences d'emplacement ...................................................... 21

Spécifications électriques........................................................ 22

Exigences concernant l’évacuation ........................................ 23

INSTRUCTIONS D’INSTALLATION – SECHE-LINGE

ELECTRIQUE .......................................................................... 25

Installation du dispositif d’évacuation......................................25

Préparation du sèche-linge ......................................................25

Raccordement électrique ........................................................26

Réglage de l’aplomb et évacuation du sèche-linge ................27

Contrôle du fonctionnement ....................................................28

Votre sécurité et celle des autres sont très importantes.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil électroménager.

Assurez-vous de toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d'alerte de sécurité.

Ce symbole d'alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves.

Tous les messages de sécurité suivront le symbole d'alerte de sécurité et le mot “DANGER” ou “AVERTISSEMENT”.

Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

suivez pas immédiatement les instructions

Risque possible de décès ou de blessure grave si vous ne

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel, comment réduire le risque de blessure et ce qui peut se

produire en cas de non-respect des instructions.

suivez pas les instructions.

IMPORTANTES INSTRUCTIONS DE SECURITE

Afin de réduire le risque d'incendie, de choc électrique ou de blessures corporelles lors de

AVERTISSEMENT :

l'utilisation du sèche-linge, il convient d'observer certaines précautions fondamentales, notamment :

■ Lire toutes les instructions avant d'utiliser le sèche-linge.

■ Ne pas entreposer d’articles tâchés d’huile de cuisson

dans votre sèche-linge. Les articles couverts d’huile de

cuisson peuvent provoquer une réaction chimique et

enflammer la charge de vêtements.

■ Ne pas sécher d'articles qui ont été précédemment

nettoyés, lavés, trempés ou tachés avec de l'essence, des

solvants pour nettoyage à sec ou d'autres substances

inflammables ou explosives; ces substances dégagent des

vapeurs qui pourraient s'enflammer ou exploser.

■ Ne pas laisser des enfants jouer sur le sèche-linge ou à

l'intérieur de celui-ci. Une surveillance attentive des enfants

est nécessaire lorsque le sèche-linge est utilisé à proximité

d’enfants.

■ Ôter la porte ou le couvercle du sèche-linge avant de le

retirer pour entretien ou de le mettre au rebut.

■ Ne pas accéder à l’intérieur du sèche-linge pendant le

fonctionnement du tambour.

■ Ne pas installer ou entreposer le sèche-linge dans un

endroit où il sera exposé aux intempéries.

■ Ne pas effectuer d'intervention non autorisée sur les

commandes.

■ Ne pas réparer ou remplacer une quelconque pièce du

sèche-linge ou effectuer tout entretien qui ne serait pas

expressément recommandé dans le Guide d'utilisation et

d'entretien ou dans des instructions de réparation par

l'utilisateur que vous comprenez et que vous êtes capables

d'exécuter.

■ Ne pas utiliser d’adoucissants ou de produits pour éliminer

l’électricité statique à moins que ce ne soit recommandé

par le fabricant de l’adoucissant ou du produit.

■ Ne pas sécher à la chaleur des articles contenant du

caoutchouc mousse ou des matières similaires.

■ Nettoyer le filtre à peluches avant ou après chaque charge.

■ La zone située autour de l’ouverture d’évacuation et les

zones adjacentes doivent être propres, exemptes de

peluches et poussières.

■ L’intérieur du sèche-linge et le ventilateur d’évacuation

doivent être nettoyés régulièrement par un personnel

d’entretien qualifié..

■ Voir les instructions d’installation pour les spécifications

de mise à la terre.

CONSERVEZ CES INSTRUCTIONS

21

Exigences d'emplacement

IMPORTANT : Observer les dispositions de tous les codes et

règlements en vigueur

■ Vérifier les exigences des codes : Certains codes limitent ou

n’autorisent pas l’installation d’un sèche-linge dans un

garage, un placard ou une chambre à coucher. Communiquer

avec l’inspecteur des bâtiments local.

■ S’assurer que les rebords inférieurs de la caisse, les côtés

arrière et inférieurs du sèche-linge, sont bien dégagés pour

permettre une évacuation adéquate de l’air de combustion.

Voir la section “Instructions d’installation dans un

encastrement ou un placard” pour connaître les dimensions

d’espacement minimum.

REMARQUE : Le sèche-linge ne doit pas être installé ou

entreposé dans un endroit où il sera exposé à l’eau et/ou aux

intempéries. Si la température ambiante est inférieure à 7ºC

(45ºF), les programmes automatiques peuvent ne pas s’arrêter.

EXIGENCES D'INSTALLATION

Instructions d’installation dans un encastrement ou

un

Ce sèche-linge peut être installé dans un encastrement ou un

placard. Pour les installations dans un encastrement ou un

placard, les dimensions minimales sont indiquées sur l’étiquette

du numéro de série du sèche-linge.

Les dimensions d’installation sont en centimètres et constituent le

minimum applicable. Un espace supplémentaire peut être

nécessaire pour faciliter l’installation, l’entretien et pour observer

les codes et règlements locaux.

Si une porte de placard est installée, une ouverture d’évacuation

de l’air minimale est nécessaire dans les parties supérieure et

inférieure. Les portes à claire-voie offrant des ouvertures

équivalentes sont acceptables.

Le sèche-linge doit être évacué à l’extérieur.

Aucun autre appareil consommant un combustible ne doit être

installé dans le même placard que le sèche-linge.

Outillage et pièces

Rassembler les outils et pièces nécessaires avant de commencer

l’installation. Lire et suivre les instructions fournies avec les outils

indiqués ici.

Outils nécessaires

■ Tournevis à lame plate

■ Tournevis Phillips

■ Clé à molette ouverture : 2,5 cm (1")

■ Clé à douille hexagonale

■ Niveau

■ Clé à douille ou tourne-écrou de 0,63 cm (¹⁄₄")

■ Couteau universel

■ Brides de serrage pour conduit d’évacuation

■ Composé d’étanchéité des raccords filetés – résistant au GPL

■ Pistolet à calfeutrage et composé de calfeutrage (pour

l’installation d’un nouveau conduit d’évacuation)

■ Cisaille de ferblantier

Pièces fournies

Retirer le sac de pièces du tambour du sèche-linge. Vérifier la

présence de toutes les pièces.

■ 4 pieds de réglage de l’aplomb

Vue encastrée de face Vue latérale du placard

Dégagements de séparation minimums

Des espacements supplémentaires pour le mur, la porte et les plinthes peuvent

être nécessaires si on utilise un coude d’évacuation externe.

Porte du

placard

Vue de

face

7.6 cm (3")

7.6 cm (3")

155 cm

2

(24"2)

310 cm

2

(48"2)

*Dimension minimale pour une porte de placard.

Les portes à claire-voie offrant des ouvertures équivalentes sont acceptables.

2.5 cm (1")

Porte du

placard

35.6 cm

(14") max.

2.5 cm (1")

2.5 cm (1")

45.7 cm

(18")*

10.2 cm

(4")

■ L’inclinaison maximale sous le sèche-linge doit être inférieure

à 2,5 cm (1"). Si l’inclinaison est supérieure à 2,5 cm (1"),

installer l'ensemble de pieds d’extension, pièce no 279810. Si

le sèche-linge n'est pas de niveau, le linge peut ne pas

culbuter convenablement et les programmes automatiques

commandés par détecteur peuvent ne pas fonctionner

correctement. Le sol doit pouvoir supporter le poids du sèchelinge 79,4 kg (175 lbs).

Instructions d’installation dans un encastrement ou

un placard

AVERTISSEMENT

Risque d'explosion

Garder les matières et les vapeurs inflammables, telle

que l'essence, éloignées du sèche-linge.

Placer le sèche-linge au moins 46 cm au-dessus du sol

pour une installation dans un garage.

Le non-respect de ces instructions peut causer un

décès, une explosion ou un incendie.

22

Dimensions du produit

74.3 cm

(29-1/4")

couvercle du boîtier

de branchement

cordon

d’alimentatio

n/serre-câble

109.5 cm

(43-1/8")

27.9 cm

(11")

Dimensions illustrées avec pieds allongés à 2,5 cm (1")

sous le sèche-linge.

97.2 cm

(38-1/4")

68.6 cm (27")

35.6

cm

(14")

Conduit d'évacuation à

gauche ou à droite

Evacuation

par l’arrière

10.8 cm

(4-1/4")

26 cm

(10-1/4")

35.9 cm

(14-1/8")

10.2 cm

(4")

Dimensions pour l’évacuation

La porte du sèchelinge dépasse de 35,6

cm par rapport à

l’avant du sèche-linge

lorsqu’elle est

complètement ouverte.

Spécifications électriques

Important : Observer les dispositions de tous les codes et

règlements en vigueur.

Ce sèche-linge est équipé d’un cordon d’alimentation

électrique et d’une prise de 16 A respectant les normes

européennes. Il doit être connecté à une prise de courant

correspondant au voltage indiqué sur la plaque signalétique.

La capacité minimale du fusible d’alimentation doit être de

16 A. Le sèche-linge doit être installé de façon à ce que la

prise soit accessible. Si la prise correspondante n’est pas

utilisée, la connexion électrique doit être effectuée par un

électricien compétent conformément aux codes locaux et

nationaux.

Si le cordon d’alimentation est endommagé, il doit être remplacé

par un cordon à embout spécifique par un agent d’entretien

autorisé ou une personne compétente similaire.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Si les codes le permettent et si on utilise un conducteur distinct

de liaison à la terre, il est recommandé qu’un électricien qualifié

vérifie la qualité de la liaison à la terre.

AVERTISSEMENT

Risque de choc électrique

Une mise à la terre est nécessaire sur ce sèche-linge.

Ne pas utiliser une tuyauterie de gaz pour le

raccordement à la terre.

Ne pas changer la prise du cordon d’alimentation. Si

elle ne correspond pas à la prise de sortie, la faire

installer par un électricien qualifié.

Ne pas installer de fusible dans le circuit neutre ou de

liaison à la terre.

Ne pas utiliser un câble de rallonge avec ce

sèche-linge.

Consulter un électricien qualifié pour s’assurer que le

sèche-linge est correctement branché.

Ne pas connecter le cordon d’alimentation à une prise

sous tension avant de le connecter au boîtier de

connexion du sèche-linge.

Ne pas réutiliser un cordon d’alimentation usagé.

Le non-respect de ces instructions peut causer un

décès, un incendie ou une blessure grave.

23

Méthode recommandée de mise à la

terre

■ Vous devez contacter un installateur électrique qualifié pour

garantir une installation conforme au code électrique national,

ANSI/NFPA 70, dernière édition, et aux autres codes et

règlements locaux.

Exigences concernant l’évacuation

AVERTISSEMENT : Pour réduire le risque d’incendie, ce

sèche-linge doit EVACUER L’AIR A L’EXTERIEUR.

■ Le conduit d'évacuation du sèche-linge ne doit pas être

connecté à une évacuation de gaz, une cheminée, un mur, un

plafond, un vide de construction ou tout autre orifice

d’évacuation.

■ Ne pas utiliser un clapet d’évacuation à fermeture

magnétique.

■ Ne pas installer le conduit métallique flexible dans les cavités

fermées des murs, plafonds ou sols.

■ Utiliser un conduit d’évacuation métallique robuste de 10 cm

(4") et des brides de fixation.

■ Utiliser des brides pour sceller tous les joints. Le conduit

d'évacuation ne doit pas être connecté ou fixé avec des vis

ou avec tout autre dispositif de serrage qui se prolonge à

l'intérieur du conduit. Ne pas utiliser de ruban adhésif pour

conduit.

IMPORTANT : Observer les dispositions de tous les codes et

règlements en vigueur.

Utiliser un conduit d'évacuation en métal lourd. Ne pas utiliser de

conduit de plastique ou de métal très mince.

On recommande d’utiliser un conduit métallique rigide pour

réduire les risques d’écrasement et de déformation.

Un conduit métallique flexible doit être totalement déployé et

soutenu lorsque le sèche-linge est à sa position finale. Enlever

tout excès de conduit flexible pour éviter tout affaissement et

déformation susceptible de réduire la capacité d’évacuation et le

rendement.

Te rminer le conduit d’évacuation par un clapet de décharge pour

empêcher les rongeurs et insectes d’entrer dans l’habitation ou le

local.

Le clapet de décharge doit être situé à au moins 30,5 cm (12")

au-dessus du sol ou de tout autre objet susceptible de se trouver

sur le trajet de l’air humide rejeté (par exemple, fleurs, roches ou

buissons, etc.).

Méthode recommandée de mise à la terre

INSTRUCTIONS DE LIAISON A LA TERRE

■

Pour un sèche-linge relié à la terre et connecté par un

cordon :

Ce sèche-linge doit être relié à la terre. En cas d'anomalie

de fonctionnement ou de panne, la liaison à la terre réduira

le risque de choc électrique en offrant au courant électrique

un itinéraire d'évacuation de moindre résistance. Ce

sèche-linge est alimenté par un cordon électrique

comportant un conducteur relié à la terre et une fiche de

liaison à la terre. La fiche doit être branchée sur une prise de

courant appropriée qui est bien installée et reliée à la terre

conformément à tous les codes et règlements locaux.

■

Pour un sèche-linge raccordé en permanence :

Ce sèche-linge doit être raccordé à un système de câblage

permanent en métal relié à la terre ou un conducteur relié à

la terre doit être en fonction avec les conducteurs de circuit

et raccordés à la borne de liaison à la terre ou la borne sur

le sèche-linge.

AVERTISSEMENT: Un raccordement inapproprié

du conducteur de liaison à la terre peut causer un risque de

choc électrique.

En cas de doute concernant la liaison à la terre du

sèche-linge, consulter un électricien qualifié, un agent ou

personnel d’entretien. Ne pas modifier la fiche sur le cordon

d’alimentation : si elle ne correspond pas à la prise de sortie,

faire installer une prise appropriée par un électricien qualifié.

CONSERVER CES INSTRUCTIONS

AVERTISSEMENT

Risque d'incendie

Utiliser un conduit d'évacuation en métal lourd.

Ne pas utiliser de conduit d’évacuation en plastique.

Ne pas utiliser de conduit d’évacuation en feuille de

métal.

Le non-respect de ces instructions peut causer un

décès ou un incendie.

24

Longueur du système d’évacuation

La longueur maximale du système d’évacuation dépend du type

de conduit utilisé, du nombre de coudes et du type de clapet

d’évacuation. La longueur maximale des conduits rigides et

flexibles est illustrée sur le tableau.

Pour les systèmes d’évacuation non illustrés dans le tableau de

spécification (notamment les raccordements multiples, les

plénums, et les ventilateurs motorisés), voir dans le Manuel

d’entretien Whirlpool la section “Evacuation des sèche-linge

Whirlpool”, pièce n° LIT603197, disponible chez votre revendeur

de pièces Whirlpool.

Si le sèche-linge est installé dans une zone confinée, telle qu’une

chambre, une salle de bain ou un placard, prévoir un espace

suffisant pour la combustion et la ventilation de l’air. (Vérifier les

dispositions des codes et règlements en vigueur.) Voir

“Instructions d’installation dans un encastrement ou un placard”

dans la section “Exigences d’emplacement”.on Instructions” in

the “Location Requirements” section.

Il est préférable d’utiliser un clapet d’évacuation de 10,16 cm (4").

Cependant, on peut utiliser un clapet d’évacuation de 6,4 cm

(2 ¹⁄₂"). Une sortie de 6,4 cm (2 ¹⁄₂") cause davantage de contrepression que les autres types d’installation. Pour une installation

permanente, un système d’évacuation fixe est requis.

Nbre de

changements de

direction à 90°

Nbre de

changements de

direction à 90°

Conduit métallique flexible

Clapets d’évacuation – Diamètre de 10,2 cm

Longueur maximale du conduit

15.8 m (52 ft.)

13.4 m (44 ft.)

11.0 m (36 ft.)

8.2 m (27 ft.)

6.1 m (20 ft.)

9.4 m (31 ft.)

7.9 m (26 ft.)

6.7 m (22 ft.)

6.1 m (20 ft.)

5.5 m (18 ft.)

0

1

2

3

4

0

1

2

3

4

13.4 m (44 ft.)

11.0 m (36 ft.)

8.5 m (28 ft.)

6.4 m (21 ft.)

4.3 m (14 ft.)

7.0 m (23 ft.)

5.5 m (18 ft.)

4.3 m (14 ft.)

3.7 m (12 ft.)

3.0 m (10 ft.)

Clapet de type

boîte et à

persiennes

Clapet incliné

Clapet de type

boîte et à

persiennes

Clapet incliné

Conduit métallique rigide

Lors de l’utilisation d’un système de décharge existant, nettoyer

et éliminer les peluches sur toute la longueur du système et veiller

à ce que le clapet de décharge ne soit pas obstrué par une

accumulation de peluches. Remplacer tout conduit de plastique

ou de feuille métallique par un conduit métallique rigide ou

souple.

Planifier l'installation pour introduire le nombre minimal de coudes

et de changements de direction.

Eviter les changements de direction à 90º.

Si des coudes ou changements de direction sont utilisés, prévoir

autant d'espace que possible. Plier le conduit graduellement pour

éviter de le déformer.

On peut acheminer le conduit d’évacuation vers le haut, vers le

bas, vers la gauche, vers la droite ou en ligne droite depuis

l’arrière du sèche-linge.

Vérification d’entretien : La contre-pression de tout système

d’évacuation ne doit pas excéder 15,2 mm (0.6") dans la colonne

d’eau (mesure obtenue à l’aide d’un manomètre au point de

connexion entre le conduit d’évacuation et le sèche-linge).

La sortie d’évacuation est située au centre de la partie arrière du

sèche-linge.

La conception du système d’évacuation doit permettre à toute

condensation formée pendant le fonctionnement de l’appareil

d’être retenue puis évaporée et évacuée. En suivant ces

instructions d’installation, ces exigences sont convenablement

respectées.

A

B

Débit de l’air évacué

A. Optimal

B. Correct

25

INSTRUCTIONS D’INSTALLATION – SECHE-LINGE ELECTRIQUE

Installation du dispositif d’évacuation

1. Installer le clapet d’évacuation. Calfeutrer l’ouverture murale

à l’extérieur autour du clapet d’évacuation.

2. Raccorder le conduit d’évacuation au clapet. (Le conduit

d’évacuation DOIT s’insérer dans le clapet.) Fixer ensemble

le conduit et le clapet avec une bride de 100 mm (4").

3. Acheminer le conduit d’évacuation jusqu’à l’emplacement du

sèche-linge. Utiliser l’itinéraire le plus rectiligne possible.

Eviter les changements de direction à 90º. Utiliser des brides

de 100 mm (4") pour fixer les pièces du conduit. Des cisailles

de ferblantier peuvent être nécessaires pour couper le

conduit à la longueur désirée.

2. Placer deux cornières découpées dans le carton du sèche-

linge sur le sol à l’arrière du sèche-linge. Agripper fermement

le corps du sèche-linge et l’allonger doucement sur sa partie

postérieure sur les cornières de carton.

3. Commencer à visser les pieds manuellement. Utiliser une clé

à molette ou un tourne-écrou de 2,5 cm (1") pour finir de

fixer les pieds jusqu’à atteindre le bord du symbole

(losange).

4. Placer le sèche-linge en position verticale sur le carton ou le

panneau dur.

Symbole de

losange

Préparation du sèche-linge

1. Retirer le ruban adhésif de la caisse du sèche-linge. Ouvrir la

porte du sèche-linge et retirer le ruban adhésif du tambour.

(Tous les tambours de sèche-linge ne sont pas couverts de

ruban adhésif.) Retirer la grille de séchage, si présente.

Tourner le tambour du sèche-linge dans le sens inverse des

aiguilles d’une montre pour s’assurer que tout le ruban

adhésif a été retiré. Essuyer le tambour avec un chiffon

humide pour retirer toute la poussière.

AVERTISSEMENT

Risque du poids excessif

Deux personnes ou plus sont nécessaires pour

déplacer et installer le sèche-linge.

Le non-respect de cette instruction peut causer une

blessure au dos ou d’autres blessures.

26

Raccordement électrique

Brancher le cordon d’alimentation dans une prise reliée à la terre.

Il doit être connecté à une prise de courant correspondant au

voltage indiqué sur la plaque signalétique. La capacité minimale

du fusible d’alimentation doit être de 16 A. Le sèche-linge doit

être installé de façon à ce que la prise soit accessible. Si la prise

correspondante n’est pas utilisée, la connexion électrique doit

être effectuée par un électricien compétent conformément aux

codes locaux et nationaux.

Si le cordon d’alimentation est endommagé, il doit être remplacé

par un cordon à embout spécifique par un agent d’entretien

autorisé ou une personne compétente similaire.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Important : Observer les dispositions de tous les codes et

règlements en vigueur.

Si les codes le permettent et si on utilise un conducteur distinct

de liaison à la terre, il est recommandé qu’un électricien qualifié

vérifie la qualité de la liaison à la terre.

AVERTISSEMENT

Risque de choc électrique

Une mise à la terre est nécessaire sur ce sèche-linge.

Ne pas utiliser une tuyauterie de gaz pour le

raccordement à la terre.

Ne pas changer la prise du cordon d’alimentation. Si

elle ne correspond pas à la prise de sortie, la faire

installer par un électricien qualifié.

Ne pas installer de fusible dans le circuit neutre ou de

liaison à la terre.

Ne pas utiliser un câble de rallonge avec ce

sèche-linge.

Consulter un électricien qualifié pour s’assurer que le

sèche-linge est correctement branché.

Ne pas connecter le cordon d’alimentation à une prise

sous tension avant de le connecter au boîtier de

connexion du sèche-linge.

Ne pas réutiliser un cordon d’alimentation usagé.

Le non-respect de ces instructions peut causer un

décès, un incendie ou une blessure grave.

27

Le sèche-linge doit être d’aplomb pour réduire le bruit et

garantir un fonctionnement correct.

Faire glisser le sèche-linge sur le carton ou le panneau dur

avant de le déplacer, pour empêcher d’endommager le sol.

1. Approcher le sèche-linge de son emplacement final. Laisser

suffisamment d’espace pour connecter le conduit

d’évacuation. Retirer le carton ou le panneau dur situé sous

le sèche-linge.

2. Placer un niveau au-dessus du sèche-linge pour vérifier

l’aplomb, d’un côté à l’autre puis de l’avant vers l’arrière. Si

le sèche-linge n'est pas d’aplomb, ajuster les pieds vers le

haut ou vers le bas.

3. Si les pieds ne sont pas assez longs pour obtenir un aplomb

correct du sèche-linge, commander un Ensemble de pieds

d’extension pour sèche-linge, pièce n° 279810 (deux pieds

par ensemble), chez un revendeur.

4. Connecter le conduit d’évacuation à la bouche d’évacuation

du sèche-linge. Le conduit d’évacuation du sèche-linge doit

être fixé sur la bouche d’évacuation du sèche-linge et dans

le clapet d’évacuation.

Utiliser des brides de conduit de 100 mm (4") pour calfeutrer

tous les joints et fixer le conduit d’évacuation à la bouche

d’évacuation du sèche-linge.

5. Placer le sèche-linge à son emplacement final.

Réglage de l’aplomb et évacuation du sèche-linge

Bride de

10,2 cm (4")

Bride de

10,2 cm (4")

1. Vérifier que :

■ aucune étape n’a été oubliée.

■ toutes les pièces sont installées.

■ les pieds de nivellement sont correctement installés.

■ le sèche-linge est d’aplomb.

■ tous les joints du conduit d’évacuation sont fixés avec des

brides de 100 mm.

■ tous les outils sont présents.

2. Brancher le cordon d’alimentation dans la prise de liaison à

la terre ou connecter la prise directe à l’alimentation

électrique. Ouvrir la source d'alimentation.

3. Lire le Guide d’utilisation et d’entretien pour bien

comprendre le fonctionnement de votre nouveau sèchelinge. Sélectionner un programme complet avec chaleur (pas

le programme de séchage à l’air) et mettre en marche le

sèche-linge. Après cinq minutes, ouvrir la porte du sèchelinge. On doit ressentir de la chaleur à l’intérieur du sèchelinge.

Si le sèche-linge ne fonctionne pas correctement, vérifier ce qui

suit :

■ la prise de courant est correctement alimentée.

■ les fusibles du domicile sont intacts et serrés; ou le

disjoncteur n’est pas déclenché.

■ la porte du sèche-linge est fermée.

■ les commandes sont réglées à la position de marche ou

“ON”.

■ le bouton Start (mise en marche) a été enfoncé fermement.

Si le sèche-linge fait un bruit anormal, vérifier s’il est d’aplomb.

Contrôle du fonctionnement

Caractéristiques techniques