Whirlpool 8516 917 22703 Service Manual

.; WASHING MACHINE AWB 917/3 PH

!

~ ~@NÖ~@

~@NÖ~@

( Service

c+

"-

'I -

j(

.

(

~, Service Manual

,,~

0)r ""

r

\,

~

f'

I

f'

)

r W A1 -TECHNICAL DA TA

W E1 -ADJUSTMENTS AND WATER LEVELS

r W F1 -DIAGRAMS AND PROGRAMME CHART

DESCRIPTION OF BASIC PROGRAMMES

(' W G1 -EXPLODED VIEWS AND SPARE PARTS LIST~()

'}

tr

(,

('

~.

eHILIPS Subjecttomodification .

(

C ~ Printed in Italy -TBL/I 0688 -Ed. 01

PH ILIPS~ 481972968053 (N -SF)

,_,:,,- ~

(\

AWB 917/3 PH -W A1

cf-:-

,

r

('

(" Front loading automatic washing machine, variable spin-drying speed tram 400 and 850 r .p.m., load capacity 4.5 kg

,(' Model : AWB917/3PH-11programmesandthepossibilityofmore

1!Ji:'-.,

~ \

" Description of the "Energy saving" function :

r" In t~is model t.here are same pr~grammes that ~llow a savi.ng ~f 30 % energ:. ~ith the programmes of 90 °C, it is

\ posslble to obtaln the above mentloned energy savlng by pushlng-ln the button Indlcated by" e ".

r mechanical action of the machine after the temperature of 60 °c has been reached. In this way an equalized washing

, action is obtained.

r The increased mechanical action (drum rotation) is obtained by increasing the duration of the timer impulses 7. 9, 10

\. and 12 tram 3' to 12' (button" e ., pushed-in).

TECHNICAL DATA

GENERAL

dry laundry.

combinations, see the survey of the wash programmes on

page W F3

The principle followed is to reduce the maximum temperature of the cycle tram 90 °c to 60 °c, and increasing the

(0, The cycle dur~tion is .pra~ticaIIY .the sam~, either with or -:vithout button" e "pushed-in, bec~use .the increased time

1,,- of the mechanlcal action In the first case IS compensated, In the second case. by the reduced heatlng time.

~ Mains voltage : 220/380 V .:!: 10 % -50 Hz

Max. power consumption : approx. 2800 W

('

Mains fuse : 10 A

(\ Connections:

Electrical : Four-leads cable 4x 1,5 -1,7 m lang

f" inlet hose 1.40 m lang, provided with 3/4" and 1/2"

! Water supply : .

Water draining : drain hose 1.50 m lang

l\ height should be between 60 cm and 90 cm

Heating element : approx. 2800 W (1850 W + 950 W)

('

(~ ~ Width : about 596 mm

-Depth : about 520 mm,~(:

Dimensions:

Height : about 850 mm

coupllng nuts

~

Packed machine ,: about 78 kg

r Unpacked machine Il'Jq1: about 71 kg

' m.Q.1

Base support 'l' O[~ : by means of 4 adjustable feet

.m(~.

C

r

('(

"

(' Ed. 01 -Jun. 88

\

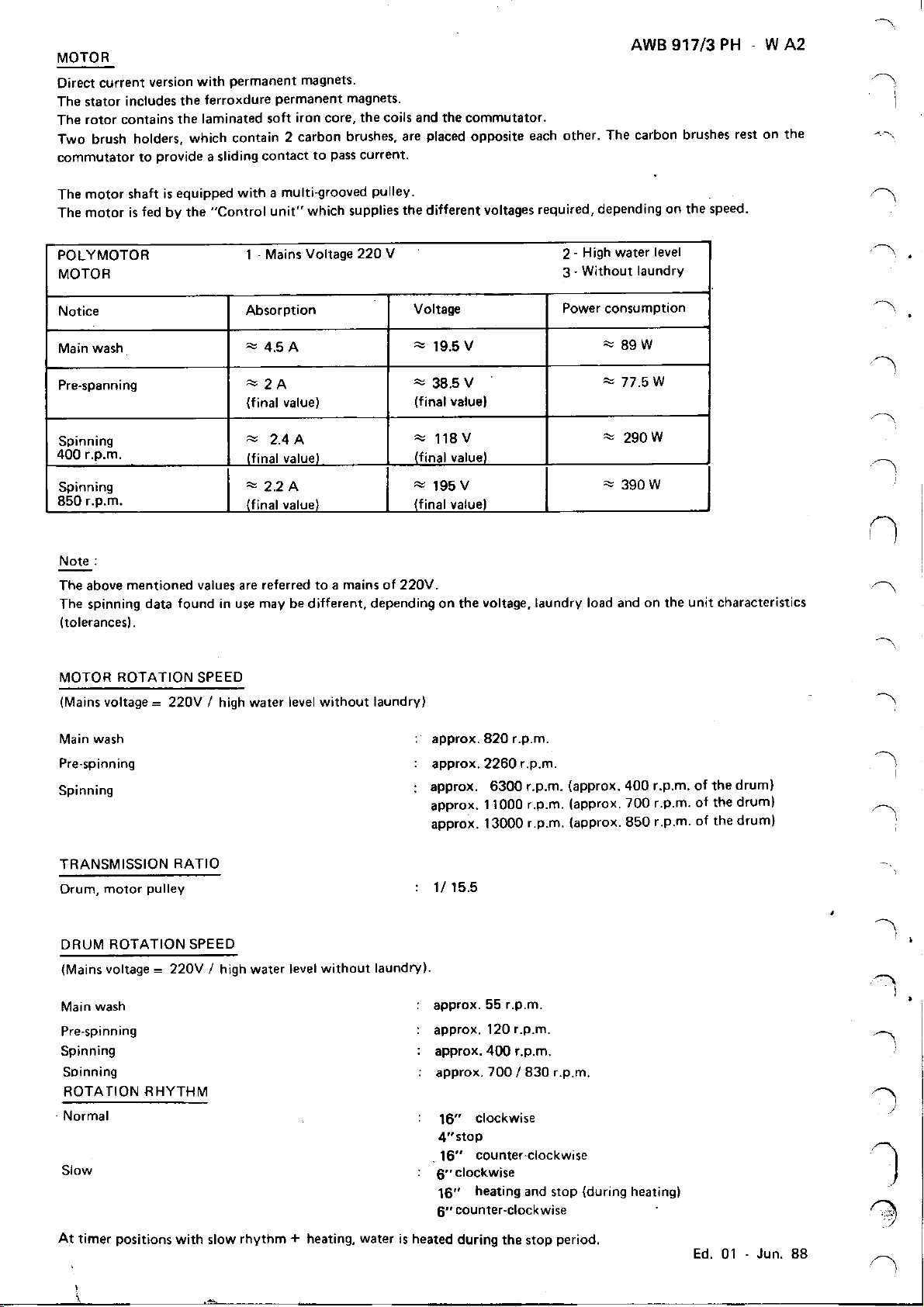

MOTOR AWB 917/3 PH -W A2

Direct current version with permanent magnets. (\

The stator inclu~es the ferr.oxdure per~anent magnets.. i 1

The rotor contalns the laminated soft Iron core, the colls and the commutator.

Two brush holders, which contain 2 carbon brushes, are placed opposite each other. The carbon brushes rest on the

commutator to provide a sliding contact to pass current.

The motor shaft is equipped with a multi-grooved pulley. ~

The motor is fed by the "Control unit" which supplies the different voltages required, depending on the speed.

POLYMOTOR 1 -Mains Voltage 220 V 2 -High water level ~

MOTOR 3 -Without laundry ...'

Notice Absorption Voltage Power consumption ~

Main wash ~ 4.5 A ~ 19.5 V ~ 89 W

P .

2 !~ re-spannlng ~ A ~ 38.5 V ~ 77.5 W

(final value) (final value)

~

Spinning ~ 2.4 A ~ 118 V ~ 290 W

400 r .p.m. (final value) (final value)

~

Spinning ~2.2A ~195V ~390W ,I

850 r.p.m. (final valuel (final value)

n

Note:

The ab~ve. mentioned val~es are referred ~o a mains of 22?V .~

The splnnlng data found In use may be different, dependlng on the voltage, laundry load and on the unit characteristics

(tolerances) .

MOTOR ROTATION SPEED

(Mains voltage = 220V / high water level without laundry) ~

."

\

I .

.

I

Main wash : approx. 820 r .p.m.

Pre-spinning : approx. 2260 r .p.m. ,~

Spinning : approx. 6300 r .p.m. (approx. 400 r .p.m. of the drum) ,

approx. 11000 r.p.m. (approx. 700 r.p.m. of the drum) n

approx. 13000 r .p.m. (approx. 850 r .p.m. of the drum) !

TRANSMISSION RATIO

Drum, motor pulley : 1/ 15.5

I

DRUM ROTATION SPEED \ .

(Mains voltage = 220V / high water level without laundrv).

M . h j

aln was : approx. 55 r .p.m. '

Pre-spinning : approx. 120 r .p.m.

Spinning : approx. 400 r .p.m. 1\

Spinning : approx. 700/830 r .p.m.

ROTA flON RHYTHM

Normal 16" clockwise ~

4" stop

Slow 6" clockwise ' j

16" counter-clockwise ~

16" heating and stop (during heating) -

~

6" counter-clockwise ~

At timer positions with slow rhythm + heating, water is heated during the stop period. -I

Ed. 01 -Jun. 88 n

r-

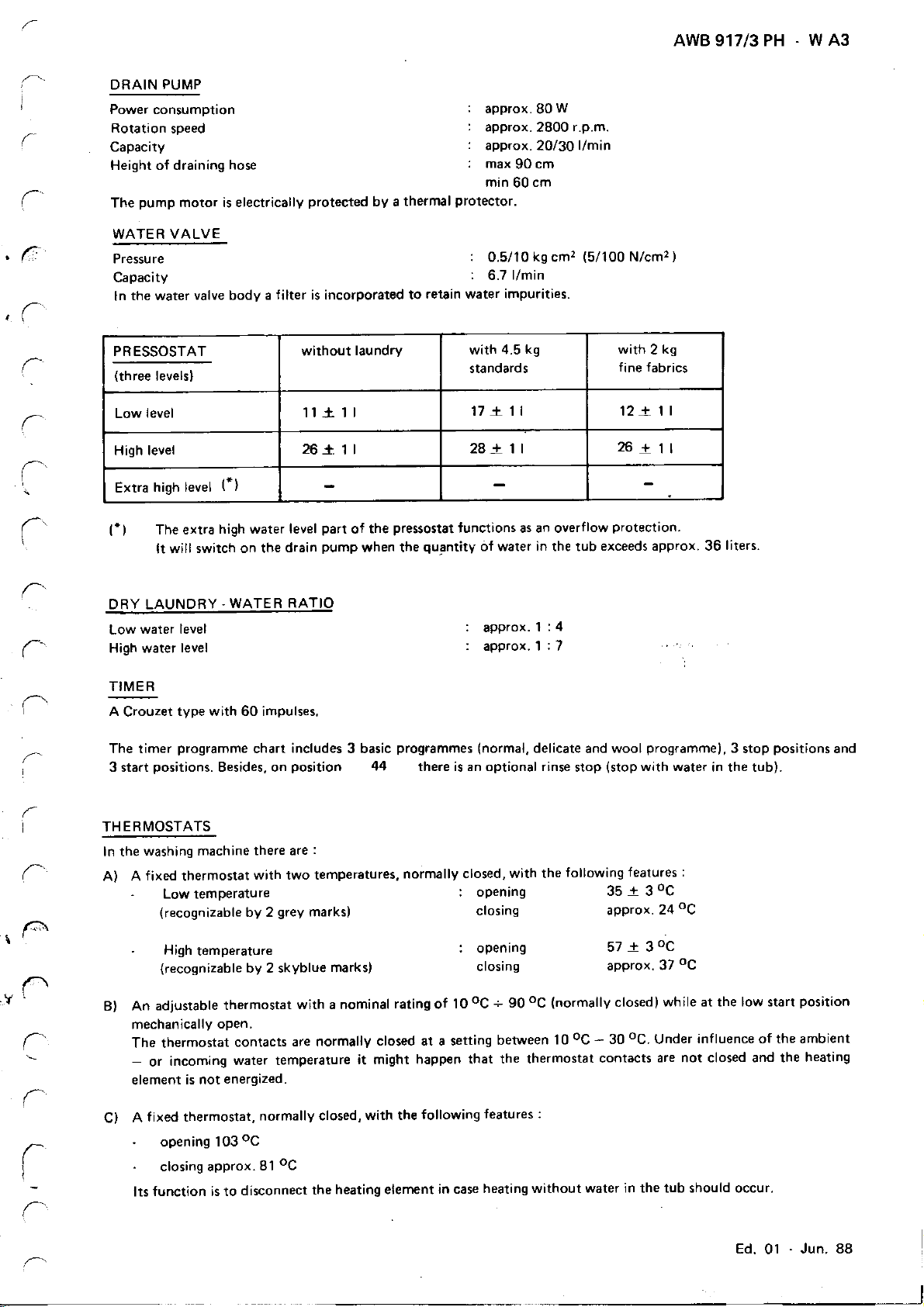

r DRAIN PUMP

Power consumption : approx. 80 W

/' Rotati.on speed : approx. 2800 r .p.m.

( CapacIty : approx. 20/30 I/min

Height of draining hose : max 90 cm

min 60 cm

( The pump motor is electrically protected by a thermal protector.

WATER VALVE

.(!i:' Pressure : 0.5/10 kg cm2 (5/100 N/cm2 )

Capacity : 6.7 I/min

In the water valve body a filter is incorporated to retain water impurities.

!l

PR ESSOSTAT without laundry with 4.5 kg with 2 kg

("' (three levels) standards fine fabrics

(: Lowlevel 11.:f:.11 17.:t.11. 12.:f:.11

High level 26:r- 1 I 28.:f:. 1 I 26 .:f:. 1 I

AWB 917/3 PH -W A3

r Extra high level (*) ---

(', (*) The extra high water level part of the pressostat functions as an overflow protection.

" It will switch on the drain pump when the qu~ntity of water in the tub exceeds approx. 36 liters.

r

, DRY LAUNDRY. WATER RATIO

Low water level : approx. 1 : 4

r' High water level : approx. 1 : 7

TIMER

~ 'AC-;~zet type with 60 impulses.

r The timer .p~ogramm.e chart incl.u~es 3 basic program~es (nor~al, delicate and wool programme), 3 stop positions and

I 3 start positions. Besldes, on position 44 there IS an optlonal rinse stop (stop with water in the tub).

"

r THERMOSTATS

In the washing machine there are:

(' A) A fixed thermostat with two temperatures, normally closed, with the following features:

Low temperature : opening 35 :f: 3 °c

(recognizable by 2 grey marks) closing approx. 24 °c

, .

P'"

High temperature : opening 57 .:f:. 3 °c

(recognizable by 2 skyblue marks) closing approx. 37 °c

r

Y '- B) An adjustable thermostat with a nominal rating of 10 °c ...90 °c (normally closed) while at the low start position

(" The thermostat contacts are normally closed at a setting between 10 °c -30 °C. Under influence of the ambient

""'~ -or incoming water temperature it might happen that the thermostat contacts are not closed and the heating

(\

mechanicallyopen.

element is not energized.

C) A fixed thermostat, normally closed, with the following features:

r opening 103 °c

closing approx. 81 °c

-Its function is to disconnect the heating element in ca se heating without water in the tub should occur.

C

r Ed. 01 .Jun. 88

.

r-'"\,

AWB 917/3 PH -W E1

~

ADJUSTMENTS AND WATER LEVELS )

/ ',

1) Driving belt (item 125 of the exploded view)

The drivir'lg belt used is a poly V belt and its tension is of 15 -16 kg. \

To adjust the belt, one must loosen the nut fixing the motor to the tub bracket in the respective adjusting slot )

and press the motor downwards tor the correct belt tension tighten the nut again.

2) Control rod (timer-tub/detergent) pos. 322 of the exploded view ~ .

a. In order to adjust the water flow in the prewash compartment, position the timer knob corresponding to pro-

gramme 1 and loosen the adjusting screw (pos. 322). ~ .

b. Move the drawer sliding contact to the end of cycle (right side). Tighten the screw.

If the adjusting hag been correctly made, water should flow in the compartment 1 of the detergent drawer. ')

/\,

,

3) Tub and tub clamping ring (items 389, 395, 398 of the expoloded view) /\

To position the tub and the rear plate of the tub correctly, the reference marks (""'-' ) on the tub edges have to i

face. This reference mark on the tub must be in the centre of theclamping ring opening when positioning the

ring. I')

4) Tub suspension springs (item 332 of the exploded view)

The two springs must be hooked in the lower holes of the two tub brackets. ~

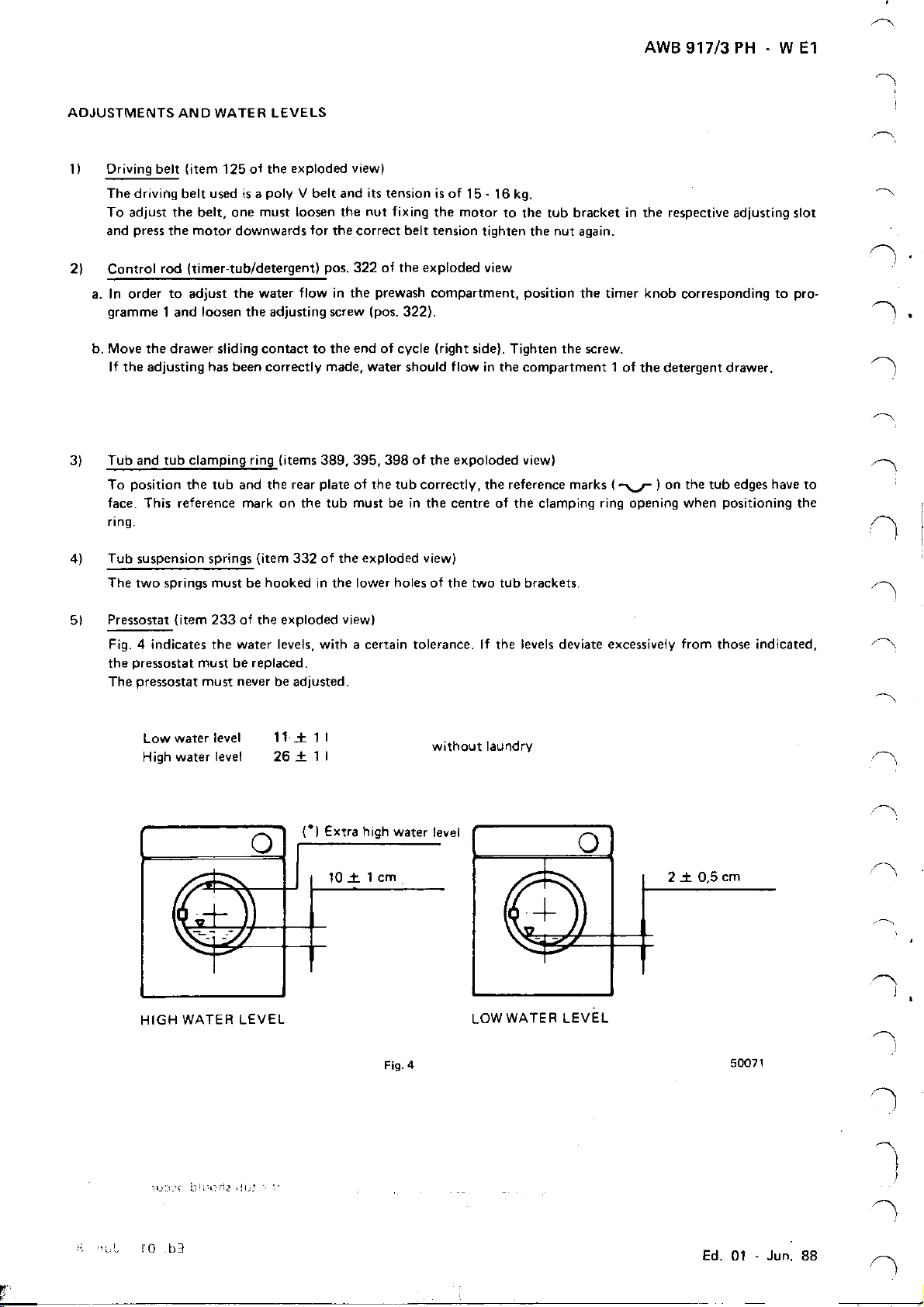

5) Pressostat (item 233 of the exploded view)

Fig. 4 indicates the water levels, with a certain tolerance. If the levels deviate excessively tram those indicated, I~

the pressostat must be replaced.

The pressostat must never be adjusted.

Low water level 11. i 1 I .

High water level 26.I 1 I f/'j

0 (*) Extra high water level 0 i

10i 1 cm 2i 0,5cm () i

h I dWlt out aun ry

~

I

~

i

~

HIGH WATER LEVEL LOW WATER LEVEL

Fig.4 50071

~

lU:!}{;' bjuorl~ ('lU'; "i! --c-

8 nt.,L ro b3 Ed. 01 -Jun. 88 f\:

~

\

.

J

.

I)

l

)

')

; I

Loading...

Loading...